1. Introduction

Organizations motivated to deliver products and services aligned with customer expectations increasingly use assessment techniques to identify potential risks [

1]. Prioritizing failures in a system and planning corrective actions are two essential components of risk management in any organization [

2]. The Failure Mode and Effect Analysis (FMEA) is the most widely used structured and qualitative technique to identify failure modes in the system, evaluate their impact, and plan corrective actions. FMEA is the first step in reliability studies [

3]. This technique has been applied in manufacturing, food, education, construction, electronics, health, aerospace, and hydrocarbons [

4].

Artificial intelligence techniques are increasingly present in solving engineering problems, providing excellent results and greater reliability. A concrete example is the fuzzy logic technique that allows us to develop fuzzy systems that become indispensable tools in risk analysis. A fuzzy-rule-based system is the most common way to represent and systematically model human reasoning, using a rough and linguistic description that reflects our communication language [

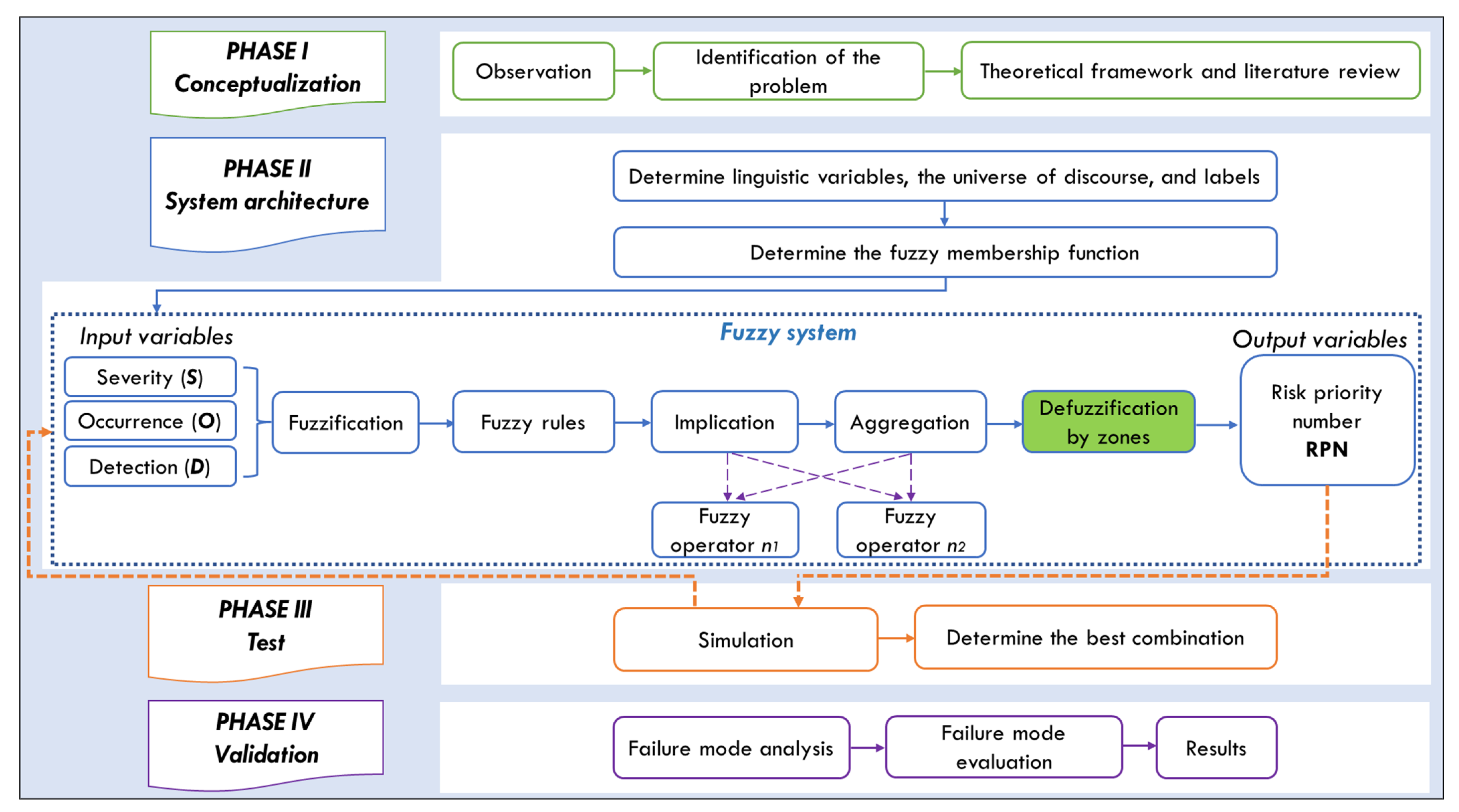

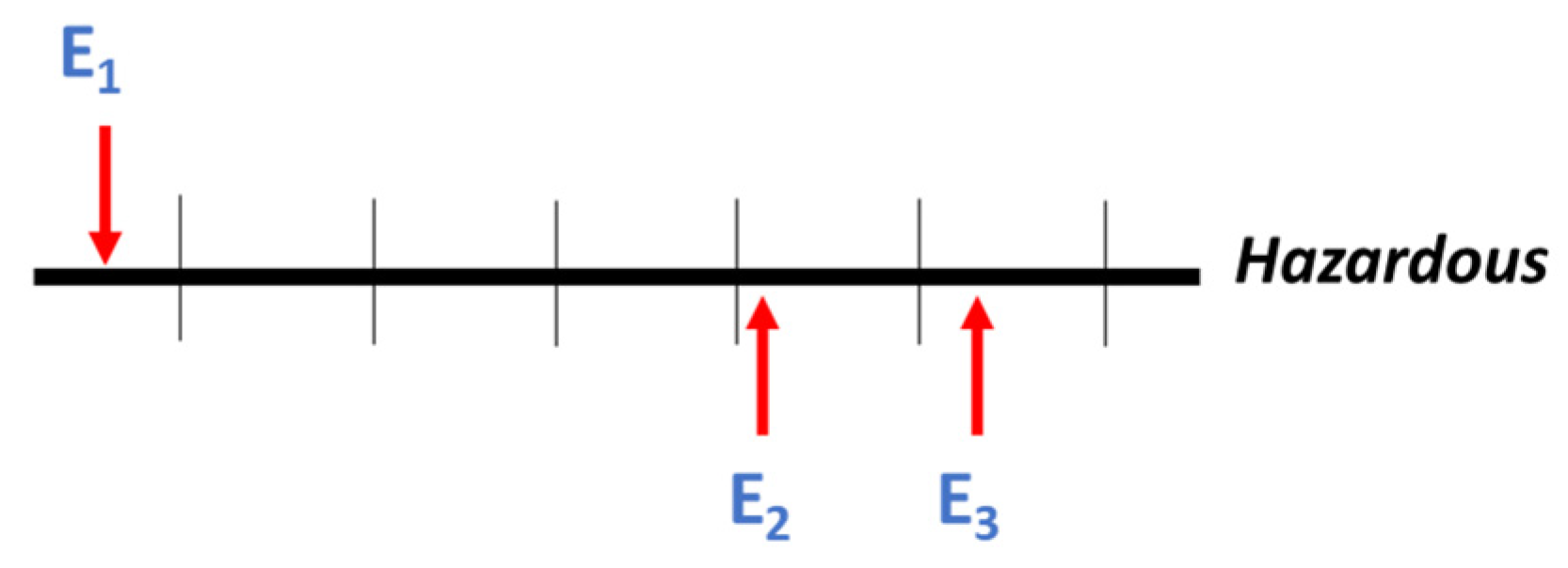

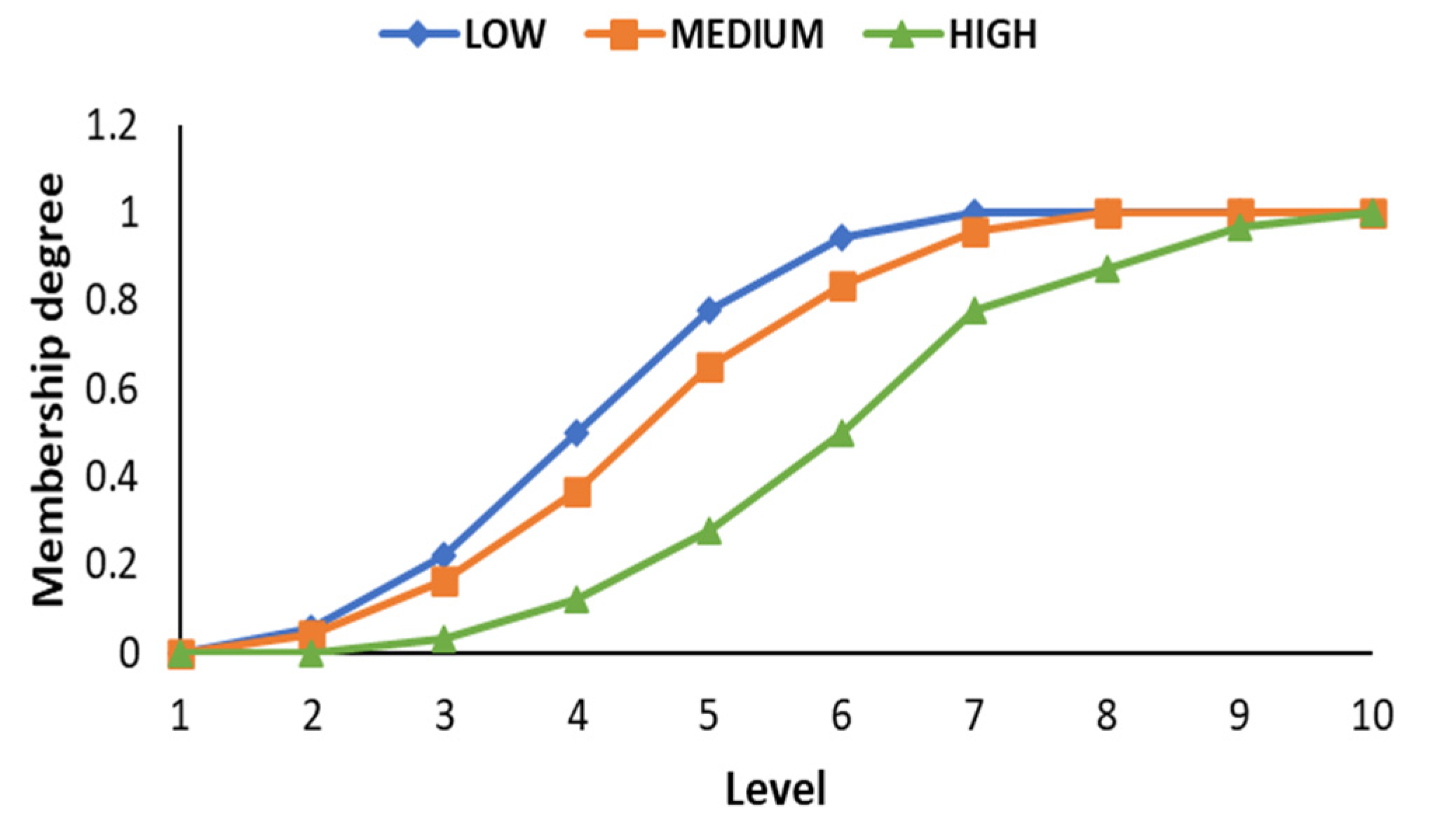

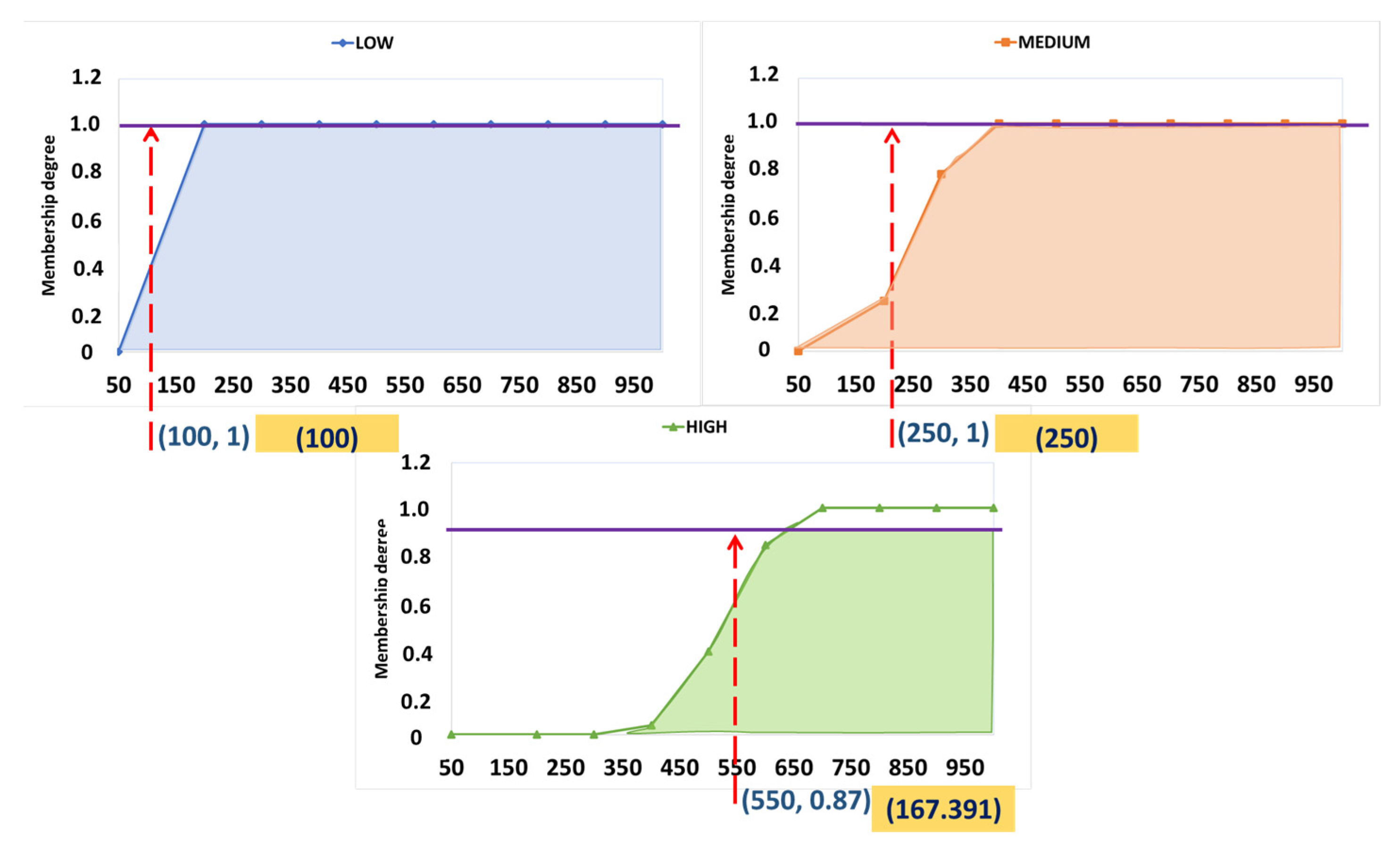

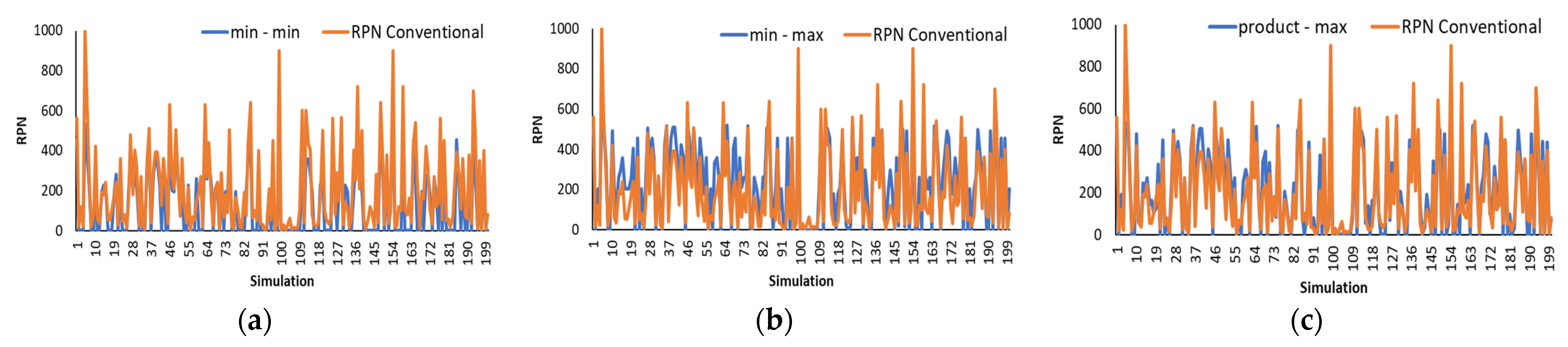

5]. Considering the aspects of communication and human reasoning, to develop an FMEA, the participation of a multidisciplinary team of experts is necessary to evaluate the different failure modes that can compromise the reliability and correct operation of a system or process. Each team member’s interpretations regarding the failures can generate a degree of imprecision. Therefore, when experts analyze failure modes and consider natural language, they express their point of view based on their knowledge and experience. Likewise, to determine the risk priority number (RPN), the experts develop a qualitative analysis based on a table of specific criteria. Therefore, the evaluation of the severity (S), occurrence (O), and detection (D) factors is highly subjective. Consequently, this research proposes a fuzzy logic evaluation system that mathematically models and emulates experts’ decision making when performing failure mode analysis. In this work, a Mamdani Type-1 fuzzy inference model is proposed. Different scenarios are proposed in the implication and aggregation stages, combining the fuzzy operators. The test of the evaluation system was carried out via simulations to determine the best structure of the system. Therefore, values of the risk priority number (RPN) output variable are obtained with greater reliability.

