2.1. Positioning of This Study in the Overall Context of the OREWA Project

Improving DHNs with low-investment measures ensures their cost- and energy-efficient operation in the future and is vital for energy transition. The ongoing research project ‘OREWA’ (optimization and restructuring of DHNs including evaluation of transferability, ecology, and economy) contains the collection of optimization measures in a catalog up to the application of these measures. The three methodical steps are illustrated in

Figure 1.

The first step of the OREWA project shown in

Figure 1 involves collecting optimization measures from published studies and from the ongoing investigation. The catalog is intended to serve as a guideline for district heating operators. Based on typical DHN characteristics such as overall energy demand, heat density, network temperatures or key performance indicators like those defined in [

19], the measures are extracted that can be useful and economical for a specific network. Thus, in the second step (cf.

Figure 1), a selection process is implemented. The measurements which are identified to be sensible must be examined more closely for the operator’s DHN. This procedure will be demonstrated in the third step using two exemplary DHNs.

Within the third step, the presented investigation is to be placed, and the step will be shown exemplarily. For the specific DHNs, several measures from the catalog are eliminated because of their specific characteristics. The DHNs are small and have high heat losses and high DHN return temperatures. Therefore, the measures identified as beneficial are the upgrade of the substations and subsequently the reduction of the return temperatures. This paper focuses on the laboratory experiment used to determine the potential optimization of the DHS and thus for the district heating system. The results are then used to calculate the thermal savings via simulation. In addition, the cost of improving the substation must be calculated accurately.

