Improving Resource Efficiency in Plant Protection by Enhancing Spray Penetration in Crop Canopies Using Air-Assisted Spraying

Abstract

1. Introduction

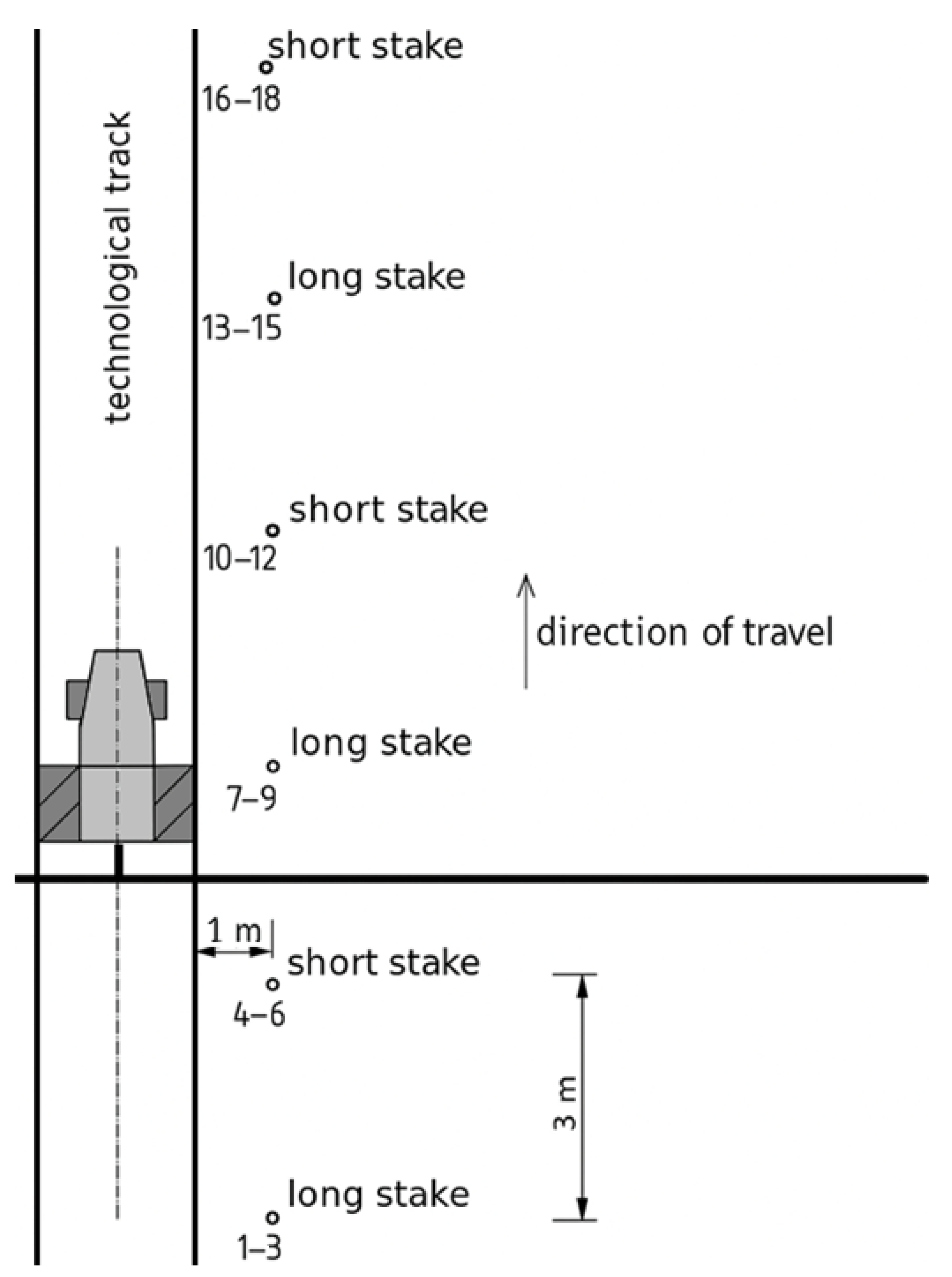

2. Materials and Methods

- stage I (NAA—No Air Assistance): spraying without the air assistance;

- stage II (WAA—With Air Assistance): spraying with the air stream activated.

