1. Introduction

Experimental teaching holds a crucial place in student education, and the integration of information technology is pivotal for enhancing the quality of higher education through the modernization of experimental teaching [

1,

2]. As information technology continues to advance, traditional experimental teaching methods in colleges and universities fall short of meeting the diverse demands of society for talent. Consequently, institutions are compelled to reform their existing experimental methods and platforms [

3]. Traditional experimental teaching methods relying on physical resources are constrained by factors such as equipment availability, location, and time. They are also associated with high risks, substantial costs, and resource-intensive processes, which do not align with the imperatives of energy conservation, emission reduction, and the evolving needs of experimentation [

4]. With the transformation of digital education, the experimental teaching model using virtual simulation technology effectively mitigates the limitations of physical environments and offers engaging experimental content that significantly stimulates students’ enthusiasm for experimentation [

5].

Over the last decade, both domestic and international colleges and universities have established subject-specific virtual simulation experimental teaching centers. Central South University [

6] has set up a Mechanical Engineering Virtual Simulation Experimental Teaching Center capable of simulating complex processes, including curved surface manufacturing, microelectronics manufacturing, and more. Nankai University [

7] has established a Medical Virtual Simulation Experimental Teaching Center capable of conducting virtual anatomy experiments. This center eliminates the need for the traditional reliance on human bodies and cadavers and is no longer confined by limitations of time and space. The Electromechanical Virtual Simulation Experimental Teaching Center at Xiamen University [

8] has created a meticulously detailed virtual environment, complete with various experimental courses such as electrical technology, numerical control technology, and electronic technology practical training. Students have the convenience of remote access to the virtual experimental platform. IE Business School [

9] in Madrid, Spain, utilizes the educational game software ‘10 Downing Street’ in experimental teaching. Through this software, students can take on the role of the British Prime Minister, engaging in the resolution of significant national events. This experiment enhances students’ critical thinking and problem-solving skills. The University of Colorado has built a structured virtual laboratory that allows students to conduct personalized learning and independent experiments. The University of California, San Diego, has developed a virtual simulation system to show students a Jordanian fortress from the 10th century B.C. in order to solve the architectural mystery of this giant fortress. The British Open University has developed an experiment management platform that supports remote control, virtual instruments, interactive multimedia experiments, online analysis, and comprehensive research, which can quickly realize the management functions of all university laboratories online. The virtual simulation experiment platforms constructed above lack a real-time interaction between virtual and physical spaces and have not yet established a seamless connection between them. In recent years, digital twin technology, an emerging information technology, builds upon virtual simulation technology, facilitating the seamless integration of the physical and information worlds. The digital twin is used to create a virtual model of a physical entity in the digital space, simulate the real behavior of the physical entity by means of simulation and acquisition of sensor data, and empower the physical entity through means such as virtual–real interaction, data analysis, and decision optimization [

10].

Numerous scholars have identified the drawbacks of traditional experimental teaching and have developed experimental platforms using information technology. Li et al. [

11] developed a workshop production line simulation system using digital twin technology. This system enables the display of workshop production status, key production data, and virtual simulations of the production process. Guo et al. [

12] addressed workshop layout issues in discrete manufacturing workshops by researching the optimization of layouts using a digital twin. Real-time data collection and value-added processing of twin data inform equipment layout decisions. The application of virtual reality (VR) in education not only offers educators a broad spectrum of experimental development experiences but also actively engages students in the learning process [

13]. Alpala et al. [

14] proposed a VR-based experimental development framework aimed at enhancing collaboration and communication within the 3D virtual world. This framework will be applied to education and production departments within smart factories. Zhu et al. [

15] introduced a method for building a virtual simulation experimental platform using bibliometric analysis and the analytic hierarchy process. This platform is rooted in a task-driven teaching approach and can be adapted for use in various disciplines. In another study [

16], ANSYS Fluent software was employed to investigate numerical solutions for heat transfer, mass flow transfer, and the simulation of nitrogen oxide emissions. Wei et al. [

17] employed a self-developed teaching software, VTPCE, in power system analysis experiments. This software, combined with hardware experimental equipment, facilitates experimental teaching and establishes a link between theory and practice. The analysis of research results related to the application of information technology on the experiment platform is presented in

Table 1. In their exploration of Convolutional Neural Networks (CNN), Xu et al. devised a fusion simulation approach for the intelligent identification of faults in rotating machinery. This method’s effectiveness was confirmed through practical case studies [

18,

19].

The problems existing in the current experimental teaching platform based on virtual simulation technology include the following:

- (1)

The inability to adjust the simulation model in real time based on real-world conditions leads to discrepancies between the model and reality, resulting in inaccurate predictive decisions;

- (2)

Simulation models are typically intricate to construct, demanding precise modeling techniques and significant computing resources, making them challenging to apply in complex and large-scale scenario tasks;

- (3)

Simulations typically rely on known data and predefined rules, which restrict their ability to address unknown situations and impose limitations on timeliness;

- (4)

Commercial products tend to be bulky, difficult to deploy, and incompatible with multiple platforms. Furthermore, their high cost often makes them unaffordable for many schools and individuals. Virtual simulation experiment resources follow an open sharing principle, which necessitates the development of lightweight experimental platforms.

The “Production Planning and Control” course is a cornerstone in the curriculum of industrial engineering majors at higher engineering colleges. It provides a systematic education in production planning and control, equipping students with fundamental principles, methods, and advanced production models. The most distinctive aspect of this course is its emphasis on practical application. However, the current experimental sessions in the course still rely on traditional on-site physical operations, which may seem somewhat outdated in the context of the relatively mature development of virtual simulation technology. The current approach faces several challenges: (1) Experimental equipment is confined to the laboratory, requiring students to be physically present for experiments, which hinders pre-class preparation and the opportunity for repeated experiments; (2) equipment resources are inflexible and challenging to upgrade. For instance, Automatic Guided Vehicles (AGVs) equipped with advanced sensors are continually evolving, leading to discrepancies between classroom teaching content and outdated experimental equipment; and (3) limited experimental space and equipment availability make it impossible to accommodate multiple students simultaneously for experimental teaching.

