Investigation of the Influence of Different Vegetable Oils as a Component of Blended Biofuel on Performance and Emission Characteristics of a Diesel Engine for Agricultural Machinery and Commercial Vehicles

Abstract

:1. Introduction

2. Materials and Methods

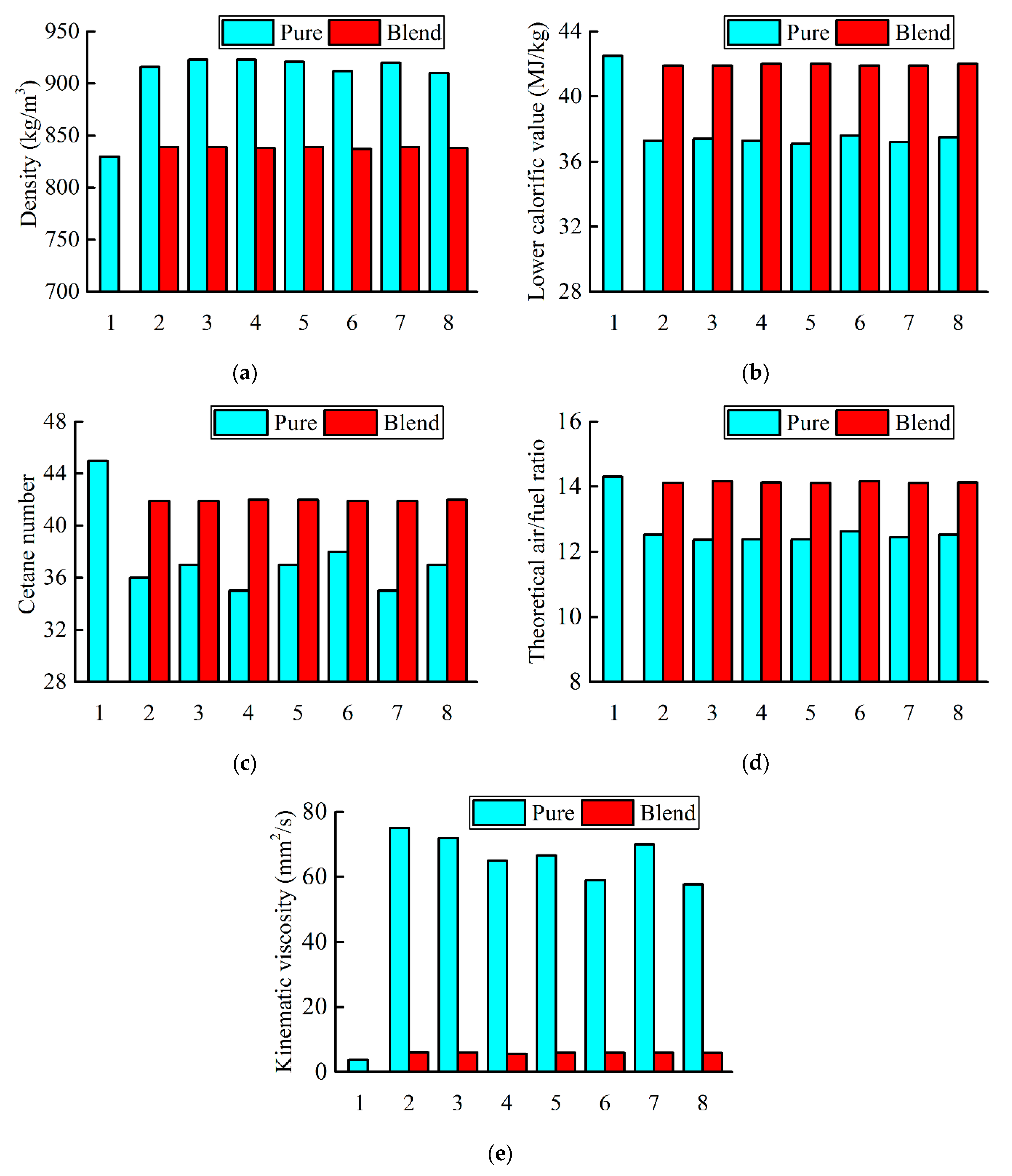

2.1. Composition and Properties of Vegetable Oils

2.2. Experimental Setup and Test Procedure

2.3. Methodology of Processing Experimental Results

3. Results and Discussion

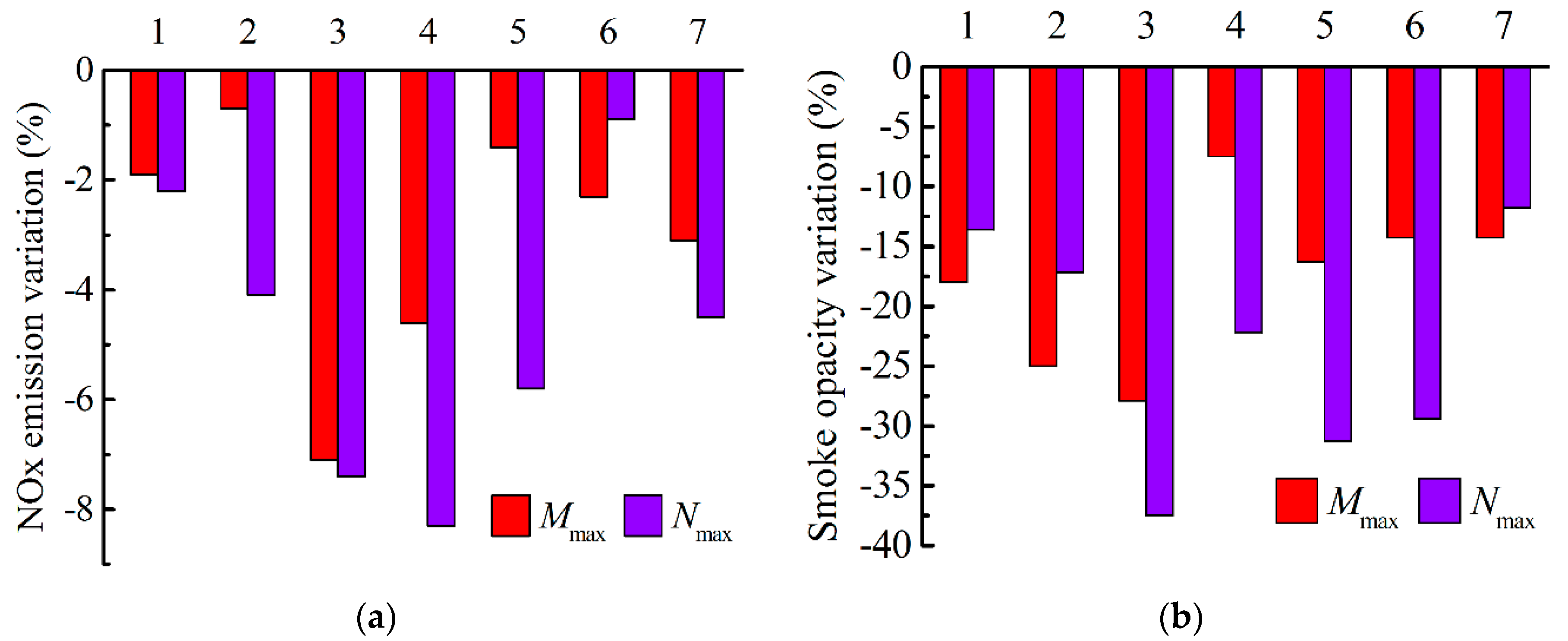

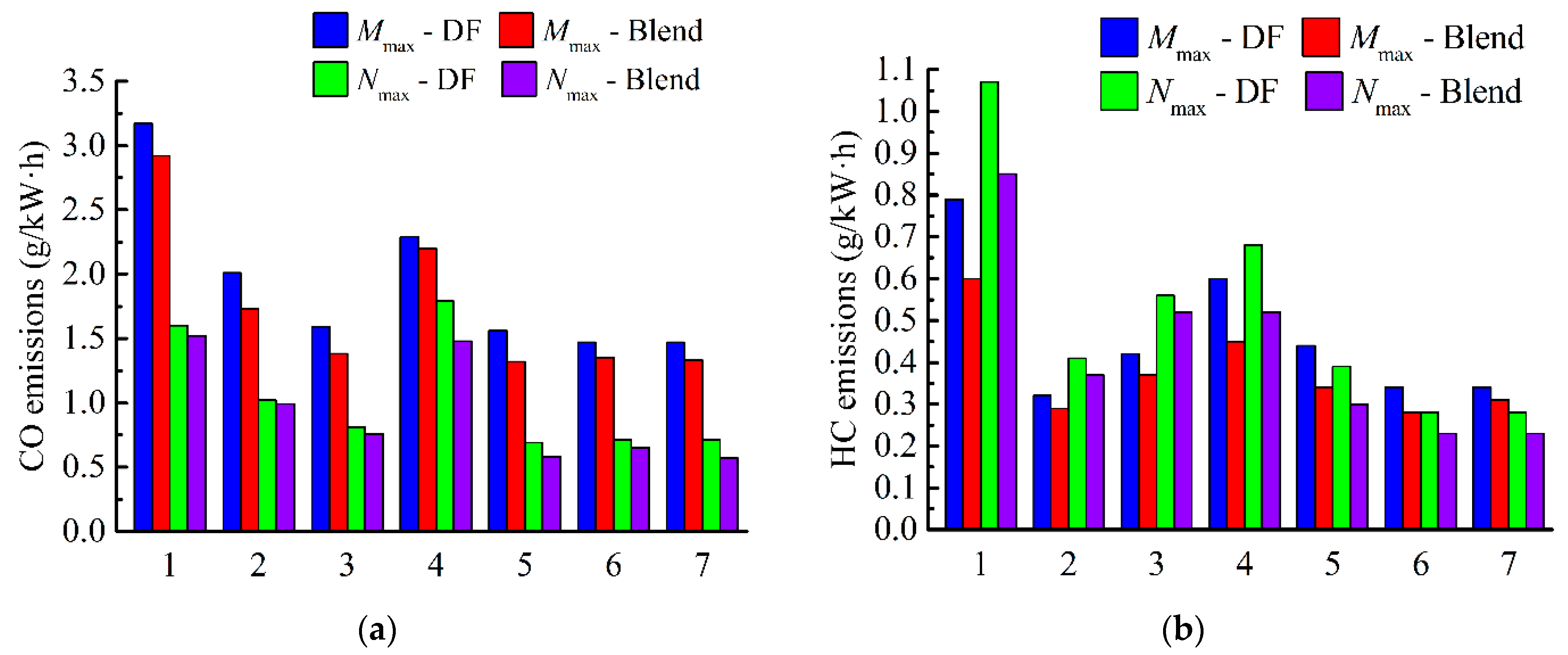

3.1. Test Results of the Diesel Engine D-245.12S in the Operating Modes of Maximum Power and Maximum Torque

