Abstract

Modern industry has become very complex and requires an equally complex engineering technology system, which includes resource utilization, energy conversion, product research and development, technological innovation, environmental protection and industrial ecology, and other aspects of the system. Continued development of large-scale, streamlined, and continuous processes is critical; however, there are also problems such as data redundancy, overcapacity, redundant construction, and waste of resources. Based on the system synergy theory, this paper introduces the system analysis method from the perspective of flow structure, with the purpose of solving the management defects of complex industrial production systems. First, we analyze the complex industrial production system as a collaborative structure of three subsystems: material flow, energy flow, and information flow. The following concepts are clarified: “material flow is the main body, energy flow is attached to and drives material flow, material flow and energy flow generate information flow, and information flow reversely drives material flow and energy flow”. Secondly, the collaborative evolution process of the complex industrial production system is divided into three periods, which are the generation period, the stalemate period, and the maturity period, and a synergy degree evaluation model is established, which considers the Theil index and subsystem gray correlation method, and extends the dynamic differential equation model of three-stage collaborative evolution. Subsequently, we used MATLAB numerical simulation to demonstrate that the collaborative evolution of production systems is related to four aspects. They are the self-organizing ability of the system, the dominant role of order parameters, the competition and cooperation between order parameters, and whether mutations can become order parameters. At the same time, it was also found that it is basically independent of other factors, such as attenuation inertia. Then, the self-organizing map network (SOM) algorithm was used for the rapid identification of mutation data. Finally, we use the empirical research of SG enterprises to show that their production level and management system are advanced, but they were in a non-cooperative state from 2014 to 2021. In 2022, they had the basic conditions and trends to enter the synergistic generation period, and a synergistic management model is required. At the end of the article, we give a collaborative management method for complex industrial enterprises with a good management foundation. These include the management mechanism based on flow structure collaboration and the management path based on collaborative evolution. Of course, the management countermeasures given in this study are also applicable to other complex process-based industrial enterprises.

1. Introduction

With the continuous improvement of technology and manufacturing, modern industry is developing towards large-scale, complex, process-oriented, and continuous development. In many fields, such as metallurgy, chemical industry, etc., it is no longer a single integrated system but is composed of many coordinated and integrated subsystems. There are numerous contradictions within complex industrial production systems, such as frequent dynamic fluctuations, and the operation process must consider the global performance. In addition to external environmental interference, the system itself also has strong nonlinear characteristics; however, the supply, use, and allocation of resources and energy, as well as their management methods, directly determine the operational status of the production system, which in turn affects production efficiency, product quality, product costs, and so on. The current integrated management system has been implemented for several years. The method is to use manufacturing platforms such as ERP and MRP to achieve information sharing, thereby achieving order-driven production and on-time delivery, and to prevent unexpected problems by implementing separate lean improvement projects. Although integrated management has achieved many results, there is still a widespread problem of overcapacity. A large amount of redundant data reduces the efficiency of management work and has poor management accuracy. Due to the wide variety of products, frequent batch changes, and the lack of a unified model for equipment data management, problems of redundant construction and resource waste exist. The construction of manufacturing platforms is still based on modular or departmental management, lacking a management mechanism compatible with the coordinated development of enterprise informatization.

For any system in the objective world, matter is the carrier, providing tangible entities, such as production resources; energy is the executor, providing production power; and information is the conductor and the soul that forms the process. The static and dynamic operational structures of production systems at different levels are closely related to material flow, energy flow, and information flow. The same applies to enterprise production systems; therefore, in recent years, the development of interdisciplinary cooperation within such systems as engineering, dynamics, and management has brought new directions to industrial production management. Many scholars analyze industrial production systems from the perspective of flow structure to save management effort and simultaneously achieve cost-effectiveness and environmental benefits.

In spite of this, there are many different analytical methods for production systems, such as process flow, capital flow, value flow, green energy flow, material flow, energy flow, information flow, capital flow, and other structures. It is worth noting that there are analysis defects, such as inconsistent subsystem levels and unclear flow structure characteristics. For instance, both cash flow and information flow have the functions of scheduling, controlling, and commanding production; however, the optimization of cash flow aims to reduce costs, while the research focus of information flow is to shorten delivery times. The fundamental goal of both is to improve efficiency. Another issue is the lack of distinction between spatial flow paths (material flow and energy flow, etc.) and temporal flow paths (information flow and financial flow, etc.). Moreover, when analyzing the “potential” and “resistance” of the “flow” structure, as well as the “drive” and “dissipation” of the system, the absence of combining dynamic principles results in relatively single model construction and incomplete variable analysis.

Nowadays, complex industrial production systems involve various elements, such as humans, machines, the environment, and management. Managing these systems’ internal structure, organizational form, and functional processes is a complex task. People are increasingly paying attention to the dynamic utilization of energy in industrial enterprises; however, most studies are limited to energy flow and overlook the characteristics of complex industrial production systems, such as nonlinearity, dynamism, openness, and orderliness. The changes in material flow parameters and the driving force of information flow are the root causes of changes in energy flow; therefore, whether solving subsystem problems or large-scale system problems, research should focus on the operational mechanism of the overall large-scale system and the role of the relationships between subsystems in the large-scale system. Scholars emphasize the concepts of “coordinated progress” and “collaborative innovation”, aiming to provide a theoretical analysis and practical guidance for industrial enterprises using the concept of synergy to improve economic efficiency. Starting from the research on the composition of enterprise systems, this paper innovatively explores the connections between various subsystems within the enterprise and the external environment and proposes new solutions for the organizational form of the enterprise. There is limited research on the mechanism and influencing factors of subsystem synergy, and there is no indication of the path through which this advanced concept should be implemented. The research on collaborative management in industrial enterprises coincides with the research direction of collaborative theory from the perspective of system flow structure; therefore, it is extremely important to deepen the understanding of the collaboration among various subsystems of the production system as a whole and to reflect the optimization results in management decisions in order to build a management mechanism and path that is easy to implement and promote. In the current context, industrial enterprises need to comprehensively consider factors such as human, machine, environment, and management to achieve efficient and collaborative operation of production systems, thereby achieving the goal of improving economic efficiency.

This study provides a collaborative research framework for material flow, information flow, and energy flow in complex industrial production systems. We have constructed a collaborative evaluation and collaborative evolution model, which can clarify the conditions for collaborative evolution, identify the direction of enterprise collaborative management, and take an important step towards achieving a clear path from comprehensive integrated management to collaborative management. This method is easy to generalize to other industrial enterprises that already have advanced management system practice environments and is especially suitable for complex nonlinear process-oriented industrial enterprises. The main innovation points cover the following aspects:

(1) Based on the theory of synergetics, we provide a combination of system dynamics research methods and flow structure co-evolution research.

(2) We apply system dynamics methods to analyze the collaborative evolution of flow structures and construct evolution models. Additionally, we extend the evolution model to a three-stage system of equations.

(3) When establishing a synergy evaluation model, we considered the Taylor index and the system’s gray relationship. Furthermore, we utilize the self-organizing mapping network (SOM) algorithm to identify sudden disturbance data in industrial production systems.

The remaining content of this article is structured as follows: In Section 2, a literature review is presented, encompassing system synergy, system flow perspective, and complex industrial management. Section 3 outlines the construction of a collaborative model for the flow structure within complex industrial production systems. Section 4 delves into a collaborative model of the production system’s flow structure, employing SG enterprise as a case study. Lastly, Section 5 provides a comprehensive summary of the entire text.