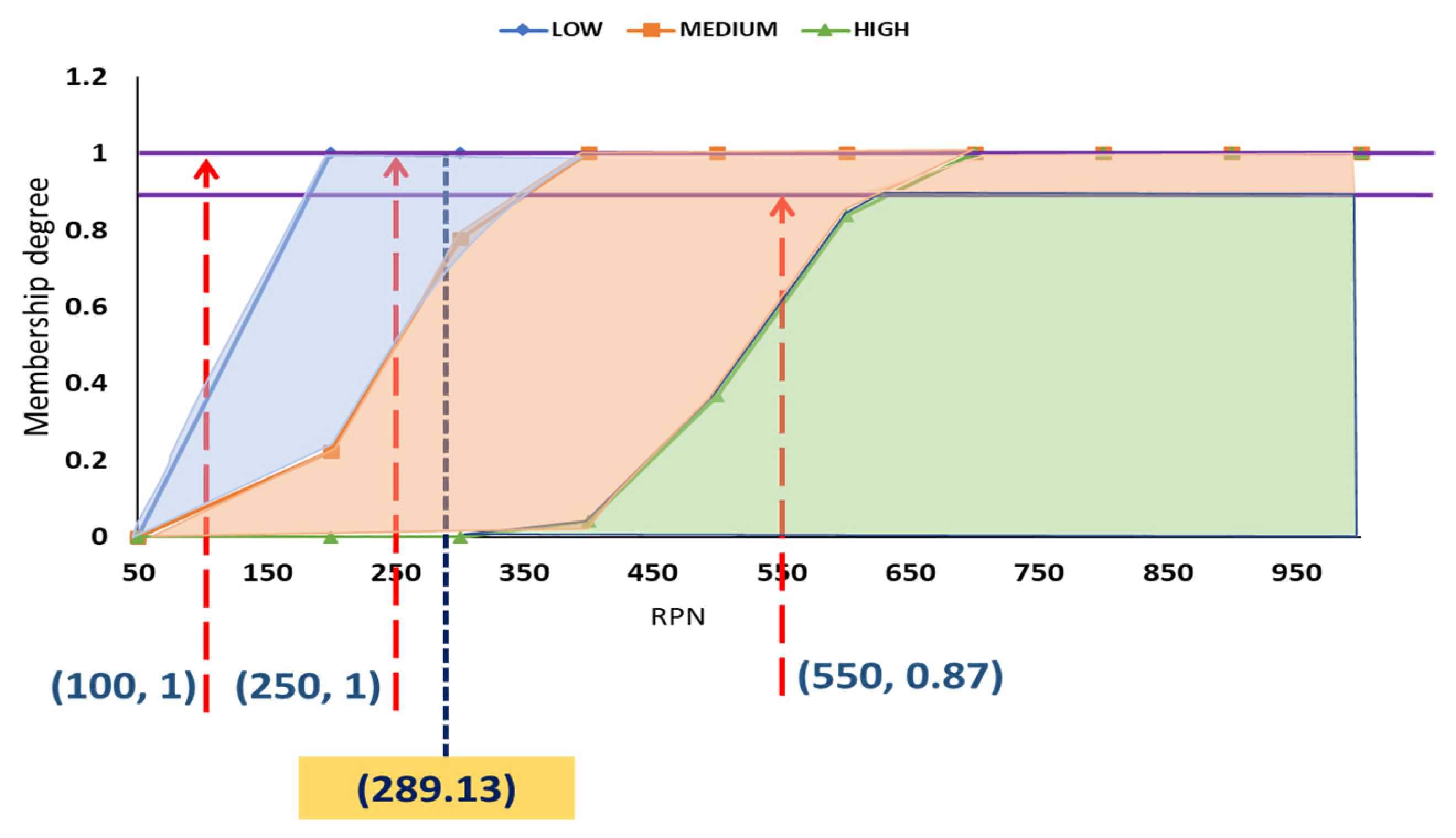

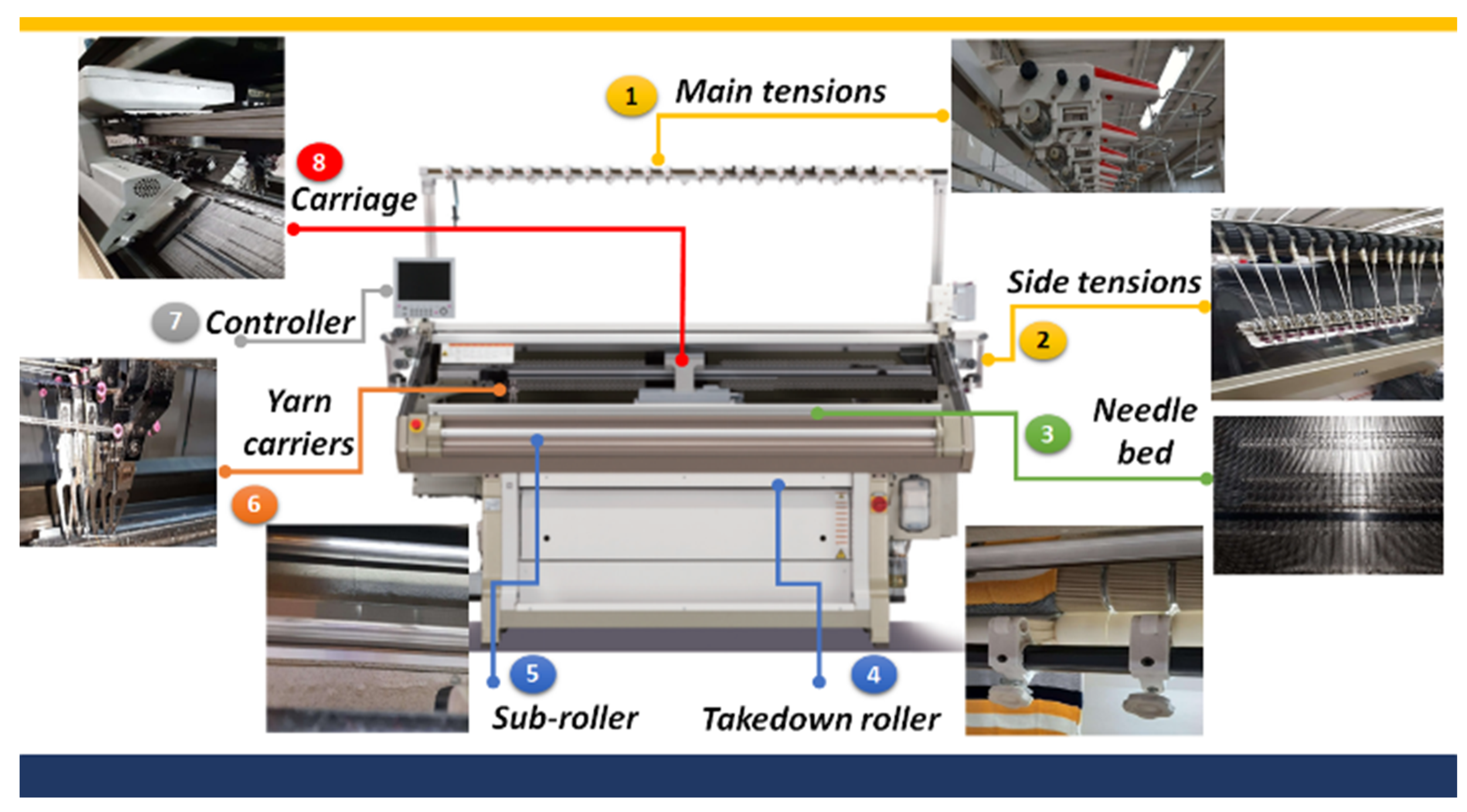

A case study was developed in the knitting department of a company in the textile sector. The evaluation system was validated, and the failure modes of the knitting machinery were prioritized. The main contribution of this research is a modification of the centroid method used in the defuzzification stage. In our proposal, defuzzification is carried out via zones of each fuzzy set to obtain results close to the conventional RPN.

