The Impact of the Industrial Innovation Ecosystem on Innovation Performance—Using the Equipment Manufacturing Industry as an Example

Abstract

1. Introduction

2. Materials and Methods

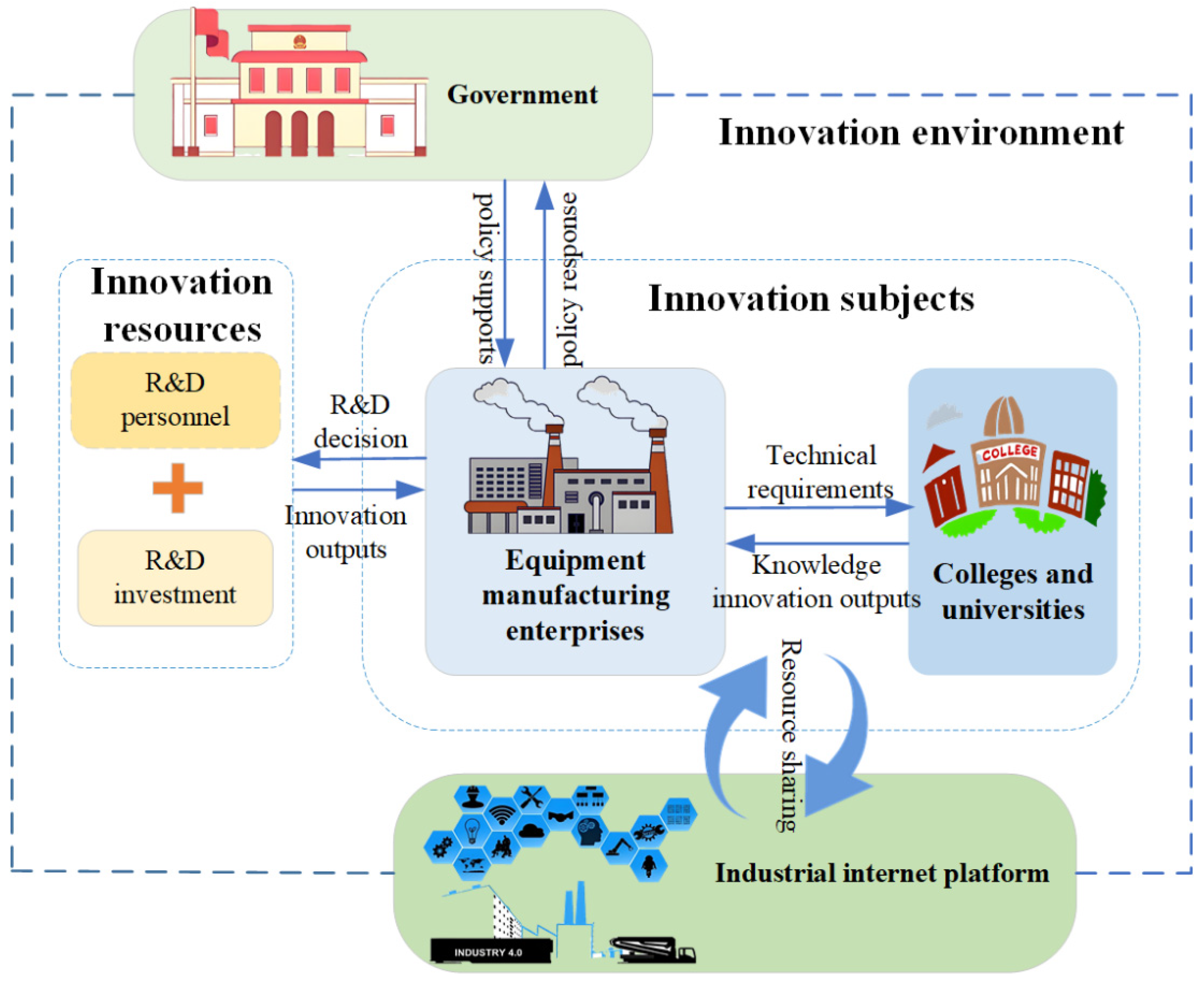

2.1. Theoretical Framework

- Innovation subjects

- 2.

- Innovation resources

- 3.