2. Literature Review

2.1. System Synergetics

Haken proposed the collaborative theory in the 1970s, which is based on system theory and control theory, using a combination of dynamic and statistical analysis methods. Its main focus is to study the cooperation, coordination, and synchronization mechanisms of various components or subsystems within complex systems during operation (Haken, 2013) [1]. As an important branch of systems science theory, the research methods of collaborative theory are applicable in various systems, especially for complex, large-scale systems. Meng (2000) [2] pointed out that the collaboration of complex systems is a process of achieving the overall effect of the system through internal self-organization and external regulation and management activities. Meng emphasized that a subsystem analysis should be conducted from a reasonable perspective. Peng (2009) [3] regards logistics and manufacturing as two subsystems of the modern economy. By utilizing the sequential parameter evolution process of synergy theory, the mechanism of symbiotic evolution of these two subsystems was explored, emphasizing that the interdependence and cooperation between modern logistics and advanced manufacturing are natural outcomes of industrial evolution. Zheng et al. (2010) [4] applied the principles and methods of collaborative theory to study the supply and demand relationship between automotive manufacturers and suppliers, providing decision support for optimizing the automotive supply chain. Anbanadam et al. (2011) [5] considered various variables, such as management commitment, information sharing, cooperative trust, relationship risk, and return sharing. They constructed a supply chain collaboration model with manufacturers and retailers as subsystems. The degree of collaboration is measured to evaluate the degree of supply chain cooperation, while also providing potential cooperation opportunities for other elements outside the supply chain subsystem.

After Haken introduced the term “order parameter” into synergetics, the concept of the order parameter was extensively expanded in fields such as management, economy, and society. The order parameter plays a dominant and pivotal role in coevolution, exerting a synergistic effect on the system (Leydesdorff et al., 2013) [6]; however, the order parameter identification method based on Haken’s classical model mostly remains at the macro-level and lacks a detailed analysis of the information in the collaborative evolution process. Wanger (1994) [7] improved Haken’s three algorithms, and Schanz and Pelster (2012) [8] used this method to identify the order parameters of nonlinear time-delay systems. May et al. (2015) [9] provided an identification method and indicator system for order parameters in energy systems. Hryshchuk et al. (2016) [10] updated the dynamic meaning of order parameters: due to self-organizing processes, the system reduces its dynamic parameters to a limited number of variables, which can maintain stability under disturbances. Xu et al. (2017) [11] used this method to identify the system order parameters in the coevolutionary model. Additionally, there are the main melody analysis method based on objective programming (Warm et al., 2011) [12], the optimized relaxation coefficient method (Zheng et al., 2013) [13], and the order parameter identification model constructed based on the gray system theory (Wu et al., 2017) [14]. With the expansion of the research scope, order parameter analysis has entered more fields. Wang Haiyan et al. (2017) [15] proposed a method for identifying order parameters in food quality chain collaborative systems based on the gray correlation degree and attribute reduction, and provided a method for solving order parameters considering the overlap degree. The focus of this method is to determine the collaborative elements, establish parameters that represent the system state, and define overlapping relationships between the parameters. Wen et al. (2020) [16] analyzed the formation process of multi-order parameters from the perspective of output/input. Combined with its impact on the system evolution process, an improved data envelopment analysis method was applied to establish an efficiency-oriented multi-order parameter identification model for the system evolution process.

Based on the identification of order parameters, research on system collaboration issues is mainly conducted from two perspectives: complex system theory and economics. For example, research covers aspects such as system collaborative optimization, collaborative mechanisms, collaborative operational performance, and collaborative degree measurement. Li et al. (2012) [17] proposed a composite system synergy model based on order parameters and made significant progress in evaluating the synergy levels. Additionally, Tang et al. (2010) [18] introduced the Euclidean distance method into the evaluation model of system collaborative development and analyzed the Chinese economic and technological system through empirical research. Cui (2016) [19] emphasized that the collaborative level of the system cannot be simply evaluated using the general method of assessing the development level of the system. The development level primarily measures the evolution trajectory of the system from a vertical perspective, while the level of collaboration emphasizes the consistency of relationships between various elements within the system from a horizontal perspective. Deng et al. (2016) [20] pointed out that the synergy of various subsystems in a large system can impact the synergy of a composite system. Chen Lilan (2016) [21] studied the integrated management of engineering project elements based on collaboration theory and constructed a model to measure the degree of internal element collaboration in engineering projects. This model also calculates collaboration based on order degree and proposes using a large sample survey method to correct the identification results of order parameters. Luo and Dong (2017) [22] divided the synergy of regional economic systems into three stages: primary stage (synergy degree of 0–0.4), intermediate stage (synergy degree of 0.4–0.7), and advanced stage (synergy degree of 0.7–1) and expanded the synergy model into dynamic and static parts. Li et al. (2016) [23] believe that the low synergy of the macroeconomic system is less than 0.3. Chen et al. (2016) [24] studied regional intellectual property management systems and improved the traditional collaborative evaluation model, proposing the concept of subsystem “consistency”. When the consistency of each subsystem is high, the synergy will fall within the [0, 1] range; conversely, it will fall within the [−1, 0] range. Zhang et al. (2017) [25] extended the concept of synergy to the research field of regional development, analyzing the Beijing–Tianjin–Hebei greater system from the perspective of five subsystems and studying the spatial differences in the order of collaborative development. Li et al. (2017) [26] also measured the level of coordinated development between Beijing, Tianjin, and Hebei. They also discussed the development and synergy of the system, pointing out the positive impact of development strategies on the collaborative process. They believe that every game synergy mutation process pushes the collaborative development of urban agglomerations to a higher level of synergy and presents a phased pattern.

The development of systems science has expanded the range of applications for synergetics. In recent years, scholars have predominantly employed synergetics to examine self-organizing processes in macroscopic systems. Lv Tong et al. (2002) [27] proposed that the energy economy environment system also qualifies as a dissipative structure. During system evolution, the influence of fluctuation mechanisms can give rise to phenomena such as synergistic and non-synergistic spiral escalation, aligning with the fundamental tenets of synergy theory. Bao et al. (2014) [28] devised a bilevel programming mathematical model to optimize the allocation of resources for product customization by analyzing collaborative manufacturing resource allocation for such customization. Employing an optimized hybrid genetic algorithm, they attained the optimal solution for collaborative manufacturing resource allocation in product customization. Fang (2017) [29] asserts that the collaborative process of socio-economic systems follows a nonlinear spiral progression involving game, collaboration, mutation, re-game, re-collaboration, and re-mutation. This analysis, too, rests on synergy theory. Lychkina (2016) [30] delved into the collaborative development of socio-economic subsystems and noted constraints in traditional socio-economic models. To create effective models, interdisciplinary perspectives, such as system dynamics and strategic decision simulation, must be applied to study cyclic collaborative evolution phenomena from a dynamic standpoint, bridging macro- and micro-system collaborative research. Meynhardt et al. (2016) [31] examined service ecosystems at micro- and macro-levels utilizing synergy theory, emphasizing the value characteristics inherent in dynamic collaborative evolution. Using nine collaborative attributes, including critical points, stability, endogenous variables, nonlinearity, feedback, and finite prediction as starting points, pathways for enhancing value can be identified. Zheng et al. (2017) [32] expanded the concept of collaborative management to the realm of industrial economy, illustrating the dual effects of supply chain collaborative management using steel enterprises as an illustration. These effects involve achieving both financial and ecological performance, as well as internal and external performance for a single enterprise. Yang et al. (2019) [33] identified that the original classical model could solely address the limitations of static system synergy. They advanced a speed feature model based on improvements, quantifying the quality and effectiveness of system synergy evolution through co-driving the “evolution speed state” and “evolution speed trend”. This model integrates weight information and accounts for the “functionality” and “coordination” of order parameters. Guo et al. (2019) [34] employed collaborative analysis methods in the e-commerce and big data industries. They established an e-commerce big data system (EBDS) collaborative evolution model founded on the classic Haken model. Through quantitative evaluation of order and synergy, they presented managerial recommendations for the secondary industry encompassing collaborative application, industrial chain, risk, external environment, and ecosystem dimensions.

