Path Exploration of Artificial Intelligence-Driven Green Supply Chain Management in Manufacturing Enterprises: A Study Based on Random Forest and Dynamic QCA Under the TOE Framework

Abstract

1. Introduction

2. Literature Review and Research Framework

2.1. Green Supply Chain Management

2.2. TOE Framework

2.3. TOE Framework and Green Supply Chain Management

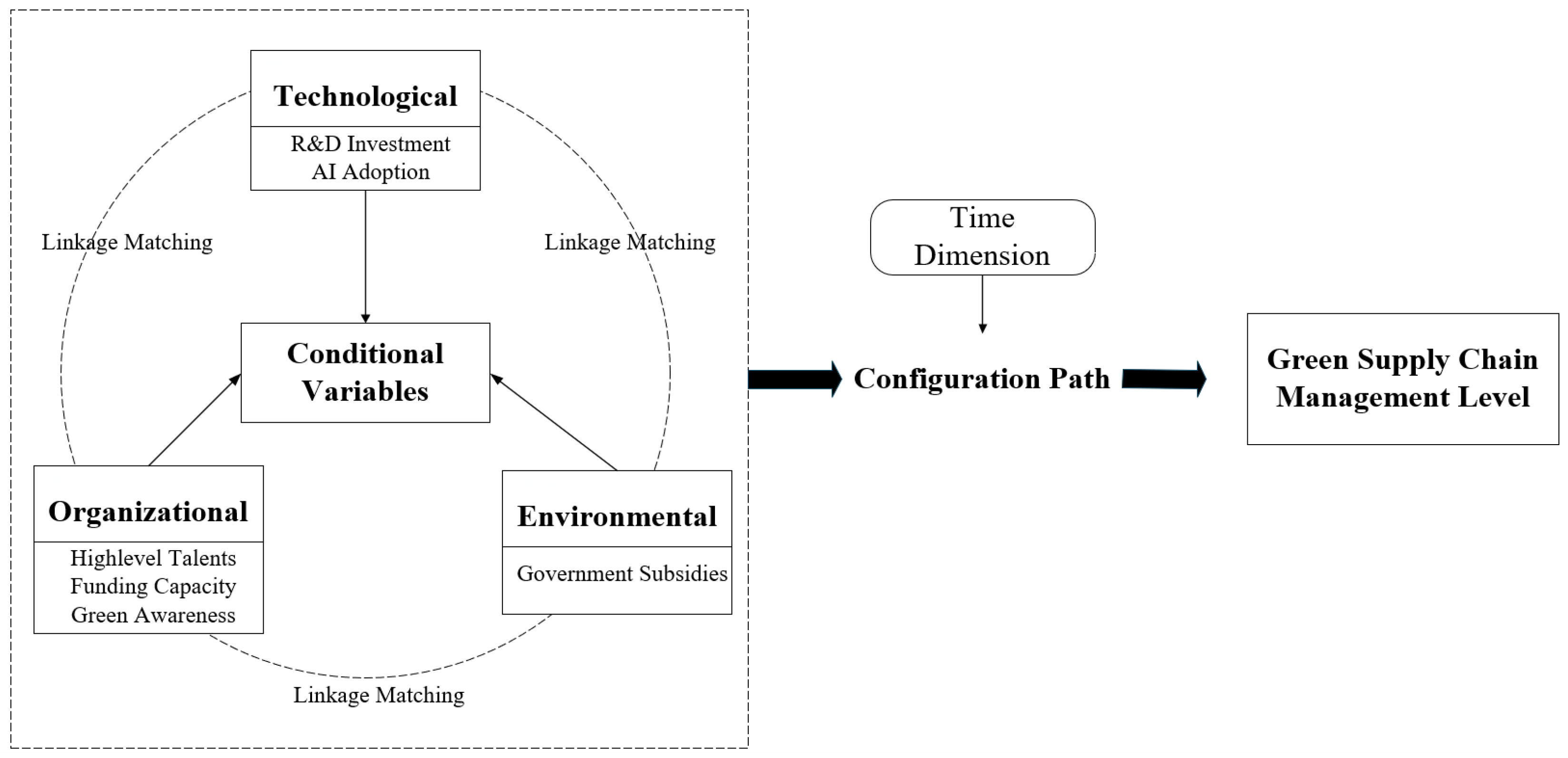

2.4. Model Construction

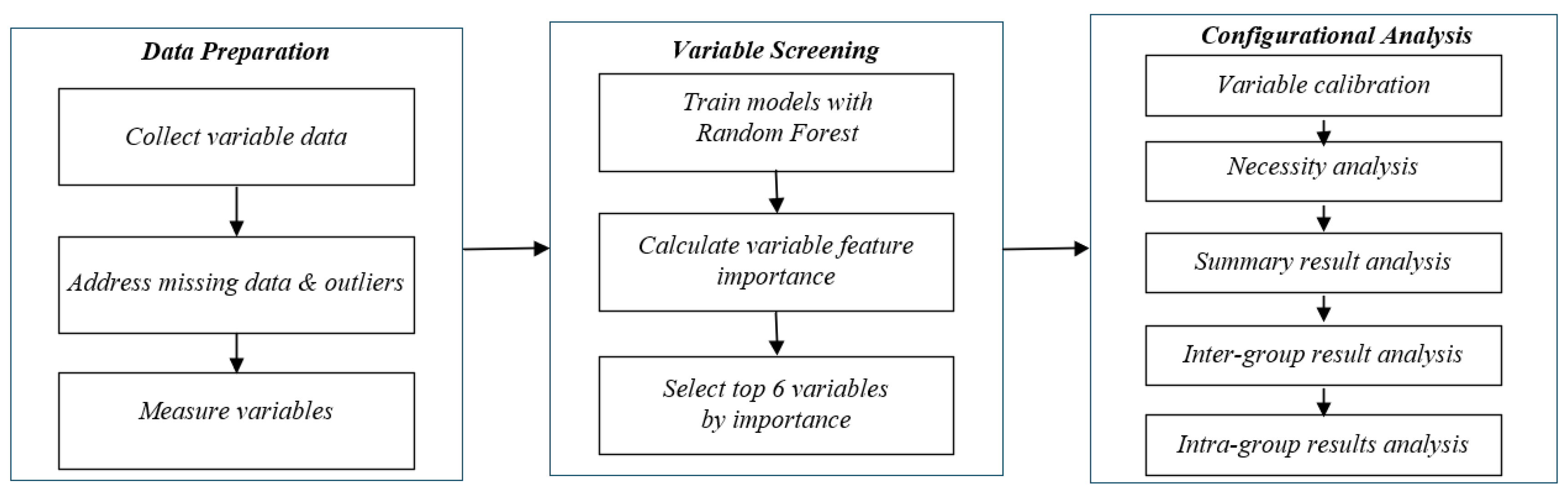

3. Methodology

3.1. Research Methods

3.1.1. Random Forest Model Based on Machine Learning

3.1.2. Dynamic QCA Method

3.2. Data Sources

3.3. Variable Measurement

3.3.1. Result Variable

3.3.2. Conditional Variables

- (1)