- Innovation environment

2.2. Method

2.3. Samples and Data

2.4. Measurement

2.4.1. Innovation Subjects

2.4.2. Innovation Resources

2.4.3. Innovation Environment

2.5. Data Calibration

3. Results

3.1. Necessity Analysis

3.2. Configuration Analysis

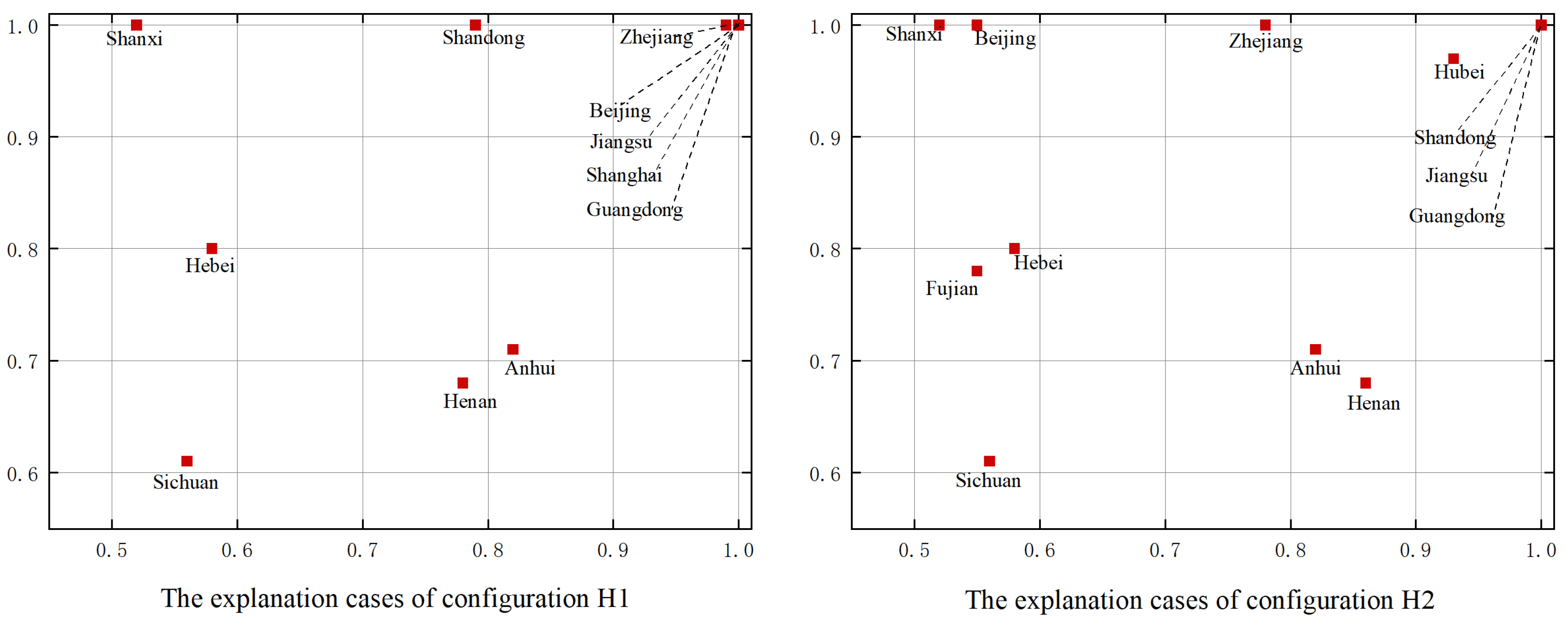

3.3. Analysis of Explanation Cases

3.4. Robustness Test

4. Discussion

4.1. Theoretical Implications

4.2. Practical Implications

4.3. Limitations and Future Research

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Sun, H.Y.; Huang, J.C.; Huang, Q.B. Low-end lock-in of Chinese equipment manufacturing industry and the global value chain. Sustainability 2020, 12, 2981. [Google Scholar] [CrossRef]

- Hou, X.N.; Gao, X.; Yin, S.; Li, J.M. A three evolutionary game model for driving mechanism of industry-university-research collaborative innovation in agricultural innovation ecosystems. PLoS ONE 2023, 18, e0289408. [Google Scholar] [CrossRef]

- Hong, S.; Lv, R.S. A review of the research on China’s industrial innovation ecosystem. Inq. Into Econ. Issues 2017, 418, 42–48+54. [Google Scholar]

- Visscher, K.; Hahn, K.; Konrad, K. Innovation ecosystem strategies of industrial firms: A multilayered approach to alignment and strategic positioning. Creat. Innov. Manag. 2021, 30, 619–631. [Google Scholar] [CrossRef]

