Abstract

Furniture production is a specific industrial sector with a high human labor demand, a wide range of materials processed, and short production runs caused by high customization of end products. The difficulty of measuring the aesthetic requirements of customers is also specific to furniture. This review of academic papers identifies and explains effective quality management strategies in furniture production. The reviewed literature highlights a range of quality management methodologies, including concurrent engineering (CE), total quality management (TQM), lean manufacturing, lean six sigma, and kaizen. These strategies encompass a variety of pro-quality tools, such as 5S, statistical process control (SPC), quality function deployment (QFD), and failure mode and effects analysis (FMEA). The strengths of these quality management strategies lie in their ability to enhance efficiency, reduce waste, increase product diversity, and improve product quality. However, the weaknesses concern implementation challenges and the need for culture change within organizations. Successful quality management in furniture production requires tailoring strategies to the specific context of the furniture production industry. Additionally, the importance of sustainability in the furniture industry is emphasized, which entails incorporating circular economy principles and resource-efficient practices. The most important finding from the literature analysis is that early detection and correction of poor quality yields the most beneficial outcomes for the manufacturer. Therefore, it is essential to strengthen the rigor of quality testing and analysis during the early stages of product development. Consequently, a deep understanding of consumer perspectives on required furniture quality is crucial. The review identified two research gaps: (1) the impact of unnecessary product over-quality on the efficiency of furniture production and (2) the influence of replacing CAD drawings with a model-based definition (MBD) format on quality management in furniture production.

Keywords:

supply chain; furniture industry; five whys; Ishikawa diagram; fishbone diagram; excessive quality; wooden furniture; upholstery furniture; concurrent engineering (CE); total quality management (TQM); lean manufacturing; lean six sigma; kaizen; 5S; statistical process control (SPC); quality function deployment (QFD); failure mode and effects analysis (FMEA) 1. Introduction

Furniture production is characterized by features that differentiate it from other manufacturing sectors. Multiple factors collide to create intricate quality control hurdles in the furniture industry, including labor-intensive manual production technologies, diverse input materials, demand for product customization, globalization of raw material procurement and end-product supply chains, and stringent sustainability norms.

Furniture production is more labor-intensive than other manufacturing sectors due to the complexity of furniture products, making them less amenable to automation in the production process [1]. Craftsmanship also plays a crucial role: skilled artisans contribute their expertise, adding unique touches to the final product [2]. Even in mass-produced furniture, some stages, such as upholstery, heavily rely on the craftsmanship of skilled employees. While some furniture is mass-produced, many manufacturers engage in batch production in small series. This approach simultaneously creates a limited number of similar pieces, allowing customization while maintaining production efficiency [3].

Furniture production utilizes diverse raw materials, including solid wood, wood-derived materials, metal, glass, plastics, leather, artificial leather, and upholstery fabrics. The diversity of materials significantly impacts the production process, making process planning challenging [4,5].

A notable aspect of modern furniture is its extensive capacity for tailoring final products, encompassing form, size, finish, and functionality variations [6]. This extensive level of customization is relatively uncommon in other industries [7]. Furthermore, the furniture design is dynamic. Furniture style trends shift seasonally, influenced by factors like rapidly changing fashion in interior design, cultural shifts, scientific progress [8], and technological advancements [4]. Manufacturers in the furniture sector must remain agile and adaptable to stay competitive [9]. The furniture production industry blends modern automated manufacturing, traditional craftsmanship, mass customization, and personalization [10]. Meeting consumers’ needs and preferences diverse presents a unique set of challenges. Every imperfection or flaw in furniture products is readily apparent and profoundly impacts customer satisfaction [11]. An effective quality management strategy ensures that the final products meet specific standards.

The globalized nature of the furniture industry, with raw materials and components sourced from a vast array of countries, poses challenges to supply chain management and renders it more susceptible to disruptions arising from geopolitical instability or trade disputes.

Handling and shipping furniture pose challenges due to its bulkiness and often delicate nature. Specialized storage, transportation, and delivery logistics are required [12]. Additionally, planning the assembly of ready-to-assemble furniture, which non-specialists typically do, presents challenges [13]. Contemporary industrially produced furniture is sold through specialized retail channels, including brick-and-mortar stores, online platforms, and showrooms. Many retailers also offer supplementary services such as assembly and delivery.

Sustainability is an increasingly vital concern in furniture production [14]. Responsible wood sourcing, eco-friendly materials, and waste reduction are critical considerations for modern manufacturers [15,16,17].

Quality control in the furniture industry includes preproduction, in-process, and postproduction quality management:

- Inspecting raw materials, product components, and tools to ensure they meet quality standards before being used in manufacturing.

- Conducting audits to ensure manufacturing processes comply with regulatory standards and industry best practices.

- Conducting inspections of finished products to ensure they meet all quality standards (appearance, functionality, durability, and safety). Interpreting consumer feedback.

Many varied methodologies and tools of quality control are used in production sectors [18]. Considering this multitude of quality management strategies and the specificity of furniture production, there is a justified need to provide insights and data to assist decision-makers within the furniture industry in making informed choices about optimal quality management strategies in the furniture industry. The intricate nature of quality management in the furniture industry necessitates a combined approach that integrates a narrative review with a systematic literature search. This synergistic combination supports neutrality and prevents the oversight of crucial details. This article analyses scientific and practical approaches to quality management in the contemporary furniture industry. The study aims to review scientific knowledge that assists professionals and decision-makers in navigating the complexities of quality management in the furniture industry, ultimately fostering efficiency, sustainability, and customer satisfaction.

2. Materials and Methods

We conducted a literature review to identify scientific literature on quality control strategies in the furniture industry utilizing Scopus, Web of Science, and Google Scholar databases. In Scopus, we specifically searched for articles containing the keywords “quality” and “furniture.” For Web of Science, we targeted original and review articles by searching in the abstracts for the same keywords. In Google Scholar, we focused on documents published between 1980 and 2023, searching all fields with “quality”, “furniture”, and “production” keywords. Table 1 summarizes the search criteria implemented in each database.

Table 1.

Criteria used to identify and screen literature sources.

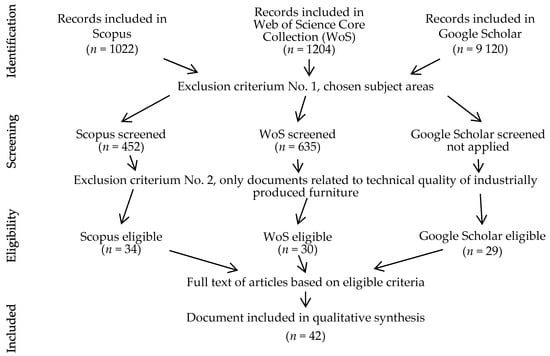

Figure 1 shows the steps and quantitative results of the search for scientific papers on quality management strategies in the furniture industry. These steps follow PRISMA principles.

Figure 1.

Flow chart of the literature analysis on quality in the furniture industry.

A comprehensive analysis of 42 scientific literature documents on quality management strategies in furniture production reveals three distinct categories: preproduction, in-process, and postproduction methodologies, each meticulously tailored to the industry’s unique demands.

