Efficiency in High-Rise Building Design: A Lean Approach to Waste Identification and Reduction

Abstract

1. Introduction

2. Literature Review

2.1. Definitions of Fundamental Concepts

2.2. Design Process in High-Rise Buildings and Lean Principles

2.3. Waste in Building Design

2.4. Impact of Lean on Building Design Efficiency

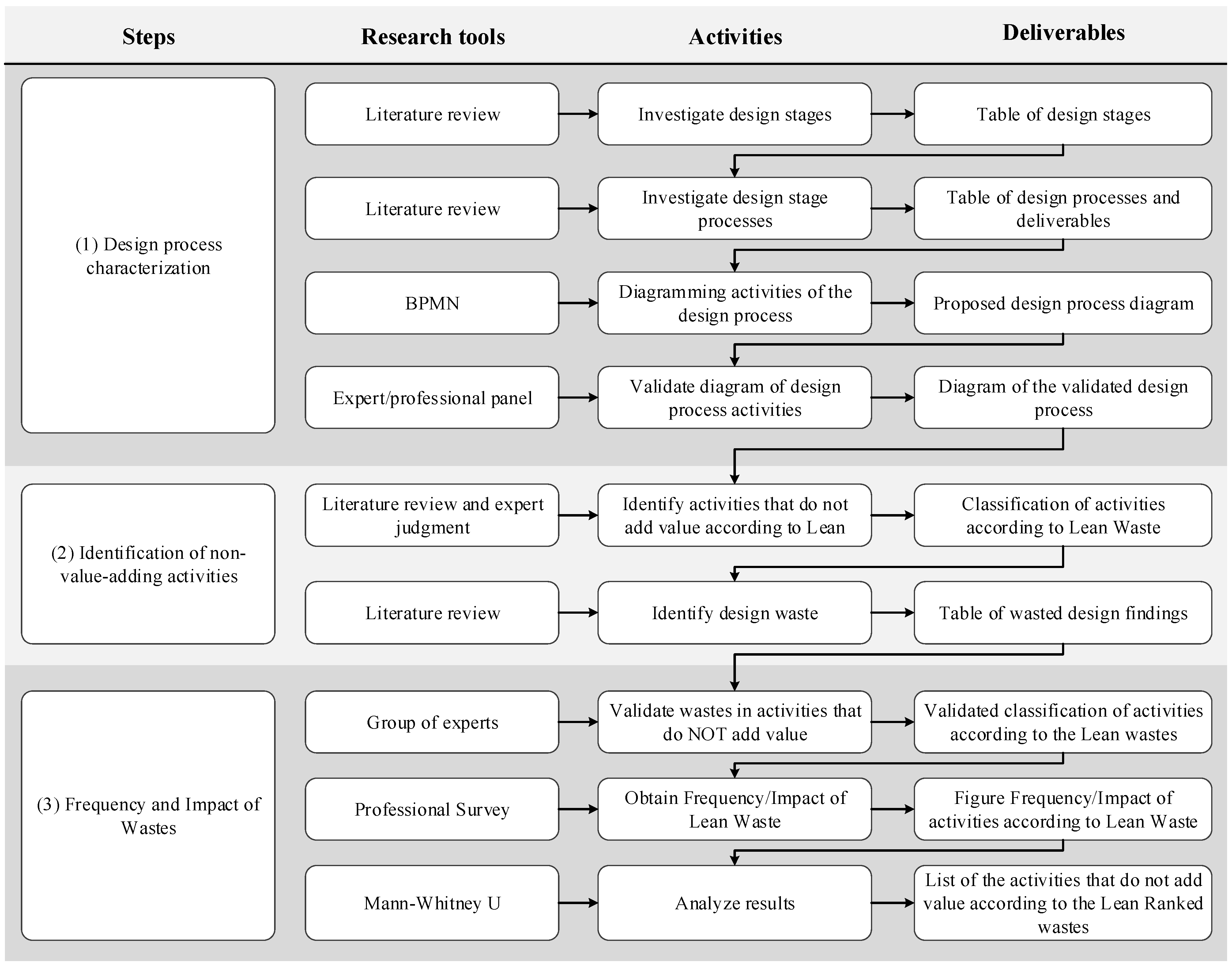

3. Research Method

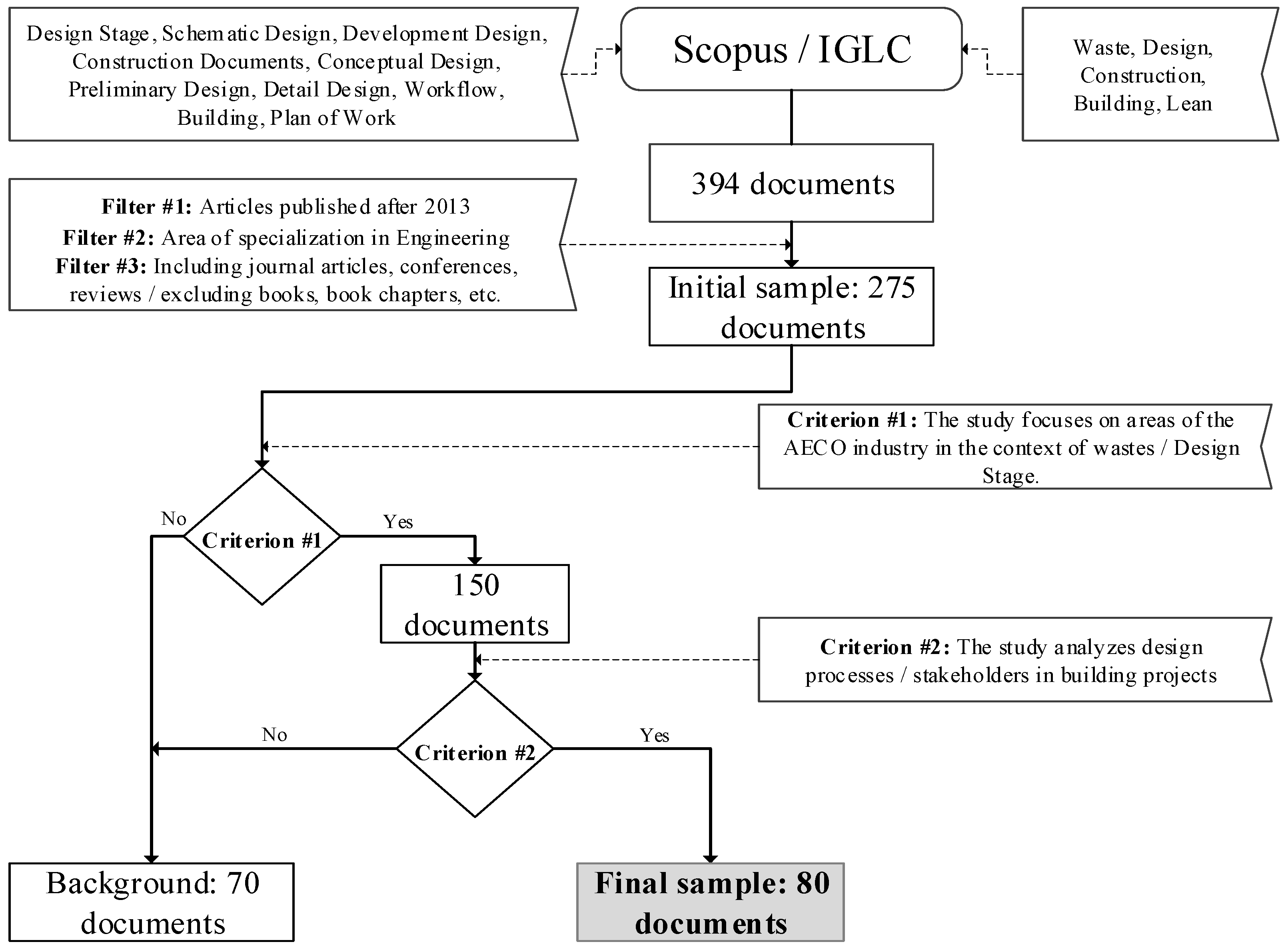

3.1. Stage 1: Design Process Characterization

3.2. Stage 2: Identification of Non-Value-Adding Activities

