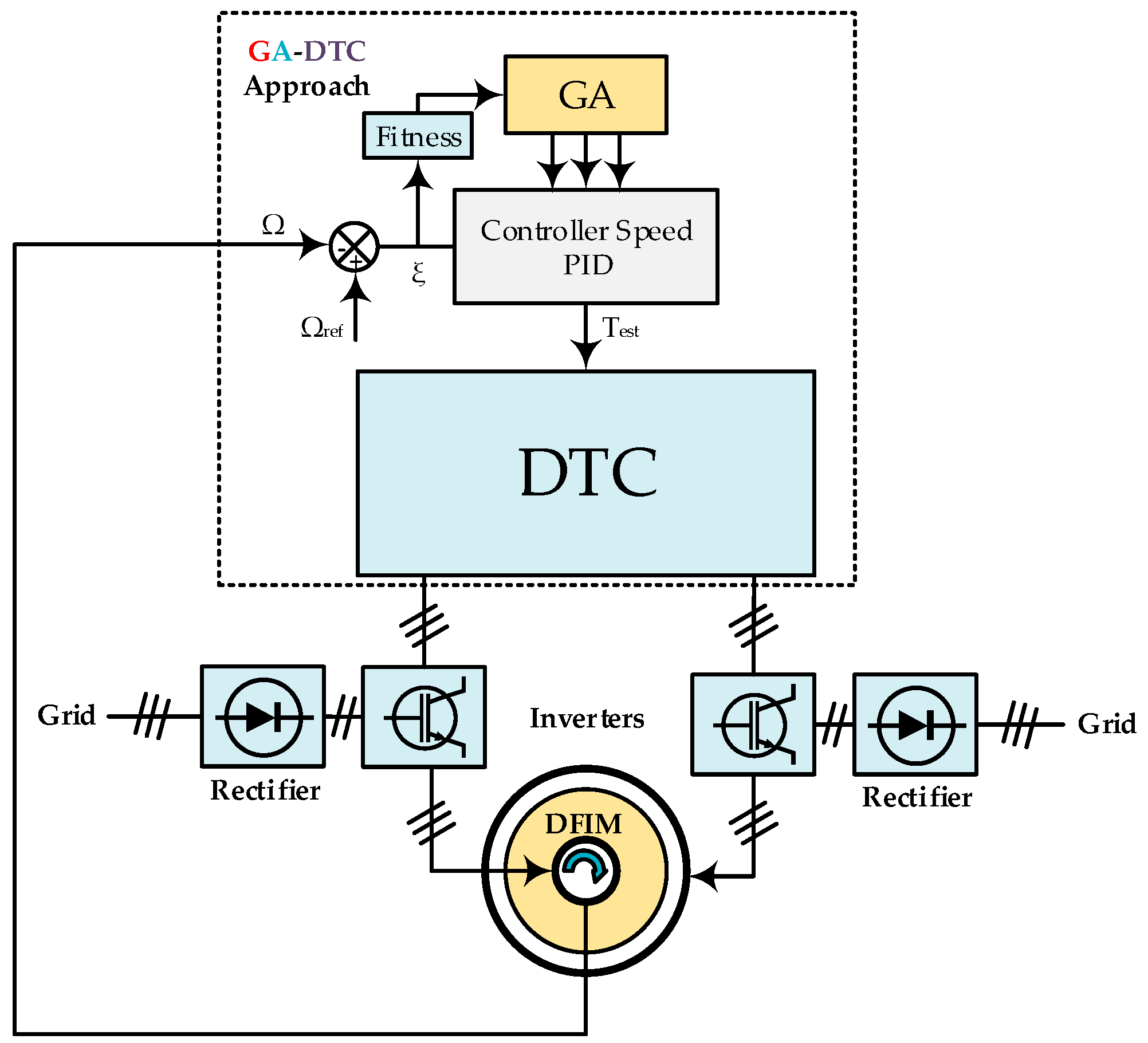

A New Strategy-Based PID Controller Optimized by Genetic Algorithm for DTC of the Doubly Fed Induction Motor

Abstract

1. Introduction

- Minimization of torque and flux ripples influenced by the variation of machine parameters (inverters, hysteresis comparator, flux, and torque estimators).

- Conservation of DTC control performances.

- Improvement of speed and electromagnetic torque performances.

- Reduction of the THD rate of the stator and rotor currents.

2. Model of the DFIM

- Electrical equations:

- Magnetic equations:

- Mechanical equations:

3. DTC Strategy

3.1. Flux and Torque Correctors

3.2. Elaboration of the Switching Table

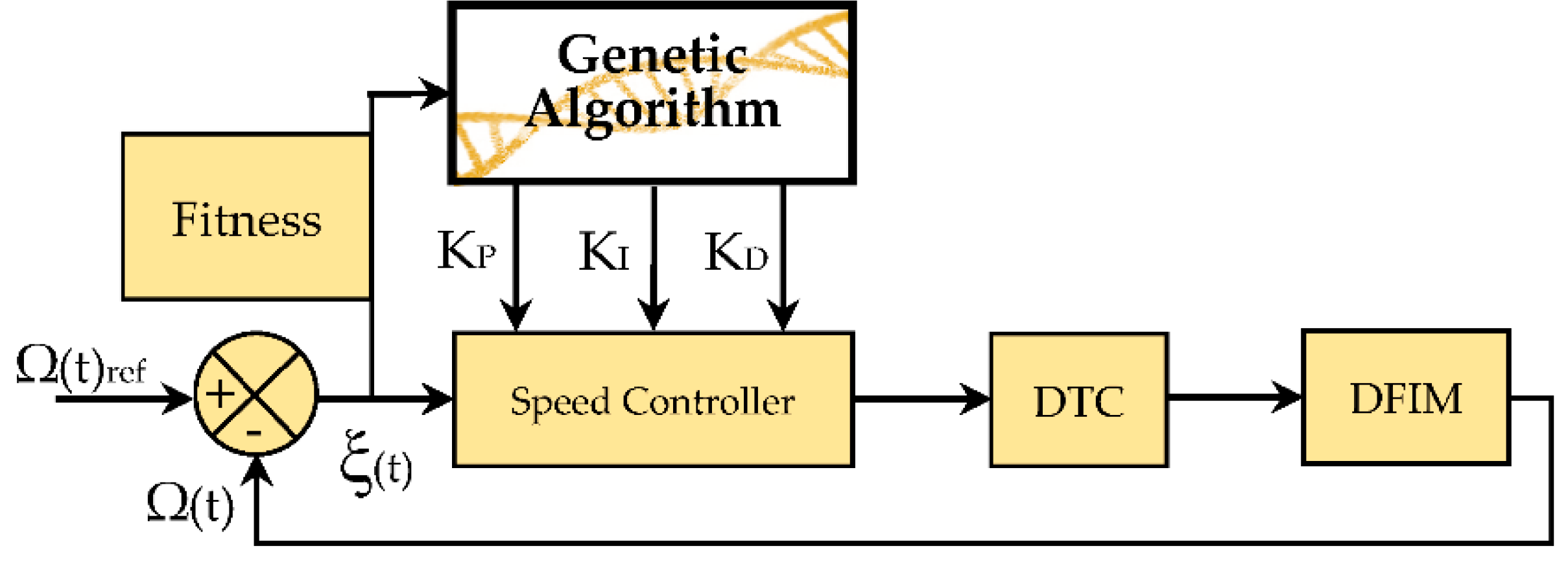

4. Optimization of the PID Parameters by GA

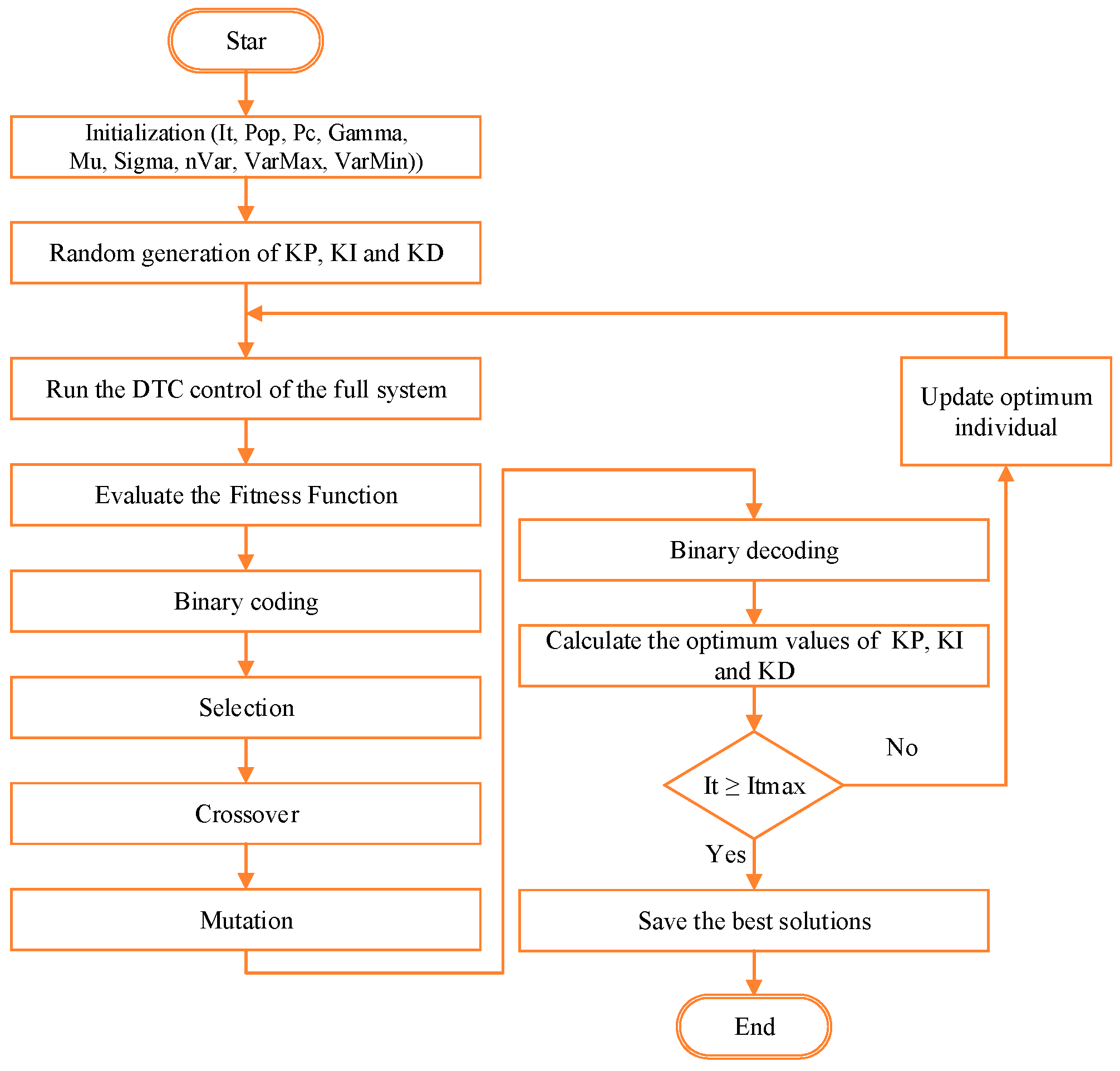

| Algorithm 1 Genetic Algorithm |

| Begin Step 1. Initialize the algorithm parameters (It, Pop, Pc, Gamma, Mu, Sigma, nVar, VarMax, VarMin). Step 2. Generate parameters for the PID controller randomly. Step 3. Execute DTC control of the complete system. Step 4. Calculate and evaluate the value of the Fitness function. Step 5. Apply binary coding. Step 6. Proceed to the selection operation. Step 7. Proceed to the crossover operation. Step 8. Proceed to the mutation operation. Step 9. Proceed to the mutation operation. Step 10. Apply binary decoding. Step 11. Update optimum individual and repeat step 3 until the maximum number of iterations has been reached. Step 12. Save the best solutions. End |

