1. Introduction

As competition within global value chains intensifies, the role and strengthening of competitiveness of SMEs are becoming increasingly important for national economic development. The economic crisis caused by COVID-19 represents both a threat to survival and an opportunity for innovation and growth for SMEs. In this dynamic environment, technological innovation capability is emerging as a key factor for enhancing SMEs’ resilience in crisis [

1] and sustainable growth. Previous research suggests dynamic capabilities and technology-based innovation capabilities as methods to mitigate economic crises [

2], and for SMEs to overcome economic crises in the global competitive environment, the systematic development of technological innovation capabilities is essential, along with organizational and operational innovation [

3]. Particularly in today’s business environment characterized by high uncertainty, advanced technological innovation approaches such as digital transformation have a decisive impact on reducing uncertainty for SMEs and ascending global value chains, establishing the foundation for long-term competitive advantage [

4].

While the extant literature has predominantly focused on analyzing the relationship between technological innovation and competitiveness in large corporations, research considering the unique characteristics of SMEs has been relatively scarce. Moreover, there is a paucity of systematic studies examining the relationship between SMEs’ positional changes within GVCs and their innovation activities. This study aims to address these research gaps by empirically analyzing the relationships among innovation routines, value chain upgrading, and global competitiveness in the context of Korean SMEs.

The originality of this research can be discerned in three key aspects. First, whereas previous studies have primarily concentrated on innovation outcomes, this study introduces the concept of ‘innovation routines’, focusing on the everyday innovation activities of SMEs and their systematization processes. Second, by operationalizing positional changes in GVCs as ‘value chain upgrading’, we provide a concrete analysis of how innovation activities influence a firm’s global standing. Third, by comprehensively examining the relationships among innovation routines, value chain upgrading, and global competitiveness within the specific context of Korean SMEs, we offer novel insights into SME development strategies in emerging markets.

This study conducts an empirical analysis based on a survey of 131 small- and medium-sized manufacturing enterprises located in Korea’s representative industrial clusters. Our findings elucidate the impact of innovation routine systematization on product development routines and manufacturing routines, the influence of these routines on value chain upgrading, and ultimately, their effect on enhancing firms’ global competitiveness.

Our research contributes to the academic literature by offering a new perspective to the fields of innovation management and global value chain research. From a practical standpoint, it provides valuable implications for SME managers and policymakers. Specifically, this study’s significance lies in presenting actionable guidelines on how SMEs can systematize their daily innovation activities and thereby elevate their position within global value chains.

The dynamic capabilities view [

5,

6,

7,

8] and the routines-based perspective [

9,

10] provide the theoretical underpinnings for our research. By integrating these frameworks with the concept of GVC upgrading [

11], we develop a novel theoretical model that explicates the mechanisms through which innovation routines drive value chain upgrading and competitiveness enhancement in SMEs.

Our study responds to recent calls in the literature for a more nuanced understanding of innovation processes in SMEs [

12,

13,

14] and the role of routines in shaping organizational capabilities [

10,

15,

16,

17]. Furthermore, by focusing on the Korean context, we contribute to the growing body of literature on innovation in emerging economies.

The subsequent sections of this paper review relevant theories and prior research, present our research model and hypotheses, discuss the empirical analysis results, and elaborate on their implications for theory and practice.

2. Theoretical Background

This study primarily discusses theories related to technological innovation capabilities, value chain upgrading, and competitive advantage enhancement.

2.1. Technological Innovation Capability and Routines

According to Zahra and George, routines are defined as the “process through which firms acquire, assimilate, transform, and exploit knowledge”, suggesting that routines act as a primary source of dynamism and innovation [

18]. From this perspective, numerous preceding studies assert that organizations modify or create routines to adapt to organizational and environmental changes or to respond to uncertainties [

19,

20,

21]. Consequently, routines that possess the ability to swiftly respond to environmental changes can be deemed as essential elements in achieving competitive performance [

5].

Furthermore, Peng et al. classified routines from an operational management perspective into ‘operational routines’ related to the enhancement of current performance and ‘exploratory routines’ related to the improvement of future performance [

22]. They argued that innovation performance could be achieved in the manufacturing industry through the utilization of these routines. These research findings underscore the importance of routines and provide a profound understanding of how they contribute to a firm’s innovation and performance.

