Joint Optimization of Preventive Maintenance and Spare Parts Ordering Considering Imperfect Detection

Abstract

:1. Introduction

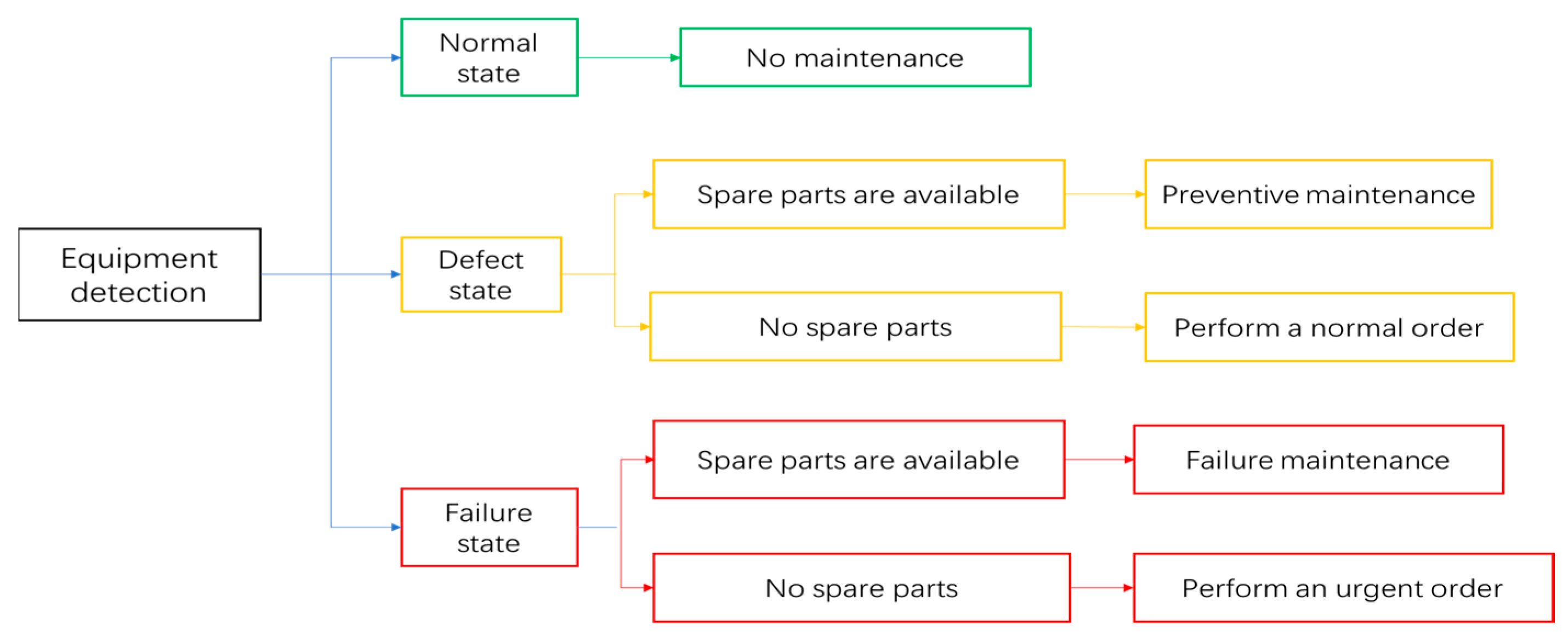

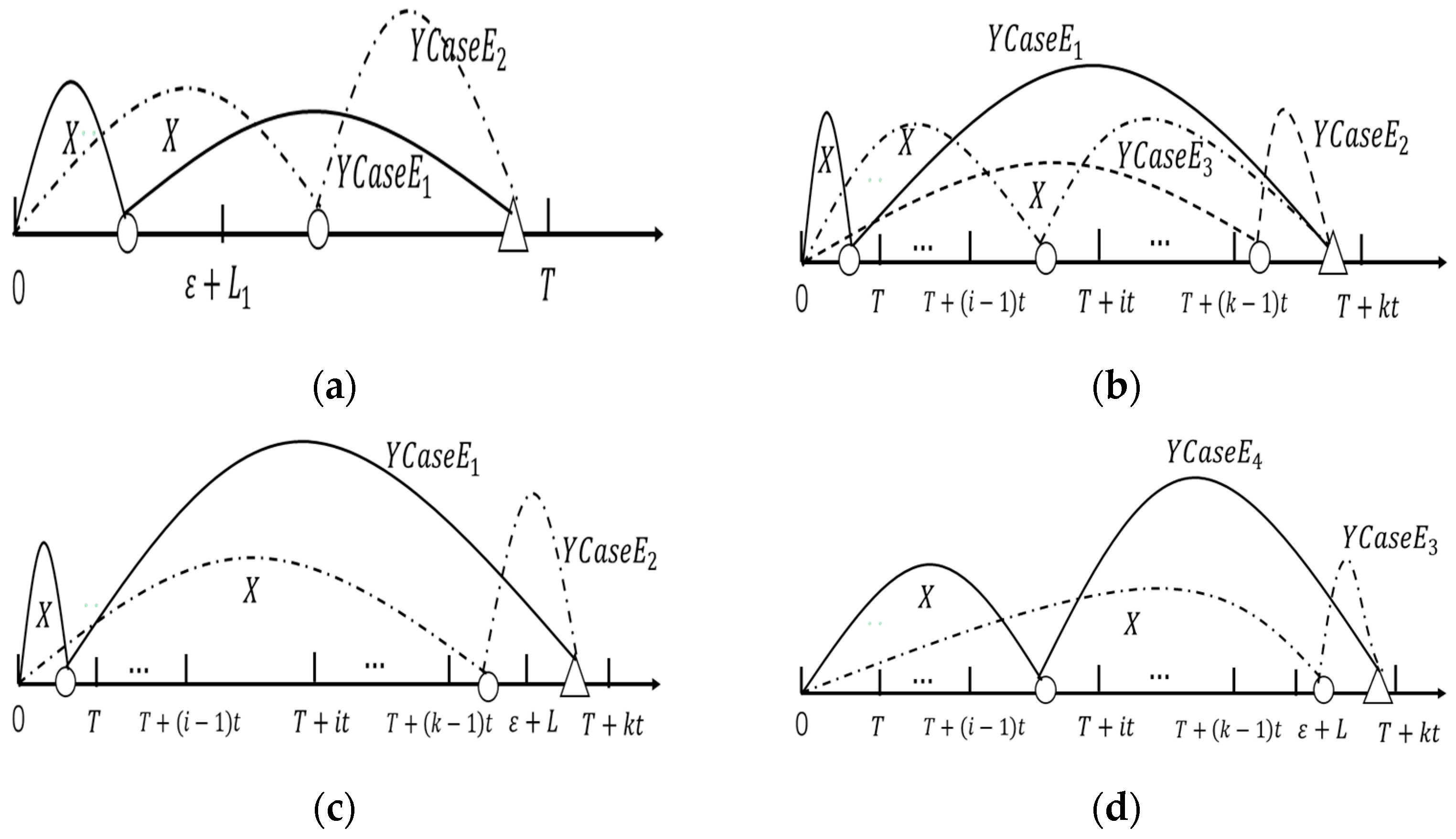

2. Problem Description

2.1. Maintenance Model Assumptions

- The equipment is a single component system and is not repairable.

- There is only one failure mode of the equipment, and the time domain is infinite.

- A two-phase inspection strategy is adopted, the first stage is executed at the moment, and then the equipment is tested in cycles , and the cost of each test is . The detection consumption time is much smaller than the detection cycle and is negligible.

- The detection is imperfect, and a false negative event occurs according to the probability of detection, that is, the equipment is actually in a defective state, and the detection is judged by probability that the equipment is in a normal state.

- When a defective condition is detected, a preventive maintenance is carried out at cost . Equipment failure will automatically shut down, at this time the fault maintenance is carried out at the cost .

- A delayed ordering strategy is adopted, i.e., spare parts are ordered at the ε (ε > 0) moment, with a lead time of for normal orders and for urgent orders, and an order quantity of 1. There may be 3 different states of spare parts when the equipment is maintenanced: a spare parts state of 0 indicates that the spare parts have not been ordered; A spare part states of 1 indicates that it has been ordered and has not yet entered the inventory; A states of 2 for a spare part indicates that the part is currently being stored and is available in inventory.

- The penalty cost per unit time of waiting for spare parts for preventive and faulty maintenance of equipment is and , and < , respectively. The unit of time holding cost of spare parts in inventory is . The cost of equipment renewal or includes the cost of ordering spare parts, own costs, and maintenance personnel.