2.2. System Flow Perspective

In the 1960s, Reiter (1966) [35] pioneered the study of production systems, introducing the concept of “Lot Streaming” and examining the transfer of product batches. This focus on production batch flow and transfer modes continued with subsequent researchers, such as Jacobs (1984) [36], Graves, and Kostreva (1986) [37], who identified batch transfer modes in their respective fields. The 1980s saw the emergence of the just-in-time production theory and optimal production technology. Truscott (1985) [38] utilized heuristic methods to address continuous flow challenges in general workshops with equal sub-batches. Potts (1989) [39] applied the method of equal quantity batch to flow shop problems and employed heuristics for multi-batch solutions. Vickson (1995) [40] employed a fast polynomial algorithm to solve flow shop multi-batch problems, considering the job setting time and sub-batch transfer time. Etinkaya (2006) [41] extended this by incorporating units and independent settings to optimize batch problems in dual-machine process workshops, termed batch flow integration optimization. Despite these advancements, such research mainly focuses on small-scale device environments, with limited exploration of multi-flow integration at the production line level.

In recent years, international scholars have primarily explored complex large-scale systems through the lens of “flow” structure, yielding extensive applications in industrial production systems. Ruth (1995) [42] delved into the interplay between material flow, energy flow, and information flow, utilizing the industrial balance theory. She noted that energy propels physical state changes alongside information transmission. Simons et al. (2003) [43] examined the production value stream, shifting from a time-centric approach to a sustainable value stream, thus analyzing energy use and identifying the least environmentally friendly links, particularly in relation to carbon dioxide emissions. This tool has proven highly effective in energy consumption analysis through practical application. Long et al. (2008) [44] emphasized that the analysis of “flow” primarily concerns the flow rate and velocity, providing an initial depiction of material flow, energy flow, and information flow characteristics and relationships within extensive systems. Bascur et al. (2009) [45] explored production material flow and energy flow, utilizing historical data and shared production information to foster continuous enhancement grounded in quality monitoring, process control, and variable analysis. William et al. (2014) [46] expanded the original value stream map by incorporating raw material utilization and energy consumption. This comprehensive approach vividly highlights the waste and potential pollution aspects of a company, furnishing a global perspective for enhancing the company’s sustainability.

Taulo et al. (2016) [47] analyzed the material and energy flows within the tea industry supply chain from a collaborative stance. They argued that this approach can illuminate environmental issues early in production and offer a basis for prioritizing factory improvement projects. Suominen et al. (2016) [48] introduced a nonlinear optimization scheduling scheme tailored for production, grounded in material and energy flow networks within production systems. This scheme optimizes production efficiency via process simulation, furnishing effective production conversion plans and establishing predictive mathematical models for equipment parameters. Yin (2016) [49] viewed the production process as a multifaceted network encompassing various manufacturing processes. His emphasis lay in addressing energy flow concerns accompanying material flow to ensure minimal production costs. Collaborative research on flow structure, from an energy management perspective, becomes pivotal for modern steel mills, supplying solutions and system support for energy-saving decisions. Zhang et al. (2017) [50] merged an environmental values stream analysis with the Flexsim simulation tool, enhancing the value-added ratio of energy consumption during production. Zheng et al. (2017) [51] proposed a collaborative approach to material and energy flows in steel enterprises. They underscored the need to plan the coupling of material and energy flows at unit equipment and process network levels, supported by digitization and informatization, to optimize resource utilization. Yu et al. (2018) [52] identified a coupling synergy between material, value, and energy flows, calculating the synergy coefficients between them. Li et al. (2018) [53] constructed a multi-stream collaborative model encompassing “material flow, energy flow, information flow, and capital flow” in information physics energy systems. Their approach considered production costs, energy consumption, collaborative scheduling, and market aspects. Huang et al. (2019) [54] analyzed the structure and attributes of “flow”, introducing a collaborative framework for the security of the “four flows” within a system, and conceptualizing a model. Collectively, these scholars’ research highlights three perspectives within system collaboration from the flow standpoint: micro (human–machine systems), meso (organizational systems within enterprises, encompassing various flows), and macro (energy economy environment system synergy within social and economic systems).

2.3. Complex Industrial Management

The study of complex industrial production control management theory and industrial system dynamics are complementary. Qi et al. (2008) [55] used the system dynamics method (SD) to study the knowledge transitive model within industrial enterprises and obtained the change law of knowledge potential energy under different factors. Based on the industrial system dynamics modelling method, Jiang (2011) [56] proposed two breakthrough management deficiency optimization paths to improve the performance level of enterprises. Wang et al. (2012) [57] constructed a dynamics model of the logistics operation of an industrial enterprise and proposed a simulation optimization scheme for the crafts industry, demonstrating the feasibility and applicability of system dynamics applied to production cost control.

In the realm of industrial production’s general management methods, key solutions encompass factors influencing management system optimization (Love et al., 2002) [58], enhancing efficiency and reducing costs across all production aspects (Zhang et al., 2007) [59], employing dynamic programming for management strategies (Lee et al., 2006) [60], embracing the enterprise development life cycle and self-organizational learning mode (Hu Bin et al., 2006) [61], and more. A dynamic simulation analysis of enterprise business model operations, conducted by Dai and Chen (2014) [62], explored developmental drivers through an organizational structure lens. Gary et al. (2018) [63] introduced an innovative dynamic model to investigate the cost, performance, and development strategy matters within automotive manufacturing enterprises. Hanafi et al. (2019) [64] crafted a quantitative system dynamics model for the smelting industry, tackling intricate production investment competition challenges.

The energy revolution has substantially boosted productivity while inducing shifts in industrial management and production structures (Stan et al., 2015) [65]. Larson et al. (2004) [66] introduced the “Lean and Green” concept, highlighting their intricate interrelation. Lean manufacturing, with its well-established history and widespread application in developed countries, has yielded impressive outcomes, leading to a focus on the environmental impacts of unnoticed lean practices. This initial research phase explored how lean manufacturing, through waste elimination, enhances environmental performance (Zhang et al., 2018) [67]. Kurdve et al. (2014) [68] devised a comprehensive bottom-up system incorporating value-driven and operational-driven approaches, providing an expansion path for implementing this new system alongside existing structures. Yang (2015) [69] outlined the evolution of enterprise management in the low-carbon era, emphasizing the integration of energy conservation and consumption reduction into core values and developmental goals. This involves a shift in traditional management paradigms, aiming for mutually beneficial outcomes between energy preservation and profitability, guiding institutional innovation through energy transformation responsibility, and aligning carbon emission mandates with market dynamics. Modern management techniques, such as benchmarking, technology outsourcing, standard operations, and personnel training, are believed to reduce energy expenses for enterprises. Tetiana et al. (2018) [70] stress the significance of informed green lean decision-making, particularly for industries heavily reliant on conventional energy sources. Taking power enterprises as an illustration, they present specific conditions for implementation, including structural reformation of the energy sector and technological transitions in the industrial realm. Jarrahi et al. (2019) [71] discussed the connection and difference between the two production modes of “Lean manufacturing” and “Industry 4.0”. They connected two important research fields of the industrial production management system and provided a collaborative integration scheme of the two.