Potential limitations of the study

The search strategy focused on original and review articles retrieved from Scopus, Web of Science, and Google Scholar, which may have excluded relevant gray literature, such as conference proceedings, technical reports, and industry publications. The search was conducted only in English, which may have excluded relevant work published in other languages.

3. Results of Literature Research

3.1. Preproduction Quality Management: Supply Chain Impact on Furniture Quality

A supply chain refers to the interconnected network of organizations, activities, processes, and resources in creating and distributing furniture products. The components of this network are:

- Suppliers of tools and other production equipment.

- Suppliers of raw materials for processing and suppliers of typical furniture hardware.

- Subcontractors producing specific furniture components.

- Sale and after-sale services.

Fassoula (2006) presented several conclusions about supply chain improvement in furniture production: (1) any transformation of the supply chain is a complex process that involves a fundamental shift in how organizations manage their operations; (2) the supply chain transformation requires a holistic approach considering all aspects, including production maintenance service, suppliers of raw materials, subcontractors, distributors, and customers; (3) continuous supply chain transformation improves efficiency, quality, and customer satisfaction; (4) adopting new technologies such as enterprise resource planning (ERP), and supply chain management (SCM) play a critical role in the transformation of the supply chain; and (5) the supply chain transformation requires strong leadership, effective communication, and a willingness to change. Fassoula highlights the importance of transforming the supply chain to remain competitive in today’s global marketplace. The cited article introduces a novel project management tool for supply chain transformation [19].

González et al. (2004) conducted a case study in the chair manufacturing industry to determine the importance of the supplier selection process. They found that supplier selection was critical to manufacturing performance, with supplier quality and delivery performance being the most important selection criteria. The study also revealed that effective supplier selection could lead to improved cost savings, increased production efficiency, and higher levels of customer satisfaction [20]. Nádasdi (2008) examined value methodology to enhance the supply chain’s competitiveness. The study found that value methodology improves production efficiency, reduces costs, and increases customer satisfaction. The research also revealed that value methodology could enhance a company’s competitive position in the market [21].

In industrial furniture production, raw material input characteristics must fall within established quality parameters, exhibit minimal variation, and remain relatively consistent across different batches. Skorupińska et al. (2021) addressed large-scale furniture manufacturing challenges when materials are sourced from diverse suppliers. This scenario typically arises during supply chain disruptions. While these materials are of the same type, they often exhibit variations in their structural properties. Consequently, a need to empirically assess these properties for each batch arises. The researchers conducted material tests involving five different suppliers to tackle this issue. They employed an innovative method and a specialized research apparatus, which offered two distinct advantages: firstly, the tests were cost-effective and expeditious, allowing for on-site implementation, and secondly, the assessments were conducted directly on actual furniture components, ensuring reliable and immediate results [22].

Technological advancements can sometimes lead to unforeseen alterations in the specifications of input raw materials. For instance, Wiaderek et al. (2020) analyzed the impact of inaccuracy in the specifications of steel springs used in upholstered furniture. The findings revealed that transitioning from manual to robotic assembly in upholstery frame production necessitated the implementation of spring selection to standardize their properties. Such standardization was unnecessary in the previous manual assembly process [23].

Sustainable practices and compliance with environmental regulations are increasingly important in the furniture industry supply chain. Anderson and Hansen (2004) examined the impact of environmental certification on wood furniture customers’ preferences. The study found that consumers would pay a premium for environmentally certified wood furniture. The research also revealed that certification of raw materials could enhance a company’s reputation and provide a competitive advantage in the market [24].

3.2. In-Process Quality Management

Klarić et al. (2015) employed the analytic hierarchy process (AHP) and the preference ranking organization method for enrichment evaluation (PROMETHEE) to identify and prioritize critical factors related to total quality management (TQM) in the context of wood science and the woodworking sector. The research identified several key factors influencing product quality and process efficiency. They assigned priority rankings to these critical factors. The study provided decision support tools and insights for professionals and managers in the woodworking sector, enabling them to make informed decisions regarding quality management and process improvement. The research emphasized the importance of integrating wood science principles and knowledge into the woodworking sector to enhance TQM practices and overall performance, including the significance of data mining as a proactive approach to managing defective products. Implementing automation in furniture assembly allows for real-time monitoring and quality control, reducing the likelihood of defects and product recalls [25]. These findings are confirmed by other studies [26,27].

Abu et al. (2019) and Urbina et al. (2022) reviewed the literature on implementing lean manufacturing (LM) principles in the wood furniture industry. Common motives for implementing LM include improving productivity, reducing production costs, enhancing product quality, and remaining competitive in the market. Both studies recognize the existence of barriers and challenges when implementing LM. These include resistance to change, lack of employee training, and the need for significant cultural and organizational shifts. Urbina et al., in particular, focus on reducing non-conforming products through a quality management model. This aligns with the broader quality improvement goals discussed in the literature [28,29].

The Toyota production system (TPS) and LM share common principles and objectives. Hunter (2008) found that implementing the TPS led to several benefits for upholstery furniture manufacturers, including reduced lead times, increased productivity, reduced costs, improved quality, and improved employee morale. However, the study also found some challenges associated with implementing the TPS, such as changing the organization’s culture and investing in new equipment and training. The TPS has been widely studied and adopted in various furniture technology stages [30].

Guerrero et al. (2017) conducted a study that applied “lean six sigma” principles within the wood furniture industry, specifically focusing on a small-scale company. In the context of this smaller furniture enterprise, the integration of lean and six sigma methodologies yielded several notable benefits. This strategic combination reduced production cycle times, lowered operational costs and notably increased overall productivity [31]. The application of lean six sigma plays a pivotal role in identifying and eliminating various forms of waste within the production process. As a result, product quality saw significant enhancements, leading to a reduction in defects and an overall increase in customer satisfaction. Notably, the study underscored that adopting lean six sigma practices can substantially enhance the competitiveness of small businesses operating in the wood furniture sector, enabling them to compete effectively alongside more prominent industry players.

Moreover, it was highlighted that lean six sigma can contribute substantially to sustainability within the wood furniture industry. This methodology aligns with sustainable practices by reducing resource consumption and minimizing environmental impact. The authors emphasized that employees’ active involvement and engagement were pivotal in successfully implementing lean six sigma strategies.

Radharamanan et al. (1996) focused on applying kaizen principles in a custom-made furniture industry setting. The findings of this research demonstrate that implementing kaizen principles resulted in significant enhancements in customized furniture production [32]. Kaizen-induced changes were instrumental in achieving notable improvements in product quality, including reductions in defects, minimization of rework occurrences, and enhanced consistency in the quality of custom-made furniture products. The study also underscores the positive impact of kaizen practices on productivity within the manufacturing process. This productivity gain was attained through process optimization, reduced downtime, and more streamlined workflows. Kaizen principles can be adapted and applied effectively in various manufacturing settings, including those with unique production requirements [32]. Implementing kaizen necessitates a cultural shift within an organization. Kaizen requires active involvement and participation from employees at all levels of the organization. Radharamanan et al. highlight that involving employees in continuous improvement efforts is a key driver of success.

