Leveraging IoT Micro-Factories for Equitable Trade: Enhancing Semi-Finished Orange Juice Value Chain in a Citriculture Society

Abstract

1. Introduction

1.1. Background

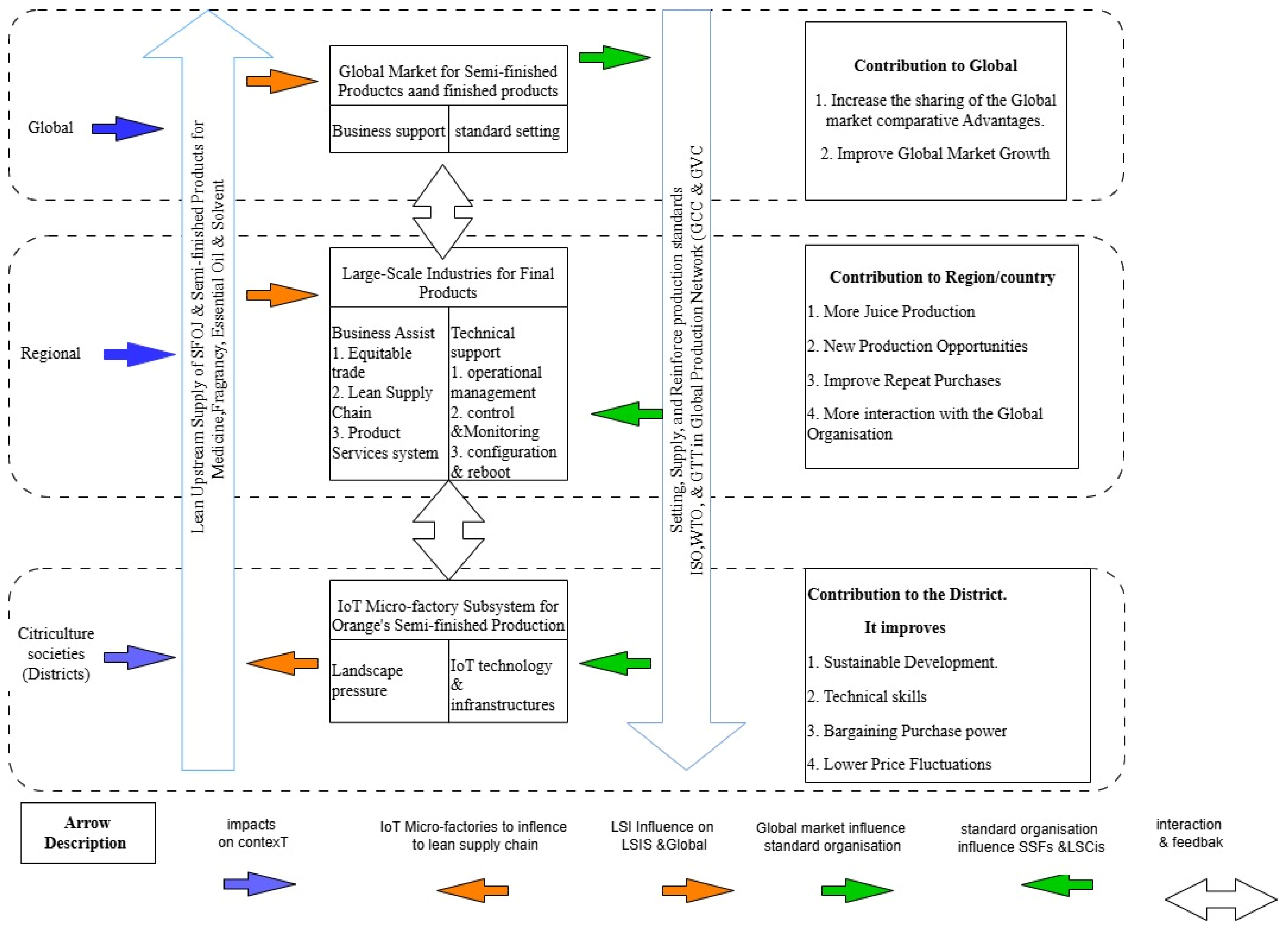

1.2. Theoretical Framework

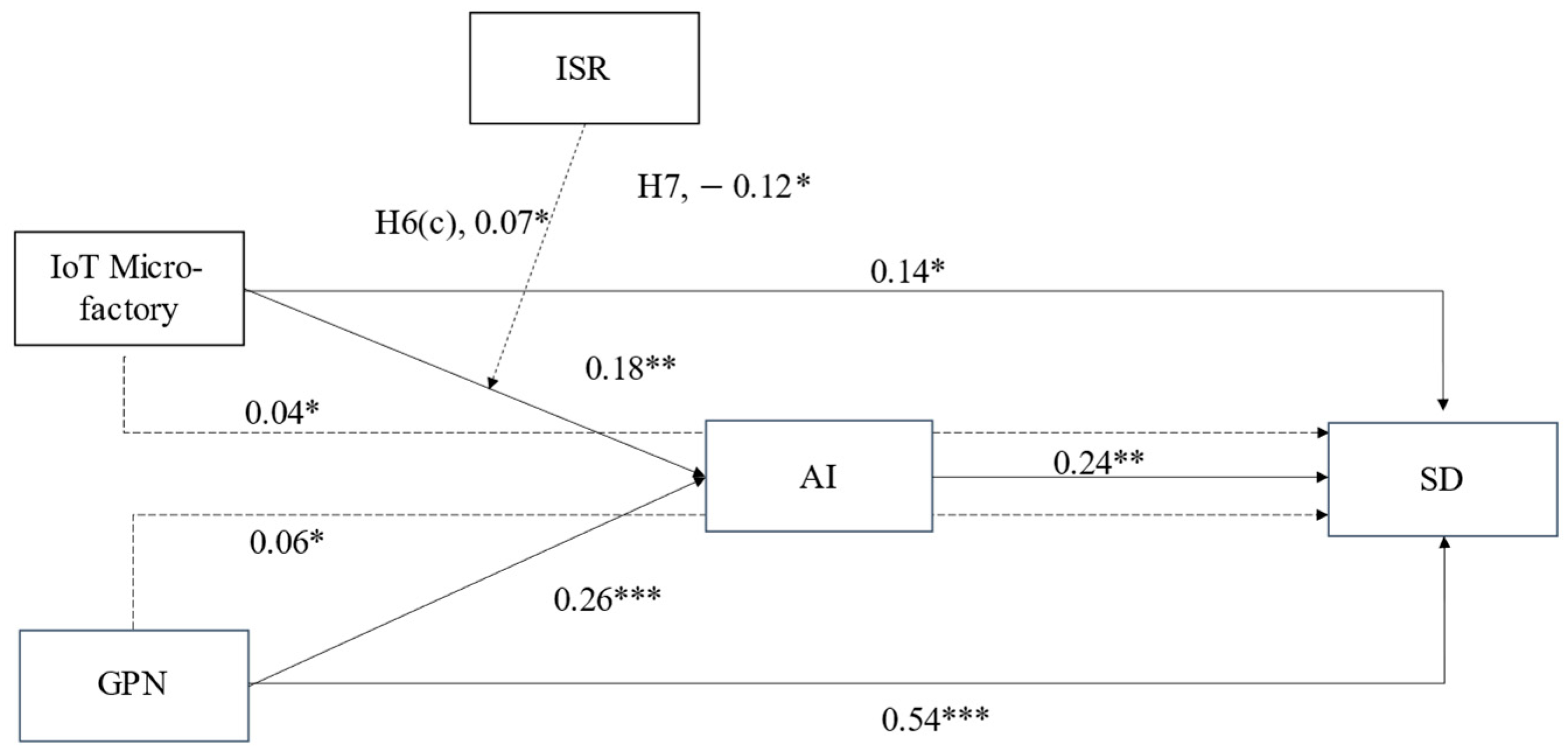

1.3. Development of Hypothesis

1.3.1. Sustainable Development Through IoT Micro-Factory Diffusion

1.3.2. Global Production Network

1.3.3. The Roles of Architectural Innovation in IoT Micro-Factory Era

1.3.4. Mediating Role of Architectural Innovation

1.3.5. Moderating Role of Industrial Symbiotic Relationship

2. Materials and Methods

2.1. Data Collection

Data Analysis

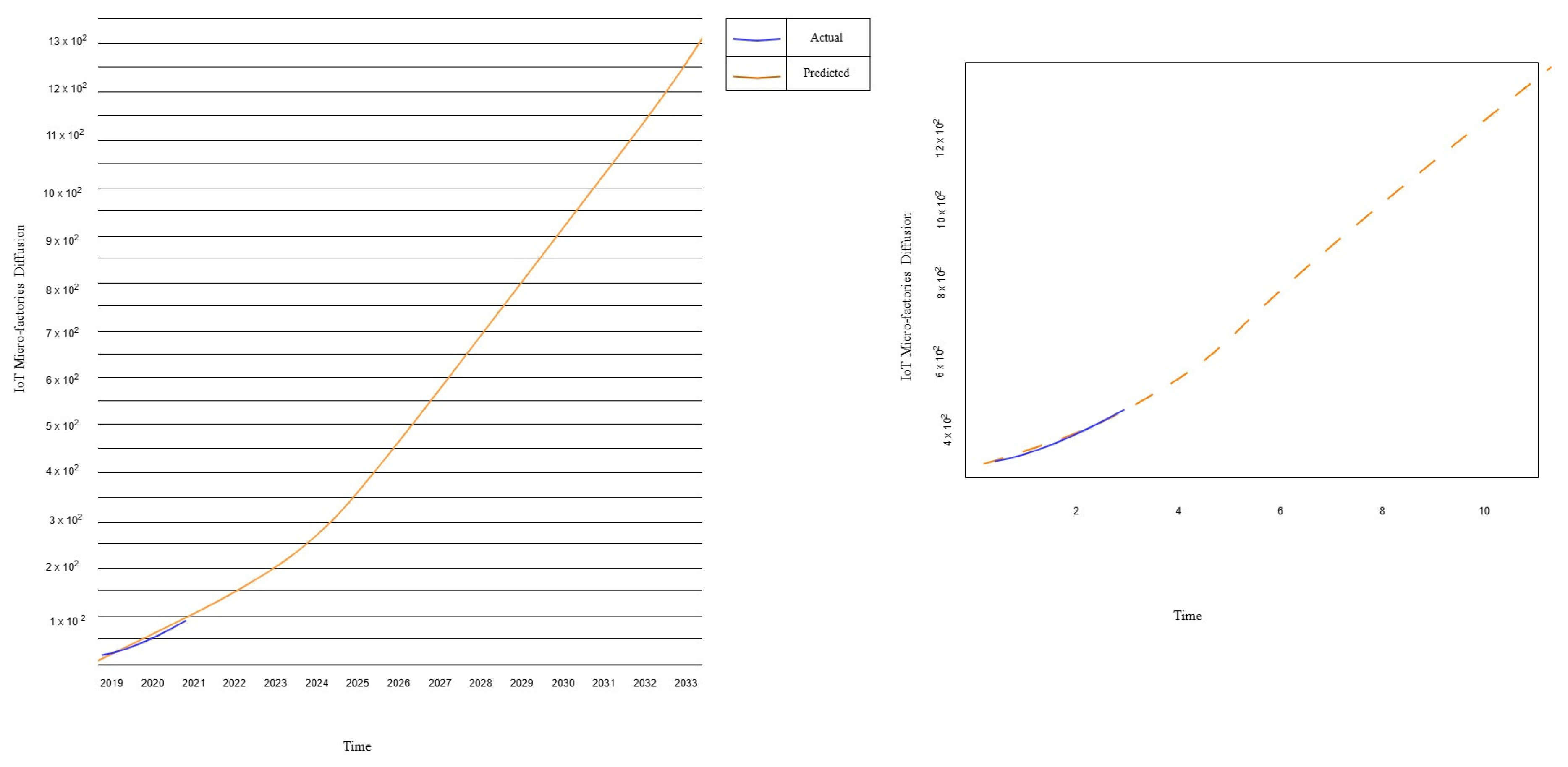

2.2. Diffusion of IoT Micro-Factories

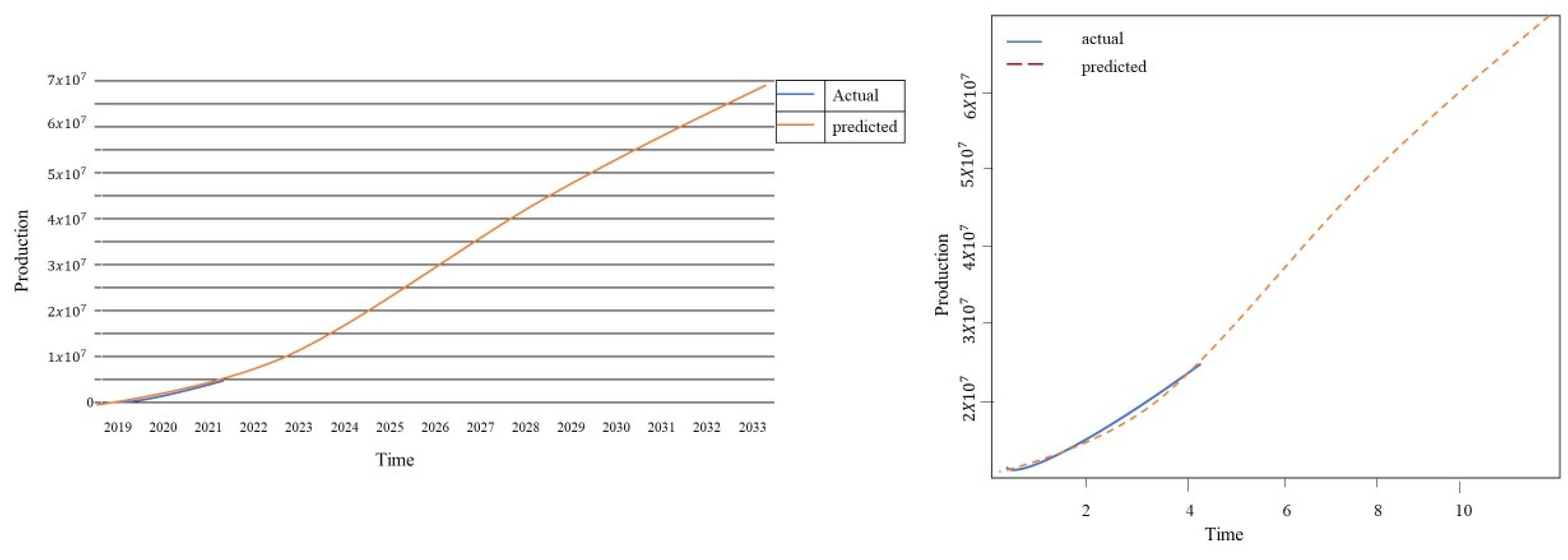

2.3. Diffusion of SFOJ (HS200919)

3. Results and Discussion

3.1. Descriptive Data Analysis

3.1.1. Measurement Model Assessment

3.1.2. Structural Model

