Neighborhood-Scale Urban Water Reclamation with Integrated Resource Recovery for Establishing Nexus City in Munich, Germany: Pipe Dream or Reality?

Abstract

:1. Introduction

2. State-of-the-Art of Water Reclamation with Resource Recovery in Europe

2.1. Jenfelder Au Quarter in Hamburg, Germany

2.2. Lanxmeer District in Culemborg, The Netherlands

2.3. Flintenbreite in Lübeck, Germany

2.4. Am Römerweg in Knittlingen, Germany

2.5. Allermöhe Settlement in Hamburg, Germany

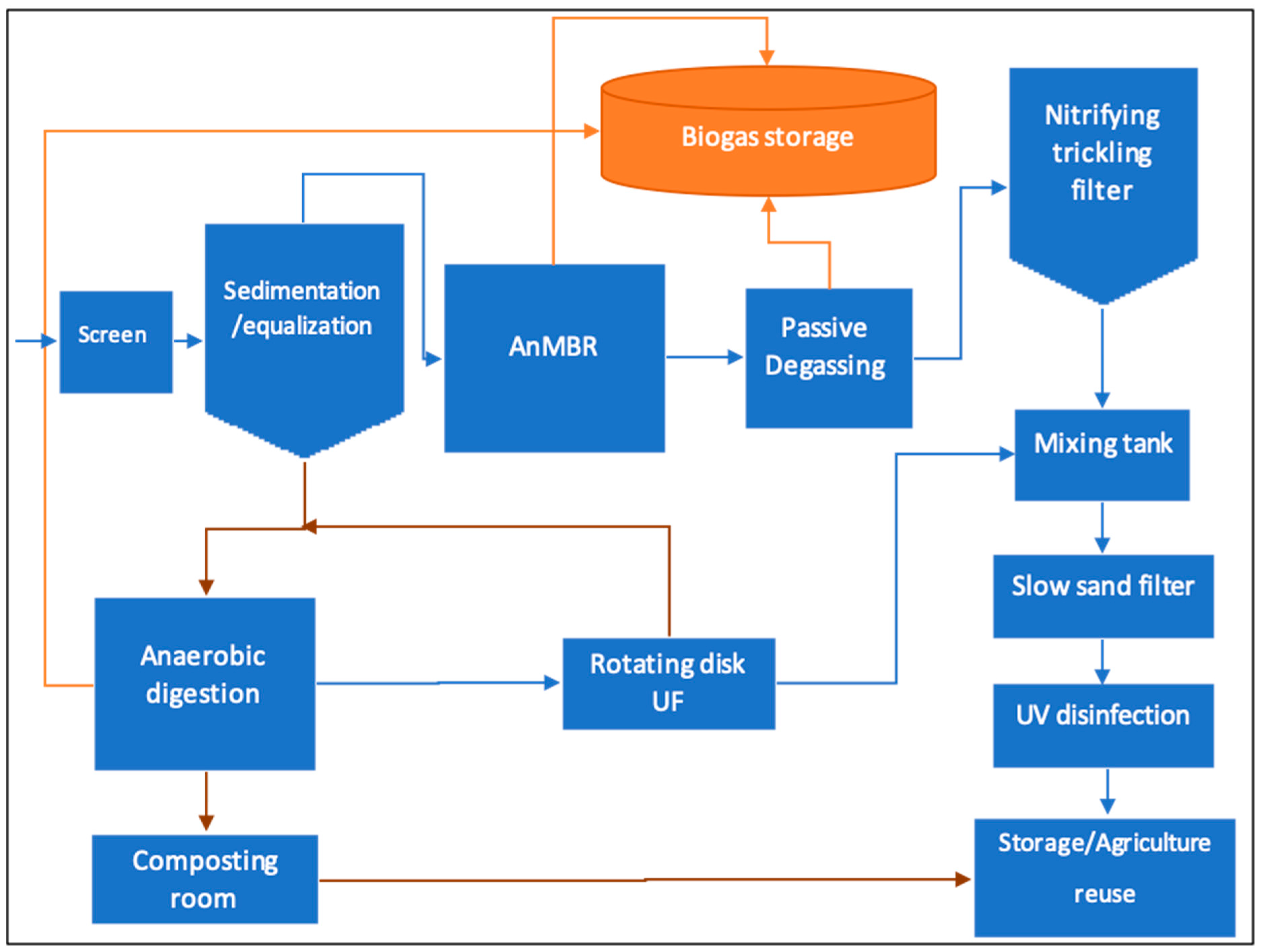

3. Decentralized Water Reclamation with Resource Recovery Application in Maxvorstadt

3.1. Synthesis of the Literature Review

3.2. Captial Costs and Operation and Maintenance Estimates of the Two Systems

3.2.1. The Status Quo

3.2.2. Expected Capital Costs of the Decentralized System

3.2.3. Expected Operational Costs

4. Comparison between the Status Quo and the Suggested Decentralized System

4.1. Rainwater Harvesting and Water Reuse Potentials

4.2. Biogas and Energy Generation Potential

4.3. Nutrient Generation and Recovery Potential

4.4. Total Potential Savings by Implementing the Proposed System and Amortization

5. Discussion about Implementation of the Decentralized System and Its Co-Benefits

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hoff, H. Understanding the Nexus. Background Paper for the Bonn2011 Conference: The Water, Energy and Food Security Nexus. In The Water, Energy and Food Security Nexus: Solutions for A; Stockholm Environment Institute: Stockholm, Sweden, 2011; pp. 1–52. [Google Scholar]