- Technical Dimension

- (2)

- Organizational Dimension

- (3)

- Environmental Dimension

4. Empirical Results

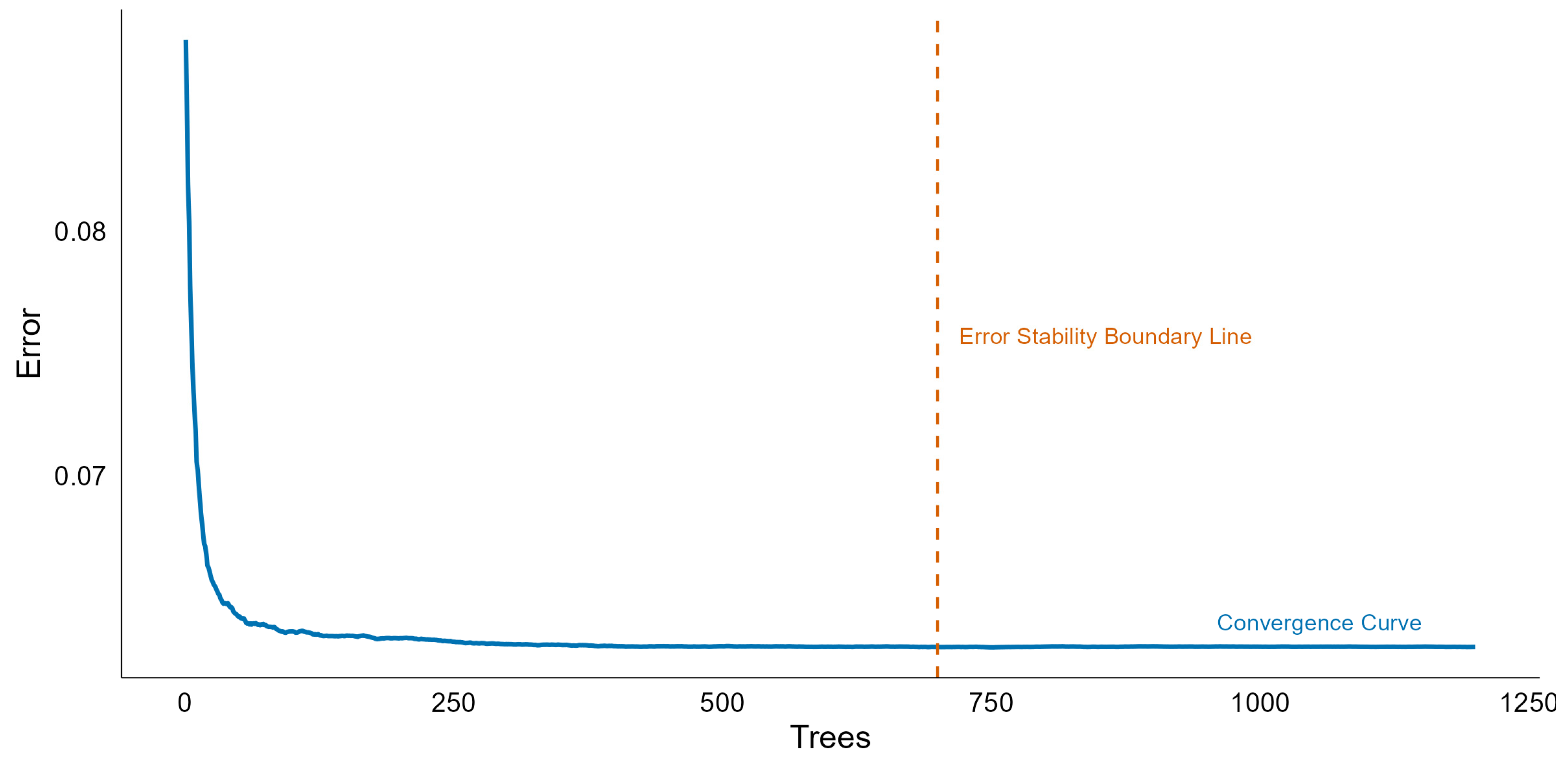

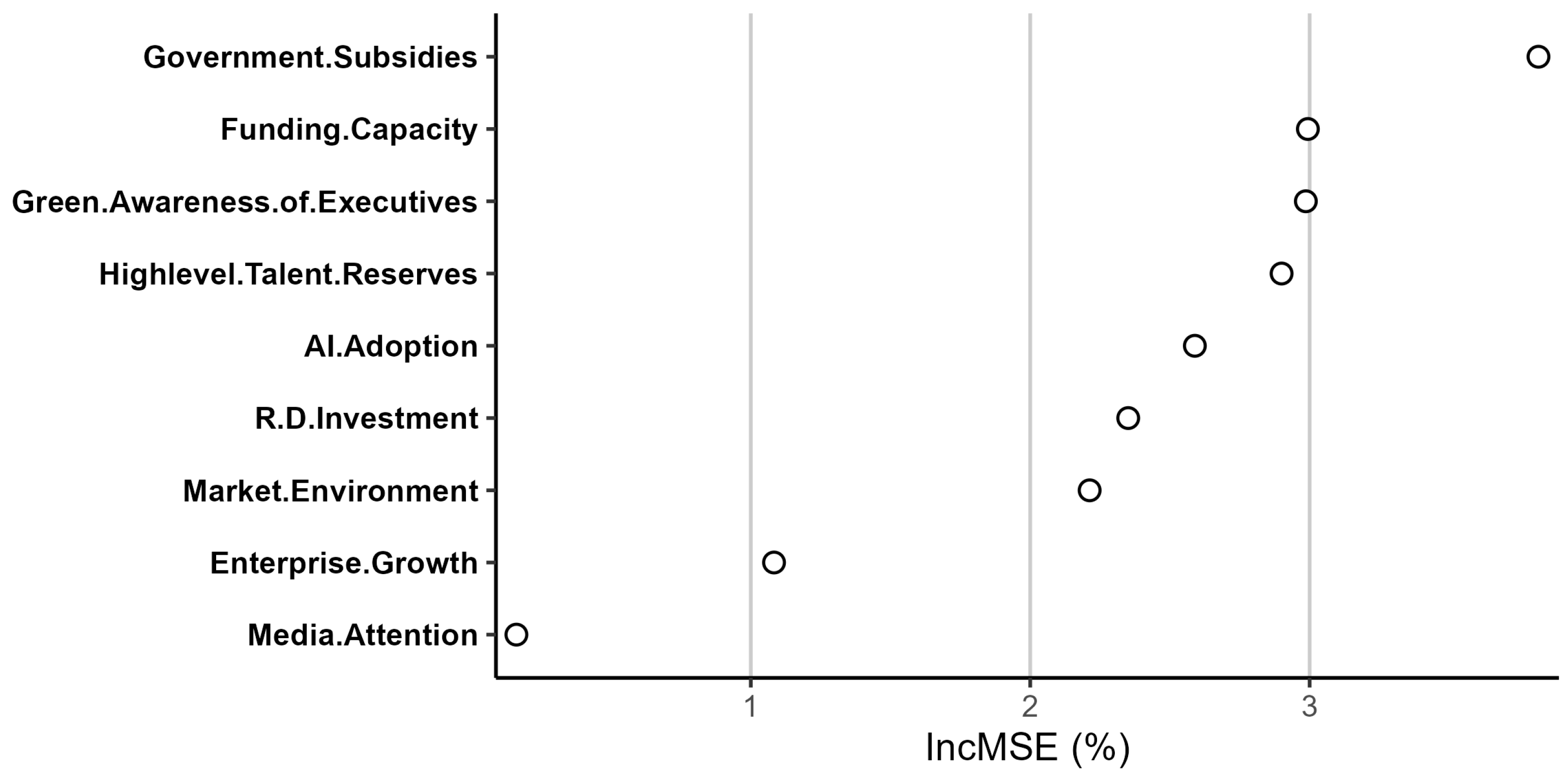

4.1. Variable Selection Based on Random Forest Model

4.2. Variable Calibration

4.3. Analysis of the Necessity of a Single Condition

4.4. Configuration Analysis

4.4.1. Summary Result Analysis

- (1)

- The Strategic Resource-driven path

- (2)

- AI Technology Innovation-driven path

4.4.2. Inter-Group Result Analysis