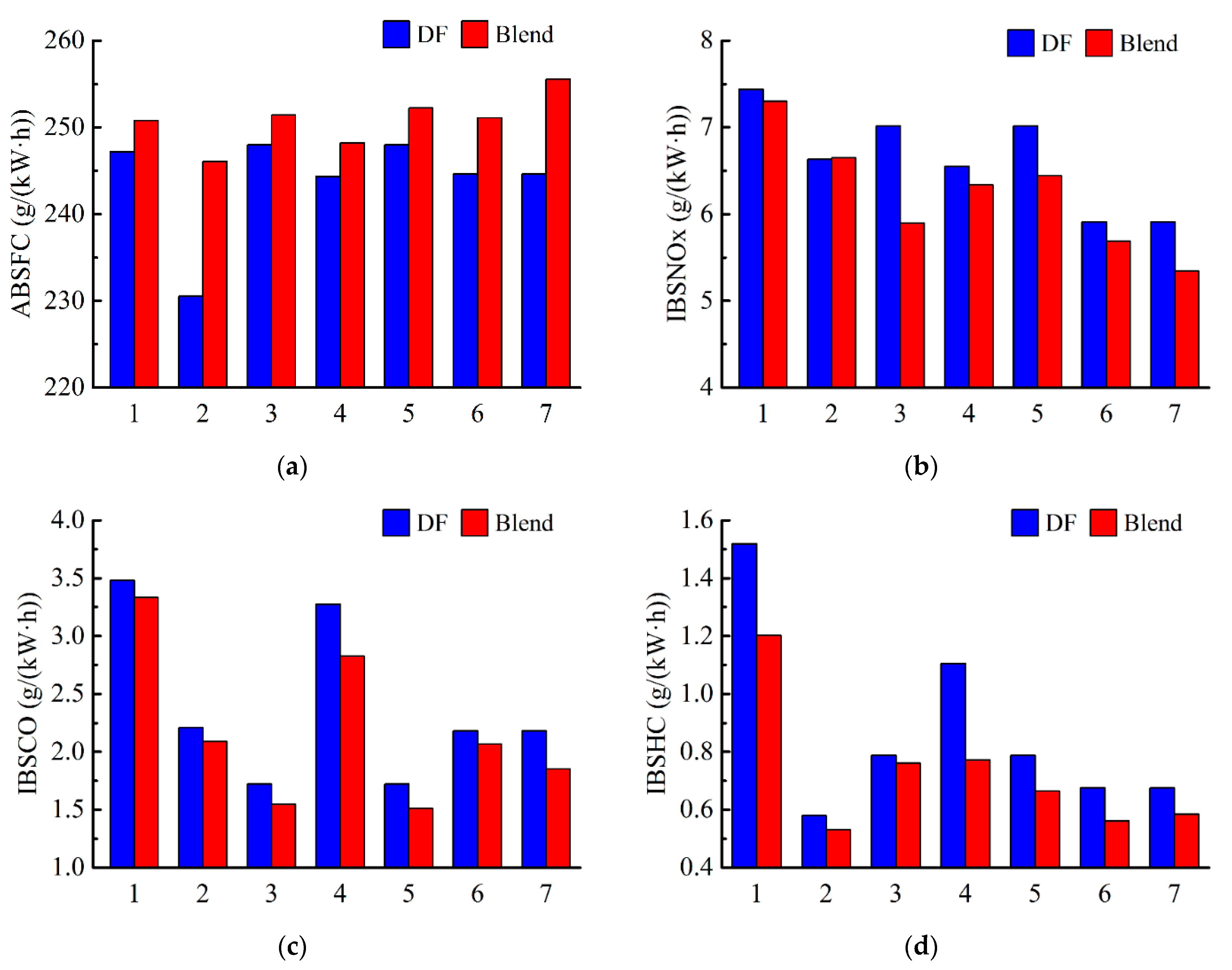

3.2. Test Results of the Diesel Engine D-245.12S in the Operating Conditions of the 13-Mode Steady-State Test Cycle (ECE R49)

4. Conclusions

- All basic physicochemical properties of blended biofuels, consisting of 90% petroleum DF and 10% one of the vegetable oils, RO, SuO, SoO, CoO, LO, MO, CaO, differ from the properties of petroleum DF by no more than 1–2.2%. An exception is the kinematic viscosity of blended biofuels, which increases by 1.47–1.84 times. Small differences in the physicochemical properties of blended fuels allow all tests of the diesel engine D-245.12S to be carried out with unchanged fuel equipment controls.