3.2. Diffusion Estimation of IoT Micro-Factory and SFOJ Production

4. Conclusions

Author Contributions

Funding

Institution Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brooks, A.; Simon, D. Unravelling the Relationships between Used-Clothing Imports and the Decline of African Clothing Industries. Dev. Change 2012, 43, 1265–1290. [Google Scholar] [CrossRef]

- Ayetor, G.K.; Mbonigaba, I.; Sackey, M.N.; Andoh, P.Y. Vehicle regulations in Africa: Impact on used vehicle import and new vehicle sales. Transp. Res. Interdiscip. Perspect. 2021, 10, 100384. [Google Scholar] [CrossRef]

- Morris, M.; Fessehaie, J. The industrialisation challenge for Africa: Towards a commodities based industrialisation path. J. Afr. Trade 2014, 1, 25. [Google Scholar] [CrossRef]

- Mold, A. Running Up That Hill? The Challenges of Industrialization in the East African Community. Development 2015, 58, 577–586. [Google Scholar] [CrossRef]

- Pel, B.; Kemp, R. Between innovation and restoration; towards a critical-historicizing understanding of social innovation niches. Technol. Anal. Strateg. Manag. 2020, 32, 1182–1194. [Google Scholar] [CrossRef]

- Schot, J.; Kanger, L. Deep transitions: Emergence, acceleration, stabilization and directionality. Res. Policy 2018, 47, 1045–1059. [Google Scholar] [CrossRef]

- Markard, J.; Geels, F.W.; Raven, R. Challenges in the acceleration of sustainability transitions. Environ. Res. Lett. 2020, 15, 081001. [Google Scholar] [CrossRef]

- Trancossi, M.; Pascoa, J.; Mazzacurati, S. Sociotechnical design a review and future interdisciplinary perspectives involving thermodynamics in today’s societal contest. Int. Commun. Heat Mass Transf. 2021, 128, 105622. [Google Scholar] [CrossRef]

- Orellana-Palma, P.; Petzold, G.; Torres, N.; Aguilera, M. Elaboration of orange juice concentrate by vacuum-assisted block freeze concentration. J. Food Process Preserv. 2018, 42, e13438. [Google Scholar] [CrossRef]