Various management methods, including system engineering, optimization theory, lean manufacturing, sustainable development, and enterprise production, have been deeply integrated into production management. This has led to the inclusion of input–output analysis, production energy conservation control, energy consumption analysis, and regulation (Javied et al., 2019) [72]. Dues et al. (2013) [73] pointed out that challenges exist between managing energy resources and production. Scholars continuously strive to introduce new methods and modeling ideas. Lee et al. (2014) [74] introduced Six Sigma, a lean quality management tool, into the energy plan. They pioneered the Six Sigma energy management approach, now a part of modern production management systems. Pampanelli et al. (2014) [75] created models for implementing environmental management based on lean manufacturing. This integrated lean concept with environmental sustainability improves resource use and reduces the environmental impact. Zhang et al. (2016) [76] developed an energy demand prediction model for industrial enterprises. It considers how production systems and energy management interact across time and space. This model was optimized under uncertain decision-making and applied to power demand management. Li et al. (2017) [77] built a system dynamics model with five subsystems: economic development, primary and secondary aluminum production, carbon dioxide emission intensity, and policy formulation. This model can analyze trends in carbon dioxide emissions from the aluminum industry. Hilorme et al. (2019) [78] established adaptive and multiplication models for energy technology implementation based on seasonal factors and overall energy management trends. They used a space analysis matrix. Laura et al. (2020) [79] created a system dynamics model combining technological advancements and economic evaluation. This model analyzes the cost impact of implementing carbon dioxide capture technology in cement plants. It evaluates the economic benefits of the cement industry under different carbon capture scenarios.

In terms of modern innovation in management systems, Chang (2005) [80] and Sarin (2008) [81] both studied production management from the perspective of flow by using batch flow to study the comprehensive integration of just-in-time production management methods. Zeng (2018) [82] believes that a good management system is the foundation for the healthy development of enterprises. It helps to break down technical, institutional, and market barriers between energy subsystems within enterprises. Hillman et al. (2018) [83] studied the value of enterprises as drivers of low-carbon transformation, believing that the driving force of enterprises for sustainable development in the world is currently underestimated. In order to address contemporary ecological challenges, industrial enterprises should adopt a continuous improvement organizational model. Domestic and foreign scholars have gradually constructed an effective management system based on continuous improvement and focused on energy management, referencing the architecture of ISO. It has been widely applied in the implementation monitoring and optimization management of industrial production processes (Zhang et al., 2019) [84]. Until the end of the twentieth century, innovative industrial production management ideas continued to emerge, including total quality management, Lean Six Sigma, etc. Subsequently, enterprises all over the world favored this low-risk organizational change mode and built an enterprise operation management system with this as the core. In the 21st century, the production management system centered on lean concepts has been widely applied and has evolved into a world-class manufacturing (WCM) system. Over the past thirty years, the management system has undergone continuous development, leading to improved technological efficiency and a focus on achieving efficient resource utilization through production management. Industrial enterprises have advanced their production management thinking, progressing from individual equipment resource management to the strategic planning and control of production process resources.

2.4. Commentary

Based on an analysis of the existing literature, comprehensive discussions have taken place on collaborative research within large-scale systems, both domestically and internationally. These studies encompass separate examinations of elements such as material flow, energy flow, and information flow within large systems. They also delve into collaborative interactions between multiple flows of elements, spanning micro-, meso-, and macro-levels. The existing research primarily focuses on empirical studies concerning subsystem analyses, collaborative evaluation methods, and complex interrelationships within large-scale systems. The synergy theory-based evaluation method emphasizes guiding and constraining factors in system development, highlighting the significance of order parameters and collaborative trends. This stands in contrast to traditional system evaluation methods, which prioritize enhancing indicator systems and collecting numerical values; however, due to the extensive data support and specialized nature required for order parameter identification, the current models are complex and demand significant effort. With the increasing complexity of industrial production systems and the infusion of diverse research methods and perspectives from various disciplines, scholars have expanded the application of synergy theory and flow structure. This expansion ranges from industrial production systems to macroeconomic systems. Despite this progress, certain challenges persist. These include inconsistent subsystem levels, unclear characteristics of flow structures, and analytical limitations. Additionally, the current model construction is relatively singular due to the insufficient integration of dynamic principles, resulting in an incomplete variable analysis. It is noteworthy that several methods used to address energy flow issues in production systems are not directly adaptable to complex industrial production systems. The latter exhibit characteristics such as nonlinearity, dynamism, and openness, posing unique challenges for research.

Amidst the ongoing trends of intelligent manufacturing and green manufacturing, scholars have put forth a perspective that seeks to advance and break new ground through comprehensive integrated management. They emphasize concepts such as “coordinated progress” and “collaborative innovation”, with the goal of offering both a theoretical analysis and practical guidance to industrial enterprises using the principles of synergetics. This approach begins by examining the composition of enterprise systems and innovatively exploring the relationships between various subsystems within the enterprise and their external environment; however, there is currently a lack of sufficient research on the mechanisms and influencing factors of subsystem synergy. Furthermore, there is no clear indication of the precise path to implement this advanced concept. Correspondingly, the research focus on collaborative management within industrial enterprises aligns with the direction of collaborative theory from the standpoint of system flow structure. Deepening the understanding of collaboration among diverse subsystems of the production system is of the utmost importance. This understanding should be reflected in management decisions, enabling the creation of management mechanisms and pathways that are both practical and promotable.

3. Construction of Flow Structure Collaborative Model for Complex Industrial Production Systems

3.1. Preparation of Flow Structure Modeling for Complex Industrial Production Systems

3.1.1. Analysis and Modeling Assumptions of Complex Industrial Production Systems

The complex industrial production system is an open large-scale system that has both energy exchange and material exchange with the outside world. P represents the set of all processes and equipment in the system, R signifies the comprehensive network of interrelations within the same system, and the complex industrial production system can be simply expressed as Formula (1) [85].

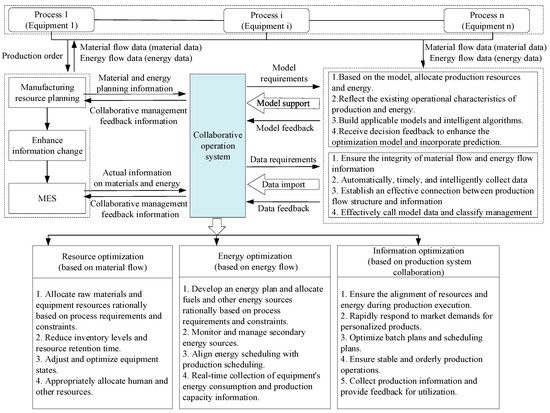

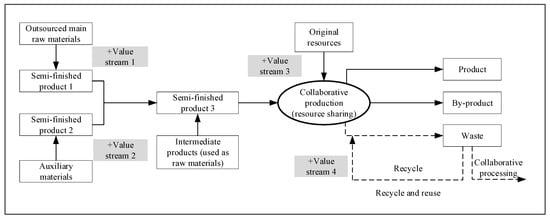

In explaining Formula (1), we can understand “R” as encompassing the storage and transportation of raw materials and energy within the production layer of complex industrial systems. This layer involves various stages, such as raw material processing, forming, and packaging, resembling both continuous and intermittent production processes. It can also be viewed as a system made up of different subsystems, each with distinct functions. Encompassing dimensions of material flow, energy flow, and information flow, this process system operates based on changes in the state and properties of matter. A complex industrial production system fundamentally constitutes a large-scale engineering construct. It is marked by high nonlinearity, multivariability, and limited information. Its intricate nature comprises various components, multiple tiers, openness, nonlinearity, and dynamic orderliness, ultimately giving rise to a significant attribute: structural complexity. Analyzing its dynamic structure involves addressing three key facets. The first is the dynamic essence of the system’s flow structure, which encompasses characteristics of propulsion and dissipation. Second are the factors governing subsystem behavior (comprising material flow, energy flow, and information flow). Last are the interrelations among subsystems and their collective impact on the overall system.