4.1. GA Operators and Parameters

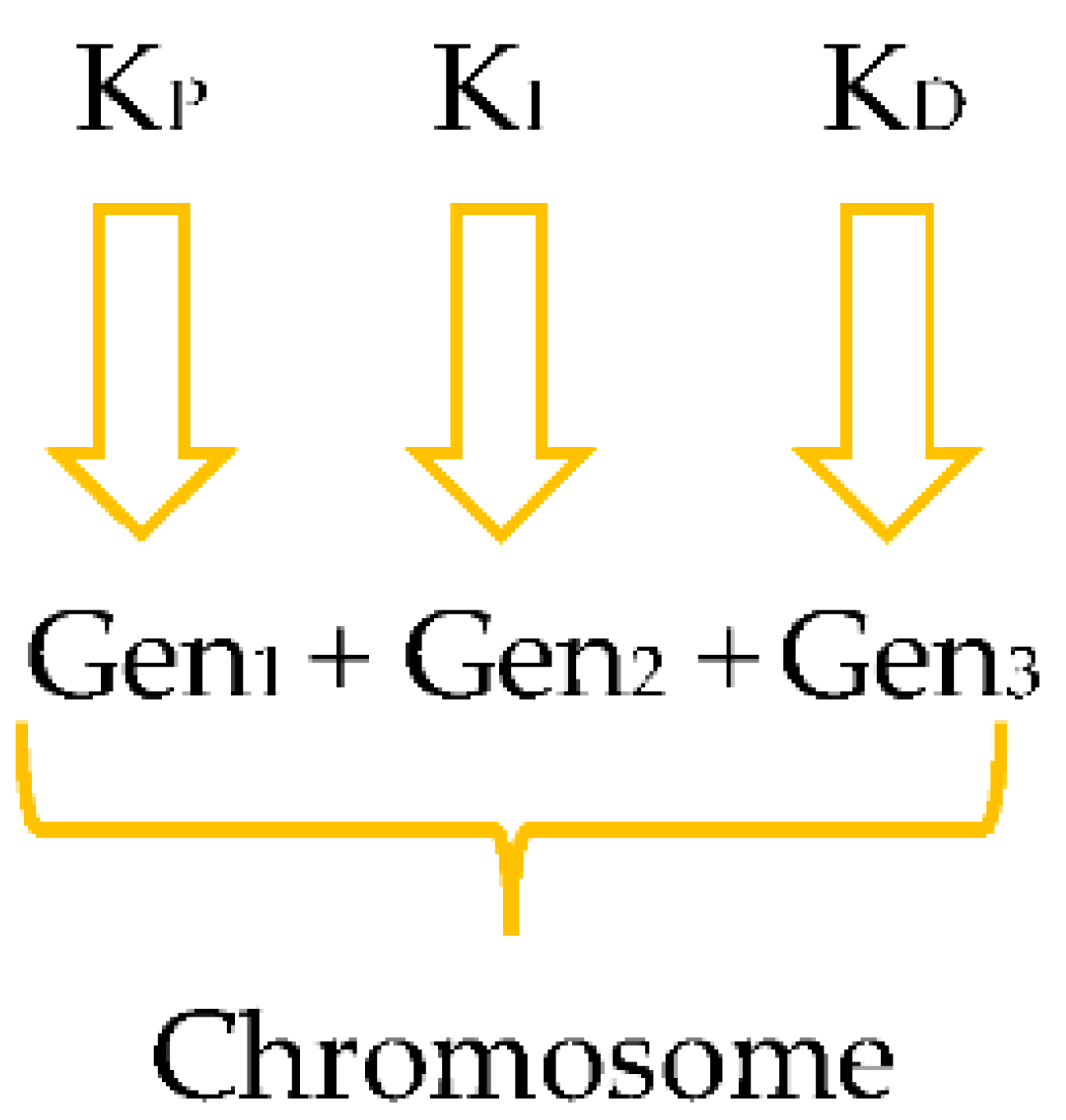

4.1.1. Chromosome Coding

4.1.2. Creating First Population

4.1.3. Learning of the PID Gains by GA

4.1.4. Fitness

4.1.5. Initialization of Populations

4.1.6. Selection Operator

4.1.7. Crossover Operator

4.1.8. Mutation Operator

5. Simulation Procedure and Interpretation

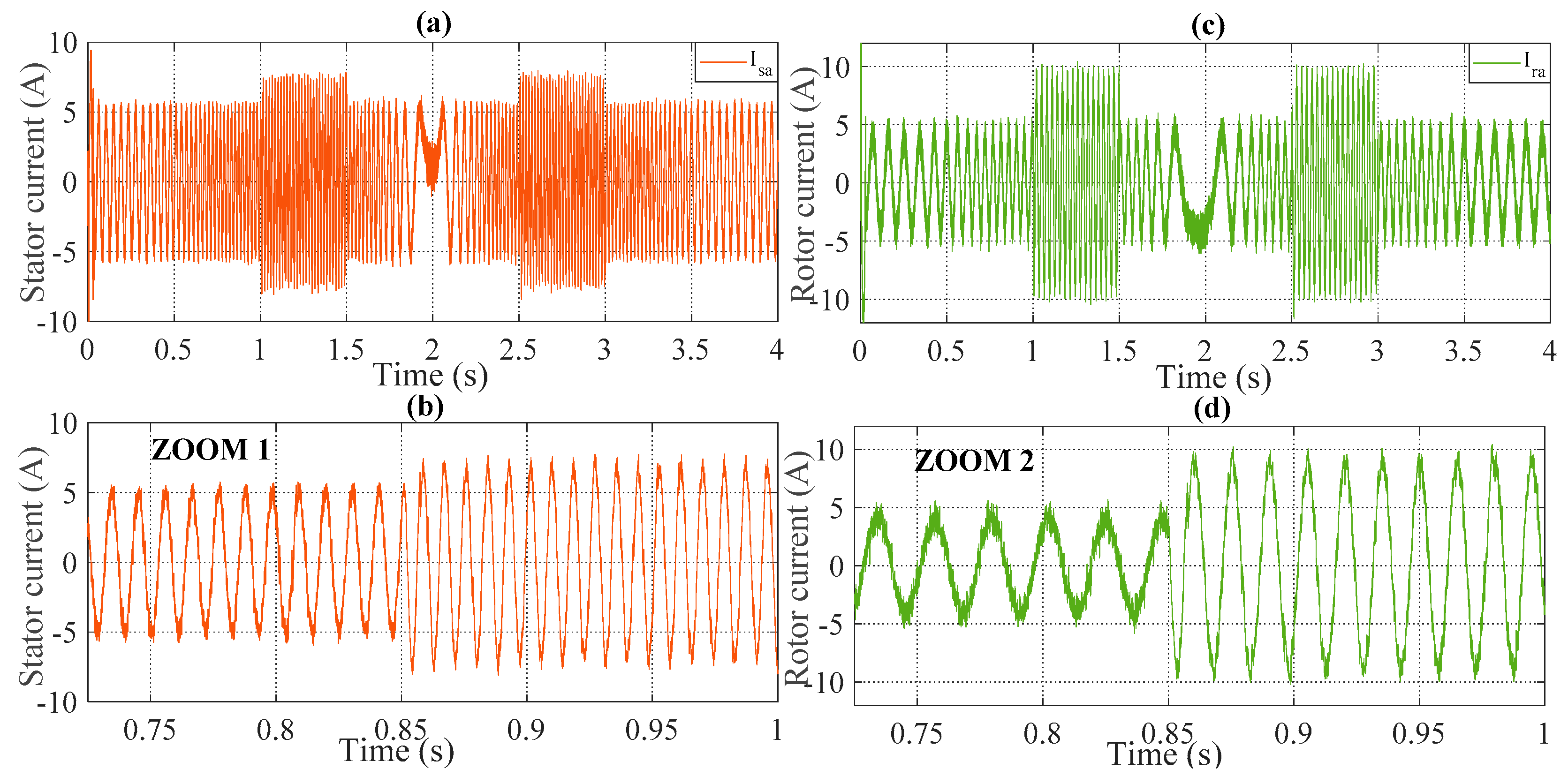

- The sampling frequency: fs = 10 kHz, this frequency presents the standard frequency used by designers of machine controls, so choosing a frequency lower than 10 kHz results in poor fluxes and torque ripples and undesired THD, and choosing a frequency greater than 10 kHz may not be implemented on programmable boards, especially dSPACE DS 1104 for this type of controls.

- The widths of the hysteresis bands: ΔTem = ±0.01 Nm, ΔΨs = ±0.001 Wb and ΔΨr = ±0.001 Wb, with the hysteresis comparators, we try to maintain the fluxes and torque variations at bands, which are close to zero, if the bands are greater than to values chosen, it risks having torque and fluxes ripples, and if these bands are lower than the chosen values, it will give the same results, because the comparators will not exceed their capacity limits.