2.3. Description of the State-of-the-Art and Optimized DHS Setup

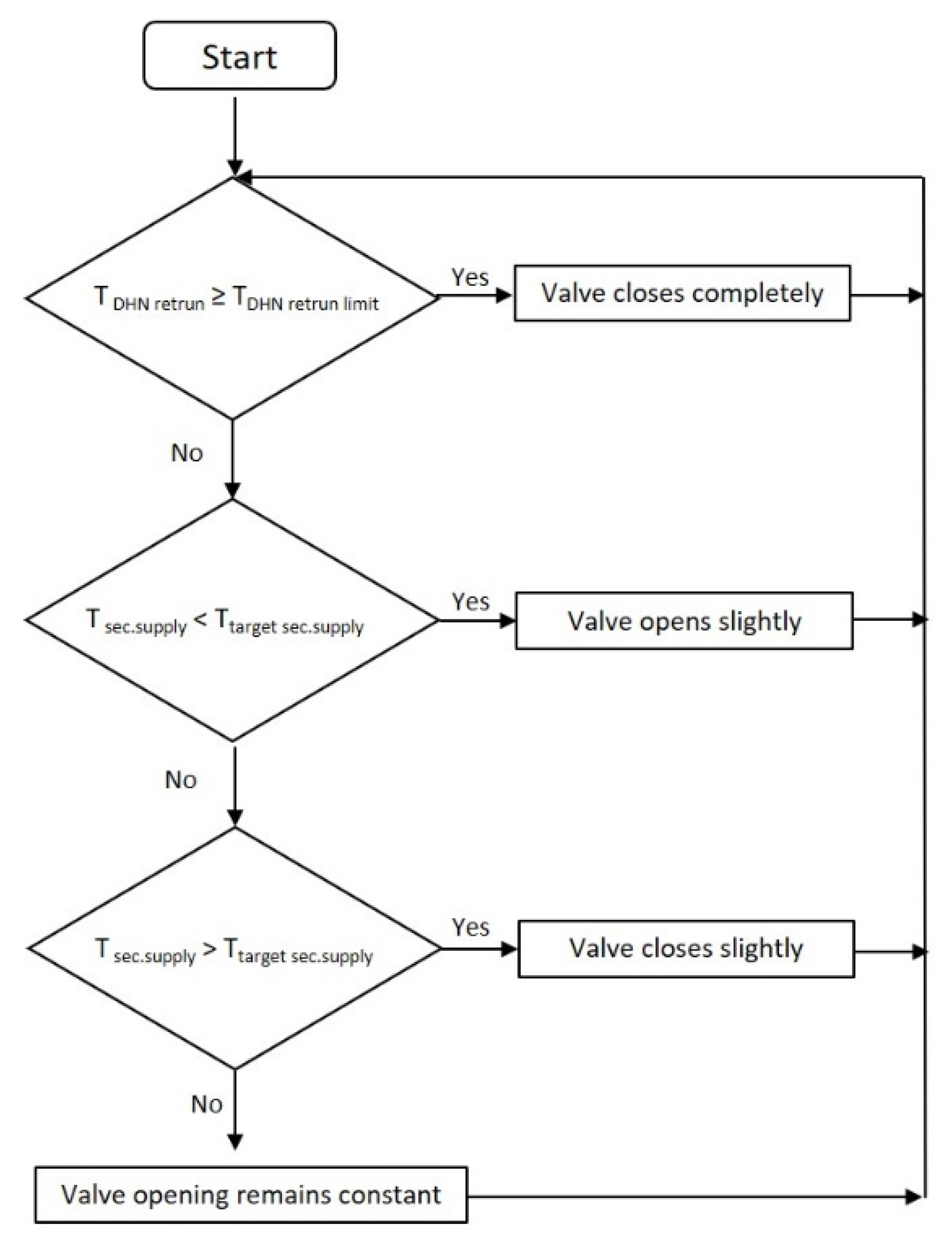

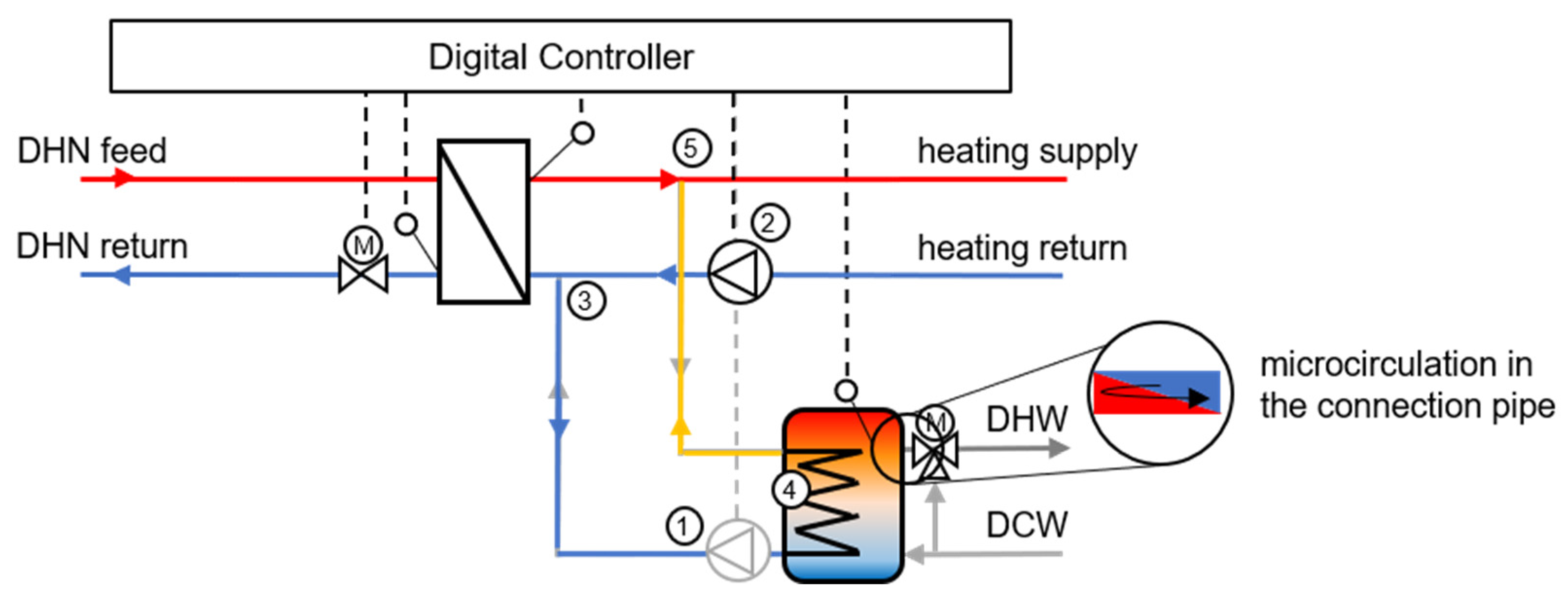

The DHS, which is installed in the two specific networks, is shown in

Figure 2a. The part of the DHS setup from the DHN to heat exchanger is called the primary side. The domestic installation is referred to as the secondary side. Originally, the heating systems in such SFHs were supplied by oil boilers. By removing these oil boilers, the domestic hot water (DHW) storages, as well as the controllers of the pumps, were left independent from the new heat transfer components. In principle, the DHN is coupled into the existing house system via a plate heat exchanger and a thermostatic valve. The thermostatic valve is set to a target return temperature on the primary side (cf.

Figure 2a). Fluid between the sensor and the valve expands to a greater or lesser extent proportionally to the DHN return temperature and thus determines the degree of opening of the valve. In the case of a low temperature in the DHW return pipe, the consumption by the consumer is assumed to be high. Subsequently, the fluid within the thermostat sensor contracts, allowing the valve to open further. If the demand is small or non-existent, i.e., the DHN return temperature is close to the DHN feed temperature, the valve almost closes completely. A permanent small opening of the valve is necessary for the proper functioning of the thermostatic valve. However, this leads to the fact that during times of low heat demand (e.g., summer), a small mass flow with high temperature permanently flows through the pipes, causing high thermal losses of the DHN. The thermostat DHS is an ‘uncontrolled DHS’, as the secondary side cannot be set to specific set points. As a result, the temperature on the secondary side solely depends on the temperature on the primary side.