4.4.3. Intra-Group Results Analysis

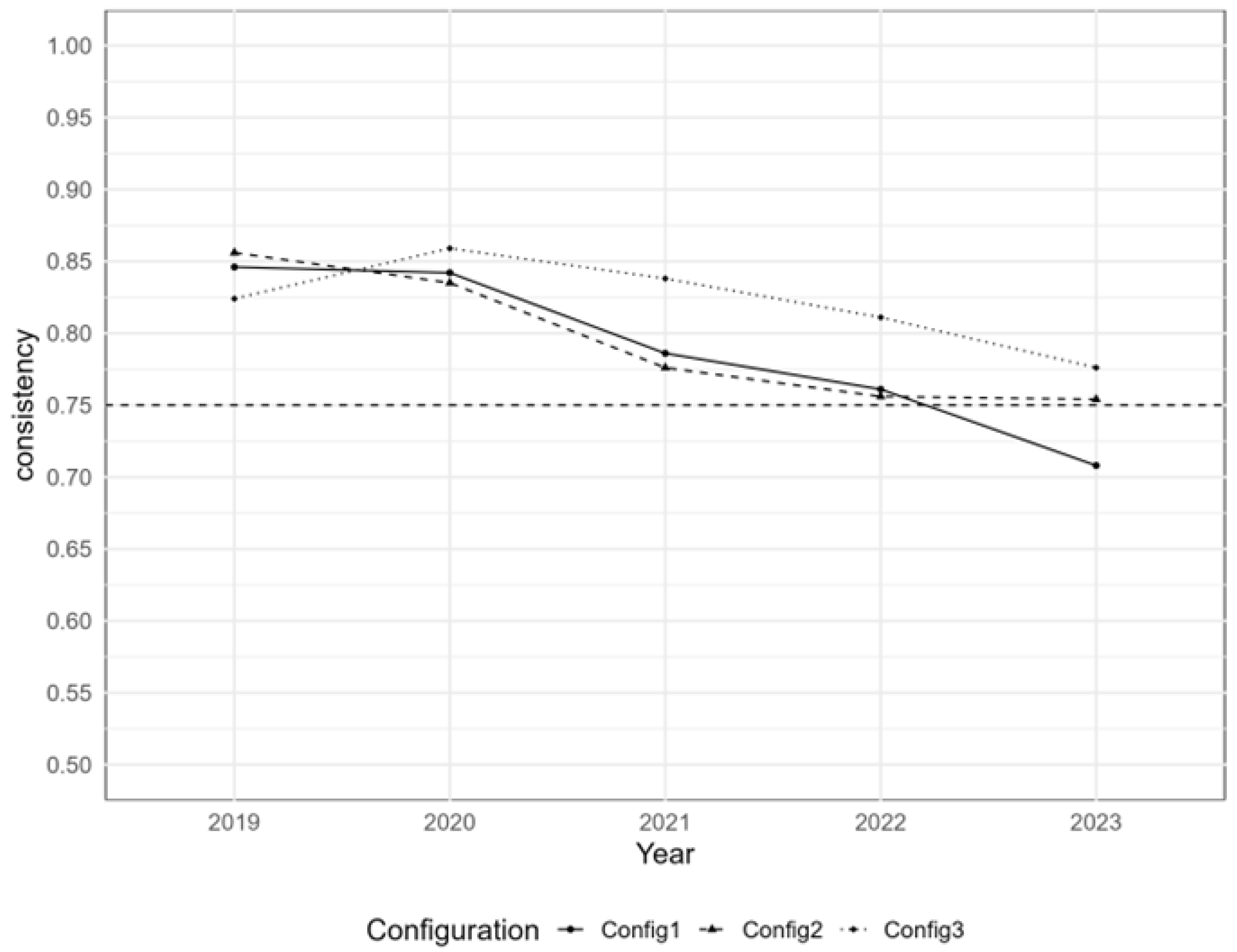

4.4.4. Robustness Test

5. Conclusions

5.1. Findings

5.2. Discussion

5.3. Theoretical Contribution

5.4. Practical Contribution

5.5. Limitations and Future Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, X.W.; Salman, W.; Hussain, M.; Sun, Y.; Kirikkaleli, D. China carbon neutrality target: Revisiting FDI-trade-innovation nexus with carbon emissions. J. Environ. Manag. 2021, 294, 113043. [Google Scholar] [CrossRef]