- Keller, I.; Tukuitonga, C. The WHO/FAO Fruit and vegetable promotion initiative. Acta Hortic. 2007, 744, 27–37. [Google Scholar] [CrossRef]

- Petzold, G.; Orellana, P.; Moreno, J.; Valeria, P. Physicochemical Properties of Cryoconcentrated Orange Juice. Chem. Eng. Trans. 2019, 75, 37–42. [Google Scholar] [CrossRef]

- Chinnici, G. A Model of Circular Economy of Citrus Industry. Paper presented at the 19th SGEM International Multidisciplinary Scientific GeoConference EXPO Proceedings, Florence, Italy, 22–24 October 2019. [Google Scholar] [CrossRef]

- Uusikartano, J.; Saha, P.; Aarikka-Stenroos, L. The industrial symbiosis process as an interplay of public and private agency: Comparing two cases. J. Clean. Prod. 2022, 344, 130996. [Google Scholar] [CrossRef]

- Köhler, J.; Geels, F.W.; Kern, F.; Markard, J.; Onsongo, E.; Wieczorek, A.; Alkemade, F.; Avelino, F.; Bergek, A.; Boons, F.; et al. An agenda for sustainability transitions research: State of the art and future directions. Environ. Innov. Soc. Transit. 2019, 31, 1–32. [Google Scholar] [CrossRef]

- Meyer, K.E.; Li, C.; Schotter, A.P.J. Managing the MNE subsidiary: Advancing a multi-level and dynamic research agenda. J. Int. Bus. Stud. 2020, 51, 538–576. [Google Scholar] [CrossRef]

- El Bilali, H. Transition heuristic frameworks in research on agro-food sustainability transitions. Environ. Dev. Sustain. 2020, 22, 1693–1728. [Google Scholar] [CrossRef]

- Kanger, L.; Schot, J. Deep transitions: Theorizing the long-term patterns of socio-technical change. Environ. Innov. Soc. Transit. 2019, 32, 7–21. [Google Scholar] [CrossRef]

- Geels, F.W. Micro-foundations of the multi-level perspective on socio-technical transitions: Developing a multi-dimensional model of agency through crossovers between social constructivism, evolutionary economics and neo-institutional theory. Technol. Forecast. Soc. Change 2020, 152, 119894. [Google Scholar] [CrossRef]

- Geels, F.W. Socio-technical transitions to sustainability: A review of criticisms and elaborations of the Multi-Level Perspective. Curr. Opin. Environ. Sustain. 2019, 39, 187–201. [Google Scholar] [CrossRef]

- Franke, G.; Sarstedt, M. Heuristics versus statistics in discriminant validity testing: A comparison of four procedures. Internet Res. 2019, 29, 430–447. [Google Scholar] [CrossRef]

- Schlüter, L.; Mortensen, L.; Kørnøv, L. Industrial symbiosis emergence and network development through reproduction. J. Clean. Prod. 2020, 252, 119631. [Google Scholar] [CrossRef]

- Sullivan, K.; Thomas, S.; Rosano, M. Using industrial ecology and strategic management concepts to pursue the Sustainable Development Goals. J. Clean. Prod. 2018, 174, 237–246. [Google Scholar] [CrossRef]

- Saavedra, Y.M.B.; Iritani, D.R.; Pavan, A.L.R.; Ometto, A.R. Theoretical contribution of industrial ecology to circular economy. J. Clean. Prod. 2018, 170, 1514–1522. [Google Scholar] [CrossRef]

- Fussone, R.; Dominguez, R.; Cannella, S.; Framinan, J.M. Implications of implementing industrial symbiosis for supply chain dynamics. IFAC-Paper 2022, 55, 3118–3123. [Google Scholar] [CrossRef]

- Kobayashi, H.; Murata, H.; Fukushige, S. Connected lifecycle systems: A new perspective on industrial symbiosis. Procedia CIRP 2020, 90, 388–392. [Google Scholar] [CrossRef]

- Duan, Y.; Huang, L.; Luo, X.; Cheng, T.C.E.; Liu, H. The moderating effect of absorptive capacity on the technology search and innovation quality relationship in high-tech manufacturing firms. J. Eng. Technol. Manag. 2021, 62, 101656. [Google Scholar] [CrossRef]

- Cuevas-Vargas, H.; Cortés-Palacios, H.A.; Leana-Morales, C.; Huerta-Mascotte, E. Absorptive Capacity and Its Dual Effect on Technological Innovation: A Structural Equations Model Approach. Sustainability 2022, 14, 12740. [Google Scholar] [CrossRef]

- Fuenfschilling, L.; Binz, C. Global socio-technical regimes. Res. Policy 2018, 47, 735–749. [Google Scholar] [CrossRef]

- Peukert, S.; Hörger, M.; Lanza, G. Fostering robustness in production networks in an increasingly disruption-prone world. CIRP J. Manuf. Sci. Technol. 2023, 41, 413–429. [Google Scholar] [CrossRef]

- Kano, L.; Tsang, E.W.K.; Yeung, H.W. Global value chains: A review of the multi-disciplinary literature. J. Int. Bus. Stud. 2020, 51, 577–622. [Google Scholar] [CrossRef]

- Lanza, G.; Ferdows, K.; Kara, S.; Mourtzis, D.; Schuh, G.; Váncza, J.; Wang, L.; Wiendahl, H.-P. Global production networks: Design and operation. CIRP Ann. 2019, 68, 823–841. [Google Scholar] [CrossRef]

- Instytut Nauk Ekonomicznych PAN; Pietrewicz, L. Technology, Business Models and Competitive Advantage in the Age of Industry 4.0. Probl. Zarz. 2019, 17, 32–52. [Google Scholar] [CrossRef]

