Research on Collaborative Mechanisms of Railway EPC Project Design and Construction from the Perspective of Social Network Analysis

Abstract

:1. Introduction

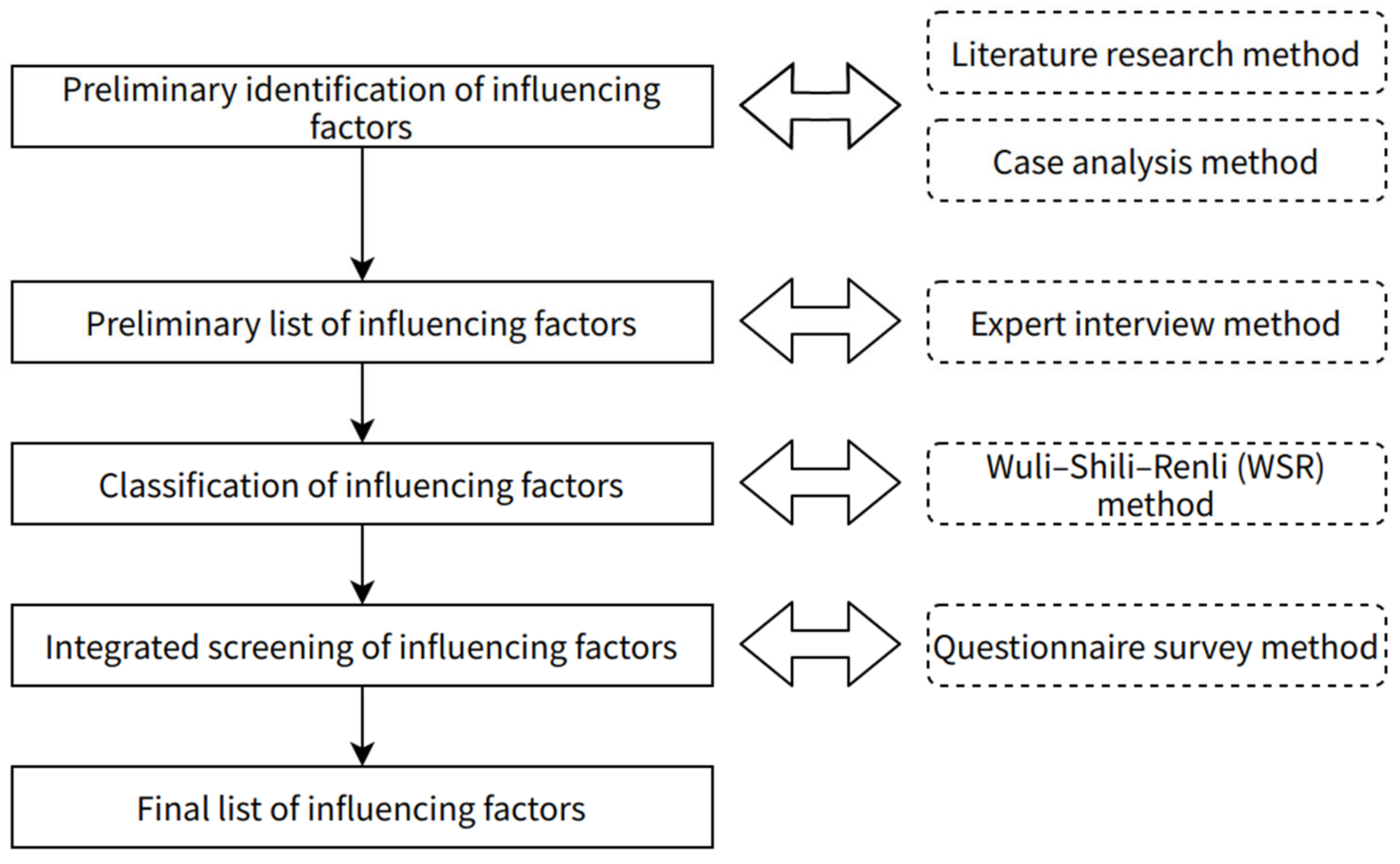

2. Research Design

2.1. Data Collection

2.2. Analysis of Design and Construction Coordination Problems

2.2.1. Design Optimization Problems

2.2.2. Process Coordination Problems

2.2.3. Resource Coordination Problems

2.2.4. Organizational Coordination Problems

2.3. Identification of Core Elements

2.3.1. Core Elements of Physics

2.3.2. Core Elements of Affairs

2.3.3. Core Elements of Human

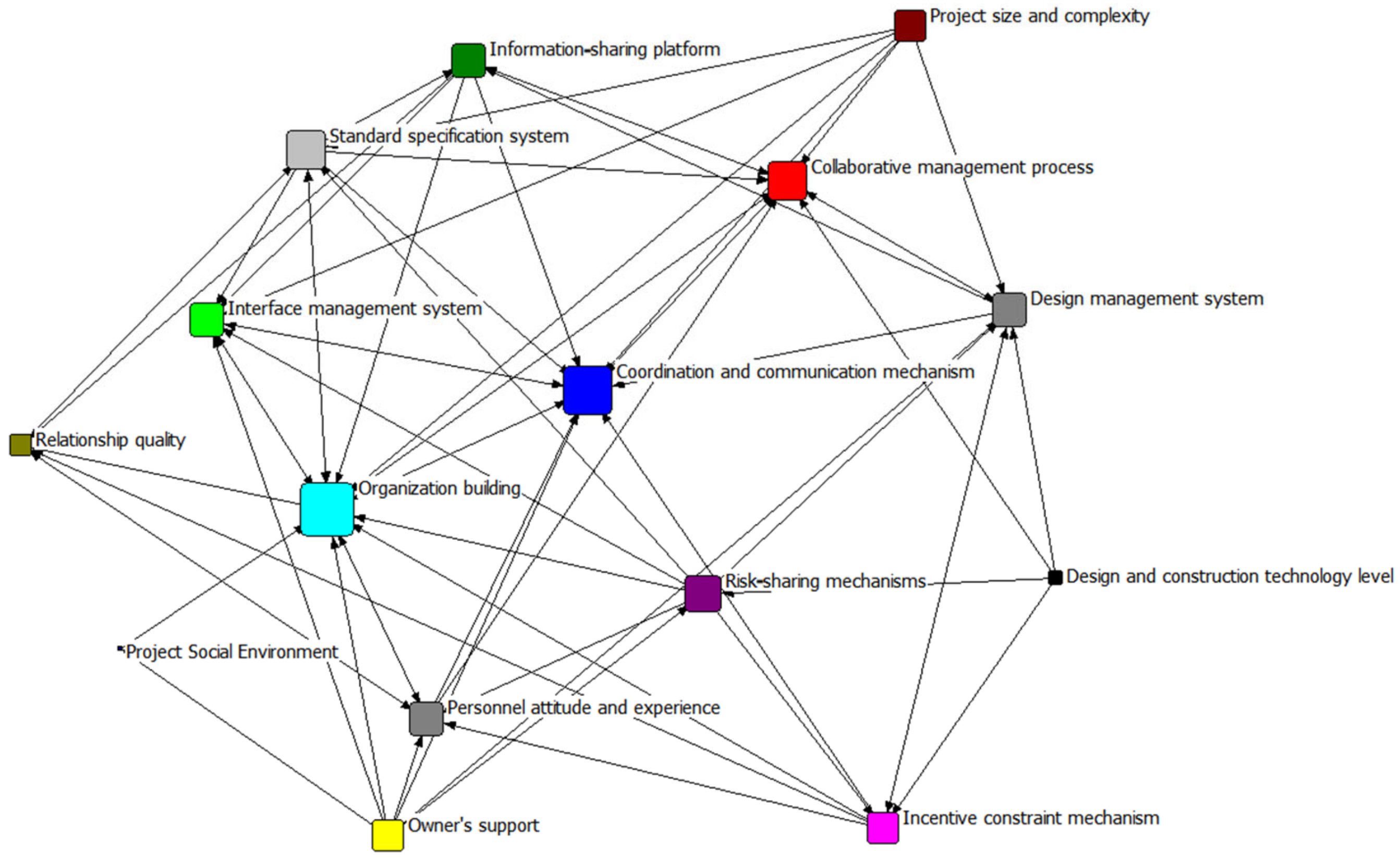

2.4. Construction of Relational Network Structure

3. Results and Analysis

3.1. Analysis of Overall Network Properties

3.1.1. Analysis of Network Density

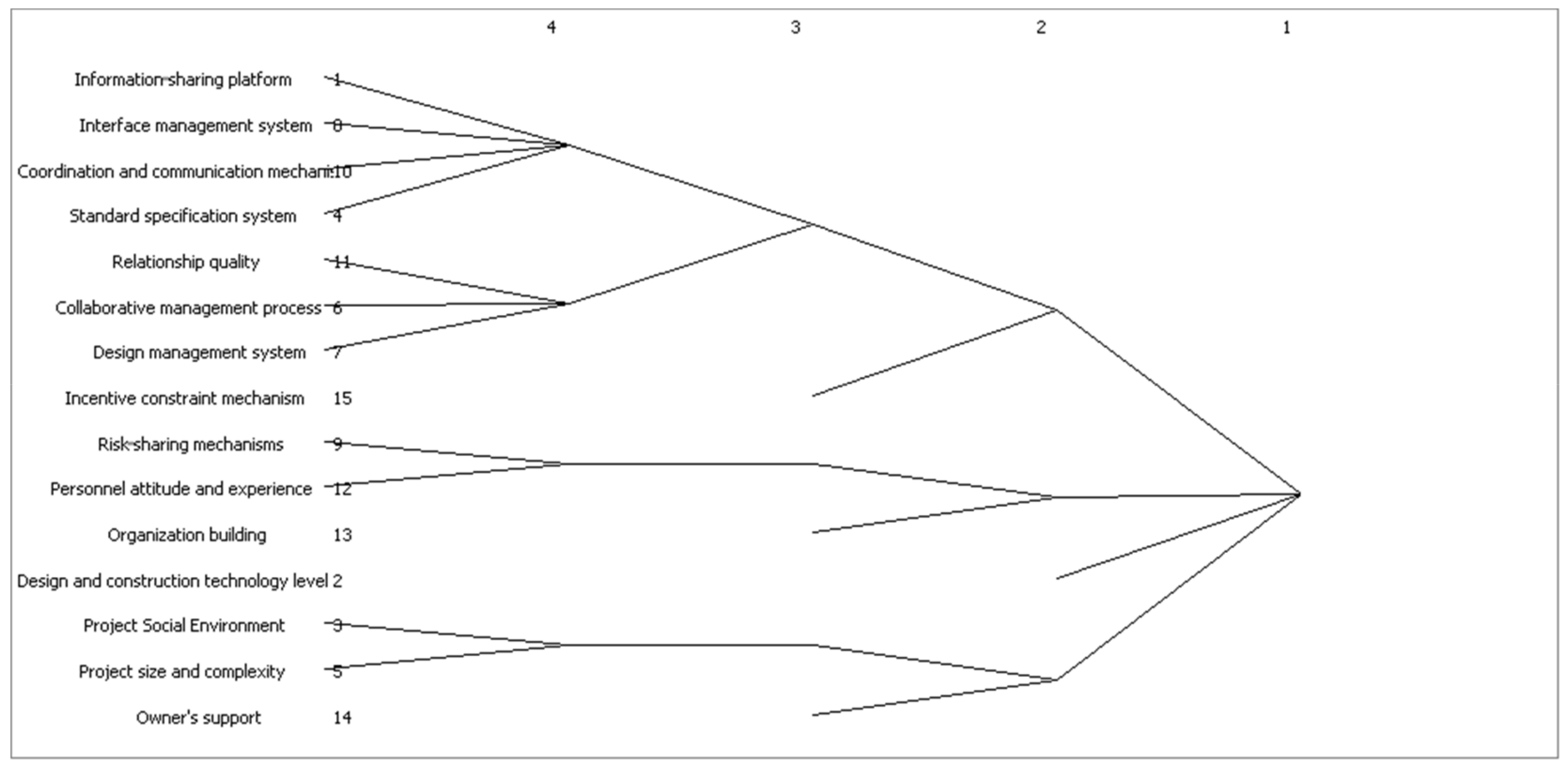

3.1.2. Analysis of Condensed Subgroups

3.2. Analysis of Individual Network Attributes

3.2.1. Analysis of Centrality

3.2.2. Analysis of Structural Hole

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, C.Y.; Chong, H.Y.; Li, Q.; Wang, X.Y. Joint Contract-Function Effects on BIM-Enabled EPC Project Performance. J. Constr. Eng. Manag. 2020, 146, 04020008. [Google Scholar] [CrossRef]

