Green Supplier Evaluation in E-Commerce Systems: An Integrated Rough-Dombi BWM-TOPSIS Approach

Abstract

1. Introduction

2. Evaluation Indicators of Green Supplier Selection for ECEs

2.1. E-Commerce Sustainability and Green Supply Chain Management

2.2. Evaluation Framework

3. Research Method

3.1. Model Assumptions

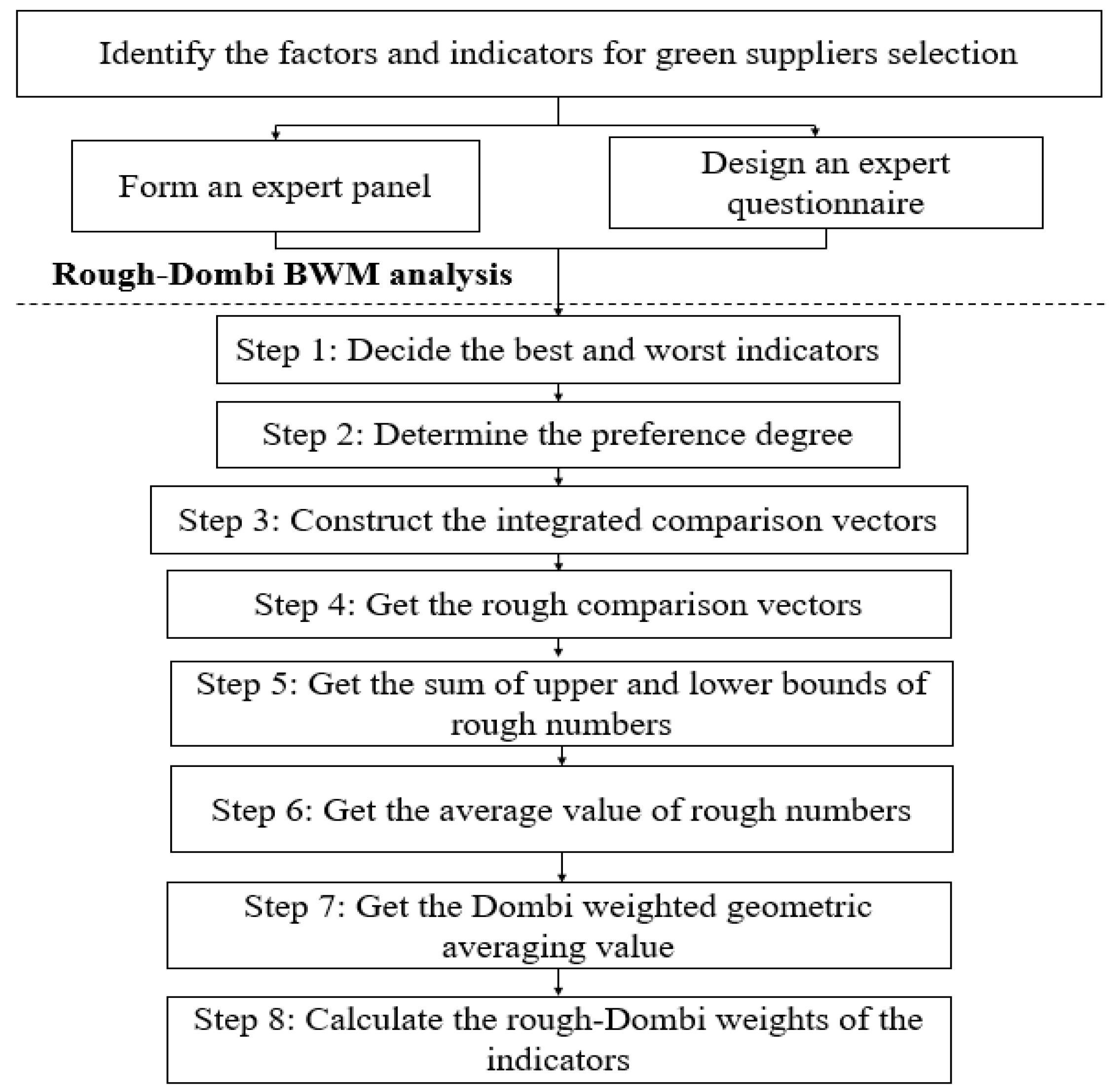

3.2. Algorithmic Implementation

3.2.1. Rough Set

3.2.2. Rough-Dombi BWM

3.2.3. Rough-TOPSIS Method

4. Empirical Analysis and Results

4.1. Case Context and Sample Selection

4.2. Weight Calculation

4.3. Green Supplier Performance Evaluation of ECEs

4.4. Validation Analysis and Comparative Analysis

4.5. Sensitivity Analysis

5. Discussion

5.1. Factor Importance Analysis

5.2. Practical Implications and Implementation Challenges

5.3. Recommendations for Policymakers

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Yang, J.; Xing, Y.; Han, Y. Utilization of E-commerce for fossil fuels allocation and green recovery. Resour. Policy 2023, 85, 103980. [Google Scholar] [CrossRef]

- Yang, Y.; Habib, K.; Wood, M. Establishing best practices for E-commerce transport packaging waste management in Canada: A systematic review. J. Clean. Prod. 2023, 429, 139377. [Google Scholar] [CrossRef]

- Nanayakkara, P.R.; Jayalath, M.M.; Thibbotuwawa, A.; Perera, H.N. A circular reverse logistics framework for handling e-commerce returns. Clean. Logist. Supply Chain. 2022, 5, 100080. [Google Scholar] [CrossRef]