In addition to implementing comprehensive quality management strategies, methodological tools for quality control are crucial, including statistical process control (SPC), failure mode and effects analysis (FMEA), and others. Patterson and Anderson (1996) suggested applying SPC within the cabinet manufacturing sector. During their study, SPC techniques, commonly employed in industries such as automotive and electronics, had not yet gained widespread adoption in the furniture manufacturing sector [33]. One of the study’s primary findings underscored the significant advantages of implementing SPC in the furniture industry. SPC involves systematically monitoring critical process parameters to detect defects early in production. This approach effectively reduces waste, saves costs, and produces higher-quality products. These benefits are realized by minimizing the need for rework, reducing material wastage, and streamlining production processes. However, it is essential to note that the cited authors also acknowledged the challenges associated with adopting SPC in the furniture industry. These challenges encompass the necessity for workforce training and education in statistical methods, potential resistance to depart from traditional manufacturing practices, and the perceived complexity of statistical techniques.

SPC plays a pivotal role at various stages of furniture technology, including:

- Accepting raw materials from external suppliers involves meticulous checks to ensure that the raw materials received meet the required criteria for seamless machine operation [22].

- Supervising robotic technologies, where a proactive approach by the internal maintenance department is essential to maintain the reliability of all automatic devices (especially the raw materials’ alignment with the robot’s operational requirements [23]).

- Supervising manual technologies, where human factors, crew variability, and employee qualifications are paramount in manual processes. Variations in these factors can significantly impact the quality of the final product [1].

- Final product inspection, for instance, evaluating the product’s resilience to packaging and assembly by an end user.

- Analysis of end-customer complaints.

Each stage involves data collection, providing insights for further preventive actions. Customer complaint data serves as a fundamental source of quality-related information. These data guide quality controllers at every stage of the process. For instance, in a study by Skorupińska et al. (2022), customer complaints prompted research on the impact of different materials on the risk of T-nuts falling out, making it impossible for the customer to assemble the RTA upholstered furniture on his own and such a situation means complaints. The customer complaints, combined with the study findings, triggered several technological decisions, including adjusting the frequency of machine inspections, modifying the “Must Check” list for each machine, and creating an analogical checklist for operators. Detailed technological standards for inserting T-nuts, including critical parameters, were established. These changes effectively resolved the nut-related issues, enhancing product quality [34].

The importance of SPC is emphasized in several publications. Laurence et al. (2011) focused on SPC in a single furniture manufacturer and highlighted the significance of statistical quality control as a valuable tool for monitoring and improving product quality [35]. Patterson and Anderson (1996) stated that SPC is most effective when used with other quality improvement tools and techniques [33], while Laurence et al. (2011) did not mention this. Laurence’s et al. findings are more specific to the furniture manufacturer they studied.

Savsar and Alotaibi (2020) conducted a study to enhance the quality of sofa furniture production. They implemented engineering statistics and quality control techniques to reduce process variability. This approach led to a reduction in excess material waste and an improvement in meeting customer requirements. As part of future research, the authors suggested the establishment of quantitative indicators to detect process shifts promptly, which could significantly reduce overhead costs. They also recommended expanding control charts to monitor other quality attributes beyond the length of strip woodcuts, mainly focusing on fabric cutting and sewing processes to minimize wasted fabric material and benefit the company’s profits [36].

An example of the practical application of FMEA results in manufacturing is integrating quality control measures into the chair frame production process. These seat frames have mounting holes for securing armrests, which must be fitted with claw nuts to ensure a secure fit. Moreover, the asymmetrical component must be correctly positioned within the seat frame to prevent assembly issues for non-professional end-users assembling ready-to-assemble (RTA) furniture. The jig depicted in Figure 2 accurately aligns the frame elements with their designated positions, eliminating the need for manual quality verification of the chair frame by assembly workers.

Figure 2.

A jig for verifying claw nuts’ correct insertion and arrangement of holes in an asymmetrical furniture element.

The jig depicted in Figure 2 is an instance of quality control embedded within the manufacturing process.

3.3. Postproduction Quality Analysis as Input Information into Production

Culbreth et al. (1996) proposed the concurrent engineering (CE) approach to ensuring furniture production quality. They outlined a comprehensive system designed to guide designers, product developers, and technological process planners regarding potential enhancements to product design, ultimately leading to product quality and manufacturing efficiency improvements. The principles underlying CE encompass early customer involvement, integration, simultaneous engineering, design for manufacturability (DfM), and design for quality (DfQ). This approach finds relevance and applicability across diverse industries, including but not limited to the aerospace, automotive, electronics, and furniture sectors [37].

Wan and Siu (2007) explored quality in design and creating identity in street furniture design. The study found that quality in design could enhance a company’s brand identity and customer satisfaction. The research also revealed that quality in product design leads to increased market share and competitive advantage [38].

Prekrat et al. (2009) proposed a comprehensive set of quality criteria for furniture that can be used to ensure high-quality end products during the design process. The proposed measures were categorized into four groups: functional, aesthetic, ergonomic, and environmental. The authors emphasized the importance of considering all of these criteria during the design phase to ensure that the end product meets the customers’ needs and expectations while being sustainable and environmentally friendly. The authors proposed a methodology for assessing the proposed quality criteria, which designers and manufacturers can use to evaluate their products and identify areas for improvement. The study highlighted the need for more research in this area to refine further and validate the proposed quality criteria and assessment methodology [39].

Toivonen (2012) highlights the importance of understanding consumer perspectives on product quality and value, specifically in the context of wooden products [40]. Greger et al. (2013) present a framework for assessing the technological process capability in furniture manufacturing, emphasizing the importance of criteria ranking in decision-making [41]. Hisjam et al. (2016) proposed a manufacturer–buyer relationship model for the export-oriented furniture industry with sustainability considerations [42]. Renata et al. (2019) explored quality management in specific areas of woodworking and the furniture industry, emphasizing the importance of implementing wood science in the woodworking sector [43]. Chadge et al. (2020) examined the role of Industry 4.0 in improving the performance of the furniture cluster, highlighting the potential benefits of technologies such as artificial intelligence and the Internet of Things [44]. Overall, these articles emphasize the importance of understanding consumer perspectives, implementing effective quality management practices, and leveraging technological advancements to improve the performance of the furniture industry. Sustainability considerations are also emphasized as an essential aspect of industry development.

Yang et al. (2013) postulated that the quality function deployment (QFD) method can be used to improve the design of campus furniture by considering the needs of users and the properties of wooden materials. The study found that applying the QFD method to creating campus furniture led to several benefits, including improved product quality by identifying and eliminating potential design flaws, reduced furniture development time, and reduced production costs. The authors identified durability, comfort, safety, aesthetics, and cost as critical design factors for campus furniture. The most important design factors for campus furniture are durability and safety. The study recommends that other furniture manufacturers could use the QFD method to improve the design of their products [45].

Erdil (2020) confirmed Yang and coauthors’ findings. While QFD can identify customers’ needs and translate these needs into technical requirements for products, Pareto analysis (PA) can prioritize the technical requirements and identify critical factors for improving product quality and customer satisfaction. Erdil’s study provides strong evidence that using PA and QFD together can be an effective way for furniture manufacturers to enhance product development and customer loyalty, including the voice of the customer (VoC) [46].