- Baldwin, C.Y.; Bogers, M.L.A.M.; Kapoor, R.; West, J. Focusing the ecosystem lens on innovation studies. Res. Policy 2024, 53, 104949. [Google Scholar] [CrossRef]

- Gomes, G.; Seman, L.O.; Berndt, A.C.; Bogoni, N. The role of entrepreneurial orientation, organizational learning capability and service innovation in organizational performance. Rev. Gestão 2022, 29, 39–54. [Google Scholar] [CrossRef]

- Peukert, S.; Lohmann, J.; Haefner, B.; Lanza, G. Towards Increasing Robustness in Global Production Networks by Means of an Integrated Disruption Management. Procedia CIRP 2020, 93, 706–711. [Google Scholar] [CrossRef]

- Magnusson, T.; Anderberg, S.; Dahlgren, S.; Svensson, N. Socio-technical scenarios and local practice—Assessing the future use of fossil-free alternatives in a regional energy and transport system. Transp. Res. Interdiscip. Perspect. 2020, 5, 100128. [Google Scholar] [CrossRef]

- Mortensen, L.; Kørnøv, L. Critical factors for industrial symbiosis emergence process. J. Clean. Prod. 2019, 212, 56–69. [Google Scholar] [CrossRef]

- Lennon, N.J. Balancing incremental and radical innovation through performance measurement and incentivization. J. High Technol. Manag. Res. 2022, 33, 100439. [Google Scholar] [CrossRef]

- Bygstad, B.; Øvrelid, E. Architectural alignment of process innovation and digital infrastructure in a high-tech hospital. Eur. J. Inf. Syst. 2020, 29, 220–237. [Google Scholar] [CrossRef]

- Mohi Ud Din, Q.; Zhang, L. Leadership impact on innovation: A sequential mediation of trust and safety. WORK A J. Prev. Assess. Rehabil. 2025, 10519815251321952. [Google Scholar] [CrossRef]

- Kim, H.; Park, C.; Lee, H. The Effect of Incremental Innovation and Switching-Over to Architectural Innovation on the Sustainable Performance of Firms: The Case of the NAND Flash Memory Industry. Sustainability 2019, 11, 7105. [Google Scholar] [CrossRef]

- Le Roy, F.; Bez, S.M.; Gast, J. Unpacking the management of Oligo-coopetition strategies in the absence of a moderating third party. Ind. Mark. Manag. 2021, 98, 125–137. [Google Scholar] [CrossRef]

- Skalli, D.; Charkaoui, A.; Cherrafi, A. Assessing interactions between Lean Six-Sigma, Circular Economy and industry 4.0: Toward an integrated perspective. IFAC-Paper 2022, 55, 3112–3117. [Google Scholar] [CrossRef]

- Lu, C.; Wang, S.; Wang, K.; Gao, Y.; Zhang, R. Uncovering the benefits of integrating industrial symbiosis and urban symbiosis targeting a resource-dependent city: A case study of Yongcheng, China. J. Clean. Prod. 2020, 255, 120210. [Google Scholar] [CrossRef]

- Henderson, R. Innovation in the 21st Century: Architectural Change, Purpose, and the Challenges of Our Time. Manag. Sci. 2021, 67, 5479–5488. [Google Scholar] [CrossRef]

- Park, W.-Y.; Ro, Y.K.; Kim, N. Architectural innovation and the emergence of a dominant design: The effects of strategic sourcing on performance. Res. Policy 2018, 47, 326–341. [Google Scholar] [CrossRef]

- Din, A.U.; Yang, Y.; Khan, M.I.M.; Khuram, W. Innovative Technological Solutions for Environmental Sustainability in Chinese Engineering Practices. Eng. Technol. Appl. Sci. Res. 2024, 14, 13648–13657. [Google Scholar] [CrossRef]

- Quy, V.K.; Chehri, A.; Quy, N.M.; Han, N.D.; Ban, N.T. Innovative Trends in the 6G Era: A Comprehensive Survey of Architecture, Applications, Technologies, and Challenges. IEEE Access 2023, 11, 39824–39844. [Google Scholar] [CrossRef]

- Wang, C.-H. How firms’ openness promotes radical innovation performance: The joint interaction effects of political ties and business ties. J. Eng. Technol. Manag. 2022, 66, 101705. [Google Scholar] [CrossRef]

- Doğan, H.; Nebioğlu, O.; Aydın, O.; Doğan, İ. Architectural Innovations are Competitive Advantage for Hotels in Tourism Industry?: What Customers, Managers and Employees Think about it? Procedia -Soc. Behav. Sci. 2013, 99, 701–710. [Google Scholar] [CrossRef]

- Jiménez-Castro, M.P.; Buller, L.S.; Sganzerla, W.G.; Forster-Carneiro, T. Bioenergy production from orange industrial waste: A case study. Biofuels Bioprod. Bioref. 2020, 14, 1239–1253. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Role of additive manufacturing applications towards environmental sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Knight, H.H.; De Angelis, R.; Telg, N.; Morgan, R.E. Towards the Coopetitive Circular Business Model: Theoretical foundations, conceptual envisioning, and future research imperatives. Ind. Mark. Manag. 2025, 124, 20–39. [Google Scholar] [CrossRef]

- Din, A.U.; Yang, Y.; Yan, R.; Wei, A.; Ali, M. Growing success with sustainability: The influence of green HRM, innovation, and competitive advantage on environmental performance in the manufacturing industry. Heliyon 2024, 10, e30855. [Google Scholar] [CrossRef]

- Liu, Z.; Sampaio, P.; Pishchulov, G.; Mehandjiev, N.; Cisneros-Cabrera, S.; Schirrmann, A.; Jiru, F.; Bnouhanna, N. The architectural design and implementation of a digital platform for Industry 4.0 SME collaboration. Comput. Ind. 2022, 138, 103623. [Google Scholar] [CrossRef]