- Khorsheed, M.S. Learning from global pacesetters to build the country innovation ecosystem. J. Knowl. Econ. 2017, 8, 177–196. [Google Scholar] [CrossRef]

- Cooke, P. Regional innovation systems: Competitive regulation in the new Europe. Geoforum 1992, 23, 365–382. [Google Scholar] [CrossRef]

- Burström, T.; Parida, V.; Lahti, T.; Wincent, J. AI-enabled business-model innovation and transformation in industrial ecosystems: A framework, model and outline for further research. J. Bus. Res. 2021, 127, 85–95. [Google Scholar] [CrossRef]

- Zeng, J.; Chen, X.; Liu, Y.; Cui, R.; Zhao, P. How does the enterprise green innovation ecosystem collaborative evolve? Evidence from China. J. Clean. Prod. 2022, 375, 134181. [Google Scholar] [CrossRef]

- Tan, J.; Song, J.; Chen, X.H. The formation and evolution of industrial innovation ecosystem: ‘Architect’ transition and the evolution of its strategic behavior. J. Manag. World 2021, 37, 167–191. [Google Scholar]

- Chu, W.J.; Wu, R.; Li, Z.Y. Study of the constitution and mechanism of the innovation ecosystem empowered by big data and intellectual technology. Inf. Stud. Theory Appl. 2023, 46, 1–8. [Google Scholar]

- Chen, Y.Z.; Huang, S.H.; Wang, S.Y. The operational efficiency of the regional innovation ecosystem in China: A study based on the perspective of innovation value chain. Sci. Res. Manag. 2022, 43, 11–19. [Google Scholar]

- Gawer, A. Bridging differing perspectives on technological platforms: Toward an integrative framework. Res. Policy 2014, 43, 1239–1249. [Google Scholar] [CrossRef]

- Cai, Y.Z.; Etzkowitz, H. Theorizing the Triple Helix model: Past, present, and future. Triple Helix 2020, 7, 189–226. [Google Scholar] [CrossRef]

- Li, M.F.; Liu, Y.J. The influence of digital innovation ecosystem of high-end equipment manufacturing on the intelligent maturity of enterprise: An empirical study on the configuration of the ‘three-layer core-periphery’ structure. Bus. Process Manag. J. 2024, 30, 199–221. [Google Scholar] [CrossRef]

- Xin, B.L.; Geng, J.J.; Zhu, C.F. Research on the constructing and operating mechanism of the innovation ecosystem of China’s ice and snow industry. China Soft Sci. 2024, 5, 48–57. [Google Scholar]

- Xing, X.P.; Chen, T.T.; Yang, X.M.; Liu, T.S. Digital transformation and innovation performance of China’s manufacturers? A configurational approach. Technol. Soc. 2023, 75, 102356. [Google Scholar] [CrossRef]

- Zheng, L.; Ulrich, K.; Sendra-García, J. Qualitative comparative analysis: Configurational paths to innovation performance. J. Bus. Res. 2021, 128, 83–93. [Google Scholar] [CrossRef]

- Wang, H.Q.; Zhao, T.Y.; Cooper, S.Y.; Wang, S.S.; Harrison, R.T.; Yang, Z. Effective policy mixes in entrepreneurial ecosystems: A configurational analysis in China. Small Bus. Econ. 2023, 60, 1509–1542. [Google Scholar] [CrossRef]

- Curado, C.; Muñoz-Pascual, L.; Galende, J. Antecedents to innovation performance in SMEs: A mixed methods approach. J. Bus. Res. 2018, 89, 206–215. [Google Scholar] [CrossRef]

- Ardito, L.; Raby, S.; Albino, V.; Bertoldi, B. The duality of digital and environmental orientations in the context of SMEs: Implications for innovation performance. J. Bus. Res. 2021, 123, 44–56. [Google Scholar] [CrossRef]

- Gebauer, H.; Fleisch, E.; Lamprecht, C.; Wortmann, F. Growth paths for overcoming the digitalization paradox. Bus. Horiz. 2020, 63, 313–323. [Google Scholar] [CrossRef]

- Burger-Helmchen, T. Crowdsourcing of inventive cctivities, AI, and the NIH syndrome. Adm. Sci. 2024, 14, 300. [Google Scholar] [CrossRef]

- Tang, K.Y.; Ouyang, J.; Ren, H.; Cheng, J.Q. What kind of innovation ecosystem can produce high innovation performance in high-tech zones?: A fuzzy set qualitative comparative analysis based on 116 cases. Sci. Sci. Manag. ST 2022, 43, 116–133. [Google Scholar]

