Abstract

Smart manufacturing systems enable simultaneous addressing of productivity, sustainability, and social improvements. The implementation of such systems in industries such as the automotive industry represents a promising way to meet stakeholders’ requirements concerning the decarbonization of their productive activities. In fact, this task is truly challenging for the automotive industry considering their complex organizational issues, generating knowledge sharing problems, and the diversity of plants’ context and characteristics. These facts make any decarbonization solution local, instead of being spread to a maximum of production units to potentially enhance decarbonization time efficiency. This article tackles these issues by providing a new organizational concept dealing with the relationships between decarbonization actors (energy managers and consultants) supported by the technical design of an IT knowledge management tool. These contributions will be based on the concept of decarbonization measure (DM) and illustrated by the case of Stellantis, one of the world leaders in terms of vehicle production, which develops a new organizational structure from local energy managers to corporate energy consultants.

1. Introduction

Anthropogenic activities are the main cause of climate disruption and greenhouse gas (GHG) emissions being responsible for global warming, threatening the future of life on Earth [1,2]. The Intergovernmental Panel on Climate Change (IPCC) has set a capital goal which consists of maintaining the average atmosphere temperature augmentation below +1.5 °C by 2050 [3], and pushes for all industrial sectors in the European Union (EU) to reach zero net GHG emissions in order to meet sustainability goals [4], supported by the Paris Agreement. Industrial sectors willing to deliver the goods undertake deep organizational and technical transitions to reduce their carbon footprint [5], which has been proven to be a key factor for their evolution towards sustainability [6].

The automotive industry, making no exception to this context, must face two challenges to meet these requirements: produce principally low-emission vehicles (LEVs) (GHG protocol scope 3) and decarbonize its factories (GHG protocol scope 1 and 2) [7,8]. The automotive production plant decarbonization issue, although being less popular than LEV production, deserves serious attention because of its complexity [9]. The method automotive companies use to perform this decarbonization is quite straightforward: corporate mainly asks for plants to search, find, and implement technologies or practices allowing the reduction of CO2 emissions related to their plant’s activity.

However, the lack of horizontal plant-to-plant communication combined with the complexity and uniqueness of plant designs make these new solutions exclusively local. This situation implies that project scalability and adaptability to other plants are very rarely assessed, which represents clear missed opportunities of decarbonization-related knowledge sharing between plants. The decarbonization task is therefore difficult for employees in charge of it, mainly working in plant energy teams. The automotive industry, similar to other industries, is aiming and searching for new smart manufacturing systems to assist them and boost their working efficiency [10].

These systems are part of Industry-4.0-related technologies that are promising thanks to their analysis and intelligent usage of data. Introducing Industry 4.0 is a well-known and mature process in companies [11]; in our case, it mainly concerns the Internet of Things (IoT), data analysis, artificial intelligence (AI), and high-level performance production technology. The implementation of such technologies would imply the need to train the concerned employees, which is difficult, but crucial when jobs are very new: energy managers and energy consultants are booming in many companies. The challenge for companies is to reskill technicians and engineers as a central and strategic role [12] to interpret data, document decision making, and, at the executive level, to implement innovative solutions and monitor the progress.

This article aims to suggest a way to overcome these knowledge management weaknesses in order to accelerate the decarbonization process of automotive production plants via the design of a knowledge-sharing mechanism.

Knowledge is managed by companies using different methods [13]. Two main approaches exist: the human-based approach and the IT-based approach, representing a real interest for companies since it could bypass the constant issues of human resources and knowledgeable employees’ availability. The application of knowledge management for sustainability is arousing increasing interest [14]. The spreading and sharing of new sustainable concepts and ideas is mainly performed via human interactions, developing a culture to which every employee can contribute and participate. The design of IT systems handling knowledge management for sustainability purposes is therefore quite new, and a gap exists concerning the application and development of such technologies for automotive plants’ decarbonization purposes.

This paper’s contribution to fill this gap resides first in the analysis and reorganization of communication between plant automotive decarbonization actors. Second, this paper supports this idea with an IT technical approach. For this purpose, a data model that will be the backbone for a knowledge management system based on the new concept of decarbonization measure is designed. The consequences of its future implementation and the efficiency of its features are discussed in the context of Stellantis, one of the world leaders in the automotive field and partner of this research.