- Bharani, S.; Tawde, S.; Roy, S. Consumer’s preference for sustainable e-commerce practices. J. Retail. Consum. Serv. 2023, 70, 102984. [Google Scholar]

- Wang, X.; Liu, Z.; Kong, H.; Peng, G. Research on the evaluation of green suppliers of high energy-consuming enterprises--based on rough number-grey correlation TOPSIS method. Heliyon 2024, 10, e21700. [Google Scholar] [CrossRef]

- Gao, H.; Ju, Y.; Santibanez Gonzalez, E.D.R.; Zhang, W. Green supplier selection in electronics manufacturing: An approach based on consensus decision making. J. Clean. Prod. 2020, 245, 118781. [Google Scholar] [CrossRef]

- Nekmahmud, M.; Naz, F.; Ramkissoon, H.; Fekete-Farkas, M. Transforming consumers’ intention to purchase green products: Role of social media. Technol. Forecast. Soc. Change 2022, 185, 122067. [Google Scholar] [CrossRef]

- Goodarzi, F.; Abdollahzadeh, V.; Zeinalnezhad, M. An integrated multi-criteria decision-making and multi-objective optimization framework for green supplier evaluation and optimal order allocation under uncertainty. Decis. Anal. J. 2022, 4, 100087. [Google Scholar] [CrossRef]

- Hamdan, S.; Cheaitou, A.; Shikhli, A.; Alsyouf, I. Comprehensive quantity discount model for dynamic green supplier selection and order allocation. Comput. Oper. Res. 2023, 160, 106372. [Google Scholar] [CrossRef]

- Sotoudeh-Anvari, A. The applications of MCDM methods in COVID-19 Pandemic: A state of the art review. Appl. Soft Comput. 2022, 126, 109238. [Google Scholar] [CrossRef]

- Liou, J.J.H.; Chang, M.H.; Lo, H.W.; Hsu, M.H. Application of an MCDM model with data mining techniques for green supplier evaluation and selection. Appl. Soft Comput. 2021, 109, 107534. [Google Scholar] [CrossRef]

- Wu, J.; Dong, M. Research on customer satisfaction of pharmaceutical e-commerce logistics service under service encounter theory. Electron. Commer. Res. Appl. 2023, 58, 101246. [Google Scholar] [CrossRef]

- Mondal, C.; Giri, B.C. Analyzing strategies in a green e-commerce supply chain with return policy and exchange offer. Comput. Ind. Eng. 2022, 171, 108492. [Google Scholar] [CrossRef]

- Zha, X.; Zhang, X.; Liu, Y.; Dan, B. Bonded-warehouse or direct-mail? Logistics mode choice in a cross-border e-commerce supply chain with platform information sharing. Electron. Commer. Res. Appl. 2022, 54, 101181. [Google Scholar] [CrossRef]

- Jalil, F.; Yang, J.; AI-Okaily, M.; Rehman, S.U. E-commerce for a sustainable future: Integrating trust, green supply chain management and online shopping satisfaction. Asia Pac. J. Mark. Logist. 2024, 36, 2354–2370. [Google Scholar] [CrossRef]

- Islam, M.S.; Proma, A.M.; Wohn, C.; Berger, K.; Uong, S.; Kumar, V.; Korfmcher, K.S.; Hoque, E. SEER: Sustainable E-commerce with Environmental-impact Rating. Clean. Environ. Syst. 2023, 8, 10014. [Google Scholar] [CrossRef]

- Matsui, K. Should competing suppliers with dual-channel supply chains adopt agency selling in an e-commerce platform. Eur. J. Oper. Res. 2024, 312, 587–604. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, Z.; Qin, Y.; Song, W. Performance evaluation of technological service platform: A rough Z-number-based BWM-TODIM method. Expert Syst. Appl. 2023, 230, 120665. [Google Scholar] [CrossRef]

- Shao, Q.G.; Liou, J.J.H.; Weng, S.S.; Su, P.Y. Constructing an entrepreneurship project evaluation system using a hybrid model. J. Bus. Econ. Manag. 2020, 21, 1329–1349. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57. [Google Scholar] [CrossRef]

- Rezaei, J.; Hemmes, A.; Tavasszy, L. Multi-criteria decision-making for complex bundling configurations in surface transportation of airfreight. J. Air Transp. Manag. 2017, 61, 95–105. [Google Scholar] [CrossRef]

- Pawlak, Z.; Słowinski, R. Decision analysis using rough sets. Int. Trans. Oper. Res. 1994, 1, 107–114. [Google Scholar] [CrossRef]

- Pawlak, Z. Rough sets and fuzzy sets. Fuzzy Sets Syst. 1985, 17, 99–102. [Google Scholar] [CrossRef]

- Deveci, M.; Erdogan, N.; Pamucar, D.; Kucuksari, S.; Cali, U. A rough Dombi Bonferroni based approach for public charging station type selection. Appl. Energy 2023, 345, 121258. [Google Scholar] [CrossRef]

- Iordache, M.; Pamucar, D.; Deveci, M.; Chisalita, D.; Wu, Q.; Iordache, I. Prioritizing the alternatives of the natural gas grid conversion to hydrogen using a hybrid interval rough based Dombi MARCOS model. Int. J. Hydrogen Energy 2022, 47, 10665–10688. [Google Scholar] [CrossRef]