With the rapid advancement of computer technology and communication technology, virtual simulation experiments based on the digital twin have become increasingly mature [

20]. This paper’s research work on teaching innovation is based on the Comprehensive Laboratory of Industrial Engineering at HIT. It combines digital twin technology to design and develop a virtual simulation experiment for assembly line workshop scheduling optimization. The experiment platform is specifically designed to cater to the needs of the “Production Planning and Control” course. The workshop AGV functional digital twin model constructed can engage in a two-way real-time data interaction with the actual production system. This simulation experiment platform is used to validate various workshop scheduling strategies and iteratively enhance the logistics process, thereby improving the manufacturing system through a combination of virtual and real methods.

The remainder of this paper is organized as follows.

Section 2 introduces the construction process of the functional digital twin model of workshop AGVs. An experimental platform based on the AGV twin model is designed according to the teaching syllabus in

Section 3. Furthermore, the display and analysis of an experimental teaching case are provided in

Section 4. Finally,

Section 5 offers the conclusions and future work.

2. Functional Digital Twin Model of Workshop AGVs

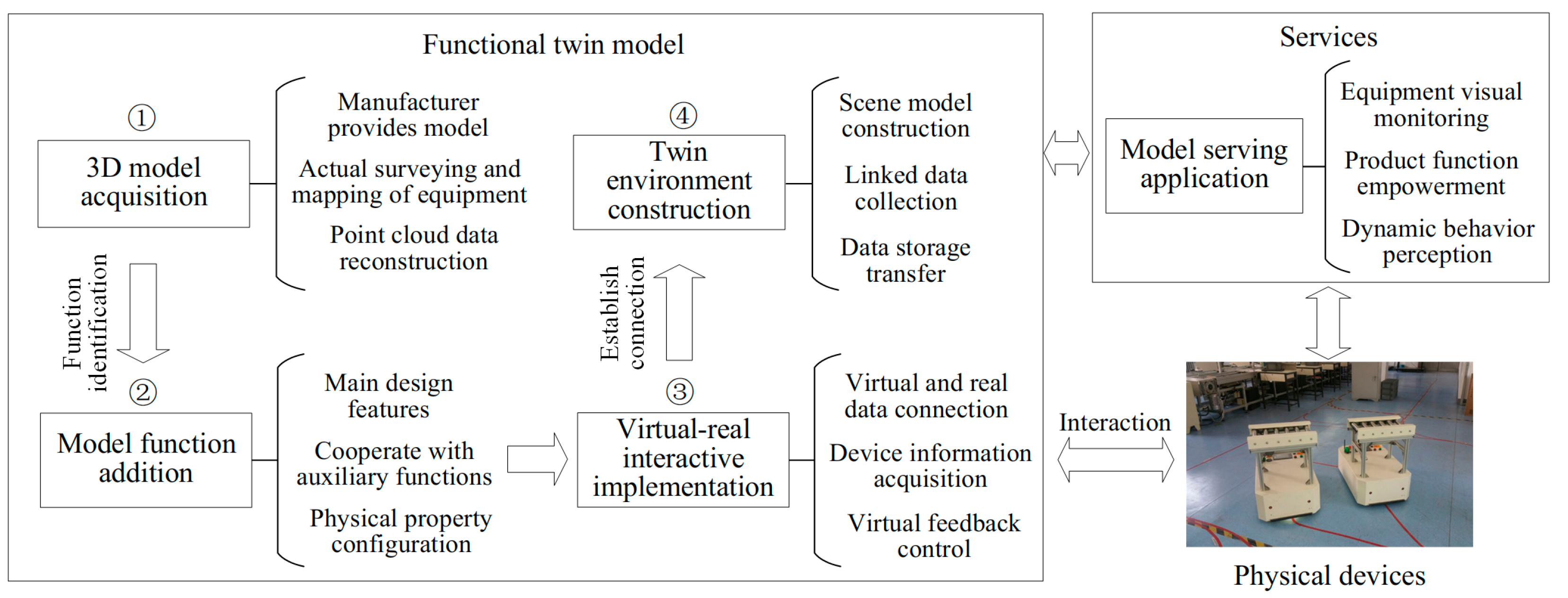

With the ongoing trend toward automation in workshop production and logistics, AGV scheduling has become a prevalent approach in material transportation operations, representing one of the recent research hotspots. Within the workshop logistics process, the loading, unloading, and transportation phases account for the majority of the total time, resulting in elevated workshop logistics and transportation expenses. People are focusing on whether workshop AGVs can effectively reduce transportation time and costs by addressing dynamic issues during transportation. The AGV twin model is an integral component of the digital twin of the workshop. It not only monitors the AGV’s real-time operational performance but also facilitates visual path planning, workshop scheduling solutions design, and workshop logistics simulation. The construction framework of the workshop AGV functional digital twin model is illustrated in

Figure 1.

The system is administered through model-driven engineering, aiming to attain synchronization between the system and the model [

21]. The digital twin seamlessly integrates both models and data, facilitating their efficient and effective application. The AGV functional digital twin model construction process consists of four parts: 3D model acquisition, model function addition, virtual–real interactive implementation, and the establishment of a twin environment. The 3D model serves as the foundation for twin model construction. It includes the addition of functions, attributes, and operational rules based on real equipment. At this stage, the twin model can perform simulation functions. It further establishes a data connection between virtual and real devices, employing the WebSocket network transmission protocol as a data interaction bridge. To align the AGV twin model with the logistics scheduling requirements for the workshop and establish the twin environment of the workshop, the physical AGV communicates with the server via the User Datagram Protocol (UDP). The host computer connects to the server database through WebSocket to receive AGV data and feedback control instructions. The movement path of the AGV is pre-planned in the laboratory. Empowered by the twin model, workshop scheduling strategy testing and real-time AGV monitoring become feasible, providing students with a deeper understanding of the workshop logistics scheduling process. Throughout this process, physical equipment, twin models, and twin services undergo iterative optimization.