The methodology that led to the production of this paper consisted firstly of understanding how an automotive plant works (in terms of process, energy demand, etc.) thanks to both the literature and immersion. Secondly, energy manager feedback was collected in a database that was then analyzed to understand the decarbonization status of their plant and underline knowledge management issues. Research of the literature was performed in order to find how companies manage their knowledge. Finally, the concept brought about in this article was created as a first attempt to answer the needs related to decarbonization acceleration based on knowledge management.

The paper is set out as follows. After this introduction section (Section 1), the reasons for automotive companies to engage the decarbonization of their plants are presented in order to highlight the main research question dealt with in this paper: How can we make local sustainable industrial projects (SIPs) profitable to a maximum of plants in a vehicle-producing company (Section 2)? As it is mainly a communication issue, the concept of knowledge management is analyzed in Section 3 to extract the research gap and finally the objective of the paper. The decarbonization measure concept (DM) is suggested to structure the decarbonization solutions and their implementation conditions (Section 4). The data model supporting the decarbonization measure implementation is detailed in Section 4. A concrete industrial case in Stellantis is discussed in Section 5 and clarifies the implementation features. Section 6 concludes the paper.

2. Introduction to the Environmental Concerns Surrounding the Automotive Industry

2.1. The Necessity to Decarbonize the Automotive Industry

Global reduction of CO2 emissions is a critical issue to maintain the atmosphere’s average temperature augmentation below 2 °C by 2050 [1,2]. In fact, carbon dioxide is responsible for 65% of the mass of the yearly greenhouse gases (GHGs) coming from anthropogenic activities [3], and its production has been increasing exponentially since 1850 [15].

According to recent IEA reports, in 2021 36.5 GT CO2 eq. related to energy combustion and industrial processes were emitted [16]. Industry and road transports are, respectively, responsible for the emission of 9.31 GT CO2 eq. and 5.95 GT CO2 eq. in 2021. To this day, no study gives the exact GHG emission generated by the activity of automotive factories (direct emissions) and their energy supply (indirect emissions). However, it has been proven in some specific cases that the efforts that automotive factories should make in order to meet the net-zero GHG emissions requirement are still significant [17]. Measures have been taken by global organizations to curb industrial companies’ environmental impact [7], and the automotive sector makes no exception to this policy.

An additional key element of context would be the consequences of the war in Ukraine, generating a massive increase of the energy prices [18]. With fossil fuels prices increasing, a transition towards other kinds of energy is mandatory for the industry in general. This could be seen as an environmental transition accelerating factor.

The GHG Protocol ([8], p. 5) defined three different scopes related to GHG emissions:

- Scope 1: Direct emissions. These CO2 emissions are related to the activity of plants and the energy consumed on site.

- Scope 2: Indirect emissions. These CO2 emissions are related to the activity of energy suppliers that plants rely on.

- Scope 3: Value chain emissions. These CO2 emissions are the consequences of a company’s activity that is not controlled or owned by it. In the case of the automotive industry, this scope would contain the emissions of vehicle utilization by end users, end-of-life management of cars, etc.

This article will focus on scopes 1 and 2, dealing with direct and indirect vehicle plant emissions.

To accelerate this decarbonization process, governmental organizations implemented indirect ways to place financial pressure on automotive companies. For example, in the EU, industrial companies should buy CO2 quotas depending on the number of CO2 tons produced by their production. The price of each quota is defined by the EU Emissions Trading System, and the EU plans to keep on raising it until it becomes sufficiently expensive to trigger environmental behavior from the companies. However, it is important to remember the fact that the EU context is not the only one to consider; each region of the world has its own policy regarding environmental issues.

Stakeholders also apply considerable environmental pressure on automotive brands, since their mindsets have undoubtedly changed recently [19]. In fact, people are nowadays generally more concerned about the fate of our planet and ask for eco-friendly and eco-responsible behavior and production [20]. These new and intense requirements are naturally expressed by customers, but also by automotive group employees, implying that environmental considerations need to be considered at all stages of a vehicle’s lifecycle.

Thus, automotive sector decarbonization appears to be essential to reach the goals set by the IPCC for 2050; plus, it is a must for vehicle companies to avoid becoming overwhelmed by the increasing prices of fossil fuels.