- In the operating modes of maximum power and maximum torque, the use of blended biofuels resulted in a drop in the engine brake power and a simultaneous increase in the hourly fuel consumption by no more than 1.5%. An exception was RO-blended DF, for which the brake torque increased by 1.33–2.05%, accompanied by an increase in the hourly fuel consumption by 3.03% and 4.71% in the same modes. BSFC for all blended biofuels increased by 1.2–4.3%.

- The emissions of regulated harmful substances with the use of blended fuels were significantly reduced in the maximum power and maximum torque modes: NOx emissions—by 0.7–8.3%, exhaust smoke opacity—by 7.5–37.5%, CO emissions—by 3.0–20.0%, and HC emissions—by 8.3–27.9%.

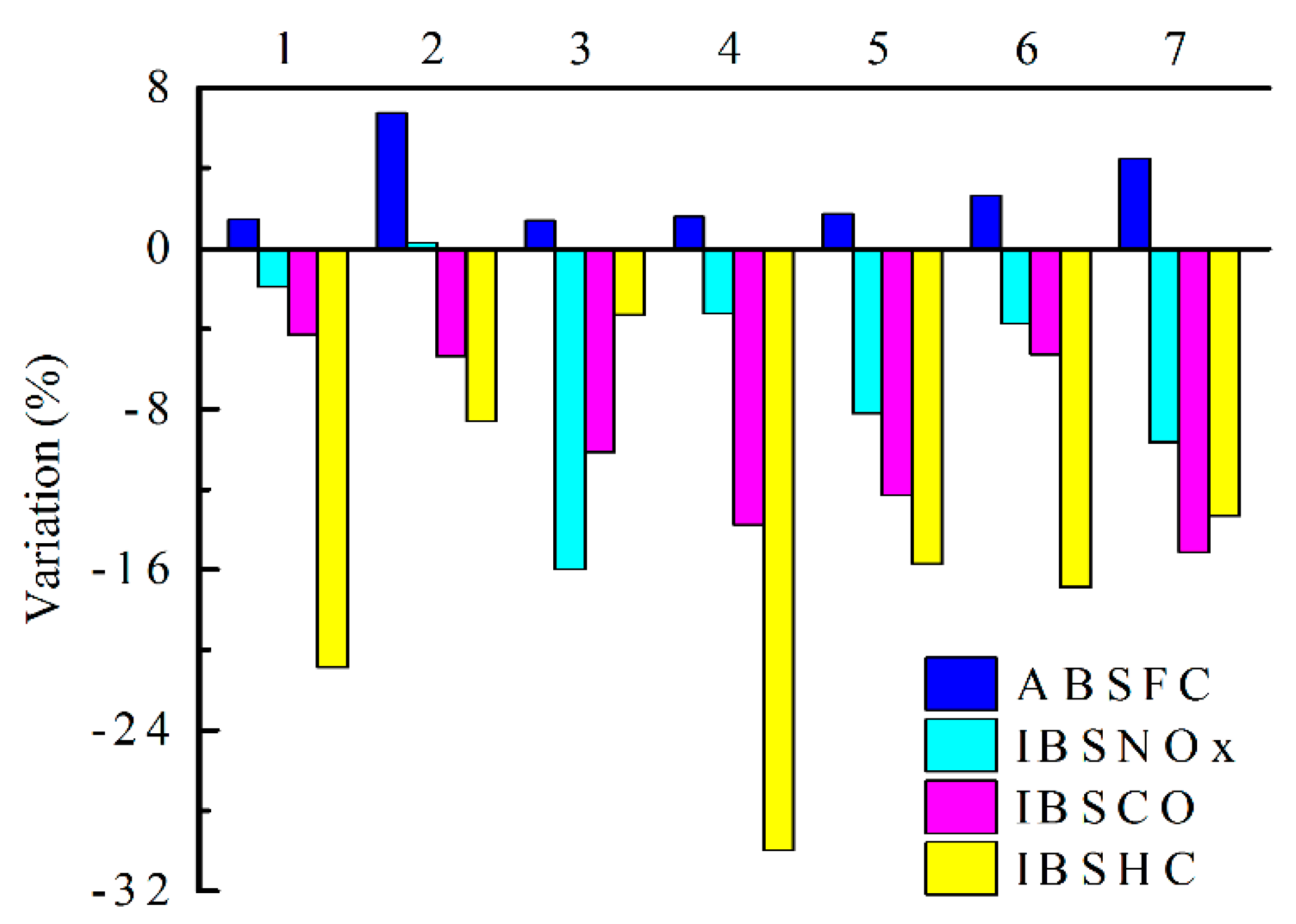

- When the diesel engine was tested in the European 13-mode steady-state test cycle (ECE R49), reductions in IBSHC of 3.0–3.3%, IBSCO of 4.3–15.0%, and IBSNOx of 1.9–16.0% were also achieved. Only for SuO-blended DF did IBSNOx increase by 0.29%. ABSFC increased over a wide range: from a minimum value of 1.39% for RO-blended DF to a maximum of 6.75% for SuO-blended DF.

- The results obtained indicate the feasibility and rationality of using the investigated vegetable oils as a 10% additive in blended biofuel for diesel engines. This use will save fossil fuels and improve the harmful effect on the environment with a slight decrease in the technical and economic indicators of diesel engine D-245.12S for agricultural machinery and commercial vehicles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DF | diesel fuel |

| RO | rapeseed oil |

| SuO | sunflower oil |

| SoO | soybean oil |

| CoO | corn oil |

| LO | linseed oil |

| MO | mustard oil |

| CaO | camelina oil |

| ABSFC | average brake-specific fuel consumption |

| BSFC | brake-specific fuel consumption |

| FDPC | fuel delivery per cycle |

| IBSCO | integral brake-specific carbon monoxide |

| IBSHC | integral brake-specific hydrocarbons |

| IBSNOx | integral brake-specific nitrogen oxides |

References

- Singh, D.; Sharma, D.; Soni, S.L.; Inda, C.S.; Sharma, S.; Sharma, P.K.; Jhalani, A. A comprehensive review of physicochemical properties, production process, performance and emissions characteristics of 2nd generation biodiesel feedstock: Jatropha curcas. Fuel 2021, 285, 119110. [Google Scholar] [CrossRef]

- Dey, S.; Reang, N.M.; Das, P.K.; Deb, M. A comprehensive study on prospects of economy, environment, and efficiency of palm oil biodiesel as a renewable fuel. J. Clean. Prod. 2021, 286, 124981. [Google Scholar] [CrossRef]

- Simsek, S. Effects of biodiesel obtained from Canola, sefflower oils and waste oils on the engine performance and exhaust emissions. Fuel 2020, 265, 117026. [Google Scholar] [CrossRef]

- Benjamin Franklin, S.; Arul, R. Experimental investigation on EGR technique and performance evaluation of diesel engine using diesel blend cotton seed oil as renewable fuel. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Raman, L.A.; Deepanraj, B.; Rajakumar, S.; Sivasubramanian, V. Experimental investigation on performance, combustion and emission analysis of a direct injection diesel engine fuelled with rapeseed oil biodiesel. Fuel 2019, 246, 69–74. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Aydin, M.; Yilbasi, Z.; Arslan, M. Investigation on the structural effects of the addition of alcohols having various chain lengths into the vegetable oil-biodiesel-diesel fuel blends: An attempt for improving the performance, combustion, and exhaust emission characteristics of a compressi. Fuel 2020, 269, 117455. [Google Scholar] [CrossRef]