Particularly in the context of SMEs, the development and utilization of effective routines become even more crucial due to limited resources. In this study, we conceptualize the technological innovation systematization routine as a form of exploratory routine, and product development and manufacturing routines as forms of operational routines. This reflects the dual challenge faced by SMEs in pursuing innovation while maintaining operational efficiency in their daily activities.

Innovation is an important factor in explaining South Korea’s economic growth, and it is closely related to technology, which has a variety of effects on technological progress and the way goods are supplied. Technological innovation capability is the ability to respond quickly to changes in the environment, which is essential to enhance a firm’s competitiveness [

5,

23,

24]. Especially in the current era of intense global competition, it is essential for firms to continuously invest in technological innovation to develop new products or services to ensure their survival and competitiveness. In resource-poor countries such as Korea, developing high-value-added products or services through technological innovation is an important means of gaining a competitive advantage. In addition, technological innovation can play an important role in reshaping markets that are currently dominated by developed firms and gaining a competitive advantage [

25].

Technological innovation can be most effective when it combines closed innovation, which is based on the company’s own capabilities, and open innovation, which values cooperation from various external sources. In the past, the innovation capacity within a company was considered important. However, recently, it has become important to explore and acquire knowledge or technology related to innovation in the industrial communities surrounding the company [

26].

Therefore, companies aiming for successful innovation should possess operational routines that can continuously improve their current products and processes, as well as technological innovation systematization routines that can organize knowledge resources inside and outside the company that can bring innovation to their products and processes. In other words, companies should explore and collect technological innovation inside and outside, systematize it, and be able to apply the results to the improvement of their product development and manufacturing technology. Only then can they be said to possess technological innovation capabilities.

Based on this discussion, the researchers propose the following hypotheses:

Hypothesis H1. A company’s technological innovation systematization routine has a positive impact on the company’s operational routines.

Hypothesis H1-1. The technological innovation systematization routine has a positive impact on the product development routine.

Hypothesis H1-2. The technological innovation systematization routine has a positive impact on the manufacturing routine.

2.2. Technological Innovation Capabilities and Value Chain Upgrading

According to prior research [

27], value chain upgrading primarily occurs through four pathways: process upgrading, product upgrading, functional upgrading, and inter-sectoral upgrading. Among these, enterprises typically pursue product and process upgrading, as proposed by Fernandez-Stark and Gereffi [

28].

Product upgrading aims to transform into a higher value-added product within the same value chain. Product development upgrading requires product development capabilities, which often require close collaboration between R&D, engineering, and manufacturing, and is achieved through process improvements such as process modifications or completely new production methods in addition to product development [

29,

30,

31].

Process upgrading refers to the enhancement of a company’s manufacturing capabilities to improve technical efficiency and productivity, enabling it to produce existing products more efficiently [

14]. Reichstein and Salter argue that companies that successfully implement process changes make product functions or designs more feasible [

32], and Damanpour and Gopalakrishnan also argue that early investment in processes helps lay the foundation for subsequent product innovation [

33].

Particularly for small- and medium-sized manufacturing enterprises, which primarily supply parts rather than final products in the GVC supply chain, the primary goal is to produce better parts through more efficient processes. Achieving this goal requires Innovation capabilities for VC upgrading, including the ability to develop new products and new processes.

In light of this context, this study posits the following hypotheses:

Hypothesis H2. An enterprise’s operational routines positively impact its value chain upgrading.

Hypothesis H2-1. Product development routines positively impact an enterprise’s product upgrading.

Hypothesis H2-2. Product development routines have a positive effect on the company’s process upgrades.

Hypothesis H2-3. Manufacturing routines have a positive effect on a company’s product upgrading.

Hypothesis H2-4. Manufacturing routines positively impact an enterprise’s process upgrading.