3.3. Stage 3: Evaluation of the Frequency and Impact of Waste

4. Results and Discussion

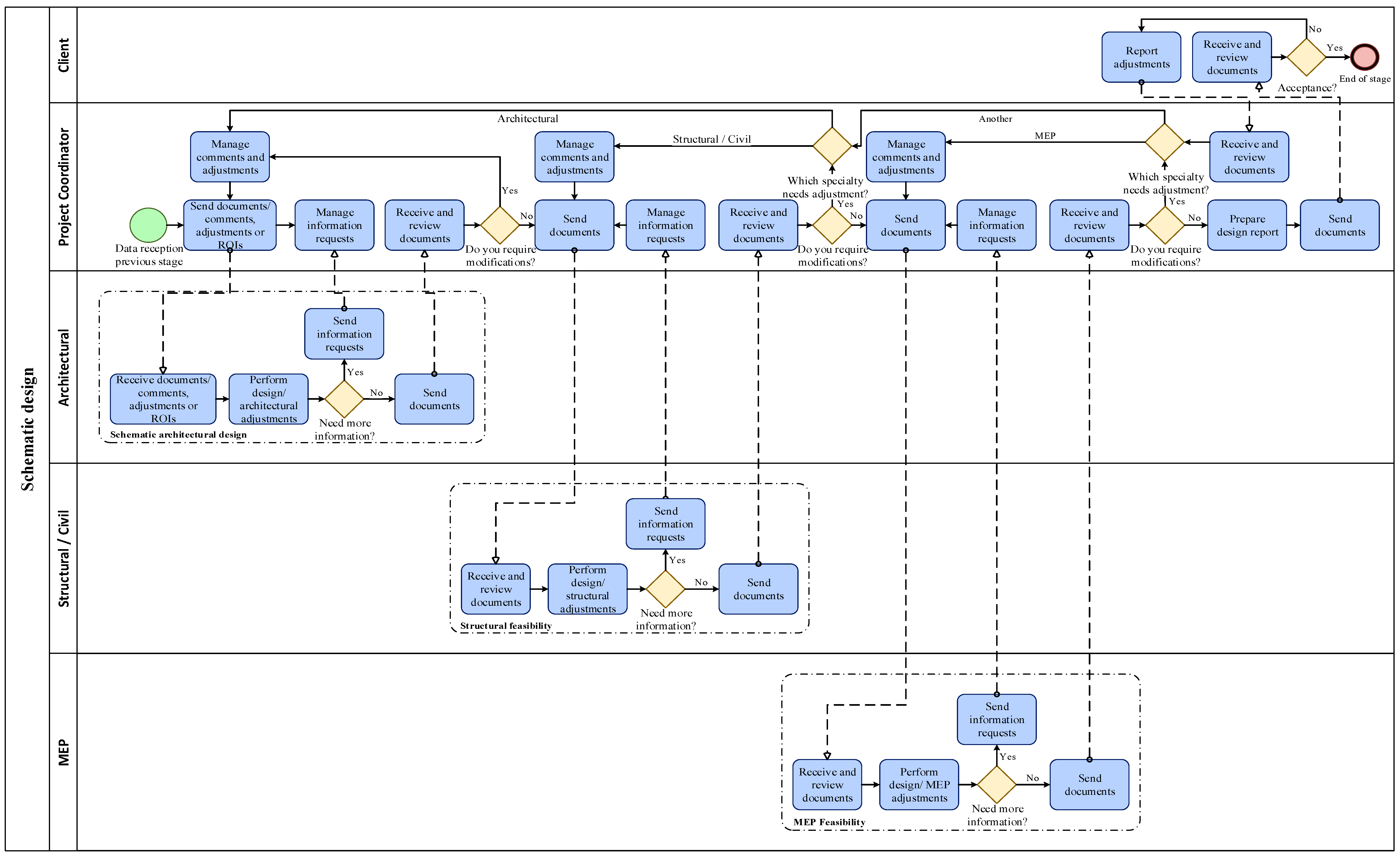

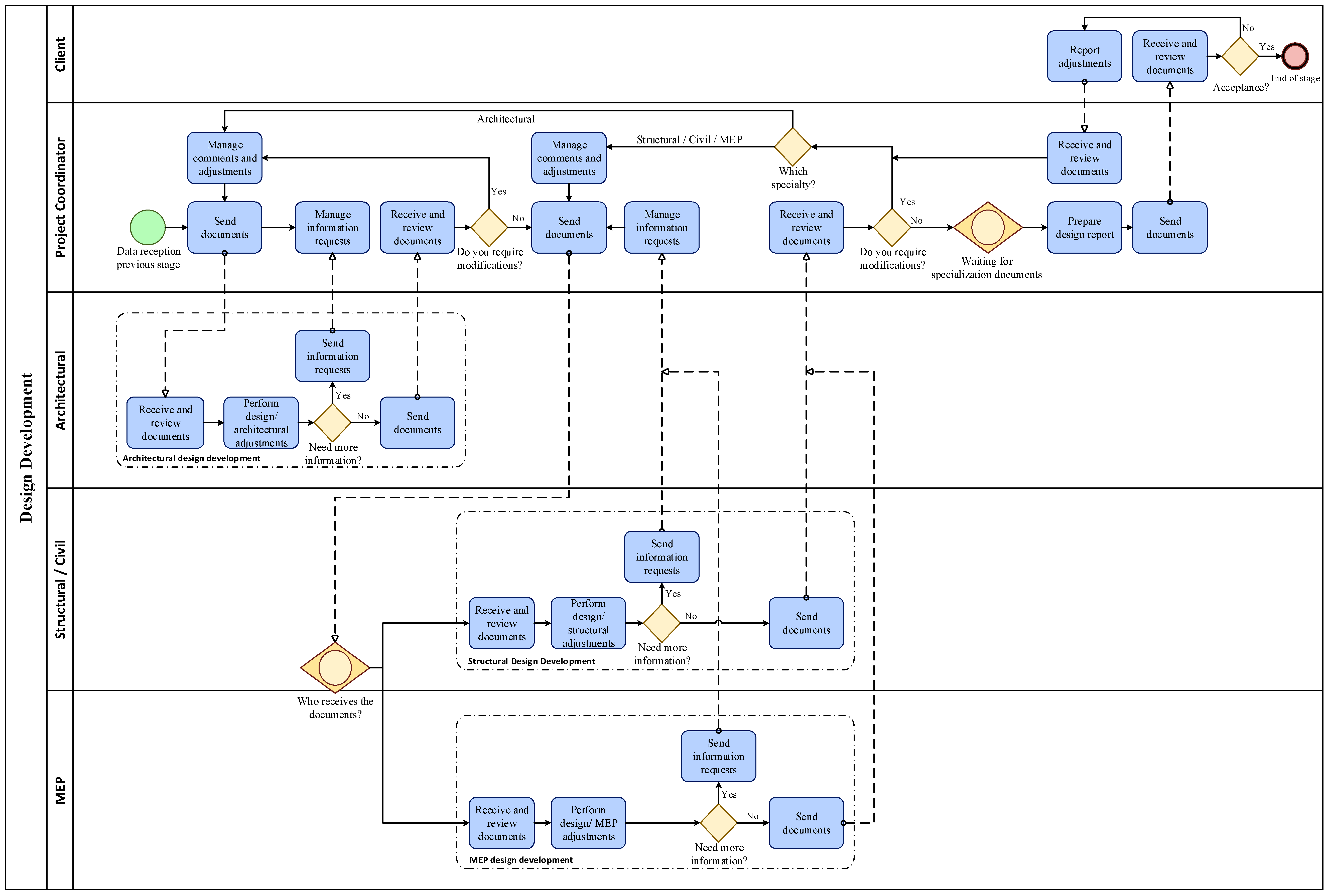

4.1. Design Process Characterization

4.1.1. Schematic Design (SD)

4.1.2. Design Development (DD)

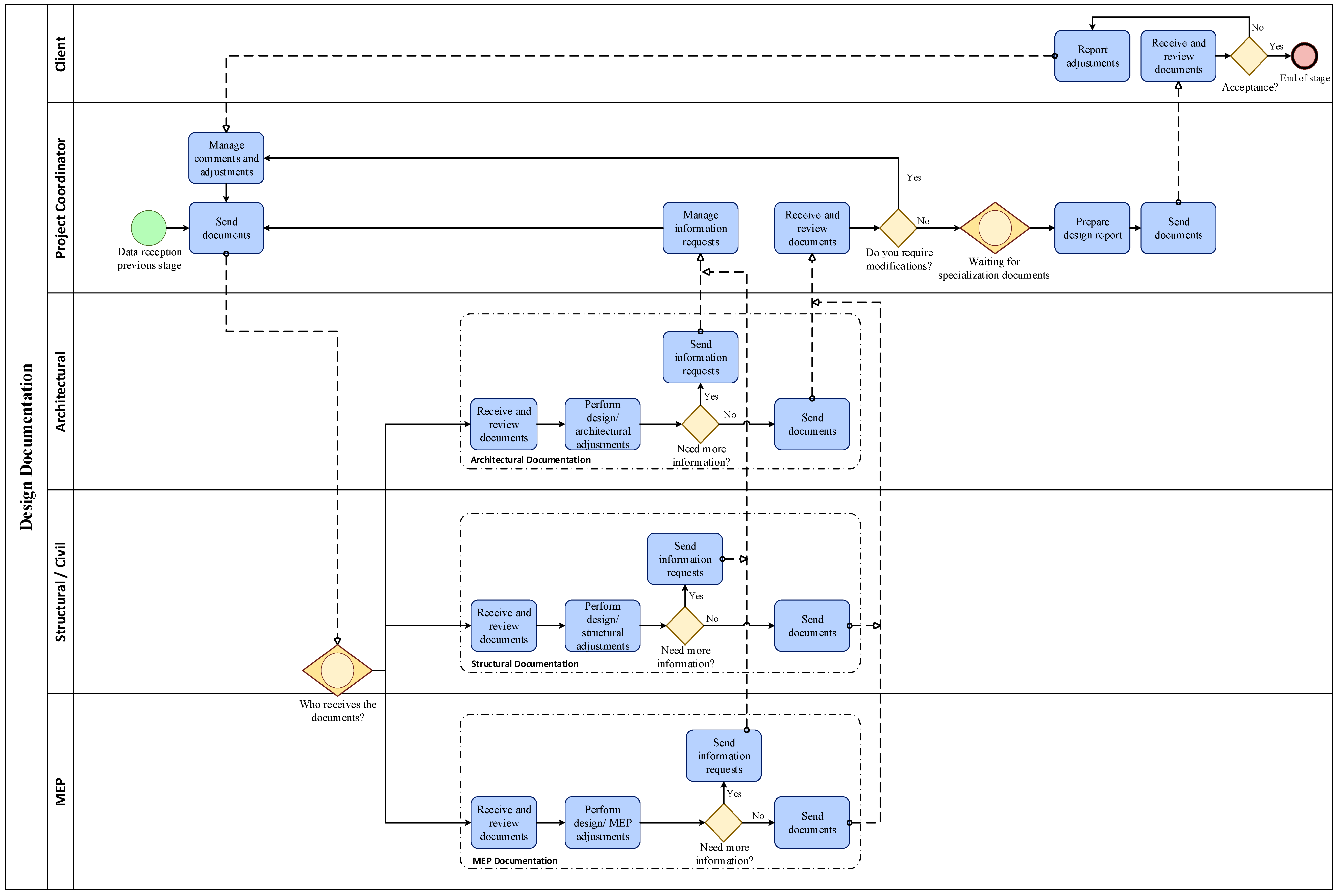

4.1.3. Construction Documentation

4.2. Identification of Non-Value-Adding Activities

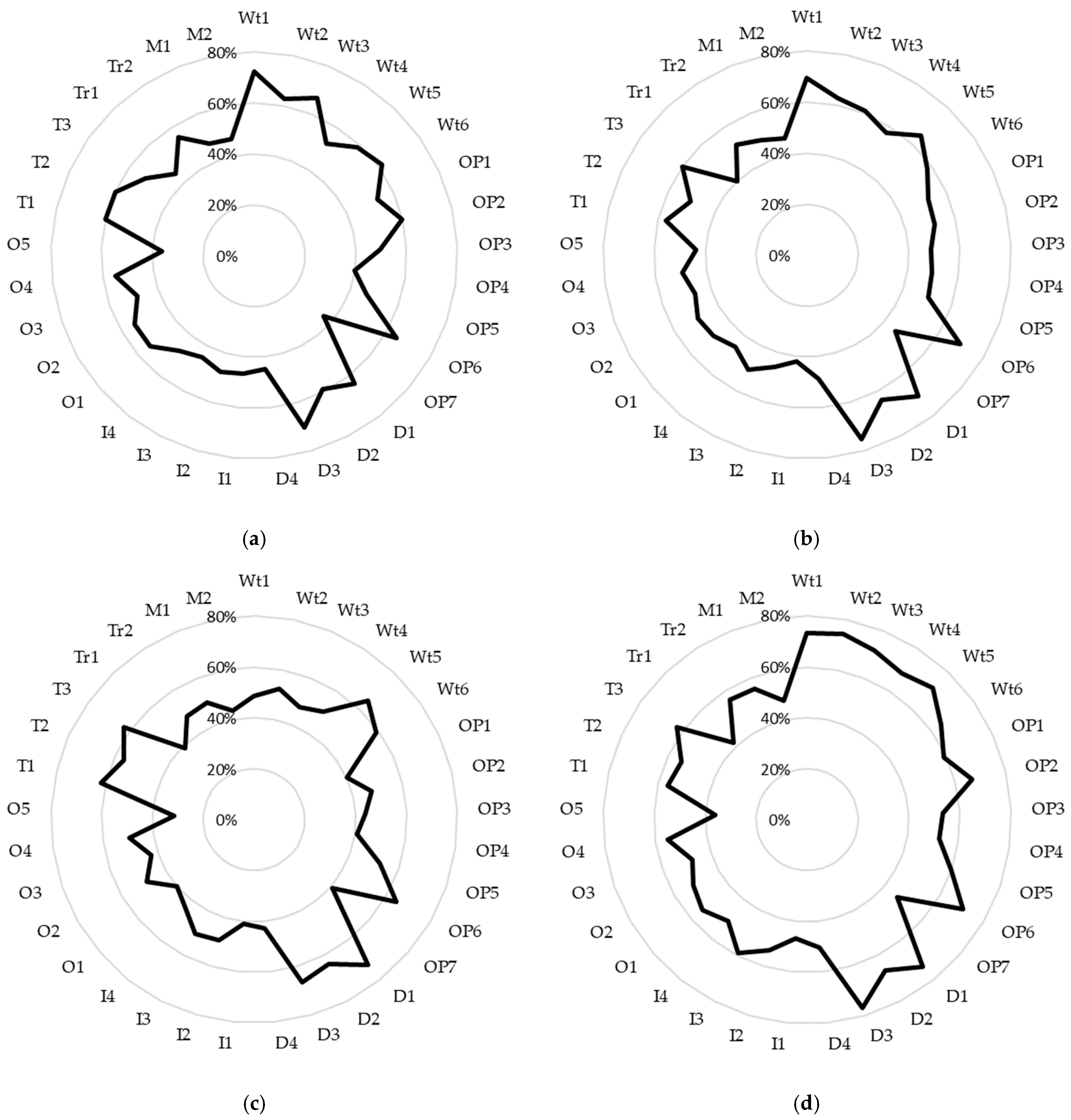

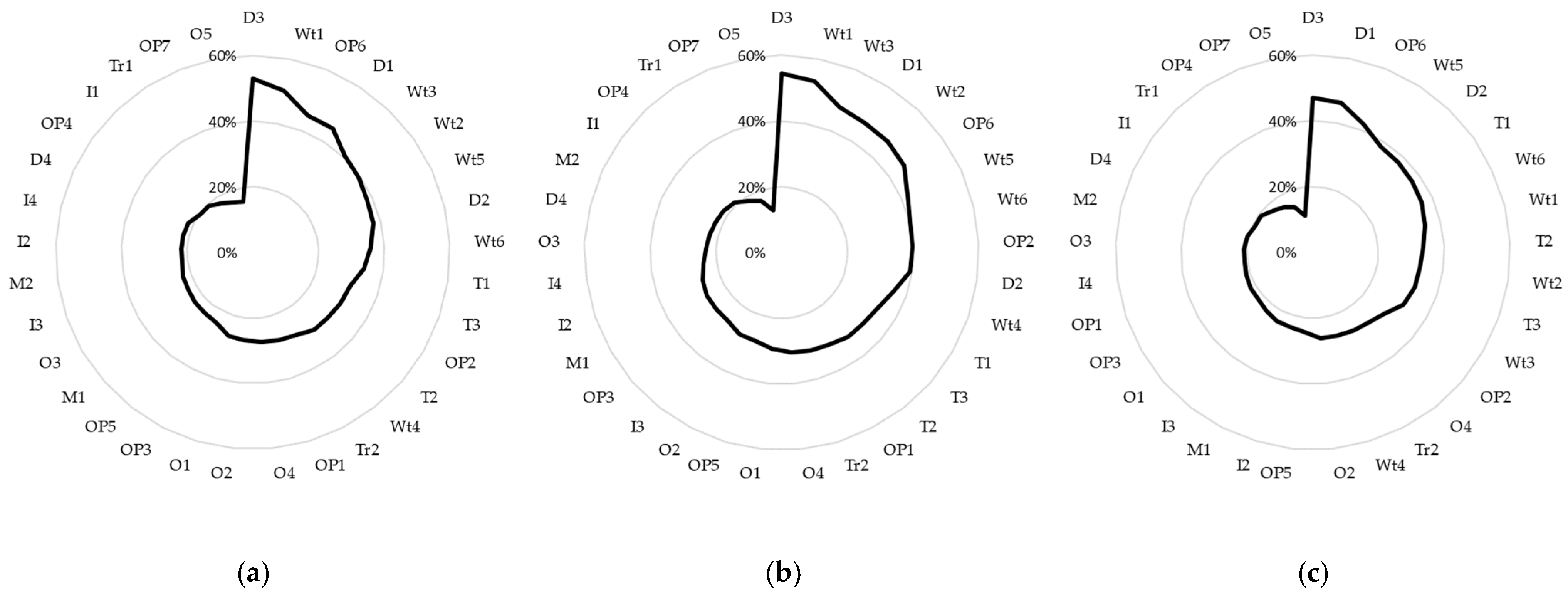

4.3. Frequency and Impact of Wastes

Ranking of Wastes According to the Frequency Adjusted to Importance Index (FAII)

- “Changes in designs in late stages (D3)”. This waste obtained the highest FAII values for cost, schedule, and quality, with values of 53%, 54%, and 46%, respectively, making it the most relevant waste in the study.

- “Waiting for resources and information (Wt1)”. This waste ranks 2nd in the cost and schedule categories and 8th in the quality category, with values of 50%, 53%, and 35%, respectively.

- “Clarification of needs in late design stages (OP6)”. This waste ranks 3rd in the cost and quality categories and 6th in the schedule category, with values of 45%, 41%, and 45%, respectively.

- “Errors/omissions in work (D1)”. This waste ranks 2nd in the quality category and 4th in the cost and schedule categories, with values of 46%, 44%, and 46%, respectively.

- “Delays in information delivery (Wt3)”. This waste ranks 3rd in the schedule category and 5th in the cost category, with values of 47% and 40%, respectively.

- “Delays in starting tasks (Wt2)”. This waste ranks 5th in the cost and schedule categories, with scores of 39% and 46%, respectively.

- “Rework (D2)” ranks 5th in the quality category with a score of 38%.