- Han, H. Theory of green purchase behavior (TGPB): A new theory for sustainable consumption of green hotel and green restaurant products. Bus. Strategy Environ. 2020, 29, 2815–2828. [Google Scholar] [CrossRef]

- Yao, F.M.; Yan, Y.L.; Li, Y.; Sun, J.Y. Green Design and Green Marketing Decisions of Supply Chain from the Perspective of Environmental Responsibility. Manag. Rev. 2024, 36, 255–265. (In Chinese) [Google Scholar] [CrossRef]

- Li, G.; Shao, S.; Zhang, L. Green supply chain behavior and business performance: Evidence from China. Technol. Forecast. Soc. Change 2019, 144, 445–455. [Google Scholar] [CrossRef]

- Xie, X.M.; Zhu, Q.W. Innovative Pivots or Conservative Shackles: How Can Green supply chain Management Practices SpurCorporate Performance? Chin. J. Manag. Sci. 2022, 30, 131–143. (In Chinese) [Google Scholar] [CrossRef]

- Ghaderi, Z.; Shakori, H.; Bagheri, F.; Hall, C.M.; Rather, R.A.; Moaven, Z. Green supply chain management, environmental costs and supply chain performance in the hotel industry: The mediating role of supply chain agility and resilience. Curr. Issues Tour. 2024, 27, 2101–2117. [Google Scholar] [CrossRef]

- Akhtar, F.; Huo, B.; Wang, Q. Embracing Green Supply Chain Collaboration through Technologies: The Bridging Role of Advanced Manufacturing Technology. J. Bus. Ind. Mark. 2023, 38, 2626–2642. [Google Scholar] [CrossRef]

- Li, T.; Donta, P.K. Predicting Green Supply Chain Impact with SNN-Stacking Model in Digital Transformation Context. J. Organ. End. User Comput. 2023, 35, 1–19. [Google Scholar] [CrossRef]

- Naseer, S.; Song, H.; Adu-Gyamfi, G.; Abbass, K.; Naseer, S. Impact of Green Supply Chain Management and Green Human Resource Management Practices on the Sustainable Performance of Manufacturing Firms in Pakistan. Environ. Sci. Pollut. Res. 2023, 30, 48021–48035. [Google Scholar] [CrossRef]

- Rouholamin, A.; Varposhti, S.; Alavian, A.; Talebi, S. Relationship between Green Intellectual Capital, Green Human Resource Management, Sustainable Supply Chain Management, and Sustainable Performance. J. Organ. Behav. Res. 2023, 8, 91–106. [Google Scholar] [CrossRef]

- Yi, S.; Wen, G. Game Model of Transnational Green Supply Chain Management Considering Government Subsidies. Ann. Oper. Res. 2023, 1–22. [Google Scholar] [CrossRef]

- Tseng, M.L.; Islam, M.S.; Karia, N.; Fauzi, F.A.; Afrin, S. A literature review on green supply chain management: Trends and future challenges. Resour. Conserv. Recycl. 2019, 141, 145–162. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Samar Ali, S. Exploring the Relationship between Leadership, Operational Practices, Institutional Pressures and Environmental Performance: A Framework for Green Supply Chain. Int. J. Prod. Econ. 2015, 160, 120–132. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. The Impacts of Critical Success Factors for Implementing Green Supply Chain Management towards Sustainability: An Empirical Investigation of Indian Automobile Industry. J. Clean. Prod. 2016, 121, 142–158. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Sarkis, J. Manufacturing strategy and environmental consciousness. Technovation 1995, 15, 79–97. [Google Scholar] [CrossRef]

- Beamon, B.M. Designing the Green Supply Chain. Logist. Inf. Manag. 1999, 12, 332–342. [Google Scholar] [CrossRef]

- Sarkis, J. A boundaries and flows perspective of green supply chain management. Supply Chain. Manag. 2012, 17, 202–216. [Google Scholar] [CrossRef]

- Cousins, P.D.; Lawson, B.; Petersen, K.J.; Fugate, B. Investigating green supply chain management practices and performance The moderating roles of supply chain ecocentricity and traceability. Int. J. Oper. Prod. Manag. 2019, 39, 767–786. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, J.Z.; Cao, Y.; Kazancoglu, Y. Intelligent transformation of the manufacturing industry for Industry 4.0: Seizing financial benefits from supply chain relationship capital through enterprise green management. Technol. Forecast. Soc. Change 2021, 172, 120999. [Google Scholar] [CrossRef]

- Yi, Y.L.; Demirel, P. The impact of sustainability-oriented dynamic capabilities on firm growth: Investigating the green supply chain management and green political capabilities. Bus. Strategy Environ. 2023, 32, 5873–5888. [Google Scholar] [CrossRef]

- Awan, F.H.; Dunnan, L.; Jamil, K.; Mustafa, S.; Atif, M.; Gul, R.F.; Guangyu, Q. Mediating Role of Green Supply Chain Management Between Lean Manufacturing Practices and Sustainable Performance. Front. Psychol. 2022, 12, 810504. [Google Scholar] [CrossRef] [PubMed]

- Tornatizky, L.G.; Fleischer, M. Processes of Technological Innovation; Lexington Books: Lexington, KY, USA, 1990. [Google Scholar]

- Chittipaka, V.; Kumar, S.; Sivarajah, U.; Bowden, J.L.H.; Baral, M.M. Blockchain Technology for Supply Chains operating in emerging markets: An empirical examination of technology-organization-environment (TOE) framework. Ann. Oper. Res. 2023, 327, 465–492. [Google Scholar] [CrossRef]

- Li, W.; Xiao, X.; Yang, X.; Li, L. How Does Digital Transformation Impact Green Supply Chain Development? An Empirical Analysis Based on the TOE Theoretical Framework. Systems 2023, 11, 416. [Google Scholar] [CrossRef]

- Baral, M.M.; Chittipaka, V.; Pal, S.K.; Mukherjee, S.; Shyam, H.S. Investigating the factors of blockchain technology influencing food retail supply chain management: A study using TOE framework. Stat. Transit. 2023, 24, 129–146. [Google Scholar] [CrossRef]

- Abdurrahman, A.; Gustomo, A.; Prasetio, E.A. Impact of dynamic capabilities ondigital transformation and innovation to improve banking performance: A TOE framework study. J. Open Innov. Technol. Mark. Complex. 2024, 10, 100215. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, J.; Yang, Z.; Wang, Y. Critical success factors of green innovation: Technology, organization and environment readiness. J. Clean. Prod. 2020, 264, 121701. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, J.; Kong, C.; Zheng, X.; Zhang, X. What factors influence the motivation of logistics enterprises to adopt green technology? An empirical study based on the TOE model. Br. Food J. 2025, 127, 4742–4766. [Google Scholar] [CrossRef]