Using FMEA in the context of aesthetic functions can be a valuable approach to ensuring product quality during the planning stage. While FMEA is traditionally associated with assessing and mitigating risks related to functional aspects of a product or process, it can be adapted to address aesthetic concerns [26,47].

3.4. The Strengths and Weaknesses of Quality Management Strategies

The strengths and weaknesses of quality management strategies in furniture production can vary depending on the specific methodology. Table 2 summarizes an analysis of some common quality management strategies mentioned in the literature.

Table 2.

Strengths and weaknesses of quality management strategies employed in the furniture industry (based on the literature review).

4. Discussion

4.1. Importance of Methodological Tools and Strategies in Quality Control

Quality management methods are pivotal in industrial furniture production [59]. One of the most comprehensive approaches to quality management is total quality management (TQM) [25]. Many furniture manufacturers implement standard ISO 9001:2015 quality management systems [60]. This internationally recognized standard provides a systematic framework for quality management, involving establishing documented processes, setting quality objectives, and regular audits to maintain compliance. TQM focuses on continuously improving processes and products across the entire organization. It strongly emphasizes customer satisfaction, involving employees at all levels and making data-driven decisions to enhance quality. Continuous improvement, often called kaizen, encourages minor, incremental improvements in processes and products. Involving employees at all levels, this approach fosters a culture of constant learning and adaptation to changing market conditions.

Lean manufacturing (LM) is another widely adopted method in the furniture industry [28,29,61,62]. It aims to eliminate waste in production processes by applying principles such as value stream mapping, 5S, and just-in-time production [9].

Six sigma is a data-centric methodology designed to reduce process defects and variations. It follows the define, measure, analyze, improve, control (DMAIC) approach and relies on statistical analysis to achieve a high level of quality, where defects become rare occurrences [29,31].

Methodological quality analysis tools are also essential. Statistical process control (SPC) monitors and controls production processes. Tools like control charts and process capability analysis help identify variations that may impact product quality, allowing for prompt corrective actions. Root cause analysis techniques, including the Pareto chart, “five whys,” scatterplot diagrams, fishbone diagrams, FMEA, and fault tree analysis (FTA), uncover the underlying causes of quality issues and proactively identify and assess potential quality issues. Root cause analysis prioritizes risks and helps develop strategies to prevent or mitigate defects by identifying failure modes and their effects. QFD and voice of the customer (VoC) analysis translate customer requirements into specific product and process characteristics. By aligning product development with customer needs and expectations, manufacturers can create products more likely to meet market demands [63].

4.2. Costs Related to Quality That Is Too Low or Too High (Excessive Quality)

The costs associated with poor product quality vary significantly depending on when discrepancies are detected in the product’s life cycle. The earlier they are identified, the lower the correction costs and potential negative impacts on the company (Table 3).

Table 3.

Poor-quality costs in dependence on the production stage.

Therefore, companies aim to detect and resolve discrepancies early, preferably during the design and production stages, to minimize costs and the risk of introducing defective products. Implementing effective quality control systems and using tools like SPC to identify problems at early production stages reduces the risk of high correction costs and losses later in the product’s life cycle.

The term “excessive quality” in furniture production is worth explaining. This term defines furniture built with materials and construction exceeding usual standards for its designated lifespan, functionality, and price point. It means that the furniture is manufactured to a quality level that exceeds the customer’s expectations. Excessive quality can manifest in various ways:

- Using premium or rare materials that are not necessary for the furniture’s function or aesthetic.

- Over-engineering furniture durability to withstand conditions or wear and tear that it is unlikely to encounter.

- Incorporating intricate and costly design elements or decorative features that are not standard in the market segment.

Excessive quality produces furniture significantly more expensive than similar items due to luxurious materials or labor-intensive processes.

Excessive quality is relative and depends on the target market, customer expectations, and the intended use of the furniture. While some consumers might appreciate and be willing to pay a premium for excessively high-quality furniture, others may find it impractical or unnecessarily expensive [64].

The results of the review of scientific documents highlighted distinct research gaps in studying the impact of excess product quality on the overall efficacy of furniture production.

4.3. Human Factors

A case study by Sujová and Simanová (2021) highlights the importance of human factors in quality management and focuses on enhancing production process capability in the furniture industry. The authors identify key factors affecting production processes and propose solutions to improve their efficiency. The study reveals that inadequate production planning, insufficient capacity utilization, and a lack of employee training are major hindrances to smooth production operations. The authors suggest implementing a lean manufacturing approach, increasing automation, and enhancing employee training to address these issues. The study also demonstrates that implementing these solutions improves production process capability. The authors strongly advocate for a systematic approach to process enhancement, emphasizing a comprehensive framework that involves identifying critical factors affecting production processes, formulating a strategic plan to address these issues, and continuously monitoring outcomes to ensure ongoing improvement [65].

Many enterprises invest significant funds in human capital [60,61]. These investments ultimately prove to increase the performance of businesses, which is reflected in the increased quality of final products [62,63,64]. However, to improve and maintain employees’ productivity, it is necessary to ensure their education, training, motivation, and further development at the right time and in the right way [65,66]. The company’s performance depends on the employees’ efficiency [67]. Benefits and improved performance are primarily due to the development of employees, individuals, and work groups [68]. One possibility is the implementation of motivational programs, because this improves individual and organizational performance [69].

4.4. Innovations and Business Performance in the Context of Furniture Quality

Forker et al. (1996) studied the contribution of quality to business performance. They found that quality positively impacted financial performance, customer satisfaction, and employee satisfaction. The study also indicated that companies that focused on quality had higher levels of innovation, increased market share, and improved competitiveness [63].

Vickery et al. (1997) examined the furniture industry’s manufacturing strength dimensions. The study found that quality, flexibility, and delivery were the most critical factors contributing to manufacturing strength. The research also revealed that companies that emphasized these dimensions had higher levels of customer satisfaction and higher profitability [66]. Consumers want to personalize their homes, and furniture is vital in achieving this aim. Modular furniture is one of the most effective ways to address this demand. Modular furniture pieces are designed with interchangeable components, allowing consumers to create customized furniture arrangements that suit their preferences. In addition to modularity, there are other techniques for customization. These include individualized production, web product configurators that allow consumers to design personalized furniture, and temporary retail spaces that allow consumers to personalize their furniture. By adopting these and other strategies, furniture manufacturers can cater to the growing demand for customization, enhancing customer satisfaction and driving brand loyalty.

Sustainability is essential in the context of business performance. Alfranca et al. (2009) examine the role of environmental and quality strategies in promoting technological innovation in Spain’s wood-based industry. The study finds that environmental and quality systems positively impact the adoption of technological innovations [67]. Ratnasingam et al. (2013) explore quality expectations in the Malaysian wooden furniture industry from the perspective of foreign buyers [68]. The study finds that foreign buyers expect high-quality products to be delivered on time, meet their specifications, and be priced competitively. Gejdoš (2015) investigates quality management in the wood processing industry in Slovakia and the Czech Republic. The study finds that companies in the industry face challenges in implementing quality management systems and a lack of awareness about the benefits of quality management [69]. Prasetyo et al. (2018) examined furniture production efficiency in the Indonesian context. The study finds that the Indonesian furniture industry faces challenges related to production efficiency, including the need to improve raw material utilization, reduce production costs, and increase productivity [70]. Barbaritano et al. (2019) analyzed sustainability and quality management in the Italian luxury furniture sector from a circular economy perspective. The study finds that adopting circular economy principles can help companies achieve sustainable and high-quality production [71].