4.4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sarhan, J.G.; Xia, B.; Fawzia, S.; Karim, A. Lean Construction Implementation in the Saudi Arabian Construction Industry. Constr. Econ. Build. 2017, 17, 46–69. [Google Scholar] [CrossRef]

- Hakansson, H.; Ingemansson, M. Industrial Renewal within the Construction Network. Constr. Manag. Econ. 2013, 31, 40–61. [Google Scholar] [CrossRef]

- Yeganeh, A.A.; Azizi, M.; Falsafi, R. Root Causes of Design-Construction Interface Problems in Iranian Design-Build Projects. J. Constr. Eng. Manag. 2019, 145, 05019014. [Google Scholar] [CrossRef]

- AIA California Council. Integrated Project Delivery: A Guide. Am. Inst. Archit. 2007, 1, 1–62. [Google Scholar]

- Gambatese, J.A.; Pestana, C.; Lee, H.W. Alignment between Lean Principles and Practices and Worker Safety Behavior. J. Constr. Eng. Manag. 2017, 143, 04016083. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R. Green Lean Six Sigma for Sustainable Development: Integration and Framework. Environ. Impact Assess. Rev. 2020, 83, 106396. [Google Scholar] [CrossRef]

- Planbim (CORFO). Estándar BIM Para Proyectos Públicos; CORFO: Santiago, Chile, 2021. [Google Scholar]

- Muñoz-La Rivera, F.; Vielma, J.C.; Herrera, R.F.; Gallardo, E. Waste Identification in the Operation of Structural Engineering Companies (SEC) According to Lean Management. Sustainability 2021, 13, 4249. [Google Scholar] [CrossRef]

- Mazlum, S.K.; Pekeriçli, M.K. Lean Design Management—An Evaluation of Waste Items for Architectural Design Process (1). Metu J. Fac. Archit. 2016, 33, 1–20. [Google Scholar] [CrossRef]

- Freire, J.; Alarcón, L.F. Achieving Lean Design Process: Improvement Methodology. J. Constr. Eng. Manag. 2002, 128, 248–256. [Google Scholar] [CrossRef]

- Olanrewaju, S.D.; Ogunmakinde, O.E. Waste Minimisation Strategies at the Design Phase: Architects’ Response. Waste Manag. 2020, 118, 323–330. [Google Scholar] [CrossRef]

- Nölle, T. CLiAR A Digital Tool for the Conscious Use of Resources. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 032012. [Google Scholar] [CrossRef]

- Quiñones, R.; Llatas, C.; Montes, M.V.; Cortés, I. Quantification of Construction Waste in Early Design Stages Using Bim-Based Tool. Recycling 2022, 7, 63. [Google Scholar] [CrossRef]

- Baldwin, A.; Poon, C.-S.; Shen, L.-Y.; Austin, S.; Wong, I. Designing out Waste in High-Rise Residential Buildings: Analysis of Precasting Methods and Traditional Construction. Renew. Energy 2009, 34, 2067–2073. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O. Critical Design Factors for Minimising Waste in Construction Projects: A Structural Equation Modelling Approach. Resour. Conserv. Recycl. 2018, 137, 302–313. [Google Scholar] [CrossRef]

- Franco, J.V.; Picchi, F.A. Lean Design in Building Projects: Guiding Principles and Exploratory Collection of Good Practices. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 18–24 July 2016; pp. 113–123. [Google Scholar]

- Majerus, N. Leveraging Lean Principles in R&D: The experience of The Goodyear Tire & Rubber Company shows how applying to Lean principles to R&D can improve the efficiency and effectiveness of new product development. Res.-Technol. Manag. 2017, 60, 17–25. [Google Scholar] [CrossRef]

- Lee, H.W.; Tommelein, I.D.; Ballard, G. Product Development and Design Management. In Proceedings of the 18th Annual Conference of the International Group for Lean Construction, Haifa, Israel, 14 July 2010; pp. 113–122. [Google Scholar]

- Aslam, M.; Gao, Z.; Smith, G. Optimizing Construction Design Process Using The Lean Based Approach. Lean Constr. J. 2020, 176–204. Available online: https://leanconstruction.org/lean-construction-journal/doi-info-2020-176-204/ (accessed on 25 August 2025).

- Mossad, G.N.; Othman, A.A.E.; Harinarain, N. Lean Thinking as an Approach for Improving Client Communication During the Design Process. In Construction in 5D: Deconstruction, Digitalization, Disruption, Disaster, Development; Springer International Publishing: Cham, Switzerland, 2023; pp. 309–325. [Google Scholar]

- Hashemi, M.H.; Haj, N.; Mamaghani, M.H.; Daei, M. Design and Utilization Wastes in Construction. ARPN J. Eng. Appl. Sci. 2014, 9, 2212–2219. [Google Scholar]

- Waheed, W.; Khodeir, L.; Fathy, F. Integrating Lean and Sustainability for Waste Reduction in Construction from the Early Design Phase. HBRC J. 2024, 20, 337–364. [Google Scholar] [CrossRef]

- Elsawaf, L.A.; Othman, A.A.E. Design out Waste as an Approach for Achieving Sustainability in Egyptian Housing Projects. IOP Conf. Ser. Mater. Sci. Eng. 2020, 974, 012022. [Google Scholar] [CrossRef]

- Othman, A.A.E.; Abdelrahim, S.M. Achieving Sustainability through Reducing Construction Waste during the Design Process. J. Eng. Des. Technol. 2019, 18, 362–377. [Google Scholar] [CrossRef]

- Moreton, A.; Coffey, V.; Sadiqi, Z. Training for Reduction of Design Waste. Proc. Inst. Civ. Eng.–Waste Resour. Manag. 2016, 169, 123–130. [Google Scholar] [CrossRef]

- Kelly, M.; Dowd, D. A Review of Construction Waste Management Practices on Selected Case Studies in Ireland. Proc. Inst. Civ. Eng.–Waste Resour. Manag. 2017, 170, 78–84. [Google Scholar] [CrossRef]

- Vallero, D.A. Green Engineering and Sustainable Design Aspects of Waste Management. In Waste; Elsevier: Amsterdam, The Netherlands, 2011; pp. 11–21. [Google Scholar]

- Thyberg, K.; Tonjes, D. A Management Framework for Municipal Solid Waste Systems and Its Application to Food Waste Prevention. Systems 2015, 3, 133–151. [Google Scholar] [CrossRef]

- Royal Institute of British Architects. RIBA Plan of Work 2020 Overview; Royal Institute of British Architects: London, UK, 2020. [Google Scholar]

- Norton, J.N.; Brouwer, A.B. The Planning, Design and Construction Process. In Planning and Designing Research Animal Facilities; Elsevier: Amsterdam, The Netherlands, 2009; pp. 17–44. [Google Scholar]

- Lam, P.T.I.; Wong, F.W.H. Improving Building Project Performance: How Buildability Benchmarking Can Help. Constr. Manag. Econ. 2009, 27, 41–52. [Google Scholar] [CrossRef]

- Park, Y.-J.; Yi, C.-Y. Resource-Based Quality Performance Estimation Method for Construction Operations. Appl. Sci. 2021, 11, 4122. [Google Scholar] [CrossRef]

- Rachmawati, F.; Mudjahidin, M.; Dewi Widowati, E. Work Rate Modeling of Building Construction Projects Using System Dynamic to Optimize Project Cost and Time Performance. Int. J. Constr. Manag. 2024, 24, 213–225. [Google Scholar] [CrossRef]

- Ling, F.Y.Y. Key Determinants of Performance of Design-Bid-Build Projects in Singapore. Build. Res. Inf. 2004, 32, 128–139. [Google Scholar] [CrossRef]

- Cha, H.S.; Kim, C.K. Quantitative Approach for Project Performance Measurement on Building Construction in South Korea. KSCE J. Civ. Eng. 2011, 15, 1319–1328. [Google Scholar] [CrossRef]

- Senge, P. The Fifth Discipline: The Art and Practice of Learning Organization; Bantam Doubleday Dell Publishing Group, Inc.: New York, NY, USA, 1990; ISBN 9780385260947. [Google Scholar]