- Lei, Y.; Guo, Y.; Zhang, Y.; Cheung, W. Information technology and service diversification: A cross-level study in different innovation environments. Infor. Manage-Amster 2021, 58, 103432. [Google Scholar] [CrossRef]

- Li, L.; Zhu, W.; Chen, L.; Liu, Y. Generative AI Usage and Sustainable Supply Chain Performance: A Practice-Based View. Transp. Res. E Logist. Transp. Rev. 2024, 192, 103761. [Google Scholar] [CrossRef]

- Zhou, L.; Shi, X.; Wang, Z.; Ma, C.; Gao, L. Exploration of Applications with ChatGPT for Green Supply Chain Management. Ann. Oper. Res. 2025, 1–34. [Google Scholar] [CrossRef]

- Nguyen, N.M.; Hoai, T.T.; Vo, H.V.; Nguyen, N.P. Digital Approach toward Environmental Sustainability in Supply Chains: Evidence from Vietnamese Firms. Sustain. Dev. 2023, 31, 3303–3317. [Google Scholar] [CrossRef]

- Lai, K.; Feng, Y.; Zhu, Q. Digital Transformation for Green Supply Chain Innovation in Manufacturing Operations. Transp. Res. E Logist. Transp. Rev. 2023, 175, 103145. [Google Scholar] [CrossRef]

- Alves, R.; Lerman, L.V.; Benitez, G.B. Configuring Digital Supply Chains for Green Supply Chain Management. J. Manuf. Technol. Manag. 2025, 1–21. [Google Scholar] [CrossRef]

- Huang, S.; Lei, Y.; Fu, H. Impacts of Optimistic Green R&D in a Sustainable Supply Chain with Information Asymmetry. Sustainability 2025, 17, 6970. [Google Scholar] [CrossRef]

- Epoh, R.L.; Langton, I.; Mafini, C. A model for green supply chain management in the South African manufacturing sector. Cogent Bus. Manag. 2024, 11, 2390213. [Google Scholar] [CrossRef]

- Haldorai, K.; Kim, W.G.; Phetvaroon, K.; Gazzoli, G. Green synergy: Integrating green human resource management and green supply chain management for sustainable performance in the Thai hospitality industry. Int. J. Hosp. Manag. 2025, 128, 104196. [Google Scholar] [CrossRef]

- Karim, R.A.; Rabiul, M.K.; Ahamed, T.; Karim, D.N.; Mehzabeen, M. Integrating Green Entrepreneurial Orientation, Green Information Systems, and Management Support with Green Supply Chain Management to Foster Firms’ Environmental Performance. Sustainability 2024, 16, 4921. [Google Scholar] [CrossRef]

- Xu, J.; Cao, J.; Wang, Y.; Shi, X.; Zeng, J. Evolutionary Game on Government Regulation and Green Supply Chain Decision-Making. Energies 2020, 13, 620. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, Y.; Cheng, T.; Guo, X. The Influence of Customer ESG Performance on Supplier Green Innovation Efficiency: A Supply Chain Perspective. Sustainability 2025, 17, 5519. [Google Scholar] [CrossRef]

- Chan, H.K.; He, H.; Wang, W.Y.C. Green Marketing and Its Impact on Supply Chain Management in Industrial Markets. Ind. Mark. Manag. 2012, 41, 557–562. [Google Scholar] [CrossRef]

- Cappa, F.; Franco, S.; Rosso, F. Citizens and cities: Leveraging citizen science and big data for sustainable urban development. Bus. Strategy Environ. 2022, 31, 648–667. [Google Scholar] [CrossRef]

- Liu, L.D.; Song, W.Y.; Liu, Y. Leveraging digital capabilities toward a circular economy: Reinforcing sustainable supply chain management with Industry 4.0 technologies. Comput. Ind. Eng. 2023, 178, 109113. [Google Scholar] [CrossRef]

- Feng, H.; Wang, F.Y.; Song, G.M.; Liu, L.L. Digital Transformation on Enterprise Green Innovation: Effect and Transmission Mechanism. Int. J. Environ. Res. Public Health 2022, 19, 10614. [Google Scholar] [CrossRef]

- Xie, J.; Abbass, K.; Li, D. Advancing eco-excellence: Integrating stakeholders’ pressures, environmental awareness, and ethics for green innovation and performance. J. Environ. Manage 2024, 352, 120027. [Google Scholar] [CrossRef]

- Ellström, D.; Holtström, J.; Berg, E.; Josefsson, C. Dynamic capabilities for digital transformation. J. Strategy Manag. 2022, 15, 272–286. [Google Scholar] [CrossRef]

- Li, Y.G.; Fang, X.Y. Comparing the Effects of Corporate Strategic Deviance on Corporate Growth and Corporate Profit: Evidence from Chinese Firms. Sage Open 2024, 14, 21582440241240549. [Google Scholar] [CrossRef]

- Zhao, L.H.; Wang, Y.J. Financial Ecological Environment, Financing Constraints, and Green Innovation of Manufacturing Enterprises: Empirical Evidence From China. Front. Environ. Sci. 2022, 10, 891830. [Google Scholar] [CrossRef]

- Wan, Q.C.; Ye, J.F.; Zheng, L.; Tan, Z.H.; Tang, S.Y. The impact of government support and market competition on China’s high-tech industry innovation efficiency as an emerging market. Technol. Forecast. Soc. Change 2023, 192, 122585. [Google Scholar] [CrossRef]

- Sun, X.J.; Tang, J.; Li, S.L. Promote Green Innovation in Manufacturing Enterprises in the Aspect of Government Subsidies in China. Int. J. Environ. Res. Public Health 2022, 19, 7864. [Google Scholar] [CrossRef]

- Li, J.; Wu, T.; Liu, B.; Zhou, M. Can digital transformation enhance corporate ESG performance? The moderating role of dual environmental regulations. Financ. Res. Lett. 2024, 62, 105241. [Google Scholar] [CrossRef]

- Li, J.; Li, Q.Q.; Chen, Y.T.; An, Q. How digital transformation facilitates ESG performance to heavy polluting enterprises:A panel fsQCA based on national big data comprehensive pilot zones. Technol. Forecast. Soc. Change 2025, 221, 124366. [Google Scholar] [CrossRef]

- Zeng, G.; Li, Y.P. The Innovation Quality Elevation Path of SRDI SMES:Based on the Perspective ofInnovation Incentive Policiesand Business Environment Optimization. Soft. Sci. 2025, 39, 93–100. [Google Scholar] [CrossRef]