2.2. Symbol Description

3. Maintenance Cost Models

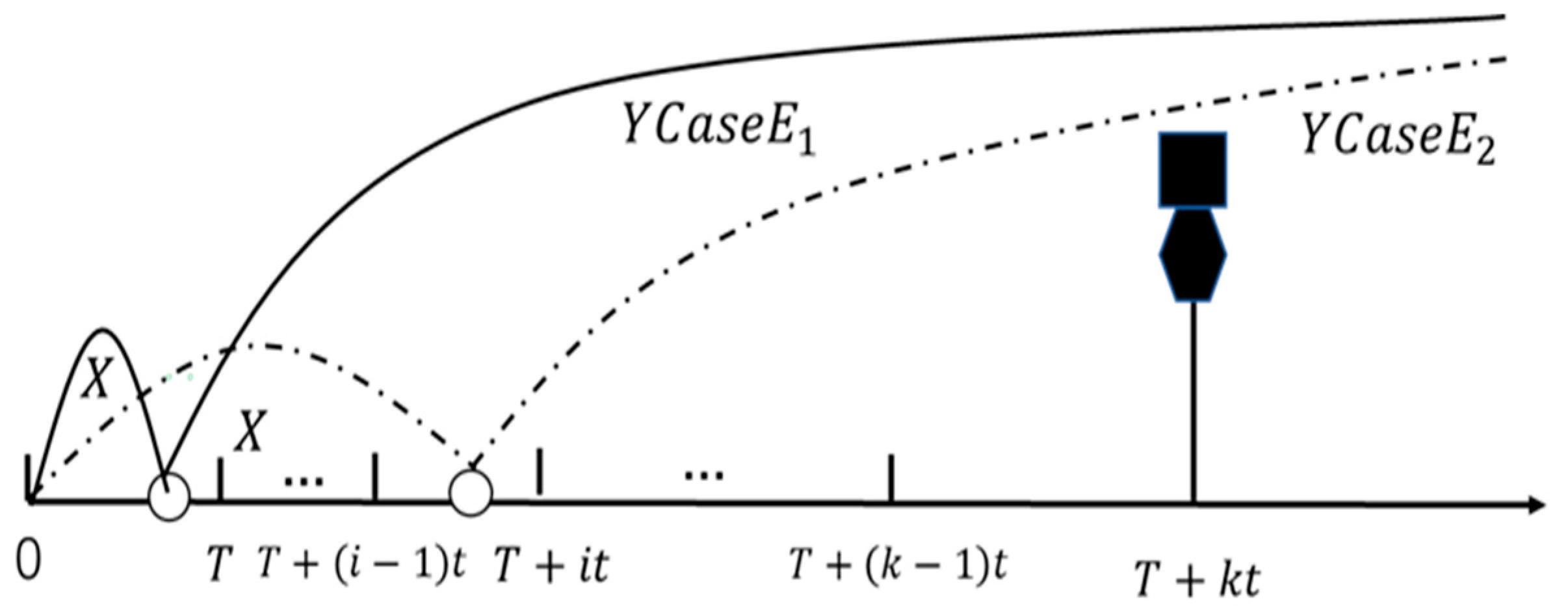

3.1. Renewal Scenarios 1 and 2

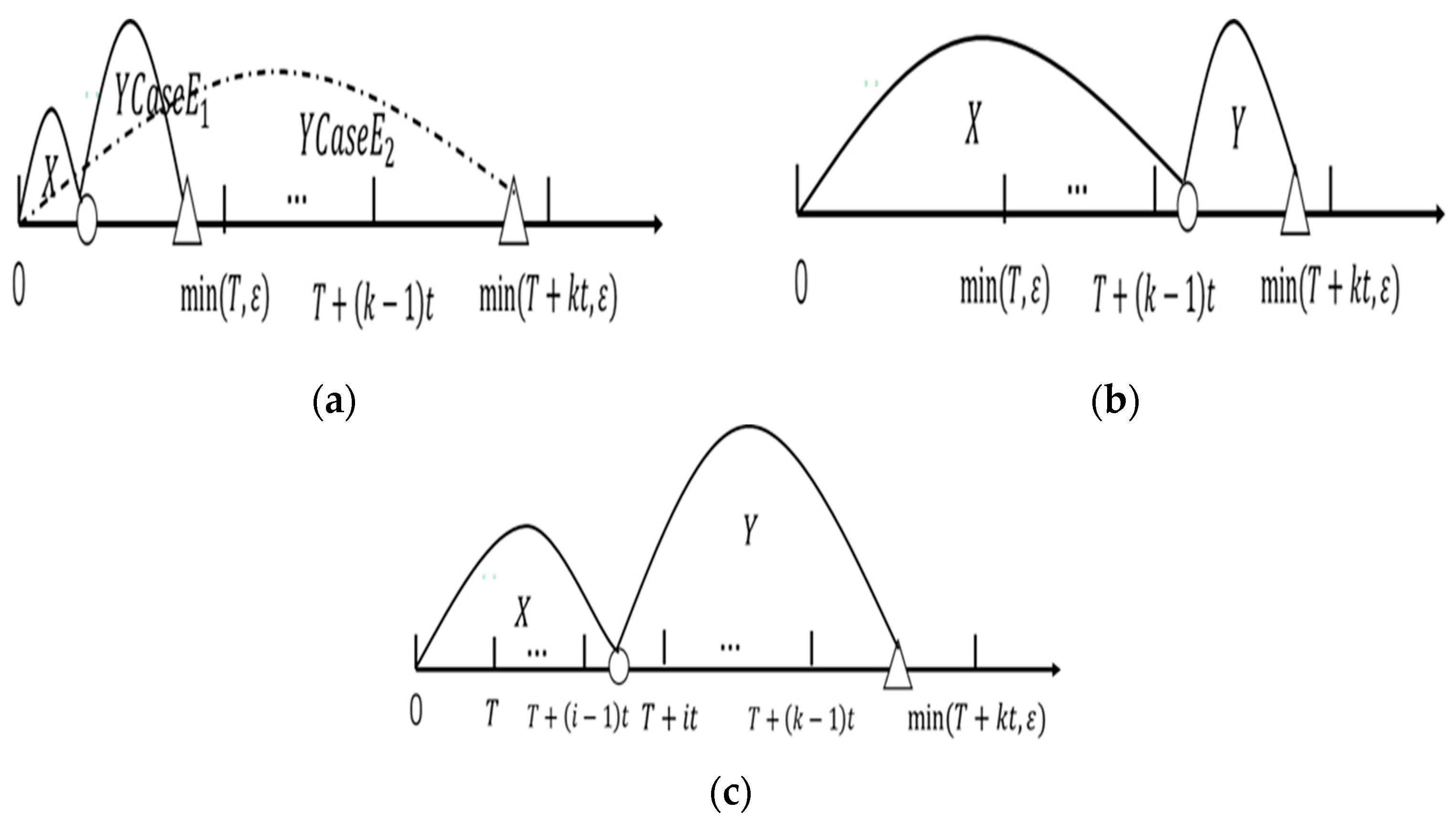

3.2. Renewal Scenario 3

3.3. Renewal Scenario 4

3.4. Renewal Scenario 5

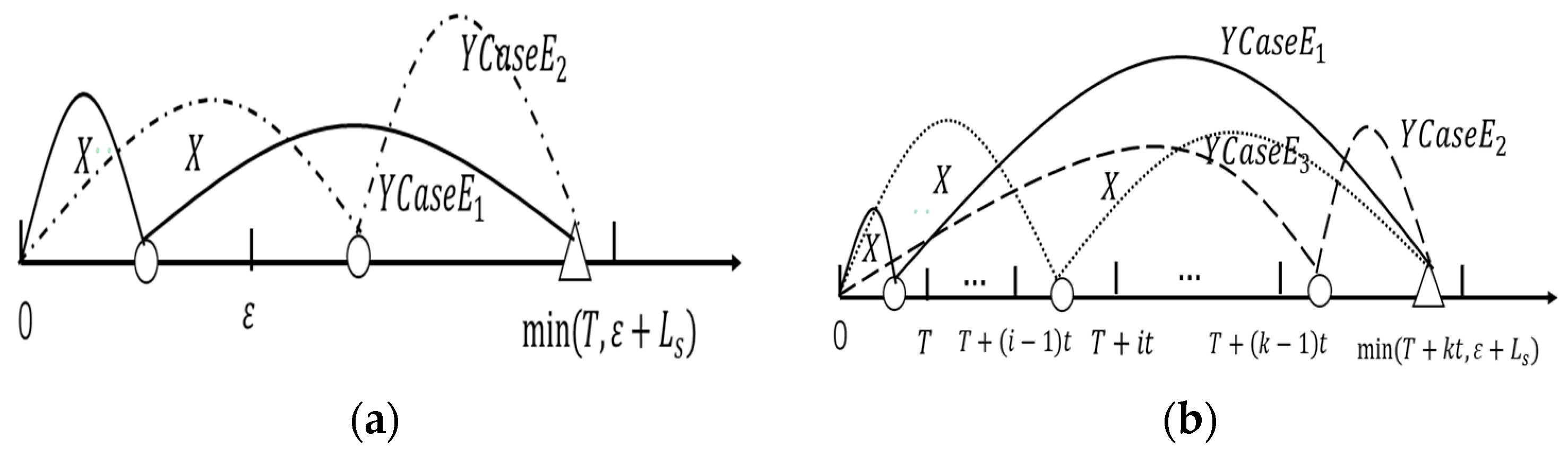

3.5. Renewal Scenario 6

3.6. Joint Decision Model

4. Numerical Examples

4.1. Model Solving Using Particle Swarm Optimization Algorithm

| Algorithm 1. Joint decision model algorithm process. |

| Step 1: Initialization process |

| FOR each particle FOR each dimension Initialize the position randomly of each particle Plug in the initial solution to Formula (37) to obtain the personal best position of each particle Initialize the population’s best position value ) END FOR END FOR |

| Step 2: Iterative optimization process. |

| Iteration DO FOR each particle Calculate fitness value personal best position and value IF objective function for each = for each END IF END FOR Choose the particle having the best fitness value as the FOR each particle FOR each dimension Calculate the dynamic inertia weight value. Maintenance position and velocity values. Boundary condition handling. END FOR END FOR % Use to record the historical global best solution. %When the number of iterations reaches , the iteration process ends. The best solution obtained in each iteration will be obtained, and the largest is the global best solution: |