- Galaz-Delgado, E.I.; Herrera, R.F.; Atencio, E.; Rivera, F.M.-L.; Biotto, C.N. Problems and Challenges in the Interactions of Design Teams of Construction Projects: A Bibliometric Study. Buildings 2021, 11, 461. [Google Scholar] [CrossRef]

- Koskela, L. An Exploration Toward a Production Theory and Its Application to Construction; VTT Technical Research Centre of Finland: Espoo, Finland, 2000. [Google Scholar]

- Waheed, W.; Khodeir, L.; Fathy, F. Investigation of Sustainability and Lean Approaches for Efficient Architecture Design Management. Results Eng. 2025, 27, 105847. [Google Scholar] [CrossRef]

- Ballard, G. The Last Planner System of Production Control. Ph.D. Thesis, The University of Birmingham, Birmingham, UK, 2000. [Google Scholar]

- Khanapure, V.U.; Shastri, S.S. A Sustainable–Lean Implementation Methodology: A Catalyst for Sustainability Enhancement of High-Rise Residential Projects. Eng. Constr. Archit. Manag. 2024, 31, 2585–2603. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation; Free Press: New York, NY, USA, 2010; ISBN 0-7432-4927-5. [Google Scholar]

- Garcés, G.; Forcael, E.; Osorio, C.; Castañeda, K.; Sánchez, O. Systematic Review of Lean Construction: An Approach to Sustainability and Efficiency in Construction Management. J. Infrastruct. Preserv. Resil. 2025, 6, 1–28. [Google Scholar] [CrossRef]

- Hines, P.; Taylor, D. Going Lean; Lean Enterprise Research Centre: Cardiff, UK, 2000; ISBN 0-9537982-0-8. [Google Scholar]

- Rahmanasari, D.; Sutopo, W.; Rohani, J.M. Implementation of Lean Manufacturing Process to Reduce Waste: A Case Study. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1096, 012006. [Google Scholar] [CrossRef]

- Liker, J.K. The 14 Principles of the Toyota Way: An Executive Summary of the Culture behind TPS. In The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill: New York, NY, USA, 2004; pp. 35–41. ISBN 0071392319. [Google Scholar]

- Mahinkanda, M.M.M.P.; Ochoa Paniagua, J.J.; Rameezdeen, R.; Chileshe, N.; Gu, N. Design Decision-Making for Construction Waste Minimisation: A Systematic Literature Review. Buildings 2023, 13, 2763. [Google Scholar] [CrossRef]

- Aziz, R.M.; Nasreldin, T.I.; Hashem, O.M. The Role of BIM as a Lean Tool in Design Phase. J. Eng. Appl. Sci. 2024, 71, 23. [Google Scholar] [CrossRef]

- Aslam, M.; Gao, Z.; Smith, G. Integrated Implementation of Virtual Design and Construction (VDC) and Lean Project Delivery System (LPDS). J. Build. Eng. 2021, 39, 102252. [Google Scholar] [CrossRef]

- Marzouk, M.; Elmaraghy, A. Design for Deconstruction Using Integrated Lean Principles and BIM Approach. Sustainability 2021, 13, 7856. [Google Scholar] [CrossRef]

- Dumas, M.; La Rosa, M.; Mendling, J.; Reijers, H.A. Fundamentals of Business Process Management; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-642-33142-8. [Google Scholar]

- Formoso, C.T.; Isatto, E.L.; Hirota, E.H. Method for Waste Control in the Building Industry. In Proceedings of the 7th Annual Conference of the International Group for Lean Construction (IGLC), Berkeley, CA, USA, 26–28 July 1999; pp. 330–353. [Google Scholar]

- Akadiri, P.O.; Olomolaiye, P.O.; Chinyio, E.A. Multi-Criteria Evaluation Model for the Selection of Sustainable Materials for Building Projects. Autom. Constr. 2013, 30, 113–125. [Google Scholar] [CrossRef]

- da Silva Etges, B.M.B. Value-Adding Activities Level in Brazilian Infrastructure Construction Companies—9 Cases Study. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction (IGLC), Chennai, India, 18–22 July 2018; pp. 1323–1333. [Google Scholar]

- Zhao, Y.; Chua, D.K.H. Relationship Between Productivity and Non Value-Adding Activities. In Proceedings of the 11th Annual Conference of the International Group for Lean Construction (IGLC), Blacksburg, VA, USA, 22–24 July 2003. [Google Scholar]

- Hallowell, M.R.; Gambatese, J.A. Qualitative Research: Application of the Delphi Method to CEM Research. J. Constr. Eng. Manag. 2010, 136, 99–107. [Google Scholar] [CrossRef]

- Forcael, E.; Morales, H.; Agdas, D.; Rodríguez, C.; León, C. Risk Identification in the Chilean Tunneling Industry. Eng. Manag. J. 2018, 30, 203–215. [Google Scholar] [CrossRef]

- Tavakol, M.; Dennick, R. Making Sense of Cronbach’s Alpha. Int. J. Med. Educ. 2011, 2, 53–55. [Google Scholar] [CrossRef]

- Sánchez, O.; Castañeda, K.; Mejía, G.; Pellicer, E. Delay Factors: A Comparative Analysis between Road Infrastructure and Building Projects. In Proceedings of the Construction Research Congress 2020, Tempe, AZ, USA, 8–10 March 2020; American Society of Civil Engineers, Ed.; American Society of Civil Engineers: Reston, VA, USA, 2020; pp. 223–231. [Google Scholar]

- Gunduz, M.; Abu-Hijleh, A. Assessment of Human Productivity Drivers for Construction Labor through Importance Rating and Risk Mapping. Sustainability 2020, 12, 8614. [Google Scholar] [CrossRef]

- Abdelalim, A.M.; Salem, M.; Al- Sabah, R.; Said, S.O.; ElShafei, H.M.; Galal Badawy, M. Optimizing Claim Management Process Groups to Enhance Construction Project Success. Int. J. Constr. Manag. 2025, 1–13. Available online: https://www.tandfonline.com/doi/full/10.1080/15623599.2025.2453931 (accessed on 25 August 2025). [CrossRef]

- Giri, B.C.; Molla, M.U.; Biswas, P. TOPSIS Method for Neutrosophic Hesitant Fuzzy Multi-Attribute Decision Making. Informatica 2020, 31, 35–63. [Google Scholar] [CrossRef]

- Sun, C.; Li, S.; Deng, Y. Determining Weights in Multi-Criteria Decision Making Based on Negation of Probability Distribution under Uncertain Environment. Mathematics 2020, 8, 191. [Google Scholar] [CrossRef]

- Bahrami, S.; Yaakob, R.; Azman, A.; Atan, R. An Integrated of Fuzzy Rule Base System and TOPSIS Technique for Multi-Attribute Decision Making. In Proceedings of the 3rd International Conference on Software Engineering and Information Management, New York, NY, USA, 12 January 2020; pp. 58–62. [Google Scholar]

- Kelly, D.; Ilozor, B. Performance Outcome Assessment of the Integrated Project Delivery (IPD) Method for Commercial Construction Projects in USA. Int. J. Constr. Manag. 2020, 22, 2808–2816. [Google Scholar] [CrossRef]