This article is structured as follows.

Section 2 presents the literature review, where the authors use fuzzy logic to improve the qualities of FMEA. In

Section 3, the proposed methodology and approach are presented.

Section 4 presents the development of the fuzzy system with a case study in the textile sector. The discussion is presented in

Section 5. Finally, the main findings are concluded in

Section 6.

2. Literature Review

The authors of [

6] performed a comprehensive risk analysis on public–private partnership (PPP) projects for water treatment. An innovative risk assessment model is proposed based on intuitionistic fuzzy multi-objective optimization and the FMEA tool. Through interviews with experts, the literature, and the statistical frequency method, they identified five primary levels of risk and classified the degree of these risks. It should be noted that they assigned weights to each factor (O, S, and D). The domain of the RPN output variable of the case study is between (0, 1). Moreover, ref. [

7] proposed a new method to classify risks in the working environment of an oil refinery. The Mamdani model and the triangular and trapezoidal functions for the linguistic variables were used. Their work is relevant because they develop a further prior evaluation of the input parameters (S, O, and D) by combining fuzzy inference systems into a single evaluation system. Therefore, with the proposed method, they obtain greater precision in risk prioritization.

Furthermore, the work of [

8] developed a significant model to analyze the reasons for the failure of the logistics system during the COVID-19 pandemic. The FMEA methodology and the Analytic Hierarchy Process (AHP) method were used to calculate the weights of the factors (O, S, and D). They proposed a new fuzzy risk priority-weighted number (F-RPWN). As a result, it was determined that the most critical types of risk in the logistics system are security, commercial risks, and particular problems. The scale of the output variable in the case study to prioritize risks is less than (0.2). The models proposed by the authors [

6,

7,

8] are novel and relevant to improving the FMEA technique. However, the scales of the RPN output variables differ significantly from the conventional RPN values. Also, ref. [

9] proposes a novel methodology that combines the AHP and Partial Risk Map (PRISM) methods to assess risks based on pairwise comparison. They validated the methodology by developing a case study to assess the risks of strategic incidents in the logistic business processes of a nuclear power plant. A relevant aspect was the consistency test of the expert group after the evaluation.

The authors of [

10] conducted an FMEA and tested their system in a private hospital, finding nine risk types. They use a Mamdani model with max–min operators. The invaluable implementation of this model in medical sterilization units is highlighted, in which risk analysis has been little explored. They make a comparison between two matrix approaches to classify risks. However, when a matrix approach with five levels is used for the linguistic variables, 125 IF-THEN rules are generated. Expert knowledge is based on relatively few possible combinations between variables. In our research, the knowledge base comprises 27 fuzzy rules, which is computationally practical. However, it also has greater approximation and simplicity when evaluating the RPN factors.

The researchers of [

11] analyzed the risks in a hybrid fuel cell and gas turbine system for marine propulsion. With the FMEA, they determine 40 failure modes. A Mamdani-type fuzzy logic model is used for risk assessment. Their study provides an essential framework for developing a new propulsion system with safety in mind. It can be noted that the scale of the RPN output variable was (12.9, 38.0). The model we propose in this work improves the output scale with a closer approximation to the result of the score of the conventional technique. The authors of [

12] propose using fuzzy logic and FMEA to analyze risks in student projects. The system integrates the agent-based model to build the membership function and classify the inference rules. They use the Mamdani model, the triangular function, and the max–min operators. The proposal provides a tool to improve the analysis and development of projects in the learning process.

The author’s research [

1] focuses on the failure analysis of manufacturing systems proposing an approach based on the fuzzy cognitive map method (FCM), the FMEA for processes, and the delta-rule-learning algorithm considering the opinion of the experts. The results highlight the power of the approach with a food industry case study. The scale of the output variable RPN was (0.65, 0.97). In research [

1,

12], the most common membership functions are not explicitly related to the meaning of the severity, occurrence, and detection factors. This aspect is relevant and fundamental because the functions represent the degree of membership and the behavior of the system variables.

The work of [

13] successfully combines fuzzy logic and product FMEA. The triangular membership function and the Mamdani model with max–min operators were used in the fuzzy system. Sixteen failure modes are analyzed in a family farming equipment cutting module to mechanize artichoke processing. The scale of the RPN output variable for the analyzed failure modes varies between (576.35, 833.47). In a numerical example presented by the authors, the output value is practically twice the value of the conventional RPN. In this present investigation, defuzzification is carried out via zones (sets). With the above, obtaining a value in the output variable close to the conventional RPN is possible.

In ref. [

14], via an FMEA, the authors evaluated eight risks in Smart Networks. A combination of ICT (Information and Communication Technology) with autonomous energy equipment from the electrical network. The results demonstrate the ability to improve risk perception and classify the impact of failures. The scale of the RPN output variable was (85.2, 116). Their Mamdani-type model incorporated the impact variable as an additional factor. A relevant aspect of this work is the test of the system with two types of membership functions (triangular and Gaussian), and later they perform a comparison of the outputs. However, the functions’ relationship concerning the system variables must be explained. In this present investigation, we explain the relationship of the sigmoidal function concerning the meaning and behavior of the factors (O, S, and D).