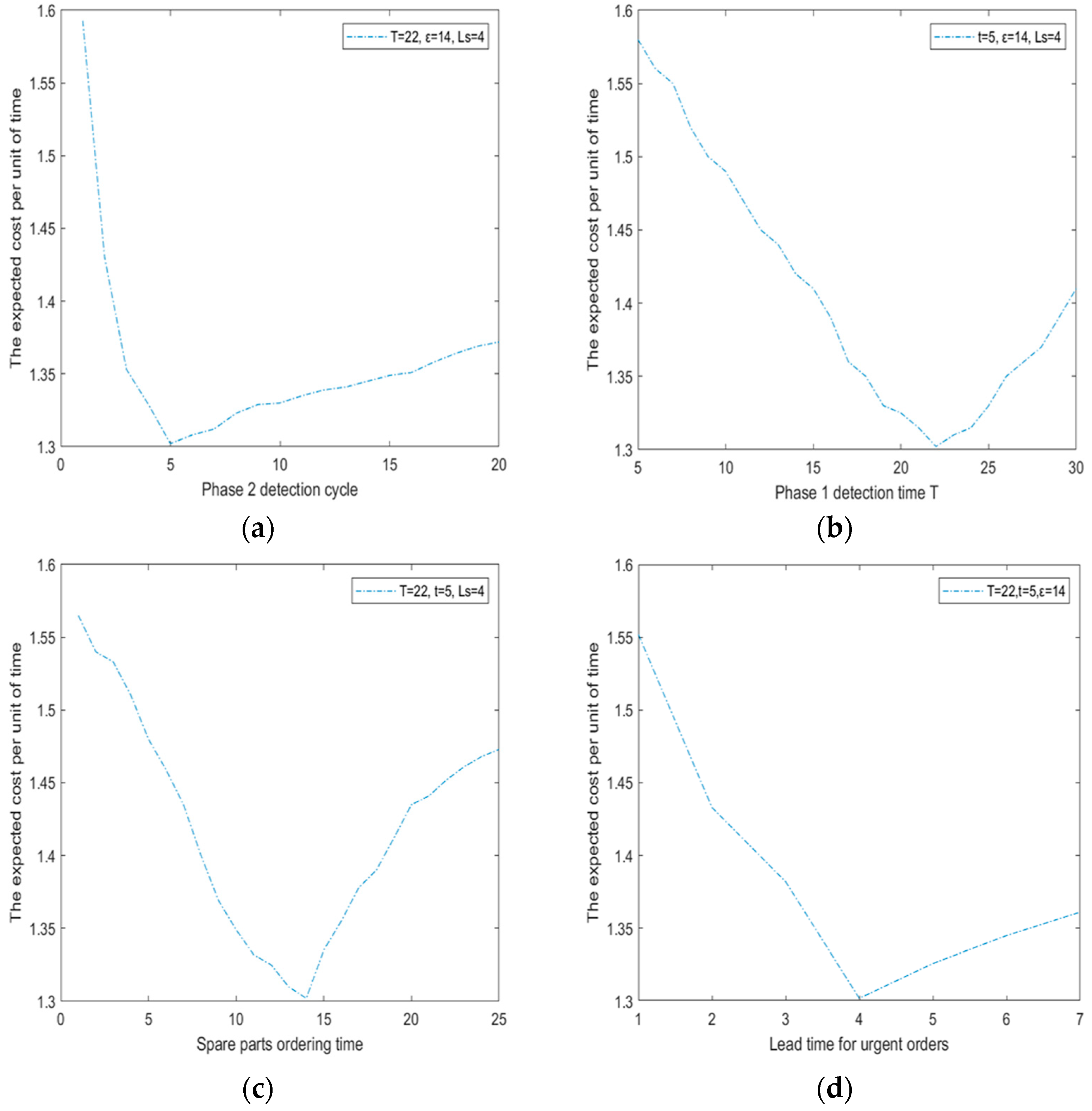

4.2. Sensitivity Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Basri, E.I.; Razak, I.H.A.; Ab-Samat, H.; Kamaruddin, S. Preventive maintenance (PM) planning: A review. J. Qual. Maint. Eng. 2017, 23, 114–143. [Google Scholar] [CrossRef]

- Aminu Sahabi Abubakar, Z.H.; Aime, C. Nyoungue, Production System Optimisation with a Multi-Level Process Control Tool Integrated into Maintenance and Quality Strategies under Services and Quality Constraints. Eur. J. Sci. Innov. Technol. 2023, 3, 302–320. [Google Scholar]

- Syamsundar, A.; Naikan, V.; Wu, S. Estimating maintenance effectiveness of a repairable system under time-based preventive maintenance. Comput. Ind. Eng. 2021, 156, 107278. [Google Scholar] [CrossRef]

- Chuang, C.; Ningyun, L.; Bin, J.; Yin, X. Condition-based maintenance optimization for continuously monitored degrading systems under imperfect maintenance actions. J. Syst. Eng. Electron. 2020, 31, 841–851. [Google Scholar] [CrossRef]

- Dao, C.D.; Kazemtabrizi, B.; Crabtree, C.J.; Tavner, P.J. Integrated condition-based maintenance modelling and optimisation for offshore wind turbines. Wind Energy 2021, 24, 1180–1198. [Google Scholar] [CrossRef]