- Murta, A.L.S.; De Freitas, M.A.V.; Ferreira, C.G.; Da Costa Lima Peixoto, M.M. The use of palm oil biodiesel blends in locomotives: An economic, social and environmental analysis. Renew. Energy 2021, 164, 521–530. [Google Scholar] [CrossRef]

- Tun, M.M.; Juchelková, D. Biomass Sources and Energy Potential for Energy Sector in Myanmar: An Outlook. Resources 2019, 8, 102. [Google Scholar] [CrossRef] [Green Version]

- Tun, M.M.; Juchelkova, D.; Win, M.M.; Thu, A.M.; Puchor, T. Biomass Energy: An Overview of Biomass Sources, Energy Potential, and Management in Southeast Asian Countries. Resources 2019, 8, 81. [Google Scholar] [CrossRef] [Green Version]

- Yaşar, F. Comparision of fuel properties of biodiesel fuels produced from different oils to determine the most suitable feedstock type. Fuel 2020, 264, 116817. [Google Scholar] [CrossRef]

- Raghuvaran, S.; Ashok, B.; Veluchamy, B.; Ganesh, N. Evaluation of performance and exhaust emission of C.I diesel engine fuel with palm oil biodiesel using an artificial neural network. Mater. Today Proc. 2021, 37, 1107–1111. [Google Scholar] [CrossRef]

- Che Mat, S.; Idroas, M.Y.; Hamid, M.F.; Zainal, Z.A. Performance and emissions of straight vegetable oils and its blends as a fuel in diesel engine: A review. Renew. Sustain. Energy Rev. 2018, 82, 808–823. [Google Scholar] [CrossRef]

- Rajak, U.; Verma, T.N. Effect of emission from ethylic biodiesel of edible and non-edible vegetable oil, animal fats, waste oil and alcohol in CI engine. Energy Convers. Manag. 2018, 166, 704–718. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Fattah, I.M.R.; Maitra, S.; Mahlia, T.M.I. A ranking scheme for biodiesel underpinned by critical physicochemical properties. Energy Convers. Manag. 2021, 229, 113742. [Google Scholar] [CrossRef]

- Çelikten, İ.; Koca, A.; Ali Arslan, M. Comparison of performance and emissions of diesel fuel, rapeseed and soybean oil methyl esters injected at different pressures. Renew. Energy 2010, 35, 814–820. [Google Scholar] [CrossRef]

- Elkelawy, M.; Alm-Eldin Bastawissi, H.; Esmaeil, K.K.; Radwan, A.M.; Panchal, H.; Sadasivuni, K.K.; Ponnamma, D.; Walvekar, R. Experimental studies on the biodiesel production parameters optimization of sunflower and soybean oil mixture and DI engine combustion, performance, and emission analysis fueled with diesel/biodiesel blends. Fuel 2019, 255, 115791. [Google Scholar] [CrossRef]

- Markov, V.A.; Kamaltdinov, V.G.; Zykov, S.A.; Savastenko, A.A. Multicomponent Biofuels for Agricultural Diesel Machines. J. Phys. Conf. Ser. 2019, 1260. [Google Scholar] [CrossRef]

- Kanthasamy, S.; Karthick, A.; Ramalingam, V.; Praveen, M.V.J. Performance and emission characteristics of diesel engine fueled with ternary blends of linseed and rubber seed oil biodiesel. Fuel 2021, 285, 119255. [Google Scholar] [CrossRef]

- Hoseini, S.S.; Najafi, G.; Ghobadian, B.; Rahimi, A.; Yusaf, T.; Mamat, R.; Sidik, N.A.C.; Azmi, W.H. Effects of biodiesel fuel obtained from Salvia macrosiphon oil (ultrasonic-assisted) on performance and emissions of diesel engine. Energy 2017, 131, 289–296. [Google Scholar] [CrossRef] [Green Version]

- Madheshiya, A.K.; Vedrtnam, A. Energy-exergy analysis of biodiesel fuels produced from waste cooking oil and mustard oil. Fuel 2018, 214, 386–408. [Google Scholar] [CrossRef]

- Sharma Dugala, N.; Singh Goindi, G.; Sharma, A. Evaluation of physicochemical characteristics of Mahua (Madhuca indica) and Jatropha (Jatropha curcas) dual biodiesel blends with diesel. J. King Saud Univ. Eng. Sci. 2020. [Google Scholar] [CrossRef]

- Mirhashemi, F.S.; Sadrnia, H. NOX emissions of compression ignition engines fueled with various biodiesel blends: A review. J. Energy Inst. 2020, 93, 129–151. [Google Scholar] [CrossRef]

- Hazrat, M.A.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N.; Rufford, T.E. Emission characteristics of waste tallow and waste cooking oil based ternary biodiesel fuels. Energy Procedia 2019, 160, 842–847. [Google Scholar] [CrossRef]

- Lešnik, L.; Biluš, I. The effect of rapeseed oil biodiesel fuel on combustion, performance, and the emission formation process within a heavy-duty DI diesel engine. Energy Convers. Manag. 2016, 109, 140–152. [Google Scholar] [CrossRef]

- Lešnik, L.; Iljaž, J.; Hribernik, A.; Kegl, B. Numerical and experimental study of combustion, performance and emission characteristics of a heavy-duty DI diesel engine running on diesel, biodiesel and their blends. Energy Convers. Manag. 2014, 81, 534–546. [Google Scholar] [CrossRef]

- Bari, S.; Hossain, S.N. Performance and emission analysis of a diesel engine running on palm oil diesel (POD). Energy Procedia 2019, 160, 92–99. [Google Scholar] [CrossRef]

- Ellappan, S.; Rajendran, S. A comparative review of performance and emission characteristics of diesel engine using eucalyptus-biodiesel blend. Fuel 2021, 284, 118925. [Google Scholar] [CrossRef]

- Osei, I.; Akowuah, J.O.; Kemausuor, F. Techno-Economic Models for Optimised Utilisation of Jatropha curcas Linnaeus under an Out-Grower Farming Scheme in Ghana. Resources 2016, 5, 38. [Google Scholar] [CrossRef] [Green Version]

- Kanth, S.; Debbarma, S. Comparative performance analysis of diesel engine fuelled with hydrogen enriched edible and non-edible biodiesel. Int. J. Hydrog. Energy 2021, 46, 10478–10493. [Google Scholar] [CrossRef]

- Botia, G.P.; Ochoa, G.V.; Forero, J.D. Characterization of emissions in a diesel engine using biodiesel blends produced from agro-industrial residues of Elaeis Guineensis. Int. J. Energy Convers. 2020, 8, 45–52. [Google Scholar] [CrossRef]

- Manieniyan, V.; Velumani, V.; Senthilkumar, R.; Sivaprakasam, S. Effect of EGR (exhaust gas recirculation) in diesel engine with multi-walled carbon nanotubes and vegetable oil refinery waste as biodiesel. Fuel 2021, 288, 119689. [Google Scholar] [CrossRef]

- Rajak, U.; Verma, T.N. A comparative analysis of engine characteristics from various biodiesels: Numerical study. Energy Convers. Manag. 2019, 180, 904–923. [Google Scholar] [CrossRef]

- Simsek, S.; Uslu, S. Comparative evaluation of the influence of waste vegetable oil and waste animal oil-based biodiesel on diesel engine performance and emissions. Fuel 2020, 280, 118613. [Google Scholar] [CrossRef]

- Tsai, W.-T. Mandatory Recycling of Waste Cooking Oil from Residential and Commercial Sectors in Taiwan. Resources 2019, 8, 38. [Google Scholar] [CrossRef] [Green Version]