- Santos, V.E.N.; Magrini, A. Biorefining and industrial symbiosis: A proposal for regional development in Brazil. J. Clean. Prod. 2018, 177, 19–33. [Google Scholar] [CrossRef]

- Herczeg, G.; Akkerman, R.; Hauschild, M.Z. Supply chain collaboration in industrial symbiosis networks. J. Clean. Prod. 2018, 171, 1058–1067. [Google Scholar] [CrossRef]

- Gernsheimer, O.; Kanbach, D.K.; Gast, J. Coopetition research—A systematic literature review on recent accomplishments and trajectories. Ind. Mark. Manag. 2021, 96, 113–134. [Google Scholar] [CrossRef]

- Dzhunushalieva, G.; Teuber, R. Roles of innovation in achieving the Sustainable Development Goals: A bibliometric analysis. J. Innov. Knowl. 2024, 9, 100472. [Google Scholar] [CrossRef]

- Inigo, E.A. Sustainable Innovation: Creating Solutions for Sustainable Development. In Decent Work and Economic Growth; Leal Filho, W., Azul, A.M., Brandli, L., Lange Salvia, A., Wall, T., Eds.; Encyclopedia of the UN Sustainable Development Goals; Springer International Publishing: Cham, Switzerland, 2021; pp. 996–1006. [Google Scholar] [CrossRef]

- Romero, D.; Larsson, L.; Rönnbäck, A.Ö.; Stahre, J. Strategizing for Production Innovation. In Advances in Production Management Systems. The Path to Intelligent, Collaborative and Sustainable Manufacturing; Lödding, H., Riedel, R., Thoben, K.-D., Von Cieminski, G., Kiritsis, D., Eds.; IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2017; Volume 513, pp. 3–12. [Google Scholar] [CrossRef]

- Xie, Q.; Gao, Y.; Xia, N.; Zhang, S.; Tao, G. Coopetition and organizational performance outcomes: A meta-analysis of the main and moderator effects. J. Bus. Res. 2023, 154, 113363. [Google Scholar] [CrossRef]

- Ghosh, A.; Kato, T.; Morita, H. Incremental innovation and competitive pressure in the presence of discrete innovation. J. Econ. Behav. Organ. 2017, 135, 1–14. [Google Scholar] [CrossRef]

- Qiao, N.; Niu, L. The Impact of the Industrial Innovation Ecosystem on Innovation Performance—Using the Equipment Manufacturing Industry as an Example. Systems 2024, 12, 578. [Google Scholar] [CrossRef]

- Granstrand, O.; Holgersson, M. Innovation ecosystems: A conceptual review and a new definition. Technovation 2020, 90–91, 102098. [Google Scholar] [CrossRef]

- Wang, B.; Gong, S.; Yang, Y. Innovation capability, global cooperation, and sustainable development along the Belt and Road Initiative. Sustain. Dev. 2023, 31, 3490–3512. [Google Scholar] [CrossRef]

- Mohi Ud Din, Q.; Zhang, L. Unveiling the Mechanisms through Which Leader Integrity Shapes Ethical Leadership Behavior: Theory of Planned Behavior Perspective. Behav. Sci. 2023, 13, 928. [Google Scholar] [CrossRef]

- Sharma, S.; Mudgal, S.; Thakur, K.; Gaur, R. How to calculate sample size for observational and experiential nursing research studies? Natl. J. Physiol. Pharm. Pharmacol. 2019, 10, 1–8. [Google Scholar] [CrossRef]

- Al-Ababneh, M.M. Linking Ontology, Epistemology And Research Methodology. Sci. Philos. 2020, 8, 75–91. [Google Scholar] [CrossRef]

- Sharma, S.K.; Mudgal, S.K.; Gaur, R.; Chaturvedi, J.; Rulaniya, S.; Sharma, P. Navigating Sample Size Estimation for Qualitative Research. J. Med. Evid. 2024, 5, 133–139. [Google Scholar] [CrossRef]

- Ma, Y.; Al Mamun, A.; Hoque, M.E.; Masukujjaman, M.; Ja’afar, R. Modeling behavioral insights to mobilize private investment in climate change adaptation: Evidence from Chinese investors. Environ. Dev. Sustain. 2025. [Google Scholar] [CrossRef]

- Walliman, N. Research Methods: The Basics; In the Basics; Routledge: London, UK; New York, NY, USA, 2011; ISBN 978-0-415-48991-1. [Google Scholar]

- Lim, H.; Jun, D.B.; Hamoudia, M. A choice-based diffusion model for multi-generation and multi-country data. Technol. Forecast. Soc. Change 2019, 147, 163–173. [Google Scholar] [CrossRef]

- Panagoulias, D.P.; Virvou, M.; Tsihrintzis, G.A. A novel framework for artificial intelligence explainability via the Technology Acceptance Model and Rapid Estimate of Adult Literacy in Medicine using machine learning. Expert Syst. Appl. 2024, 248, 123375. [Google Scholar] [CrossRef]

- Chien, C.-F.; Chen, Y.-J.; Peng, J.-T. Manufacturing intelligence for semiconductor demand forecast based on technology diffusion and product life cycle. Int. J. Prod. Econ. 2010, 128, 496–509. [Google Scholar] [CrossRef]

- Lotfi, A.; Jiang, Z.; Lotfi, A.; Jain, D.C. Estimating Life Cycle Sales of Technology Products with Frequent Repeat Purchases: A Fractional Calculus-Based Approach. Inf. Syst. Res. 2023, 34, 409–422. [Google Scholar] [CrossRef]

- Bhagat, R.; Muralidharan, S.; Lobzhanidze, A.; Vishwanath, S. Buy It Again: Modeling Repeat Purchase Recommendations. In Proceedings of the 24th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining, London, UK, 19–23 August 2018; ACM: London, UK, 2018; pp. 62–70. [Google Scholar] [CrossRef]