- Wang, J.; Qiu, Q.; Wang, H.; Lin, C. Optimal condition-based preventive maintenance policy for balanced systems. Reliab. Eng. Syst. Saf. 2021, 211, 107606. [Google Scholar] [CrossRef]

- Hussain, Z.; Jan, H. Establishing simulation model for optimizing efficiency of CNC machine using reliability-centered maintenance approach. Int. J. Model. Simul. Sci. Comput. 2019, 10, 1950034. [Google Scholar] [CrossRef]

- Palei, S.K.; Das, S.; Chatterjee, S. Reliability-Centered Maintenance of Rapier Dragline for Optimizing Replacement Interval of Dragline Components. Min. Metall. Explor. 2020, 37, 1121–1136. [Google Scholar] [CrossRef]

- Kuppulakshmi, V.; Sugapriya, C.; Kavikumar, J.; Nagarajan, D. Fuzzy Inventory Model for Imperfect Items with Price Discount and Penalty Maintenance Cost. Math. Probl. Eng. 2023, 2023, 1246257. [Google Scholar] [CrossRef]

- Zhang, J.-X.; Du, D.-B.; Si, X.-S.; Hu, H.-W. Joint optimization of preventive maintenance and inventory management for standby systems with hybrid-deteriorating spare parts. Reliab. Eng. Syst. Saf. 2021, 214, 107686. [Google Scholar] [CrossRef]

- de Pater, I.; Mitici, M. Predictive maintenance for multi-component systems of repairables with Remaining-Useful-Life prognostics and a limited stock of spare components. Reliab. Eng. Syst. Saf. 2021, 214, 107761. [Google Scholar] [CrossRef]

