Improvement of MBBR Performance by the Addition of 3D-Printed Biocarriers Fabricated with 13X and Bentonite

Abstract

1. Introduction

2. Materials and Methods

2.1. List of Reagents Used

- ✓

- D(+)glucose, anhydrous;

- ✓

- Starch from corn;

- ✓

- Ammonium chloride;

- ✓

- Proteose peptone;

- ✓

- Potassium phosphate monobasic;

- ✓

- Magnesium sulfate;

- ✓

- Manganese (II) sulfate monohydrate;

- ✓

- Ferrous sulfate;

- ✓

- Sodium bicarbonate;

- ✓

- Bentonite;

- ✓

- Organic binders;

- ✓

- Silica, colloidal;

- ✓

- Bovine serum albumin;

- ✓

- Na2Tartrate.2H2O;

- ✓

- Folin and Ciocalteu’s phenol reagent 2Ν;

- ✓

- Phenol;

- ✓

- Sulfuric acid 95–97%.

- ✓

- Glucose;

- ✓

- Sodium chloride;

- ✓

- Sodium hydroxide;

- ✓

- Sodium carbonate;

- ✓

- Copper(II) sulfate 5-hydrate.

- ✓

- phiX control library;

- ✓

- Illumina MiSeqTM platform;

- ✓

- MiSeq Reagent Nano Kit version 2 chemistry (500-cycle).

- ✓

- 13X zeolite.

- ✓

- LCK kits for COD, total N, NH4-N, and NO3-N measurement.

- ✓

- DNeasy PowerSoil Pro Kit;

- ✓

- QIAseq Library Quant Assay Kit.

- ✓

- 341f/805r primer pair.

- ✓

- Qubit™ 4 fluorometer.

- ✓

- Agarose low EEO for biochemistry.