- Nirmala, N.; Dawn, S.S.; Harindra, C. Analysis of performance and emission characteristics of Waste cooking oil and Chlorella variabilis MK039712.1 biodiesel blends in a single cylinder, four strokes diesel engine. Renew. Energy 2020, 147, 284–292. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, Y.; Gu, J.; Xin, Z.; Sun, S. Butyl-biodiesel production from waste cooking oil: Kinetics, fuel properties and emission performance. Fuel 2019, 236, 1489–1495. [Google Scholar] [CrossRef]

- Simsek, S.; Uslu, S. Determination of a diesel engine operating parameters powered with canola, safflower and waste vegetable oil based biodiesel combination using response surface methodology (RSM). Fuel 2020, 270, 117496. [Google Scholar] [CrossRef]

- Gnanasekaran, S.; Saravanan, N.; Ilangkumaran, M. Influence of injection timing on performance, emission and combustion characteristics of a DI diesel engine running on fish oil biodiesel. Energy 2016, 116, 1218–1229. [Google Scholar] [CrossRef]

- Sanli, H. An experimental investigation on the usage of waste frying oil-diesel fuel blends with low viscosity in a Common Rail DI-diesel engine. Fuel 2018, 222, 434–443. [Google Scholar] [CrossRef]

- de Almeida D´Agosto, M.; da Silva, M.A.V.; Franca, L.S.; de Oliveira, C.M.; Alexandre, M.O.L.; da Costa Marques, L.G.; Murta, A.L.S.; de Freitas, M.A.V. Comparative study of emissions from stationary engines using biodiesel made from soybean oil, palm oil and waste frying oil. Renew. Sustain. Energy Rev. 2017, 70, 1376–1392. [Google Scholar] [CrossRef]

- Vieira da Silva, M.A.; Lagnier Gil Ferreira, B.; da Costa Marques, L.G.; Lamare Soares Murta, A.; Vasconcelos de Freitas, M.A. Comparative study of NOx emissions of biodiesel-diesel blends from soybean, palm and waste frying oils using methyl and ethyl transesterification routes. Fuel 2017, 194, 144–156. [Google Scholar] [CrossRef]

- Gad, M.S.; El-Shafay, A.S.; Abu Hashish, H.M. Assessment of diesel engine performance, emissions and combustion characteristics burning biodiesel blends from jatropha seeds. Process. Saf. Environ. Prot. 2021, 147, 518–526. [Google Scholar] [CrossRef]

- Mendoza-Casseres, D.; Valencia-Ochoa, G.; Duarte-Forero, J. Experimental assessment of combustion performance in low-displacement stationary engines operating with biodiesel blends and hydroxy. Therm. Sci. Eng. Prog. 2021, 23, 100883. [Google Scholar] [CrossRef]

- Madiwale, S.; Karthikeyan, A.; Bhojwani, V. Properties investigation and performance analysis of a diesel engine fuelled with Jatropha, Soybean, Palm and Cottonseed biodiesel using Ethanol as an additive. Mater. Today Proc. 2018, 5, 657–664. [Google Scholar] [CrossRef]

- Shote, A.S.; Betiku, E.; Asere, A.A. Characteristics of CO and NOx emissions from combustion of transmethylated palm kernel oil-based biodiesel blends in a compression ignition engine. J. King Saud Univ. Eng. Sci. 2019, 31, 178–183. [Google Scholar] [CrossRef]

- Senthur Prabu, S.; Asokan, M.A.; Prathiba, S.; Ahmed, S.; Puthean, G. Effect of additives on performance, combustion and emission behavior of preheated palm oil/diesel blends in DI diesel engine. Renew. Energy 2018, 122, 196–205. [Google Scholar] [CrossRef]

- Pipitone, E.; Costanza, A. An experimental investigation on the long-term compatibility of preheated crude palm oil in a large compression ignition diesel engine. Biofuel Res. J. 2018, 5, 900–908. [Google Scholar] [CrossRef] [Green Version]

- Shrivastava, P.; Verma, T.N.; Pugazhendhi, A. An experimental evaluation of engine performance and emisssion characteristics of CI engine operated with Roselle and Karanja biodiesel. Fuel 2019, 254, 115652. [Google Scholar] [CrossRef]

- Roy, M.M.; Islam, M.S.; Alam, M.N. Biodiesel from Crude Tall Oil and Its NOx and Aldehydes Emissions in a Diesel Engine Fueled by Biodiesel-Diesel Blends with Water Emulsions. Processes 2021, 9, 126. [Google Scholar] [CrossRef]

- Reza Miri, S.M.; Mousavi Seyedi, S.R.; Ghobadian, B. Effects of biodiesel fuel synthesized from non-edible rapeseed oil on performance and emission variables of diesel engines. J. Clean. Prod. 2017, 142, 3798–3808. [Google Scholar] [CrossRef]

- Patel, C.; Tiwari, N.; Agarwal, A.K. Experimental investigations of Soyabean and Rapeseed SVO and biodiesels on engine noise, vibrations, and engine characteristics. Fuel 2019, 238, 86–97. [Google Scholar] [CrossRef]

- Markov, V.; Kamaltdinov, V.; Bykovskaya, L.; Sa, B. Performance of a diesel engine running on mixed biofuels with the addition of gasoline. E3S Web Conf. 2019, 140. [Google Scholar] [CrossRef] [Green Version]

- Markov, V.A.; Devyanin, S.N.; Bowen, S. Emission Performance of a Diesel Engine Running on Petroleum Diesel Fuel with Different Vegetable Oil Additives. In Proceedings of the 2020 International Multi-Conference on Industrial Engineering and Modern Technologies (FarEastCon), Vladivostok, Russian, 6–9 October 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Roy, M.M.; Wang, W.; Bujold, J. Biodiesel production and comparison of emissions of a DI diesel engine fueled by biodiesel-diesel and canola oil-diesel blends at high idling operations. Appl. Energy 2013, 106, 198–208. [Google Scholar] [CrossRef]

- Qi, D.H.; Lee, C.F.; Jia, C.C.; Wang, P.P.; Wu, S.T. Experimental investigations of combustion and emission characteristics of rapeseed oil–diesel blends in a two cylinder agricultural diesel engine. Energy Convers. Manag. 2014, 77, 227–232. [Google Scholar] [CrossRef]

- Qi, D.H.; Bae, C.; Feng, Y.M.; Jia, C.C.; Bian, Y.Z. Combustion and emission characteristics of a direct injection compression ignition engine using rapeseed oil based micro-emulsions. Fuel 2013, 107, 570–577. [Google Scholar] [CrossRef]

- Valente, O.S.; da Silva, M.J.; Pasa, V.M.D.; Belchior, C.R.P.; Sodré, J.R. Fuel consumption and emissions from a diesel power generator fuelled with castor oil and soybean biodiesel. Fuel 2010, 89, 3637–3642. [Google Scholar] [CrossRef]

- Azizzadeh Hajlari, S.; Najafi, B.; Faizollahzadeh Ardabili, S. Castor oil, a source for biodiesel production and its impact on the diesel engine performance. Renew. Energy Focus 2019, 28, 1–10. [Google Scholar] [CrossRef]

- Qi, D.; Xing, W.; Luo, P.; Liu, J.; Chen, R. Effect of alcohols on combustion characteristics and particle size distribution of a diesel engine fueled with diesel-castor oil blended fuel. Asia-Pacific J. Chem. Eng. 2020, 15, e2477. [Google Scholar] [CrossRef]