- Pedersen, T.I.; Liu, X.; Vatn, J. Maintenance optimization of a system subject to two-stage degradation, hard failure, and imperfect repair. Reliab. Eng. Syst. Saf. 2023, 237, 109313. [Google Scholar] [CrossRef]

- Duran, O.; Afonso, P.S.L.P. An activity based costing decision model for life cycle economic assessment in spare parts logistic management. Int. J. Prod. Econ. 2020, 222, 107499. [Google Scholar] [CrossRef]

- Zheng, M.; Ye, H.; Wang, D.; Pan, E. Joint Optimization of Condition-Based Maintenance and Spare Parts Orders for Multi-Unit Systems with Dual Sourcing. Reliab. Eng. Syst. Saf. 2021, 210, 107512. [Google Scholar] [CrossRef]

- Diallo, C.; Venkatadri, U.; Khatab, A.; Liu, Z.; Aghezzaf, E.-H. Optimal joint selective imperfect maintenance and multiple repairpersons assignment strategy for complex multicomponent systems. Int. J. Prod. Res. 2018, 57, 4098–4117. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, C.; Tang, T. A Review of Sustainable Maintenance Strategies for Single Component and Multicomponent Equipment. Sustainability 2022, 14, 2992. [Google Scholar] [CrossRef]

- Christer, A. Developments in delay time analysis for modelling plant maintenance. J. Oper. Res. Soc. 1999, 50, 1120–1137. [Google Scholar] [CrossRef]

- Redmond, D.; Christer, A.; Rigden, S.; Burley, E.; Tajelli, A.; Abu-Tair, A. OR modelling of the deterioration and maintenance of concrete structure. Eur. J. Oper. Res. 1997, 99, 619–631. [Google Scholar] [CrossRef]

- Christer, A.H.; Waller, W.M. Delay Time Models of Industrial Inspection Maintenance Problems. J. Oper. Res. Soc. 1984, 35, 401–406. [Google Scholar] [CrossRef]

- Wang, W. An overview of the recent advances in delay-time-based maintenance modelling. Reliab. Eng. Syst. Saf. 2012, 106, 165–178. [Google Scholar] [CrossRef]

- Golpîra, H.; Tirkolaee, E.B. Stable maintenance tasks scheduling: A bi-objective robust optimization model. Comput. Ind. Eng. 2019, 137, 106007. [Google Scholar] [CrossRef]

- Zhang, A.; Srivastav, H.; Barros, A.; Liu, Y. Study of testing and maintenance strategies for redundant final elements in SIS with imperfect detection of degraded state. Reliab. Eng. Syst. Saf. 2021, 209, 107393. [Google Scholar] [CrossRef]

- Duan, C. Dynamic Bayesian monitoring and detection for partially observable machines under multivariate observations. Mech. Syst. Signal Process. 2021, 158, 107714. [Google Scholar] [CrossRef]

- Lee, C.J.; Park, S.K.; Lim, M.T. Multi-target Tracking and Track Management Algorithm Based on UFIR Filter with Imperfect Detection Probability. Int. J. Control Autom. Syst. 2019, 17, 3021–3034. [Google Scholar] [CrossRef]

- Wang, X.; Brownlee, A.E.I.; Weiszer, M.; Woodward, J.R.; Mahfouf, M.; Chen, J. An Interval Type-2 Fuzzy Logic-Based Map Matching Algorithm for Airport Ground Movements. Trans. Fuzzy Syst. 2022, 31, 582–595. [Google Scholar] [CrossRef]

- Çınar, Z.M.; Nuhu, A.A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Shin, W.; Han, J.; Rhee, W. AI-assistance for predictive maintenance of renewable energy systems. Energy 2021, 221, 119775. [Google Scholar] [CrossRef]

- Zhang, F.; Shen, J.; Ma, Y. Optimal maintenance policy considering imperfect repairs and non-constant probabilities of inspection errors. Reliab. Eng. Syst. Saf. 2020, 193, 106615. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, X.; Liu, Y.; Do, P. Maintenance optimisation for systems with multi-dimensional degradation and imperfect inspections. Int. J. Prod. Res. 2020, 59, 7537–7559. [Google Scholar] [CrossRef]

- Cavalcante, C.A.; Scarf, P.A.; de Almeida, A.T. A study of a two-phase inspection policy for a preparedness system with a defective state and heterogeneous lifetime. Reliab. Eng. Syst. Saf. 2011, 96, 627–635. [Google Scholar] [CrossRef]