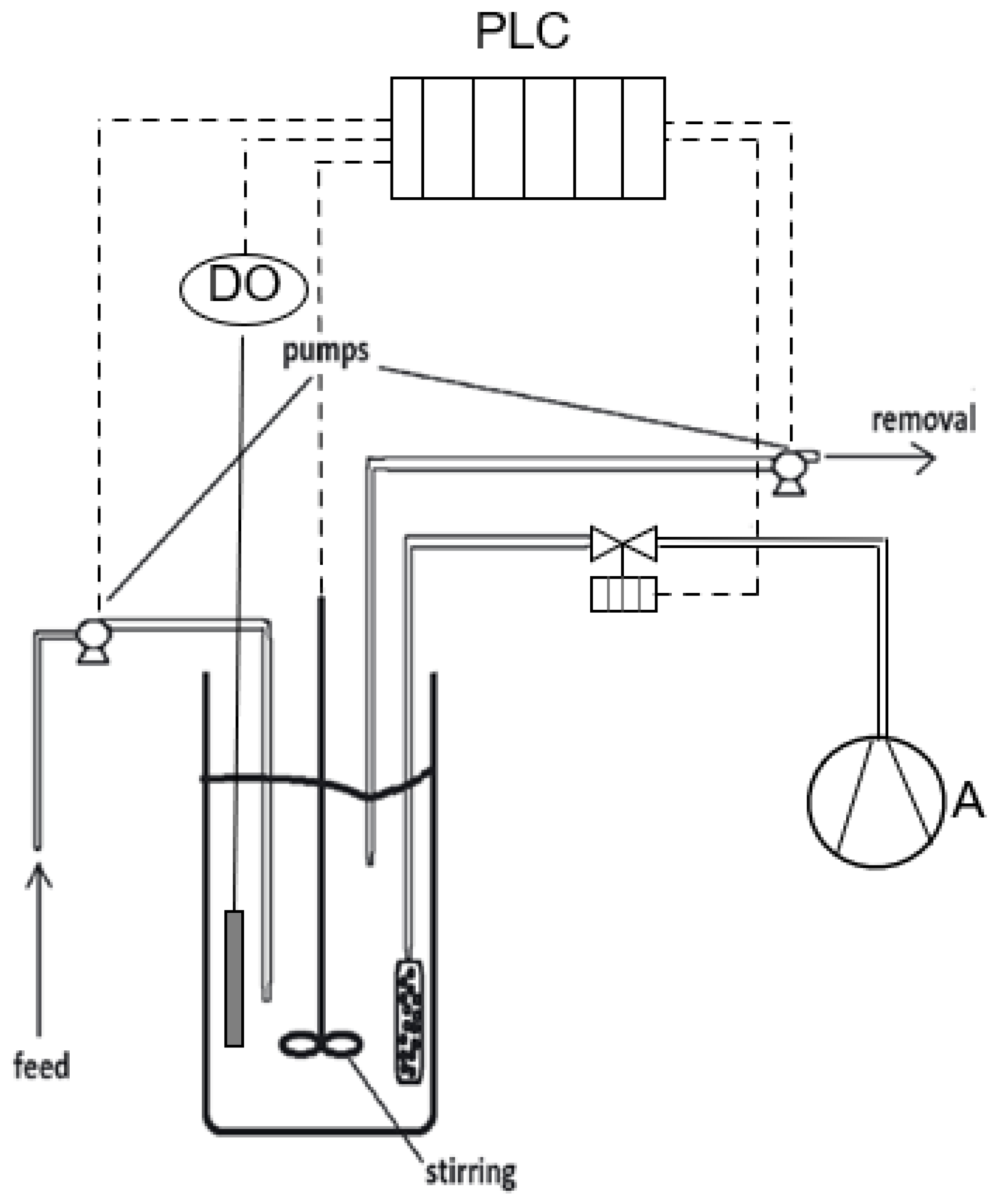

2.2. Moving Bed Biofilm Reactor Set-Up and Operating Conditions

2.3. Biofilm Extraction Method

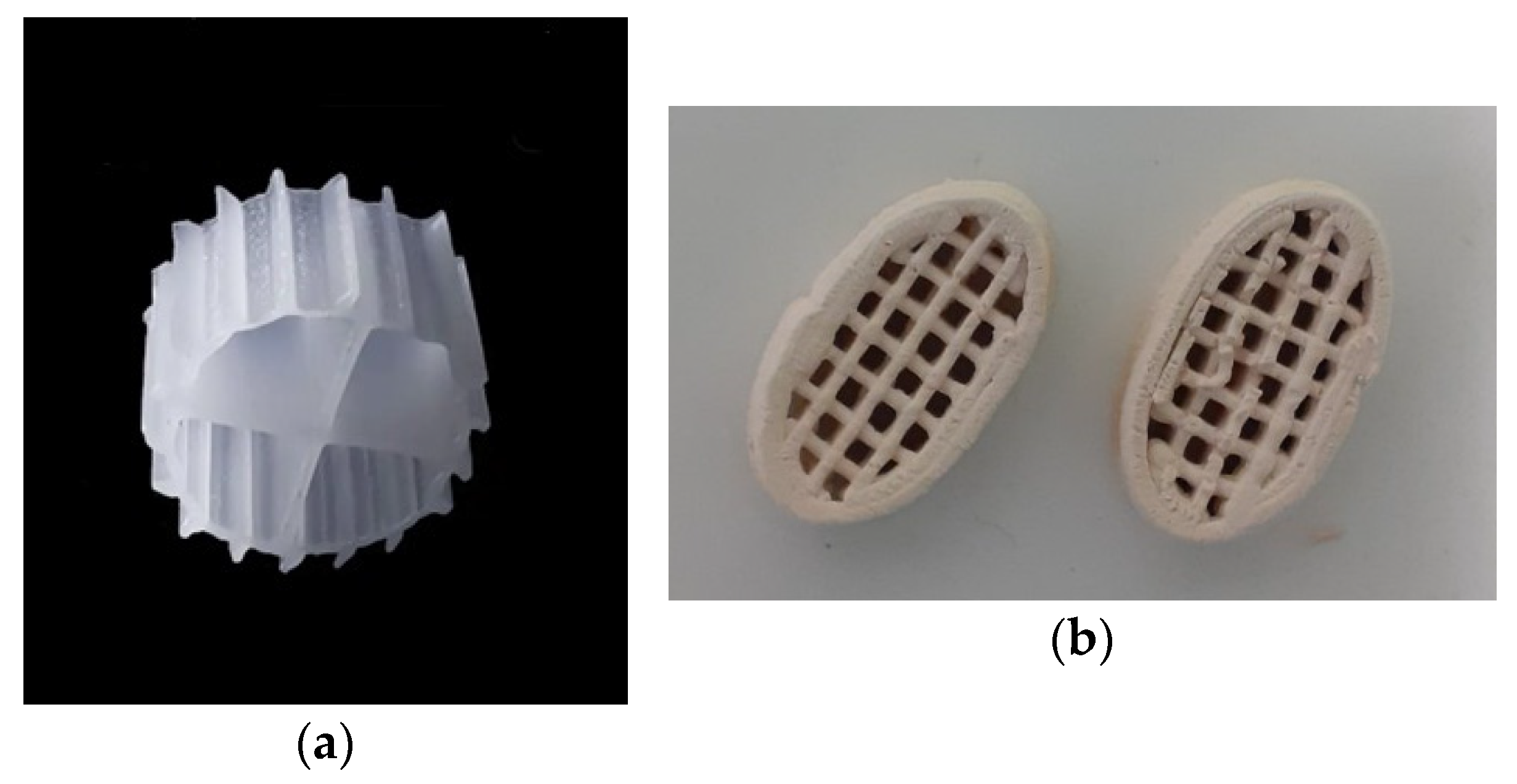

2.4. Printing Methodology of the 3D-Printed Biocarriers with 13X and Bentonite and Their Characterization

2.5. Determination of the Physicochemical Parameters

2.6. DNA Extraction and 16S rRNA Gene Amplicon Sequencing

2.7. Bioinformatics

3. Results

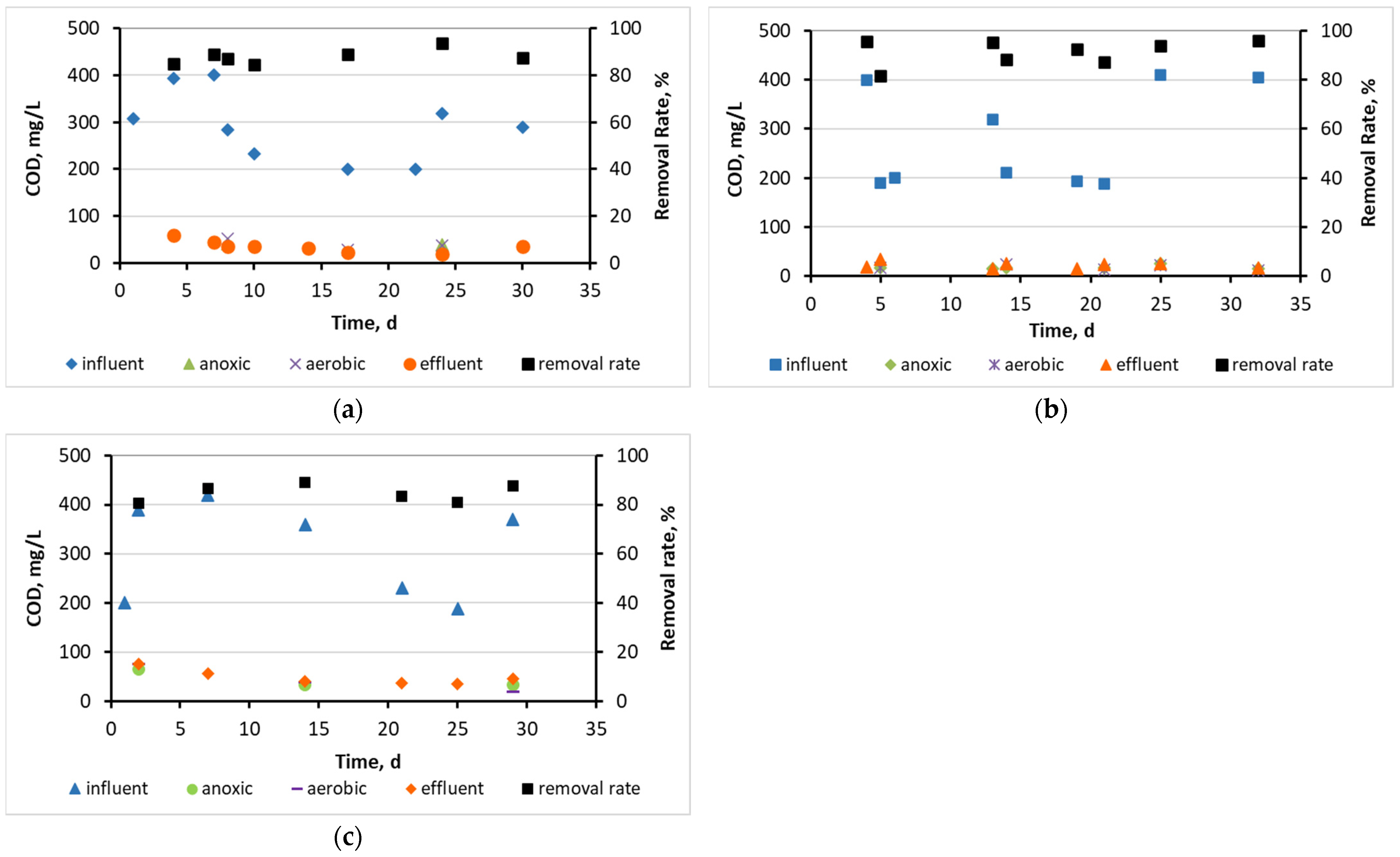

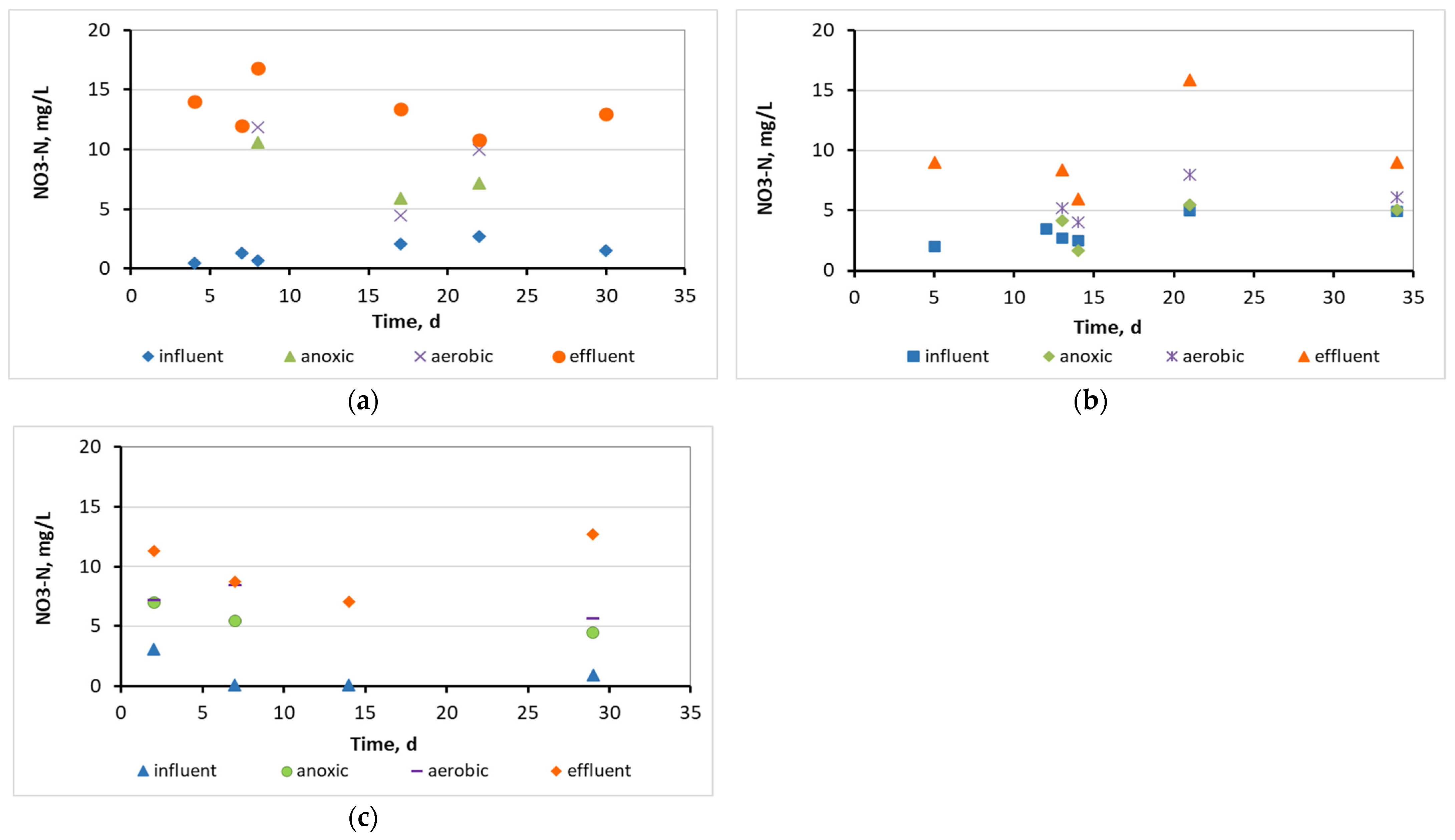

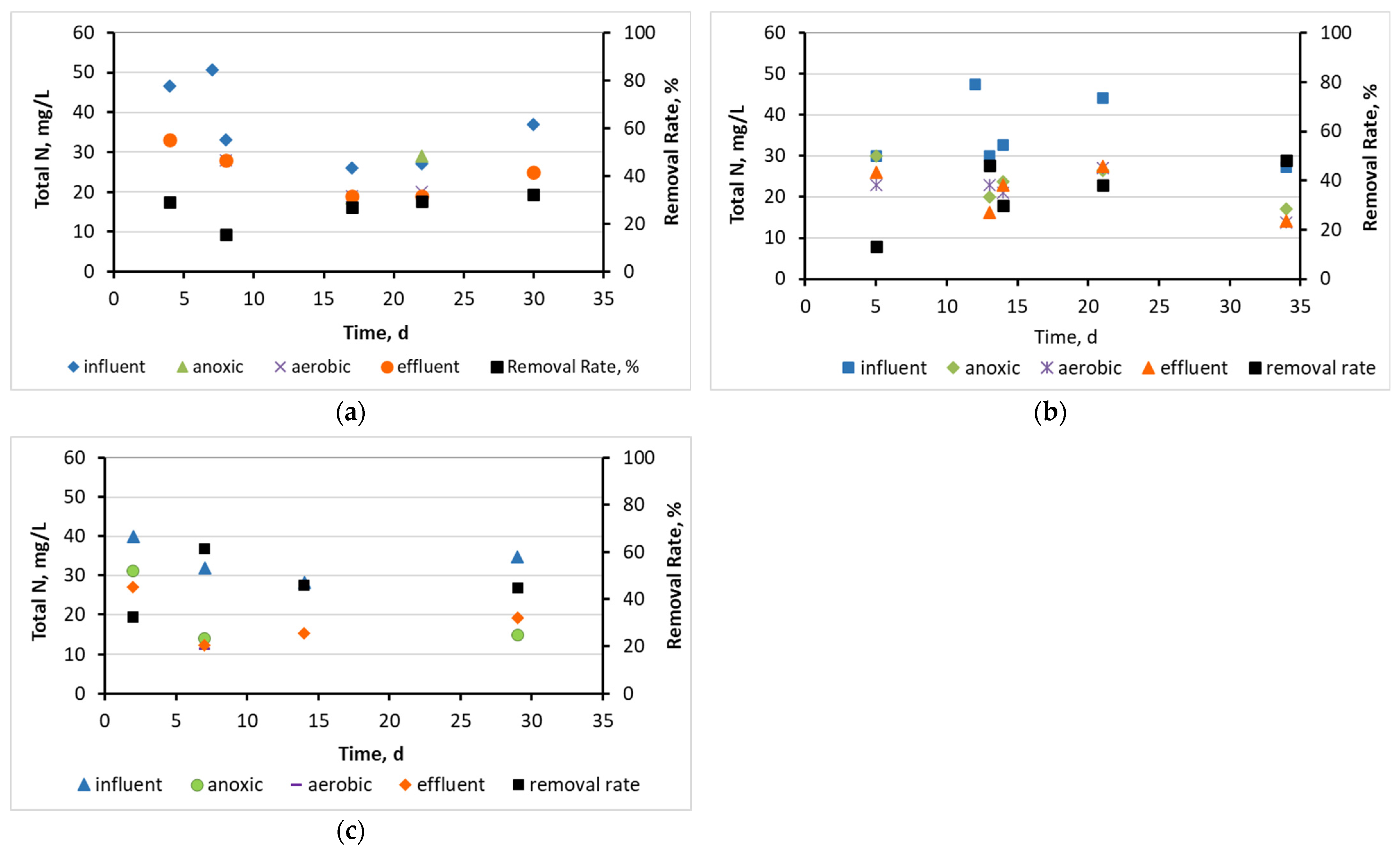

3.1. Wastewater Treatment Efficiency and Physicochemical Parameters in the Three MBBRs

3.2. Evaluation of the Biofilm Developed on the Surfaces of Biocarriers

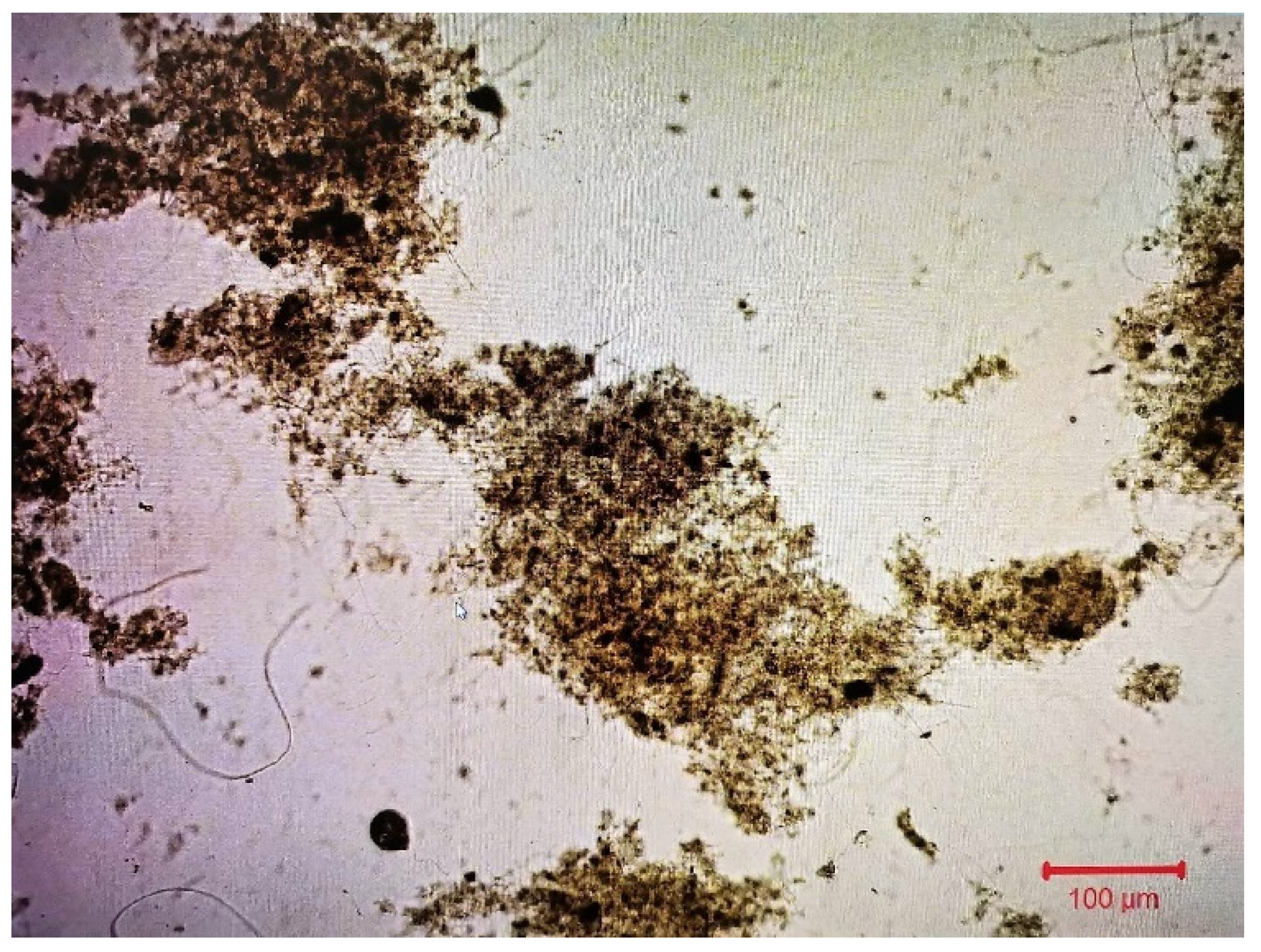

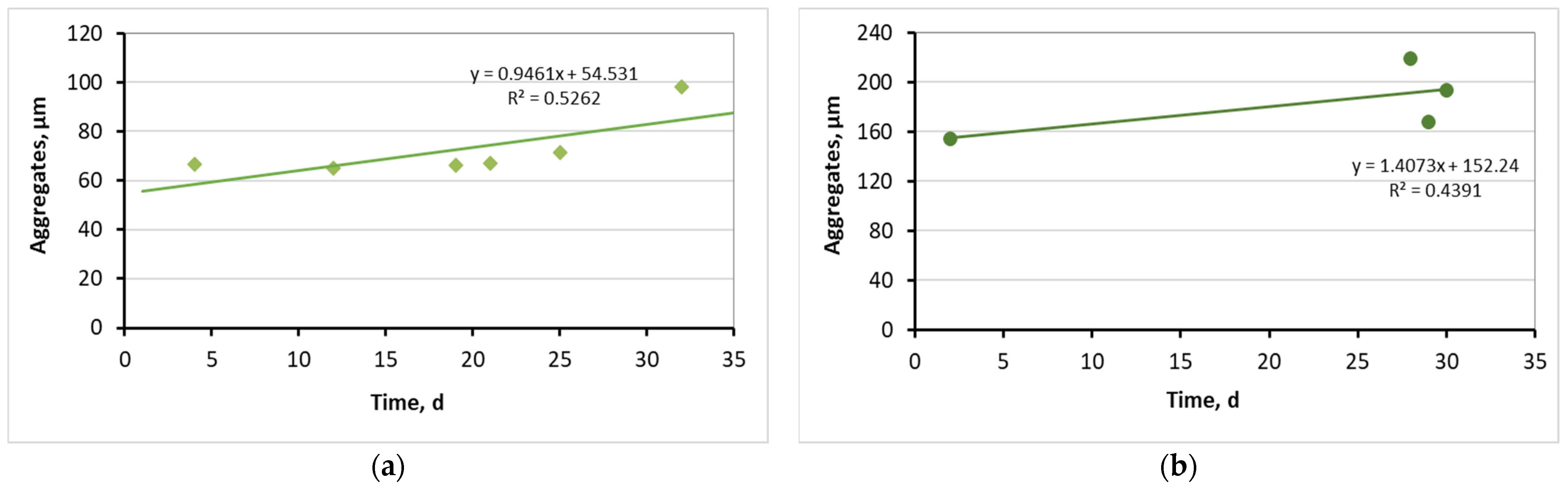

3.2.1. Biofilm Developed on the Kaldnes K1 Biocarriers

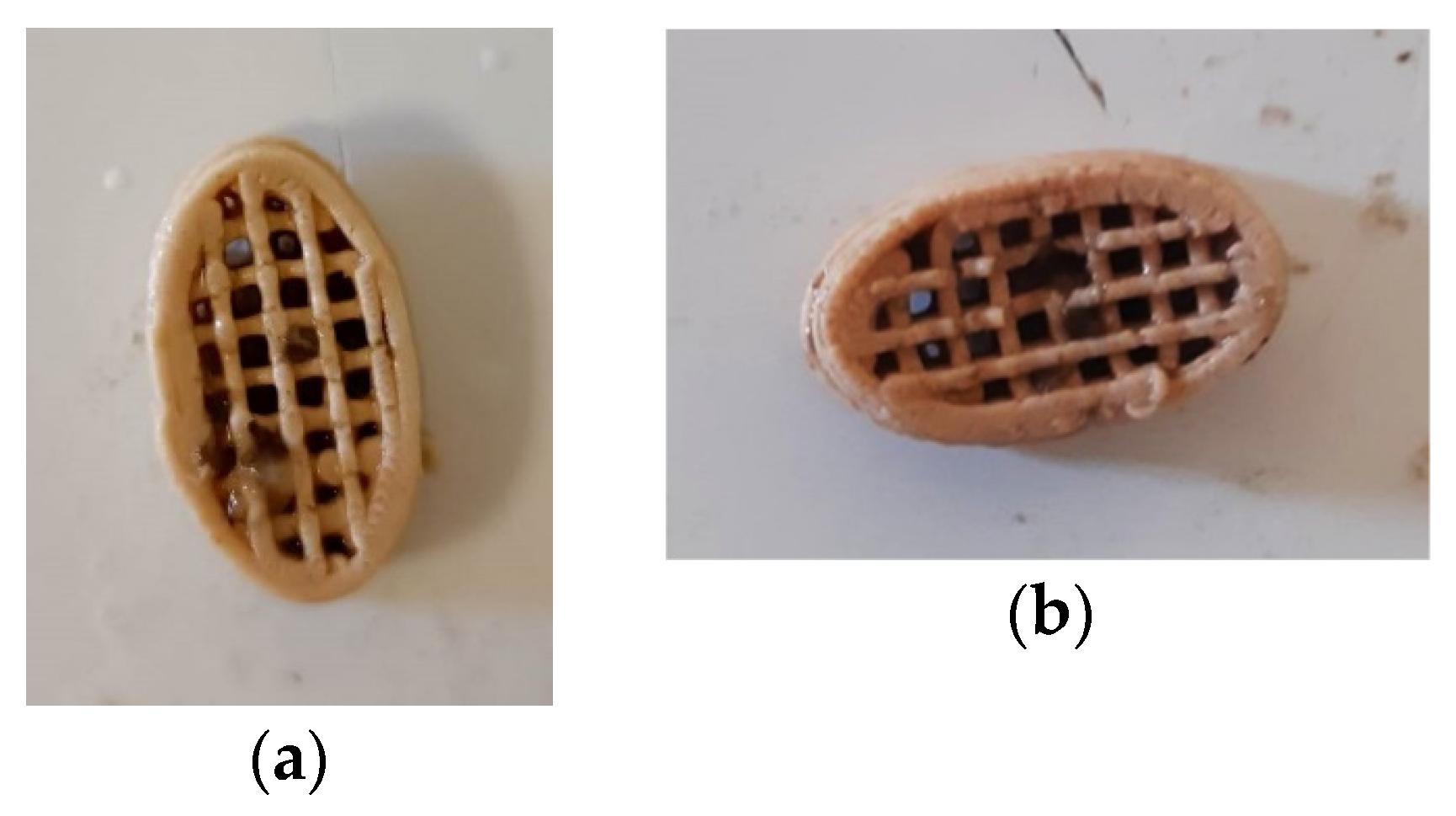

3.2.2. Biofilm on the 3D-Printed Biocarriers Developed with 13X and Bentonite

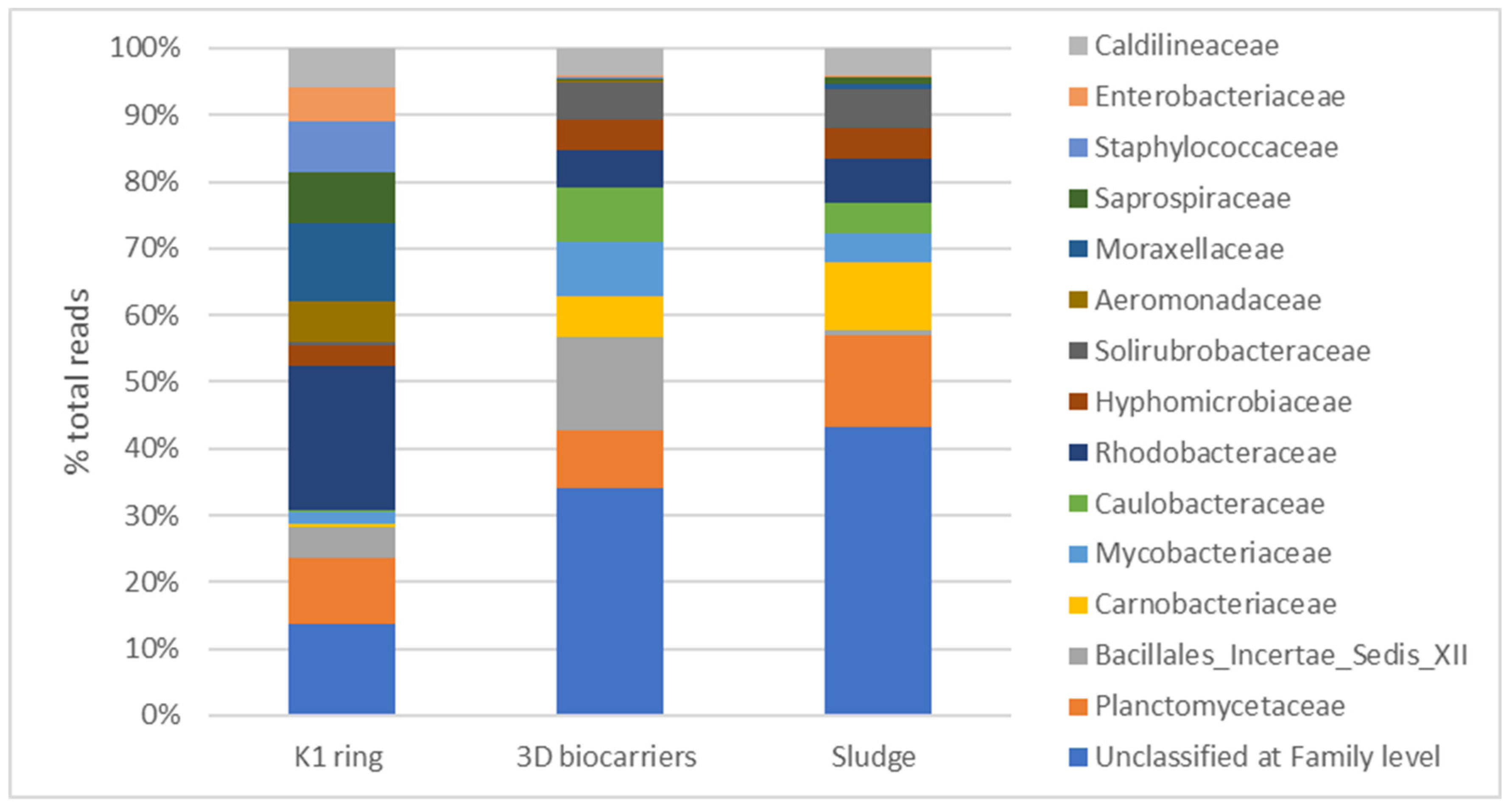

3.2.3. Biofilm Microbiome Analysis on Biocarriers through 16S rRNA Sequencing