2.2. Decarbonization Challenges for Vehicle Production Plants

In order to align with the urgent and increasing environmental requirements, automotive companies are all working on the decarbonization of their plants. However, what is important to mention is the fact that each automotive company manages this topic on its own: there are no common objectives and directives that every company should follow. They all work independently on their environmental issues, even though they are quite similar.

The heart of the strategy adopted to accomplish these challenges is the implementation of sustainable industrial projects (SIPs) that will help automotive production plants (APPs) reduce their carbon footprint on both scopes 1 and 2.

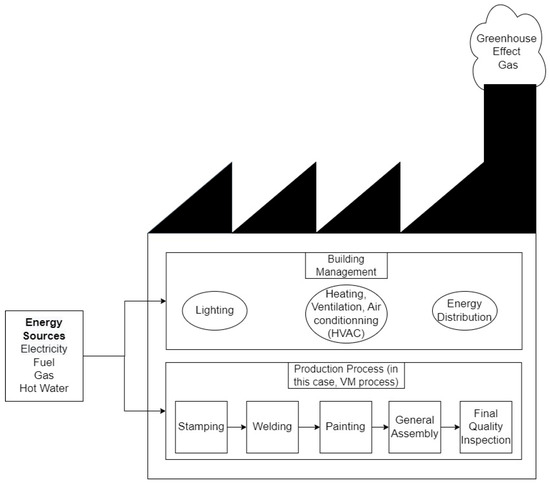

According to Stellantis feedback, there are four main challenges for APPs to overcome in order to implement solutions in the automotive industry that would help reduce GHG emissions related to scope 1. The first challenge would be to understand with precision why, where, and how CO2 is emitted in an APP. As shown in Figure 1, automotive plants consume energy in order to fulfil two complementary kinds of activities: building management and production process operation, subdivided in a succession of production steps. As an example, an internal document of the automotive manufacturer Stellantis says that building management would account for 31% of the total energy consumption of a plant, and production process 69%.

Figure 1.

Simplified model of activities performed in a plant (here, vehicle manufacturing).

The second would be to consider the particularities of each plant: the specificity of the automotive industry is the fact that production plants belonging to a vehicle company are heterogenous. Its plants are numerous, dispatched all around the world, usually old, not standardized (different in the way they produce and work), and different from one another in many aspects. Automotive plants are, therefore, complex, which makes their evolution towards the environmental requirements difficult [21].

Third would be for the plants to adapt to the new sustainable technologies and concepts. In fact, APPs will have to learn and adapt to new technologies and concepts that they are not familiar with as the automotive industry is going through a massive change due to the recent evolution in terms of environmental issues and sanctions. They have to look at their carbon footprint and energy consumption, which has never been the case before, and have started monitoring equipment [22], including how it relates to product design [23]. Therefore, these companies are just starting to learn how to produce in a sustainable way, meaning that new knowledge shall be dealt with and managed.

Finally, another challenge emerges once a deeper look is taken at the organization of APPs. Nowadays, most automotive companies are multinational companies possessing several APPs dispatched all over the world. Despite producing similar cars, these plants belong to different contexts. Geographical and contextual divergence leads to a lack of communication [24] among plants, simply because they are independent and do not need others to work properly. This becomes problematic when the way SIPs are implemented is considered. In fact, they are deployed locally most of the time, which means that only a handful of plants, sometimes only one, will be aware of this measure and the concepts it involves. These projects are therefore not exploited to their full potential because the knowledge related to them is not spread or shared. Without communication, no information is shared, and without information sharing, a plant would never have the opportunity to consider the concepts brought up by these projects and evaluate their transferability. A clear knowledge transfer issue exists. As a consequence, the efficiency of this strategy is highly diminished, and this could lead to time struggles for automotive companies that need to answer the environmental demands as soon as possible.

Reducing GHG emissions related to scope 2 is a different task. In fact, as scope 2 covers the indirect emissions related to energy suppliers, automotive companies could reduce energy demand (which brings the issue back to scope 1 and plant energy efficiency) or opt for cleaner energy sources and/suppliers. Still, an effective sharing of plants’ progress on these topics seems to be crucial for decarbonization purposes.