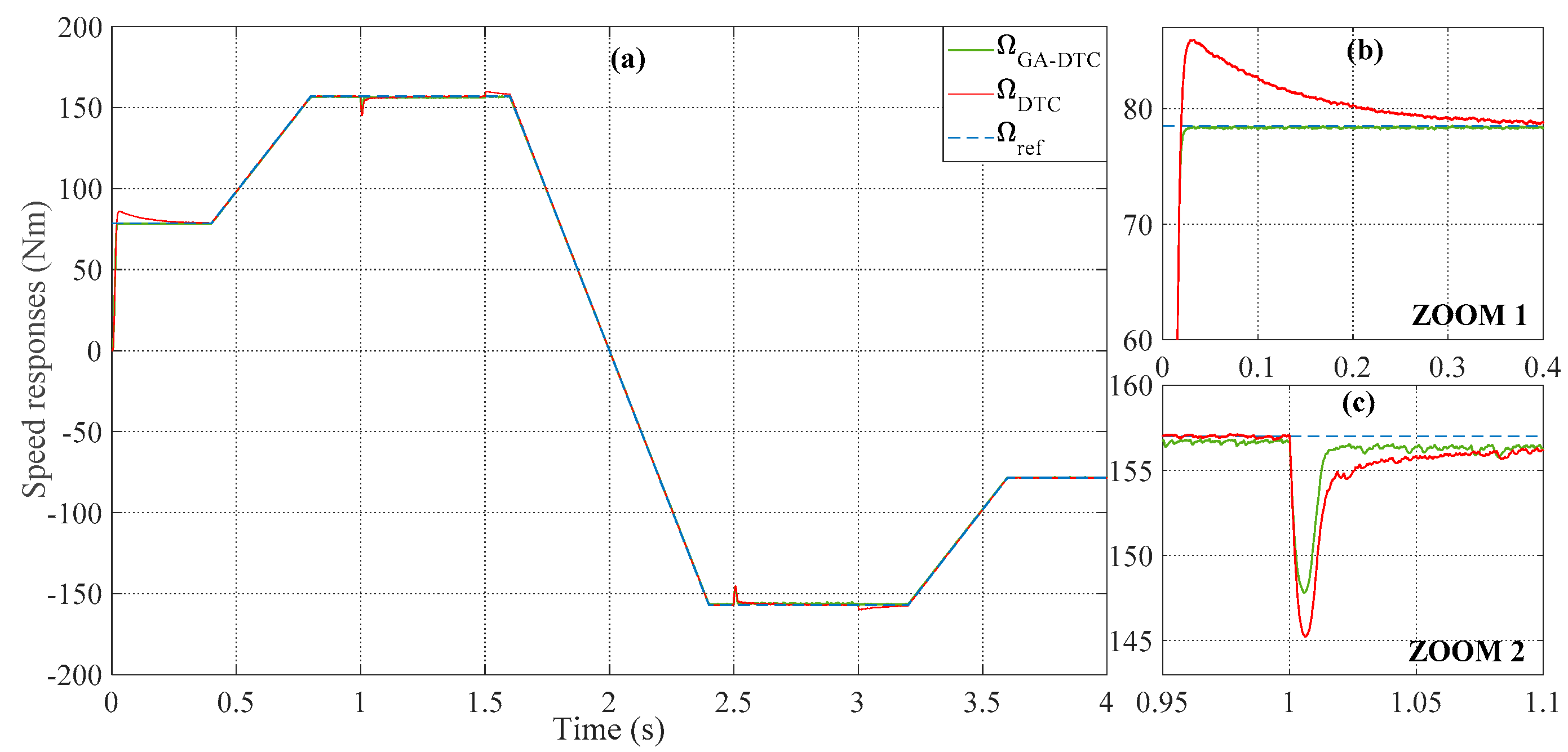

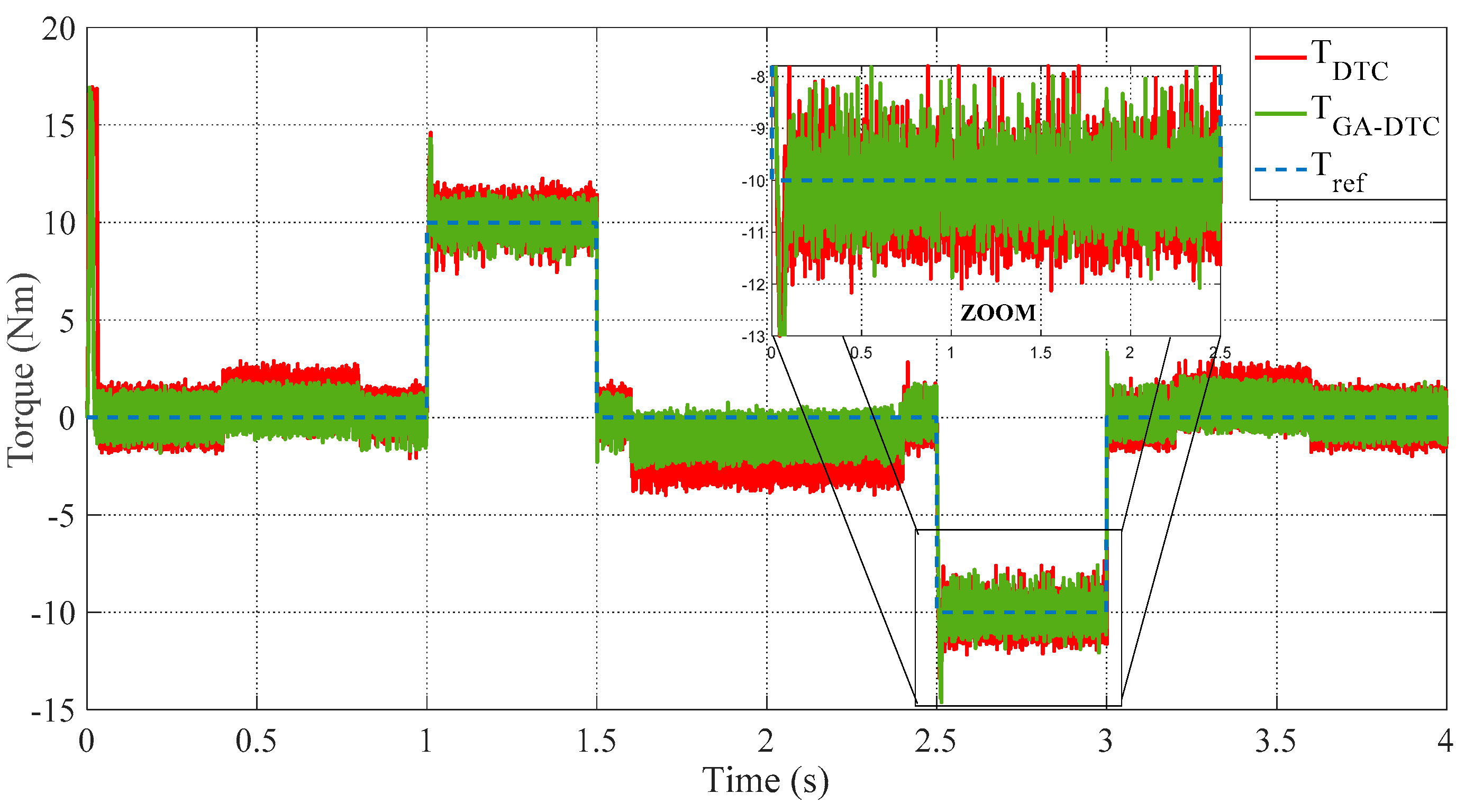

- Application of a nominal load (TL = 10 Nm and TL = −10 Nm) at t = 1 s and at t = 2.5 s, 10 Nm presents the nominal torque of a 1.5 kW machine, and −10 Nm is the torque in the opposite rotation, because in the instant t = 2.5 s, the rotation direction of the machine is reversed.