2.3. Value Chain Upgrading and Competitive Advantage Enhancement

In the context of business, it is imperative for a company to maintain a competitive edge over its rivals. This can be achieved through product upgrades, which enhance the novelty and quality of the company’s offerings. From a Global Value Chain (GVC) perspective, a product upgrade signifies the occurrence of product innovation. Through product innovation, a company can differentiate itself in the market and provide new products or services, thereby garnering customer satisfaction. Consequently, product improvements and the development of new products that satisfy customers can be defined as product innovation or product upgrades [

34,

35].

Moreover, demonstrating superiority over competitors in terms of process implies that a process upgrade has been achieved through process innovation. A process upgrade refers to the development of a better manufacturing or service process than the current one, enabling the company to achieve improved results. This new process, which reduces the company’s management costs and enables greater production, can be seen as the outcome of technological innovation [

34,

35].

To survive in a fiercely competitive environment, companies must secure a competitive advantage. Essentially, a competitive advantage refers to the ‘value’ that a company can generate for buyers beyond its costs. This superior value is created by offering equal benefits to buyers at a lower price, or by providing unique benefits that offset a higher price [

36]. This strategy involves occupying a better position in the market by providing more economic value to customers than competitors. Therefore, a competitive advantage begins with efforts to differentiate oneself from competitors, and the differences between oneself and competitors form the basis for gaining an advantage. The areas that show differences between oneself and competitors can occur in various aspects such as product innovation, process improvement, organizational capability enhancement, and supply chain optimization, and these innovative efforts are manifested in outcomes such as quality improvement, cost reduction, and enhanced price competitiveness. In particular, Min emphasizes that supply chain innovation is a key element in mitigating crises during supply chain threats such as economic downturns, and this plays a decisive role in helping SMEs overcome economic uncertainty and strengthen their global competitiveness [

37].

As can be seen from the approach of ‘profiting from innovation’, innovators can reap benefits as pioneers. This implies a positive correlation between innovation and competitive advantage [

38]. Therefore, researchers have set the following hypotheses:

Hypothesis H3. Value chain upgrading has a positive impact on enhancing competitiveness.

Hypothesis H3-1. Product upgrading has a positive impact on enhancing a company’s competitiveness.

Hypothesis H3-2. Process upgrading has a positive impact on enhancing a company’s competitiveness.

Based on this theoretical background and hypotheses, this study aims to empirically analyze the process by which SMEs’ technological innovation routines lead to competitive advantage enhancement through value chain upgrading. Specifically, we will comprehensively examine the impact of technological innovation systematization routines on product development and manufacturing routines, the influence of these routines on value chain upgrading (product and process upgrading), and ultimately, how this upgrading affects the enhancement of a company’s competitiveness.

3. Research Methods

3.1. Characteristics of the Sample

This study conducted a survey targeting small- and medium-sized manufacturing enterprises located in representative industrial clusters in South Korea. In the Korean context, SMEs are defined as companies with total assets below 500 billion KRW (approximately 375 million USD) and average annual sales below 40 billion KRW (approximately 30 million USD). For our research, we selected sample companies from industrial clusters in the Seoul-Gyeonggi region, Changwon, and the Busan-Ulsan regions. These areas serve as core regions driving manufacturing innovation in Korea and feature high concentrations of companies across diverse industrial sectors, making them particularly suitable locations for examining trends in technological innovation and value chain upgrading.

The main reasons for selecting companies located in these clusters as research subjects are as follows:

Technological Innovation Capability: Companies in these regions generally possess sufficient technological innovation capabilities, making them suitable for examining the study’s themes of technological innovation routines and value chain upgrading.

Economic Importance: The selected companies record high average sales, occupying important positions in the Korean economy. This contributes to enhancing the economic implications of the study’s results.

Diversity: The selected clusters encompass various manufacturing sectors, increasing the generalizability of the research findings.

The survey was conducted from 12 August 2023 to 20 September 2023, targeting CEOs or senior managers of each company. A total of 131 valid responses were collected, with 55 companies participating from the Seoul-Gyeonggi region, 40 from Changwon, and 36 from the Busan-Ulsan region.

Examining the characteristics of the respondents, the gender distribution was 103 males (78.6%) and 28 females (21.4%). The educational background distribution was 25 graduate school graduates (19.1%), 85 university graduates (64.9%), 15 junior college graduates (11.5%), and 6 high school graduates and others (4.6%).