- Liou, J.H.; Liu, Y.L.; Huang, S.W. Exploring the key barriers to ESG adoption in enterprises. Syst. Soft Comput. 2023, 5, 200066. [Google Scholar] [CrossRef]

- Haeri, S.A.S.; Rezaei, J. A grey-based green supplier selection model for uncertain environments. J. Clean. Prod. 2019, 221, 768–784. [Google Scholar] [CrossRef]

- Tanrıverdi, G.; Ecer, F.; Şahin Durak, M. Exploring factors affecting airport selection during the COVID-19 pandemic from air cargo carriers’ perspective through the triangular fuzzy Dombi-Bonferroni BWM methodology. J. Air Transp. Manag. 2022, 105, 102302. [Google Scholar] [CrossRef]

- González-Romero, I.; Ortiz Bas, Á.; Prado-Prado, J.C. Last-mile strategies in e-commerce. Identifying barriers to sustainability from online retailers’ perspectives. Res. Transp. Bus. Manag. 2025, 60, 101367. [Google Scholar] [CrossRef]

- Gong, C.; Song, H.; Chen, D.; Day, S.J.; Ignatius, J. Logistics sourcing of e-commerce firms considering promised delivery time and environmental sustainability. Eur. J. Oper. Res. 2024, 317, 60–75. [Google Scholar] [CrossRef]

- Long, R.; Yuan, X.; Wu, M. Consumers’ green product purchase intention considering para-social interaction: An experimental study based on live-streaming e-commerce. J. Clean. Prod. 2024, 481, 144169. [Google Scholar] [CrossRef]

- Qi, B.; Shen, Y.; Xu, T. An artificial-intelligence-enabled sustainable supply chain model for B2C E-commerce business in the international trade. Technol. Forecast. Soc. Change 2023, 191, 122491. [Google Scholar] [CrossRef]

- Ju, C.; Liu, H.; Xu, A.; Zhang, J. Green logistics of fossil fuels and E-commerce: Implications for sustainable economic development. Resour. Policy 2023, 85, 103991. [Google Scholar] [CrossRef]

- Clement, L.; Spinler, S. From returns to re-usage: A data-driven strategy for sustainable packaging—A case study in e-commerce. J. Clean. Prod. 2025, 510, 145584. [Google Scholar] [CrossRef]

- Gao, R.; Hua, K.; Wang, X.; Wei, J. Analysis of green e-commerce supply chain considering delivery time under reward–penalty mechanism based on confidence level. Socio-Econ. Plan. Sci. 2025, 99, 102203. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Hamdan, S.; Cheaitou, A. Supplier selection and order allocation with green criteria: An MCDM and multi-objective optimization approach. Comput. Oper. Res. 2017, 81, 282–304. [Google Scholar] [CrossRef]

- Fallahpour, A.; Olugu, E.U.; Musa, S.N.; Wong, K.Y.; Noor, S. A decision support model for sustainable supplier selection in sustainable supply chain management. Comput. Ind. Eng. 2017, 105, 391–410. [Google Scholar] [CrossRef]

- Han, G.; Feng, Z.; Chen, S.; Xue, X.; Wu, H. Evaluating differential pricing in e-commerce from the perspective of utility. Electron. Commer. Res. Appl. 2024, 64, 101373. [Google Scholar] [CrossRef]

- Ghosh, K.; Basu, S.; Avittathur, B.; Govindan, K. Agency or reseller: The role of supply chain finance in deciding E-commerce channel under product return risk. Transp. Res. Part E Logist. Transp. Rev. 2025, 201, 104182. [Google Scholar] [CrossRef]

- Xu, M.; Tang, W.; Zhao, R. Should reputable e-retailers undertake service activities along with sales? J. Retail. Consum. Serv. 2023, 74, 103427. [Google Scholar] [CrossRef]

- Zeng, Q.; Lin, L.; Jiang, R.; Hung, W.; Lin, D. NNEnsLeG: A novel approach for e-commerce payment fraud detection using ensemble learning and neural networks. Inf. Process. Manag. 2025, 62, 103916. [Google Scholar] [CrossRef]

- Qian, Z.; Chen, Y.; Xu, Y. Strategy design of fresh e-commerce pre-warehouse based on mass customization. Comput. Ind. Eng. 2024, 192, 110180. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Yang, L. Uncovering the influence mechanism between top management support and green procurement: The effect of green training. J. Clean. Prod. 2020, 251, 119674. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, Y. Can green public procurement change energy efficiency? Evidence from a quasi-natural experiment in China. Energy Econ. 2022, 113, 106244. [Google Scholar] [CrossRef]

- Liu, C.; Ma, T. Green logistics management and supply chain system construction based on internet of things technology. Sustain. Comput. Inform. Syst. 2022, 35, 100773. [Google Scholar] [CrossRef]

- Starostka-Patyk, M.; Bajdor, P.; Białas, J. Green logistics performance Index as a benchmarking tool for EU countries environmental sustainability. Ecol. Indic. 2024, 158, 111396. [Google Scholar] [CrossRef]

- Putz-Egger, L.M.; Pfoser, S.; Plasch, M. Intergenerational differences of consumers’ perception related to the value of green logistics: A focus on transport, packaging, and waste management. Sustain. Futures 2025, 9, 100458. [Google Scholar] [CrossRef]

- Sun, H.; Li, J. Behavioural choice of governments, enterprises and consumers on recyclable green logistics packaging. Sustain. Prod. Consum. 2021, 289, 459–471. [Google Scholar] [CrossRef]