Based on the situation described above, in order to construct a more scientific mathematical model for evaluating the collaborative degree and dynamic collaborative evolution of complex industrial production systems, we make the following modeling assumptions:

① A complex industrial production system functions as an open system, facilitating continuous exchanges of materials, energy, and information between internal and external components. This dynamic interaction occurs not only among various subsystems within the system itself, but also among the diverse elements within each subsystem.

② Within a specific time and space range, the system displays a relatively stable state, known as dynamic stability. During this state, the diverse resources of the production system (including labor, capital, raw materials, technology, fuel, etc.) remain at a consistent scale. A value range denoted as N characterizes the level of collaborative evolution in production systems, and this value is positively linked to the system’s resource count. In simpler terms, collaborative evolution does not have a final point, but it does lead to recognizable phased results. Following a certain disturbance (such as the emergence of a problem), the system gradually transitions to a stable and organized state, referred to as the collaborative evolution process of the system.

③ The timing of system state reduction and feedback is allowed, as the system state is not only related to the resource situation at a specific time, but is also influenced by factors such as the supply chain environment, policy requirements, and management methods.

3.1.2. Determination of Order Parameters

Based on the theory of collaboration given herein, the collaborative order parameters of complex industrial systems represent the behavior between subsystems of material flow, energy flow, and information flow. They are also the dominant factors that cause subsystems to compete and make large systems tend to collaboratively evolve.

In the context of identifying order parameters, Haken introduced three methodologies in his works, “Introduction to Synergy” and “Advanced Synergy”. These methodologies comprise the relaxation coefficient method, the maximum information entropy method, and the adiabatic elimination method. In recent years, both domestic and international scholars have proposed novel approaches. These include a theme analysis, identification based on target programming, and identification rooted in the input–output analysis. Prior research has effectively synthesized a spectrum of feasible order parameters. Furthermore, the Ministry of Industry and Information Technology of the People’s Republic of China issued the “Evaluation Specification for the Integration of Informatization and Industrialization of Industrial Enterprises” (National Standard GB/T23020) in September 2013. This standard establishes the evaluation criteria for industrial enterprises across aspects such as materials, information, and management, accentuating the interplay and synergy between resource efficiency and subjective production factors. Drawing on the available data, this study has curated an illustrative list of order parameters, as outlined in Appendix A Table A1. By referencing the research findings of May et al. (2015) [9], Wu et al. (2017) [14], Zheng et al. (2017) [51], and Wen et al. (2020) [16] in the domain of order parameter identification, and in conjunction with Appendix A Table A1, a comprehensive compilation of order parameters suited for intricate industrial production systems is presented in Table 1.

Table 1.

Order parameter of industrial production system (comprehensive identification).

3.2. Collaborative Evaluation Model Based on Order Parameters

3.2.1. Collaborative Evaluation Considering the Taylor Index

Synergy is a dynamic indicator that is difficult to measure at all times. Based on the Haken model and referring to the synergy measurement model proposed by Meng et al. (2000) [2] and Li et al. (2016) [23], it refers to the use of the order degree at a certain moment to measure the collaborative development results of the system from the initial moment to that moment. Assuming that the production system is , the material flow subsystem, energy flow subsystem, and information flow subsystem are , , and , respectively; then, , where Sij represents the j-th element in the i-th system, such as S21 representing the first element in the energy flow subsystem. The order parameters of the material flow subsystem, the energy flow subsystem, and the information flow subsystem are represented by , , and , respectively:

; the corresponding value is ;

; the corresponding value is ;

; the corresponding value is .

According to the index characteristics, the order parameters can be divided into three types. The larger the value, the more favorable the system synergy is. For example, the overall efficiency of equipment, yield, etc., are called positive effect order parameters, and their effect value is expressed as ODij+. Another thought is that the smaller the value is, the more favorable the system synergy is. For example, the comprehensive energy consumption per unit product is called the negative effect order parameter, and its effect value is expressed as ODij−. Another is that the closer its value is to a certain target value, the more beneficial it is to the system synergy. In other words, it is not the greater the better or the smaller the better, for example, the proportion of wastewater recycling and information construction costs, whose effect value is expressed as ODij*. This type of order parameter is called a moderate order parameter. We define as the minimum value of order parameters for each subsystem, and as the maximum value of order parameters for each subsystem. Based on the information above, calculate the fffect size of the three order parameters according to Formula (2):

The number of subsystems is expressed in m relative to the long coevolution process, and there can be n order parameters in each subsystem. Indeed, during infinitesimal time intervals, each subsystem possesses only one order parameter. The effect value of the order parameter is expressed as xij. If the number of order parameters in a subsystem is less than n, the lesser part of the effect value is expressed as 0, then the order parameter eigenvector matrix of the system can be expressed as Formula (3):

The standardization of the data in the matrix is performed according to Formula (4):

After obtaining the new transformation matrix , considering that the order parameters of each subsystem play different roles in the collaborative development process of the dominant system, it is necessary to calculate the weights of the order parameters of each subsystem. Since the numerical value of the order parameter represents a type of information about the state of the subsystem, the Thiel index is introduced here, which is an indicator based on the information entropy calculation method to measure the gap between objects. The larger the Thiel index, the greater the amount of information provided by the order parameter (symbol). We calculate the Theil index according to Formula (5) to convert the negative effect size to a positive value.

The weight of the order parameter is defined as Formula (6):

The greater the effect size of the order parameter in each subsystem is, the greater is the contribution value of the order parameter to the coordinated order state of the subsystem. Here, we define the contribution of the three subsystems to the coordination degree of the large system as the order degree. At any time t, the order degree of the material flow subsystem, energy flow subsystem, and information flow subsystem is calculated as Formula (7):

The order degree of the large system is:

According to the order degree of the three subsystems and the order degree of the large system, the synergy degree of the large system is calculated as:

Among them, when , , is simultaneously valid, takes a positive value, otherwise it takes a negative value. The larger the value of is, the higher is the level of coevolution, and vice versa. The extremely non-coevolutive state when is −1 and the extremely cooperative state when is 1 are relatively rare. The value of reflects the collaborative state of the system at a certain time, displaying the static state of the system’s collaborative measure and the evolution results during a certain period. Formula (14) takes into account the comprehensive situation of all subsystems. Even if the degree of order of a certain subsystem increases significantly, it cannot eliminate the impact of the decrease in the degree of order of other subsystems. This is reflected in , which means that the collaboration of a large system is based on the cooperation of two subsystems, and the large system is ultimately in a stable and orderly state.

3.2.2. Collaborative Analysis Considering Gray Correlation

The collaborative evaluation method for large systems is based on the calculation of the following two factors: subsystem order degree and Thiel index weighting. For situations where there is both clear and unclear information in production, the evolution process and trend should be clarified, and the collaborative mechanism between subsystems should also be studied. Wu Yuying et al. (2017) [14] and Wang Haiyan et al. (2017) [15] both used a gray correlation analysis when studying collaborative problems, but it is limited to identifying the order parameters of subsystems, that is, clearly identifying the order parameters that dominate the trend of subsystems based on the gray relationship between the subsystems. In this study, the gray synergy analysis is carried out for the subsystem. First, the original data are dimensionally removed and standardized, such as in Formula (10), and then the data are normalized according to Formula (11).

The Taylor index method is still used to calculate the weight , and the subsystem information balance is calculated according to Formula (12).