Ongkowijoyo et al. (2022) emphasize the importance of absorptive capacity for small and medium-sized enterprises (SMEs) in furniture manufacturing. Absorptive capacity refers to an enterprise’s ability to identify, assimilate, and utilize external knowledge and information to enhance performance. SMEs with higher absorptive capacity tend to perform better in business performance indicators such as revenue growth, profitability, and market competitiveness. SMEs prioritizing product quality achieve higher customer satisfaction, leading to repeat business and positive word-of-mouth referrals [72].

Model-based definition (MBD) represents a paradigm shift in design and production, relying on CAD 3D models as the primary and definitive source of all product information, supplanting traditional CAD 2D drawings [73]. This methodology not only has the potential to eliminate the need for technical drawings in the design, production, and presentation phases of product development but also heralds a more streamlined and efficient approach to these processes.

Despite the transformative capabilities of MBD, technical drawings, while labor-intensive to create and not easily interpretable by machines, remain indispensable for human comprehension and are likely to persist in usage. MBD-based product design has given rise to adopting limited dimension drawings (LDDs) in industrial practices. These drawings serve specific purposes within the production process, such as facilitating communication with some subcontractors or aiding in assembly procedures.

Implementing model-based definition (MBD) significantly enhances quality management in furniture companies through several benefits:

- MBD provides a centralized repository for all product data within a single 3D CAD model, streamlining the tracking and management of design changes. This enables access to up-to-date information for all stakeholders, including design, engineering, manufacturing, and quality assurance teams.

- MBD fosters seamless communication and collaboration across different departments within the furniture company. Product information can be seamlessly shared between design and engineering teams, engineering and manufacturing teams, and manufacturing and quality assurance teams. This collaborative approach enables early identification and resolution of potential problems, preventing costly delays and rework.

- MBD empowers automated quality checks by comparing the manufactured product to the up-to-date 3D model. This automated process enhances the accuracy and efficiency of quality control.

The literature review results highlighted a lack of studies exploring the influence of generating design documentation in the model-based definition format on quality management within furniture production.

5. Conclusions

The review highlights several observations made in scientific documents, including quality’s positive impact on financial and business performance, customer and employee satisfaction, innovation, market share, and competitiveness. Supplier selection, environmental certification, quality in design, value methodology, and supply chain transformation are crucial factors in improving efficiency, reducing costs, increasing customer satisfaction, and enhancing a company’s competitive position in the market. Additionally, the text stresses the significance of understanding consumer perspectives and implementing effective quality management practices while considering sustainability an essential element in the industry’s development.

The most striking observations based on this literature review and practical implications are:

- Increased quality positively impacts the furniture producer’s financial performance, employee satisfaction, and customer satisfaction. Companies that focus on quality management have higher levels of innovation, increased market share, and improved competitiveness. At the same time, “excessive quality,” e.g., using premium or rare materials that are not necessary for the furniture’s function or aesthetic, harms furniture enterprise performance.

- Many well-known methodological tools that support quality management can be adopted from other areas of engineering and successfully applied in the furniture industry. These include total quality management (TQM), lean manufacturing (LM), six sigma, ISO 9001 quality management systems, continuous improvement (Kaizen), supplier quality management (SQM), statistical process control (SPC), quality function deployment (QFD), voice of the customer (VoC) analysis, and root cause analysis techniques such as the Pareto chart, the five whys, scatterplot diagrams, fishbone diagrams, failure mode and effects analysis (FMEA), and fault tree analysis (FTA).

- The supplier network is critical to manufacturing performance in terms of quality. The supply chain’s continuous transformation significantly improves efficiency, quality, and customer satisfaction and requires strong leadership, effective communication, and a willingness to change.

- Consumers are willing to pay a premium for environmentally certified wood furniture, enhancing a company’s reputation and providing a competitive advantage. The quality criteria for furniture can ensure that the end product meets the customers’ needs and expectations while being sustainable and environmentally friendly.

- Integrating quality control into the entire furniture production process is essential to mitigate the risk of errors and subsequently lower production costs. The level of meticulousness in quality control should increase as we move earlier in the product life cycle. Consequently, the most critical quality-enhancing efforts should be concentrated on product design, raw material selection, and production technology. The approach to quality management in furniture production should start from the customer requirements and develop a quality supervision system from general to detail, going down to the subsequent production processes. After the product has been introduced to the market, the voice of the consumer (VoC) should be the basis for continuous changes in production processes.

- The review identifies two research gaps that warrant further exploration:

- The literature lacks studies examining the detrimental effects of “excessive quality” on furniture production, such as overspending on premium materials or employing excessive production processes that add unnecessary costs without enhancing product value.

- While model-based definition (MBD) benefits are recognized in other industries, research is needed to investigate their impact on quality management within furniture production. There is a lack of studies exploring the influence of generating design documentation in the MBD format on quality management within furniture production.

Author Contributions

Conceptualization, E.S.; methodology, M.S.; validation, M.H. and M.S.; formal analysis, M.H.; investigation, E.S.; resources, E.S.; data curation, M.S.; writing—original draft preparation, E.S.; writing—review and editing, M.S. and E.S.; visualization, E.S.; supervision, M.S.; project administration, M.H.; funding acquisition, M.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by APVV-20-0004 (“The effect of an increase in the anthropometric measurements of the Slovak population on the functional properties of furniture and the business processes”), KEGA 012UCM-4/2022 (“Human Resources Management in a Digital World—A Bilingual (Slovak–English) Course Book with E-Learning Modules based on Multimedia Content”), APVV-22-0001 (“Optimization of main health and safety risks in the use of forest biomass for energy purposes”), and KEGA 004TU Z-4/2023 (“Innovative methods for assessing the quality potential of forest stands”).

Data Availability Statement

All analyzed data are presented in this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Turbański, W.; Matwiej, Ł.; Wiaderek, K.; Sydor, M. Comparative Analysis of the Manual and Robotic Upholstery Frame Assembly Processes. Study Based on Many Years of Research. In Proceedings of the MATEC Web of Conferences, Bydgoszcz, Poland, 16 February 2021; Borowski, S., Ligaj, B., Strzelecki, P., Hujo, Ľ., Eds.; EDP Sciences: Bydgoszcz, Poland, 2021; Volume 338, p. 01028. [Google Scholar]

- Lourenço, V.L.; Catarino, A.W.; Fonseca, M.J.; Sousa, B.B. Consumer-Brand Relationship and Use of the Website in Virtual Communication in the Luxury Furniture Industry. In Advances in Marketing, Customer Relationship Management, and E-Services; Rodrigues, P., Borges, A.P., Eds.; IGI Global: Hershey, PA, USA, 2021; pp. 158–177. ISBN 978-1-79984-369-6. [Google Scholar]