- Du, Y.Z.; Liu, Q.C.; Chen, K.W.; Xiao, R.Q.; Li, S.S. Ecosystem of Doing Business, Total Factor Productivity and Multiple Patterns of High-quality Development of Chinese Cities: A Configuration Analysis Based on Complex Systems View. J. Manag. World 2022, 38, 127–145. (In Chinese) [Google Scholar] [CrossRef]

- Rihoux, B.; Ragin, C.C. Configurational Comparative Methods: Qualitative Comparative Analysis (QCA) and Related Techniques; Sage Publications: Thousand Oaks, CA, USA, 2008; p. 6. [Google Scholar]

- Garcia-Castro, R.; Arino, M.A. A General Approach to Panel Data Set-Theoretic Research. J. Adv. Manag. Sci. Inf. Syst. 2016, 2, 63–76. [Google Scholar] [CrossRef]

- Xue, Y.; Li, M.Z.; Feng, Y.H. Study on Peer Effect of Green Supply Chain Management in Manufacturing Enterprises: Based on the Perspective of Value Network Embeddedness. East. China Econ. Manag. 2023, 37, 107–116. (In Chinese) [Google Scholar] [CrossRef]

- Wu, B.; Ren, K.J.; Fu, Y.; He, D.F.; Pan, M.M. Institutional investor ESG activism and green supply chain management performance: Exploring contingent roles of technological interdependences in different digital intelligence contexts. Technol. Forecast. Soc. 2024, 209, 123789. [Google Scholar] [CrossRef]

- ISO 14001:2015; Environmental Management Systems—Requirements with Guidance for Use. International Organization for Standardization (ISO): Geneva, Switzerland, 2015.

- Issa, H.; Jabbouri, R.; Palmer, M. An artificial intelligence (AI)-readiness and adoption framework for AgriTech firms. Technol. Forecast. Soc. Change 2022, 182, 121874. [Google Scholar] [CrossRef]

- Yao, J.Q.; Zhang, K.P.; Guo, L.P.; Feng, X. How Does Artificial Intelligence Improve Firm Productivity?Based on the Perspective of Labor Skill Structure Adjustment. J. Manag. World 2024, 40, 101–116+133+117–122. (In Chinese) [Google Scholar] [CrossRef]

- Jing, H.; Zhang, S.Y. The Impact of Artificial Intelligence on ESG Performance of Manufacturing Firms: The Mediating Role of Ambidextrous Green Innovation. Systems 2024, 12, 499. [Google Scholar] [CrossRef]

- Ma, J.; Xie, T.T. Customer artificial intelligence, supply chain spillover effects, and supplier capacity utilization. Int. Rev. Econ. Financ. 2025, 103, 104572. [Google Scholar] [CrossRef]

- Li, J.; Yi, M.; Sun, Q. Artificial intelligence and supply chain risk: Mediating effects of supply chain efficiency and resilience. Int. Rev. Financ. Anal. 2025, 108, 104700. [Google Scholar] [CrossRef]

- Dong, Z.; Xin, Z.; Liu, D.; Yu, F. The impact of artificial intelligence application on company environmental investment in Chinese manufacturing companies. Int. Rev. Financ. Anal. 2024, 95, 103403. [Google Scholar] [CrossRef]

- Yang, L.; He, X.; Gu, H.F. Top Management Team’s Experiences, Dynamic Capabilities and Firm’s Strategy Mutation: Moderating Effect of Managerial Discretion. J. Manag. World 2020, 36, 168–188+201+252. (In Chinese) [Google Scholar] [CrossRef]

- Li, Y.B.; Xia, Y.; Zhao, Z. The Relationship between Executives’ Green Perception and Firm Performance in Heavy-pollution Industries: A Moderated Mediating Effect Model. Sci. Technol. Progress. Policy 2023, 40, 113–123. [Google Scholar] [CrossRef]

- Guo, M.; Yan, M.; Yan, X.; Li, Y. Systemic Configurations of Functional Talent for Green Technological Innovation: A Fuzzy-Set QCA Study. Systems 2025, 13, 604. [Google Scholar] [CrossRef]

- Hadlock, C.J.; Pierce, J.R. New Evidence on Measuring Financial Constraints: Moving beyond the KZ Index. Rev. Financ. Stud. 2010, 23, 1909–1940. [Google Scholar] [CrossRef]

- Chen, Y.P.; Liu, Y. The Mechanism of How Media Coverage Influences High-polluting Enterprises’ Green Technology Innovation—Based on the Mediating Effect of Government Environmental Regulation and Public Participation. Manag. Rev. 2023, 35, 111–122. (In Chinese) [Google Scholar] [CrossRef]

- Liaw, A.; Wiener, M. Classification and regression by RandomForest. R. News 2001, 2, 18–22. [Google Scholar]

- Zhang, L.F. Research on Importance of Influencing Factors of Resident Outbound Tourism in China Based on Random Forest Model. Resour. Dev. Mark. 2017, 33, 711–716,726. (In Chinese) [Google Scholar] [CrossRef]

- Kafouros, M.; Wang, C.; Piperopoulos, P.; Zhang, M.S. Academic collaborations and firm innovation performance in China: The role of region-specific institutions. Res. Policy 2015, 44, 803–817. [Google Scholar] [CrossRef]

- Lu, R.Y.; Zhang, L.K.; Chen, X.L.; Zhou, D.M. The Configuration and Path of Factors Affecting the Development of Science-based Industries: A QCA Analysis Based on the Pharmaceutical Manufacturing Industry in 31 Provinces of Chinese Mainland. Sci. Technol. Progress. Policy 2022, 39, 20–28. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, H. External Resource Dependence and Implementation Efficiency of Education for Sustainable Development (ESD): A Hybrid Design Based on Data Envelopment Analysis (DEA) and Dynamic Qualitative Comparative Analysis (QCA). Sustainability 2025, 17, 3809. [Google Scholar] [CrossRef]

- Zhang, M.; Lan, H.L.; Chen, H.W.; Zeng, P. Research on the Antecedent Configuration and Performance of Strategic Change. J. Manag. World 2020, 36, 168–188. (In Chinese) [Google Scholar] [CrossRef]

- Li, F.B.; Zhang, H.F. The impact of green supply chain management on corporate performance under the full process model: A MASEM analysis based on heterogeneous moderation. J. Clean. Prod. 2024, 481, 144099. [Google Scholar] [CrossRef]

- Wang, J.N.; Duan, K.Y.; Zheng, Y.L. Green supply chain management, green technology innovation and firms’ energy consumption intensity. Energy Econ. 2025, 141, 108133. [Google Scholar] [CrossRef]