- Cheung, G.W.; Cooper-Thomas, H.D.; Lau, R.S.; Wang, L.C. Reporting reliability, convergent and discriminant validity with structural equation modeling: A review and best-practice recommendations. Asia Pac. J. Manag. 2024, 41, 745–783. [Google Scholar] [CrossRef]

- Mohi Ud Din, Q.; Tahir, A.; Xiaojuan, Y.; Alqahtani, S.; Gul, N. Ethical climate in higher education: The interplay of leadership, moral efficacy, and team cohesion in diverse cultural contexts. Acta Psychol. 2025, 255, 104986. [Google Scholar] [CrossRef]

- Rönkkö, M.; Cho, E. An Updated Guideline for Assessing Discriminant Validity. Organ. Res. Methods 2022, 25, 6–14. [Google Scholar] [CrossRef]

- Aburumman, O.J.; Omar, K.; Al Shbail, M.; Aldoghan, M. How to Deal with the Results of PLS-SEM? In Explore Business, Technology Opportunities and Challenges After the COVID-19 Pandemic; Alareeni, B., Hamdan, A., Eds.; Lecture Notes in Networks and Systems; Springer International Publishing: Cham, Switzerland, 2023; Volume 495, pp. 1196–1206. [Google Scholar] [CrossRef]

- Roemer, E.; Schuberth, F.; Henseler, J. HTMT2—An improved criterion for assessing discriminant validity in structural equation modeling. Ind. Manag. Data Syst. 2021, 121, 2637–2650. [Google Scholar] [CrossRef]

- Yaacob, N.A.; Ab Latif, Z.; Abdul Mutalib, A.; Ismail, Z. Farmers’ Intention in Applying Food Waste as Fertilizer: Reliability and Validity Using Smart-PLS. Asian J. Vocat. Educ. Humanit. 2021, 2, 27–34. [Google Scholar] [CrossRef]

- Atemoagbo, O.P. Confirmatory Factor Analysis on Climate Change Impact on Human Migration Patterns and Social Vulnerability. Int. J. Eng. Comput. Sci. 2024, 13, 26057–26068. [Google Scholar] [CrossRef]

- Hu, C.; Mohi Ud Din, Q.; Tahir, A. Artificial Intelligence Symbolic Leadership in Small and Medium-Sized Enterprises: Enhancing Employee Flexibility and Technology Adoption. Systems 2025, 13, 216. [Google Scholar] [CrossRef]

- Ali, Q.M.; Nisar, Q.A.; Abidin, R.Z.U.; Qammar, R.; Abbass, K. Greening the workforce in higher educational institutions: The pursuance of environmental performance. Environ. Sci. Pollut. Res. 2022, 30, 124474–124487. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, M.Y.; Dodgson, M.; Gann, D.; Cai, H. Seizing windows of opportunity by using technology-building and market-seeking strategies in tandem: Huawei’s sustained catch-up in the global market. Asia Pac. J. Manag. 2019, 36, 849–879. [Google Scholar] [CrossRef]

- Zhang, L. Internet of things vs. factory of things: An evaluation of evolving technologies for corporate sustainable development. Int. J. Electron. Bus. 2025, 20, 17–33. [Google Scholar] [CrossRef]

- Gosain, A.; Ray, S. Integration of Indian inventor networks in global value chains in pharmaceuticals industry. Innov. Dev. 2024, 1–20. [Google Scholar] [CrossRef]

- Satar, M.S.; Alenazy, A.; Alarifi, G.; Alharthi, S.; Omeish, F. Digital capabilities and green entrepreneurship in SMEs: The role of strategic agility. Innov. Dev. 2024, 1–30. [Google Scholar] [CrossRef]

- Maswood, S.J. Revisiting Globalization and the Rise of Global Production Networks; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Kavre, M.; Narwane, V.S.; Gardas, B.B.; Sunnapwar, V. Role of human factors in cloud manufacturing adoption across manufacturing micro, small and medium enterprises. Int. J. Comput. Integr. Manuf. 2023, 36, 611–633. [Google Scholar] [CrossRef]

- Yusof, N.; Kamal, E.M.; Lou, E.C.W.; Kamaruddeen, A.M. Effects of innovation capability on radical and incremental innovations and business performance relationships. J. Eng. Technol. Manag. 2023, 67, 101726. [Google Scholar] [CrossRef]

- Meissner, D.; Burton, N.; Galvin, P.; Sarpong, D.; Bach, N. Understanding cross border innovation activities: The linkages between innovation modes, product architecture and firm boundaries. J. Bus. Res. 2021, 128, 762–769. [Google Scholar] [CrossRef]

- López-Gamero, M.D.; Molina-Azorín, J.F.; Pereira-Moliner, J.; Pertusa-Ortega, E.M. Agility, innovation, environmental management and competitiveness in the hotel industry. Corp. Soc. Responsib. Environ. 2023, 30, 548–562. [Google Scholar] [CrossRef]

- Mourtzis, D. The mass personalization of global networks. In Design and Operation of Production Networks for Mass Personalization in the Era of Cloud Technology; Elsevier: London, UK, 2022; pp. 79–116. [Google Scholar] [CrossRef]

- Cecil, J.; Albuhamood, S.; Ramanathan, P.; Gupta, A. An Internet-of-Things (IoT) based cyber manufacturing framework for the assembly of microdevices. Int. J. Comput. Integr. Manuf. 2019, 32, 430–440. [Google Scholar] [CrossRef]

- Edquist, H.; Goodridge, P.; Haskel, J. The Internet of Things and economic growth in a panel of countries. Econ. Innov. New Technol. 2021, 30, 262–283. [Google Scholar] [CrossRef]

- Sui, L.; Mollick, A.V.; Wu, S. The effect of necessity and opportunity entrepreneurship and SME financing on sustainable development. Environ. Dev. Sustain. 2025. [Google Scholar] [CrossRef]