- Li, H.M.; Lv, L.L.; An, X.W.; Dong, G.H. Profit Sharing Mechanism of Large EPC Project considering the Behavior of Fairness Concern. Adv. Civ. Eng. 2020, 2020, 3725254. [Google Scholar] [CrossRef]

- Tang, Y.J.; Liu, R.K.; Sun, Q.X. Schedule control model for linear projects based on linear scheduling method and constraint programming. Autom. Constr. 2014, 37, 22–37. [Google Scholar] [CrossRef]

- Yang, C.W.; Li, Z.H.; Guo, X.Y.; Yu, W.Y.; Jin, J.; Zhu, L. Application of BP Neural Network Model in Risk Evaluation of Railway Construction. Complexity 2019, 2019, 2946158. [Google Scholar] [CrossRef]

- Lesniak, A.; Janowiec, F. Risk Assessment of Additional Works in Railway Construction Investments Using the Bayes Network. Sustainability 2019, 11, 5388. [Google Scholar] [CrossRef]

- Jafari, A.; Love, P.E.D. Quality Costs in Construction: Case of Qom Monorail Project in Iran. J. Constr. Eng. Manag. 2013, 139, 1244–1249. [Google Scholar] [CrossRef]

- Lu, C.F.; Cai, C.X. Challenges and Countermeasures for Construction Safety during the Sichuan-Tibet Railway Project. Engineering 2019, 5, 833–838. [Google Scholar] [CrossRef]