2.1. 3D Model Acquisition

Initially, to provide an accurate representation of the AGV’s operational processes, a 3D digital model of the AGV must be established in a virtual space. This 3D model closely mirrors the size, behavior, and logic rules of the physical AGV. The geometric attributes, visual appearance, and material properties of the AGV are meticulously studied and recreated on the 3D modeling platform. This attention to detail enables the virtual model to faithfully replicate the physical AGV, laying a solid foundation for the AGV twin model’s effective service in real production scenarios.

2.2. Model Functions Addition

The established 3D model closely resembles the appearance of the actual device but lacks the attributes and functionalities of the actual device during operation. This paper concentrates on the motion states and navigation and obstacle avoidance performance of AGVs within the workshop. When constructing a 3D digital model, it is crucial to provide detailed descriptions of components that directly impact AGV motion, such as wheels and drive motors, while other components may receive more simplified modeling. Following the definition of the digital twin, physical AGVs are equipped with sensors to perceive their surroundings, facilitating navigation and obstacle avoidance. The AGV twin model, in turn, must possess this capability to enable the interactive mapping of the physical and virtual entities. By incorporating virtual sensors, the AGV within the virtual environment can sense its surroundings, resulting in a high-fidelity simulation of a real AGV.

2.2.1. Construction of AGV Kinematics Model

Kinematics represents the fundamental study of mechanical system operations and serves as the cornerstone for navigation and motion control in mobile robots. The kinematics model encompasses both forward kinematics and inverse kinematics: The forward kinematics model leverages the known rotational speed of differential drive wheels to calculate the linear velocity and angular velocity of the robot’s body. Conversely, the inverse kinematics model uses the known speed of the robot or target position to compute the required angles or speeds at which the two driving wheels should rotate. These two models find distinct practical applications within the field. The core essence of the digital twin resides in the meticulous mapping of virtual representations to their physical counterparts. Within the virtual simulation experiment platform established in this paper, the AGV stands as the linchpin for conducting experiments. Its precise appearance, dimensions, and movements wield a profound influence on the visual orchestration within the workshop’s simulated environment. The pivotal significance of building an AGV kinematics model lies in its ability to authentically mirror the actual AGV’s motion attributes within the virtual realm. This model, encapsulating the AGV’s driving form, speed, and operational states, ensures a high-fidelity replication of the real AGV. By leveraging this kinematic model, the virtual AGV can accurately emulate the behaviors and operational dynamics of its physical counterpart. After the AGV scheduling optimization algorithm is called on the experimental platform, the output results directly drive the virtual AGV movement. For students performing remote experiments, the AGV movement seen in the twin software (Version 4.27.2) interface is consistent with the actual AGV.

From theoretical mechanics, it is evident that there exists a point at which the velocity is instantaneously zero during the plane motion of a rigid body. This point is known as the instant center of velocity, denoted as P. In

Figure 2, all two-wheel differential drive robots can be roughly approximated and represented as the ideal model depicted. In this model, point P represents the instantaneous center of speed for the AGV, while L and R denote the geometric centers of the two drive wheels, respectively. Additionally, O represents the midpoint of the line connecting the centers of the drive wheels.

The forward kinematics model relies on the speeds of the left and right driving wheels to compute the linear speed of the AGV. It can be expressed as follows:

where the angular velocity of the AGV is represented by w, the linear velocity by v

c, the turning radius by r

c, the speeds of the centers of the left and right driving wheels by v

l and v

r, and the distance between the centers of the two driving wheels by d.

The inverse kinematics model relies on the AGV’s speed to compute the speeds of the left and right driving wheels. It can be expressed as follows:

2.2.2. AGV Virtual Sensor Addition

Currently, various modeling engines, such as Unreal Engine 4 (UE 4, Version 4.27.2) and Unity, provide support for object detection within virtual environments. They utilize computer graphics techniques, including vector measurements and ray detection, commonly used in game programming. These methods involve emitting detection rays towards the target, allowing the identification of the object’s status and distance based on reflection information.

A virtual infrared sensor is positioned on the front of the 3D digital model of the AGV, emitting a virtual infrared beam along the normal direction of the front surface of the AGV. When the beam encounters an obstacle, it is reflected, allowing real-time calculation of the distance between the AGV and the obstacle within the virtual environment’s coordinate system. This information is used to simultaneously control both the virtual and actual AGV, enabling the adoption of an avoidance strategy based on the predetermined distance threshold.

2.3. Interaction of Virtuality and Reality

Following the digital twin five-dimensional structural model [

22], a dynamic real-time interactive connection seamlessly merges the virtual model with the physical entity, enabling the effective bidirectional transmission of data and information between the two components. The construction of AGV kinematics and virtual sensor models serves the purpose of employing computer technology to describe AGV functions, effectively simulating the real AGV. However, offline simulation of the physical world lacks the capability for analysis and iterative optimization. To fulfill the requirements of a digital twin, data acquisition and analysis methods are essential to perceive physical entities, provide diagnostic and predictive services, and, in turn, optimize physical entities. This continuous process leads to the enhancement of the twin model over time.