2.3. Research Question for Automotive Production Plants (APPs) Decarbonization Challenges

To decarbonize their plants, the automotive industry would need to deploy SIPs with a focus on decarbonization, but their strategical weakness resides in the lack of information and knowledge sharing between plants, leading to the locality and unexploited knowledge serving decarbonization. This state highlights the research question raised in this article: how can we make local decarbonization SIPs profitable to a maximum of plants in a vehicle-producing company? This question leads to the following sub-problematics: Which method should be used in order to achieve this knowledge sharing? What is the related knowledge that needs to be shared from a plant to another in order to provide sufficient information for transferability evaluation? What technology should be used in order to perform this complex task?

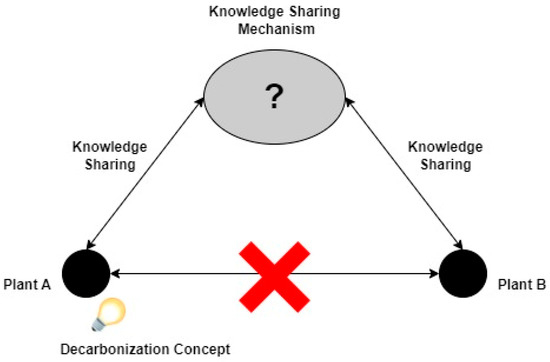

The main assumption made to tackle those questions comes from the lack of communication among plants, illustrated in Figure 2. Plant A has developed and implemented a new way of reducing its GHG emissions, and plant B would potentially be interested in adapting this solution to meet its decarbonization goals. However, due to the communication issues existing among plants, necessary elements for the understanding and transferability evaluation of the solution developed in plant A will not, or partially, be passed on to plant B. Creating a direct communication flow between A and B is not an option since their differences will remain, and so will their lack of interest in communicating with each other. A solution could be to somehow bypass this problem via the intervention of a neutral third party that is yet to be defined but looks similar to a knowledge management mechanism to be invented.

Figure 2.

The principle of bypassing interplant communication issues.

The knowledge sharing mechanism must store, compare/identify, retrieve, and transfer knowledge. It is one aspect of knowledge management, a widely addressed topic that has gained increasing interest since the 1990s. Knowledge management analysis would be interesting to understand what knowledge is captured and the tools and concepts of which companies relate to managing the knowledge they deal with.

3. Literature Review on Knowledge Management

Now that the subject of research has been defined, a literature review will follow to study the notion of knowledge management and the way it is handled in companies (especially when it comes to sustainability) in order to specify the research gap.

3.1. Concept of Knowledge Management and Its Application in Companies

The notion of knowledge was introduced in the previous analysis of vehicle companies’ difficulties (Section 2.2); however, no definition was given: What is knowledge? Unfortunately, there is no clear and unique answer to this question. According to Alavi and Leidner ([25], p. 113), a set of different perspectives of knowledge exists, such as the state of mind perspective, the object perspective, the process perspective, etc., all bringing up a unique aspect of knowledge. What is clear, however, among these multiple interpretations is the fact that knowledge is a human being’s appropriation of information during cognitive experiences [26], which implies that knowledge lies in people’s minds, and that everything else is either data or information.

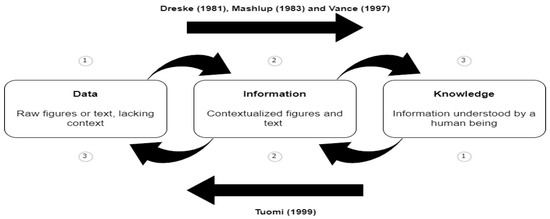

These three elements (data, information, and knowledge) are distinct and are all part of a hierarchy that explains how knowledge is produced. Two interpretations of this hierarchy exist: the one shared by [27,28,29], and the one introduced by [30], as shown in Figure 3.

Figure 3.

Data-information-knowledge hierarchy and interpretations [27,28,29,30] (inspired by Alavi and Leidner, 2001 [25]).

In the first hierarchy, data are at the bottom: this term covers all raw numbers or textual content that are without context, hardly exploitable for learning purposes. Then comes information, which is basically data provided with context, becoming intelligible content. Finally comes knowledge, which is the appropriation of information by a human being. The second hierarchy is opposite, since its principle implies that knowledge is essential to understand the information and data that are being dealt with.