- Gondhalekar, D.; Ramsauer, T. Nexus City: Operationalizing the urban Water- Energy-Food Nexus for climate change adaptation in Munich, Germany. Urban Clim. 2016, 19, 28–40. [Google Scholar] [CrossRef]

- BINE Information Service. Energy from Wastewater Supplies Urban District. 2014. Available online: http://www.bine.info/fileadmin/content/Presse/Projektinfos_2014/PM_09_2014/ProjektInfo_0914_engl_internetx.pdf (accessed on 24 October 2017).

- Hamburg Wasser. Energetische Optimierung des HAMBURG WATER Cycle ® im Stadtquartier Jenfelder au Forschungsvorhaben 0327400Y Schlussbericht; Hamburg Wasser: Hamburg, Germany, 2013. [Google Scholar]

- Van Timmeren, A. Decentralized Energy Generation and Waste (Water) Treatment in Residential Districts: The “Sustainable Implant”. 2007. Available online: http://www.irbnet.de/daten/iconda/CIB5042.pdf (accessed on 24 October 2017).

- Van Timmeren, A.; Tawil, M. Integration of Living Machine and Biogas Plant Case EVA Centre Lanxmeer, Culemborg, 6–8. 2006. Available online: http://www.unige.ch/cuepe/html/plea2006/Vol1/PLEA2006_PAPER892.pdf (accessed on 24 October 2017).

- Otter-Wasser. Case Study of Sustainable Sanitation Projects Ecological Housing Estate, Flintenbreite, Lübeck, Germany. 2009. Available online: http://www.susana.org/_resources/documents/default/2-59-en-susana-cs-germany-luebeck-ecological-housing-bobx.pdf (accessed on 12 February 2022).

- Lazarova, V.; Takashi, A.; Bahri, A.; John, A. Milestones in Water Reuse: The Best Success Stories; The International Water Association: London, UK, 2013. [Google Scholar]

- Rauschning, G.; Berger, W.; Ebeling, B.; Schöpe, A. Ecological Settlement in Allermöhe Hamburg, Germany—Case Studies. 2009. Available online: http://www.susana.org/en/resources/case-studies/details/56 (accessed on 26 September 2017).

- StMUG: Bayerisches Staatsministerium für Umwelt und Gesundheit (Bavarian State Ministry for Environment and Health). Bayerische Klima-Anpassungsstrategie (BayKLAS) (Bavarian Climate Adaptation Strategy); StMUG: Munich, Germany, 2009; p. 68. (In German)

- MSE: Münchner Stadtentwässerung. In Geschäftsbericht 2015 Leitbild; StMUG: Munich, Germany, 2016.

- Hongjun, L.; Jianrong, C.; Fangyuan, W.; Linxian, D.; Huachang, H. Feasibility evaluation of submerged anaerobic membrane bioreactor for municipal secondary wastewater treatment. Desalination 2011, 280, 120–126. [Google Scholar] [CrossRef]

- IGB: Fraunhofer-Institut für Grenzflächen- und Bioverfahrenstechnik. DEUS 21—Regeneratives Wassermanagement. Available online: https://www.igb.fraunhofer.de/content/dam/igb/de/documents/broschueren/ubt/DEUS21_Regeneratives_Wassermanagement.pdf (accessed on 29 October 2017).

- bls.gov. CPI Inflation Calculator. Available online: https://data.bls.gov/cgi-bin/cpicalc.pl (accessed on 6 November 2017).

- SIUE. Primary Sedimentation Tanks. Available online: http://www.ce.siue.edu/rproject/sist/primary/pts.html (accessed on 29 October 2017).

- Waleed, M.Z. Cost analysis of trickling filtration and activated sludge plants for the treatment of municipal wastewater. In Proceedings of the Seventh Saudi Engineering Conference, Riyadh, Saudi Arabia, 23–25 November 2007. [Google Scholar]

- Bart, V.; Thomas, M.; Ingmar, N.; Christoph, B.; Simon, J. The cost of a large-scale hollow fibre MBR. Water Res. 2010, 44, 5274–5283. [Google Scholar] [CrossRef]

- EPA: US Environmental Protection Agency. Wastewater Technology Fact Sheet Trickling Filter Nitrification. 2000. Available online: https://www3.epa.gov/npdes/pubs/trickling_filt_nitrification.pdf (accessed on 29 October 2017).

- nzdl.org. 15.2 Operating and Maintenance Costs. 1996. Available online: http://www.nzdl.org/gsdlmod?e=d-00000-00---off-0hdl--00-0----0-10-0---0---0direct-10---4-------0-1l--11-en-50---20-about---00-0-1-00-0--4----0-0-11-10-0utfZz-8-00&cl=CL1.16&d=HASH01ccfcc122c3ed3492c9f50c.6.8.2>=1 (accessed on 6 November 2017).