The authors of [

15] develop an FMEA to study fluid-filling systems in automobile assembly lines, finding 23 failure modes. Aspects such as expert characteristics, scale variation, four membership functions, and four defuzzification algorithms were integrated into the fuzzy model. The scale of the RPN output variable was between (46, 610). Its system improves decision making, maintenance plans, and high levels of availability and security. However, the type of model used is not specified. In this research, a Mamdani model is developed with each stage, and the fuzzy rule base is presented.

In the investigation of [

16], an FMEA was carried out with a root cause analysis in mining machinery, finding 16 potential risks via a Mamdani inference model; the Gaussian membership function was used for the input variables, and the triangular function for the output variable, as well as the max–min operators. The electrical subsystem was determined as a priority failure. The scale of the RPN output variable was (32.0, 142.0). The authors of [

17] studied the components of a lathe machine via a risk analysis incorporating the fuzzy aspect. The scale of the RPN output variable was (3.50, 7.41). The results show that the fuzzy FMEA approach is superior in criticality analysis.

The researchers in [

18] proposed a fuzzy-rule-based model incorporating the Gupta–Ghasemian formula and the Dempster–Shafer theory to quantify uncertainty. Their study analyzed 20 failure modes of an industrial centrifugal pump using an FMEA. Ten experts evaluated the failure modes, and the scale of the RPN output variable was (2.11, 7.49). The studies of [

16,

17,

18] present important models and applications that demonstrate the need to integrate fuzzy logic in the FMEA. However, the result of the output variables is found in ranges with low values. In this present investigation, we propose in the fuzzification stage an adjustment that allows the values of the output variable to be on a scale close to the conventional values of RPN. Moreover, the research of [

19] in their study of enterprise architectures carried out an FMEA. The authors analyzed twenty failure modes with a fuzzy model incorporating an eight-step method with multi-criteria optimization. A triangular function and inference rules were used based on expert criteria and weights, best–worst, and min–max operators. The NPR output scale in their case study is (0.63, 9.66). They prioritize and identify significant priorities such as labor practice and infrastructure with their model.

Other studies focused on innovative proposals to build a failure analysis, integrating other techniques to test consistency, pairwise comparison, and ideal solution. For example, the authors of [

20] propose a Mamdani-type fuzzy inference system built from the experience of experts. They validate their model in a diesel engine turbocharger system. The analysis of the mechanical system is highlighted by considering its components, subsystems, and the interdependence between failure modes. In addition, they developed a platform as an evaluation interface where experts from different disciplines can share information. In ref. [

21], the authors developed a rule-based fuzzy expert system to offer a tool to assess risks associated with marine engineering and offshore transportation issues. They use three membership functions to create fuzzy sets and perform sensitivity analyses for the most critical failure modes. Thus, they demonstrate the effectiveness of their model for risk assessment.

The investigation of [

22] proposes a fuzzy inference system implemented in a nuclear reliability engineering problem. They develop an FMEA in a chemical and volume control system. The results demonstrate the potential of the inference system for this class of problems. In addition, it provides the advantage of being used for systems where security data are unavailable or unreliable. The authors of [

23] develop an FMEA using the fine-tuned trapezoidal fuzzy-based technique for the order of preference by similarity to the ideal solution. Its objective was to reduce the risks in the preparation or collection of data using hierarchical matrix management. The proposed model considers the interdependencies between failure modes, the relative importance of risk, and the non-subjective nature of conventional RPN functions. In the research by [

24], they propose a novel method incorporating the stages of the FMEA technique. The method allows pairwise comparison, calculating the weights of importance and consistency in the evaluation by the groups of experts from the FMEA. With the above, they determine the indices of S, O, and D. By using basic mathematical operations, the method is easily applied. Previous research demonstrates the importance of integrating fuzzy logic and FMEA techniques. The most relevant characteristics of our contribution that motivate the realization of this study are as follows:

The modification of the centroid method is one of the main contributions of this research since it allows obtaining RPN values close to the conventional technique;

Likewise, when using the sigmoid function, the relationship with the factors is described, and finally, different scenarios are explored to establish the best combination of fuzzy operators;

In this study, the proposal of a generalizing system based on a simulation process of multiple runs is made.

5. Discussion

At present, the prioritization and risk analysis with the FMEA technique have become more relevant, and proof of this is the studies that try to overcome the inherent limitations of the method. Risk assessment systems have been proposed in the literature from various approaches. The fuzzy approach is one of the most used, and even integrating it with other techniques forms novel tools. In this research, a fuzzy system was developed to evaluate failure modes to offer a robust tool capable of emulating how an expert in their area of expertise evaluates the risks that limit the operation of a system or process. The evaluation system is based on the Mamdani-type model, where the inference rules allow us to transfer the knowledge of the experts to a mathematical model and strengthen decision making.