3. Results

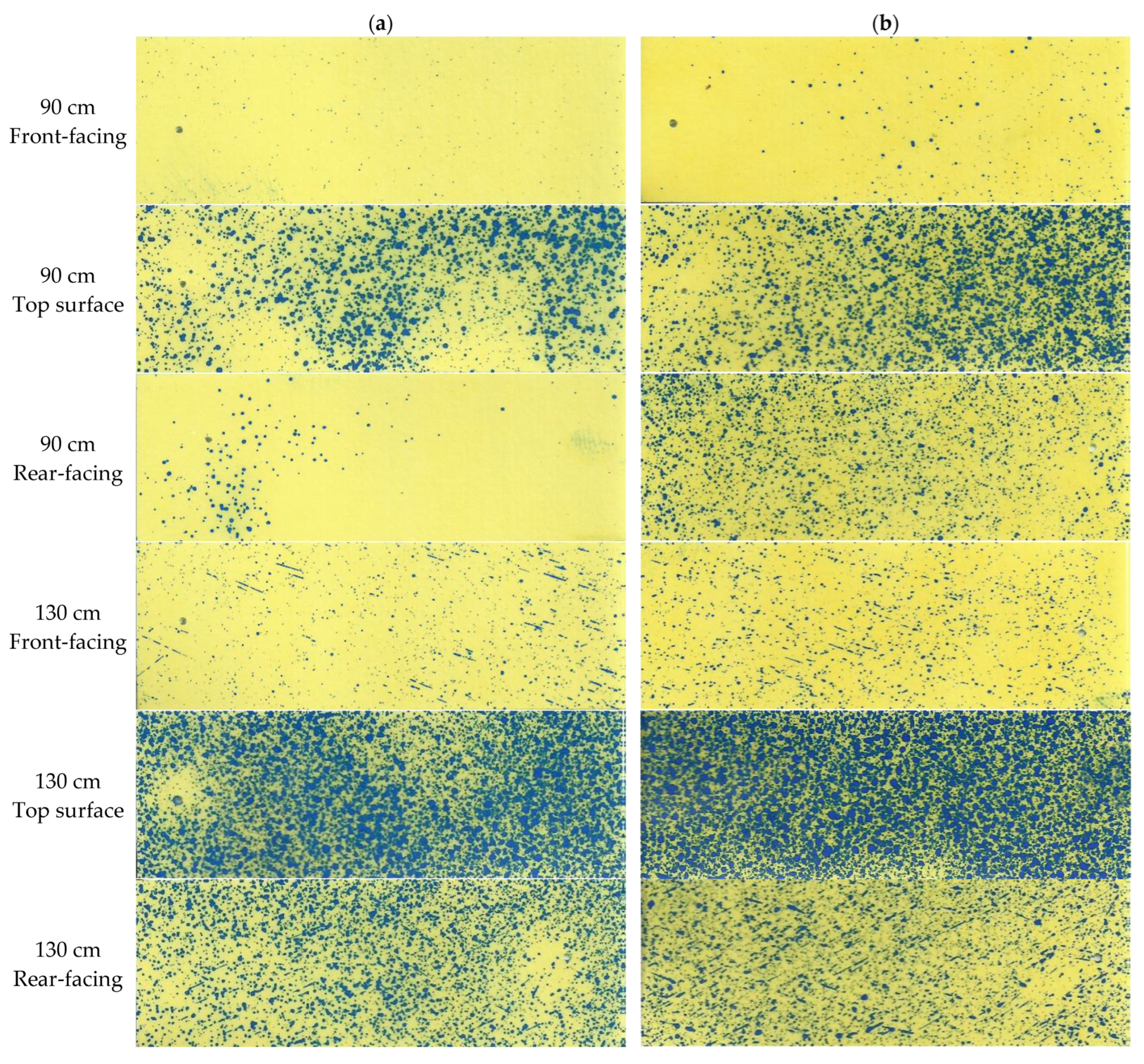

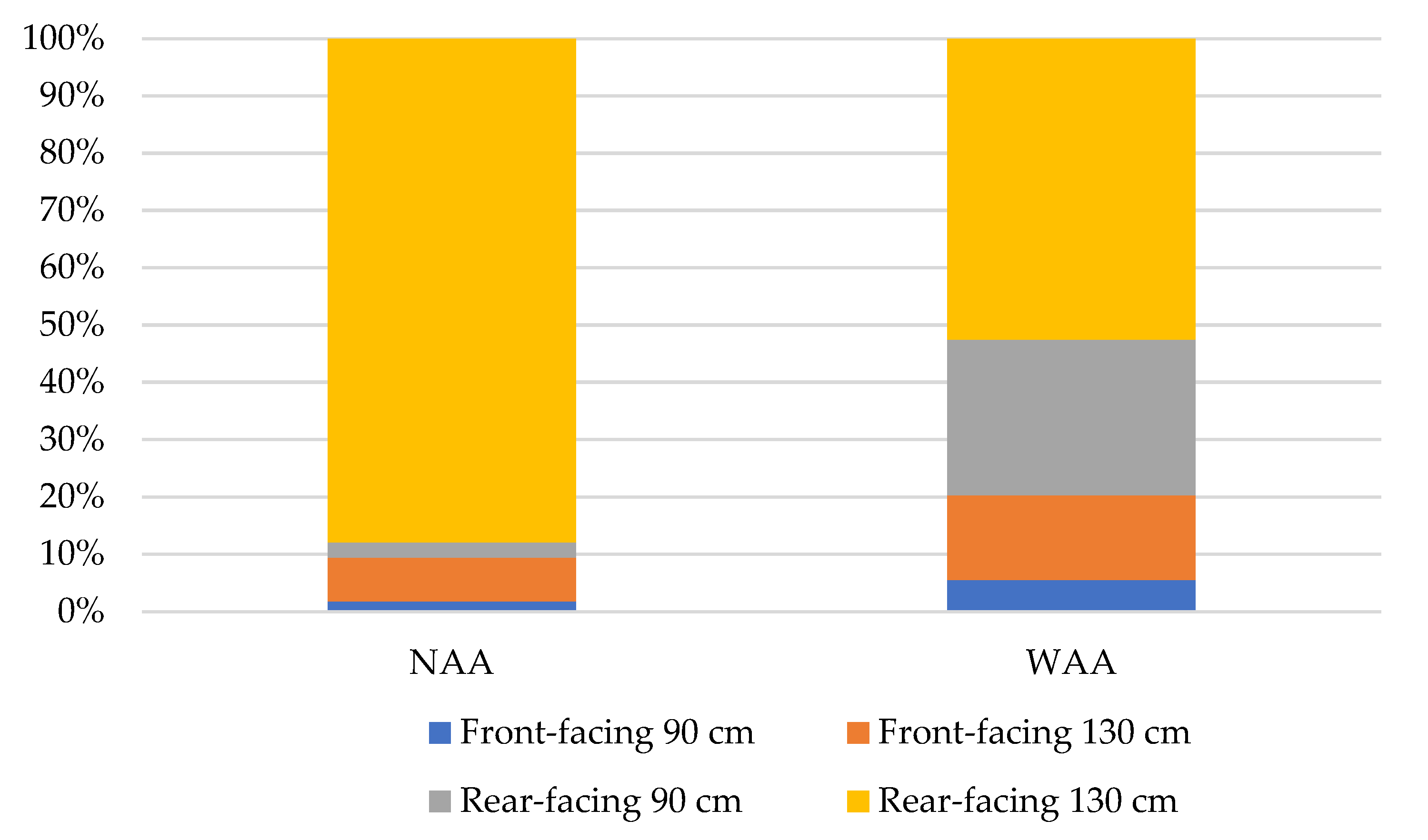

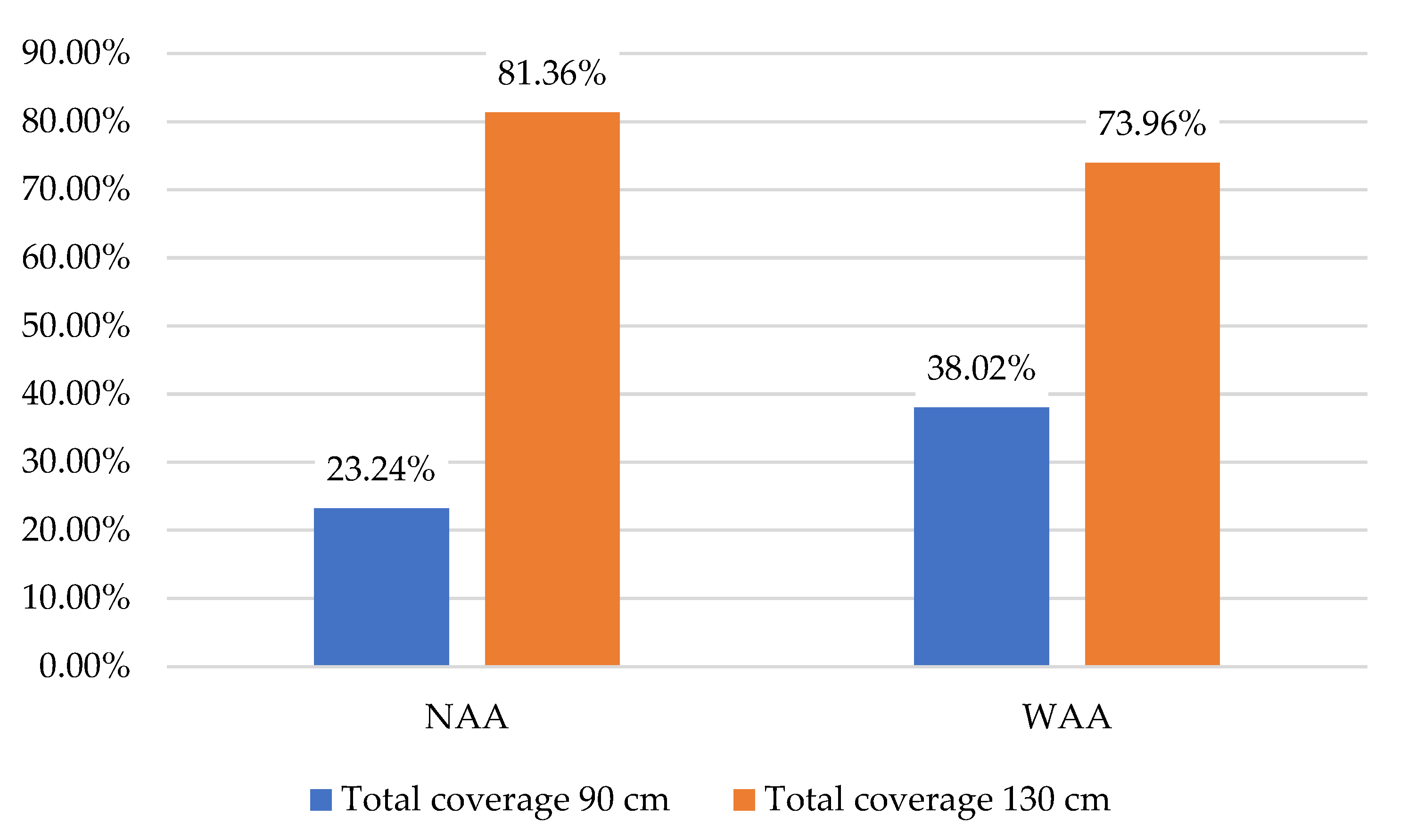

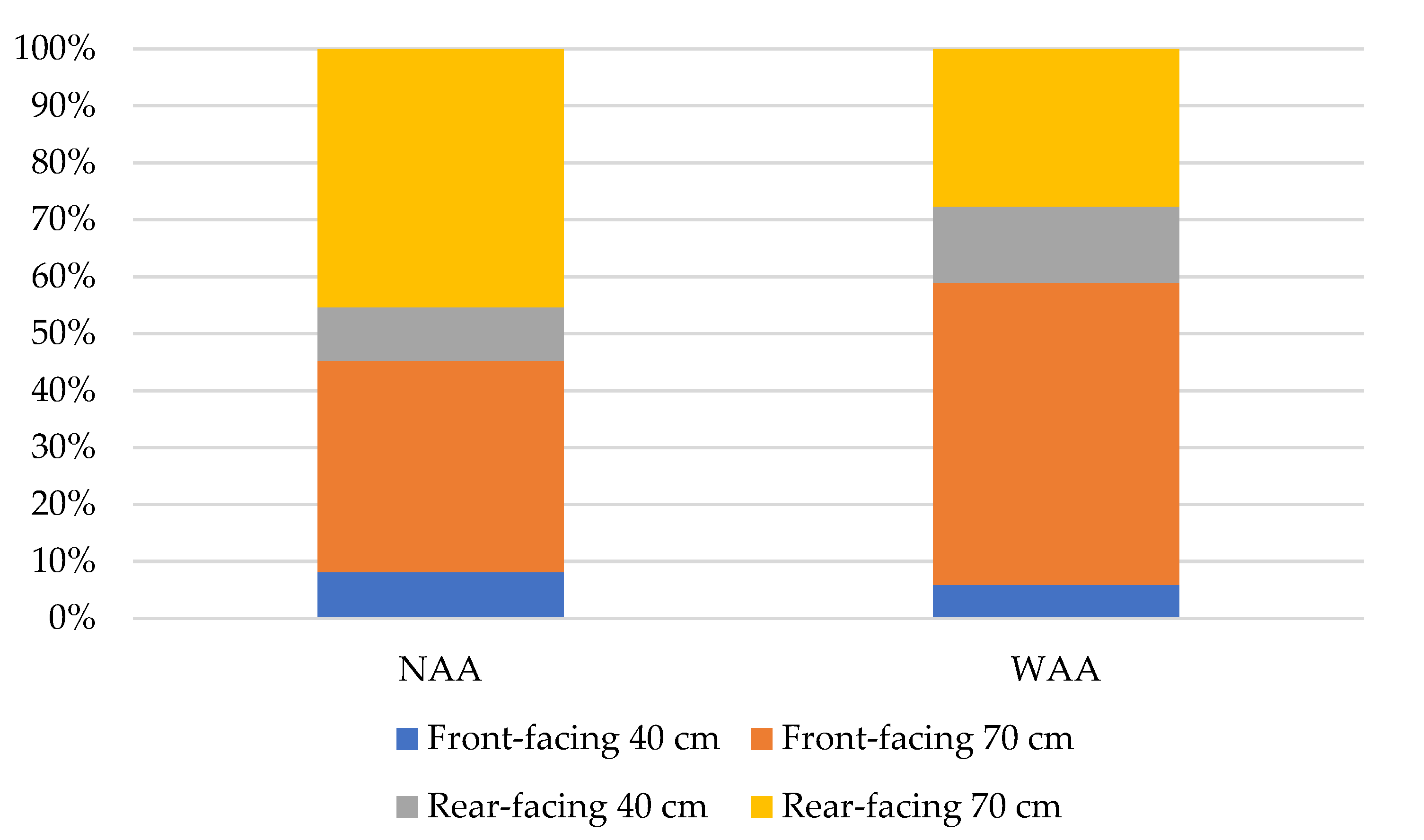

3.1. Spray Penetration in Oilseed Rape Canopy

3.2. Spray Penetration in Wheat Canopy

4. Discussion

- air assistance is more beneficial in dense canopies, where natural droplet penetration is limited;

- in more open canopies like wheat, the optimal airflow intensity and travel speed must be carefully balanced to avoid negative effects on spray deposition;

- the interaction between airflow, canopy structure, and forward speed plays a critical role in determining the effectiveness of air-assisted spraying.