The common consequence of these points of view is that knowledge resides in employees’ heads, which is not fully exploitable. In fact, this knowledge is considered tacit, made from “intuitions, unarticulated mental models, or embodied technical skills” [31], which are hardly exploitable by companies. Even though knowledgeable employees play a key role in their performance, their tacit knowledge needs to be extracted and converted into explicit knowledge (“a meaningful set of information articulated in clear language including numbers or diagrams” [31]) in order to ensure its transfer and legacy inside a company. This approach consists of translating knowledge into exploitable information.

As the concept of knowledge was explained, it is now important to justify the importance of its management inside companies, and especially multinational companies. In order to answer this question, the concept of theories of the firm must be introduced.

Theories of the firm are perspectives/visions of companies that aim to understand and explain, for example, how firms work, how they are organized, what resources they use, how they use them, etc., in order to optimize their performances [32]. What is important to keep in mind is that these are visions and perspectives: there are, therefore, no “true” or “false” theories, each one of them shows firms via its own point of view.

Among the different theories of the firm exists the knowledge-based theory of the firm, which considers that knowledge is one of the most important resources that a company possesses [25]. Therefore, its management becomes a main issue for companies, and this is due to many reasons. First of all, international companies are made from a complex network of units [33] that are dispatched in different locations and contexts, which makes their management hard, since they do not share the exact same roles, interests, and behavior [24]. Communication between these units becomes logically more difficult, which directly implies that the knowledge transfer is affected since no information/explicit knowledge can be shared without communication.

Secondly, international companies are considered as huge knowledge-producing entities; therefore, dealing with such constant and diversified knowledge is essential for these companies to remain competitive [34,35].

In addition, several empirical studies have proven the benefits of knowledge management inside companies, boosting their performance, competitiveness, and innovation [36,37,38,39,40,41].

Knowledge management is, therefore, according to the theory of the firm and the several studies ensuing, a most relevant topic to consider. Knowledge management mainly consists of five different elements [25]:

- Collect/create knowledge;

- Stock knowledge;

- Retrieve this knowledge after being stocked;

- Transfer this knowledge to other units;

- Apply the knowledge.

The management of decarbonization-related knowledge will logically consist of the application of these five pillars. Before even considering their transferability, a tool allowing collection, stocking, and retrieval of the related knowledge shall be designed.

3.2. Managing Knowledge in Companies

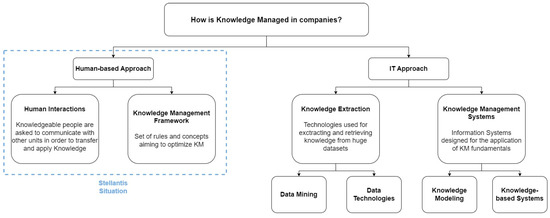

Different methodologies, concepts, and technologies mostly based on IT have been developed to achieve KM goals [13,42] (see Figure 4):

Figure 4.

Ways to manage knowledge in companies according to Liao (2003) [13].

- KM framework: Set of rules and concepts coming from a KM perspective that aims to optimize KM performances

- Information and communication technology: Technology that allows information circulation and communication between units and employees

- Data mining: Science consisting in extracting information from large databases using machine learning, AI, and statistics [43]

- Database technology: Technology allowing the design of databases and extraction of specific content thanks to dedicated languages (e.g., SQL).

- Knowledge-based systems (KBSs): IT systems that use knowledge and data analysis in order to solve complex problems. An expert system is a special kind of KBS that consists of reproducing the expertise of experts in a digital tool.

- Knowledge modeling: A science consisting of defining and describing knowledge through IT tools such as databases or knowledge representation languages.

These different concepts do not serve the same purpose and can be classified via the KM task they fulfil (inspired by [44]):

- The KM framework expresses rules that concern all five KM objectives.

- Digital technology contributes to knowledge transfer via the circulation of information it allows.

- Data mining and database technologies participate in the creation, stockage, and knowledge retrieval.

- Knowledge-based systems and knowledge modeling apply to all five KM objectives.