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Boltz, J.P.; Smets, B.F.; Rittmann, B.E.; Van Loosdrecht, M.C.M.; Morgenroth, E.; Daigger, G.T. From biofilm ecology to reactors: A focused review. Water Sci. Technol. 2017, 75, 1753–1760. [Google Scholar] [CrossRef]

- Kawan, J.A.; Abu Hasan, H.; Suja, F.; Jaafar, O.; Abd-Rahman, R. A review on sewage treatment and polishing using moving bed bioreactor (MBBR). J. Eng. Sci. Technol. 2016, 11, 1098–1120. [Google Scholar]

- Avellán, T.; Hahn, A.; Kirschke, S.; Müller, A.; Benavides, L.; Caucci, S. Co-generating knowledge in nexus research for sustainable wastewater treatment. Resources 2022, 11, 93. [Google Scholar] [CrossRef]

- Banti, D.C.; Tsangas, M.; Samaras, P.; Zorpas, A. LCA of a membrane bioreactor compared to activated sludge system for municipal wastewater treatment. Membranes 2020, 10, 421. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, D.; Huang, W.; Yang, Y.; Ji, M.; Nghiem, L.D.; Trinh, Q.T.; Tran, N.H. Insights into biofilm carriers for biological wastewater treatment processes: Current state-of-the-art, challenges, and opportunities. Bioresour. Technol. 2019, 288, 121619. [Google Scholar] [CrossRef] [PubMed]