- Anderson, C.; Lee, Y. Unlocking the enigma: Navigating American passivity in e-waste recycling through push-pull mooring insights. J. Clean. Prod. 2025, 508, 145554. [Google Scholar] [CrossRef]

- Tian, X.; Yan, B.; Zhou, X.; Yan, Y. Impact of logistics delivery performance on consumers’ future purchase behavior: Evidence from an e-commerce platform in China. Electron. Commer. Res. Appl. 2025, 72, 101509. [Google Scholar] [CrossRef]

- Li, L.; Lin, J.; Benitez, J.; Luo, X.; Mikalef, P. Seeking decision-making performance: Examining the role of E-commerce capability, digital business intensity, and organizational agility. Inf. Manag. 2025, 6, 104064. [Google Scholar] [CrossRef]

- Carvalho, H.; Naghshineh, B.; Govindan, K.; Cruz-Machado, V. The resilience of on-time delivery to capacity and material shortages: An empirical investigation in the automotive supply chain. Comput. Ind. Eng. 2022, 171, 108375. [Google Scholar] [CrossRef]

- Ma, B.; Zhang, J. Tie strength, organizational resilience and enterprise crisis management: An empirical study in pandemic time. Int. J. Disaster Risk Reduct. 2022, 81, 103240. [Google Scholar] [CrossRef]

- Zhang, Z. E-commerce logistics performance and resilience: The influence of inter-organizational trust and organizational flexibility. Technol. Soc. 2025, 81, 102777. [Google Scholar] [CrossRef]

- Li, D.; Mishra, N. Engaging suppliers for reliability improvement under outcome-based compensations. Omega 2021, 102, 102343. [Google Scholar] [CrossRef]

- Sonar, H.; Gunasekaran, A.; Agrawal, S.; Roy, M. Role of lean, agile, resilient, green, and sustainable paradigm in supplier selection. Clean. Logist. Supply Chain 2022, 4, 100059. [Google Scholar] [CrossRef]

- Dehury, P.; Kumar, K.A. Identification of hazardous substances and occupational morbidity associated with steel and power industry workers in Odisha, India. Clin. Epidemiol. Glob. Health 2023, 22, 101312. [Google Scholar] [CrossRef]

- Zhu, Y.; Lin, Y.; Tan, Y.; Liu, B.; Wang, H. The potential nexus between fintech and energy consumption: A new perspective on natural resource consumption. Resour. Policy 2024, 89, 104589. [Google Scholar] [CrossRef]

- Yue, R.; Xu, X.; Li, Z.; Bai, Q. Reusable packaging adoption in e-commerce markets with green consumers: An evolutionary game analysis. J. Retail. Consum. Serv. 2024, 81, 103818. [Google Scholar] [CrossRef]

- Haq, U.N.; Alam, S.M.R. Implementing circular economy principles in the apparel production process: Reusing pre-consumer waste for sustainability of environment and economy. Clean. Waste Syst. 2023, 6, 100108. [Google Scholar] [CrossRef]

- Grandhi, S.P.; Dagwar, P.P.; Dutta, D. Policy pathways to sustainable E-waste management: A global review. J. Hazard. Mater. Adv. 2024, 16, 100473. [Google Scholar] [CrossRef]

- Qu, S.; Xu, Y.; Wu, Z.; Xu, Z.; Ji, Y.; Qu, D.; Han, Y. An Interval-Valued Best-Worst Method with Normal Distribution for Multi-Criteria Decision-Making. Arab. J. Sci. Eng. 2021, 46, 1771–1785. [Google Scholar] [CrossRef]

- Chen, Z.; Luo, W. An integrated interval type-2 fuzzy rough technique for emergency decision making. Appl. Soft Comput. 2023, 137, 110150. [Google Scholar] [CrossRef]

- Yoon, K.P.; Kim, W.K. The behavioral TOPSIS. Expert Syst. Appl. 2017, 89, 266–272. [Google Scholar] [CrossRef]

- Gupta, H.; Barua, M.K. Supplier selection among SMEs on the basis of their green innovation ability using BWM and fuzzy TOPSIS. J. Clean. Prod. 2017, 152, 242–258. [Google Scholar] [CrossRef]

- Alves, R.; Pereira, C.A.; Lima, R.S. Operational cost analysis for e-commerce deliveries using agent-based modeling and simulation. Res. Transp. Econ. 2023, 101, 101348. [Google Scholar] [CrossRef]

- Ji, G.; Fu, T.; Li, S. Optimal selling format considering price discount strategy in live-streaming commerce. Eur. J. Oper. Res. 2023, 309, 529–544. [Google Scholar] [CrossRef]

- Pahwa, A.; Jaller, M. A cost-based comparative analysis of different last-mile strategies for e-commerce delivery. Transp. Res. Part E Logist. Transp. Rev. 2022, 164, 102783. [Google Scholar] [CrossRef]