5.1. Simulation Results

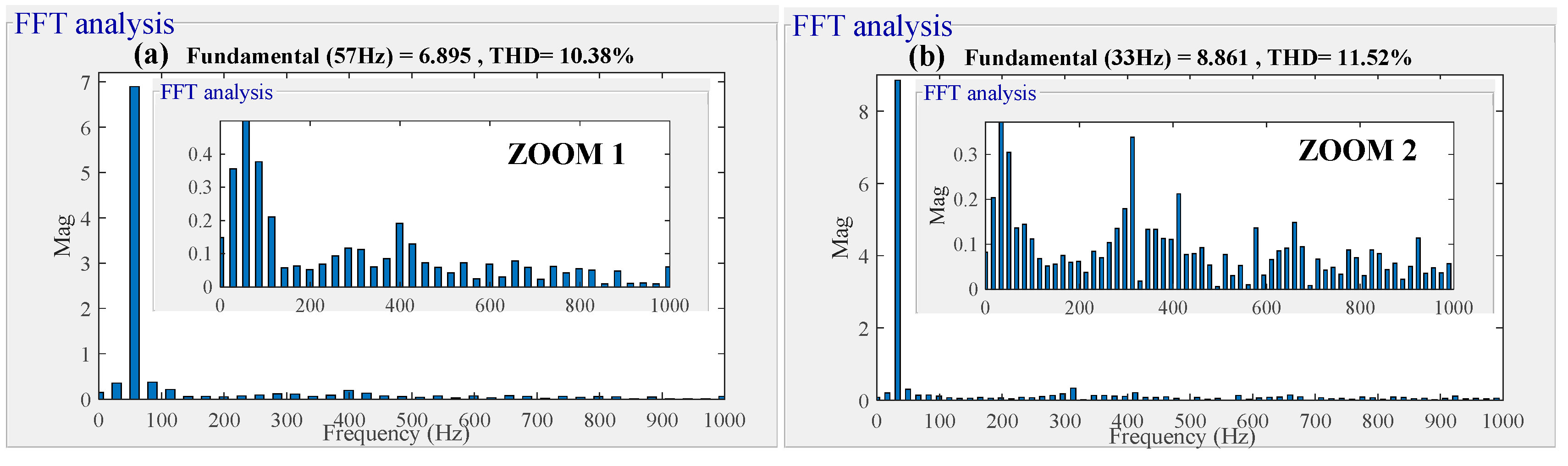

5.2. Interpretation

6. Conclusions

- The response time, rejection time, and overshoot are improved by 82.67%, 72.21%, and 100%, respectively.

- The electromagnetic torque ripples are reduced by 16.16%.

- Minimization of THD in stator and rotor currents by 53.76% and 34.55%, respectively.

- The implementation of this control on an experimental prototype, to test the GA-DTC control.

- Reduction of the effect of the hysteresis comparators by using the ANN controller.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Symbols | Values (Unit) |

|---|---|

| 1.5 Kw | |

| 400 v | |

| 130 v | |

| 2 | |

| 50 Hz | |

| 1.75 Ω | |

| 1.68 Ω | |

| 0.295 H | |

| 0.104 H | |

| 0.165 H | |

| 0.0027 kg.m2/s | |

| 0.01 kg.m2 |

| Description | Type/Value |

|---|---|

| Population size | 20 |

| Maximum iteration | 50 |

| Crossover Probability | 0.9 |

| Mutation Probability | 0.001 |

| Beta | 1 |

| Sigma | 0.1 |

| Gamma | 0.1 |

| Coding | Binary |

| Selection | Uniform |

| Crossover | Roulette Wheel Selection |

| Mutation | Uniform |

| Parameters | Description |

|---|---|

| Vsα, Vsβ,Vrα and Vrβ | Stator and rotor voltages in (α, β) plan |

| Udcs and Udcr | Stator and rotor directs voltages |

| Isα, Isβ, Irα, and Irβ | Stator and rotor currents in (α, β) plan |

| Ψsα, Ψsβ, Ψrα, and Ψrβ | Stator and rotor fluxes in (α, β) plan |

| Rs, Rr | Stator and rotor resistors |

| Ls, Lr | Stator and rotor inductors |

| Lm | Mutual Inductance |

| P | Number of pairs of poles |

| ωr | Rotor angular speed |

| ωs | Stator angular speed |

| Ω | Rotation speed |

| Tem | Electromagnetic torque |

| Tr | Resistant torque |

| f | Viscous friction coefficient |

| J | Moment of inertia |

| Abbreviation | Wording |

|---|---|

| DFIM | Doubly Fed Induction Motor |

| DTC | Direct Torque Control |

| GA | Genetic Algorithm |

| GA-DTC | Genetic Algorithm-Direct Torque Control |

| PID | Proportional Integrator Derivator |

| DTFC | Direct Torque Fuzzy Control |

| DTNC | Direct Torque Neural Control |

| DTNFC | Direct Neural Fuzzy Torque Control |

| ANFIS | Adaptive Neuro-Fuzzy Inference System |

References

- Takahashi, I.; Ohmori, Y. High-performance direct torque control of an induction motor. IEEE Trans. Ind. Appl. 1989, 25, 257–264. [Google Scholar] [CrossRef]

- Takahashi, I.; Noguchi, T. Take a look back upon the past decade of direct torque control [of induction motors]. In Proceedings of the IECON’97 23rd International Conference on Industrial Electronics, Control, and Instrumentation (Cat. No. 97CH36066), New Orleans, LA, USA, 14 November 1997; Volume 2, pp. 546–551. [Google Scholar]

- Baader, U.; Depenbrock, M.; Gierse, G. Direct self control (DSC) of inverter-fed induction machine: A basis for speed control without speed measurement. IEEE Trans. On Ind. Appl. 1992, 28, 581–588. [Google Scholar] [CrossRef]

- Khadar, S.; Kouzou, A. Dual Direct Torque Control of Doubly Fed Induction Machine using Artificial Neural Network. In Proceedings of the 2018 3rd International Conference on Pattern Analysis and Intelligent Systems (PAIS), Tebessa, Algeria, 24–25 October 2018; pp. 1–7. [Google Scholar] [CrossRef]

- El Ouanjli, N.; Derouich, A.; Ghzizal, A.E.L.; Motahhir, S.; El Mourabit, Y.; Taoussi, M. Modern improvement techniques of direct torque control for induction motor drives—A review. Prot. Control Mod. Power Syst. 2019, 7, 11. [Google Scholar] [CrossRef]

- Abbas, A.S.; El-Sehiemy, R.A.; El-Ela, A.; Ali, E.S.; Mahmoud, K.; Lehtonen, M.; Darwish, M.M. Optimal Harmonic Mitigation in Distribution Systems with Inverter Based Distributed Generation. Appl. Sci. 2021, 11, 774. [Google Scholar] [CrossRef]