To establish the data connection between physical space and digital space, it is essential to begin by analyzing the various types of state data in the physical space and subsequently matching these state data with corresponding models in the virtual space [

23]. The AGV control module examined in this paper utilizes a Programmable Logic Controller (PLC) from OMRON, which is equipped with an Ethernet communication module. This module enables real-time status monitoring and control of the PLC through the host computer. The AGV status data, encompassing motion data, guidance data, and obstacle information are transmitted to the server via UDP and recorded in the database. In the virtual environment, the AGV accesses the database through WebSocket to acquire this data, automatically synchronizing the motion status and attributes. Once the workshop logistics scheduling strategy is configured in the twin model of AGVs, movement instructions are sent through WebSocket, enabling the twin model to guide the actual AGV in completing logistics tasks.

2.4. Construction of Twin Environment

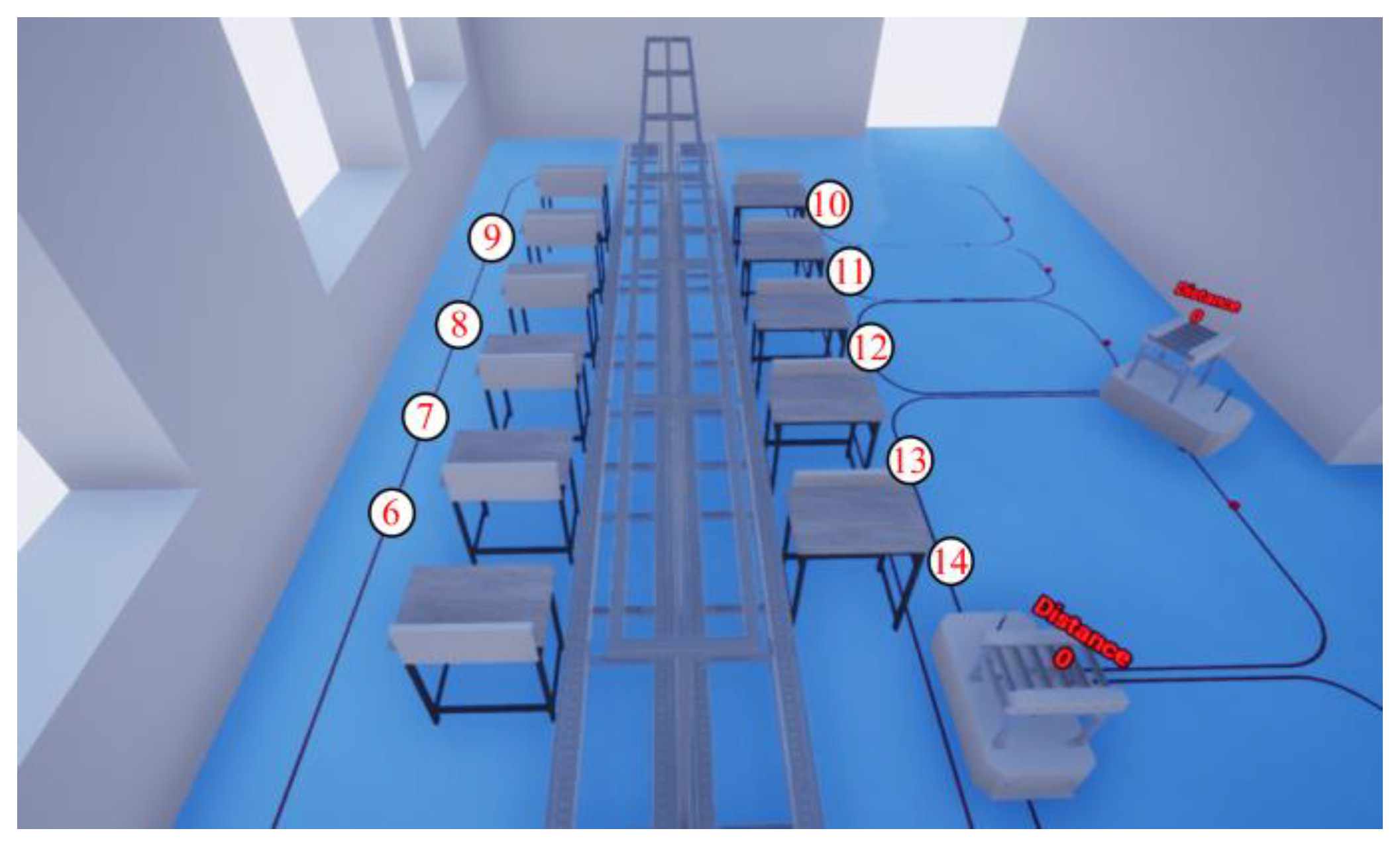

For this paper we chose the intelligent manufacturing prototype workshop within the industrial engineering comprehensive laboratory as the focus of digital modeling. It includes the digital modeling of typical equipment found in the workshop, such as AGVs and the assembly line. Within the workshop, there exists an assembly line featuring a U-shaped production layout, responsible for the assembly of WPA and WPO reducers. This workshop reducer assembly line is visually depicted in

Figure 3. The numbers in the figure are stations that guide AGVs movement. The construction of the workshop twin environment primarily consists of two components: workshop virtual modeling and the storage and retrieval of twin data.

2.4.1. Virtual Scene Modeling

The workshop environment encompasses the overall appearance of the digital scene, including the workshop model, layout, material systems, and more. To obtain the 3D geometric dimensions of the physical scene, precise measurements of the workshop’s size and layout were conducted. SolidWorks and 3ds Max software were employed to perform 3D modeling of the workshop scene. The virtual model was meticulously arranged to replicate the real workshop’s layout, ensuring that the virtual environment faithfully mirrored the realistic production setting. This approach guaranteed a one-to-one correspondence between the constructed virtual scene model and the proportion and details of the physical workshop.