- Yu, X.Z.; Mou, R.F. System Modeling and Risk Analysis of the Sichuan-Tibet Railway Project. J. Transp. Eng. Part A-Syst. 2021, 147, 04021094. [Google Scholar] [CrossRef]

- Ganbat, T.; Chong, H.Y.; Liao, P.C.; Leroy, J. Identification of critical risks in international engineering procurement construction projects of Chinese contractors from the network perspective. Can. J. Civ. Eng. 2020, 47, 1359–1371. [Google Scholar] [CrossRef]

- Habibi, M.; Kermanshachi, S. Phase-based analysis of key cost and schedule performance causes and preventive strategies: Research trends and implications. Eng. Constr. Archit. Manag. 2018, 25, 1009–1033. [Google Scholar] [CrossRef]

- Shen, Z.Z.; Zhao, J.Y.; Guo, M. Evaluating the Engineering-Procurement-Construction Approach and Whole Process Engineering Consulting Mode in Construction Projects. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2023, 47, 2533–2547. [Google Scholar] [CrossRef]

- Nikjow, M.A.; Liang, L.; Qi, X.J.; Sepasgozar, S.M.E.; Chileshe, N. Triggers of Delays in International Projects Using Engineering Procurement and Construction Delivery Methods in the Belt and Road Initiative: Case Study of a High-Speed Railway Projects. Sustainability 2021, 13, 9503. [Google Scholar] [CrossRef]