- Mahfoud, S.; Derouich, A.; El Ouanjli, N.; Mohammed, T.; Hanafi, A. Field Oriented Control of Doubly Fed Induction Motor using Speed Sliding Mode Controller. E3s Web Conf. Edp Sci. 2021, 229, 01061. [Google Scholar] [CrossRef]

- El Ouanjli, N.; Derouich, A.; El Ghzizal, A.; Chebabhi, A.; Taoussi, M.; Bossoufi, B. Direct torque control strategy based on fuzzy logic controller for a doubly fed induction motor. Iop Conf. Ser. Earth Environ. Sci. 2018, 161, 012004. [Google Scholar] [CrossRef]

- Menghal, P.M.; Laxmi, A.J. Real time control of induction motor using neural network. In Proceedings of the 2018 International Conference on Communication information and Computing Technology (ICCICT), Mumbai, India, 2–3 February 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Grabowski, P.Z.; Kazmierkowski, M.P.; Bose, B.K.; Blaabjerg, F. A simple direct-torque neuro-fuzzy control of PWM-inverter-fed induction motor drive. IEEE Trans. Ind. Electron. 2000, 47, 863–870. [Google Scholar] [CrossRef]

- Banda, G.; Kolli, S.G. An Intelligent Adaptive Neural Network Controller for a Direct Torque Controlled eCAR Propulsion System. World Electr. Veh. J. 2021, 12, 44. [Google Scholar] [CrossRef]

- Taoussi, M.; Karim, M.; Bossoufi, B.; Hammoumi, D.; Lagrioui, A.; Derouich, A. Speed variable adaptive backstepping control of the doubly-fed induction machine drive. Int. J. Of Autom. Control 2016, 10, 12–33. [Google Scholar] [CrossRef]

- Pujar, J.; Kodad, S. Robust Sensorless Speed Control of Induction Motor with DTFC and Fuzzy Speed Regulator. Int. J. Electr. Comput. Eng. 2011, 5, 1041–1050. [Google Scholar] [CrossRef]

- Zemmit, A.; Messalti, S.; Harrag, A. A new improved DTC of doubly fed induction machine using GA-based PI controller. Ain Shams Eng. J. 2018, 9, 1877–1885. [Google Scholar] [CrossRef]

- Das, K.R.; Das, D.; Das, J. Optimal tuning of PID controller using GWO algorithm for speed control in DC motor. In Proceedings of the 2015 International Conference on Soft Computing Techniques and Implementations (ICSCTI), Faridabad, India, 8–10 October 2015; pp. 108–112. [Google Scholar] [CrossRef]

- Madadi, A.; Motlagh, M.M. Optimal control of DC motor using grey wolf optimizer algorithm. Tech. J. Eng. Appl. Sci. 2014, 4, 373–379. [Google Scholar]

- Kanojiya, R.G.; Meshram, P.M. Optimal tuning of PI controller for speed control of DC motor drive using particle swarm optimization. In Proceedings of the 2012 International Conference on Advances in Power Conversion and Energy Technologies (APCET), Mylavaram, India, 2–4 August 2012; pp. 1–6. [Google Scholar]

- Ayala HV, H.; dos Santos Coelho, L. Tuning of PID controller based on a multiobjective genetic algorithm applied to a robotic manipulator. Expert Syst. Appl. 2012, 39, 8968–8974. [Google Scholar] [CrossRef]

- Krohling, R.A.; Rey, J.P. Design of optimal disturbance rejection PID controllers using genetic algorithms. IEEE Trans. On Evol. Comput. 2001, 5, 78–82. [Google Scholar] [CrossRef]

- Nagaraj, B.; Murugananth, N. A comparative study of PID controller tuning using GA, EP, PSO and ACO. In Proceedings of the 2010 International Conference on Communication Control and Computing Technologies, Nagercoil, India, 7–9 October 2010; pp. 305–313. [Google Scholar]

- Elsisi, M.; Tran, M.Q.; Mahmoud, K.; Lehtonen, M.; Darwish, M.M. Robust Design of ANFIS-Based Blade Pitch Controller for Wind Energy Conversion Systems Against Wind Speed Fluctuations. IEEE Access 2021, 9, 37894–37904. [Google Scholar] [CrossRef]

- El Ouanjli, N.; Derouich, A.; El Ghzizal, A.; Bouchnaif, J.; El Mourabit, Y.; Taoussi, M.; Bossoufi, B. Real-time implementation in dSPACE of DTC-backstepping for a doubly fed induction motor. Eur. Phys. J. Plus 2019, 134, 566. [Google Scholar] [CrossRef]

- Jayachitra, A.; Vinodha, R. Genetic Algorithm Based PID Controller Tuning Approach for Continuous Stirred Tank Reactor. Adv. In Artif. Intell. 2014, 2014, 791230. [Google Scholar] [CrossRef]

- Yusoff, T.A.F.K.; Atan, M.F.; Rahman, N.A.; Salleh, S.F.; Wahab, N.A. Optimization of pid tuning using genetic algorithm. J. Of Appl. Sci. Process Eng. 2015, 2. [Google Scholar] [CrossRef]

- Meena, D.C.; Devanshu, A. Genetic algorithm tuned PID controller for process control. In Proceedings of the 2017 International Conference on Inventive Systems and Control (ICISC), Coimbatore, India, 19–20 January 2017; pp. 1–6. [Google Scholar]

- Schockenhoff, F.; Zähringer, M.; Brönner, M.; Lienkamp, M. Combining a Genetic Algorithm and a Fuzzy System to Optimize User Centricity in Autonomous Vehicle Concept Development. Systems 2021, 9, 25. [Google Scholar] [CrossRef]