2.4.2. Storage and Retrieval of AGV Status Data

The Redis database, a non-relational database, serves to store frequently accessed data in cache, offering rapid read speeds that significantly enhance system performance [

24]. Consequently, the status data generated during AGV operations were stored in the Redis database, and unified management was facilitated through the use of Navicat software (Version 16.0.11).

Within the workshop, the AGV follows a designated path, which includes multiple stations that guide the AGV’s movement and stopping. Information regarding the route and station details was stored within the twin environment. The AGV data collection program retrieves status data from the PLC for AGV via the Socket communication interface and stores these data in the Redis database. Key status data for the AGV include the AGV number (id_AGV), obstacle status (block), guidance status (guide), and site information (station), among others (keywords in brackets denote database key values). However, as the type of the status data is string, it cannot be directly applied to the twin model of AGV. To make these data compatible with the twin model, they require decoding and conversion into a format that the twin model can readily interpret.

3. Design of Experimental Platform Based on Digital Twin

3.1. Design of Platform Functions

Following the syllabus of the “Production Planning and Control” course at HIT, there are two experimental modules: workshop facility layout optimization and assembly line workshop scheduling optimization. Each module involves a series of experimental tasks that must be completed in accordance with the prescribed requirements. In

Section 2, we successfully constructed the AGV’s functional digital twin model and the workshop twin environment. Building upon this foundation and aligning with the course experiment requirements, we designed a virtual simulation experiment platform. The primary objective of this simulation experiment was to offer students a virtual experimental environment in which they can validate various assembly line workshop scheduling strategies and refine the multi-AGV scheduling algorithm by seamlessly integrating virtual and real methods.

3.1.1. Workshop Facility Layout Optimization Experiment

The digital twin virtual simulation experiment platform offers a virtual representation of the workshop’s facility layout and faithfully reconstructs the interplay between the workshop’s various components and its operational processes. After gaining a comprehensive understanding of the entire process, encompassing raw material delivery, sorting, production, quality inspection, and finished product warehousing within the laboratory, students systematically analyzed the encountered issues. They leveraged the digital twin virtual simulation experiment platform to integrate the laboratory’s flexible production line. Drawing from measured processing data and considering various constraints, they strategically arranged production tasks for WPA and WPO reducers at each station while achieving a balanced production rhythm. A comparison was made between the line balance rate before and after optimization. Throughout the experiment, students gain profound insights into the importance of workshop facility layout optimization and acquire a proficiency in basic workshop facility layout optimization techniques.

3.1.2. Optimization Experiment of Assembly Line Workshop Scheduling

In this experiment, we achieved a seamless interaction between the digital twin virtual simulation experiment platform and the actual physical equipment. Students work with multi-AGV logistics transportation lines to execute precise and timely material distribution between various sites, all while adhering to multiple real-world constraints in the production environment. The order of material distribution is known, yet the scheduling strategy remains a mystery. Students are tasked with utilizing the available laboratory equipment to compare multiple strategies and effectively arrange the order of scheduling operations. Throughout this process, students must acquire proficiency in operation sorting methods governed by different rules and learn to leverage intelligent algorithms to determine the optimal operation sequence. The experiment fosters students’ abilities to observe, analyze, and solve problems through the examination of phenomena in the experimental process and the analysis and interpretation of experimental results.

3.2. Experimental Platform Architecture Based on Digital Twin

The virtual simulation experiment platform, built on the foundation of digital twin technology, employs a teaching method that seamlessly combines a virtual simulation with physical experiments. This unique approach provides students with an immersive experimental environment, deepening their comprehension of theoretical knowledge. Simultaneously, it enhances their ability to apply systematic thinking to analyze and solve problems while strengthening their hands-on skills. This experimental platform accommodates both offline virtual simulation experiments and online virtual and real experiments. The development architecture of the virtual simulation experiment platform based on the digital twin is illustrated in

Figure 4.

Traditionally, students completed course experiments by directly applying AGV scheduling strategies to physical equipment. The optimization of scheduling algorithms primarily depended on the students’ observation and analysis of the operational processes. However, this approach lacked an efficient simulation method for iterative optimization of the real scheduling process. Consequently, this paper establishes a digital twin experimental platform with the specific aim of enhancing the students’ course experiments. The platform is structured into three layers: physical, digital, and application. The physical layer encompasses essential experimental equipment, including the AGVs, assembly line, shelf, and warehouse, located within the laboratory. The data collected by the physical layer are transmitted to the digital layer, where they undergo mapping to align with the physical layer. The digital layer comprises the AGV twin model, workshop twin environment, and algorithm management unit. It analyzes data received from the physical layer and initiates twin services within the application layer. Meanwhile, the application layer consists of the workshop facility layout optimization experiment, assembly line workshop scheduling optimization experiment, and algorithm application practice, which seamlessly integrate the physical and digital layers. The operational process of the experimental platform unfolds as follows: The physical and digital layers establish a twin data connection within the workshop. Experiments conducted within the application layer are executed remotely by students. Both the virtual workshop and the physical workshop run concurrently, enabling real-time interaction. The experimental results generated by the digital layer are subsequently validated and optimized for the physical workshop.

To accommodate the demands of large-scale scene rendering and real-time requisites, the experimental platform in this article adopts a Client/Server (C/S) architecture. To engage in experiments, students install the experimental platform software, leveraging UE 4’s diverse UI controls, which facilitate human–software interaction. Within this framework, students select experiments aligned with the course requirements. For instance, considering the assembly line workshop scheduling optimization experiment, upon accessing the virtual platform, students encounter a comprehensive explanation of the experiment’s principles and operational steps. They proceed to set the material transportation order sequence and select the transportation strategy virtually. As the AGV commences its operation, students navigate the virtual scene, witnessing the AGV’s movement. Subsequently, the chosen strategy yields data on transportation distance and time. This information enables students to analyze the pivotal role of logistics distribution within manufacturing systems, integrating their acquired knowledge with the experimental process.