- Tang, K.J.; Ouyang, J.; Zhen, J.; Ren, H. How does regional innovation ecosystem drive innovation performance?—A fuzzy set qualitative comparative analysis based on 31 provinces. Sci. Sci. Manag. ST 2021, 42, 53–72. [Google Scholar]

- Wu, H.Z.; Han, Z.A.; Zhou, Y. Optimal degree of openness in open innovation: A perspective from knowledge acquisition & knowledge leakage. Technol. Soc. 2021, 67, 101756. [Google Scholar]

- Pan, X.F.; Song, M.L.; Zhang, J.; Zhou, G. Innovation network, technological learning and innovation performance of high-tech cluster enterprises. J. Knowl. Manag. 2019, 23, 1729–1746. [Google Scholar] [CrossRef]

- Zhao, L.J.; Liang, Y.; Tu, H.J. How do clusters drive firm performance in the regional innovation system? A causal complexity analysis in Chinese strategic emerging industries. Systems 2023, 11, 229. [Google Scholar] [CrossRef]

- Li, Q.; Gao, Q.Y.; Zhang, Y.; Gou, C.N. How can small and medium-sized manufacturing enterprises improve green innovation performance through innovation ecosystems? Sustainability 2024, 16, 2519. [Google Scholar] [CrossRef]

- Jacobides, M.G.; Cennamo, C.; Gawer, A. Towards a theory of ecosystems. Strateg. Manag. J. 2018, 39, 2255–2276. [Google Scholar] [CrossRef]

- Liu, X.L.; Wang, Q. New paradigm of innovation management research: Innovation ecosystems. Sci. Sci. Manag. ST 2021, 42, 20–33. [Google Scholar]

- Tsujimoto, M.; Kajikawa, Y.; Tomita, J.; Matsumoto, Y. A review of the ecosystem concept: Towards coherent ecosystem design. Technol. Forecast. Soc. Change 2018, 136, 49–58. [Google Scholar] [CrossRef]

- Dougherty, D.; Dunne, D.D. Organizing ecologies of complex innovation. Organ. Sci. 2011, 22, 1214–1223. [Google Scholar] [CrossRef]

- Adner, R.; Kapoor, R. Value creation in innovation ecosystems: How the structure of technological interdependence affects firm performance in new technology generations. Strateg. Manag. J. 2010, 31, 306–333. [Google Scholar] [CrossRef]

- Li, M.Q.; Chen, H.; Li, J.Q.; Liu, X.L. How to improve the synergetic development capabilities of the innovation ecosystems of high-tech industries in China: An fsQCA analysis based on the TOE framework. Sustainability 2023, 15, 12579. [Google Scholar] [CrossRef]

- Zhang, M.; Cheng, R.N.; Fei, J.B.; Khanal, R. Enhancing digital innovation ecosystem resilience through the interplay of organizational, technological, and environmental factors: A study of 31 provinces in China using NCA and fsQCA. Sustainability 2024, 16, 1946. [Google Scholar] [CrossRef]

- Xu, G.; Wu, Y.; Minshall, T.; Zhou, Y. Exploring innovation ecosystems across science, technology, and business: A case of 3D printing in China. Technol. Forecast. Soc. 2018, 136, 208–221. [Google Scholar] [CrossRef]

- Samara, E.; Georgiadis, P.; Bakouros, I. The impact of innovation policies on the performance of national innovation systems: A system dynamics analysis. Technovation 2012, 32, 624–638. [Google Scholar] [CrossRef]

- Liu, Q.; Wen, X.N.; Peng, H.T.; Cao, Q.W. Key technology breakthrough in new energy vehicles: Configuration path evolution from innovative ecosystem perspective. J. Clean. Prod. 2023, 423, 138635. [Google Scholar] [CrossRef]

- Moore, J.F. Predators and prey: A new ecology of competition. Harv. Bus. Rev. 1993, 71, 75–86. [Google Scholar] [PubMed]

- Lansiti, M.; Ieyien, R. The Keystone Advantage: What the New Dynamics of Business Ecosystem Mean for Strategy, Innovation, and Sustainability; Harvard Business School Press: Boston, MA, USA, 2004. [Google Scholar]

- Liu, X.L.; Ding, X.C.; Gao, Y.C. How does China build world sci-tech power: From the perspective of innovation ecosystem. Sci. Sci. Manag. ST 2018, 39, 3–15. [Google Scholar]