Through this sample selection and analysis method, this study aimed to reliably analyze the relationships among technological innovation capabilities, value chain upgrading, and competitiveness enhancement in Korean small- and medium-sized manufacturing enterprises.

The characteristics of each company are presented in

Table 1.

3.2. Development of Research Models

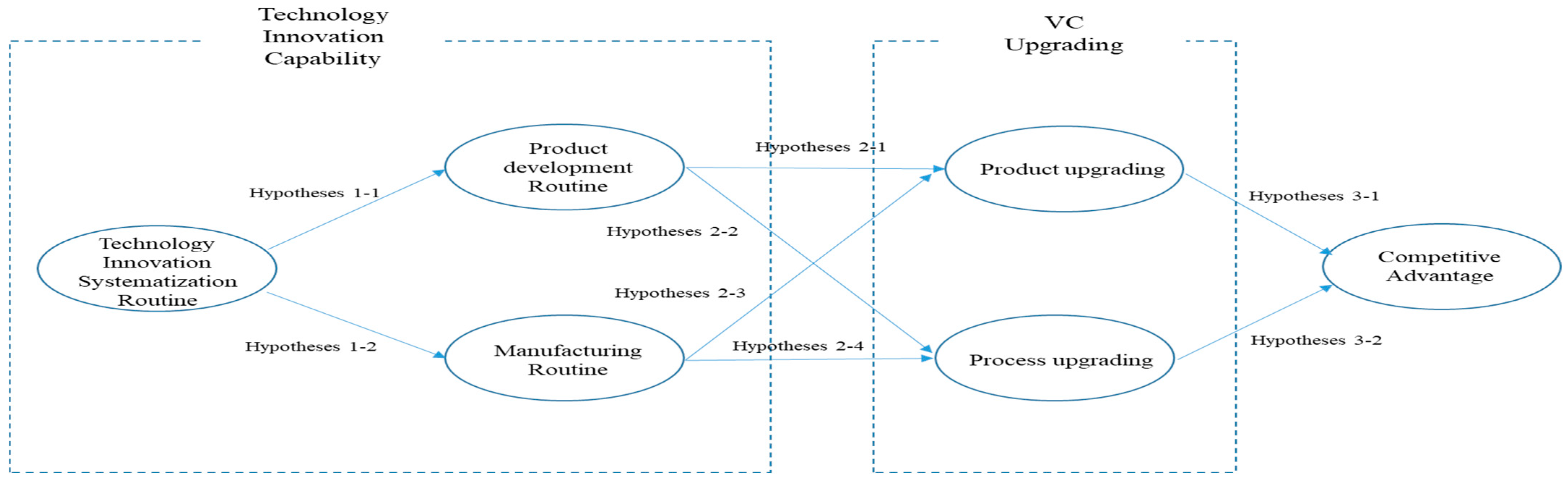

The model for this study is designed to explore the relationships among technological innovation capabilities, value chain upgrading, and competitive advantage enhancement in SMEs. In this model, technological innovation capabilities consist of technological innovation systematization routines (TISRs), product development routines (PDRs), and manufacturing routines (MRs). Value chain upgrading includes product upgrading and process upgrading.

The model proposed in this study presents the following:

First, technological innovation capabilities are composed of exploratory routines (technological innovation systematization routines) and operational routines (product development routines, manufacturing routines), with exploratory routines positively influencing operational routines (H1-1, H1-2).

Second, value chain upgrading is divided into product upgrading (PDU) and process upgrading (PCU), with operational routines positively impacting value chain upgrading (H2-1, H2-2).

Lastly, value chain upgrading positively influences the enhancement of a firm’s competitive advantage (H3-1, H3-2).

This research model comprehensively illustrates how technological innovation capabilities ultimately strengthen a firm’s competitive advantage through value chain upgrading. Specifically, it systematically analyzes the impact of technological innovation systematization routines on product development routines and manufacturing routines, the influence of these routines on product upgrading and process upgrading, respectively, and finally, how these upgrades affect the enhancement of a company’s competitiveness. This will contribute to a deeper understanding of the relationship between innovation activities and performance in SMEs.