- Dezotti, M.; Lippel, G.; Bassin, J.P. Advanced Biological Processes for Wastewater Treatment: Emerging, Consolidated Technologies and Introduction to Molecular Techniques; Springer: Berlin, Germany, 2017; ISBN 9783319588353. [Google Scholar]

- Saidulu, D.; Majumder, A.; Gupta, A.K. A systematic review of moving bed biofilm reactor, membrane bioreactor, and moving bed membrane bioreactor for wastewater treatment: Comparison of research trends, removal mechanisms, and performance. J. Environ. Chem. Eng. 2021, 9, 106112. [Google Scholar] [CrossRef]

- Conserva, S.; Tatti, F.; Torretta, V.; Ferronato, N.; Viotti, P. An integrated approach to the biological reactor-sedimentation tank system. Resources 2019, 8, 94. [Google Scholar] [CrossRef]

- Dong, Y.; Fan, S.Q.; Shen, Y.; Yang, J.X.; Yan, P.; Chen, Y.P.; Li, J.; Guo, J.S.; Duan, X.M.; Fang, F.; et al. A novel bio-carrier fabricated using 3D Printing technique for wastewater treatment. Sci. Rep. 2015, 5, 12400. [Google Scholar] [CrossRef] [PubMed]

- Tang, B.; Song, H.; Bin, L.; Huang, S.; Zhang, W.; Fu, F.; Zhao, Y.; Chen, Q. Bioresource Technology Determination of the profile of DO and its mass transferring coefficient in a biofilm reactor packed with semi-suspended bio-carriers. Bioresour. Technol. 2017, 241, 54–62. [Google Scholar] [CrossRef] [PubMed]

- Gerard, M.H. Troubleshooting the Sequencing Batch Reactor; John Wiley & Sons, Inc., Publication: Hoboken, NJ, USA, 2011; ISBN 9781118058220. [Google Scholar]

- Felföldi, T.; Jurecska, L.; Vajna, B.; Barkács, K.; Makk, J.; Cebe, G.; Szabó, A.; Záray, G.; Márialigeti, K. Texture and type of polymer fiber carrier determine bacterial colonization and biofilm properties in wastewater treatment. Chem. Eng. J. 2015, 264, 824–834. [Google Scholar] [CrossRef]

- Elliott, O.; Gray, S.; Mcclay, M.; Nassief, B.; Nunnelley, A.; Ekong, J.; Kardel, K.; Khoshkhoo, A.; Proaño, G.; David, M.; et al. Design and Manufacturing of High Surface Area 3D-Printed Media for Moving Bed Bioreactors for Wastewater Treatment. J. Contemp. Water Res. Educ. 2017, 160, 144–156. [Google Scholar] [CrossRef]