- Ilozor, B.D.; Kelly, D.J. Building Information Modeling and Integrated Project Delivery in the Commercial Construction Industry: A Conceptual Study. J. Eng. Proj. Prod. Manag. 2012, 2, 23–36. [Google Scholar] [CrossRef]

- Samset, K. Early Project Appraisal; Palgrave Macmillan: London, UK, 2010; ISBN 978-1-349-32375-3. [Google Scholar]

- Hollberg, A.; Genova, G.; Habert, G. Evaluation of BIM-Based LCA Results for Building Design. Autom. Constr. 2020, 109, 102972. [Google Scholar] [CrossRef]

- Lee, J.W.; Cho, K.; Hwang, T.; Han, J.; Kim, T. Process for Integrating Constructability into the Design Phase in High-Rise Concrete Buildings: Focused on Temporary Work. Int. J. Concr. Struct. Mater. 2018, 12, 81. [Google Scholar] [CrossRef]

- Al Hattab, M.; Hamzeh, F. Simulating the Dynamics of Social Agents and Information Flows in BIM-Based Design. Autom. Constr. 2018, 92, 1–22. [Google Scholar] [CrossRef]

- Pikas, E.; Koskela, L.; Seppänen, O. Design Management in a Design Office: Solving the Problem of Relevance. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction 2017, IGLC 2017, Heraklion, Greece, 9–12 July 2017; pp. 547–554. [Google Scholar]

- Al Hattab, M.; Hamzeh, F. A Process-Social Perspective for Understanding Design Information Flow. Lean Constr. J. 2017, 11, 1–11. [Google Scholar]

| Id | Concept | Definition | References |

|---|---|---|---|

| C1 | Lean design practices | A systematic set of management principles and methods applied to the design process to maximize customer value and minimize waste. It includes reducing variability, synchronizing information flows, standardizing and coordinating dimensions, involving stakeholders early, and continually improving. | [16,17,18,19,20] |

| C2 | Waste in the design phase | Activity or resource consumption that does not add value to the design product as perceived by the client or user; it usually appears as rework, waiting, overprocessing, unnecessary iterations, or inefficient information transfers. | [21,22,23,24,25] |

| C3 | Waste management in design | A systematic process of identifying, measuring, analyzing, prioritizing, and controlling wastes during the design phase to guide preventive and corrective interventions by stage and performance dimension. | [21,26,27,28] |

| C4 | Design stages (SD–DD–CD) | Sequential building design phases that increase in detail and commitment, each with specific goals and decision points. Schematic Design (SD): defines the project concept, explores options, and coordinates initial ideas. Design Development (DD): refines the concept into coordinated architectural, structural, and MEP systems with specs and code checks. Construction Documents (CD): provides detailed drawings and specs for permitting, procurement, and construction, including dimensions, tolerances, schedules, and notes. | [29,30] |

| C5 | Performance dimensions | A set of criteria for assessing the impact of design decisions and processes. These criteria include: cost, which refers to resource and budget usage; deadline, related to timing and plan reliability; and quality, assessed by technical adherence and requirement satisfaction. | [31,32,33,34,35] |

| Profession | Role/Position | Years of Experience (Years) |

|---|---|---|

| Architect | Owner’s Representative | >25 |

| Architect | Architecture | >25 |

| Civil Engineer, PhD. | Geotechnical engineering | >25 |

| Civil Engineer | Structural engineering | >5 |

| Civil Engineer | MEP engineering | >5 |

| Profession, Grade | Position | Years of Experience (Years) |

|---|---|---|

| Civil Engineer, PhD | Professor | >25 |

| Civil Engineer, PhD | Professor and Consultant | >10 |

| Civil Engineer, PhD | BIM manager | >5 |

| Civil Engineer, PhD | Professor | >5 |

| Civil Engineer, PhD | Consultant | >5 |

| Test | Hypotheses |

|---|---|

| 1 | H0 = There are no differences between designers and managers. |

| H1 = There are differences between designers and managers. | |

| 2 | H0. |

| . | |

| 3 | H0. |

| . | |

| 4 | H0 |

| 5 | H0 |

| 6 | H0 |

| Work Plans | Design Stage | |||

|---|---|---|---|---|

| Riba (UK) | Conceptual Design | Not used | Design Development | Technical Design |

| ACE (Europe) | Conceptual Design | Preliminary Design | Design Development | Detailed Design |

| AIA (USA) | Schematic Desing | Not used | Design Development | Construction Documentation |

| APM (Global) | Feasibility | Not used | Conceptual Design | Detailed Design |

| Spain | Basic Project | Not used | Not used | Execution Project |

| Natspec (Australia) | Conceptual Design | Schematic Desing | Design Development | Construction Documentation |

| NZCIC (New Zealand) | Conceptual Design | Schematic Desing | Design Development | Detailed Design |

| Russia | AGR stage | P stage | Bidding Phase | Construction Documentation |

| Phases | Phase Description | Stages | Stage Objective |

|---|---|---|---|

| Pre-Design | All activities that occur from the conception of the construction idea until the decision to invest in the project is made [67] | Strategic Definition | Determine the best way to meet the client’s needs [44] |

| Preparation and Briefing | Develop the needs in detail, ensuring all requirements are met to begin the Design phase, determining what, who, and how the construction will be done [44] | ||

| Design | The first step of a construction project can be defined as “the process of deciding the appearance and functionality of the structure.” The design of a project can be entirely new or a combination of ideas to meet the project’s needs [67] | (SD) | Ensure the key elements of the building align with the client’s vision, instructions, and budget. The project begins to take shape, and the main options are evaluated, tested, and selected [58] |

| (DD) | Start the coordination of the different building systems with their architecture, refining system criteria, and beginning to develop project specifications [44] | ||

| (CD) | Obtain all the necessary design information to manufacture and construct the project, coordinating plans and assessing construction feasibility [44] |

| Type of Work | Consolidated Activities |

|---|---|

| Productive | Schematic Design |

| Design Development | |

| Construction Documentation | |

| Other Specialties | |

| Contributory | Communication |

| Control and Supervision | |

| Authorizations | |

| Meetings | |

| Non-contributory | Arrangements |

| Changes | |

| Information Requests | |

| Non-project-related Activities |

| Category | ID | Waste | Description | Measures to Reduce Lean Wastes |

|---|---|---|---|---|

| W1 | Wt1 | Waiting for resources and information | Inability to start activities or processes due to the lack of necessary resources or crucial information | Use the Last Planner System with look-ahead planning to remove constraints before commitments; assign responsibilities and due dates for resources in a shared platform (BIM/Common Data Environment), and track blockers visually |

| Wt2 | Delays in starting tasks | Delays that occur when starting activities or processes | Plan task begins with pull planning based on downstream readiness, defining clear “start/entry” criteria and holding short daily huddles to confirm prerequisites before work starts | |

| Wt3 | Delays in information delivery | Delays in providing data, documents, or information | Create an information delivery plan detailing who provides what, to whom, and by when; manage it in a Common Data Environment with alerts and reminders, and escalate delays in meetings | |

| Wt4 | Work interruptions | Unplanned pauses in tasks and activities | Protect work with uninterrupted time windows, resolve constraints early (Last Planner), and use an Obeya/Big Room for quick escalation during interruptions | |

| Wt5 | Inefficient work | Delays or interruptions caused by the inefficient execution of tasks or processes | Establish standard work instructions, right-size batch sizes, apply 5S to keep tools, files, and templates ready for use, and coach teams to stabilize cycle times | |