Figure 1 provides a schematic representation of the conceptual model and hypotheses of this study.

3.3. Operational Definitions and Measurements

This study utilizes research concepts such as TISR, product development routines, manufacturing routines, product upgrading, process upgrading, and competitive advantage. All measurement items were assessed using a 7-point Likert scale (1 = strongly disagree; 7 = strongly agree).

TISR is defined as “the execution of systematic procedures that improve existing operational routines or develop new ones” [

5,

22,

39,

40,

41]. The measurement items were modified and supplemented by the researcher based on those presented by Lee [

42]. Specific items include the clarity of goals and resource procurement methods for technology development, the degree of establishment and utilization of tight networks with external institutions, efficient use of resources, systematic project management, and systematic storage and utilization of technology development results.

Product development routines refer to “the series of processes from product design, preparation for market introduction, to mass production and sales of new products”. The survey items were modified and supplemented by the researcher based on the items presented by Zhang et al. [

43]. Detailed items include the degree of standardization of the process for new product development, the excellence of the product design system owned by the company in the same industry, the possession of core technologies related to product development, and the ability to effectively utilize possessed technologies.

Manufacturing routines are defined as “the ability to improve productivity by constructing and operating production facilities to convert the results of technology development into products demanded in the market”. Manufacturing capabilities enable on-time delivery, unique service provision, and cost efficiency in complex and dynamic networks [

44,

45]. Therefore, manufacturing capabilities are considered valuable resources in competition [

46]. The survey measuring manufacturing capabilities in this study consists of the excellence of the production management system, efficient placement and operation of production facilities, appropriate management of suitable production facilities, and systematic quality management activities.

GVC upgrading refers to “the creation of new products or services, the development of new production process technologies, advancement to new stages, and entry into new industries”. However, since there are not many companies that carry out functional upgrading or industry transition in the case of small- and medium-sized manufacturing companies, which are the subjects of this study, this study defined product upgrading and process upgrading as sub-factors of GVC upgrading. The detailed items of GVC upgrading in this study were modified and supplemented by the researcher based on the items presented by Guifu and Hongjia [

47] as well as Jung and Oh [

34].

Competitive advantage as a result of GVC upgrading is based on measures proposed in studies by Chen et al., Wu et al., Li and Liu, Wongsansukcharoen and Thaweepaiboonwong, and others, including cost–quality performance, price competitiveness, rapid new product introduction capability, and access to new technologies or intellectual property rights [

48,

49,

50,

51].

4. Analysis Results

In this study, SmartPLS 4.0 was used for path analysis and confirmatory factor analysis, while Jamovi 2.6.19 was utilized for basic statistical analysis and factor analysis.

4.1. Evaluation of Measurement Models

This study utilized a sample of 131 firms, which surpasses the minimum required sample size as determined through statistical power analysis [

52], confirming that the statistical power of our study is satisfactory.

To mitigate the risk of common method bias, we first conducted an extensive literature review to develop concise and clear survey items, which were subsequently refined through pre-tests with corporate managers. During data analysis, we employed the full collinearity assessment approach [

53] to examine potential common method bias. The resulting Variance Inflation Factor (VIF) values ranged from 2.101 to 2.395, all below the critical threshold of 3.3, indicating no significant concerns for further analysis.

The measurement model was evaluated through several validity and reliability tests. First, convergent validity was verified by examining factor loadings (>0.6) and t-values (>1.96) [

54]. As can be seen in

Table 2, all measurement variables met these criteria, establishing adequate convergent validity. Additionally, composite reliability and average variance extracted (AVE) were calculated to assess measurement reliability. As shown in

Table 3, all constructs exceeded the recommended thresholds, confirming the high reliability of our measurements.

Next, discriminant validity was evaluated using the Fornell–Larcker criterion through a two-step approach. Initially, correlation analysis examined the relationships between variables in our research model, confirming both the directionality and strength of relationships.

Table 3 shows that all measured constructs demonstrated statistically significant positive correlations, aligning with our hypothesized directions. Subsequently, following the Fornell–Larcker procedure, we compared the square root of each construct’s AVE with its correlations with other constructs. Results confirmed that for each construct, the square root of AVE exceeded its correlation with any other construct, thereby establishing discriminant validity.