- Proano-Pena, G.; Carrano, A.L.; Blersch, D.M. Analysis of very-high surface area 3D-printed media in a moving bed biofilm reactor for wastewater treatment. PLoS ONE 2020, 15, e0238386. [Google Scholar] [CrossRef]

- Song, Z.; Su, X.; Li, P.; Sun, F.; Dong, W.; Zhao, Z.; Wen, Z.; Liao, R. Facial fabricated biocompatible homogeneous biocarriers involving biochar to enhance denitrification performance in an anoxic moving bed biofilm reactor. Bioresour. Technol. 2021, 341, 125866. [Google Scholar] [CrossRef]

- Chioti, A.G.; Tsioni, V.; Patsatzis, S.; Filidou, E.; Banti, D.; Samaras, P.; Economou, E.A.; Kostopoulou, E.; Sfetsas, T. Characterization of biofilm microbiome formation developed on novel 3D-printed zeolite biocarriers during aerobic and anaerobic digestion processes. Fermentation 2022, 8, 746. [Google Scholar] [CrossRef]

- Al-amshawee, S.K.A.; Bin, Y.; Yunus, M. Experimental investigation of bio fi lm carriers of varying shapes, sizes, and materials for wastewater treatment in fi xed bed bio fi lm reactor: A qualitative study of biocarrier performance. J. Chem. Technol. Biotechnol. 2022, 97, 2592–2606. [Google Scholar] [CrossRef]