- Uyumaz, A. Combustion, performance and emission characteristics of a DI diesel engine fueled with mustard oil biodiesel fuel blends at different engine loads. Fuel 2018, 212, 256–267. [Google Scholar] [CrossRef]

- Markov, V.A.; Kamaltdinov, V.G.; Zykov, S.A.; Sa, B. Optimization of the composition of blended biodiesel fuels with additives of vegetable oils. Int. J. Energy Clean Environ. 2019, 20, 303–319. [Google Scholar] [CrossRef]

- Markov, V.A.; Kamaltdinov, V.G.; Loboda, S.S. Using Mustard Oil as Ecological Additive to Petroleum Diesel Fuel. In Proceedings of the International Conference Actual Issues of Mechanical Engineering, Tomsk, Russia, 27–29 July 2017; Atlantis Press: Dordrecht, The Netherlands, 2017; pp. 484–489. [Google Scholar]

- Viswanathan, K.; Ashok, B.; Pugazhendhi, A. Comprehensive study of engine characteristics of novel biodiesel from curry leaf (Murraya koenigii) oil in ceramic layered diesel engine. Fuel 2020, 280, 118586. [Google Scholar] [CrossRef]

- Praveena, V.; Leenus Jesu Martin, M.; Edwin Geo, V. Effect of EGR on emissions of a modified DI compression ignition engine energized with nanoemulsive blends of grapeseed biodiesel. Fuel 2020, 267, 117317. [Google Scholar] [CrossRef]

- Markov, V.A.; Kamaltdinov, V.G.; Savastenko, A.A. Petroleum Diesel Fuel and Linseed Oil Mixtures as Engine Fuels. J. Phys. Conf. Ser. 2018, 944, 12077. [Google Scholar] [CrossRef]

- Hazar, H.; Sevinc, H. Investigation of the effects of pre-heated linseed oil on performance and exhaust emission at a coated diesel engine. Renew. Energy 2019, 130, 961–967. [Google Scholar] [CrossRef]

- Markov, V.A.; Kamaltdinov, V.G.; Loboda, S.S. Optimization of Diesel Fuel and Corn Oil Mixtures Composition. Procedia Eng. 2016, 150, 225–234. [Google Scholar] [CrossRef] [Green Version]

- Gaglio, M.; Tamburini, E.; Lucchesi, F.; Aschonitis, V.; Atti, A.; Castaldelli, G.; Fano, E.A. Life Cycle Assessment of Maize-Germ Oil Production and the Use of Bioenergy to Mitigate Environmental Impacts: A Gate-To-Gate Case Study. Resources 2019, 8, 60. [Google Scholar] [CrossRef] [Green Version]

- Pizzi, A.; Duca, D.; Rossini, G.; Fabrizi, S.; Toscano, G. Biofuel, Bioenergy and Feed Valorization of By-Products and Residues from Hevea brasiliensis Cultivation to Enhance Sustainability. Resources 2020, 9, 114. [Google Scholar] [CrossRef]

- Creencia, E.C.; Nillama, J.A.P.; Librando, I.L. Microwave-Assisted Extraction and Physicochemical Evaluation of Oil from Hevea brasiliensis Seeds. Resources 2018, 7, 28. [Google Scholar] [CrossRef] [Green Version]

- Jain, N.L.; Soni, S.L.; Poonia, M.P.; Sharma, D.; Srivastava, A.K.; Jain, H. Performance and emission characteristics of preheated and blended thumba vegetable oil in a compression ignition engine. Appl. Therm. Eng. 2017, 113, 970–979. [Google Scholar] [CrossRef]

- Kotaiah, K.; Periyasamy, P.; Prabhahar, M. Performance and emission characteristics of small agricultural diesel engine using Lemongrass oil and its diesel blends. Mater. Today Proc. 2020, 33, 658–662. [Google Scholar] [CrossRef]

- Qi, D.H.; Yang, K.; Zhang, D.; Chen, B.; Wei, Q.; Zhang, C.H. Experimental investigation of a turbocharged CRDI diesel engine fueled with Tung oil-diesel-ethanol microemulsion fuel. Renew. Energy 2017, 113, 1201–1207. [Google Scholar] [CrossRef]

- EL-Seesy, A.I.; He, Z.; Hassan, H.; Balasubramanian, D. Improvement of combustion and emission characteristics of a diesel engine working with diesel/jojoba oil blends and butanol additive. Fuel 2020, 279, 118433. [Google Scholar] [CrossRef]

- Food and Agriculture Organization; World Health Organization. Codex Alimentarius, Volume 8: Fats, Oils and Related Products, 2nd ed.; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2001; ISBN 9251046824. [Google Scholar]

| Vegetable Oil | Mass Fraction of Fatty Acids of Vegetable Oils, % | |||||

|---|---|---|---|---|---|---|

| Saturated Fatty Acids | Unsaturated Fatty Acids | |||||

| Myristic C14H28O2 or C 14:0 | Palmitic C16H32O2 or C 16:0 | Stearic C18H36O2 or C 18:0 | Oleic C18H34O2 or C 18:1 | Linoleic C18H32O2 or C 18:2 | Linolenic C18H30O2 or C 18:3 | |

| RO | 0 … 0.2 | 1.5 … 6.0 | 0.5 … 3.1 | 8.0 … 60.0 | 11.0 … 23.0 | 5.0 … 13.0 |

| SuO | 0 … 0.2 | 5.6 … 7.6 | 2.7 … 6.5 | 14.0 … 39.4 | 18.3 … 74.0 | up to 0.3 |

| SoO | 0 … 0.2 | 8.0 … 13.5 | 2.0 … 5.4 | 17.0 … 30.0 | 48.0 … 59.0 | 4.5 … 11.0 |

| CoO | 0 … 0.3 | 8.6 … 16.5 | 0 … 3.3 | 20.0 … 42.2 | 34.0 … 65.6 | 0 … 2.0 |

| LO | 5.4 … 11.3 | 2.5 … 8.0 | 0.4 … 1.0 | 13.0 … 36.0 | 8.3 … 30.0 | 30.0 … 67.0 |

| MO | 0 … 1.0 | 0.5 … 4.5 | 0.5 … 2.0 | 8.0 … 23.0 | 10.0 … 24.0 | 6.0 … 18.0 |

| CaO | 0 … 0.2 | 5.0 … 7.0 | 2.0 … 2.5 | 12.0 … 20.0 | 12.0 … 20.0 | 14.0 … 22.0 |

| Property | Fuel Type | |||||||

|---|---|---|---|---|---|---|---|---|

| DF | RO | SuO | SO | CO | LO | MO | CaO | |

| Density at 20 °C, kg/m3 | 830 | 916 | 923 | 923 | 921 | 912 | 920.0 | 910 |

| Kinematic viscosity at 20 °C, mm2/s | 3.8 | 75.0 | 72.0 | 65.0 | 66.6 | 59.0 | 70.0 | 57.7 |

| Lower calorific value, MJ/kg | 42.5 | 37.3 | 37.4 | 37.3 | 37.1 | 37.6 | 37.2 | 37.5 |

| Cetane number | 45 | 36 | 37 | 35 | 37 | 38 | 35 | 37 |

| Theoretical air–fuel ratio | 14.31 | 12.52 | 12.36 | 12.38 | 12.38 | 12.62 | 12.44 | 12.52 |

| Property | Fuel Type | |||||||

|---|---|---|---|---|---|---|---|---|

| DF | 90% DF + 10% RO | 90% DF + 10% SuO | 90% DF + 10% SoO | 90% DF + 10% CoO | 90% DF + 10% LO | 90% DF + 10% MO | 90% DF + 10% CaO | |