- EPA: US Environmental Protection Agency (1999). Wastewater Technology Fact Sheet Ultraviolet Disinfection. Available online: https://www3.epa.gov/npdes/pubs/uv.pdf (accessed on 31 May 2022).

- US DoE (US Department of Energy). Combined Heat and Power Technology Fact Sheet Series: Microturbines. 2015. Available online: https://energy.gov/sites/prod/files/2016/09/f33/CHP-Microturbines_0.pdf (accessed on 29 October 2017).

- SWM: Stadtwerke München. SWM Strom. 2017. Available online: https://www.swm.de/privatkunden/mein-swm/tarifberatung#TarifberaterPlace:&kundengruppe=PK&nebenzeit=0&plz=80799&sparte=STROM&verbrauch=2500&zaehler=ET (accessed on 24 October 2017).

- Zupančič, G.D.; Roš, M. Heat and energy requirements in thermophilic anaerobic sludge digestion. Renew. Energy 2003, 28, 2255–2267. [Google Scholar] [CrossRef]

- SWM: Stadtwerke München. SWM Erdgas. 2017. Available online: https://www.swm.de/privatkunden/mein-swm/tarifberatung#TarifberaterPlace:&kundengruppe=PK&nebenzeit=0&plz=80799&sparte=ERDGAS&verbrauch=4800&zaehler=ET (accessed on 24 October 2017).

- DEMOWARE. The project “Innovation Demonstration for a Competitive and Innovative European Water Reuse Sector”. Available online: http://demoware.ctm.com.es/en (accessed on 24 October 2017).

- SWM: Stadtwerke München. M-Wasser—Erstklassiges Naturprodukt Direkt von der Quelle. 2015. Available online: https://www.swm.de/dam/jcr:8b4ae6b1-0654-47db-bab4-e98037b32f7c/m-wasser-broschuere.pdf (accessed on 29 October 2017).

- SWM: Stadtwerke München. Wasserkosten in München: Wasser-Preise der SWM. 2017. Available online: https://www.swm.de/privatkunden/m-wasser/preise.html (accessed on 24 October 2017).

- Jonathan, M. Determining the Rate of Used Cooking Oil Output by the Restaurant Industry in the Salt Lake. 2007. Available online: https://nature.berkeley.edu/classes/es196/projects/2007final/MillerJ.pdf (accessed on 29 October 2017).

- SWM: Stadtwerke München. Preisfakten zu M/Strom der Stadtwerke München. 2017. Available online: https://www.swm.de/privatkunden/m-strom/informationen/preisinfo.html (accessed on 24 October 2017).

| Parameter | Unit | Remarks |

|---|---|---|

| Population in 2014 | 51,642 people | Of this, 48,474 people live in 136 housing blocks (in 2011) |

| Water consumption | 6.01 million L/day, of which 1.64 is for toilet flushing | Based on a population of 46,960 which excludes children less than 3 years of age, who consume less water and energy [2] |

| Dry sewage generated in 2015 | 3,870,913 m3/year | Average dry sewage (excluding stormwater) generated was around 82.43 m3/capita/year, for a population of 46,960 [11] |

| Item | Capital Cost (€) |

|---|---|

| Reactor tanks | 1.630.000 |

| Gas storage tank | 15.000 € |

| Pumps | 126.100 |

| Membrane | 1.400.000 |

| Screening | 73.200 |

| Control boards | 54.700 |

| Gas scouring | 163.800 |

| Nitrifying trickling filter | 12.100 |

| Slow sand filter | 626.200 |

| UV disinfection | 200.000 |

| CHP microturbine | 2.100.000 |

| Other costs (land, extra equipment, building retrofitting) | 4.000.000 |

| TOTAL | 10.400.000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Azzawi, M.S.M.; Gondhalekar, D.; Drewes, J.E. Neighborhood-Scale Urban Water Reclamation with Integrated Resource Recovery for Establishing Nexus City in Munich, Germany: Pipe Dream or Reality? Resources 2022, 11, 64. https://doi.org/10.3390/resources11070064

Al-Azzawi MSM, Gondhalekar D, Drewes JE. Neighborhood-Scale Urban Water Reclamation with Integrated Resource Recovery for Establishing Nexus City in Munich, Germany: Pipe Dream or Reality? Resources. 2022; 11(7):64. https://doi.org/10.3390/resources11070064

Chicago/Turabian StyleAl-Azzawi, Mohammed S. M., Daphne Gondhalekar, and Jörg E. Drewes. 2022. "Neighborhood-Scale Urban Water Reclamation with Integrated Resource Recovery for Establishing Nexus City in Munich, Germany: Pipe Dream or Reality?" Resources 11, no. 7: 64. https://doi.org/10.3390/resources11070064

APA StyleAl-Azzawi, M. S. M., Gondhalekar, D., & Drewes, J. E. (2022). Neighborhood-Scale Urban Water Reclamation with Integrated Resource Recovery for Establishing Nexus City in Munich, Germany: Pipe Dream or Reality? Resources, 11(7), 64. https://doi.org/10.3390/resources11070064