The human-based approach is the oldest and most common one in companies. Different techniques related to it exist and generate positive results inside firms thanks to the wealth and adaptability of human interactions [45]. However, the people having the knowledge required to teach others on a specific topic are rare and not always available, making it difficult to apply the human-based approach systematically. Knowledge management systems (KMSs) are “a class of information systems applied to managing organizational knowledge” ([25], p. 114), which means that they can be considered as information systems with specific features placing emphasis on KM pillars. These features are various: they can consist of the modeling of human knowledge inside IT systems (leading to expert systems, for example) [46], the usage of AI to help people solve complex problems [47], production of data insights thanks to data extraction tools [13], etc. What appears common to these approaches is the desire to help the end user recreate and apply knowledge through efficient cognitive experience in a quasi-automated manner. Such systems could potentially accomplish every task required for KM without involving the activity of any employee apart from the learning and input tasks, which would imply a 24/7 centralized knowledge availability, learning opportunities [47], and knowledgeable people’s agenda lightening.

3.3. Knowledge Management for Sustainability

The notion of decarbonization in knowledge management introduced at the beginning of the article belongs to a broader KM field, with its application being for sustainability purposes.

The interest in the development of KM technologies and concepts contributing to the sustainability enhancement of firms is arousing increasing interest in researching fields [14]. As previously mentioned (Section 2.2), sustainability is a field that essentially involves innovation since this topic is rather new to the industry. This new knowledge can come from inside a given firm, on any granularity levels, or from the outside, brought by external actors, creating a huge flow of knowledge that needs to be managed properly. Collection and dissemination of sustainability-related knowledge in firms is essentially performed via human interactions and the application of environmental-specific KM frameworks. The usage of platforms such as social media [48,49,50] and the development of a “knowledge sharing culture” [51] allows any employee to be part of the environmental transition process. This participates in the spreading of innovative ideas, boosting firms’ innovation performance [52,53,54]. However, a lack of action research methodology was outlined [55] in the field of KM applied to sustainability. By definition, action research consists of the suggestion of a solution to a concrete problem and the evaluation of the results of its implementation. Therefore, this implies the existence of clear research opportunities involving the design of KM tools dedicated to sustainability with a particular emphasis on data approaches [14].

Digital KM represents a mostly interesting tool for firms since it allows firms to create, collect, stock, retrieve, transfer, and apply knowledge whenever needed with minimal human intervention. It also involves the usage of data, which represents an ideal tool to follow plant energy performances in real time, justifying their digitalization and concepts such as Industry 3.0, 4.0. Despite lacking the versatility, intelligence, and intuitiveness of human interaction and communication [46], KMS could become a relevant tool for automotive industries to overcome the constraints related to human-based KM approaches that still are, to this day, time- and resource-consuming despite the great digital development.

This technology could answer the need for the automotive industry to efficiently implement decarbonization SIPs on each of their plants, since it would centralize the data, making them available 24/7 for any employee, and use the data to help them evaluate their transferability. However, no clear definition of the concept underlying plant decarbonization exists in the literature despite being one of the key elements to consider for any company willing to achieve its environmental transition. In addition, the design of such tools is rare and missing.

In a nutshell, after specifying the issues related to automotive plant decarbonization, thanks to Stellantis feedback, the research gap concerning the application of KMS for decarbonization purposes was found. The paper will now focus on the concept of decarbonization measure (DM) in order to create a data model which will be the foundation of a KMS that would help automotive companies deal with their KM issues. This will provide content matching the research gap since it will suggest an IT approach for KM applied to sustainability with an emphasis on decarbonization of automotive plants. A case study in Stellantis will then help analyze this system’s relevancy and find some methods for improvement.

4. Decarbonization Measure (DM) Concept Definition and Application

4.1. Decarbonization Measure (DM) Definition

This part will help define DMs in a detailed way in order to structure a data model that will allow their understanding, structured energy data storage, and easy data retrieval. This data model will represent the backbone of the KMS that is thought to be a relevant solution that will answer the problematic brought up. For this model to be designed, a clear definition of the concept of DM should be established, and will be suggested in this article. A DM is an action taken by a plant that has the main purpose of reducing CO2 emissions related to this plant’s activity. In other terms, DMs are SIPs with a particular focus on decarbonization. This action consists of the implementation of a technology or a practice inside the considered plant to meet the positive environmental impact desired by the automotive group. A DM can be considered as an industrial project, having implementation costs and generating benefits depending on its performance. Finally, a DM is defined by its scalability, representing its potential to be implemented in other plants than the one that implemented it first (pilot plant).