| Density at 20 °C, kg/m3 | 830 | 839 | 839 | 838 | 839 | 837 | 839 | 838 |

| Kinematic viscosity at 20 °C, mm2/s | 3.8 | 6.1 | 6.0 | 5.6 | 5.9 | 5.9 | 5.9 | 5.8 |

| Lower calorific value, MJ/kg | 42.5 | 41.9 | 41.9 | 42 | 42 | 41.9 | 41.9 | 42 |

| Cetane number | 45 | 44.1 | 44.2 | 44 | 44.2 | 44.3 | 44 | 44.2 |

| Theoretical air–fuel ratio | 14.31 | 14.12 | 14.16 | 14.13 | 14.11 | 14.16 | 14.11 | 14.13 |

| Element mass content, % | ||||||||

| C | 87 | 86 | 86.1 | 85.9 | 86 | 86.1 | 86 | 86.1 |

| H | 12.6 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 |

| O | 0.4 | 1.5 | 1.4 | 1.6 | 1.5 | 1.4 | 1.5 | 1.4 |

| Parameters | Value |

|---|---|

| Engine type | Four-stroke, in-line, diesel |

| Number of cylinders | 4 |

| Cylinder diameter D, mm | 110 |

| Piston stroke S, mm | 125 |

| Total cylinder capacity iVh, L | 4.32 |

| Compression ratio ε | 15.1 |

| Combustion chamber (CC) type, air–fuel mixing method | CC of type CNIDI (Central Diesel Engine Research Institute), space atomization and film evaporation |

| Nominal speed n, rpm | 2400 |

| Nominal power Ne, kW | 80 |

| Fuel supply system type | Separate fuel system |

| High-pressure fuel pump | In-line plunger pump Motorpal PP4M10U1f |

| Diameter of plunger dpl, mm | 10 |

| Plunger stroke hpl, mm | 10 |

| Length of high-pressure oil pipe Lh, mm | 540 |

| Injector | Type FDM-22 OJSC |

| Initial injection pressure, MPa | 21.0 |

| Measured Parameter | Measuring Range | Accuracy | Uncertainty |

|---|---|---|---|

| Engine speed | 0–5000 rpm | ±5 rpm | ±0.1% |

| Torque moment | 0–500 Nm | ±5 Nm | ±1% |

| Engine power | 0–100 kW | ±0.5 kW | ±1% |

| Fuel consumption | 0–40 kg/h | ±0.1 kg/h | ±0.25% |

| Air consumption | 0–1000 kg/h | ±10 kg/h | ±1% |

| NOx | 0–4000 ppm | <1000 ppm: ±10 ppm | ≥1000 ppm: ±5% |

| CO | 0–5 vol % | <1 vol %: ±0.03 vol % | ≥1 vol %: ±3 vol % |

| HC | 0–2000 ppm | <200 ppm: ±10 ppm | ≥200 ppm: ±5% |

| Exhaust gas smoke | 0–100% | ±1% full-scale reading | - |

| Fuel Type | Engine Indicators | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ne in Nmax, kW | Ne inMmax, kW | n in Nmax, rpm | n inMmax, rpm | Me in Nmax, N·m | Me in Mmax, N·m | Gf in Nmax, kg/h | Gf in Mmax, kg/h | ge in Nmax, g/(kW·h) | ge in Mmax, g/(kW·h) | |

| Petroleum DF | 75.54 | 53.59 | 2397 | 1501 | 301 | 341 | 18.81 | 12.1 | 249 | 225.8 |

| 90% DF + 10% RO | 76.90 | 55.38 | 2408 | 1520 | 305 | 348 | 19.38 | 12.67 | 252 | 228.8 |

| Petroleum DF | 79.82 | 61.64 | 2405 | 1600 | 317 | 368 | 19.7 | 13.72 | 246.8 | 222.6 |

| 90% DF + 10% SuO | 79.43 | 61.57 | 2400 | 1602 | 316 | 367 | 19.96 | 13.97 | 251.3 | 226.9 |

| Petroleum DF | 80.92 | 57.91 | 2400 | 1503 | 322 | 368 | 20.1 | 13.1 | 248.4 | 226.2 |

| 90% DF + 10% SoO | 80.44 | 56.79 | 2401 | 1502 | 320 | 361 | 20.4 | 13.01 | 253.6 | 229.1 |

| Petroleum DF | 78.08 | 56.20 | 2398 | 1499 | 311 | 358 | 19.31 | 12.56 | 247.3 | 223.5 |

| 90% DF + 10% CoO | 76.89 | 55.74 | 2400 | 1500 | 306 | 355 | 19.36 | 12.52 | 251.8 | 224.6 |

| Petroleum DF | 80.92 | 57.91 | 2400 | 1503 | 322 | 368 | 20.1 | 13.1 | 248.4 | 226.2 |

| 90% DF +10% LO | 80.29 | 57.71 | 2404 | 1502 | 319 | 367 | 20.24 | 13.28 | 252.1 | 230.1 |

| Petroleum DF | 80.58 | 57.47 | 2397 | 1508 | 321 | 364 | 20 | 13 | 248.2 | 226.2 |

| 90% DF + 10% MO | 79.91 | 57.01 | 2400 | 1500 | 318 | 363 | 20.25 | 13.22 | 253.4 | 231.9 |

| Petroleum DF | 80.58 | 57.47 | 2397 | 1508 | 321 | 364 | 20 | 13 | 248.2 | 226.2 |

| 90% DF + 10% CaO | 79.77 | 56.38 | 2403 | 1504 | 317 | 358 | 20.23 | 13.3 | 253.6 | 235.9 |

| Fuel Type | Engine Indicators | |||||||

|---|---|---|---|---|---|---|---|---|

| CNOx in Nmax, ppm/g/kW·h | ΔCNOx, % | CNOx in Mmax, ppm/g/kW·h | ΔCNOx, % | KX in Nmax, % (H.) | Δ KX, % | KX in Mmax, % (H.) | Δ KX, % | |

| Petroleum DF, RO-blended DF | ||||||||

| Petroleum DF | 675/8.27 | - | 800/5.81 | - | 11.0 | - | 25.0 | - |

| 90% DF + 10% RO | 660/8.05 | −2.2/−2.6 | 785/5.67 | −1.9/−2.4 | 9.5 | −13.6 | 20.5 | −18.0 |

| Petroleum DF, SuO-blended DF | ||||||||

| Petroleum DF | 605/7.40 | - | 680/5.20 | - | 14,5 | - | 20.0 | - |

| 90% DF + 10% SuO | 580/7.10 | −4.1/−4.0 | 675/5.17 | −0.7/−0.6 | 12,0 | −17.2 | 15.0 | −25.0 |

| Petroleum DF, SoO-blended DF | ||||||||

| Petroleum DF | 605/7.80 | - | 700/5.48 | - | 16.0 | - | 43.0 | - |

| 90% DF + 10% SoO | 560/7.23 | −7.4/−7.3 | 650/5.11 | −7.1/−6.9 | 10.0 | −37.5 | 31.0 | −27.9 |

| Petroleum DF, CoO-blended DF | ||||||||

| Petroleum DF | 600/7.37 | - | 650/5.44 | - | 18.0 | - | 40.0 | - |

| 90% DF + 10% CoO | 550/6.77 | −8.3/−8.1 | 620/5.11 | −4.6/−4.4 | 14.0 | −22.2 | 37.0 | −7.5 |