- Wang, Q.E.; Wang, J. Research on Key Risk Factors and Risk Transmission Path of Procurement in International Engineering Procurement Construction Project. Buildings 2022, 12, 534. [Google Scholar] [CrossRef]

- Kim, M.H.; Lee, E.B.; Choi, H.S. A Forecast and Mitigation Model of Construction Performance by Assessing Detailed Engineering Maturity at Key Milestones for Offshore EPC Mega-Projects. Sustainability 2019, 11, 1256. [Google Scholar] [CrossRef]

- Shen, W.X.; Tang, W.Z.; Wang, S.L.; Duffield, C.F.; Hui, F.K.P.; You, R.C. Enhancing Trust-Based Interface Management in International Engineering-Procurement-Construction Projects. J. Constr. Eng. Manag. 2017, 143, 04017061. [Google Scholar] [CrossRef]

- Sun, C.S.; Wang, M.; Man, Q.P.; Wan, D.J. Research on the BIM Application Mechanism of Engineering-Procurement-Construction Projects Based on a Tripartite Evolutionary Game. J. Constr. Eng. Manag. 2023, 149, 04022182. [Google Scholar] [CrossRef]

- Wang, M. The Research of Epc Total Project Contract with the Design as the Main Body. Available online: https://www.proquest.com/dissertations-theses/research-epc-total-project-contract-with-design/docview/1874977292/se-2?accountid=32743 (accessed on 21 May 2023).

- Zhao, Z.Z.; Meng, Q.C.; Pang, N.S. Research on Construction Risk Evaluation of EPC Project of Transmission and Distribution Engineering Based on Design Enterprise. In Proceedings of the International Conference on Energy, Environment and Bioengineering (ICEEB), Electronic Network, Xi’an, China, 7–9 August 2020. [Google Scholar]

- Zhang, J.W.; Wang, F.S.; Zhou, R.S.; Liu, B. Purchase Research on Supply Chain for EPC Project. In Proceedings of the International Conference on Materials, Transportation and Environmental Engineering (CMTEE 2013), Taichung, Taiwan, 21–23 August 2013; p. 1762. [Google Scholar]

- Mutikanga, H.E.; Nabi, M.A.; Ali, G.G.; El-adaway, I.H.; Caldwell, A. Postaward Construction and Contract Management o f Engineering, Procurement, and Construction Hydropower Projects: Two Case Studies from Uganda. J. Manag. Eng. 2022, 38, 05022012. [Google Scholar] [CrossRef]

- Botelle, M.; Avery, R.; Hooper, A.; Feeney, S. HS2 Old Oak Common: Collaborative delivery of the UK’s largest new-build station. Proc. Inst. Civ. Eng. Civ. Eng. 2022, 176, 24–32. [Google Scholar] [CrossRef]

- Chen, G.C.; Chen, J.Y.; Tang, Y.C.; Li, Q.M.; Luo, X.W. Identifying Effective Collaborative Behaviors in Building Information Modeling-Enabled Construction Projects. J. Constr. Eng. Manag. 2022, 148, 04022026. [Google Scholar] [CrossRef]

- Khouja, A.; Lehoux, N.; Cimon, Y.; Cloutier, C. Collaborative Interorganizational Relationships in a Project-Based Industry. Buildings 2021, 11, 502. [Google Scholar] [CrossRef]

- Shen, L.; Zhang, Z.K.; Tang, L.Y. Research on Determining Resource Utilization Rates of Regional Construction and Demolition Waste from the Perspective of Collaborative Governance. Ksce J. Civ. Eng. 2023, 27, 27–39. [Google Scholar] [CrossRef]

- Elsayegh, A.; El-adaway, I.H. Collaborative Planning Index: A Novel Comprehensive Benchmark for Collaboration in Construction Projects. J. Manag. Eng. 2021, 37, 04021057. [Google Scholar] [CrossRef]

- Elsayegh, A.; El-adaway, I.H. Holistic Study and Analysis of Factors Affecting Collaborative Planning in Construction. J. Constr. Eng. Manag. 2021, 147, 04021023. [Google Scholar] [CrossRef]

- Dong, Y.G.; Sui, H.Z.; Zhu, L. Application of Cloud Computing Combined with GIS Virtual Reality in Construction Process of Building Steel Structure. Math. Probl. Eng. 2022, 2022, 4299756. [Google Scholar] [CrossRef]

- Gondia, A.; Ezzeldin, M.; El-Dakhakhni, W. Dynamic networks for resilience-driven management of infrastructure projects. Autom. Constr. 2022, 136, 104149. [Google Scholar] [CrossRef]

- Sanchez-Silva, M.; Calderon-Guevara, W. Flexibility and adaptability within the context of decision-making in infrastructure management. Struct. Infrastruct. Eng. 2022, 18, 950–966. [Google Scholar] [CrossRef]

- Walker, D.H.T.; Serra, P.V.; Love, P.E.D. Improved reliability in planning large-scale infrastructure project delivery through Alliancing. Int. J. Manag. Proj. Bus. 2022, 15, 721–741. [Google Scholar] [CrossRef]

- Rosok, O.P.; de Bruijne, M.L.C.; Veeneman, W.W. Dealing with Cross-Sectoral Uncertainty: A Case Study on Governing Uncertainty for Infrastructures in Transition. Sustainability 2023, 15, 3750. [Google Scholar] [CrossRef]