- Oh, D.S.; Phillips, F.; Park, S.; Lee, E. Innovation ecosystems: A critical examination. Technovation 2016, 54, 1–6. [Google Scholar] [CrossRef]

- Wang, B. Dual innovation and innovation performance of manufacturing enterprises: Based on the role of knowledge transformation ability and coordination flexibility. Front. Sci. Technol. Eng. Manag. 2023, 42, 53–59. [Google Scholar] [CrossRef]

- Ratinho, T.; Henriques, E. The role of science parks and business incubators in converging countries: Evidence from Portugal. Technovation 2010, 30, 278–290. [Google Scholar] [CrossRef]

- Poonjan, A.; Tanner, A.N.; Andersen, P.D. How regional factors influence the performance of science and technology parks: A comparative analysis of regional science parks in Thailand. Asian J. Technol. Innov. 2022, 30, 364–386. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Grigoroudis, E.; Campbell, D.F.; Meissner, D.; Stamati, D. The ecosystem as helix: An exploratory theory-building study of regional co-opetitive entrepreneurial ecosystems as Quadruple/Quintuple Helix Innovation Models. RD Manag. 2018, 48, 148–162. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Chen, X.F.; Chu, J.F.; Zhu, Q.Y. Industrial development environment and innovation efficiency of high-tech industry: Analysis based on the framework of innovation systems. Technol. Anal. Strateg. Manag. 2018, 30, 434–446. [Google Scholar] [CrossRef]

- Brow, W.B.; Gobeli, D. Observations on the measurement of R&D productivity: A case study. IEEE Trans. Eng. Manag. 1992, 39, 325–331. [Google Scholar]

- Jiao, H.; Zhou, J.H.; Gao, T.S.; Liu, X.L. The more interactions the better? The moderating effect of the interaction between local producers and users of knowledge on the relationship between R&D investment and regional innovation systems. Technol. Forecast. Soc. 2016, 110, 13–20. [Google Scholar]

- Bin, G. Technology acquisition channels and industry performance: An industry-level analysis of Chinese large- and medium-size manufacturing enterprises. Res. Policy 2008, 37, 194–209. [Google Scholar] [CrossRef]

- Li, X.D.; Zhang, X.Y. Research of the influence mechanism of regional innovation ecosystem on regional innovation performance. Forecasting 2018, 37, 22–28. [Google Scholar]

- Wang, S.; Fan, J.; Zhao, D.T.; Wang, S. Regional innovation environment and innovation efficiency: The Chinese case. Technol. Anal. Strateg. Manag. 2016, 28, 396–410. [Google Scholar] [CrossRef]

- Lin, B.Q.; Ma, R.Y. Green technology innovations, urban innovation environment and CO2 emission reduction in China: Fresh evidence from a partially linear functional-coefficient panel model. Technol. Forecast. Soc. 2022, 176, 121434. [Google Scholar] [CrossRef]

- Rehman, S.U.; Ashfaq, K.; Bresciani, S.; Giacosa, E.; Mueller, J. Nexus among intellectual capital, interorganizational learning, industrial internet of things technology and innovation performance: A resource-based perspective. J. Intellect. Cap. 2023, 24, 509–534. [Google Scholar] [CrossRef]

- Wu, L.C.; Wei, Y.Q.; Wang, C.G.; McDonald, F.; Han, X. The importance of institutional and financial resources for export performance associated with technological innovation. Technol. Forecast. Soc. 2022, 185, 122040. [Google Scholar] [CrossRef]

- Lee, E.Y.; Cin, B.C. The effect of risk-sharing government subsidy on corporate R&D investment: Empirical evidence from Korea. Technol. Forecast. Soc. 2010, 77, 881–890. [Google Scholar]

- Gao, Y.; Yang, P.; Hu, Y.M. How R&D subsidies influence high-tech SMEs’ knowledge creation through universities. IEEE Trans. Eng. Manag. 2024, 71, 1757–1772. [Google Scholar]

- Neukam, M.; Bollinger, S. Encouraging creative teams to integrate a sustainable approach to technology. J. Bus. Res. 2022, 150, 354–364. [Google Scholar] [CrossRef]

- Wang, X.Z.; Zou, Z.H.; Zheng, Y.; Jiang, Z.J. How will different types of industry policies and their mixes affect the innovation performance of wind power enterprises? Based on dual perspectives of regional innovation environment and enterprise ownership. J. Environ. Manag. 2019, 251, 109586. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Dong, J.Y.; Wei, J. Digital innovation management: Theoretical framework and future research. J. Manag. World 2020, 36, 198–217+219. [Google Scholar]