- Wei, X.; Wei, Q.; Yang, L. Induced green innovation of suppliers: The “green power” from major customers. Energy Econ. 2023, 124, 106775. [Google Scholar] [CrossRef]

| Dimensions | Criteria | Explanation | Literature |

|---|---|---|---|

| Cost (C1) | Product price (C11) | Product pricing competitiveness relative to market benchmarks. | [38,39] |

| Freight cost (C12) | Cost-effectiveness of transportation considering safety–speed–cost trade-offs. | [40] | |

| Warehousing cost (C13) | ECEs store their goods purchased from suppliers in the suppliers’ warehouses. | [14] | |

| After-sales service cost (C14) | The installation and commissioning services, technical training, on-site maintenance, etc. | [41] | |

| Other cost (C15) | Communication cost, etc. | [42] | |

| Green competitiveness (C2) | Green design (C21) | Environmental consideration integration in product design. | [43,51] |

| Green logistics (C22) | A logistics model that can save resources and reduce waste gas emissions. | [44,45,46,47] | |

| Green procurement (C23) | Give priority to the purchase and use of energy saving, water saving, material saving and other raw materials and products conducive to environmental protection. | [45,47,48,51] | |

| Green packaging (C24) | An environment-friendly packaging that is conducive to recycling, easy to degrade and sustainable development. | [46,49] | |

| Material reuse (C25) | Realize sustainable development of environmental protection by reducing energy consumption and environmental pollution caused by the use of new raw materials in the production process. | [47,48,51] | |

| Service level (C3) | On-time delivery capability (C31) | Deliver on time according to the agreement with the ECEs. | [50] |

| Product quality (C32) | Products that can meet the needs of the ECEs. | [51,52] | |

| Organization and management (C33) | The process and method of establishing a suitable organization to achieve the goals of the management. | [53,54] | |

| Flexibility (C34) | The ability to schedule and change orders and the level of flexibility in supplying materials and supplying material prices. | [55,56] | |

| Reliability (C35) | The ability of an enterprise service or product to be executed without failure within a certain period. | [55,56] | |

| External environmental management (C4) | Resource consumption (C41) | The amount of resources consumed in a certain time and conditions. | [57,58,59] |

| Pollution control (C42) | The ability to control the size of the pollution involved. | [54,59] | |

| Renewable energy (C43) | Able to maintain the amount of increased or stored energy. | [58,59] | |

| Waste reuse (C44) | The size of the innovative capacity for waste recycling and utilization. | [59,60,61] | |

| Hazardous substance management (C45) | To manage hazardous substances in the production process, the company should implement preventive management methods for restricted chemicals. | [2,62] | |

| Corporate Social Responsibility (C5) | Stakeholder rights (C51) | Attaches great importance to the interests and rights of shareholders, consumers, communities and related personnel. | [56] |

| Employees’ interests and rights (C52) | Pay attention to the relevant requirements of employees to achieve long-term sustainable development. | ||

| Work safety and labor health (C53) | Pay attention to work safety and health concepts | ||

| Environmental awareness (C54) | Have the concept of environmental protection. | ||

| Information disclosure (C55) | The ability to provide customers or stakeholders with information about the use of materials, and to make the information open and trustworthy. |

| Suppliers | Employee Strength (2022) | Turnover (2022) | Industries | Products |

|---|---|---|---|---|

| S1 | 9758 | CNY 2,220,000,000 | Toiletries | Shampoo, shower gel |

| S2 | 18,590 | CNY 33,239,000,000 | Beverage | Mineral water |

| S3 | 1900 | CNY 5,300,000,000 | Computer accessories | Memory module, monitor, mouse |

| S4 | 25,789 | CNY 11, 223,000,000 | Home furnishings | Dining table, mattress |

| S5 | 12,000 | CNY 2,000,000,000 | Cosmetics | Lipstick, perfume |

| No. | Work Area | Job Title | Years of Service (Years) |

|---|---|---|---|

| 1 | Supply chain management | University professor | 15 |

| 2 | Supply chain management | University professor | 19 |

| 3 | Supply chain management | University professor | 21 |

| 4 | Operation Management | Operations director | 13 |

| 5 | Operation Management | Operations director | 12 |

| 6 | Operation Management | Operations director | 12 |

| 7 | Operation Management | Operations director | 10 |

| 8 | Marketing management | Marketing manager | 16 |

| 9 | Marketing management | Marketing manager | 13 |

| 10 | Marketing management | Marketing manager | 15 |

| Dimension | Criteria | |||||

|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | ||

| Best | C1 | C11 | C24 | C32 | C42 | C51 |

| Worst | C5 | C15 | C25 | C33 | C43 | C55 |

| Scale | Definition | Explanation |

|---|---|---|

| 1 | Equally important | The two indicators are of equal importance |

| 3 | Slightly important | One indicator is slightly more important than the other |

| 5 | Important | One indicator is significantly more important than the other |

| 7 | Very important | One indicator is much more important than the other |

| 9 | Extremely important | One indicator is extremely important compared to the other |

| 2, 4, 6, 8 | -- | The median value of the above adjacent judgments |

| Relative Importance | ||||||

|---|---|---|---|---|---|---|

| Optimal indicators | Equal importance | Slightly important | Clearly important | Very important | Extremely important | |

| Cost | Cost | |||||

| Green competitiveness | ||||||

| Service level | ||||||

| External environmental management | ||||||

| Corporate social responsibility | ||||||

| Experts | Best Dimension | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|---|