- Tokede, O.; Ahiaga-Dagbui, D.; Morrison, J. Praxis of knowledge-management and trust-based collaborative relationships in project delivery: Mediating role of a project facilitator. Int. J. Manag. Proj. Bus. 2022, 15, 595–618. [Google Scholar] [CrossRef]

- Vom Brooke, J.; Lippe, S. Managing collaborative research projects: A synthesis of project management literature and directives for future research. Int. J. Proj. Manag. 2015, 33, 1022–1039. [Google Scholar] [CrossRef]

- Song, T.R.; Pu, H.; Schonfeld, P.; Liang, Z.; Zhang, M.; Hu, J.P.; Zhou, Y.H.; Xu, Z.J. Mountain railway alignment optimization integrating layouts of large-scale auxiliary construction projects. Comput. Aided Civ. Infrastruct. Eng. 2023, 38, 433–453. [Google Scholar] [CrossRef]

- Liu, K.; Liu, Y.M.; Zhao, X.; Kou, Y.Y. Study on Design Optimization in Major Railway Projects with Fair Preference Based on Stackelberg Game. Math. Probl. Eng. 2022, 2022, 5336591. [Google Scholar] [CrossRef]

- Zhang, S.; Loosemore, M.; Sunindijo, R.Y.; Galvin, S.; Wu, J.; Zhang, S.Y. Assessing Safety Risk Management Performance in Chinese Subway Construction Projects: A Multistakeholder Perspective. J. Manag. Eng. 2022, 38, 05022009. [Google Scholar] [CrossRef]

- Zheng, J. Analysis of collaborative design and construction collaborative mechanism of cloud bim platform construction project based on green computing technology. J. Intell. Fuzzy Syst. 2018, 34, 819–829. [Google Scholar] [CrossRef]

- Kim, H.Y.; Shin, M.H.; Han, S.C.; Choi, Y.W.; Kim, C.H. Benefit-Cost Analysis of BIM Application—Case Study on Osong Test Line Railway. KIBIM Mag. 2018, 8, 41–48. [Google Scholar] [CrossRef]

- Andric, J.M.; Wang, J.Y.; Zhong, R.Y. Identifying the Critical Risks in Railway Projects Based on Fuzzy and Sensitivity Analysis: A Case Study of Belt and Road Projects. Sustainability 2019, 11, 1302. [Google Scholar] [CrossRef]

- Cheng, J.J.; Huang, L.; Jiang, L.X.; Chen, J.H.; Chen, W.W.; He, Y.P. Fostering Knowledge Collaboration in Construction Projects: The Role of BIM Application. Buildings 2023, 13, 812. [Google Scholar] [CrossRef]

- Trebbe, M.; Hartmann, T.; Doree, A. 4D CAD models to support the coordination of construction activities between contractors. Autom. Constr. 2015, 49, 83–91. [Google Scholar] [CrossRef]

- Xue, X.L.; Zhang, R.X.; Wang, L.; Fan, H.Q.; Yang, R.J.; Dai, J. Collaborative innovation in construction project: A social network perspective. Ksce J. Civ. Eng. 2018, 22, 417–427. [Google Scholar] [CrossRef]

- Lavikka, R.H.; Smeds, R.; Jaatinen, M. Coordinating collaboration in contractually different complex construction projects. Supply Chain. Manag. Int. J. 2015, 20, 205–217. [Google Scholar] [CrossRef]

- Gao, S.C.; Song, X.Y.; Ding, R.G. Dynamic Agent-Based Simulation of Information Transfer in Collaborative Project Network. In Proceedings of the ASCE International Conference on Computing in Civil Engineering (i3CE), Georgia Inst Technol, Atlanta, GA, USA, 17–19 June 2019; pp. 602–610. [Google Scholar]

- Gu, J.; Zhu, Z.C. The Wu-Li Shi-Li Ren-Li Approach (WSR): An Oriental Systems Methodology; The University of Hull Press: Hull, UK, 1995; pp. 31–40. [Google Scholar]

- Gu, J.; Zhu, Z. Knowing Wuli, sensing Shili, caring for Renli: Methodology of the WSR approach. Syst. Pract. Action Res. 2000, 13, 11–20. [Google Scholar] [CrossRef]

- Bolisani, E.; Bratianu, C.J. Knowledge strategy planning: An integrated approach to manage uncertainty, turbulence, and dynamics. J. Knowl. Manag. 2017, 21, 233–253. [Google Scholar] [CrossRef]

- Caro, D.J. The nexus of transformational leadership of emergency services systems: Beyond the Wu-Shi-Ren (WSR)-Li paradigm. Int. J. Emerg. Serv. 2016, 5, 18–33. [Google Scholar] [CrossRef]

- Pillet, M.; Mignon, E.; Boillon, R.; Horlogerie, C. L’amélioration Continue à L’européenne, ce N’est Pas du Luxe. In Proceedings of the CPIM de France 2008, Paris, France, 9 January 2008. [Google Scholar]

- Brugha, C.M. Foundation of nomology. Eur. J. Oper. Res. 2015, 240, 734–747. [Google Scholar] [CrossRef]

- Brugha, C.M. Systemic thinking in China: A meta-decision-making bridge to Western concepts. Syst. Pract. Action Res. 2001, 14, 339–360. [Google Scholar] [CrossRef]