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AAS | Air-assisted spraying |

| LAI | Leaf area index |

| NAA | No air assistance |

| WAA | With air assistance |

| WSP | Water-sensitive paper |

References

- Getahun, S.; Kefale, H.; Gelaye, Y. Application of precision agriculture technologies for sustainable crop production and environmental sustainability: A systematic review. Sci. World J. 2024, 1, 2126734. [Google Scholar] [CrossRef] [PubMed]

- Rasche, L. Estimating Pesticide Inputs and Yield Outputs of Conventional and Organic Agricultural Systems in Europe under Climate Change. Agronomy 2021, 11, 1300. [Google Scholar] [CrossRef]

- Washuck, N.; Hanson, M.; Prosser, R. Yield to the data: Some perspective on crop productivity and pesticides. Pest Manag. Sci. 2022, 78, 1765–1771. [Google Scholar] [CrossRef]

- Zhan, X.; Shao, C.; He, R.; Shi, R. Evolution and Efficiency Assessment of Pesticide and Fertiliser Inputs to Cultivated Land in China. Int. J. Environ. Res. Public Health 2021, 18, 3771. [Google Scholar] [CrossRef]

- Lipiński, A.J.; Lipiński, S.; Burg, P.; Sobotka, S.M. Influence of the instability of the field crop sprayer boom on the spraying uniformity. J. Agric. Food Res. 2022, 10, 100432. [Google Scholar] [CrossRef]