- Sun, X.B.; Zhang, M.C.; Wang, Y.X. Case study of the mechanism of industrial internet platform enablement to promote the construction of digital business ecosystem. Manag. Rev. 2020, 34, 322–337. [Google Scholar]

- Ranjan, K.R.; Read, S. Value Co-creation: Concept and Measurement. J. Acad. Market. Sci. 2016, 44, 290–315. [Google Scholar] [CrossRef]

- Chen, W.; Chen, J.A.; Li, Y.P. Industrial internet platform: Connotation, evolution and empowerment. Bus. Manag. J. 2022, 44, 189–208. [Google Scholar]

- Yu, F.F.; Chen, J.Q. The impact of industrial internet platform on green innovation: Evidence from a quasi-natural experiment. J. Clean. Prod. 2023, 414, 137645. [Google Scholar] [CrossRef]

- Rong, K.Z.; Lu, Q.B. Research on the influence of Chinese government innovation subsidies on dual innovation performance. Sci. Res. Manag. 2024, 45, 64–73. [Google Scholar]

- Tian, H.N.; Zhao, L.Y.; Li, Y.F.; Wang, W. Can enterprise green technology innovation performance achieve “corner overtaking” by using artificial intelligence?-Evidence from Chinese manufacturing enterprises. Technol. Forecast. Soc. Change 2023, 194, 122732. [Google Scholar] [CrossRef]

- Sarbu, M. The impact of industry 4.0 on innovation performance: Insights from German manufacturing and service firms. Technovation 2022, 113, 102415. [Google Scholar] [CrossRef]

- Kraus, S.; Ribeiro-Soriano, D.; Schüssler, M. Fuzzy-set qualitative comparative analysis (fsQCA) in entrepreneurship and innovation research: The rise of a method. Int. Entrep. Manag. J. 2018, 14, 15–33. [Google Scholar] [CrossRef]

- Kumar, S.; Sahoo, S.; Lim, W.M.; Kraus, S.; Bamel, U. Fuzzy-set qualitative comparative analysis (fsQCA) in business and management research: A contemporary overview. Technol. Forecast. Soc. Change 2022, 178, 121599. [Google Scholar] [CrossRef]

- Salonen, A.; Zimmer, M.; Keränen, J. Theory development in servitization through the application of fsQCA and experiments. Int. J. Oper. Prod. Manag. 2021, 41, 746–769. [Google Scholar] [CrossRef]

- Rihoux, B.; Ragin, C.C. Configurational Comparative Methods: Qualitative Comparative Analysis (QCA) and Related Techniques; Sage Publications: London, UK, 2008. [Google Scholar]

- Li, Y.; Zhang, Y.R.; Li, Y.K.; Ding, R.H. Exploring the impact of dynamic capabilities on the sustainable delivery of international engineering projects: A configurational approach. IEEE Trans. Eng. Manag. 2023, 71, 9003–9018. [Google Scholar] [CrossRef]

- Liu, H.Y.; Subramanian, A.M.; Hang, C.C. In search of the perfect match: A configurational approach to technology transfer in Singapore. IEEE Trans. Eng. Manag. 2019, 68, 574–585. [Google Scholar] [CrossRef]

- Fiss, P. Building better causal theories: A fuzzy set approach to typologies in organization research. Acad. Manag. J. 2011, 54, 393–420. [Google Scholar] [CrossRef]

- Ragin, C.C. Redesigning Social Inquiry: Fuzzy Sets and Beyond; University of Chicago Press: Chicago, IL, USA, 2008. [Google Scholar]

- National Bureau of Statistics. 2017 National Economic Industry Classification (GB/T4754-2017). Available online: https://www.stats.gov.cn/xxgk/tjbz/gjtjbz/201710/t20171017_1758922.html (accessed on 30 June 2017).