| 1 | C1 | 1 | 1 | 3 | 1 | 7 |

| 2 | 1 | 2 | 1 | 3 | 8 | |

| 3 | 1 | 2 | 3 | 2 | 7 | |

| 4 | 1 | 2 | 3 | 2 | 6 | |

| 5 | 1 | 3 | 2 | 3 | 8 | |

| 6 | 1 | 3 | 3 | 3 | 7 | |

| 7 | 1 | 3 | 3 | 3 | 7 | |

| 8 | 1 | 1 | 5 | 2 | 7 | |

| 9 | 1 | 1 | 2 | 2 | 8 | |

| 10 | 1 | 3 | 3 | 3 | 9 |

| Experts | C1 | C2 | C3 | C4 | C5 | Worst Dimension |

|---|---|---|---|---|---|---|

| 1 | 7 | 5 | 3 | 9 | 1 | C5 |

| 2 | 8 | 7 | 7 | 4 | 1 | |

| 3 | 7 | 7 | 3 | 5 | 1 | |

| 4 | 6 | 7 | 3 | 4 | 1 | |

| 5 | 8 | 6 | 4 | 4 | 1 | |

| 6 | 7 | 6 | 4 | 5 | 1 | |

| 7 | 7 | 6 | 2 | 4 | 1 | |

| 8 | 7 | 8 | 2 | 5 | 1 | |

| 9 | 8 | 8 | 4 | 3 | 1 | |

| 10 | 9 | 8 | 2 | 4 | 1 |

| C1 (Best) | C2 | C3 | C4 | C5 | |

|---|---|---|---|---|---|

| DM1 | [0.1, 0.1] | [0.063, 0.081] | [0.114, 0.098] | [0.049, 0.087] | [0.081, 0.092] |

| DM2 | [0.1, 0.1] | [0.094, 0.099] | [0.045, 0.084] | [0.119, 0.109] | [0.081, 0.092] |

| DM3 | [0.1, 0.1] | [0.094, 0.099] | [0.114, 0.098] | [0.089, 0.093] | [0.118, 0.104] |

| DM4 | [0.1, 0.1] | [0.094, 0.099] | [0.114, 0.098] | [0.089, 0.093] | [0.118, 0.104] |

| DM5 | [0.1, 0.1] | [0.132, 0.115] | [0.074, 0.089] | [0.119, 0.109] | [0.118, 0.104] |

| DM6 | [0.1, 0.1] | [0.132, 0.115] | [0.114, 0.098] | [0.119, 0.109] | [0.123, 0.118] |

| DM7 | [0.1, 0.1] | [0.132, 0.115] | [0.114, 0.098] | [0.119, 0.109] | [0.118, 0.104] |

| DM8 | [0.1, 0.1] | [0.063, 0.081] | [0.125, 0.149] | [0.089, 0.093] | [0.097, 0.098] |

| DM9 | [0.1, 0.1] | [0.063, 0.081] | [0.074, 0.089] | [0.089, 0.093] | [0.048, 0.086] |

| DM10 | [0.1, 0.1] | [0.132, 0.115] | [0.114, 0.098] | [0.119, 0.109] | [0.097, 0.098] |

| C1 | C2 | C3 | C4 | C5 (Worst) | |

|---|---|---|---|---|---|

| DM1 | [0.103, 0.1] | [0.144, 0.115] | [0.07, 0.097] | [0.117, 0.108] | [0.1, 0.1] |

| DM2 | [0.103, 0.1] | [0.1, 0.098] | [0.056, 0.077] | [0.117, 0.108] | [0.1, 0.1] |

| DM3 | [0.103, 0.1] | [0.1, 0.098] | [0.124, 0.103] | [0.091, 0.099] | [0.1, 0.1] |

| DM4 | [0.103, 0.1] | [0.1, 0.098] | [0.124, 0.103] | [0.117, 0.108] | [0.1, 0.1] |

| DM5 | [0.089, 0.1] | [0.082, 0.089] | [0.124, 0.103] | [0.079, 0.089] | [0.1, 0.1] |

| DM6 | [0.103, 0.1] | [0.082, 0.089] | [0.14, 0.155] | [0.079, 0.089] | [0.1, 0.1] |

| DM7 | [0.083, 0.1] | [0.082, 0.096] | [0.124, 0.103] | [0.084, 0.096] | [0.1, 0.1] |

| DM8 | [0.103, 0.1] | [0.111, 0.105] | [0.056, 0.077] | [0.106, 0.102] | [0.1, 0.1] |

| DM9 | [0.103, 0.1] | [0.111, 0.105] | [0.056, 0.077] | [0.106, 0.102] | [0.1, 0.1] |

| DM10 | [0.103, 0.1] | [0.111, 0.105] | [0.124, 0.103] | [0.106, 0.102] | [0.1, 0.1] |

| DWGAV | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| D (aBi) | [1.00, 1.00] | [1.45, 2.55] | [2.04, 3.28] | [1.88, 2.74] | [3.82, 5.91] |

| D (aiW) | [8.36, 8.96] | [6.03, 7.80] | [1.55, 3.11] | [6.20, 8.32] | [1.00, 1.00] |

| Dimensions | Weights | Ranking | Criteria | Weights | Rank |

|---|---|---|---|---|---|

| Cost (C1) | [0.490, 0.490] | 1 | Product price (C11) | [0.318, 0.318] | 1 |

| Freight cost (C12) | [0.271, 0.271] | 2 | |||

| Warehousing cost (C13) | [0.249, 0.249] | 3 | |||

| After-sales service cost (C14) | [0.125, 0.125] | 5 | |||

| other cost (C15) | [0.037, 0.037] | 15 | |||

| Green competitiveness (C2) | [0.192, 0.192] | 2 | Green design (C21) | [0.285, 0.304] | 7 |