- Huded, S.; Savadatti, E.; Sharanappa, C.H.; Deb, L.; Borah, A.; Singh, V.; Panigrahi, C.K. Examining modern strategies for effective and sustainable agricultural plant protection techniques: A review. Int. J. Environ. Clim. Change 2023, 13, 1331–1343. [Google Scholar] [CrossRef]

- Kalogiannidis, S.; Kalfas, D.; Chatzitheodoridis, F.; Papaevangelou, O. Role of Crop-Protection Technologies in Sustainable Agricultural Productivity and Management. Land 2022, 11, 1680. [Google Scholar] [CrossRef]

- Lipiński, S.; Kaliniewicz, Z.; Markowski, P.; Szczyglak, P. Evaluation of Air-Assisted Spraying Technology for Pesticide Drift Reduction. Sustainability 2025, 17, 5036. [Google Scholar] [CrossRef]

- Ru, Y.; Hu, C.; Chen, X.; Yang, F.; Zhang, C.; Li, J.; Fang, S. Droplet Penetration Model Based on Canopy Porosity for Spraying Applications. Agriculture 2023, 13, 339. [Google Scholar] [CrossRef]

- Sharpe, S.M.; Boyd, N.S.; Dittmar, P.J.; MacDonald, G.E.; Darnell, R.L.; Ferrell, J.A. Spray penetration into a strawberry canopy as affected by canopy structure, nozzle type, and application volume. Weed Technol. 2018, 32, 80–84. [Google Scholar] [CrossRef]

- Womac, A.R.; Ozkan, E.; Zhu, H.; Kochendorfer, J.; Jeon, H. Status of spray penetration and deposition in dense field crop canopies. J. ASABE 2022, 65, 1107–1117. [Google Scholar]

- Zheng, J.; Xu, Y. A Review: Development of Plant Protection Methods and Advances in Pesticide Application Technology in Agro-Forestry Production. Agriculture 2023, 13, 2165. [Google Scholar] [CrossRef]

- Al-Barzinjy, M.; Stølen, O.; Christiansen, J.L. Comparison of growth, pod distribution and canopy structure of old and new cultivars of oilseed rape (Brassica napus L.). Acta Agric. Scand. Sect. B Plant Soil Sci. 2003, 53, 138–146. [Google Scholar] [CrossRef]

- Ferguson, J.C.; Chechetto, R.G.; Hewitt, A.J.; Chauhan, B.S.; Adkins, S.W.; Kruger, G.R.; O’Donnell, C.C. Assessing the deposition and canopy penetration of nozzles with different spray qualities in an oat (Avena sativa L.) canopy. Crop Prot. 2016, 81, 14–19. [Google Scholar] [CrossRef]

- Wang, S.; Xu, T.; Li, X. Development Status and Perspectives of Crop Protection Machinery and Techniques for Vegetables. Horticulturae 2022, 8, 166. [Google Scholar] [CrossRef]

- Cui, H.; Wang, C.; Yu, S.; Xin, Z.; Liu, X.; Yuan, J. Two-stage CFD simulation of droplet deposition on deformed leaves of cotton canopy in air-assisted spraying. Comp. Electron. Agric. 2024, 224, 109228. [Google Scholar] [CrossRef]

- Dorr, G.; Hanan, J.; Adkins, S.; Hewitt, A.; O’Donnell, C.; Noller, B. Spray deposition on plant surfaces: A modelling approach. Funct. Plant Biol. 2008, 35, 988–996. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Li, Z.; Jia, W.; Ou, M.; Dong, X.; Zhang, Z. A Review on the Evolution of Air-Assisted Spraying in Orchards and the Associated Leaf Motion During Spraying. Agriculture 2025, 15, 964. [Google Scholar] [CrossRef]

- Elsoragaby, S.; Yahya, A.; Nawi, N.M.; Mahadi, M.R.; Su, A.S.M.; Mairghany, M. Energy Use Field Performance and Greenhouse Gas Emission Evaluations of Pesticide Spraying Operations in Wetland Rice Cultivation in Malaysia. AMA Agric. Mech. Asia Afr. Lat. Am. 2021, 52, 4323–4344. [Google Scholar]

- Failla, S.; Bisaglia, C.; Schillaci, G.; Longo, D.; Romano, E. Sprayer Axial Fan Layout Affecting Energy Consumption and Carbon Emissions. Resources 2020, 9, 136. [Google Scholar] [CrossRef]

- Fathi, R.; Ghasemi-Nejad-Raeini, M.; Abdanan Mehdizadeh, S.; Taki, M.; Mardani Najafabadi, M. Energy-environmental evaluation of conventional and variable rate technology sprayer; application of Life Cycle Assessment. PLoS ONE 2025, 20, e0314911. [Google Scholar]

- Hermoso, V.; Carvalho, S.B.; Giakoumi, S.; Goldsborough, D.; Katsanevakis, S.; Leontiou, S.; Markantonatou, V.; Rumes, B.; Vogiatzakis, I.N.; Yates, K.L. The EU Biodiversity Strategy for 2030: Opportunities and challenges on the path towards biodiversity recovery. Environ. Sci. Policy 2022, 127, 263–271. [Google Scholar] [CrossRef]

- Lazarević-Pašti, T.; Milanković, V.; Tasić, T.; Petrović, S.; Leskovac, A. With or Without You?—A Critical Review on Pesticides in Food. Foods 2025, 14, 1128. [Google Scholar] [CrossRef] [PubMed]

- Nicastro, R.; Papale, M.; Fusco, G.M.; Capone, A.; Morrone, B.; Carillo, P. Legal Barriers in Sustainable Agriculture: Valorization of Agri-Food Waste and Pesticide Use Reduction. Sustainability 2024, 16, 8677. [Google Scholar] [CrossRef]

- Mowlds, S. The EU’s farm to fork strategy: Missing links for transformation. Acta Innov. 2020, 36, 17–30. [Google Scholar] [CrossRef]

- Claas Utility Tractors Axos Series Axos 330 C Full Specifications. Available online: https://machinerylink.com/tractors/claas-axos-330-cv-specifications/ (accessed on 27 September 2025).