| Wt6 | Communication problems | Delays or interruptions caused by difficulties in information transmission | Define communication protocols (who shares what, when, how), use structured forms for info requests and submissions, and maintain a single source of truth to prevent teams from chasing conflicting messages | |

| W2 | OP1 | Unnecessary additional processes | Unnecessary performance of tasks or processes that do not add real value | Run Value Stream Mapping to remove non-value steps, standardize workflows, and confirm value with the client or users |

| OP2 | Unnecessary approval processes | Review and authorization procedures that do not add significant value to the outcome of a process | Simplify the approval map, delegate low-risk decisions, and use digital workflows with clear service targets so reviews happen once | |

| OP3 | Unnecessary information exchange | Transmission of data or information that does not add value or is irrelevant to a process or task | Share only essential information by stage via a Common Data Environment instead of email chains; avoid duplicate reports | |

| OP4 | Overqualified results | Situations where results or products unnecessarily exceed the requested requirements | Use Target Value Design with stage-appropriate detail levels to meet client and contract requirements without exceeding them | |

| OP5 | Excessive supervision | Excessive review and control of interdisciplinary processes or internal controls | Define roles and authorities, use risk-based reviews and checklists, and replace blanket oversight with sampling and specific audits | |

| OP6 | Clarification of needs in late design stages | Identification or review of essential project requirements in the advanced stages of its development | Front-load requirements workshops, early validation, freeze a baseline at the right milestone, and apply formal change management with impact checks | |

| OP7 | Excessive training times | Exaggerated use of resources in training personnel to perform specific tasks or functions | Provide standard work guides and concise, just-in-time training focused on the specific task; use mentoring and reusable resources to avoid repeating sessions | |

| W3 | D1 | Errors/omissions in work | Mistakes, inaccuracies, failures, or omissions in performing tasks or processes | Use checklists, peer reviews, BIM clash detection, model validation, and brief quality checks at key points |

| D2 | Rework | Repetition of tasks or processes due to errors, lack of quality, or lack of clarity in instructions | Prevent rework with quality at the source (clear inputs, templates, and standards), confirm readiness in Last Planner meetings, and fix root causes using A3 problem solving | |

| D3 | Changes in designs in the late stages | Significant modification or review of project plans or designs | Align stakeholders early, explore options with set-based concurrent engineering, and enforce change control with explicit criteria and impact analysis | |

| D4 | Equipment/infrastructure/software/hardware failures | Technical problems, malfunctions, or breakdowns in tools, devices, and infrastructure, among others. | Standardize toolsets, schedule preventive maintenance and timely updates, keep reliable backups, and provide responsive technical support | |

| W4 | I1 | Excess materials/data | Unnecessary accumulation of physical materials or digital information not needed for near-term processing | Apply just-in-time information flow and small batches; produce only what is needed for the next milestone and avoid premature detailing |

| I2 | Storing defective information/documentation | Practice of keeping records, data, documents, or files with deficiencies, errors, or quality problems | Validate content before storage using checklists and version control; quarantine or remove obsolete/incorrect files | |

| I3 | Loss of material/information | Disappearance, degradation, or unintentional elimination of physical materials or digital information | Store work in a centralized platform with permissions, backups, and naming conventions; avoid local ad hoc storage that risks loss | |

| I4 | Searching for information/data | Exaggerated use of resources in obtaining, locating, and retrieving information or data | Use 5S for digital information (standard names, folders, and tags), maintain a shared index or dashboard, and agree on where to find each type of data | |

| W5 | O1 | Creation of unused documentation | Unnecessary generation of documents, reports, or records that are not used or lack purpose in a process or project | Define required deliverables with the client and downstream users; generate documents only when tied to a decision or milestone |

| O2 | Obtaining duplicate information | Use of resources in acquiring repeated or redundant information or data | Assign data ownership, enter information once and reuse it via integrations, and eliminate re-entry across systems | |

| O3 | Receiving information requirements prematurely | Requesting or providing information requirements without proper evaluation or prior analysis | Gate information requests by milestone, verify the need with the requester, and trigger data only when the next process is ready | |

| O4 | Receiving excessive information requiring classification | Overwhelming flow of data or details that need to be organized, categorized, or classified | Use standard templates and data schemas, filter inputs to essentials, and automate classification where possible | |

| O5 | Excessive space | Disproportionate allocation or use of physical space | Optimize layouts using lean space planning, consolidate archives, retire low-value materials, and set clear rules for physical and digital storage | |

| W6 | T1 | Inefficient use of people’s capabilities | Situations where individuals’ skills, knowledge, or capabilities are not fully utilized, leading to less benefit for the organization | Build a skills matrix, match tasks to strengths, remove low-value admin from specialists, and offer purposeful cross-training |

| T2 | Unutilized creativity | Situations where individuals’ or teams’ creative potential is not fully utilized | Run continuous improvement (Kaizen) workshops, use A3 problem solving to turn ideas into trials, and recognize implemented improvements | |

| T3 | High demands on unqualified specialists | The practice of assigning tasks or responsibilities requiring specialized skills or knowledge to individuals lacking the necessary training | Define competency requirements, provide targeted training before assignment, pair with mentors, and stage supervision until proficiency is proven | |

| W7 | Tr1 | Unnecessary information transfers | Transport of data, documents, or communications that are not essential | Share work through a single collaboration platform (links, not file copies), automate system integrations, and remove redundant handoffs |

| Tr2 | Impractical communication channels | Complicated, inefficient, or ineffective methods or means of transmitting information | Choose simple, direct channels with visual management (dashboards, boards, Obeya reviews) and standard templates to avoid long, fragmented threads | |

| W8 | M1 | Excessive personnel movement outside the workspace | Excessive movement of employees outside the work area to perform tasks or activities related to their job | Provide remote access to models, documents, and approvals; collocate key roles in Big Room/Obeya sessions when physical presence adds value |

| M2 | Excessive personnel movement within the workspace | Frequent and inefficient movements of employees within their work environment | Redesign the layout using spaghetti diagrams, apply 5S so tools and information are at the point of use, and enable mobile access to data |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales-Caballero, N.; Castañeda, K.; Forcael, E.; Herrera, R.F. Efficiency in High-Rise Building Design: A Lean Approach to Waste Identification and Reduction. Systems 2025, 13, 782. https://doi.org/10.3390/systems13090782

Morales-Caballero N, Castañeda K, Forcael E, Herrera RF. Efficiency in High-Rise Building Design: A Lean Approach to Waste Identification and Reduction. Systems. 2025; 13(9):782. https://doi.org/10.3390/systems13090782

Chicago/Turabian StyleMorales-Caballero, Nicolás, Karen Castañeda, Eric Forcael, and Rodrigo F. Herrera. 2025. "Efficiency in High-Rise Building Design: A Lean Approach to Waste Identification and Reduction" Systems 13, no. 9: 782. https://doi.org/10.3390/systems13090782

APA StyleMorales-Caballero, N., Castañeda, K., Forcael, E., & Herrera, R. F. (2025). Efficiency in High-Rise Building Design: A Lean Approach to Waste Identification and Reduction. Systems, 13(9), 782. https://doi.org/10.3390/systems13090782