| Petroleum DF, LO-blended DF | ||||||||

| Petroleum DF | 605/7.38 | - | 700/5.87 | - | 16.0 | - | 43.0 | - |

| 90% DF +10% LO | 570/6.96 | −5.8/−5.7 | 690/5.80 | −1.4/−1.2 | 11.0 | −31.3 | 36.0 | −16.3 |

| Petroleum DF, MO-blended DF | ||||||||

| Petroleum DF | 550/6.30 | - | 640/5.01 | - | 17.0 | - | 42.0 | - |

| 90% DF +10% MO | 545/6.25 | −0.9/−0.8 | 625/4.90 | −2.3/−2.2 | 12.0 | −29.4 | 36.0 | −14.3 |

| Petroleum DF, CaO-blended DF | ||||||||

| Petroleum DF | 550/6.30 | - | 640/5.01 | - | 17.0 | - | 42.0 | - |

| 90% DF + 10% CaO | 525/6.03 | −4.5/−4.3 | 620/4.86 | −3.1/−3.0 | 15 | −11.8 | 36.0 | −14.3 |

| Fuel Type | Engine Indicators | |||||||

|---|---|---|---|---|---|---|---|---|

| CCO in Nmax, ppm/g/kW·h | ΔCCO in Nmax, % | CCO in Mmax, ppm/g/kW·h | ΔCCO in Mmax, % | CHC in Nmax, ppm/g/kW·h | ΔCHC in Nmax, % | CHC in Mmax, ppm/g/kW·h | ΔCHC in Mmax, % | |

| Petroleum DF, RO-blended DF | ||||||||

| Petroleum DF | 210/1.60 | - | 330/3.17 | - | 150/1.07 | - | 170/0.79 | - |

| 90% DF + 10% RO | 200/1.52 | −4.8/−5.0 | 305/2.92 | −7.6/7.9 | 120/0.85 | −20.0/−20.5 | 130/0.60 | −23.5/−24.0 |

| Petroleum DF, SuO-blended DF | ||||||||

| Petroleum DF | 165/1.02 | - | 315/2.01 | - | 105/0.41 | - | 82/0.32 | - |

| 90% DF + 10% SuO | 160/0.99 | −3.0/−2.9 | 270/1.73 | −14.3/−13.9 | 95/0.37 | −9.5/−9.7 | 73/0.29 | −11.0/−9.4 |

| Petroleum DF, SoO-blended DF | ||||||||

| Petroleum DF | 102/0.81 | - | 330/1.59 | - | 108/0.56 | - | 170/0.42 | - |

| 90% DF + 10% SoO | 96/0.76 | −5.9/−6.2 | 285/1.38 | −13.6/−13.2 | 99/0.52 | −8.3/−7.1 | 150/0.37 | −11.8/−11.9 |

| Petroleum DF, CoO-blended DF | ||||||||

| Petroleum DF | 255/1.79 | - | 470/2.29 | - | 163/0.68 | - | 201/0.60 | - |

| 90% DF + 10% CoO | 210/1.48 | −17.6/−17.3 | 450/2.20 | −4.3/−3.9 | 120/0.52 | −24.4/−23.5 | 145/0.45 | −27.9/−25.0 |

| Petroleum DF, LO-blended DF | ||||||||

| Petroleum DF | 102/0.69 | - | 330/1.56 | - | 108/0.39 | - | 170/0.44 | - |

| 90% DF +10% LO | 85/0.58 | −16.7/−15.9 | 280/1.32 | −15.2/−15.4 | 83/0.30 | −23.1/−23.1 | 130/0.34 | −23.5/−22.7 |

| Petroleum DF, MO-blended DF | ||||||||

| Petroleum DF | 100/0.71 | - | 300/1.47 | - | 76/0.28 | - | 130/0.34 | - |

| 90% DF + 10% MO | 91/0.65 | −9.0/−8.5 | 275/1.35 | −8.3/−8.2 | 61/0.23 | −19.7/−17.9 | 105/0.28 | −19.2/−17.6 |

| Petroleum DF, CaO-blended DF | ||||||||

| Petroleum DF | 100/0.71 | - | 300/1.47 | - | 76/0.28 | - | 130/0.34 | - |

| 90% DF + 10% CaO | 80/0.57 | −20.0/−19.7 | 270/1.33 | −10.0/−9.5 | 60/0.23 | −21.1/−17.8 | 116/0.31 | −10.8/−8.8 |

| Fuel Type | Engine Indicators | |||

|---|---|---|---|---|

| geave, g/(kW·h) | eNOx, g/(kW·h) | eCO, g/(kW·h) | eHC, g/(kW·h) | |

| Petroleum DF, RO-blended DF | ||||

| Petroleum DF | 247.20 | 7.442 | 3.482 | 1.519 |

| 90% DF + 10% RO | 250.79 | 7.300 | 3.332 | 1.202 |

| Petroleum DF, SuO-blended DF | ||||

| Petroleum DF | 230.52 | 6.630 | 2.210 | 0.580 |

| 90% DF + 10% SuO | 246.09 | 6.649 | 2.091 | 0.530 |

| Petroleum DF, SoO-blended DF | ||||

| Petroleum DF | 247.97 | 7.018 | 1.723 | 0.788 |

| 90% DF + 10% SoO | 251.42 | 5.896 | 1.548 | 0.762 |

| Petroleum DF, CoO-blended DF | ||||

| Petroleum DF | 244.32 | 6.549 | 3.277 | 1.104 |

| 90% DF + 10% CoO | 248.22 | 6.337 | 2.825 | 0.773 |

| Petroleum DF, LO-blended DF | ||||

| Petroleum DF | 247.97 | 7.018 | 1.723 | 0.788 |

| 90% DF + 10% LO | 252.26 | 6.441 | 1.511 | 0.664 |

| Petroleum DF, MO-blended DF | ||||

| Petroleum DF | 244.63 | 5.911 | 2.184 | 0.675 |

| 90% DF + 10% MO | 251.08 | 5.689 | 2.068 | 0.561 |

| Petroleum DF, CaO-blended DF | ||||

| Petroleum DF | 244.63 | 5.911 | 2.184 | 0.675 |

| 90% DF + 10% CaO | 255.57 | 5.341 | 1.853 | 0.585 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markov, V.; Kamaltdinov, V.; Devyanin, S.; Sa, B.; Zherdev, A.; Furman, V. Investigation of the Influence of Different Vegetable Oils as a Component of Blended Biofuel on Performance and Emission Characteristics of a Diesel Engine for Agricultural Machinery and Commercial Vehicles. Resources 2021, 10, 74. https://doi.org/10.3390/resources10080074

Markov V, Kamaltdinov V, Devyanin S, Sa B, Zherdev A, Furman V. Investigation of the Influence of Different Vegetable Oils as a Component of Blended Biofuel on Performance and Emission Characteristics of a Diesel Engine for Agricultural Machinery and Commercial Vehicles. Resources. 2021; 10(8):74. https://doi.org/10.3390/resources10080074

Chicago/Turabian StyleMarkov, Vladimir, Vyacheslav Kamaltdinov, Sergey Devyanin, Bowen Sa, Anatoly Zherdev, and Viktor Furman. 2021. "Investigation of the Influence of Different Vegetable Oils as a Component of Blended Biofuel on Performance and Emission Characteristics of a Diesel Engine for Agricultural Machinery and Commercial Vehicles" Resources 10, no. 8: 74. https://doi.org/10.3390/resources10080074

APA StyleMarkov, V., Kamaltdinov, V., Devyanin, S., Sa, B., Zherdev, A., & Furman, V. (2021). Investigation of the Influence of Different Vegetable Oils as a Component of Blended Biofuel on Performance and Emission Characteristics of a Diesel Engine for Agricultural Machinery and Commercial Vehicles. Resources, 10(8), 74. https://doi.org/10.3390/resources10080074