We further verified discriminant validity using the Heterotrait–Monotrait (HTMT) ratio. As shown in

Table 4 (bold values), while some values exceeded the strict HTMT 0.85 criterion, all values remained below the more commonly accepted 0.90 threshold, providing additional support for discriminant validity.

Based on these comprehensive analyses, we can conclude that the measurement model proposed in this study demonstrates satisfactory validity and reliability for hypothesis testing.

4.2. Evaluation of Structural Models

In this study, we evaluated the validity of the structural model using the PLS structural equation. For this, we used three key evaluation indicators: R

2, the significance of the causal relationship of the structural model, and multicollinearity. The analysis results are shown in

Figure 2.

Firstly, the R2 value of the model presented in this study ranged from 0.355 to 0.653. In PLS, it is judged that the higher the R2 value, the better the fit of the model. Therefore, the model presented in this study was deemed very suitable.

Secondly, we confirmed the significance of the causal relationship of the structural model in this study. At this time, it was important to confirm the relevance of the significant relationship. While extant literature has predominantly focused on statistical significance testing, the PLS structural equation modeling approach emphasizes that both the magnitude of path coefficients and their statistical significance are crucial for meaningful interpretation of results. As a result of the analysis of the research model presented in this study, the significant path coefficients ranged from 0.237 to 0.808, confirming that there was no problem in interpreting the relationship between each concept.

Thirdly, the appropriate criterion for multicollinearity was set to be less than 5. The VIF of the predictive constructs of the structural model presented in this study ranged from 1.000 to 2.666, confirming that multicollinearity was not a problem.

This study aims to verify three main contents through the proposed research model.

Firstly, it explores the relationship between value chain sophistication and competitive advantage. The analysis results indicate that product upgrading capabilities significantly influence corporate competitiveness (β = 0.237, t-value: 2.767). Furthermore, process upgrading capabilities also significantly influence corporate competitiveness (β = 0.582, t-value: 7.724). As suggested by previous studies, companies that develop new processes or quickly launch new products gain the advantage of being leaders. Particularly, if global competition continues in the future, the development of new products and processes is expected to significantly influence corporate survival.

Secondly, this study confirms the relationship between the technological innovation capabilities of small- and medium-sized manufacturing companies and value chain upgrades. Companies are making various efforts to gain an advantage in competition. Among them, efforts to pursue change and innovation for various product development and process improvement capabilities are major. In this study, it was assumed that technological innovation capability is an essential requirement for value chain upgrading, and the relationship between these two factors was analyzed. The empirical findings revealed that product development routine, a key dimension of technological innovation capability, exhibited a strong positive relationship with both product upgrading (β = 0.622, t-value: 5.494) and process upgrading (β = 0.360, t-value: 3.285). While manufacturing routine demonstrated a significant positive effect on process upgrading (β = 0.404, t = 3.779), its relationship with product upgrading was not statistically significant.

Lastly, this study confirms the relationship between the three sub-components of technological innovation capability: exploration routine, product development routine, and manufacturing routine. In this study, the relationship between them was analyzed on the assumption that the exploration routine has a positive influence on the product development routine and the manufacturing routine. As a result of the analysis, it was found that the exploration routine of technological innovation has a very strong positive influence on both the product development routine (β = 0.808, t-value: 22.635) and the manufacturing routine (β = 0.761, t-value: 17.712) (as shown in

Table 5).

4.3. Discussion of Research Results

This empirical study on Korean small- and medium-sized manufacturing enterprises has yielded several significant findings.

First, the analysis of the relationships among the sub-concepts of technological innovation capabilities revealed that the routine of systemizing technological innovation has a strong positive effect on both product development routines and manufacturing routines, indicating that systematic efforts to acquire, organize, and distribute relevant knowledge help Korean SMEs to enhance their product development and manufacturing routines.