- Agrola. Available online: https://www.agrola.com.pl/aktualnosci-tresc/nowy-projekt.html (accessed on 27 September 2025).

- Kaliniewicz, Z.; Lipiński, A.; Markowski, P.; Szczyglak, P.; Lipiński, S. The influence of selected operating parameters of a field sprayer on boom stability. Comp. Electron. Agric. 2024, 219, 108787. [Google Scholar]

- Markowski, P.; Kaliniewicz, Z.; Lipiński, A.; Lipiński, S.; Burg, P.; Mašán, V. Horizontal Distribution of Liquid in an Over-Row Sprayer with a Secondary Air Blower. Appl. Sci. 2024, 14, 9036. [Google Scholar] [CrossRef]

- Testo. Testo 410—Vane Anemometer. Available online: https://www.testo.com/en-UK/testo-410 (accessed on 27 September 2025).

- Van de Zande, J.C.; Rautmann, D.; Holterman, H.J.; Huijsmans, J.F.M. Joined Spray Drift Curves for Boom Sprayers in The Netherlands and Germany, Report No. 526; Plant Research International: Wageningen, The Netherlands, 2015. [Google Scholar]

- Felsot, A.S.; Unsworth, J.B.; Linders, J.; Roberts, G.; Rautman, D.; Harris, C.; Carazo, E. Agrochemical spray drift; assessment and mitigation—A review. J. Environ. Sci. Health B 2010, 46, 1–23. [Google Scholar]

- Gu, C.; Sun, J.; Li, S.; Yang, S.; Zou, W.; Zhai, C. Deposition Characteristics of Air-Assisted Sprayer Based on Canopy Volume and Leaf Area of Orchard Trees. Plants 2025, 14, 220. [Google Scholar] [CrossRef]

- Lopes, L.D.L.; Cunha, J.P.A.R.D.; Nomelini, Q.S.S. Use of unmanned aerial vehicle for pesticide application in soybean crop. AgriEngineering 2023, 5, 2049–2063. [Google Scholar] [CrossRef]

- Ferguson, J.C.; Hewitt, A.J.; O’Donnell, C.C.; Kruger, G.R. Comparison of water-sensitive paper, Kromekote and Mylar collectors for droplet deposition with a visible fluorescent dye solution. J. Plant Prot. Res. 2020, 60, 98–105. [Google Scholar]

- Wu, C.L.; Yang, C.K.; Lin, J.Y. Water-sensitive paper detection and spray analysis. Multimed. Tools Appl. 2025, 84, 38797–38851. [Google Scholar] [CrossRef]

- TeeJet Technologies. Water Sensitive Paper—Product Data Sheet. Available online: https://www.teejet.com.cn/-/media/dam/agricultural/usa/technical-documentation/product-data-sheet/20301_tj.pdf (accessed on 27 September 2025).

- Mississippi State University Extension. Adding RIGOR to On-Farm Trials: Simple Steps to Data-Driven Decision Making. Available online: https://extension.msstate.edu/publications/adding-rigor-farm-trials-simple-steps-data-driven-decision-making (accessed on 29 September 2025).

- Krysczun, D.K.; Lúcio, A.D.C.; Sari, B.G.; Diel, M.I.; Olivoto, T.; Santana, C.S.; Ubessi, C.; Schabarum, D.E. Sample size, plot size and number of replications for trials with Solanum melongena L. Sci. Hortic. 2018, 233, 220–224. [Google Scholar] [CrossRef]

- MathWorks MATLAB. Available online: https://www.mathworks.com/products/matlab.html (accessed on 27 September 2025).

- Lipiński, A.J.; Lipiński, S. Automatic valuation of the spraying quality on the basis of drops traces using the computer image analysis. Agric. Eng. 2009, 13, 163–168. [Google Scholar]

- Lipiński, A.J.; Lipiński, S. Binarizing water sensitive papers–how to assess the coverage area properly? Crop Prot. 2020, 127, 104949. [Google Scholar]

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Barros, W.K.P.; Dias, L.A.; Fernandes, M.A.C. Fully Parallel Implementation of Otsu Automatic Image Thresholding Algorithm on FPGA. Sensors 2021, 21, 4151. [Google Scholar] [CrossRef]

- Kalicka, R.; Lipiński, S. A fast method of separation of the noisy background from the head-cross section in the sequence of MRI scans. Biocybern. Biomed. Eng. 2010, 30, 15–27. [Google Scholar]

- Sezgin, M.; Sankur, B. Survey over image thresholding techniques and quantitative performance evaluation. J. Electron. Imaging 2004, 13, 146–165. [Google Scholar] [CrossRef]