Therefore, a DM can be approached as a union of three distinct entities: the solution deployed, the context of energy consumption, and the specific plant. The goal of the following study will be to dig deeper in the understanding of these three entities in order to establish the desired DM data model.

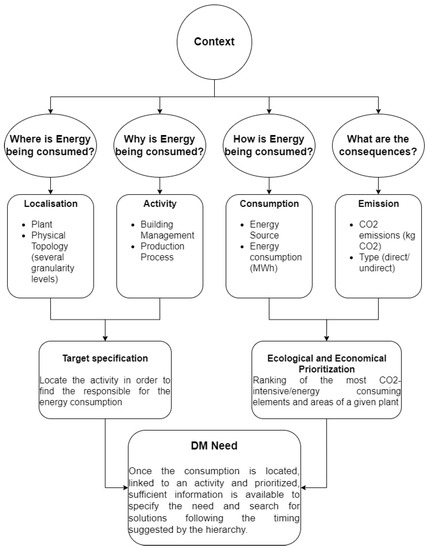

4.2. Context Modeling

Context is key to understand what the elements that justify the needs for a solution implementation are. Context can only come from the understanding of the energy consumption inside a plant and requires the following (see Figure 5):

Figure 5.

DM context breakdown.

- Localization: “Where is the energy consumed?” Answering this question with precision and accuracy will involve linking energy consumption to elements of a plant’s physical topology, which is, in this context, a slicing of the plant in subparts on several granularity levels (from macro areas to smaller areas). Even though all areas cannot be divided into the same number of slices, the ideal slicing would involve its last level made from machines/tools. According to Giampieri et al. [56], in APPs, paint shops are, for example, the most energy-consuming shops among all the other shops. Then, by digging deeper, we found out that the most energy-consuming devices inside this shop are the ovens and the paint booths, which makes them a primary target for decarbonization.

- Activity: “What is the reason for the consumption of energy?” According to the work of Oh and Hildreth [57], a panel of intrinsically different activities are accomplished in a vehicle plant. These tasks can, however, be grouped in two main categories: the production process activities and the building management activities. The first contains activities that are directly involved in the production process, designed to contribute directly to the value added to the car. As mentioned earlier (Section 2.2), these could differ from a plant to another. The second contains all the activities that are made to ensure that the production process is carried out in proper conditions, such as comfort heating/cooling, ventilation, air quality management, lighting, energy supply, nonproduction time management, etc.

- Consumption: “What is the consumption needed for to the considered activity?” Besides the energy consumption measured in Wh, the energy source as well as the energy supply cost also are truly important to consider. There are two main energy sources consumed in APPs: fuel and electricity in a quasi-50–50 proportion [56].

- Emission: “What are the environmental consequences of the energy consumption considered?” In this case, CO2 KPIs are the main answer to this question. The consumption of fuel is the only thing responsible for onsite CO2 emission because of its use for combustion purposes, and the amount of CO2 rejected can easily be calculated by APPs thanks to the knowledge related to the chemical reactions involved. Electricity is not related to any onsite CO2 emission, but its production has a specific carbon footprint, which automotive companies are officially financially responsible for. This carbon footprint (kg CO2/MWh) is provided by the energy suppliers. Finally, the actual and dramatic fuel and gas cost increase pushes plants hard to focus on the energy source and its potential replacement.

The first conclusion that can be deduced from this breakdown is that the four elements that were brought up (localization, activity, consumption, and emission) will help employees precisely understand the reasons behind the expression of decarbonization needs via energy consumption and generated emissions data. Activity and localization data will provide the information needed to specify the agent responsible for such consequences. An agent would here be defined as a machine or area performing a specific activity consuming energy leading to CO2 emissions.

However what needs to be highlighted is the fact that each DM implementation comes at a cost for the company. In the case of automotive companies, each plant has a yearly budget given by the corporation that is supposed to cover all its needs (energy supply, maintenance, etc.) and improvements including DM implementation, yet the amount of money available is finite, and not every R&D project can be subsidized. The reasoning can be taken further by considering the human resources needed to study and follow projects and implementations, not to mention the non-decarbonization-related tasks that they already possess in their agenda. The social repercussion of the emissions generated by plant activities are also to be considered, since the brand image and stakeholders’ pressure have a huge impact on companies’ policy.