- Zhang, M.L.; Li, B.Z.; Yin, S. Configurational paths to regional innovation performance: The interplay of innovation elements based on a fuzzy-set qualitative comparative analysis approach. Technol. Forecast. Soc. 2020, 32, 1422–1435. [Google Scholar] [CrossRef]

- Xie, Z.Y.; Wang, J.; Miao, L. Big data and emerging market firms’ innovation in an open economy: The diversification strategy perspective. Technol. Forecast. Soc. 2021, 173, 121091. [Google Scholar] [CrossRef]

- Hu, Y.L.; Wu, Y.H.; Zhu, Y.C. The impact of industrial internet platform application on enterprise performance. J. Kunming Univ. Sci. Technol. (Nat. Sci.) 2024, 49, 309–321. [Google Scholar]

- Wu, X.F.; Li, X.Y. The influence mechanism of industrial internet on innovation performance of manufacturing enterprises. Sci. Technol. Prog. Policy 2023, 40, 92–102. [Google Scholar]

- Buesa, M.; Heijs, J.; Martinez Pellitero, M.; Baumert, T. Regional systems of innovation and the knowledge production function: The Spanish case. Technovation 2006, 26, 463–472. [Google Scholar] [CrossRef]

- Fosfuri, A.; Tribó, J.A. Exploring the antecedents of potential absorptive capacity and its impact on innovation performance. Omega 2008, 36, 173–187. [Google Scholar] [CrossRef]

- Albahari, A.; Pérez-Canto, S.; Barge-Gil, A.; Modrego, A. Technology parks versus science parks: Does the university make the difference. Technol. Forecast. Soc. Change 2017, 116, 13–28. [Google Scholar] [CrossRef]

- Schneider, C.; Wagemann, C. Set-Theoretic Methods for the Social Sciences: A Guide to Qualitative Comparative Analysis; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Liao, C.J.; Xiang, Z.W.; Zhou, W.; Li, Z.Y.; Li, Y. Research on the configuration of value chain transition in Chinese manufacturing enterprises. Systems 2022, 10, 164. [Google Scholar] [CrossRef]

- Greckhamer, T.; Furnari, S.; Fiss, P.C.; Aguilera, R.V. Studying configurations with qualitative comparative analysis: Best practices in strategy and organization research. Strateg. Organ. 2018, 16, 482–495. [Google Scholar] [CrossRef]

- Li, W.T.; Li, Y.G. Research on the model and influencing factors of the formation of International reputation of Chinese research universities: Based on the QCA test and comparison of 76 research universities. Chongqing High. Educ. Res. 2022, 10, 19–31. [Google Scholar]

- Douglas, E.J.; Shepherd, D.A.; Prentice, C. Using fuzzy-set qualitative comparative analysis for a finer-grained understanding of entrepreneurship. J. Bus. Ventur. 2020, 35, 105970. [Google Scholar] [CrossRef]

- Chen, Y.T.; Xia, M.; Li, Q.Q.; Zhang, C.G. Research on innovation ecosystem: Qualitative evaluation Chinese context and theoretical direction. Res. Dev. Manag. 2018, 30, 37–53. [Google Scholar]

- Huang, L.C.; Mi, L.; Wu, F.F. An analysis of the current situation and trend of the industrial innovation ecosystem abroad. Sci. Res. Manag. 2019, 40, 1–12. [Google Scholar]

- Chen, X.H.; Zhou, P.; Hu, D.B. Influences of the ongoing digital transformation of the Chinese Economy on innovation of sustainable green technologies. Sci. Total Environ. 2023, 875, 162708. [Google Scholar] [CrossRef]

- Gawer, A.; Cusumano, M.A. Industry platforms and ecosystem innovation. J. Prod. Innov. Manag. 2014, 31, 417–433. [Google Scholar] [CrossRef]

| Abbreviation | Variable | Description | Source | Selection Basis |

|---|---|---|---|---|

| Outcome | ||||

| INNO | Innovation performance | Number of enterprises’ patent applications | CSMAR database | [78] |

| Antecedents | ||||

| TIS | Technological innovation subject | Number of equipment manufacturing enterprises | CSMAR database | [24,49] |

| KIS | Knowledge innovation subject | Number of universities associated with enterprises innovation | List of Chinese universities and official website information | [24,49] |

| R&DI | R&D investment | The R&D investment within equipment manufacturing enterprises | CSMAR database | [50] |

| R&DP | R&D personnel | The R&D personnel within equipment manufacturing enterprises | CSMAR database | [23,24] |

| IIP | Industrial internet platform | The application degree of industrial internet platform | Annual reports of companies on the official websites of the Shenzhen Stock Exchange and the Shanghai Stock Exchange | [79,80] |

| GS | Government subsidy | The government subsidies for equipment manufacturing enterprises | CSMAR database | [55,65] |