- Krajčovič, M.; Hančinský, V.; Dulina, Ľ.; Grznár, P.; Gašo, M.; Vaculík, J. Parameter setting for a genetic algorithm layout planner as a toll of sustainable manufacturing. Sustainability 2019, 11, 2083. [Google Scholar] [CrossRef]

- Amirjanov, A. The parameters setting of a changing range genetic algorithm. Nat. Comput. 2015, 14, 331–338. [Google Scholar] [CrossRef]

- Angelova, M.; Pencheva, T. Tuning genetic algorithm parameters to improve convergence time. Int. J. Of Chem. Eng. 2011. [Google Scholar] [CrossRef]

- Zhao, J.; Xi, M. Self-Tuning of PID Parameters Based on Adaptive Genetic Algorithm. In IOP Conference Series: Materials Science and Engineering; Modern Control Systems; Dorf, R.C., Bishop, R.H., Eds.; IOP Publishing: London, UK; Pearson: London, UK, 2020; Volume 782, p. 042028. [Google Scholar]

- Chlaihawi, A.A. Genetic algorithm error criteria as applied to PID controller DC-DC buck converter parameters: An investigation. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 671, p. 012032. [Google Scholar] [CrossRef]

- Qin, Y.; Zhao, G.; Hua, Q.; Sun, L.; Nag, S. Multiobjective genetic algorithm-based optimization of PID controller parameters for fuel cell voltage and fuel utilization. Sustainability 2019, 11, 3290. [Google Scholar] [CrossRef]

- Happyanto, D.C.; Wijayanto, A. Implementation of Genetic Algorithm for Parameter Tuning of PID Controller in Three Phase Induction Motor Speed Control. IPTEK J. Eng. 2014, 1. [Google Scholar] [CrossRef]

- Zahir, A.A.M.; Alhady, S.S.N.; Othman, W.A.F.W.; Ahmad, M.F. Genetic algorithm optimization of PID controller for brushed DC motor. In Intelligent Manufacturing Mechatronics; Springer: Singapore, 2018; pp. 427–437. [Google Scholar]

- Bharadwaj, C.S.; Babu, T.S.; Rajasekar, N. Tuning PID Controller for Inverted Pendulum Using Genetic Algorithm. In Advances in Systems, Control and Automation; Springer: Singapore, 2018; pp. 395–404. [Google Scholar]

- Tran, T.C.; Brandstetter, P.; Duy, V.H.; Vo, H.H.; Dong, C. PID speed controller optimization using online genetic algorithm for induction motor drive. In International Conference on Advanced Engineering Theory and Applications; Springer: Cham, Switzerland, 2016; pp. 564–576. [Google Scholar]

- Harrag, A.; Messalti, S. Variable step size modified P&O MPPT algorithm using GA-based hybrid offline/online PID controller. Renew. Sustain. Energy Rev. 2015, 49, 1247–1260. [Google Scholar] [CrossRef]

| Sector Si | |||||||

|---|---|---|---|---|---|---|---|

| HΨs or HΨr | HTem | S1 | S2 | S3 | S4 | S5 | S6 |

| 1 | 1 | v2 | v3 | v4 | v5 | v6 | v1 |

| 0 | v7 | v0 | v7 | v0 | v7 | v0 | |

| −1 | v6 | v1 | v2 | v3 | v4 | v5 | |

| 0 | 1 | v3 | v4 | v5 | v6 | v1 | v2 |

| 0 | v0 | v7 | v0 | v7 | v0 | v7 | |

| −1 | v5 | v6 | v1 | v2 | v3 | v4 | |

| PID Parameters | KP | KI | KD |

|---|---|---|---|

| Maximum Value | 100 | 10 | 1 |

| Minimum Value | 0 | 0 | 0 |

| Characteristics | Weighted GA-DTC | DTC | Improvement (%) | |

|---|---|---|---|---|

| ω | Response Time (ms) | 18.2 | 105 | 82.67 |

| Overshoot (rad/s) | 0 | 7.43 | 100 | |

| Rejection Time (ms) | 0.175 | 0.803 | 72.21 | |

| Undershoot (rad/s) | 9.18 | 11.76 | 21.94 | |

| Tem | Ripples (Nm) | 2.05 | 2.445 | 16.16 |

| Ψs | Ripples (wb) | 0.04304 | 0.06123 | 29.71 |

| Ψr | Ripples (wb) | 0.00893 | 0.0118 | 24.32 |

| isa | THD (%) | 4.8 | 10.38 | 53.76 |

| Ira | THD (%) | 7.54 | 11.52 | 34.55 |

| Controller Parameters | Classic DTC | Weighted GA-DTC |

|---|---|---|

| KP | 18 | 72.8895 |

| KI | 0.8 | 0.0729 |

| KD | 0 | 0.5262 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahfoud, S.; Derouich, A.; EL Ouanjli, N.; EL Mahfoud, M.; Taoussi, M. A New Strategy-Based PID Controller Optimized by Genetic Algorithm for DTC of the Doubly Fed Induction Motor. Systems 2021, 9, 37. https://doi.org/10.3390/systems9020037

Mahfoud S, Derouich A, EL Ouanjli N, EL Mahfoud M, Taoussi M. A New Strategy-Based PID Controller Optimized by Genetic Algorithm for DTC of the Doubly Fed Induction Motor. Systems. 2021; 9(2):37. https://doi.org/10.3390/systems9020037

Chicago/Turabian StyleMahfoud, Said, Aziz Derouich, Najib EL Ouanjli, Mohammed EL Mahfoud, and Mohammed Taoussi. 2021. "A New Strategy-Based PID Controller Optimized by Genetic Algorithm for DTC of the Doubly Fed Induction Motor" Systems 9, no. 2: 37. https://doi.org/10.3390/systems9020037

APA StyleMahfoud, S., Derouich, A., EL Ouanjli, N., EL Mahfoud, M., & Taoussi, M. (2021). A New Strategy-Based PID Controller Optimized by Genetic Algorithm for DTC of the Doubly Fed Induction Motor. Systems, 9(2), 37. https://doi.org/10.3390/systems9020037