To overcome the aforementioned problems, the thermostatic valve is replaced by a flow controller with an additional electric actuator (cf.

Figure 2b, red circled valve).

The automatic flow controller can be configured individually in each SFH to meet the maximum load agreed in the contract with the network operator. Configuration of the automatic flow controller allows for easier hydraulic balancing of the DHN. The particular advantage of this method is that the DHN can properly supply all consumers in the design case; even the consumers at the furthest point from the heating center receive the ordered power. In combination with the electric actuator, an electronic controller controls the flow. The required parameters are stored in the controller. Another advantage of the electronic controller is that central control from the heating center is possible. Depending on the given parameters, the controller can adjust the flow by means of the electric actuator. In case of no consumption, the valve is completely closed, therefore reducing the thermal losses of the DHN. At the same time, it is possible to separate the supply of the space heating system from charging the DHW storage. The particular advantage of such a DHW charging priority is that the storage tank can be charged as quickly as possible. The maximum load can be used for charging the storage tank. During the time when the storage tank is charged, the return temperatures are much higher than at times when only the heating is operated. Thus, a fast charging time keeps the time with high return temperatures as short as possible. This system is undoubtably more complex than the uncontrolled one. The electronic control requires a few settings, and the valve is dependent on auxiliary power.

To quantify the benefit of this setup, both DHSs were measured on a thermal test rig in the laboratory (cf.

Figure 4).

In the subsequent text, the following abbreviations are used for the systems:

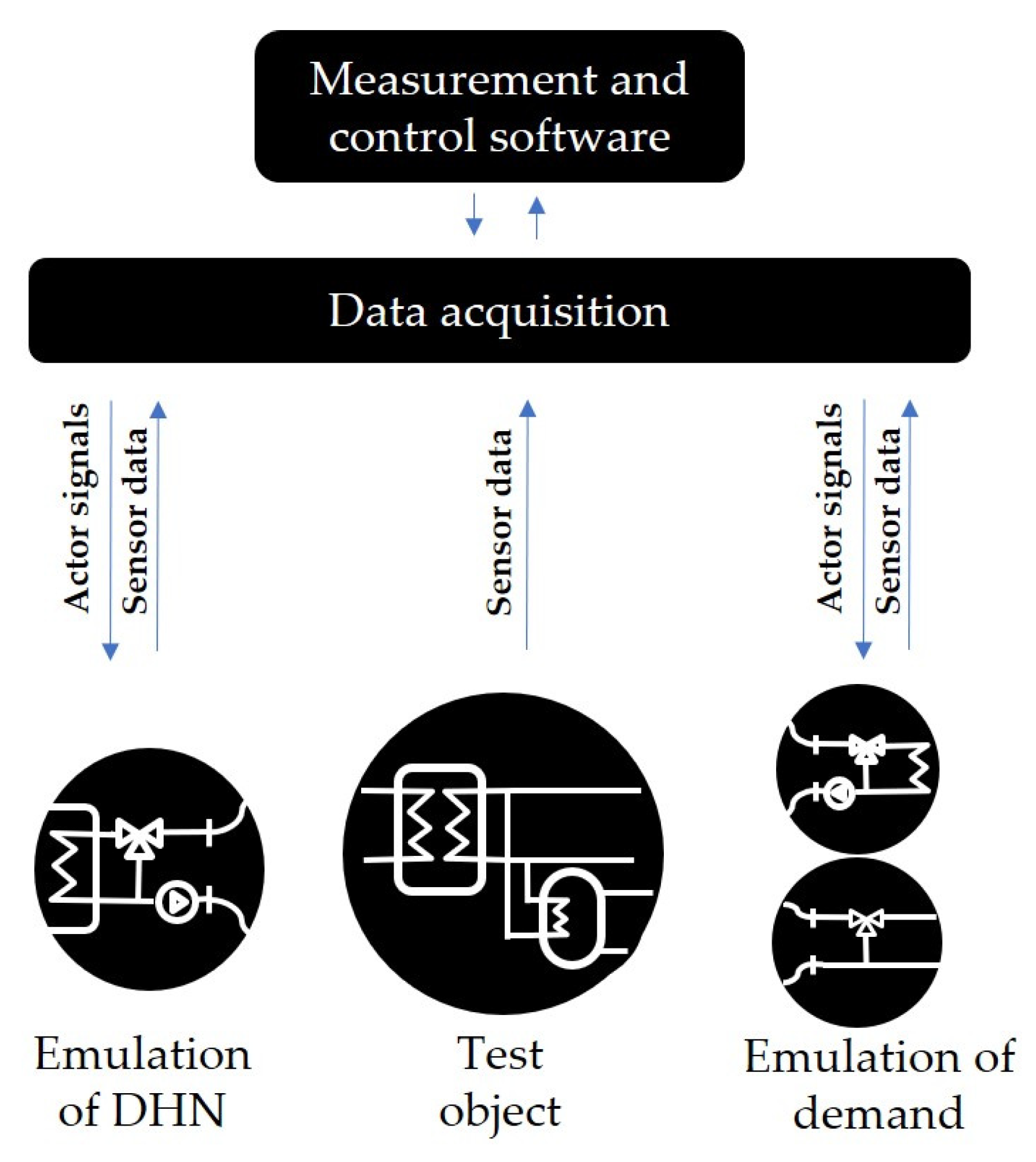

The investigation was carried out by measurements in the laboratory. For this purpose, a thermal test rig was constructed (cf.

Figure 5). All sensors and actuators were controlled and measured by software. Data acquisition devices connect the software and the hydraulic circuits. They transmit the values to the actuators and record the values from the sensors. The DHN, as well as the heating and tap water demand, are emulated with the hydraulic circuits of the test rig [

20].