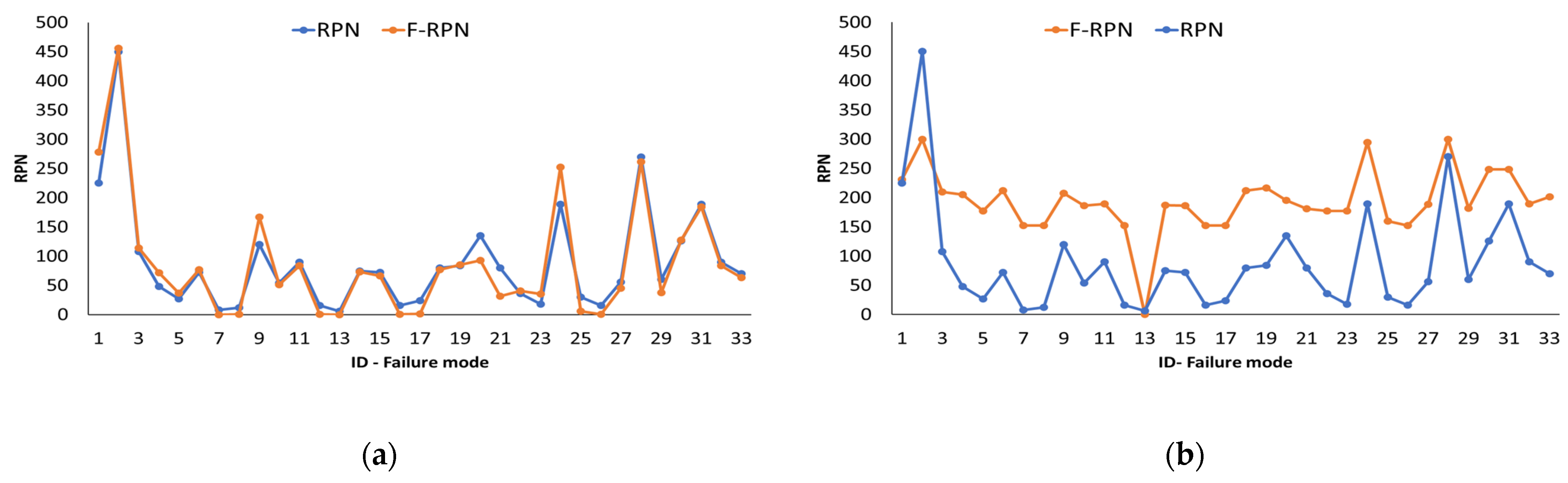

The implications of this present study are in the theoretical and practical aspects. First, a four-phase methodology is offered in the theoretical aspect, in which FMEA steps and the development of a fuzzy system are incorporated. The most relevant contribution of this research that adds value to the literature focuses on the fuzzy system, specifically in the defuzzification stage. One of the most widely used defuzzification methods in fuzzy systems is the centroid method, where the zones of each fuzzy set overlap to form a single zone. Then, the point where a vertical line divides the set into two zones with equal mass is calculated. In this study, a modification of the centroid method is proposed, where the zones that represent the fuzzy sets are treated individually, obtaining a value in each zone; the zone of the highest set is the one of most significant interest because it is the one that marks the difference between the scales of the values and that, when added together, give us the output value. This modification makes it possible to approximate the fuzzy system’s values to the conventional technique’s values. In addition, when statistically validating the results, it is confirmed that the modification allows a good approximation, as shown in the graphs of

Figure 10, where it is visualized how the proposed method best approximates the data.

The second relevant aspect is the practical aspect of the proposed approach. Offering a fuzzy evaluation system with an output value that is the F-RPN metric is essential. In a conventional FMEA environment, the RPN metric is obtained directly from the algebraic product of the three factors (O, D, and S). A central feature is the ease of calculation and straightforward interpretation. However, the F-RPN metric is derived from a robust mathematical model that integrates linguistic uncertainty conditions. Trying to approximate the results of the system to the traditional metric allows for preserving a simple interpretation.

Some limitations to consider are the fact that it is necessary to incorporate group decision-making techniques into the proposed system, where a more significant number of specialists in the area participate in evaluating failure modes, incorporate methods of comparison by pairs, consensus, and test the consistency in the opinions of the experts. Future work is contemplated to determine the factors with probability distribution functions to obtain information with a stochastic basis and integrate them into the fuzzy system. In addition, in future work, it is contemplated to develop grouped fuzzy systems and integrate expert consistency tests to reduce subjectivity in evaluating failure modes.

6. Conclusions

FMEA is undoubtedly a simple but helpful technique for people involved in risk analysis. The role of experts was central in this work. The methodology was built to strengthen this technique and offer a tool that emulates how experts evaluate failure modes. In the Type-I fuzzy system, the conditions of imprecision and subjectivity were integrated to give way to a model with a mathematical basis compared to the alternative of solely qualitative analysis.

From the knowledge of the experts, the multidisciplinary team, and how they evaluate the factors, the knowledge base based on 27 fuzzy rules was formed. The sigmoid membership function was used, checking that the relationship and behavior are related to the criteria for each factor. With the defuzzification of each set individually and giving greater importance to the high set, RPN values close to the conventional technique were obtained. This aspect was achieved by modifying the centroid method, the main proposal of this research. Creating scenarios in the implication and aggregation stages and the simulation process made it possible to establish the best structure of the fuzzy system. The validation in a textile sector company allows concluding that the fuzzy evaluation system is consistent and reliable for decision making during the failure mode and effect analysis.

By determining the priorities in the knitting machinery, it is possible to focus material, human, and financial resources on the failures that cause instability in the operations of the knitting area. The most important benefit of the proposed approach is having a system that generalizes adequately, with which any expert can perform the evaluation reliably.