Use to represent positive ideal points and to represent negative ideal points; the positive ideal points are ideal programming values for each order parameter, negative ideal points are the worst values for each order parameter, A+ is the set of positive ideal points, and A− is the set of negative ideal points. According to the ideal collaborative state, the equilibrium value of the information intensity of each subsystem is used as the evaluation variable, and the ideal value is equal to the actual value of the information equilibrium degree of another subsystem (in fact, the information equilibrium degree of one subsystem is used as the ideal value of another subsystem). For example, take Formula (13):

The distance between the subsystem and the positive and negative ideal points is calculated by Formula (14):

and represent the distance between subsystem i and the positive and negative ideal points during period t, which is the j-th value of the A+ and A− vectors. Taking the effect of each order parameter of the energy flow subsystem on the material flow subsystem as an example, we can calculate the correlation coefficient so that:

Define the correlation coefficient:

is the resolution coefficient, usually taken as 0.5, defining the gray correlation degree:

We calculate the absolute correlation between the subsystems. The larger the value is, the higher is the correlation level. Formula (18) is as follows:

Based on the evaluation of system synergy, we can combine the gray correlation coefficient to clarify such a relationship, the interaction relationship between the subsystems. We can also learn how the subsystems achieve pairwise collaboration through competition and collaboration, and then drive the overall system’s collaboration.

3.3. Dynamically Based Collaborative Evolution Model

We can use Formula (19) to concisely describe the state of the entire process of collaborative co-evolution of the system [44]:

Formula (19) sets the level of system coevolution as a function of time x(t). When no resistance is considered, the growth rate of the system coevolution level is r. The level of system coevolution will continue to increase over time, indicating that dx(t) > 0. It can be seen that the overall trend of system coevolution shows an exponential curve growth trend, and further analysis of its evolution state curve is needed.

3.3.1. Explanation of Coevolutionary Variables

Based on the dynamic analysis of the flow structure of the three subsystems of material flow, energy flow, and information flow, as well as the analysis of collaborative evolution, we considered the factors that affect the collaborative evolution process and set them as variables when modeling. The dynamic and practical significance of these variables are shown in Table 2.

Table 2.

The dynamic significance and practical significance of each variable.

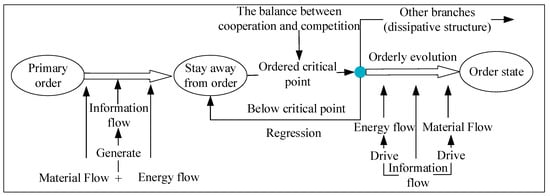

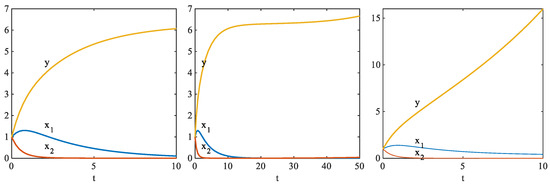

In the process of co-evolution, the system exhibits distinct characteristics that allow for the division of evolutionary stages. For instance, it can be segmented into the initial phase, competitive phase, cooperative phase, and coordinated phase based on the transformation of entities from micro- to macro-levels. Alternatively, it can be categorized into an independent stage, integrated stage, and intelligent collaborative stage based on the progression of informationization in production. Similar classification methods have also been proposed by other scholars. For example, Zhou (2013) [86] divided the evolution of manufacturing integration and industrialization based on informationization into the starting stage, single coverage stage, integrated enhancement stage, and innovative breakthrough stage. Drawing inspiration from the research achievements of Long (2008) [44], Miao et al. (2013) [87], and Li et al. (2018) [53], this study presents an evolutionary process description model and an evolutionary self-organizing control model. The co-evolution process is categorized into the collaborative generation phase, collaborative equilibrium phase, and collaborative maturity phase based on the different sources of dynamics in each stage. As depicted in Figure 1, during the initial system state, material and energy flows jointly generate information flow, and interactions among three subsystems lead to competition and cooperation, driving the system away from an ordered state and establishing the initial conditions for evolution. In this stage, exchange occurs between matter, energy, and information with the external environment, which introduces disruptive factors influencing the ordered state. With the enhancement of energy utilization efficiency, material and energy flows enter the equilibrium phase, where the critical point order parameter determines whether the system progresses toward an ordered structure. Subsequently, material, energy, and information flows harmonize to form a coordinated operational mechanism, marking the transition into the collaborative maturity phase. In the subsequent steps, we will establish a model based on a set of dynamic equations to describe these three stages of the co-evolution model.

Figure 1.

Synergetic evolution path of industrial production system.

3.3.2. Equations for the Generation Period of Collaborative Evolution

Let S1, S2, and S3 represent the three subsystems of material flow, energy flow, and information flow, respectively. The relationship between the subsystems during the evolutionary generation period is shown in Formula (20).

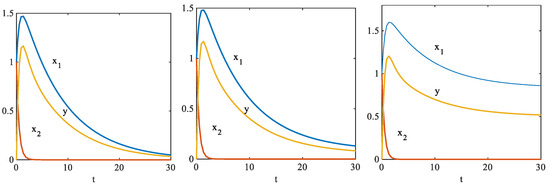

is the state parameter of that changes over time; represents the impact of the interaction between the material flow subsystem, energy flow subsystem, and information flow subsystem on the material flow subsystem itself, , , and so on; and represents the impact of random sudden disturbances, during which the system continuously undergoes energy conversion with the outside world, thus the random disturbances act more directly on the energy flow. Since the order parameter is the leader of the behavior of the subsystem, which determines the competition and cooperation state among the subsystems, and then determines the trend and result of the system’s co evolution, Equation (20) can also be regarded as the equation of state of the order parameter of the three subsystems. The action state of order parameters of each subsystem is analyzed in detail below, and the system dynamics equation of state is constructed as Equation (21).

is the order parameter of the material flow subsystem, , , and so on; , is the damping coefficient; is the synergistic trend index of the material flow subsystem, which is the contribution of to the ordered trend of the system (, analogies); this index includes the dual effects of cooperation and competition. Note that the difference between competition and damping is that competition is the behavior between the subsystems (the fundamental reason is the behavior of order parameters between subsystems), which plays a positive role in the orderly trend of the system, while damping plays a negative role. is the driving effect of the material flow subsystem on the energy flow subsystem, is the generation effect of material flow and energy flow on information flow, represents the degree of attenuation of ’s effect on the ordered tendency of the system (, analogies), represents the impact of the interaction intensity between the energy flow order parameter and the information flow order parameter on the material flow (, analogies), represents the degree of influence of subsystem on the collaborative evolution process (, analogies), represents the impact of the competing behavior of each subsystem on the overall system during the collaborative evolution process (i.e., , , comprehensive index of action), and y represents the collaborative state of the large system. This differential equation system describes the contributions of the three subsystems , , and to the collaborative process and ordered results at a certain moment in the evolutionary generation period (reflected by the dominant role of the order parameter), and the first-order derivative equation of y with respect to t illustrates how the roles of each subsystem are carried out. In fact, the collaborative relationship between the subsystems is very complex and may not be as ideal at every moment, but this typical simplified state helps to identify the main influencing factors of the collaborative process.