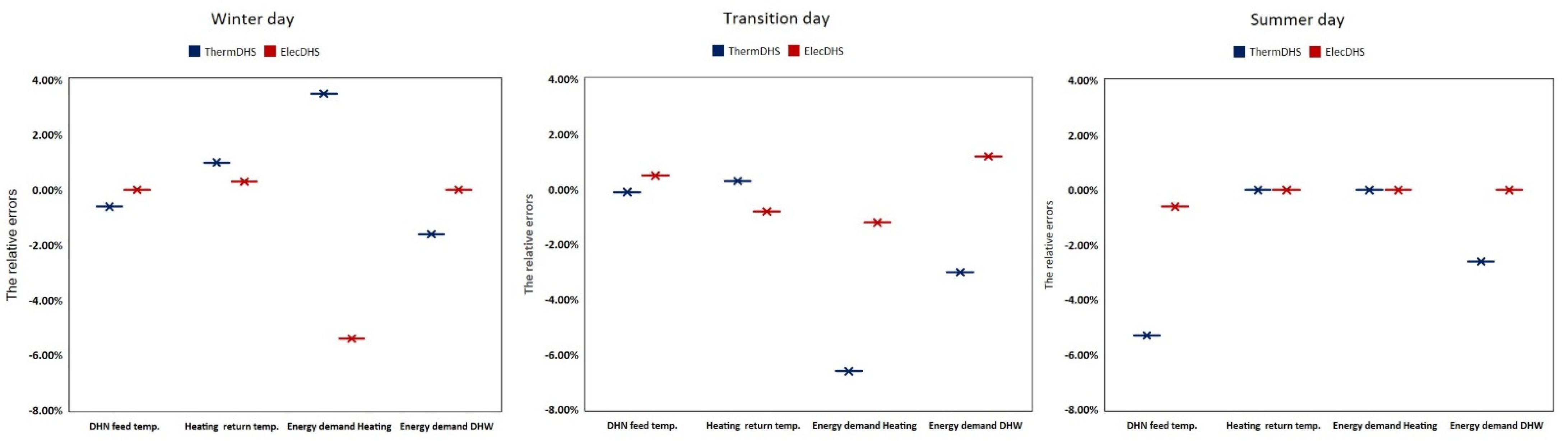

The measurement of both DHSs takes place under the same consumer demand profiles. They are measured under a representative heating load profile of a winter day and a transition day [

21]. In the case of the DHW demand, the same profile is used for winter, transition, and summer days. The measurement of each typical day means a 24 h measurement. The resolutions of the load profiles should be chosen in such a way that they provoke a realistic behavior of the DHS. Therefore, the resolutions worked out by [

14] were chosen (cf.

Table 2). A data acquisition unit recorded the measurement data every 2 s. This ensures that peaks are detected as accurately as possible.

The three measured typical days are used to calculate the values like return temperatures or DHN losses for one year (cf.

Section 3.4.2).

In order to use representative load profiles, the heating profiles according to VDI 4655 were utilized [

21]. The annual heating demand was determined from the typical demands (cf.

Table 3).

For the DHW demand profiles, a load profile with a high resolution was used (cf.

Table 2). In the case of the two investigated DHNs, an average of 3.4 people live in a household, which results in an average daily demand of 4.7 kWh. The values used as a basis for calculating the DHW demand are shown in

Table 4.

The temperature levels given in

Table 5 were used as the basis for the measurements in the laboratory. The specific DHNs are both operated with constant supply temperatures of 75 °C all year round. A heating system design temperature of 60 °C/40 °C is representative of the consumers in both existing DHNs according to the operator. However, the disadvantage with the

ThermDHS is that the secondary side supply temperature cannot be determined. It depends directly on the DHN feed temperature. Thus, the supply temperature on the secondary side for this system is 70 °C.

The heat demand profiles were calculated for measurement in the laboratory with a constant supply and return temperature. As described, these are 60 °C/40 °C for the ElecDHS and 70 °C/50 °C for the ThermDHS. Accordingly, the volume flows vary depending on the fluctuating demand.

In DHNs, a low maximum charging temperature of the storage tank is typically aimed for, as the return temperatures rise accordingly during charging. At the same time, lower charging temperatures can keep the calcification of the heat exchanger low [

14]. Therefore, 55 °C was used as the maximum storage temperature in the laboratory test. At this operating temperature, [

23] requires that the water be completely replaced at least every three days. In practice, however, to prevent legionella, the DHW storage tanks are designed to replace the water once a day. With the electronic controller, however, the once-a-day heating up to and over 60 °C can also be fulfilled. The temperature sensor is located at one-third of the way below the top of the storage tank. In the laboratory test, the storage tank in the DHS has a volume of 200 L.

With the ElecDHS, the storage tank can be charged with priority. This means that the heating is off when the storage tank is charged. As a result, the supply temperature on the secondary side can be controlled independently from the supply temperature when the heating system is in operation.

As an outcome of the presented article, the energetic benefit of reducing the return temperatures is calculated for one of the two specific DHNs. Considering the energy demand of the circulation pump allows for an extrapolation of the electrical energy savings.