- Gao, J. R-Squared (R2)—How much variation is explained? Res. Methods Med. Health Sci. 2024, 5, 104–109. [Google Scholar] [CrossRef]

- Onyutha, C. A hydrological model skill score and revised R-squared. Hydrol. Res. 2022, 53, 51–64. [Google Scholar] [CrossRef]

- Borenstein, M. Avoiding common mistakes in meta-analysis: Understanding the distinct roles of Q, I-squared, tau-squared, and the prediction interval in reporting heterogeneity. Res. Synth. Methods 2024, 15, 354–368. [Google Scholar] [CrossRef] [PubMed]

- National Bureau of Statistics (NBS). National Demographic Socio Economic Profile; NBS: Dodoma, Tanzania, 2022.

| P | Items | Factor Loadings | Cronbach’s Alpha (CA) | CR | AVE | VIF |

|---|---|---|---|---|---|---|

| IoT micro-factory | IoT C | 0.85 | 0.762 | 0.767 | 0.679 | 1.897 |

| D. IoT | 0.858 | 1.824 | ||||

| IoT I | 0.761 | 1.319 | ||||

| ISR | TS | 0.843 | 0.789 | 0.794 | 0.703 | 1.794 |

| OS | 0.843 | 1.877 | ||||

| C & M | 0.828 | 1.48 | ||||

| AI | AI | 0.877 | 0.857 | 0.859 | 0.777 | 2.024 |

| TC | 0.876 | 2.192 | ||||

| R&D | 0.892 | 2.227 | ||||

| GPN | GVC | 0.878 | 0.835 | 0.835 | 0.751 | 2.035 |

| GCC | 0.866 | 1.981 | ||||

| GCA | 0.857 | 1.828 | ||||

| SD | ECONOMIC | 0.862 | 0.820 | 0.825 | 0.734 | 1.786 |

| SOCIAL | 0.839 | 1.746 | ||||

| ENVIRONM | 0.869 | 2.099 |

| Relationship | VIF |

|---|---|

| AI → SD | 1.691 |

| GPN → AI | 1.455 |

| GPN → SD | 1.532 |

| ISR → AI | 2.089 |

| IoT micro-factory → AI | 1.655 |

| IoT micro-factory → SD | 1.502 |

| ISR × IoT micro-factory → AI | 1.337 |

| Constructs | AI | GPN | ISR | IoT Micro-Factory | SD |

|---|---|---|---|---|---|

| AI | |||||

| GPN | 0.654 | ||||

| ISR | 0.765 | 0.643 | |||

| IoT micro-factory | 0.668 | 0.584 | 0.780 | ||

| SD | 0.731 | 0.884 | 0.735 | 0.655 | |

| ISR × IoT micro-factory | 0.474 | 0.314 | 0.562 | 0.358 | 0.432 |

| Hypothesis | Relationships | β | t | p | Results |

|---|---|---|---|---|---|

| Direct effects | |||||

| H1 | IoT micro-factory → SD | 0.136 | 2.077 | 0.038 | Supported |

| H2 | GPN → SD | 0.542 | 8.22 | 0.000 | Supported |

| H3 | IoT micro-factory → AI | 0.184 | 2.684 | 0.007 | Supported |

| H4 | GPN → AI | 0.261 | 3.919 | 0.000 | Supported |

| H5 | AI → SD | 0.241 | 3.163 | 0.002 | Supported |

| Mediating effects | |||||

| H6 (a) | IoT micro-factory → AI → SD | 0.044 | 2.162 | 0.031 | Supported |

| H6 (b) | GPN → AI → SD | 0.063 | 2.362 | 0.018 | Supported |

| H6 (c) | ISR → AI → SD | 0.075 | 2.451 | 0.014 | Supported |

| Modulating effects | |||||

| H7 | ISR × IoT micro-factory → AI | −0.117 | 2.289 | 0.022 | Supported |

| Constructs | Q2 | R2 |

|---|---|---|

| AI | 0.470 | 0.507 |

| SD | 0.592 | 0.620 |

| Diffusion Variables | P (Est) | P (t-Value) | P Sig: (p-Value) | Ϥ (Est) | ϥ (t-Value) | ϥ Sig: (p-Value) | Total Forecasted |

|---|---|---|---|---|---|---|---|

| IoT micro-factory | 0.016 | 6.84856 | 0.000 | 0.254 | 7.7167 | 0.000 | 1754 |

| SFOJ (HS200919) | 0.014 | 10.302 | 0.000 | 0.233 | 11.99 | 0.000 | 95,409,069 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chakumba, J.A.; Jin, J.; Kisanga, D.H. Leveraging IoT Micro-Factories for Equitable Trade: Enhancing Semi-Finished Orange Juice Value Chain in a Citriculture Society. Systems 2025, 13, 384. https://doi.org/10.3390/systems13050384

Chakumba JA, Jin J, Kisanga DH. Leveraging IoT Micro-Factories for Equitable Trade: Enhancing Semi-Finished Orange Juice Value Chain in a Citriculture Society. Systems. 2025; 13(5):384. https://doi.org/10.3390/systems13050384

Chicago/Turabian StyleChakumba, Joseph Andrew, Jiafei Jin, and Dalton Hebert Kisanga. 2025. "Leveraging IoT Micro-Factories for Equitable Trade: Enhancing Semi-Finished Orange Juice Value Chain in a Citriculture Society" Systems 13, no. 5: 384. https://doi.org/10.3390/systems13050384

APA StyleChakumba, J. A., Jin, J., & Kisanga, D. H. (2025). Leveraging IoT Micro-Factories for Equitable Trade: Enhancing Semi-Finished Orange Juice Value Chain in a Citriculture Society. Systems, 13(5), 384. https://doi.org/10.3390/systems13050384