- Heydari, M. Two-stage failure modeling and optimal periodic inspection policy during the extended warranty period. Int. J. Manag. Sci. Eng. Manag. 2019, 14, 264–272. [Google Scholar] [CrossRef]

- Yang, L.; Ye, Z.-S.; Lee, C.-G.; Yang, S.-F. A two-phase preventive maintenance policy considering imperfect repair and postponed replacement. Eur. J. Oper. Res. 2019, 274, 966–977. [Google Scholar] [CrossRef]

- Panagiotidou, S. Joint optimization of spare parts ordering and age-based preventive replacement. Int. J. Prod. Res. 2019, 58, 6283–6299. [Google Scholar] [CrossRef]

- Wang, J.; Yang, L.; Ma, X.; Peng, R. Joint optimization of multi-window maintenance and spare part provisioning policies for production systems. Reliab. Eng. Syst. Saf. 2021, 216, 108006. [Google Scholar] [CrossRef]

| Symbol | Meaning |

|---|---|

| The random duration of the normal working phase of the equipment | |

| The random duration of the equipment defect phase | |

| (x) | Probability density function during the normal operation phase of the equipment |

| (y) | Probability density function of the equipment defect stage |

| Phase 1 detection time | |

| Phase 2 detection cycle | |

| Spare parts ordering time | |

| Equipment maintenance moment | |

| The random time at which the failure occurred | |

| The probability of a false-negative event | |

| Average cost per inspection | |

| The average cost incurred by preventive maintenance | |

| The average cost of a failed maintenance | |

| Inventory holding cost per unit of time | |

| Preventive maintenance penalty cost per unit time | |

| Failure maintenance penalty cost per unit time | |

| Lead time for normal orders | |

| Lead time for urgent orders | |

| Maintenance cycle expected cost | |

| The expected length of the maintenance cycle |

| 1 | 10 | 24 | 0.8 | 1.2 | 2.5 | 7 | 0.4 |

| 100 | 4 | 200 | 1.5 | 1.5 | 0.8 | 0.4 | 4 | −4 |

| Fixed Lead Time Detection Strategy | Consider Detection Strategies for Urgent Orders | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 17 | 4 | 10 | 1.2996 | 19 | 3 | 11 | 6 | 1.2685 |

| 0.2 | 18 | 3 | 11 | 1.3302 | 20 | 3 | 13 | 4 | 1.2897 |

| 0.4 | 20 | 3 | 13 | 1.3611 | 22 | 5 | 14 | 4 | 1.3021 |

| 0.6 | 23 | 3 | 16 | 1.3957 | 25 | 4 | 17 | 5 | 1.3554 |

| 0.8 | 29 | 4 | 22 | 1.4290 | 28 | 6 | 25 | 4 | 1.3970 |

| Parameter | Consider Detection Strategies for Urgent Orders | |||||

|---|---|---|---|---|---|---|

| 1.3 | 23 | 5 | 15 | 4 | 1.3158 + 1.05% | |

| 13 | 25 | 6 | 16 | 4 | 1.3349 + 2.52% | |

| 31.2 | 20 | 4 | 14 | 4 | 1.4297 + 9.8% | |

| 1.04 | 25 | 5 | 17 | 4 | 1.3185 + 1.26% | |

| 1.56 | 22 | 5 | 13 | 4 | 1.3044 + 0.1% | |

| 25.75 | 19 | 4 | 11 | 3 | 1.3461 + 3.38% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Gao, Z. Joint Optimization of Preventive Maintenance and Spare Parts Ordering Considering Imperfect Detection. Systems 2023, 11, 445. https://doi.org/10.3390/systems11090445

He Y, Gao Z. Joint Optimization of Preventive Maintenance and Spare Parts Ordering Considering Imperfect Detection. Systems. 2023; 11(9):445. https://doi.org/10.3390/systems11090445

Chicago/Turabian StyleHe, Yuanchang, and Zhenhua Gao. 2023. "Joint Optimization of Preventive Maintenance and Spare Parts Ordering Considering Imperfect Detection" Systems 11, no. 9: 445. https://doi.org/10.3390/systems11090445

APA StyleHe, Y., & Gao, Z. (2023). Joint Optimization of Preventive Maintenance and Spare Parts Ordering Considering Imperfect Detection. Systems, 11(9), 445. https://doi.org/10.3390/systems11090445