- Urban, W.; Łukaszewicz, K.; Krawczyk-Dembicka, E. Development Process of Customised Products, Supported by Technologies, a Case of Tailor-Made Furniture. In Advances in Manufacturing III; Trojanowska, J., Kujawińska, A., Machado, J., Pavlenko, I., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2022; pp. 90–104. ISBN 978-3-030-99309-2. [Google Scholar]

- Smardzewski, J. Furniture Design; Springer International Publishing AG: Basel, Switzerland, 2015; ISBN 3-319-19532-8. [Google Scholar]

- Eckelman, C.A. Strength Design of Furniture; Tim Tech Inc.: Casper, WY, USA, 1978. [Google Scholar]

- Zielenbach, F.; Schröer, T.; Stich, V. Customer Perspective on the Purchase and Use of Sustainable and Innovative Furniture in a Co-Creation Process. In Proceedings of the Conference on Production Systems and Logistics: CPSL 2023-1, Querétaro, Mexico, 28 February–2 March 2023; Institute for Production and Logistics Research GbR Herberger & Hübner: Offenburg, Germany, 2023; pp. 570–579. [Google Scholar]

- Gaiani, M.; Deserti, A.; Brevi, F.; Ferioli, S. Tools and Methods to Assist the Product Customization in the Field of Furniture Design. Des. Princ. Pract. Int. J.—Annu. Rev. 2011, 5, 221–238. [Google Scholar] [CrossRef]

- Miklosik, A.; Starchon, P.; Kocisova, L.; Hitka, M. Anthropometric Data Importance in Furniture Design and Marketing. AgricultForest 2022, 68, 277–284. [Google Scholar] [CrossRef]

- Yao, A.C.; Carlson, J.G.H. Agility and Mixed-Model Furniture Production. Int. J. Prod. Econ. 2003, 81–82, 95–102. [Google Scholar] [CrossRef]

- Tiihonen, J.; Felfernig, A. An Introduction to Personalization and Mass Customization. J. Intell. Inf. Syst. 2017, 49, 1–7. [Google Scholar] [CrossRef]

- Zwierzyński, P. The Determinants of Consumer Behaviours in the Furniture Market. Ann. Mark. Manag. Econ. 2017, 3, 131–143. [Google Scholar] [CrossRef]

- Guo, B.; Zhang, Y.; Hu, J.; Li, J.; Wu, F.; Peng, Q.; Zhang, Q. Two-Dimensional Irregular Packing Problems: A Review. Front. Mech. Eng. 2022, 8, 966691. [Google Scholar] [CrossRef]

- Huang, Y.-T.; Kuo, T.-J.; Chien, Y.-C.; Hwang, P. Hesitation Analysis for Exploring Difficulties During Mental Operation in RTA Furniture Assembly. In Advances in Usability and User Experience; Ahram, T., Falcão, C., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2018; Volume 607, pp. 580–590. ISBN 978-3-319-60491-6. [Google Scholar]

- Feil, A.A.; De Brito Reiter, I.; Oberherr, R.; Strasburg, V.J.; Schreiber, D. Analysis and Measurement of the Sustainability Level in the Furniture Industry. Environ. Dev. Sustain. 2022, 24, 13657–13682. [Google Scholar] [CrossRef]

- Oblak, L.; Jošt, M. Methodology for Studying the Ecological Quality of Furniture. Drv. Ind. 2011, 62, 171–176. [Google Scholar] [CrossRef]

- Xiong, X.; Ma, Q.; Yuan, Y.; Wu, Z.; Zhang, M. Current Situation and Key Manufacturing Considerations of Green Furniture in China: A Review. J. Clean. Prod. 2020, 267, 121957. [Google Scholar] [CrossRef]

- Muhammad Suandi, M.E.; Amlus, M.H.; Hemdi, A.R.; Abd Rahim, S.Z.; Ghazali, M.F.; Rahim, N.L. A Review on Sustainability Characteristics Development for Wooden Furniture Design. Sustainability 2022, 14, 8748. [Google Scholar] [CrossRef]

- Hoyle, D. ISO 9000 Quality Systems Handbook, 4th ed.; Butterworth-Heinemann/Elsevier: Oxford, UK, 2001; ISBN 0-7506-4451-6. [Google Scholar]

- Fassoula, E.D. Transforming the Supply Chain. J. Manuf. Technol. Manag. 2006, 17, 848–860. [Google Scholar] [CrossRef]

- González, M.E.; Quesada, G.; Mora Monge, C.A. Determining the Importance of the Supplier Selection Process in Manufacturing: A Case Study. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 492–504. [Google Scholar] [CrossRef]

- Nádasdi, F. Can Value Methodology Enhance the Competitiveness of the Supply Chain. In Proceedings of the 49th Annual Conference of SAVE International 2009, Detroit, MI, USA, 29 June–2 July 2009; Curran Associates Inc.: New York, NY, USA, 2008; pp. 347–385. [Google Scholar]

- Skorupińska, E.; Wiaderek, K.; Sydor, M. Porównawcze badania technologiczne wytrzymałości meblowych elementów sklejkowych / Comparative technological strength studies of furniture plywood elements. Biul. Inf. Ośr. Bad.-Rozw. Przem. Płyt Drewpoch. Czarnej Wodzie 2021, 139–147. Available online: https://biuletyn.online/biuletyn/Archiwum/Numer_3_4_2022/Artykuly/Biuletyn_3_4_2022.pdf (accessed on 31 January 2024). [CrossRef]

- Wiaderek, K.; Matwiej, Ł.; Sydor, M.; Skorupińska, E. Analiza jakości montażu ram mebli tapicerowanych w zrobotyzowanym procesie produkcji/Analysis of the assembly quality of upholstered furniture frames in a robotic production process. In Projektowanie i Eksploatacja Maszyn Roboczych; Łagoda, T., Kurek, M., Kurek, A., Eds.; Studia i Monografie; Politechnika Opolska; Oficyna Wydawnicza Politechniki Opolskiej: Opole, Poland, 2020; Volume 2, pp. 273–281. ISBN 978-83-66033-84-9. [Google Scholar]

- Anderson, R.C.; Hansen, E.N. The Impact of Environmental Certification on Preferences for Wood Furniture: A Conjoint Analysis Approach. For. Prod. J. 2004, 54, 42–50. [Google Scholar]

- Klarić, K.; Grladinović, T.; Šegotić, K.; Greger, K.; Grošelj, P.; Klarić, M. Identification of Key Factors of TQM: Application of AHP and PROMETHEE Methods. In Proceedings of the 26th International Conference on Wood Science and Technology (ICWST) “Implementation of wood science in woodworking sector”, Zagreb, Croatia, 16 October 2015; Faculty of Forestry, University of Zagreb: Zagreb, Croatia, 2015; pp. 127–134. [Google Scholar]

- Ersöz, T.; Güven, İ.; Ersöz, F. Defective Products Management in a Furniture Production Company: A Data Mining Approach. Appl. Stoch. Models Bus. Ind. 2022, 38, 901–914. [Google Scholar] [CrossRef]

- Kocaman, M.; Mertöz, C.; Gökçe, R.; Fırat, S.; Akdoğan, A.; Vanlı, A.S. Assembling Automation for Furniture Fittings to Gain Durability and to Increase Productivity. In Digitizing Production Systems; Durakbasa, N.M., Gençyılmaz, M.G., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2022; pp. 243–255. ISBN 978-3-030-90420-3. [Google Scholar]