- Jan, A.M.; Salameh, A.A.; Rahman, H.U.; Alasiri, M.M. Can blockchain technologies enhance environmental sustainable development goals performance in manufacturing firms? Potential mediation of green supply chain management practices. Bus. Strategy Environ. 2024, 33, 2004–2019. [Google Scholar] [CrossRef]

- Novitasari, M.; Wijaya, A.L.; Agustin, N.M.; Gunardi, A.; Dana, L.P. Corporate social responsibility and firm performance: Green supply chain management as a mediating variable. Corp. Soc. Responsib. Environ. Manag. 2023, 30, 267–276. [Google Scholar] [CrossRef]

- Liao, Z.J.; Zhang, M.N. Carbon finance, green supply chain management, and firms’ environmental innovation: The moderating role of financing structure. Int. J. Prod. Res. 2024, 63, 8178–8190. [Google Scholar] [CrossRef]

- Zhang, L.F.; Dou, Y.F.; Wang, H.L. Green supply chain management, risk-taking, and corporate value-Dual regulation effect based on technological innovation capability and supply chain concentration. Front. Environ. Sci. 2023, 11, 1096349. [Google Scholar] [CrossRef]

- Zhang, L.; Innab, N.; Shuhidan, S.M.; Pan, Y.; Zhang, Y.; Som, H.M.; Alasbali, N. Artificial intelligence-driven internet of things-based green supply chain for carbon reduction in sustainable manufacturing. J. Environ. Manag. 2025, 389, 126170. [Google Scholar] [CrossRef]

- Hasan, M.D.R.; Islam, M.Z.; Sumon, M.F.I.; Osiujjaman, M.; Debnath, P.; Pant, L. Integrating artificial intelligence and predictive analytics in supply chain management to minimize carbon footprint and enhance business growth in the USA. J. Bus. Manag. Stud. 2024, 6, 195. [Google Scholar] [CrossRef]

- Luo, H.T.; Yu, J.L.; Mu, T.; Zhou, P. Spillover effects of enterprise digital transformation on supply chain carbon emissions: Evidence from China. Struct. Change Econ. Dyn. 2025, 75, 606–617. [Google Scholar] [CrossRef]

- Rashid, A.; Baloch, N.; Rasheed, R.; Ngah, A.H. Big data analytics-artificial intelligence and sustainable performance through green supply chain practices in manufacturing firms of a developing country. J. Sci. Technol. Policy Manag. 2024, 16, 42–67. [Google Scholar] [CrossRef]

- Eltalhi, M.; Ojekemi, O.S.; Öz, T. The Role of Government Support in Adopting Green Supply Chain Management: The Influence of Green Market Orientation and Employee Environmental Commitment in Libya. Sustainability 2025, 17, 3012. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, H.; Ying, J.; He, S.; Zhang, C.; Yan, J. Artificial intelligence and green transformation of manufacturing enterprises. Int. Rev. Financ. Anal. 2025, 104, 104330. [Google Scholar] [CrossRef]

- Riad, M.; Naimi, M.; Okar, C. Enhancing Supply Chain Resilience Through Artificial Intelligence: Developing a Comprehensive Conceptual Framework for AI Implementation and Supply Chain Optimization. Logistics 2024, 8, 111. [Google Scholar] [CrossRef]

- Zhang, Q.; Ullah, A.; Ashraf, S.; Abdullah, M. Synergistic Impact of Internet of Things and Big-Data-Driven Supply Chain on Sustainable Firm Performance. Sustainability 2024, 16, 5717. [Google Scholar] [CrossRef]

- Xu, Y.; Jia, F.; Chen, L.; Wang, Y. Does digital transformation foster carbon emissions reduction? Evidence from China’s manufacturing supply chain. Int. J. Logist. Manag. 2024, 35, 1827–1846. [Google Scholar] [CrossRef]

| Caterogies | Positive Influences on GSCM | References |

|---|---|---|

| Technological factors | Generative AI usage | Li et al. [31] |

| Green digital learning orientation | Nguyen et al. [33] | |

| Digital transformation | Lai et al. [34] Li and Donta [8] | |

| Digital supply chains | Alves et al. [35] | |

| Green R&D | Huang et al. [36] | |

| Applications with ChatGPT | Zhou et al. [32] | |

| Organizational factors | Eco-design, green distribution, and green training | Epoh et al. [37] |

| Human resource management | Naseer et al. [9] Haldorai et al. [38] | |

| Green intellectual capital, and green human resource administration | ||

| Green Entrepreneurial Orientation, Green Information Systems, and Management Support | Karim et al. [39] | |

| Environmental factors | Government subsidies | Yi and Wen [11] |

| Government regulations | Xu et al. [40] | |

| Customer ESG Performance | Huang et al. [41] | |

| Green marketing | Chan et al. [42] |

| Primary Indicator | Secondary Indicator | Third-Level Indicator | Computational Method |

|---|---|---|---|

| Enterprise GSCM level | Resource conditions | Capital efficiency | Measured by working capital turnover ratio, calculated as (net sales revenue/average working capital balance) × 100 |

| Inventory utilization efficiency | Measured by inventory turnover rate, calculated as (cost of goods sold/average inventory balance) × 100 | ||

| Asset utilization efficiency | Measured by fixed asset turnover ratio, calculated as (revenue/average net fixed asset value) × 100 | ||

| Output status | Employee Output | Profit per capita is calculated as (total profit/average annual number of employees) × 100 | |

| Flexible horizontal | Green output | Whether the organization has passed ISO 14001 [60] certification is counted as 1 if passed, and 0 if not. | |

| Operating Income | By revenue | ||

| Supply chain flexibility | Supply chain flexibility is calculated using four metrics: accounts payable, accounts receivable, return on equity, and management expenses to total operating revenue. |

| Variable | Descriptive Statistics | Calibration Anchor | |||||

|---|---|---|---|---|---|---|---|

| Mean | Standard Deviation | Minimum | Maximum | Complete Affiliation | Intersection | Disaffiliated | |