- Zhu, Z. Systems approaches: Where the East meets the West? World Futures J. Gen. Evol. 1999, 53, 253–276. [Google Scholar] [CrossRef]

- Flood, R.L.; Jackson, M.C. Total systems intervention: A practical face to critical systems thinking. Syst. Pract. 1991, 4, 197–213. [Google Scholar]

- Shin, M.H.; Lee, H.K.; Kim, H.Y. Benefit-Cost Analysis of Building Information Modeling (BIM) in a Railway Site. Sustainability 2018, 10, 4303. [Google Scholar] [CrossRef]

- Rowlands, A.S. Effective Collaboration in Construction: The Importance of Managing Power. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2016. [Google Scholar]

- Dong, R.R.; Richards, W.C. Network evolution simulation of cooperation relationship in two phase project of zhengzhou airport based on BIM. J. Intell. Fuzzy Syst. 2018, 34, 1187–1192. [Google Scholar] [CrossRef]

- Luo, Y.Z.; Chen, Y.Z. Understanding the Relationship between Asset Specificity and Governance Choices in Construction Projects: Moderating Role of Uncertainty. J. Constr. Eng. Manag. 2023, 149, 04022178. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Lian, Q. Digital twin aided sustainability-based lifecycle management for railway turnout systems. J. Clean. Prod. 2019, 228, 1537–1551. [Google Scholar] [CrossRef]

- Cao, D.P.; Li, H.; Wang, G.B.; Luo, X.C.; Yang, X.C.; Tan, D. Dynamics of Project-Based Collaborative Networks for BIM Implementation: Analysis Based on Stochastic Actor-Oriented Models. J. Manag. Eng. 2017, 33, 04016055. [Google Scholar] [CrossRef]

| Problem Summary | Problem Keywords | Frequency |

|---|---|---|

| Design optimization problems | Design constructability | 5 |

| Willingness to optimize design | 7 | |

| Adoption of optimization suggestions | 6 | |

| Process coordination problems | Design and construction progress coordination | 9 |

| Resource coordination problems | Design–construction relevance | 7 |

| Design and construction fit | 8 | |

| Knowledge sharing | 4 | |

| Organizational coordination problems | Organizational interface | 8 |

| Staffing | 5 | |

| Personnel capacity | 8 |

| Enterprise Type | Department | Level of Understanding of Railway EPC Projects | Years of Work Experience | Number of Experts |

|---|---|---|---|---|

| Design units | General contracting department | Very familiar | >10 years | 3 |

| Design units | General contracting department | Quite familiar | >10 years | 5 |

| Design units | General contracting department | Quite familiar | 3–10 years | 1 |

| Construction units | Engineering department | Quite familiar | >10 years | 2 |

| Construction units | Metrology and compliance department | Quite familiar | >10 years | 4 |

| Construction units | Metrology and compliance department | Very familiar | >10 years | 3 |

| Professional colleges | Department of Engineering Management | Quite familiar | >10 years | 2 |

| Dimension | Core Element | Element Explanation |

|---|---|---|

| Physics (Wuli) | Information-sharing platform | Railway information technology drives innovation and development, project management systems of design units and construction units are interconnected, and management platform integration improves work efficiency. |

| Design and construction technology level | The design and construction of its own hard power, including the maturity of technology and technology, advanced technology and equipment, etc. If the construction unit cannot fully understand the design intent and technical difficulties, may cause design changes in the construction stage. | |

| Project Social Environment | Market and industry environment of Railway EPC Projects. | |

| Standard specification system | A complete standard system established within the organization. | |

| Project size and complexity | Projects vary in size and complexity. | |

| Affairs (Shili) | Collaborative management process | In practice, a complete collaborative management process has been formed. |

| Design management system | Design disclosure and joint review of drawings: The designer should fully convey the technical difficulties and design concepts to the constructor, and, at the same time, the constructor should put forward reasonable suggestions to ensure the constructability of the design drawings; reasonableness of bid division: greatly shorten the construction period and realize “Design while construction”; the efficiency of designing drawings and the response efficiency of Motion Design changes on the construction site. | |

| Interface management system | Project interface management: Whether the rights, responsibilities and interests of all parties in the design and construction are clearly defined. | |

| Risk-sharing mechanisms | The risk-sharing and sharing management system for design and construction in the face of risk events; whether the pricing method stipulated in the design and construction contract meets the reasonable risk-sharing requirements. | |

| Coordination and communication mechanism | Whether the communication between all parties is smooth, whether the collaborative work and other processes are smooth. | |

| Human (Renli) | Relationship quality | The quality of communication and mutual understanding between partners. |

| Personnel attitude and experience | Attitude and cognition of design and construction personnel towards collaborative management; traditional thinking mode and design concept. | |

| Organization building | Collaborative work, organizational structure, team building, collaborative management ability of internal personnel. | |

| Owner’s support | External support, motivation and drive of the owner. | |

| Incentive constraint mechanism | Whether there are workable incentive and restraint schemes, means and processes within the design and construction unit. |

| Core Element | Code | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 | F13 | F14 | F15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Information-sharing platform | F1 | / | 1.50 | 1.21 | 3.74 | 1.72 | 4.21 | 3.66 | 4.51 | 2.00 | 4.87 | 4.31 | 2.45 | 4.29 | 1.06 | 3.21 |