These findings provide new insights into SME innovation strategies. The importance of systematizing technological innovation routines shows that SMEs can conduct effective innovation activities despite limited resources. Unlike large firms, SMEs struggle to perform all innovation activities internally, so exploring and utilizing external knowledge can be an important strategy. The results of this study provide new insights into how resource-based theory [

46] and dynamic capabilities theory [

5] apply in the SME context. In particular, we show that technological innovation systemization routines can be an important resource and capability for SMEs. This suggests that SMEs may be able to formulate and execute effective innovation strategies with limited resources. Furthermore, our findings suggest that the development of robust innovation routines serves as an important mechanism for SMEs to weather unprecedented disruptions such as COVID-19 in their global value chains. A systematic approach to technological innovation is consistent with recent frameworks that emphasize the importance of adaptive capacity in crisis situations [

2,

24]

Second, the impact of product development routines and manufacturing routines on value chain upgrades yielded some rather interesting results. The relationships between product development routines, product upgrades, manufacturing routines, and process upgrades were naturally assumed to be positive, and the expected results were presented. However, for product development routines and process upgrades, a strong positive relationship was presented, suggesting that design and R&D-related know-how can lead to manufacturing improvements (e.g., equipment configuration and quality control) when product specifications and performance expectations are clarified through product development routines. For manufacturing routines and product upgrades, we found no significant results. This may be because manufacturing routines (e.g., cost efficiency, process control, or production scheduling) are primarily concerned with how to make products, not what to make. This non-significant relationship likely reflects the characteristics of Korean SMEs, which typically manufacture according to product specifications determined and designed by large corporations, thus limiting SMEs’ influence on product upgrades. When product specification and design are primarily driven by external entities or separate R&D teams, manufacturing expertise alone may not contribute significantly to higher levels of product upgrade.

Third, both product and process upgrades have been shown to have a strong impact on a firm’s competitiveness. Product upgrades increase differentiation and customer appeal, while process upgrades create efficiencies. Both of these are necessary for SMEs to succeed in a global value chain (GVC) context. In this study, we find that process upgrades have a greater impact on competitiveness than product upgrades. This relative importance of process upgrades reflects the unique situation of Korean manufacturing SMEs. Many Korean SMEs function as subcontractors to larger firms, and in this context, efficiency gains through process innovation can lead to short-term competitiveness gains over product innovation. However, a balanced investment in product innovation should be maintained over the long term.

5. Conclusions

5.1. Summary

By analyzing the interconnected routines of technological innovation systematization, product development, and manufacturing, this study clarifies how SMEs can achieve both product and process upgrading, thus strengthening their competitive position within global value chains. The most important finding is that product development routines directly facilitate process upgrades as well as product upgrades, while manufacturing routines significantly improve process efficiency but do not enhance product upgrades. These nuanced findings provide insights into how Korean SMEs, often acting as specialized suppliers, can balance short-term process gains with more strategic, long-term product innovations.

Ultimately, a strong technological innovation systematization routine is the foundation that enables SMEs to connect external knowledge with internal capabilities, so managers should prioritize an integrated approach that links product design insights to manufacturing execution to ensure a consistent path to competitiveness. Contributing to the literature on GVC upgrading and dynamic capabilities, this study emphasizes that different innovation routines play distinct yet complementary roles. This is an important insight for SMEs striving to move up the value chain in an increasingly competitive global environment.

5.2. Theoretical Implications

This study extends the theoretical understanding of technological innovation and value chain upgrading in SMEs in several ways:

First, Dynamic Capabilities and Routines:

The strong influence of technological innovation systematization on product development routines reinforces the role of exploratory routines in fueling operational capabilities. In line with dynamic capabilities theory [

5], this underscores how SMEs can systematically scan external knowledge sources, assimilate that knowledge, and then translate it into effective R&D or new-product initiatives.

Second, Product Development as a Catalyst for Manufacturing:

The significant path from product development routine to manufacturing routine underscores a previously underexamined linkage—where robust product development processes provide a foundation for efficient manufacturing. Rather than viewing these routines as isolated silos, this result suggests a need for integrated cross-functional collaboration, aligning R&D insights with factory-floor implementation.