- Xu, X.; Xu, S.; Jin, L.; Song, E. Characteristic analysis of Otsu threshold and its applications. Pattern Recognit. Lett. 2011, 32, 956–961. [Google Scholar] [CrossRef]

- Krédl, Z.; Středa, T.; Pokorný, R.; Kmoch, M.; Brotan, J. Microclimate in the vertical profile of wheat, rape and maize canopies. Acta Univ. Agric. Silvic. Mendel. Brun. 2012, 60, 79–90. [Google Scholar] [CrossRef]

- Sylvester-Bradley, R.; Lunn, G.; Foulkes, J.; Shearman, V.; Spink, J.; Ingram, J. Management Strategies for Yield of Cereals and Oilseed Rape. In Proceedings of the HGCA Conference: Agronomic Intelligence: The Basis for Profitable Production, Coventry, UK, 15–16 January 2002. [Google Scholar]

- Yang, X.; Zhang, W.; Marino, A.; Zhao, H.; Kang, W.; Xu, Z. Retrieval of Leaf Area Index for Wheat and Oilseed Rape Based on Modified Water Cloud Model and SAR Data. Agronomy 2025, 15, 1374. [Google Scholar] [CrossRef]

- Zhang, S.; Cai, C.; Li, J.; Sun, T.; Liu, X.; Tian, Y.; Xue, X. The Airflow Field Characteristics of the Unmanned Agricultural Aerial System on Oilseed Rape (Brassica napus) Canopy for Supplementary Pollination. Agronomy 2021, 11, 2035. [Google Scholar] [CrossRef]

- Wei, Z.; Li, R.; Xue, X.; Sun, Y.; Zhang, S.; Li, Q.; Chang, C.; Zhang, Z.; Sun, Y.; Dou, Q. Research Status, Methods and Prospects of Air-Assisted Spray Technology. Agronomy 2023, 13, 1407. [Google Scholar] [CrossRef]

- Wu, S.; Liu, J.; Wang, J.; Hao, D.; Wang, R. The motion of strawberry leaves in an air-assisted spray field and its influence on droplet deposition. Trans. ASABE 2021, 64, 83–93. [Google Scholar] [CrossRef]

- Khot, L.R.; Ehsani, R.; Albrigo, G.; Larbi, P.A.; Landers, A.; Campoy, J.; Wellington, C. Air-assisted sprayer adapted for precision horticulture: Spray patterns and deposition assessments in small-sized citrus canopies. Biosyst. Eng. 2012, 113, 76–85. [Google Scholar] [CrossRef]

- Liu, D.; Chen, L.; Tai, S.; Li, Y.; Xu, C. Model and experiment of target-specific variable spraying based on canopy volume perception. Crop Prot. 2025, 194, 107215. [Google Scholar] [CrossRef]

- Rathnayake, A.P.; Sahni, R.K.; Khot, L.R.; Hoheisel, G.A.; Zhu, H. Intelligent sprayer spray rates optimization to efficiently apply chemicals in modern apple orchards. J. ASABE 2022, 65, 1411–1420. [Google Scholar] [CrossRef]

- Salas, B.; Salcedo, R.; Garcia-Ruiz, F.; Gil, E. Design, implementation and validation of a sensor-based precise airblast sprayer to improve pesticide applications in orchards. Precis. Agric. 2024, 25, 865–888. [Google Scholar] [CrossRef]

- Jiang, Y.; Yang, Z.; Xu, X.; Shen, D.; Jiang, T.; Xie, B.; Duan, J. Wetting and deposition characteristics of air-assisted spray droplet on large broad-leaved crop canopy. Front. Plant Sci. 2023, 14, 1079703. [Google Scholar] [CrossRef]

- Liu, X.M.; Song, L.Q.; Cui, H.Y.; Liu, Y.C.; Liu, X.H.; Wu, M.Q. Decoupling the effects of aerosol droplet stress and canopy porosity changes on deposition performance. J. Agric. Machin. 2021, 52, 117–126. [Google Scholar]

- Shi, R.; Sun, H.; Qiu, W.; Lv, X.; Ahmad, F.; Gu, J.; Yu, H.; Zhang, Z. Analysing Airflow Velocity in the Canopy to Improve Droplet Deposition for Air-Assisted Spraying: A Case Study on Pears. Agronomy 2022, 12, 2424. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Q.; Zhou, H.; Liu, C.; Han, R.; Lv, X. Morphological changes and spray coverage of pear leaves and canopy at different phenological periods during air-assisted spraying. Crop Prot. 2025, 107324. [Google Scholar]

- Panneton, B.; Philion, V.; Chouinard, G. Spray deposition with conventional nozzles, low-drift nozzles, or permanent sprinklers for controlling apple orchard pests. Trans. ASABE 2015, 58, 607–619. [Google Scholar] [CrossRef]

- Godoy-Nieto, A.; Miranda-Fuentes, A.; Grella, M.; Blanco-Roldán, G.L.; Rodríguez-Lizana, A.; Gil-Ribes, J.A. Assessment of Spray Deposit and Loss in Traditional and Intensive Olive Orchards with Conventional and Crop-Adapted Sprayers. Agronomy 2022, 12, 1764. [Google Scholar] [CrossRef]

- Sinha, R.; Ranjan, R.; Khot, L.R.; Hoheisel, G.A.; Grieshop, M.J. Drift potential from a solid set canopy delivery system and an axial–fan air–assisted sprayer during applications in grapevines. Biosyst. Eng. 2019, 188, 207–216. [Google Scholar]