- Szymula, A.; Wlazło, Ł.; Sasáková, N.; Wnuk, W.; Nowakowicz-Dębek, B. The use of natural sorbents to reduce ammonia emissions from cattle faeces. Agronomy 2021, 11, 2543. [Google Scholar] [CrossRef]

- Gkotsis, P.; Banti, D.; Pritsa, A.; Mitrakas, M.; Samaras, P.; Peleka, E.; Zouboulis, A. Effect of operating conditions on membrane fouling in pilot-scale mbrs; filaments growth, diminishing dissolved oxygen and recirculation rate of the activated sludge. Membranes 2021, 11, 490. [Google Scholar] [CrossRef]

- Bassin, J.P.; Kleerebezem, R.; Rosado, A.S.; Van Loosdrecht, M.C.M.; Dezotti, M. Effect of different operational conditions on biofilm development, nitrification, and nitrifying microbial population in moving-bed biofilm reactors. Environ. Sci. Technol. 2012, 46, 1546–1555. [Google Scholar] [CrossRef]

- Gupta, B.; Kumar, A.; Sarathi, P.; Lal, S. Journal of Environmental Chemical Engineering Recent advances in application of moving bed biofilm reactor for wastewater treatment: Insights into critical operational parameters, modifications, field-scale performance, and sustainable aspects. J. Environ. Chem. Eng. 2022, 10, 107742. [Google Scholar] [CrossRef]

- Poltak, R.F. Sequencing Batch Reactor Design and Operational Considerations Manual; New England Interstate Water Pollution Control Commission: Lowell, MA, USA, 2005; Volume 27, p. 104. [Google Scholar]

- Banti, D.C.; Karayannakidis, P.D.; Samaras, P.; Mitrakas, M.G. An innovative bioreactor set-up that reduces membrane fouling by adjusting the filamentous bacterial population. J. Membr. Sci. 2017, 542, 430–438. [Google Scholar] [CrossRef]

- Banti, D.; Mitrakas, M.; Fytianos, G.; Tsali, A.; Samaras, P. Combined effect of colloids and SMP on membrane fouling in MBRs. Membranes 2020, 10, 118. [Google Scholar] [CrossRef]

- Mandakhalikar, K.D.; Rahmat, J.N.; Chiong, E.; Neoh, K.G.; Shen, L.; Tambyah, P.A. Extraction and quantification of biofilm bacteria: Method optimized for urinary catheters. Sci. Rep. 2018, 8, 8069. [Google Scholar] [CrossRef]

- Mohamed, A.; Rajaa, A.M.; Khalid, Z.; Fouad, M.; Naima, R. Comparison of three methods for the detection of biofilm formation by clinical isolates of Staphylococcus aureus isolated in Casablanca. Int. J. Sci. Res. 2013, 5, 2319–7064. [Google Scholar]

- APHA (American Public Health Association). Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 1998. [Google Scholar]

- Hwang, B.K.; Kim, J.H.; Ahn, C.H.; Lee, C.H.; Song, J.Y.; Ra, Y.H. Effect of disintegrated sludge recycling on membrane permeability in a membrane bioreactor combined with a turbulent jet flow ozone contactor. Water Res. 2010, 44, 1833–1840. [Google Scholar] [CrossRef]

- Banti, D.C.; Samaras, P.; Tsioptsias, C.; Zouboulis, A.; Mitrakas, M. Mechanism of SMP aggregation within the pores of hydrophilic and hydrophobic MBR membranes and aggregates detachment. Sep. Purif. Technol. 2018, 202, 119–129. [Google Scholar] [CrossRef]

- Hartree, E.F. Determination of protein: A modification of the Lowry method that gives a lineart photometric response. Anal. Biochem. 1972, 48, 422–427. [Google Scholar] [CrossRef]

- Dubois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.A.; Smith, F. Colorimetric Method for Determination of Sugars and Related Substances. Anal. Chem. 1956, 28, 350–356. [Google Scholar] [CrossRef]

- Eikelboom, D.H. Process Control of Activated Sludge Plants by Microscopic Investigation; IWA Publishing: Zutphen, The Netherlands, 2000. [Google Scholar]

- Banti, D.C.; Mitrakas, M.; Samaras, P. Membrane fouling controlled by adjustment of biological treatment parameters in step-aerating MBR. Membranes 2021, 11, 553. [Google Scholar] [CrossRef]

- Bolyen, E.; Rideout, J.R.; Dillon, M.R.; Bokulich, N.A.; Abnet, C.C.; Al-Ghalith, G.A.; Alexander, H.; Alm, E.J.; Arumugam, M.; Asnicar, F.; et al. Reproducible, interactive, scalable and extensible microbiome data science using QIIME 2. Nat. Biotechnol. 2019, 37, 852–857. [Google Scholar] [CrossRef]

- Benjamin, C.; McMurdie, P.; Rosen, M.; Han, A.; Johnson, A.; Holmes, S. DADA2:High resolution sample inference from Illumina amplicon data. Encycl. Med. Immunol. 2020, 13, 581–583. [Google Scholar]

- Quast, C.; Pruesse, E.; Yilmaz, P.; Gerken, J.; Schweer, T.; Yarza, P.; Peplies, J.; Glöckner, F.O. The SILVA ribosomal RNA gene database project: Improved data processing and web-based tools. Nucleic Acids Res. 2013, 41, 590–596. [Google Scholar] [CrossRef]

- Banti, D.C.; Tsali, A.; Mitrakas, M.; Samaras, P. The Dissolved Oxygen Effect on the Controlled Growth of Filamentous Microorganisms in Membrane Bioreactors. EWaS5 2020, 2, 39. [Google Scholar]

- Zinatizadeh, A.A.L.; Ghaytooli, E. Simultaneous nitrogen and carbon removal from wastewater at different operating conditions in a moving bed biofilm reactor (MBBR): Process modeling and optimization. J. Taiwan Inst. Chem. Eng. 2015, 53, 98–111. [Google Scholar] [CrossRef]

- Kora, E.; Theodorelou, D.; Gatidou, G.; Fountoulakis, M.S.; Stasinakis, A.S. Removal of polar micropollutants from domestic wastewater using a methanogenic—Aerobic moving bed biofilm reactor system. Chem. Eng. J. 2020, 382, 122983. [Google Scholar] [CrossRef]

- IFC. Environmental, Health, and Safety General Guidelines; IFC: Washington, DC, USA, 2007. [Google Scholar]

- Waqas, S.; Bilad, M.R.; Man, Z.; Wibisono, Y.; Jaafar, J.; Mahlia, T.M.I.; Khan, A.L.; Aslam, M. Recent progress in integrated fixed-film activated sludge process for wastewater treatment: A review. J. Environ. Manag. 2020, 268, 110718. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B. Performance and energy consumption evaluation of rotating biological contactor for domestic wastewater treatment. Indones. J. Sci. Technol. 2021, 6, 101–112. [Google Scholar] [CrossRef]