3.3. Key Technology of Experiment

3.3.1. Modeling and Scene Rendering

In this paper, the primary software platforms employed for constructing the 3D digital models of the AGV and the workshop were SolidWorks (Version 2020 SP0.0) and 3ds Max (Version 2022 24.0). SolidWorks excels in achieving a 1:1 scale, accurate dimensional modeling of parts, equipment, and other objects. It is particularly useful for building 3D models of entities within the workshop that demand high dimensional precision. On the other hand, 3ds Max leverages its powerful surface modeling capabilities and rendering functions to create expressive workshop structures, including walls, floors, and object surface materials. This enriches the texture and color of the workshop’s production scene. SolidWorks and 3ds Max’s 3D modeling advantages are fully harnessed to craft a detailed AGV model. This approach not only ensures a high-precision representation of the AGV’s geometric shapes and dimensions, but also faithfully recreates its appearance characteristics. As a result, the virtual AGV mirrors the behavior and rules of its physical counterpart.

UE 4 serves as a comprehensive scene-building and rendering engine, tailor-made for game developers to design and construct games, simulations, and visualizations. Its real-time, realistic rendering technology plays a pivotal role in supporting the visualization of digital workshops. This is achieved by integrating 3D models of physical entities with real-time data streaming. Real-world data from tangible entities can be utilized to animate models and create on-screen displays [

25]. To ensure that the virtual 3D workshop model closely resembles its physical counterpart, SolidWorks was employed for precise 3D digital modeling of the AGV, while 3ds Max handled scene modeling and material integration. Despite the visual similarity between the virtual and physical workshop models, the former lacks interactivity with humans and cannot effectively visualize the dynamic digital processes within the workshop. To address this, an interactive design was incorporated into the UE 4 platform, enhancing the workshop model’s usability and interactivity. An example of the workshop model created in UE 4 is illustrated in

Figure 5. The numbers in the figure are the station numbers that guide the AGVs.

3.3.2. Implantation of Multi-AGV Scheduling Problem Solving Algorithm

Genetic algorithms, a class of search algorithms, find extensive application in resolving the multi-AGV scheduling optimization dilemma within workshop scenarios. By utilizing computational models, genetic algorithms explore optimal solutions by simulating the natural selection and genetic processes. These algorithms excel in tackling combinatorial optimization problems and represent an intelligent optimization methodology rooted in principles of natural evolution and selection, offering potent global optimization capabilities [

26]. Hence, this paper employed a genetic algorithm to address the multi-AGV scheduling issue within the workshop.

The AGV scheduling problem was effectively divided into two key components: the first entails determining the shortest path for AGVs, while the second involves task assignment.

Figure 6 displays the AGV operation circuit diagram. In the first part, identifying the shortest path for AGVs involves establishing the most efficient routes for each station, ensuring the shortest distance between any two points on the map. The second part, task allocation, focuses on optimizing the overall time taken for multiple AGVs to complete a batch of tasks, ultimately minimizing the total travel distance. Besides prioritizing the shortest path for AGV travel, this approach also underscores the importance of rational task allocation. To tackle these challenges, the virtual simulation experiment platform, built on digital twin technology, leverages a genetic algorithm as the optimization method for AGV scheduling. The development of this algorithm is carried out in the Python programming language, seamlessly integrated into the virtual environment based on UE 4.

In the virtual experiment platform developed within this paper, an AGV scheduling optimization algorithm aligns with the course’s experimental requisites. This simulation platform not only executes the algorithm but also visually presents the solution alongside AGV movements. The optimization process for multi-AGV scheduling problems using genetic algorithms unfolds in several distinct stages:

Symbol-based encoding: Chromosomes representing solutions are symbolically encoded using paths. Each chromosome is depicted as an integer array, and its length equating to the number of experiment sites.

Initial solution formation: To begin, multiple sequences (equal to the population size) are generated randomly. A random number matching the site number is stored in an array.

Selection: from the pool of feasible solutions (chromosomes), a selection process akin to natural selection occurs.

Fitness calculation: solution fitness is gauged primarily by the running time.

Crossover: employing the Alternating Position Crossover (APX) method, pairs of chromosomes undergo crossover operations, blending genetic information.

Mutation: certain gene positions within individuals are randomly selected for exchange, introducing variability through mutation with a defined probability.

Termination criteria: the process terminates upon reaching the preset iteration limit, signifying the completion of algorithmic iterations.

3.3.3. Data Communication Connection

The workshop’s AGV PLC, as examined in this study, offers Ethernet connectivity. With custom-developed control software, real-time status data can be acquired from the AGV, and instructions can be transmitted to control its movements. Socket, as a process-to-process communication mechanism, facilitates the exchange of information between entities by defining IP addresses and ports [

27]. Applications use sockets to either send requests to the network or respond to network requests. Implementing a Socket connection communication typically involves at least two sockets: one operating on the server side (referred to as “jack”) and another on the client side (referred to as “plug”). Most programming languages provide Socket controls that support both TCP and UDP communication protocols. The key distinction between TCP and UDP lies in whether a connection is established beforehand when transmitting and receiving data. Given that establishing a UDP protocol connection consumes fewer system resources and aligns with the real-time requirements for acquiring AGV status data, this paper opted for UDP for communication with the PLC.

4. Experimental Teaching Case and Analysis

The Harbin Institute of Technology offers the “Production Planning and Control” course, spanning 32 h and available to multiple colleges during the first half of the junior year. This course aims to monitor market demand shifts and strategically organize materials, equipment, human resources, and finances. The objective is to curtail production costs while enhancing product quality and overall operational efficiency for enterprises. Student assessment within this course is bifurcated into written examination and experimental sessions. The written tests evaluate students’ grasp of the course material, while the experimental segment appraises their practical skills through on-site activities and subsequent experimental reports. Affiliated with the School of Mechatronics Engineering, the Industrial Engineering Comprehensive Laboratory spans 200 square meters. It encompasses a complete reducer assembly production line, including sections for raw materials, finished products, assembly, and material transportation equipment.