- Wang, Y.; Zhang, Z.; Jia, W.; Ou, M.; Dong, X.; Dai, S. A Review of Environmental Sensing Technologies for Targeted Spraying in Orchards. Horticulturae 2025, 11, 551. [Google Scholar] [CrossRef]

- Frisvold, G.B. How low can you go? Estimating impacts of reduced pesticide use. Pest Manag. Sci. 2019, 75, 1223–1233. [Google Scholar] [CrossRef] [PubMed]

- Skevas, T.; Stefanou, S.E.; Oude Lansink, A. Pesticide use, environmental spillovers and efficiency: A DEA risk-adjusted efficiency approach applied to Dutch arable farming. Eur. J. Oper. Res. 2014, 237, 658–664. [Google Scholar] [CrossRef]

- Alexoaei, A.P.; Robu, R.G.; Cojanu, V.; Miron, D.; Holobiuc, A.M. Good practices in reforming the common agricultural policy to support the european green Deal–a perspective on the consumption of pesticides and fertilizers. Amfiteatru Econ. 2022, 24, 525–545. [Google Scholar] [CrossRef]

- Boonupara, T.; Udomkun, P.; Khan, E.; Kajitvichyanukul, P. Airborne Pesticides from Agricultural Practices: A Critical Review of Pathways, Influencing Factors, and Human Health Implications. Toxics 2023, 11, 858. [Google Scholar] [CrossRef]

- Conrad, A.G.; Tolar-Peterson, T.; Gardner, A.J.; Wei, T.; Evans, M.W., Jr. Addressing Food Insecurity: A Qualitative Study of Undergraduate Students’ Perceptions of Food Access Resources. Nutrients 2022, 14, 3517. [Google Scholar] [CrossRef]

- Pimentel, M. Food as a resource. In Food and Natural Resources; Pimentel, D., Hall, C.W., Eds.; Academic Press: New York, NY, USA, 1989; pp. 409–437. [Google Scholar]

- Vivero-Pol, J.L. Food as Commons or Commodity? Exploring the Links between Normative Valuations and Agency in Food Transition. Sustainability 2017, 9, 442. [Google Scholar] [CrossRef]

| Aggregate Speed | Air Assistance | Front-Facing | Top Surface | Rear-Facing | |||

|---|---|---|---|---|---|---|---|

| 130 cm | 90 cm | 130 cm | 90 cm | 130 cm | 90 cm | ||

| 6 kmph | No | 0.94% | 2.06% | 22.56% | 53.38% | 0.60% | 27.04% |

| Yes | 1.77% | 6.69% | 41.93% | 65.48% | 9.47% | 9.77% | |

| 7 kmph | No | 0.33% | 3.08% | 19.53% | 43.31% | 1.03% | 29.99% |

| Yes | 2.79% | 4.49% | 20.93% | 44.76% | 8.60% | 13.64% | |

| 8 kmph | No | 0.37% | 1.69% | 23.58% | 61.35% | 0.78% | 22.19% |

| Yes | 0.67% | 2.80% | 20.19% | 47.85% | 7.70% | 26.40% | |

| Aggregate Speed | Air Assistance | Front-Facing | Top Surface | Rear-Facing | |||

|---|---|---|---|---|---|---|---|

| 70 cm | 40 cm | 70 cm | 40 cm | 70 cm | 40 cm | ||

| 6 kmph | No | 0.51% | 2.54% | 28.33% | 58.34% | 3.05% | 20.46% |

| Yes | 1.42% | 13.52% | 31.43% | 59.05% | 4.43% | 20.15% | |

| 7 kmph | No | 2.08% | 13.33% | 34.61% | 68.30% | 2.06% | 6.05% |

| Yes | 2.74% | 21.92% | 28.41% | 42.92% | 3.72% | 2.55% | |

| 8 kmph | No | 3.53% | 12.31% | 37.47% | 64.19% | 2.02% | 7.86% |

| Yes | 1.54% | 15.90% | 27.82% | 47.76% | 4.75% | 4.06% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lipiński, S.; Markowski, P.; Kaliniewicz, Z.; Szczyglak, P. Improving Resource Efficiency in Plant Protection by Enhancing Spray Penetration in Crop Canopies Using Air-Assisted Spraying. Resources 2025, 14, 165. https://doi.org/10.3390/resources14100165

Lipiński S, Markowski P, Kaliniewicz Z, Szczyglak P. Improving Resource Efficiency in Plant Protection by Enhancing Spray Penetration in Crop Canopies Using Air-Assisted Spraying. Resources. 2025; 14(10):165. https://doi.org/10.3390/resources14100165

Chicago/Turabian StyleLipiński, Seweryn, Piotr Markowski, Zdzisław Kaliniewicz, and Piotr Szczyglak. 2025. "Improving Resource Efficiency in Plant Protection by Enhancing Spray Penetration in Crop Canopies Using Air-Assisted Spraying" Resources 14, no. 10: 165. https://doi.org/10.3390/resources14100165

APA StyleLipiński, S., Markowski, P., Kaliniewicz, Z., & Szczyglak, P. (2025). Improving Resource Efficiency in Plant Protection by Enhancing Spray Penetration in Crop Canopies Using Air-Assisted Spraying. Resources, 14(10), 165. https://doi.org/10.3390/resources14100165