| Green logistics (C22) | [0.106, 0.112] | 14 | |||

| Green procurement (C23) | [0.278, 0.278] | 8 | |||

| Green packaging (C24) | [0.29, 0.29] | 6 | |||

| Material reuse (C25) | [0.041, 0.041] | 21 | |||

| Service level (C3) | [0.085, 0.085] | 4 | On-time delivery capability (C31) | [0.48, 0.48] | 10 |

| Product quality (C32) | [0.334, 0.452] | 12 | |||

| Organization and management (C33) | [0.049, 0.049] | 25 | |||

| Flexibility (C34) | [0.056, 0.079] | 23 | |||

| Reliability (C35) | [0.079, 0.079] | 22 | |||

| External environmental management (C4) | [0.178, 0.178] | 3 | Resource consumption (C41) | [0.17, 0.17] | 11 |

| Pollution control (C42) | [0.384, 0.384] | 4 | |||

| Renewable energy (C43) | [0.073, 0.073] | 17 | |||

| Waste reuse (C44) | [0.233, 0.233] | 9 | |||

| Hazardous substance management (C45) | [0.14, 0.14] | 13 | |||

| Corporate social responsibility (C5) | [0.055, 0.055] | 5 | Stakeholder rights (C51) | [0.322, 0.333] | 16 |