| Design and construction technology level | F2 | 3.46 | / | 1.02 | 3.50 | 1.04 | 4.35 | 4.46 | 3.03 | 4.44 | 1.81 | 3.90 | 2.79 | 3.12 | 1.98 | 4.08 |

| Project social environment | F3 | 2.66 | 2.34 | / | 3.91 | 3.99 | 2.92 | 2.98 | 3.60 | 2.87 | 3.55 | 2.71 | 2.09 | 4.10 | 3.12 | 3.51 |

| Standard specification system | F4 | 4.01 | 2.51 | 1.08 | / | 2.38 | 4.52 | 3.70 | 4.53 | 3.79 | 4.67 | 3.99 | 3.20 | 4.27 | 1.20 | 3.01 |

| Project size and complexity | F5 | 3.29 | 2.56 | 2.03 | 4.29 | / | 4.40 | 4.37 | 4.53 | 4.00 | 4.28 | 3.25 | 2.39 | 4.11 | 2.80 | 3.24 |

| Collaborative management process | F6 | 4.05 | 1.28 | 1.30 | 3.77 | 1.25 | / | 4.11 | 3.99 | 3.41 | 4.88 | 3.59 | 3.20 | 2.93 | 1.68 | 3.56 |

| Design management system | F7 | 4.30 | 2.02 | 1.26 | 2.89 | 1.09 | 4.26 | / | 3.89 | 2.38 | 4.20 | 3.48 | 2.41 | 2.33 | 1.29 | 4.47 |

| Interface management system | F8 | 3.43 | 1.67 | 1.80 | 3.00 | 1.35 | 3.77 | 3.90 | / | 3.12 | 4.71 | 3.82 | 3.93 | 4.01 | 1.00 | 2.38 |

| Risk-sharing mechanisms | F9 | 1.34 | 1.40 | 1.11 | 4.09 | 2.31 | 3.16 | 4.25 | 4.60 | / | 4.00 | 3.21 | 4.09 | 4.28 | 3.10 | 4.32 |

| Coordination and communication mechanism | F10 | 3.61 | 1.22 | 1.28 | 3.17 | 1.20 | 4.53 | 3.00 | 4.44 | 2.65 | / | 3.77 | 2.60 | 4.11 | 2.02 | 3.23 |

| Relationship quality | F11 | 3.20 | 1.00 | 2.00 | 4.03 | 1.18 | 3.51 | 2.19 | 3.82 | 3.89 | 3.90 | / | 4.33 | 3.76 | 2.30 | 3.69 |

| Personnel attitude and experience | F12 | 3.90 | 1.36 | 1.27 | 3.45 | 3.47 | 4.11 | 2.82 | 3.59 | 3.40 | 4.48 | 4.67 | / | 4.13 | 3.22 | 3.94 |

| Organization building | F13 | 3.58 | 3.05 | 1.00 | 4.61 | 2.64 | 4.50 | 3.87 | 4.08 | 3.81 | 4.22 | 4.25 | 4.21 | / | 3.69 | 3.22 |

| Owner’s support | F14 | 3.88 | 1.81 | 4.09 | 3.21 | 3.04 | 3.49 | 4.02 | 4.17 | 4.36 | 4.59 | 2.48 | 4.81 | 4.39 | / | 3.55 |

| Incentive constraint mechanism | F15 | 2.10 | 2.99 | 2.48 | 2.31 | 1.42 | 3.06 | 4.20 | 3.77 | 3.90 | 4.21 | 4.49 | 4.60 | 4.08 | 2.32 | / |

| Degree Centrality (Out-Degree) | Degree Centrality (In-Degree) | Betweenness Centrality | Closeness Centrality (In-Closeness) | Closeness Centrality (Out-Closeness) | |

|---|---|---|---|---|---|

| Information-sharing platform | 52.9 | 77.43 | 6.83 | 44.57 | 48 |

| Design and construction technology level | 47.19 | 69.07 | 4.95 | 20.1 | 42.86 |

| Project social environment | 45.35 | 66.38 | 3.92 | 19.21 | 42.86 |

| Standard specification system | 55.53 | 81.28 | 7.15 | 92.31 | 83.33 |

| Project size and complexity | 51.41 | 75.25 | 4.16 | 44.57 | 48 |

| Collaborative management process | 55.97 | 81.92 | 7.48 | 92.31 | 100 |

| Design management system | 56.63 | 82.89 | 6.65 | 100 | 100 |

| Interface management system | 57.4 | 84.02 | 9.78 | 100 | 100 |

| Risk-sharing mechanisms | 54.92 | 80.39 | 7.29 | 66.67 | 83.33 |

| Coordination and communication mechanism | 60.22 | 88.14 | 7.85 | 100 | 100 |

| Relationship quality | 55.39 | 81.07 | 6.86 | 92.31 | 83.33 |

| Personnel attitude and experience | 53.25 | 77.94 | 7.17 | 63.16 | 48 |

| Organization building | 58.21 | 85.2 | 8.15 | 100 | 100 |

| Owner’s support | 51.67 | 75.63 | 5.23 | 63.16 | 48 |

| Incentive constraint mechanism | 54.1 | 79.19 | 6.39 | 48 | 83.33 |

| Core Element | Code | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 | F13 | F14 | F15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Information-sharing platform | F1 | 0 | 0.61 | 0.61 | 0.72 | 0.61 | 0.83 | 0.72 | 0.83 | 0.61 | 0.83 | 0.72 | 0.72 | 0.83 | 0.61 | 0.72 |