3.3.3. Equations for the Stagnant Period of Collaborative Evolution

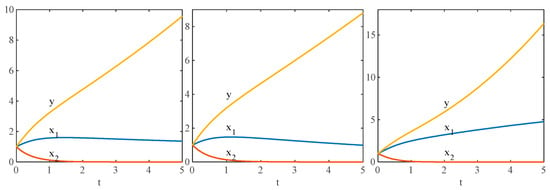

The contradictions, external disturbances, and other factors that arise between subsystems during the generation period may become factors contributing to the disorder of the system. During the period of coevolution and stalemate of the system, the key factor determining whether the system can form an ordered trend is the order parameter. Assuming that the order parameter at the end of the evolution stalemate can cause the system to produce an ordered trend, there will be two types of order parameters interacting with each other during this period: one is the competitive order parameter, and the other is the cooperative order parameter. These come from the competition and cooperation of the subsystems, promoting and coordinating each other. Using to represent the cooperative order parameter, to represent the competitive order parameter, and y to represent the collaborative state of the large-scale system, the dynamic differential equation system of Equation (22) is formulated as follows:

In the formula above, represents the collaborative trend index. , represents the damping coefficient and represents the mutual influence coefficient between and . Due to the opposing forces of and , this influence is a resistance for both parties, but the higher the value is, the faster is the process of system evolution. represents random factors, and we assume that random factors at the same time may affect cooperation or competition. represents the attenuation coefficient of competitive power, represents the coefficient of influence of cooperative forces on the collaborative evolution of the system, represents the coefficient of influence of competitive forces on the collaborative evolution of the system, represents the coefficient of influence of the combined effect of the two forces on the evolution of the subsystem, and represents the self-feedback coefficient of the system, which represents a self-organizing ability independent of two forces and is a characteristic of the system itself. The first two equations of Formula (22) describe the guiding effect of two different order parameters on the evolution trend of the system, while the third equation describes the results of the system under these two forces.

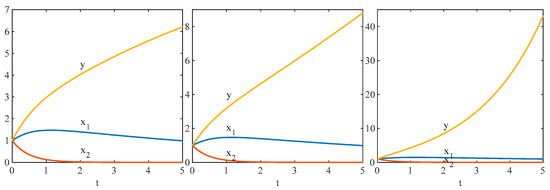

3.3.4. Equations in the Mature Stage of Collaborative Evolution

In the mature stage of collaborative evolution, the collaborative relationships between subsystems are clearer and more stable, with mutual coordination, constraints, and cooperation. At this time, the factors that affect collaborative evolution mainly come from within the system, and according to the evolution process, external forces, such as the environment, are difficult to produce substantial disturbances on the system. Each subsystem generates a self-control mechanism to achieve the optimal overall goal of the entire system based on relevant goals. Here, the system state is still described using order parameters and various parameters, and the dynamic equation system is shown in Formula (23).

is the object parameter matrix, and vector represents the parameter matrix of each subsystem, where the flow velocity of each flow can be used as a parameter. represents the feedback matrix of the synergistic effect on the subsystem ( corresponding to the material flow, energy flow, and information flow subsystems, respectively). represents the actual synergistic relationship between the energy flow and information flow subsystems and material flow subsystems, and other analogies. Let the variable represent the ideal coevolution result, that is, the stable state of the subsystem in the later stage of evolution. At the end of collaborative maturity, the evolution results are analyzed as follows: we define synergy bias as a difference between the ideal collaboration relationship and the actual collaboration relationship. See Formula (24) for details:

The smaller the collaborative deviation, the more mature the collaborative evolution stage of the system, so the minimum value of the objective function of the system can be expressed as . It can be seen that when , , the objective function value can reach the minimum, and set the total objective , then:

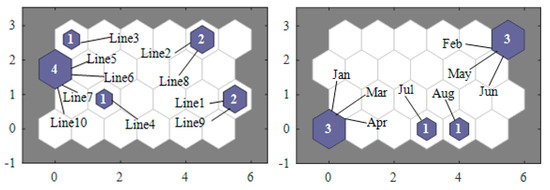

3.4. Collaborative Disturbance Recognition Based on SOM Algorithm

According to the analysis of the collaborative evolution process, the contradictions between the subsystems and the contradictions between the system and the outside are the reasons for the formation of ordered new trends. Identifying the internal and external disturbances of the flow structure allows for source management of the production system, without the need to analyze the impact of disturbances; however, due to the nonlinear and liquidity characteristics of complex industrial production systems, when non-surface disturbances occur, the essence of the problem can be sorted out from the massive data, relying on material flow. Tracing the direction of energy flow and information flow to the source of a problem is a complex and time-consuming task, especially in the multi-stream fusion process. We refer to the literature of Kohonen T (1982) [88], Chen (2020) [89], Li et al. (2013) [90]. The self-organizing map (SOM) neural network algorithm can be used to effectively identify the disturbance links and the links affected by the disturbance and reflected in the data. The distinction depends on the characteristics and internal links of the data themselves, without establishing an index system and preset categories. The process is as follows:

① When there is an unrecognizable disturbance in the production system, all links may be affected and reflected in the data; therefore, first assign random decimals to the weights of all the connection weights Wij from input neurons to output neurons. Assuming the number of recognized objects is m, as the input layer dimension, in order to explore the nonlinear relationship between the interacting links from actual production data, the discriminant function adopts the Euclidean distance method. For each input object data xi, the Euclidean distance between it and all output divine elements is calculated using Formula (26).

② Compare all the distance values and assume that the neuron with the minimum Euclidean distance is Nj*. As the winning neuron, adjust the weight according to Formula (27) and output it as “1”, while other neurons output it as “0”, as shown in Formula (28). Define the winning neighborhood as NEj*(t), and directly adjust the weights of the winning neurons within the geometric neighborhood according to Formula (29). This ensures that data with similar relationships can receive enhanced responses every time, and the position of the mapping points can reflect the clustering and distance relationships among the data. Among them, α indicates the speed of learning, and the value range is 0 < α ≤ 1, whereas represents the distance between the winning node Nj* and the nodes in its geometric neighborhood:

③ When iterating the process above, the number of iteration steps can be sequentially set to [10 50 100]. Then, determine the optimal number of iterations based on the results. When α is attenuated over time, the magnitude of weight adjustment decreases, and the geometric neighborhood NEj*(t) continues to contract. Finally, when α attenuates to 0, shrink the neighborhood to 1, train only the neuron Nj* itself to achieve self-organizing feature mapping, and the process ends.

In the application scenario of an industrial production system, although the algorithm has slow rate of convergence, it has low complexity and is easy to establish. The autonomous learning process without a mentor also corresponds well to the self-organizing ability of the mature stage of collaborative evolution of production system flow structure. One can quickly find the root cause of the problem and solve it without even identifying what type of problem it is. It can also provide excellent management decision support. For example, mutation data have the potential to become an order parameter for system collaborative evolution, and controlling this potential can achieve the “leading” and “guiding” of collaborative management. This algorithm can be used not only for rapid detection and source finding of abnormal data, but also for rapid resolution of production random problems, fault classification management of energy utilization equipment, and evaluation of production data balance management.

4. Empirical Study on Collaborative Model of Production System Flow Structure

4.1. Overview of Empirical Case SG Enterprises

SG’s main business purpose is to provide environmentally friendly, innovative, and safe automotive glass for major automobile manufacturers. It is a continuous process chemical company, with mixed input and output processes of raw materials and fuels in certain production stages, with a complex relationship between the material and energy flows that are numerous and stable.

4.2. Evaluation of Collaboration Degree of Production System

4.2.1. Calculation of Collaboration Degree of SG Enterprise Production System

Considering the data availability of various parameters in the production system of SG Enterprise, and combined with Appendix A Table A2, each subsystem selects three parameters from Table 1 as order parameters, as shown in Table 3.

Table 3.

Order parameters in SG enterprise production system.

We used the evaluation model in Section 3 to conduct a collaborative evaluation of the production system of SG enterprise, with as its appropriate data reference value. The final value used was the specified value in the SG enterprise standard operating instructions. The effect size of the order parameter of each subsystem is calculated (see Appendix A Table A3). The weight process of the order parameter and the standardized effect size of the order parameter are calculated (see Appendix A Table A4 and Table A5). The final obtained Taylor exponents of each order parameter, the weight of the order parameter in the system, the weight of the order parameter in the subsystem, and the weight of each subsystem in the large system are shown in Table 4:

Table 4.

Weight of order parameters in SG production system.