| Employees’ interests and rights (C52) | [0.236, 0.236] | 18 | |||

| Work safety and labor health (C53) | [0.184, 0.184] | 19 | |||

| Environmental awareness (C54) | [0.174, 0.218] | 20 | |||

| Information disclosure (C55) | [0.084, 0.084] | 24 |

| S1 | S2 | S3 | S4 | S5 | |

|---|---|---|---|---|---|

| C11 | 8.13 | 8.25 | 7.25 | 8.00 | 8.13 |

| C12 | 9.00 | 9.13 | 8.50 | 7.38 | 7.38 |

| C13 | 8.88 | 8.75 | 7.38 | 7.50 | 8.13 |

| C14 | 8.88 | 8.00 | 7.00 | 8.00 | 8.00 |

| C15 | 8.13 | 9.00 | 7.75 | 7.25 | 7.50 |

| C21 | 7.38 | 7.13 | 8.38 | 7.875 | 8.00 |

| C22 | 8.13 | 8.13 | 8.63 | 7.375 | 7.63 |

| C23 | 8.50 | 8.13 | 9.38 | 7.875 | 8.75 |

| C24 | 7.75 | 8.13 | 9.75 | 8.25 | 8.88 |

| C25 | 6.50 | 7.13 | 9.13 | 8.25 | 8.50 |

| C31 | 8.75 | 8.38 | 9.25 | 8.13 | 7.25 |

| C32 | 9.125 | 8.63 | 8.63 | 8.63 | 9.38 |

| C33 | 9.75 | 8.75 | 8.50 | 8.88 | 8.50 |

| C34 | 8.13 | 8.13 | 7.00 | 9.00 | 8.38 |

| C35 | 8.75 | 8.75 | 9.13 | 8.13 | 7.75 |

| C41 | 8.00 | 8.00 | 9.25 | 8.38 | 8.88 |

| C42 | 8.13 | 7.75 | 9.13 | 8.00 | 8.63 |

| C43 | 6.50 | 7.50 | 9.13 | 8.00 | 8.38 |

| C44 | 8.38 | 8.50 | 9.25 | 8.13 | 9.13 |

| C45 | 7.50 | 7.75 | 8.75 | 8.00 | 8.75 |

| C51 | 9.25 | 9.00 | 7.50 | 8.25 | 8.75 |

| C52 | 8.75 | 9.13 | 7.88 | 8.13 | 8.25 |

| C53 | 9.00 | 9.25 | 8.13 | 8.25 | 8.75 |

| C54 | 8.13 | 8.25 | 9.63 | 9.13 | 9.13 |

| C55 | 7.25 | 7.88 | 9.13 | 8.00 | 7.75 |

| S1 | S2 | S3 | S4 | S5 | |

|---|---|---|---|---|---|

| C11 | [7.67, 8.52] | [7.84, 8.78] | [7.13, 8.46] | [7.66, 8.13] | [7.82, 8.48] |

| C12 | [8.13, 9.00] | [8.18, 9.13] | [7.71, 9.08] | [7.33, 7.83] | [7.38, 8.09] |

| C13 | [8.03, 8.92] | [7.95, 8.96] | [7.21, 8.61] | [7.38, 7.96] | [7.82, 8.48] |

| C14 | [8.03, 8.92] | [7.42, 8.44] | [7.00, 8.31] | [7.66, 8.13] | [7.70, 8.34] |

| C15 | [7.67, 8.52] | [8.07, 9.06] | [7.34, 8.79] | [7.25, 7.78] | [7.44, 8.17] |

| C21 | [6.94, 8.31] | [7.13, 8.18] | [7.55, 8.96] | [7.54, 8.04] | [7.70, 8.34] |

| C22 | [7.67, 8.52] | [7.77, 8.50] | [7.84, 9.22] | [7.33, 7.83] | [7.50, 8.25] |

| C23 | [7.79, 8.81] | [7.77, 8.50] | [8.15, 9.56] | [7.54, 8.04] | [8.00, 8.81] |

| C24 | [7.21, 8.42] | [7.77, 8.50] | [8.31, 9.75] | [7.78, 8.52] | [8.09, 8.88] |

| C25 | [6.50, 8.13] | [7.13, 8.18] | [8.00, 9.42] | [7.78, 8.52] | [7.91, 8.71] |

| C31 | [7.79, 8.92] | [7.84, 8.96] | [8.00, 9.56] | [7.66, 8.52] | [7.25, 8.09] |

| C32 | [8.13, 9.38] | [7.84, 8.96] | [7.84, 9.22] | [7.78, 8.91] | [8.09, 9.38] |

| C33 | [8.13, 9.75] | [7.95, 8.96] | [7.71, 9.08] | [7.78, 9.00] | [7.91, 8.71] |

| C34 | [7.67, 8.52] | [7.77, 8.50] | [7.00, 8.31] | [7.78, 9.06] | [7.82, 8.71] |

| C35 | [7.79, 8.92] | [7.95, 8.96] | [8.00, 9.42] | [7.66, 8.25] | [7.50, 8.34] |

| C41 | [7.21, 8.52] | [7.42, 8.44] | [8.00, 9.56] | [7.78, 8.80] | [8.09, 8.88] |

| C42 | [7.67, 8.52] | [7.13, 8.44] | [8.00, 9.42] | [7.66, 8.13] | [7.91, 8.71] |

| C43 | [6.50, 8.13] | [7.13, 8.44] | [8.00, 9.42] | [7.66, 8.13] | [7.82, 8.71] |

| C44 | [7.67, 8.81] | [7.84, 8.96] | [8.00, 9.56] | [7.66, 8.25] | [8.09, 9.21] |

| C45 | [6.94, 8.42] | [7.13, 8.44] | [7.84, 9.42] | [7.66, 8.13] | [8.00, 8.81] |

| C51 | [8.13, 9.50] | [8.07, 9.06] | [7.21, 8.79] | [7.66, 8.25] | [8.00, 8.81] |

| C52 | [7.79, 8.92] | [8.18, 9.13] | [7.34, 8.96] | [7.66, 8.25] | [7.82, 8.71 |

| C53 | [8.13, 9.00] | [8.18, 9.25] | [7.34, 8.96] | [7.78, 8.25] | [8.00, 8.81] |

| C54 | [7.67, 8.52] | [7.84, 8.78] | [8.15, 9.75] | [7.78, 9.13] | [8.09, 9.21] |

| C55 | [6.50, 8.31] | [7.13, 8.44] | [8.00, 9.42] | [7.66, 8.13] | [7.50, 8.34] |

| Suppliers | Positive Ideal Resolution | Negative Ideal Resolution | Relative Closeness | Ranking |

|---|---|---|---|---|

| S1 | 0.684 | 0.740 | −0.009 | 4 |

| S2 | 0.689 | 0.723 | −0.006 | 3 |

| S3 | 0.439 | 1.056 | −0.087 | 5 |

| S4 | 1.024 | 0.381 | 0.089 | 1 |

| S5 | 0.760 | 0.660 | 0.013 | 2 |

| Method | Deals with Vagueness | Covers Range of Ambiguity | Efficacy of Blending Expert Judgments | Versatility of Expert Insight |

|---|---|---|---|---|

| AHP | No | Low | Low | Low |

| ANP | No | Low | Low | Low |

| ISM | No | Low | Low | Low |

| Fuzzy BWM | Yes | Moderate | Moderate | Moderate |

| Rough BWM | Yes | Moderate | Moderate | Moderate |

| Rough-Dombi BWM | Yes | High | High | High |

| Runs | Weight | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|---|

| 1 | 0.16 | 3 | 4 | 1 | 5 | 2 |

| 2 | 0.1 | 3 | 3 | 1 | 5 | 2 |

| 3 | 0.2 | 4 | 3 | 1 | 5 | 2 |

| 4 | 0.3 | 4 | 3 | 1 | 5 | 2 |

| 5 | 0.4 | 4 | 3 | 1 | 5 | 2 |

| 6 | 0.5 | 4 | 3 | 1 | 5 | 2 |

| 7 | 0.6 | 4 | 3 | 1 | 5 | 2 |

| 8 | 0.7 | 4 | 3 | 1 | 5 | 2 |

| 9 | 0.8 | 4 | 4 | 1 | 5 | 2 |

| 10 | 0.9 | 4 | 5 | 1 | 3 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, Q.; Liu, S.; Lin, J.; Liou, J.J.H.; Zhu, D. Green Supplier Evaluation in E-Commerce Systems: An Integrated Rough-Dombi BWM-TOPSIS Approach. Systems 2025, 13, 731. https://doi.org/10.3390/systems13090731

Shao Q, Liu S, Lin J, Liou JJH, Zhu D. Green Supplier Evaluation in E-Commerce Systems: An Integrated Rough-Dombi BWM-TOPSIS Approach. Systems. 2025; 13(9):731. https://doi.org/10.3390/systems13090731

Chicago/Turabian StyleShao, Qigan, Simin Liu, Jiaxin Lin, James J. H. Liou, and Dan Zhu. 2025. "Green Supplier Evaluation in E-Commerce Systems: An Integrated Rough-Dombi BWM-TOPSIS Approach" Systems 13, no. 9: 731. https://doi.org/10.3390/systems13090731

APA StyleShao, Q., Liu, S., Lin, J., Liou, J. J. H., & Zhu, D. (2025). Green Supplier Evaluation in E-Commerce Systems: An Integrated Rough-Dombi BWM-TOPSIS Approach. Systems, 13(9), 731. https://doi.org/10.3390/systems13090731