The virtual simulation experiment platform based on digital twins constructed in this paper supports offline experiments and online experiments. Remote students will conduct experiments in the form of an offline experimental platform and experimental data come from virtual space. When students are in the laboratory, they can conduct online virtual and real experiments through the virtual experiment platform. The twin software and experimental equipment are under the same local area network. The UDP protocol is used to connect to an AGV’s PLC to obtain AGV real-time status data. The twin software implements access to the database through WebSocket, thereby ensuring that the virtual AGV and the actual AGV run synchronously with low latency.

4.1. Experimental Principle

The production operation plan for a multi-variety, small-batch flow processing workshop entails the organization and prioritization of processed parts. When determining the sequence in which work pieces are processed, there often exist numerous potential choices. The criteria employed for selecting work pieces exert a profound influence on the quality of the sequencing plan. This, in turn, has far-reaching implications for overall work efficiency, cost management, energy consumption, and other facets of the entire flexible production system.

After completing the formulation of the production operation plan, the integration of intelligent logistics equipment, such as AGV, becomes crucial for ensuring the timely and precise transportation of materials and products. AGV scheduling involves the assignment of transportation tasks to a group of AGVs and the generation of optimized paths for these designated AGVs, enabling them to efficiently complete their tasks. The operating efficiency of AGVs plays a pivotal role in influencing the overall production and assembly efficiency of products. The timely and effective delivery of materials required by the station serves as the cornerstone for the efficient and stable operation of the workshop. Moreover, it lays the foundation for the realization of intelligent production within the workshop, where precision and efficiency go hand in hand.

4.2. Experimental Content

In this experimental scenario, students are tasked with using a digital twin virtual simulation platform to ensure the accurate and timely transportation of materials between different sites. This process is accomplished through a mapping interaction that mirrors real laboratory conditions. In real-world production situations, the sequence for material distribution is known, but the optimal scheduling strategy remains uncertain. The digital twin experiment platform offers an array of workshop scheduling strategies and a wide range of virtual experimental equipment. As part of this experiment, students are challenged to organize scheduling tasks efficiently, using various sequencing methods in accordance with different rules. Additionally, they will need to employ intelligent algorithms to find the most effective operation sequence.

Table 2 and

Table 3 provide information on known ordering sequences and the relative positions of AGV stations, which serve as essential references for this experiment.

In

Table 2, the data are organized into three columns. The first column represents the ordering sequence, detailing the sequence in which tasks or stations should be addressed. The second column contains the station numbers, providing a unique identifier for each station. The third column specifies the distance between each station and the initial position of the AGV, helping in the understanding of spatial relationships within the workspace.

Table 3, on the other hand, presents data concerning the relative positions of each station within the workshop. This information is essential for comprehending the layout and organization of the workspace.

4.3. Experimental Steps

Students’ experiments using the virtual simulation experiment platform can be divided into two stages, the experimental preview stage and the online virtual–real combination experiment stage.

Experimental Preview Stage:

When students access the simulation interface on the platform client, they are presented with pop-up windows containing information about the experimental principles, content, and precautions. These windows provide a comprehensive understanding of material transportation strategies, such as FCFS (First-Come–First-Serve) and LCFS (Last-Come–First-Serve), including their definitions and specific implementation methods. In the assembly line workshop scheduling optimization experiment, students input the order of material transportation orders into the experimental platform. Then, they select a transportation strategy integrated within the platform. As a result, the platform generates AGV motion control commands, and the AGV carries out the material transportation task within the virtual scene. The platform outputs the transportation distance and time taken by AGV to complete the assigned transportation task.

Online Virtual–Real Combination Experiment Stage:

Students initiate the virtual simulation platform client on their computers and put the actual AGVs in a standby state;

Based on the sequence of material transportation orders, the experiment involves the scheduling of two AGVs using three strategies: FCFS, SPT (Shortest Processing Time), and a combination of the shortest path and a genetic algorithm. Both the virtual AGVs within the simulation and the actual AGVs receive the motion commands simultaneously, executing motion control commands to ensure synchronized operation;

Students have the capability to remotely monitor the real-time operation of the AGVs through the platform interface. The experimental platform provides output data on the transportation distance and transportation time for each of the three strategies. Students need to analyze these data in their evaluation and comparison;

Here are some known details: (1) the AGV has a maximum load capacity of 3; (2) the AGV’s running speed is 0.1 m/s; (3) when employing the FCFS scheduling strategy, it is important to note that two AGVs cannot operate simultaneously;

As part of the experimental process, students are tasked with analyzing the prerequisites for a seamless logistics process within the manufacturing system. They must also contemplate potential intelligent upgrade solutions aimed at enhancing the efficiency of logistics operations.

4.4. Analysis of Experimental Teaching Effects

The virtual simulation experiment platform constructed in this paper introduces a functional twin model of AGV that closely mimics the size and motion attributes of the actual AGV. This functional twin model can effectively replace the physical AGV in virtual experiments. Unlike existing workshop simulation software, this platform is specifically designed to align with the student course experiment outline, providing a highly customized experience. One significant advantage of this experiment platform is its ability to address the limitations of general simulation software. It overcomes the challenges of real-time interaction and insufficient simulation performance commonly encountered in such software. Additionally, the platform offers students a broader experimental environment that is not constrained by equipment availability or physical venues.

Students utilize the data presented in

Table 2 and

Table 3 on the virtual experiment platform to derive the transportation distance and transportation time for the three material transportation strategies, based on the order of material transportation orders. The simulation results are then displayed in

Table 4. By analyzing the data in

Table 4, students can compare and evaluate the effectiveness and efficiency of the different strategies. This analysis enables them to draw conclusions about the performance of each strategy and make informed decisions regarding logistics optimization.