We calculate the order degree of the subsystem for each year according to Formula (7); we calculate the order degree of the production system according to Formula (8); and we calculate the collaboration degree of the production system according to Formula (9). The results are shown in Table 5.

Table 5.

Order degree and synergy degree of SG company’s production system.

From Table 5, it can be observed that the material flow subsystem, energy flow subsystem, and information flow subsystem of the SG enterprise production system experienced significant fluctuations from 2013 to 2019; however, since 2020, the order of these subsystems has shown an upward trend, and the order of the entire production system has gradually increased. In terms of synergy, there is a period of continuous increase and continuous decrease for several years, and from 2021 to 2022, the trend of order and synergy became more consistent. Except for 2015, which was significantly affected by energy flow, the orderliness of the material flow subsystem showed a similar trend to that of the overall production system in other years, although the fluctuations were more significant. Based on relevant research results (referring to Li and Zhang (2016) [23], Chen et al. (2016) [24], and Luo et al. (2017) [22]), we have classified the degree of order and synergy, as shown in Table 6. Next, we will further analyze these levels.

Table 6.

Ranking of orderliness and levels of collaboration.

Since 2015, except for 2017, the material flow subsystem has been in a medium- to high-order state, while the energy flow subsystem has fluctuated between low- and medium-order states with significant fluctuations, and the information flow subsystem has always been in a low-order state. From 2013 to 2017, the production system remained in a state of disorder. Starting in 2018, the production system gradually transformed into an orderly state and improved to some extent. Until 2021, the production system had not achieved collaboration, while in 2022, a low degree of collaboration occurred. It is worth noting that there is a close correlation between the orderliness of the material flow subsystem, energy flow subsystem, and information flow subsystem, as well as the orderliness and synergy of the production system. These three factors collectively affect the degree of collaboration in enterprise systems. More specifically:

① The significant difference in order between the material flow and energy flow subsystems indicates that the system is in a state of non-synergy. This phenomenon further confirms the analysis conclusion in the previous section: the material flow subsystem plays a dominant role in the production system, and the dynamic mechanisms of energy flow and information flow revolve around the material flow.

② Over the past 5 years, the orderliness of the production system of SG Enterprise has improved. This can be attributed to the effective management measures adopted by the enterprise; however, this trend is not stable because when any of the three subsystems changes, it will worsen the ordered state of the entire system. For each subsystem, the state at time “t” is usually influenced by the other two subsystems. For example, in 2015, the orderliness of both the material flow subsystem and the information flow subsystem increased, resulting in an increase in the orderliness of the energy flow subsystem in 2016; however, due to their interrelationships, it is difficult to achieve an increase in the order of the three subsystems simultaneously, and conflicts often arise. This may be one of the reasons for the instability of the increase in order.

③ The ordered state of the energy flow subsystem has a significant impact on the production system and manifests as a significant “negative impact”. For example, in 2015, the orderliness of the energy flow subsystem was very low. Even though the orderliness of both the material flow subsystem and the information flow subsystem increased, the orderliness and synergy of the production system remained at a relatively low level. Similarly, during the period from 2018 to 2020, although the orderliness of the material flow and information flow subsystems decreased, the orderliness of the energy flow subsystem increased, but this did not lead to an increase in the orderliness of the production system.

④ The orderly situation of the information flow subsystem also has a significant impact on the production system and presents a clear “positive impact”. The order degree of the information flow subsystem is relatively stable and has a similar fluctuation trend as the material flow subsystem. This reflects the dependence and driving effect of information flow on material flow. Except for 2015, the orderliness trend of the information flow subsystem has always been consistent with that of the production system. It is worth noting that the trend of collaboration in the production system lags behind the trend of order in the information flow subsystem by one year, which means that during the period from 2013 to 2022, the synergy effect of the information flow subsystem on the production system has always maintained a positive effect; however, during the period from 2018 to 2020, the orderliness of the information flow subsystem decreased, resulting in a slight decrease in the orderliness and synergy of the production system in 2020. This may be because SG Enterprise had introduced a new management information system, which is still in the adaptation stage. However, in the long run, the benefits of this state outweigh the costs (by observing the overall increase in order and synergy trends from 2018 to 2022).

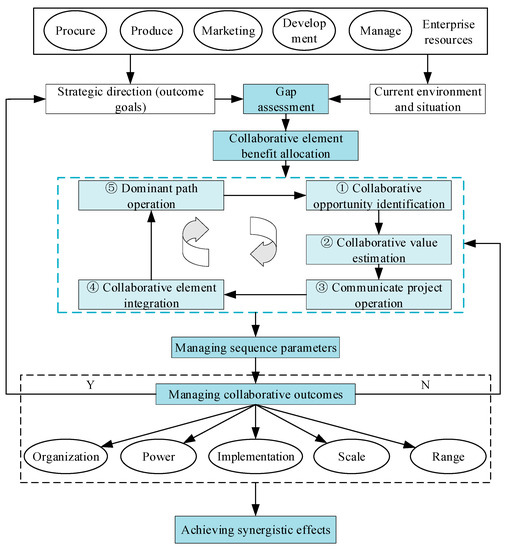

Overall, the level of collaboration in the production system of SG Enterprises shows a relatively chaotic trend from 2013 to 2014. Subsequently, in 2015, due to the implementation of the new management plan, the system had the basic conditions to enter the collaborative generation period. In the following 2015–2021 period, the conditions for co-evolution gradually deepened. By 2022, the system showed a basic trend towards entering the collaborative generation phase; however, it is currently unknown whether the ideal collaborative maturity period can be further reached, which is to form a stable collaborative state. Currently, there is still a considerable gap between the goal of collaborative management and the highly collaborative state of the production system.

4.2.2. Analysis of Gray Collaborative Relationship between Subsystems

Assume that each order parameter in the same subsystem is an independent order parameter, and there is no correlation. The original data in Appendix A Table A6 were still used to calculate the gray correlation between the two subsystems. The interval is [0, 1]. The larger the data are, the greater the correlation is. An interval of “0” means uncorrelation, and “1” means autocorrelation of this element. The correlation coefficient is shown in Appendix A Table A7, Table A8, Table A9, Table A10, Table A11 and Table A12. The variable Xij in Table 7, Table 8 and Table 9 represents the impact of i on j, for example, in the correlation matrix of the material flow subsystem and the energy flow subsystem. We can see that the number in the first row and fourth column of Table 7 is 0.68. It represents the gray correlation effect size of the first order parameter M1 of the material flow subsystem to the first order parameter E1 of the energy flow subsystem, representing the degree of synergistic influence between the two, and other analogies.

Table 7.

Gray effect value between material flow and energy flow subsystems.

Table 8.

Gray effect value between material flow and information flow subsystems.

Table 9.

Gray effect value between energy flow and information flow subsystems.

The gray correlation coefficients of different subsystems obtained by us are all greater than 0.5, with most of them above 0.6, indicating strong gray connections between the order parameters among the different subsystems. When observing data greater than 0.8, it can be seen that the order parameters of the energy flow subsystem have a more significant driving effect on the material flow subsystem, while the order parameters of the information flow subsystem have a more significant driving effect on the material flow subsystem and the energy flow subsystem. We can also draw the following conclusion: M1 “equipment comprehensive efficiency” is a comprehensive management parameter that is significantly affected by energy flow. M3 “production reliability” is an evaluative parameter that is significantly influenced by information flow. The impact of the I3 “Information Management Index” on the E3 “Wastewater Recycling Capacity” and the impact of E3 on I3 are both significant, indirectly indicating the information dependence of flow and the control power of information on flow. From the data less than 0.6, it can be seen that the order parameters M2 “finished product yield” and E2 “air pollution per unit product” have strong independence. In other words, they are less affected by the order parameters of the information flow subsystem and require special attention during management.