- Abu, F.; Gholami, H.; Mat Saman, M.Z.; Zakuan, N.; Streimikiene, D. The Implementation of Lean Manufacturing in the Furniture Industry: A Review and Analysis on the Motives, Barriers, Challenges, and the Applications. J. Clean. Prod. 2019, 234, 660–680. [Google Scholar] [CrossRef]

- Urbina, D.A.R.; Gutierrez, I.V.; Tejada, J.C.; Huamani, M.S. Reduction of Non-Conforming Products through a Quality Management Model Using Lean Manufacturing Tools in the Wood Furniture Industry. In Proceedings of the 2022 Congreso Internacional de Innovación y Tendencias en Ingeniería (CONIITI), Bogota, Colombia, 5–7 October 2022; IEEE: Bogota, Colombia, 2022; pp. 1–5. [Google Scholar]

- Hunter, S.L. The Toyota Production System Applied to the Upholstery Furniture Manufacturing Industry. Mater. Manuf. Process. 2008, 23, 629–634. [Google Scholar] [CrossRef]

- Guerrero, J.E.M.; Leavengood, S.; Gutiérrez-Pulido, H.; Fuentes-Talavera, F.J.; Silva-Guzmán, J.A. Applying Lean Six Sigma in the Wood Furniture Industry: A Case Study in a Small Company. Qual. Manag. J. 2017, 24, 6–19. [Google Scholar] [CrossRef]

- Radharamanan, R.; Godoy, L.P.; Watanabe, K.I. Quality and Productivity Improvement in a Custom-Made Furniture Industry Using Kaizen. Comput. Ind. Eng. 1996, 31, 471–474. [Google Scholar] [CrossRef]

- Patterson, D.W.; Anderson, R.B. Use of Statistical Process Control in the Furniture and Cabinet Industries. For. Prod. J. 1996, 46, 36–38. [Google Scholar]

- Skorupińska, E.; Wiaderek, K.; Sydor, M. Withdrawal Resistance of T-Nuts in Various Furniture Materials. Drv. Ind. 2022, 73, 271–277. [Google Scholar] [CrossRef]

- Laurence; Puteri Utama, C.; Hanafi, J. Statistical Quality Control Measurement on Furniture Manufacturer. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 6–9 December 2011; IEEE: Singapore, 2011; pp. 420–423. [Google Scholar]

- Savsar, M.; Alotaibi, H. A Quality Control Application in a Furniture Company. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Atlanta, GA, USA, 10–12 March 2020; IEOM Society International: Southfield, MI, USA, 2020; pp. 252–261. [Google Scholar]

- Culbreth, C.T.; Miller, M.; O’Grady, P. A Concurrent Engineering System to Support Flexible Automation in Furniture Production. Robot. Comput.-Integr. Manuf. 1996, 12, 81–91. [Google Scholar] [CrossRef]

- Wan, P.H.; Siu, K.W.M. Quality in Design: Creating Identity in Street Furniture Design. In Proceedings of the 13th ISSAT International Conference on Reliability and Quality in Design, Seattle, WA, USA, 2–4 August 2007; International Society of Science and Applied Technologies: Piscataway, NJ, USA, 2007; pp. 78–83. [Google Scholar]

- Prekrat, S.; Pervan, S.; Smardzewski, J.; Stjepan, T.; Jasna, H. Determination of Furniture Quality Criteria in the Projecting Stage. In Proceedings of the 20th International Scientific Conference “Wood is good: New Materials, Quality and Design of Products”, Zagreb, Croatia, 16 October 2009; Faculty of Forestry, University of Zagreb: Zagreb, Croatia, 2009; pp. 113–118. [Google Scholar]

- Toivonen, R.M. Product Quality and Value from Consumer Perspective-An Application to Wooden Products. J. For. Econ. 2012, 18, 157–173. [Google Scholar] [CrossRef]

- Greger, K.; Šegotić, K.; Grladinović, T.; Bičanić, K.; Perić, I. Criteria Ranking in Assessing Technological Process Capability in Furniture Manufacturing [Rangiranje Kriterija Pri Utvrdi-Vanju Sposobnosti Tehnološkog Procesa u Proizvodnji Namještaja]. Šumarski List 2013, 5–6, 285. [Google Scholar]

- Hisjam, M.; Sutopo, W.; Devi, R.A.; Widodo, K.H. A Manufacturer-Buyer Relationship Model in Export Oriented Furniture Industry with Sustainability Considerations. In Proceedings of the Joint International Conference on Electric Vehicular Technology and Industrial, Mechanical, Electrical and Chemical Engineering, ICEVT 2015 and IMECE 2015, Surakarta, Indonesia, 4–5 November 2015; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2016; pp. 298–303. [Google Scholar]

- Nováková, R.; Šujanová, J.; Horváthová, V.; Canet Nováková, N. Quality Management in Specific Areas of Woodworking and Furniture Industry. In Proceedings of the 30th International Conference on Wood Science and Technology, ICWST 2019 and 70th Anniversary of Drvna industrija Journal: Implementation of Wood Science in Woodworking Sector “Implementation of Wood Science in Woodworking Sector”, Zagreb, Croatia, 12–13 December 2019; Lučić, R.B., Živković, V., Barčić, A.P., Vlaović, Z., Eds.; Faculty of Forestry, University of Zagreb: Zagreb, Croatia, 2019; pp. 138–143. [Google Scholar]

- Chadge, R.B.; Shrivastava, R.L.; Giri, J.P.; Desai, T.N. Role of Industry 4.0 in Performance Improvement of Furniture Cluster. In New Paradigm of Industry 4.0; Patnaik, S., Ed.; Studies in Big Data; Springer International Publishing: Cham, Switzerland, 2020; Volume 64, pp. 25–35. ISBN 978-3-030-25777-4. [Google Scholar]

- Yang, C.O.; Teng, W.H. Applied QFD with Wooden Material in Campus Furniture DFA Procedure. Key Eng. Mater. 2013, 573, 113–119. [Google Scholar] [CrossRef]

- Erdil, A. Evaluation Product Development, Product Design for the Furniture-Wood Industry via Quality Function Deployment and Pareto Analysis. Sigma J. Eng. Nat. Sci. 2020, 11, 203–217. [Google Scholar]

- Antal, M.R.; Domljan, D.; Horváth, P.G. Functionality and Aesthetics of Furniture-Numerical Expression of Subjective Value. Drvna Ind. 2017, 67, 323–332. [Google Scholar] [CrossRef][Green Version]

- Suzić, N.; Stevanov, B.; Ćosić, I.; Anišić, Z.; Sremčev, N. Customizing Products through Application of Group Technology: A Case Study of Furniture Manufacturing. SV-J. Mech. Eng. 2012, 58, 724–731. [Google Scholar] [CrossRef]

- Wang, L.; He, J.; Xu, S. The Application of Industry 4.0 in Customized Furniture Manufacturing Industry. In Proceedings of the MATEC Web of Conferences, Seoul, Republic of Korea, 22–25 August 2017; Zhao, L., Xavior, A., Cai, J., You, L., Eds.; EDP Sciences: Les Ulis, France, 2017; Volume 100, p. 03022. [Google Scholar]