| Feature Words | |

|---|---|

| Industrial internet platform | Internet, industry internet, intelligent manufacturing, cloud platform, mobile internet, mobile interconnection, industrial internet, Internet+, industrial 4.0, industrial cloud, informatization, information technology, information communication technology, cloud service, internet of things, blockchain, digital twin, edge computing, big data analysis, intelligent sensing, cloud collaboration, IIoT, CPS, 5G, IPv6, TSN, SDN, CAX, ERP, MES, and SCM |

| Variables | Full Membership | Crossover Point | Full Non-Membership |

|---|---|---|---|

| INNO | 22.209 | 10.411 | 2.348 |

| TIS | 24.500 | 11.500 | 4.500 |

| KIS | 106.750 | 74.000 | 54.750 |

| R&DI | 900,374.956 | 427,827.538 | 106,880.292 |

| R&DP | 23,263.584 | 8144.667 | 3023.833 |

| IIP | 25.146 | 11.884 | 4.607 |

| GS | 17,954.479 | 2715.391 | 567.338 |

| Condition | High-Level Innovation Performance | Non-High-Level Innovation Performance | ||

|---|---|---|---|---|

| Consistency | Coverage | Consistency | Coverage | |

| TIS | 0.877406 | 0.817397 | 0.26675 | 0.282869 |

| ~TIS | 0.230221 | 0.216198 | 0.827802 | 0.884873 |

| KIS | 0.799002 | 0.755391 | 0.316218 | 0.340297 |

| ~KIS | 0.302209 | 0.279683 | 0.772699 | 0.813984 |

| R&DI | 0.874554 | 0.838115 | 0.266124 | 0.290301 |

| ~R&DI | 0.259444 | 0.236979 | 0.851597 | 0.885417 |

| R&DP | 0.878831 | 0.849173 | 0.243582 | 0.267906 |

| ~R&DP | 0.242338 | 0.219638 | 0.862868 | 0.890181 |

| IIP | 0.876693 | 0.817276 | 0.266124 | 0.282392 |

| ~IIP | 0.230221 | 0.216054 | 0.827802 | 0.884281 |

| GS | 0.797577 | 0.788028 | 0.296806 | 0.333803 |

| ~GS | 0.325731 | 0.289241 | 0.811522 | 0.820253 |

| Antecedents | High-Level Innovation Performance | Non-High-Level Innovation Performance | |||||

|---|---|---|---|---|---|---|---|

| H1a | H1b | H2a | H2b | N1 | N2 | N3 | |

| TIS | ⬤ | ● | ⬤ | ● | ● | ⊗ | ⊗ |

| KIS | ● | ● | ● | ⊗ | ⊗ | ||

| R&DI | ⬤ | ⬤ | ⬤ | ⬤ | ⨂ | ⨂ | ● |

| R&DP | ● | ● | ● | ● | ⊗ | ⨂ | |

| IIP | ● | ⬤ | ● | ⬤ | ● | ⊗ | ⊗ |

| GS | ● | ● | ⊗ | ⨂ | |||

| Consistency | 0.94 | 0.94 | 0.941 | 0.941 | 0.995 | 0.933 | 0.995 |

| Raw coverage | 0.696 | 0.696 | 0.728 | 0.728 | 0.126 | 0.649 | 0.135 |

| Unique coverage | 0.097 | 0.097 | 0.129 | 0.129 | 0.061 | 0.532 | 0.037 |

| Overall consistency | 0.938 | 0.942 | |||||

| Overall coverage | 0.825 | 0.747 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, N.; Niu, L. The Impact of the Industrial Innovation Ecosystem on Innovation Performance—Using the Equipment Manufacturing Industry as an Example. Systems 2024, 12, 578. https://doi.org/10.3390/systems12120578

Qiao N, Niu L. The Impact of the Industrial Innovation Ecosystem on Innovation Performance—Using the Equipment Manufacturing Industry as an Example. Systems. 2024; 12(12):578. https://doi.org/10.3390/systems12120578

Chicago/Turabian StyleQiao, Nan, and Lixia Niu. 2024. "The Impact of the Industrial Innovation Ecosystem on Innovation Performance—Using the Equipment Manufacturing Industry as an Example" Systems 12, no. 12: 578. https://doi.org/10.3390/systems12120578

APA StyleQiao, N., & Niu, L. (2024). The Impact of the Industrial Innovation Ecosystem on Innovation Performance—Using the Equipment Manufacturing Industry as an Example. Systems, 12(12), 578. https://doi.org/10.3390/systems12120578