| Design and construction technology level | F2 | 0.72 | 0 | 0.61 | 0.72 | 0.61 | 0.72 | 0.83 | 0.72 | 0.72 | 0.61 | 0.72 | 0.72 | 0.83 | 0.61 | 0.83 |

| Project social environment | F3 | 0.72 | 0.61 | 0 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.83 | 0.72 |

| Standard specification system | F4 | 0.72 | 0.61 | 0.61 | 0 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.83 | 0.61 | 0.72 |

| Project size and complexity | F5 | 0.72 | 0.61 | 0.72 | 0.72 | 0 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.83 | 0.72 | 0.72 |

| Collaborative management process | F6 | 0.72 | 0.61 | 0.61 | 0.72 | 0.61 | 0 | 0.72 | 0.72 | 0.72 | 0.83 | 0.72 | 0.72 | 0.72 | 0.61 | 0.72 |

| Design management system | F7 | 0.72 | 0.61 | 0.61 | 0.72 | 0.61 | 0.83 | 0 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.61 | 0.83 |

| Interface management system | F8 | 0.72 | 0.61 | 0.61 | 0.72 | 0.61 | 0.72 | 0.72 | 0 | 0.72 | 0.83 | 0.72 | 0.72 | 0.83 | 0.61 | 0.72 |

| Risk-sharing mechanisms | F9 | 0.61 | 0.61 | 0.61 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0 | 0.72 | 0.72 | 0.72 | 0.83 | 0.72 | 0.72 |

| Coordination and communication mechanism | F10 | 0.72 | 0.61 | 0.61 | 0.72 | 0.61 | 0.83 | 0.72 | 0.83 | 0.72 | 0 | 0.72 | 0.72 | 0.83 | 0.72 | 0.72 |

| Relationship quality | F11 | 0.72 | 0.61 | 0.61 | 0.72 | 0.61 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0 | 0.83 | 0.83 | 0.61 | 0.72 |

| Personnel attitude and experience | F12 | 0.72 | 0.61 | 0.61 | 0.72 | 0.61 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.83 | 0 | 0.83 | 0.72 | 0.72 |

| Organization building | F13 | 0.72 | 0.61 | 0.61 | 0.72 | 0.61 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0 | 0.72 | 0.72 |

| Owner’s support | F14 | 0.72 | 0.61 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.83 | 0.83 | 0 | 0.72 |

| Incentive constraint mechanism | F15 | 0.72 | 0.61 | 0.61 | 0.72 | 0.61 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0.72 | 0 |

| Analysis of Structural Holes | Effective Size | Efficiency | Constrain | Hierarchy |

|---|---|---|---|---|

| Information-sharing platform | 3.769 | 0.269 | 0.274 | 0.024 |

| Design and construction technology level | 3.627 | 0.259 | 0.276 | 0.017 |

| Project social environment | 3.792 | 0.271 | 0.274 | 0.009 |

| Standard specification system | 3.944 | 0.282 | 0.269 | 0.015 |

| Project size and complexity | 3.830 | 0.274 | 0.273 | 0.012 |

| Collaborative management process | 3.859 | 0.276 | 0.270 | 0.017 |

| Design management system | 3.926 | 0.280 | 0.270 | 0.014 |

| Interface management system | 3.912 | 0.279 | 0.269 | 0.016 |

| Risk-sharing mechanisms | 3.970 | 0.284 | 0.270 | 0.016 |

| Coordination and communication mechanism | 3.926 | 0.280 | 0.269 | 0.017 |

| Relationship quality | 3.925 | 0.280 | 0.270 | 0.016 |

| Personnel attitude and experience | 3.804 | 0.272 | 0.272 | 0.021 |

| Organization building | 4.121 | 0.294 | 0.266 | 0.011 |

| Owner’s support | 3.639 | 0.260 | 0.276 | 0.023 |

| Incentive constraint mechanism | 4.021 | 0.287 | 0.268 | 0.013 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Z.; Liu, Y.; Li, Y. Research on Collaborative Mechanisms of Railway EPC Project Design and Construction from the Perspective of Social Network Analysis. Systems 2023, 11, 443. https://doi.org/10.3390/systems11090443

Fan Z, Liu Y, Li Y. Research on Collaborative Mechanisms of Railway EPC Project Design and Construction from the Perspective of Social Network Analysis. Systems. 2023; 11(9):443. https://doi.org/10.3390/systems11090443

Chicago/Turabian StyleFan, Zilu, Yuming Liu, and Yaxin Li. 2023. "Research on Collaborative Mechanisms of Railway EPC Project Design and Construction from the Perspective of Social Network Analysis" Systems 11, no. 9: 443. https://doi.org/10.3390/systems11090443

APA StyleFan, Z., Liu, Y., & Li, Y. (2023). Research on Collaborative Mechanisms of Railway EPC Project Design and Construction from the Perspective of Social Network Analysis. Systems, 11(9), 443. https://doi.org/10.3390/systems11090443