- Sabri, S.; Shayan, E. Lean Strategies for Furniture Manufacturing. In Proceedings of the Fifth Asia Pacific Industrial Engineering and Management Systems Conference, Brisbane, QLD, Australia, 12–15 December 2004; Queensland University of Technology: Brisbane, QLD, Australia, 2004; Volume 18, p. 31. [Google Scholar]

- De Oliveira, A.L.G.; Junior, W.R.D.R. Productivity Improvement through the Implementation of Lean Manufacturing in a Medium-Sized Furniture Industry: A Case Study. S. Afr. J. Ind. Eng. 2019, 30, 172–188. [Google Scholar] [CrossRef]

- Hartini, S.; Ciptomulyono, U.; Anityasari, M.; Sriyanto. Manufacturing Sustainability Assessment Using a Lean Manufacturing Tool: A Case Study in the Indonesian Wooden Furniture Industry. Int. J. Lean Six Sigma 2020, 11, 943–971. [Google Scholar] [CrossRef]

- Wani, S.; Shinde, D. Study and Implementation of ‘5S’Methodology in the Furniture Industry Warehouse for Productivity Improvement. Int. J. Eng. Res. Technol. 2021, 10, 184–191. [Google Scholar]

- Susanty, A.; Sumiyati, L.S.; Syaiful, S.; Nihlah, Z. The Impact of Lean Manufacturing Practices on Operational and Business Performances at SMES in the Wooden Furniture Industry. Int. J. Lean Six Sigma 2022, 13, 203–231. [Google Scholar] [CrossRef]

- Guzel, D.; Shahbazpour Asiabi, A. Increasing Productivity of Furniture Factory with Lean Manufacturing Techniques (Case Study). Teh. Glas. 2022, 16, 82–92. [Google Scholar] [CrossRef]

- Megawati, E.; Wicaksono, P.A.; Nurkertamanda, D. Reducing Defect in Furniture Industry Using a Lean Six Sigma Approach. In Proceedings of the 5th International Conference on Industrial, Mechanical, Electrical, and Chemical Engineering 2019 (ICIMECE 2019), Surakarta, Indonesia, 17–18 September 2019; AIP Publishing: Surakarta, Indonesia, 2020; Volume 2217, p. 030180. [Google Scholar]

- Lad, K.B.; Kedar, D.A.P.; Urkudkar, M.M.; Bijwal, P.B. Productivity Improvement in Furniture Manufacturing Industry by Using Kaizen. Int. J. Sci. Dev. Res. 2016, 1, 261–266. [Google Scholar]

- Cahyono, A.; Jumali, M.A. Increasing the Productivity of the Furniture Industry with Kaizen Case Study in SBRC Furniture Jepara. J. Ind. Eng. Manag. 2023, 8, 69–78. [Google Scholar] [CrossRef]

- Gejdoš, P.; Schmidtová, J.; Knop, K. Comparison of the Attributes of the Wood Processing Industry and Automotive and Engineering Industries in the Context of Quality Management Systems. Acta Fac. Xylologiae Zvolen 2023, 65, 123–134. [Google Scholar] [CrossRef]

- ISO 9001; Quality Management Systems. International Standard Organization: Geneva, Switzerland, 2015.

- Abu, F.; Gholami, H.; Saman, M.Z.M.; Zakuan, N.; Sharif, S.; Streimikiene, D. Pathways of Lean Manufacturing in Wood and Furniture Industries: A Bibliometric and Systematic Review. Eur. J. Wood Prod. 2021, 79, 753–772. [Google Scholar] [CrossRef]

- Narula, S.; Puppala, H.; Kumar, A.; Luthra, S.; Dwivedy, M.; Prakash, S.; Talwar, V. Are Industry 4.0 Technologies Enablers of Lean? Evidence from Manufacturing Industries. Int. J. Lean Six Sigma 2023, 14, 115–138. [Google Scholar] [CrossRef]

- Forker, L.B.; Vickery, S.K.; Dröge, C.L.M. The Contribution of Quality to Business Performance. Int. J. Oper. Prod. Manag. 1996, 16, 44–62. [Google Scholar] [CrossRef]

- Conflitti, C.; Goldhammer, B.; Maier, M.; Rumler, F. Is There a Measurement Bias from Quality Adjustment in Austria and Italy. In Proceedings of the Ottawa Group, Rome, Italy, 10 June 2022; National Statistical Institute: Rome, Italy, 2022; Volume 7, pp. 1–31. [Google Scholar]

- Sujová, A.; Simanová, L. Improvement of Production Process Capability—A Case Study of Two Furniture Companies. Eng. Manag. Prod. Serv. 2021, 13, 37–49. [Google Scholar] [CrossRef]

- Vickery, S.K.; Dröge, C.L.M.; Markland, R.E. Dimensions of Manufacturing Strength in the Furniture Industry. J. Ops. Manag. 1997, 15, 317–330. [Google Scholar] [CrossRef]

- Alfranca, Ó.; Diaz-Balteiro, L.; Herruzo, A.C. Technical Innovation in Spain’s Wood-Based Industry: The Role of Environmental and Quality Strategies. For. Policy Econ. 2009, 11, 161–168. [Google Scholar] [CrossRef]

- Ratnasingam, J.; Yoon, C.Y.; Mohamed, S.; Kassim, R.M. Quality Expectations in the Malaysian Wooden Furniture Industry: The Foreign Buyers Perspective. J. Appl. Sci. 2013, 13, 889–894. [Google Scholar] [CrossRef][Green Version]

- Gejdoš, P. Quality Management in Wood Processing Industry in Slovakia and the Czech Republic. In Proceedings of the Wood Processing and Furniture Manufacturing Challenges on the World Market and Wood-Based Energy Goes Global, Dubrovnik, Croatia, 7–9 October 2015; International Association for Economics and Management in Wood Processing and Furniture Manufacturing–WOODEMA: Zagreb, Croatia, 2015; pp. 135–141. [Google Scholar]

- Prasetyo, V.E.; Belleville, B.; Ożarska, B. Furniture Production Efficiency in the Indonesian Context. In Proceedings of the 29th International Conference on Wood Modification and Technology “Implementation of Wood Science in Woodworking Sector”, Zagreb, Croatia, 6–7 December 2018; University of Zagreb, Faculty of Forestry: Zagreb, Croatia, 2018; pp. 131–140. [Google Scholar]

- Barbaritano, M.; Bravi, L.; Savelli, E. Sustainability and Quality Management in the Italian Luxury Furniture Sector: A Circular Economy Perspective. Sustainability 2019, 11, 3089. [Google Scholar] [CrossRef]

- Ongkowijoyo, G.; Koesmono, T.; Wulani, F. Increasing Furniture Manufacturing SMEs’ Business Performance Through Absorptive Capacity and Product Quality. J. Distrib. Sci. 2022, 20, 43–57. [Google Scholar] [CrossRef]

- ISO 16792; Technical Product Documentation—Digital Product Definition Data Practices. International Standard Organization: Geneva, Switzerland, 2021.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).