Third, the Nuanced Role of Manufacturing Capability:

The finding that manufacturing capability does not significantly affect product upgrading challenges some conventional wisdom. While previous literature often treats product and process innovations as mutually reinforcing, our results suggest that—for Korean SMEs—manufacturing routines matter more for how things are produced (process upgrading) than for fundamentally what is produced (product upgrading).

Fourth, Refining GVC Upgrading Perspectives:

By distinguishing between product and process upgrading, this study enriches the discourse on GVC progression. It highlights the possibility that product upgrading in SMEs relies less on production-floor know-how and more on R&D/design competencies. Meanwhile, manufacturing routines become critical for streamlining internal workflows, thus bolstering cost efficiency and quality—vital to global competitiveness.

5.3. Practical and Managerial Implications

Based on the research results, the following practical and managerial implications can be derived:

First, Foster Cross-Functional Integration:

Since product development routines positively influence manufacturing but not vice versa, managers should ensure that product-development insights (e.g., new design specifications, testing protocols) flow seamlessly into manufacturing departments. Regular cross-department meetings and integrated project teams can bridge design–production gaps.

Second, Differentiate Between “Product” vs. “Process” Focus:

For immediate gains in cost and operational excellence, investing in manufacturing routines and related process upgrades is beneficial. However, to create distinct market positioning via new features and functions, SMEs must emphasize product development capabilities.

Third, Strengthen Exploratory Routines:

Building a robust TISR is crucial for SMEs with resource constraints. Systematic scanning, networking with research institutes or lead customers, and internal knowledge management all feed into product-development insights, which then enhance manufacturing capabilities indirectly.

Fourth, Tailor Upgrading Strategies to Business Goals:

Depending on whether short-term (cost-focused) or long-term (innovation-focused) objectives are paramount, managers can calibrate their investments in manufacturing routines vs. product development. Successful GVC climbing often requires a balanced approach, ensuring neither cost-based competitiveness nor innovative differentiation is overlooked.

5.4. Limitations and Future Research Directions

This study has several limitations that should be acknowledged:

First, the cross-sectional research design significantly limits causal inference. Without longitudinal data, we cannot definitively establish the temporal sequence of relationships between innovation routines and value chain upgrades, nor can we track how these relationships evolve over time, particularly in response to external shocks like COVID-19.

Second, the sample limited to SMEs in specific regions of Korea restricts the generalizability of our findings to other contexts, industries, or countries with different innovation ecosystems and value chain structures.

Third, the absence of objective financial performance data represents a substantial limitation. Relying solely on perceptual measures of value chain upgrading without corresponding financial metrics makes it difficult to assess the actual economic impact of innovation routines on firm performance. This lack of objective performance indicators constrains our ability to make robust recommendations regarding resource allocation for innovation activities.

Fourth, our study does not adequately address the critical issue of risk in innovation activities. In today’s volatile business environment, innovation risk is a fundamental element in enterprise functioning. Our research framework lacks consideration of how SMEs evaluate, manage, and mitigate risks associated with innovation investments, particularly in the context of rapid environmental changes and competitive pressures. This omission limits our understanding of the complete innovation process and its challenges for resource-constrained SMEs.

Future research could consider various directions to complement these limitations and expand the scope of research:

First, conducting a longitudinal study using panel data over 3–5 years could capture the dynamic relationships between variables and provide stronger evidence for causal relationships between innovation routines and performance outcomes.

Second, international comparative studies targeting SMEs in East Asian countries or analysis of differences according to manufacturing sub-sectors could provide more generalizable and contextually nuanced results.

Third, analyzing the mediating role of open innovation activities or applying mixed research methodologies that combine quantitative analysis with in-depth interviews or case studies is worth considering. Such approaches could provide deeper insights into the mechanisms through which innovation routines influence value chain positioning, particularly in response to disruptions like the COVID-19 pandemic.

Fourth, future studies should incorporate risk assessment frameworks to examine how innovation risk perception and management affect SMEs’ innovation decisions, resource allocation, and ultimate success in value chain upgrading. Research exploring the relationship between financing constraints, risk tolerance, and innovation outcomes would provide valuable insights for both scholars and practitioners.

These future research directions will deepen the understanding of technological innovation and competitiveness enhancement in SMEs and provide meaningful insights both academically and practically.