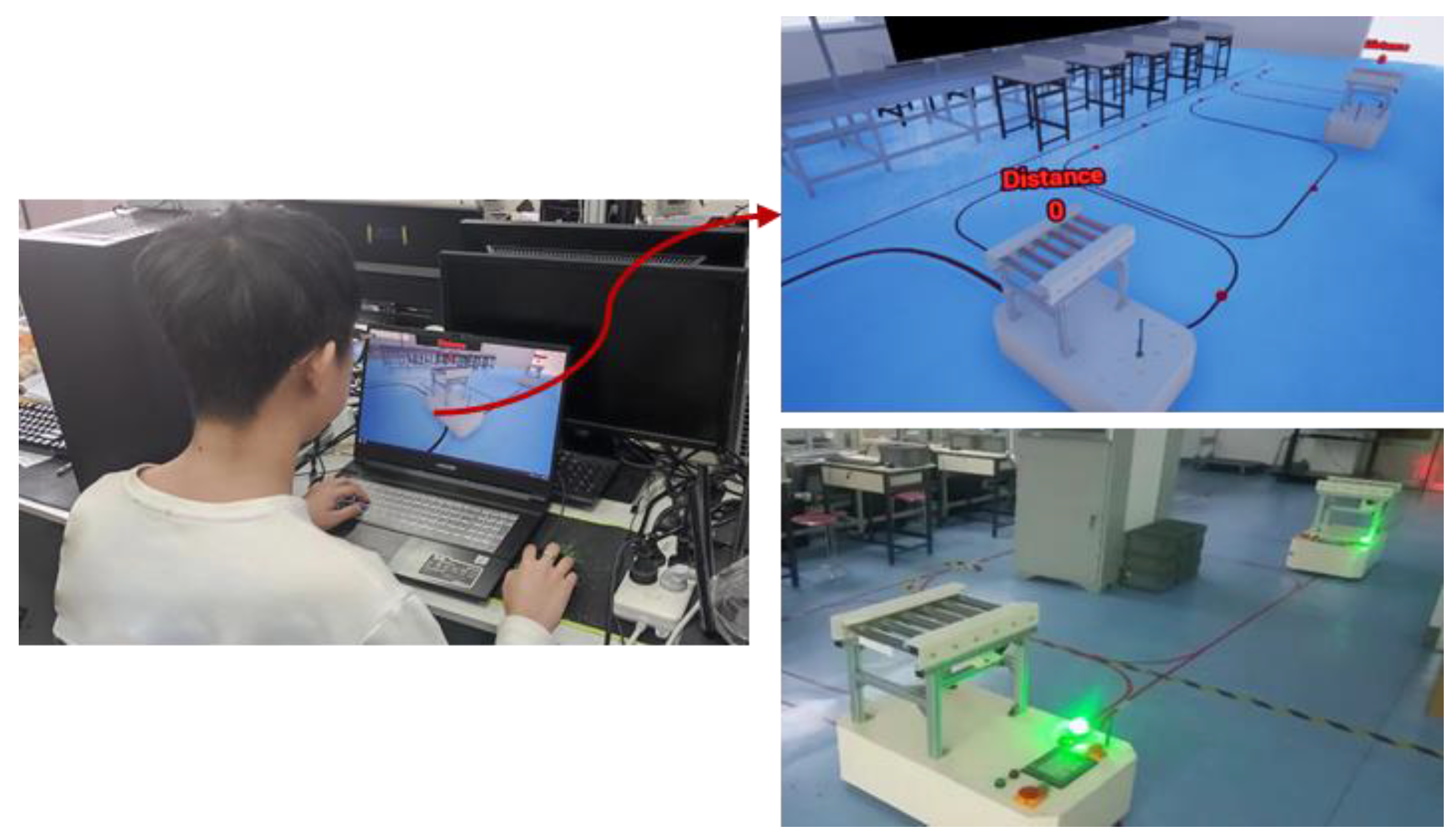

The experimental platform incorporates a design concept that combines virtual and real elements, creating a seamless connection between the virtual workshop and the physical workshop. This integration establishes a data channel that accurately represents the material transportation process within the physical workshop. In

Figure 7, a student is conducting an online virtual simulation experiment. The comparison of the AGV operating status in digital space and physical space is also shown.

Students perform experiments on the virtual simulation experiment platform and acquire data regarding the transportation distance and time under three distinct material transportation strategies. Students have the opportunity to conduct multiple simulation experiments, enabling them to compare and analyze the strengths and weaknesses of each strategy. This experimental platform offers a range of sorting methods, recognizing that certain processes may not be uniquely determined by applying a single priority rule. In such cases, students can explore an ordered combination of multiple priority rules. Through this interactive blend of virtual and real-world experimentation, students gain a deeper understanding of the knowledge they have acquired, enhancing their comprehension of the subject matter. The contributions of this paper are as follows:

The method utilized in this paper surpasses traditional simulation environments by enabling real-time data interaction between the virtual and physical spaces. Through the 1:1 restoration of the physics workshop, students are immersed in a highly realistic learning environment. This approach goes beyond video teaching, as it transcends pure animation display and incorporates real algorithms into the model. By immersing students in this interactive experiment, they can gain a genuine understanding of the impact of different transportation strategies on transportation costs.

When contrasted with the conventional experimental teaching method that exclusively relies on physical objects, the digital twin virtual simulation experimental platform, which amalgamates both virtual and tangible elements, significantly broadens the scope of experimental teaching content. In situations where physical experimental facilities are limited, the experimental platform can offer the necessary conditions for a greater number of students to engage in comprehensive experiments.