| GSCM | 0.06 | 0.068 | 0 | 0.387 | 0.136 | 0.006 | 0.002 |

| AI | 1.127 | 1.235 | 0 | 5.517 | 2.079 | 1.099 | <0.01 |

| R&D | 0.051 | 0.045 | 0 | 1.132 | 0.061 | 0.042 | 0.028 |

| HT | 0.271 | 0.181 | 0 | 0.964 | 0.362 | 0.226 | 0.135 |

| GA | 4.123 | 4.478 | 0 | 22 | 6 | 3 | 1 |

| FC | 3.973 | 0.243 | 2.6 | 5.835 | 4.113 | 3.958 | 3.827 |

| EG | 0.265 | 5.516 | −1.811 | 422.966 | 0.264 | 0.084 | <0.01 |

| ME | 0.155 | 0.113 | 0 | 1 | 0.202 | 0.134 | 0.073 |

| MA | 0.681 | 0.883 | 0 | 4.444 | 0.845 | 0.301 | <0.01 |

| GS | 7.319 | 0.598 | 4.049 | 9.758 | 7.607 | 7.272 | 6.918 |

| Condition Variable | High Level of GSCM | Low Level of GSCM | ||||||

|---|---|---|---|---|---|---|---|---|

| Total Consistency | Total Coverage | Inter-Group Consistency Adjustment Distance | Intra-Group Consistency Adjustment Distance | Total Consistency | Total Coverage | Inter-Group Consistency Adjustment Distance | Intra-Group Consistency Adjustment Distance | |

| AI | 0.635 | 0.593 | 0.035 | 0.559 | 0.573 | 0.503 | 0.072 | 0.030 |

| ~AI | 0.467 | 0.538 | 0.081 | 0.629 | 0.536 | 0.580 | 0.055 | 0.025 |

| R&D | 0.526 | 0.540 | 0.049 | 0.664 | 0.564 | 0.544 | 0.078 | 0.027 |

| ~R&D | 0.555 | 0.575 | 0.067 | 0.664 | 0.522 | 0.509 | 0.064 | 0.029 |

| HT | 0.546 | 0.563 | 0.029 | 0.664 | 0.540 | 0.524 | 0.119 | 0.029 |

| ~HT | 0.538 | 0.554 | 0.049 | 0.664 | 0.550 | 0.532 | 0.096 | 0.027 |

| GA | 0.614 | 0.602 | 0.064 | 0.559 | 0.524 | 0.483 | 0.096 | 0.030 |

| ~GA | 0.472 | 0.513 | 0.113 | 0.629 | 0.567 | 0.580 | 0.075 | 0.025 |

| FC | 0.554 | 0.576 | 0.246 | 0.629 | 0.523 | 0.511 | 0.235 | 0.030 |

| ~FC | 0.53 | 0.542 | 0.270 | 0.664 | 0.567 | 0.544 | 0.203 | 0.026 |

| GS | 0.568 | 0.617 | 0.064 | 0.699 | 0.451 | 0.461 | 0.078 | 0.029 |

| ~GS | 0.504 | 0.494 | 0.067 | 0.629 | 0.625 | 0.576 | 0.058 | 0.025 |

| Cause-and-Effect Combinations | Year | |||||

|---|---|---|---|---|---|---|

| 2019 | 2020 | 2021 | 2022 | 2023 | ||

| FC and GSCM | Inter-group consistency | 0.689 | 0.617 | 0.535 | 0.476 | 0.397 |

| Inter-group coverage | 0.617 | 0.636 | 0.557 | 0.536 | 0.483 | |

| FC and ~GSCM | Inter-group consistency | 0.382 | 0.459 | 0.553 | 0.618 | 0.699 |

| Inter-group coverage | 0.603 | 0.618 | 0.562 | 0.510 | 0.467 | |

| ~FC and GSCM | Inter-group consistency | 0.666 | 0.602 | 0.544 | 0.460 | 0.396 |

| Inter-group coverage | 0.447 | 0.442 | 0.535 | 0.569 | 0.634 | |

| ~FC and ~GSCM | Inter-group consistency | 0.429 | 0.505 | 0.549 | 0.626 | 0.677 |

| Inter-group coverage | 0.509 | 0.485 | 0.528 | 0.567 | 0.597 | |

| Condition Variable | High Level of GSCM | ||

|---|---|---|---|

| Strategic Resource-Driven | AI Innovation-Driven | ||

| Configuration 1 | Configuration 2 | Configuration 3 | |

| AI Technology Adoption | ⊗ | ⊗ | ● |

| R&D Investment | ● | ● | |

| High-level Talent Reserves | ⊗ | ⊗ | ⊗ |

| Green Awareness Among Executives | ● | ● | |

| Funding Capacity | ● | ● | |

| Government Subsidies | ● | ● | ● |

| consistency | 0.788 | 0.8 | 0.825 |

| PRI | 0.583 | 0.578 | 0.748 |

| Original coverage | 0.064 | 0.061 | 0.094 |

| Unique coverage | 0.017 | 0.014 | 0.058 |

| Inter-group consistency adjustment distance | 0.084 | 0.07 | 0.043 |

| Intra-group consistency adjustment distance | 0.175 | 0.14 | 0.175 |

| Total PRI | 0.665 | ||

| Total consistency | 0.775 | ||

| Total coverage | 0.136 | ||

| Configuration | Mean | SD | Chi-Square | P |

|---|---|---|---|---|

| Configuration 1 | 0.120 | 0.215 | 0.496 | 0.781 |

| Configuration 2 | 0.125 | 0.225 | 4.044 | 0.132 |

| Configuration 3 | 0.127 | 0.217 | 1.539 | 0.463 |

| Configuration | Eastern China | Western China | Central China |

|---|---|---|---|

| Configuration 1 | 0.129 | 0.132 | 0.136 |

| Configuration 2 | 0.105 | 0.135 | 0.100 |

| Configuration 3 | 0.092 | 0.087 | 0.106 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Hao, L.; Zhang, Z.; Zhang, H. Path Exploration of Artificial Intelligence-Driven Green Supply Chain Management in Manufacturing Enterprises: A Study Based on Random Forest and Dynamic QCA Under the TOE Framework. Systems 2025, 13, 1120. https://doi.org/10.3390/systems13121120

Cao Y, Hao L, Zhang Z, Zhang H. Path Exploration of Artificial Intelligence-Driven Green Supply Chain Management in Manufacturing Enterprises: A Study Based on Random Forest and Dynamic QCA Under the TOE Framework. Systems. 2025; 13(12):1120. https://doi.org/10.3390/systems13121120

Chicago/Turabian StyleCao, Yifei, Lingfeng Hao, Zihan Zhang, and Hua Zhang. 2025. "Path Exploration of Artificial Intelligence-Driven Green Supply Chain Management in Manufacturing Enterprises: A Study Based on Random Forest and Dynamic QCA Under the TOE Framework" Systems 13, no. 12: 1120. https://doi.org/10.3390/systems13121120

APA StyleCao, Y., Hao, L., Zhang, Z., & Zhang, H. (2025). Path Exploration of Artificial Intelligence-Driven Green Supply Chain Management in Manufacturing Enterprises: A Study Based on Random Forest and Dynamic QCA Under the TOE Framework. Systems, 13(12), 1120. https://doi.org/10.3390/systems13121120