- Das, P.; Prasad, B.; Singh, K.K.K. Applicability of Zeolite Based Systems for Ammonia Removal and Recovery From Wastewater. Water Environ. Res. 2017, 89, 840–845. [Google Scholar] [CrossRef]

- Biswas, K.; Turner, S.J. Microbial community composition and dynamics of moving bed biofilm reactor systems treating municipal sewage. Appl. Environ. Microbiol. 2012, 78, 855–864. [Google Scholar] [CrossRef]

- Sakdapetsiri, C.; Kaokhum, N.; Pinyakong, O. Biodegradation of crude oil by immobilized Exiguobacterium sp. AO-11 and shelf life evaluation. Sci. Rep. 2021, 11, 12990. [Google Scholar] [CrossRef]

- Doloman, A.; Boeren, S.; Miller, C.D.; Sousa, D.Z. Stimulating Effect of Trichococcus flocculiformis on a Coculture of Syntrophomonas wolfei and Methanospirillum hungatei. Appl. Environ. Microbiol. 2022, 88, e00391-22. [Google Scholar] [CrossRef]

- Rodriguez-Sanchez, A.; Muñoz-Palazon, B.; Hurtado-Martinez, M.; Mikola, A.; Gonzalez-Lopez, J.; Vahala, R.; Gonzalez-Martinez, A. Analysis of microbial communities involved in organic matter and nitrogen removal in a full-scale moving bed biofilm reactor located near the Polar Arctic Circle. Int. Biodeterior. Biodegrad. 2020, 146, 104830. [Google Scholar] [CrossRef]

- Niederdorfer, R.; Besemer, K.; Battin, T.J.; Peter, H. Ecological strategies and metabolic trade-offs of complex environmental biofilms. Npj Biofilms Microbiomes 2017, 3, 21. [Google Scholar] [CrossRef]

- Cheng, H.; Cheng, D.; Mao, J.; Lu, T.; Hong, P.Y. Identification and characterization of core sludge and biofilm microbiota in anaerobic membrane bioreactors. Environ. Int. 2019, 133, 105165. [Google Scholar] [CrossRef]

- Cinà, P.; Bacci, G.; Arancio, W.; Gallo, G.; Fani, R.; Puglia, A.M.; Di Trapani, D.; Mannina, G. Assessment and characterization of the bacterial community structure in advanced activated sludge systems. Bioresour. Technol. 2019, 282, 254–261. [Google Scholar] [CrossRef]

| Material | Paste Content | Zeolite/Clay Percentage | |

|---|---|---|---|

| Zeolite | 13X | 45% | 89% |

| Inorganic binder | Bentonite | 6% | 11% |

| Colloidal silica | Ludox AS-40 | 14% | |

| Water | 34% | ||

| Organic binder | Methyl cellulose | 1% |

| Materials | Specific Surface Area (m2/g) | Total Pore Volume (cc/g) | Micropore Volume (cc/g) | Mesopore Volume (cc/g) | Micropore Diameter (Å) | Mesopore Diameter (Å) |

|---|---|---|---|---|---|---|

| 13X | 688 | 0.35 | 0.29 | 0.06 | 10.2 | 55 |

| Bentonite | 52 | 0.15 | 0.02 | 0.13 | na | 55 |

| 13X/Bentonite | 590 | 0.42 | 0.24 | 0.18 | 9 | 42,116 |

| Control MBBR | MBBR K1 | MBBR 3D | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Average | Min | Max | Average | Min | Max | Average | |

| SMP proteins Anoxic phase | 10 | 22 | 16 ± 4.3 | 10 | 33 | 20 ± 7.5 | 10 | 21 | 15 ± 4.6 |

| SMP proteins Aerobic phase | 6.1 | 18 | 13 ± 4.3 | 12 | 29 | 21 ± 6.6 | 13 | 20 | 17 ± 3.6 |

| SMP carbohydrates Anoxic phase | 1.9 | 12 | 5.6 ± 3.6 | 2.7 | 12 | 5.9 ± 3.3 | 0.6 | 6.5 | 3.0 ± 3.0 |

| SMP carbohydrates Aerobic phase | 0.9 | 9.4 | 4.2 ± 2.9 | 0.3 | 5.4 | 3.3 ± 2.1 | 0.1 | 6 | 2.6 ± 2.2 |

| EPS proteins Anoxic phase | 40 | 42 | 41 ± 1.0 | 7.6 | 38 | 21 ± 8.6 | 10 | 22 | 17 ± 5.9 |

| EPS proteins Aerobic phase | 28 | 42 | 35 ± 7.0 | 11 | 38 | 20 ± 8.3 | 6.5 | 20 | 15 ± 6.5 |

| EPS carbohydrates Anoxic phase | 12 | 23 | 19 ± 5.0 | 11 | 21 | 14 ± 3.3 | 2.5 | 13 | 7.3 ± 4.9 |

| EPS carbohydrates Aerobic phase | 13 | 23 | 18 ± 5.0 | 5.7 | 16 | 11 ± 3.6 | 2.7 | 10 | 6.1 ± 3.3 |

| t, d | Dry Mass of Biofilm, mg |

|---|---|

| 14 | 3.5 ± 0.003 |

| 21 | 3.2 ± 0.007 |

| 29 | 4.5 ± 0.004 |

| 35 | 3.1 ± 0.004 |

| t, d | Dry Mass of Biofilm, mg |

|---|---|

| 7 | 772 ± 117 |

| 13 | 831 ± 46 |

| 21 | 700 ± 121 |

| 26 | 641 ± 76 |

| 35 | 867 ± 161 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banti, D.C.; Samaras, P.; Chioti, A.G.; Mitsopoulos, A.; Tsangas, M.; Zorpas, A.; Sfetsas, T. Improvement of MBBR Performance by the Addition of 3D-Printed Biocarriers Fabricated with 13X and Bentonite. Resources 2023, 12, 81. https://doi.org/10.3390/resources12070081

Banti DC, Samaras P, Chioti AG, Mitsopoulos A, Tsangas M, Zorpas A, Sfetsas T. Improvement of MBBR Performance by the Addition of 3D-Printed Biocarriers Fabricated with 13X and Bentonite. Resources. 2023; 12(7):81. https://doi.org/10.3390/resources12070081

Chicago/Turabian StyleBanti, Dimitra C., Petros Samaras, Afroditi G. Chioti, Anastasios Mitsopoulos, Michail Tsangas, Antonis Zorpas, and Themistoklis Sfetsas. 2023. "Improvement of MBBR Performance by the Addition of 3D-Printed Biocarriers Fabricated with 13X and Bentonite" Resources 12, no. 7: 81. https://doi.org/10.3390/resources12070081

APA StyleBanti, D. C., Samaras, P., Chioti, A. G., Mitsopoulos, A., Tsangas, M., Zorpas, A., & Sfetsas, T. (2023). Improvement of MBBR Performance by the Addition of 3D-Printed Biocarriers Fabricated with 13X and Bentonite. Resources, 12(7), 81. https://doi.org/10.3390/resources12070081