All in all, a prioritization of DM contexts is mandatory for plants to implement them.

According to the three spheres of sustainable development, three prioritization axes can be considered:

- Environmental concerns: When it comes to DM, this would mainly consist of reducing the quantity of CO2 generated directly (in-plant combustion) or indirectly (energy supplier carbon footprint) by APP activity. Aiming for the implementation of DMs tackling the most CO2-emitting activities in a plant will reduce the cost generated by CO2 quotas and ensure the alignment of the stakeholders’ requirements, therefore representing a mid/long-term investment and profitability. It is also essential to obtain a broader view of the environmental impacts in order to prevent burden shifting or rebound effects.

- Financial aspects: Considering the budget, human limits, and the fact that an automotive company is a profit-making organization, targeting the most onerous systems and devices of a plant is a relevant policy. As opposed to the first one, this axis implies short-term investment and quick profitability.

- Social concerns: For an automotive company to ensure the quality of its image and the quality of its relationship with the different stakeholders, it should prioritize the aspects of its plants that are the most controversial. The social impact of DMs is not to be neglected, as they will contribute to a sustainable industry and to stakeholders’ satisfaction of being part of this eco-responsible project.

These axes all lead to DM generation. However, the environmental approach should ethically stand as a priority since it holds the greatest potential to answer the global environmental issues. What becomes clear is that the consumption/emission information will serve context hierarchization.

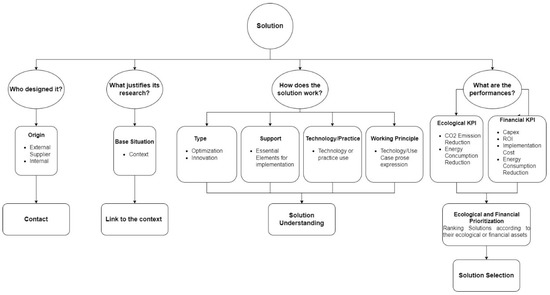

4.3. Solution Modeling

An APP context can be interpreted as the description of an initial situation that embodies the needs of decarbonization, and a DM solution is provided in order to environmentally improve this situation into a new and more viable one. This would be the logical link between a DM context and its solution. To incorporate the notion of solution inside the knowledge modeling data model, different characteristics should be considered (see Figure 6):

Figure 6.

Solution breakdown framework.

- Origin: decarbonization projects could be fully designed by the company or using an expertise/a technology coming from outside the company. In the case of an internal solution, it usually concerns local improvements/innovation in the production process, representing the main domain of expertise of the company. Nevertheless, automotive companies have the potential to suggest initiatives and design systems that are not part of their initial expertise as soon as they have collected a sufficient amount of knowledge required to do so, which is highly possible in automotive companies. However, they do not have sufficient resources to produce every single approach by themselves; therefore, help from suppliers is usually needed. Implementing these external products is usually more difficult because, opposite to internal solutions, it is hard to evaluate and estimate their performances before implementing them. Tests can be carried out in pilot plants, which are plants volunteering to help these external suppliers implement their product in order to evaluate its performance for further implementation, but this initiative is not always fruitful considering the differences between plants.

- Type: Two types of solutions are suggested in this study, the first one is the optimization solutions. They consist of decarbonating while conserving the systems/structures/machines/processes involved in the activity they are used for. Digital devices that could help optimize energy performances are also considered as optimization although they can imply the deployment of new equipment (e.g., IoT, cloud systems, etc.). The second type of solutions involves projects that imply the addition of new machines/tools in the plant or the redesign of a system/process: there is a breakthrough in the production process or the product to manufacture or the plant organization.

- Support: This covers the elements (regardless of their nature) that are essential for the solution to be deployed. It contains the critical feasibility parameters of a DM. These parameters do not necessarily share the same criticality. Let us consider two examples to illustrate this. For the first example, let us consider a solution that involves data science to monitor comfort heating inside facilities. In this case, critical parameters are data (therefore sensors) and a computerized heating system that would allow temperature setpoint changing. If data are not there, there will always be the possibility for the plant to install sensors: it is not prohibitive. For the second example, let us consider the installation of photovoltaic panels on the site to help reach energy autonomy. In that case, critical parameters are insulation and free surface. If the area is proven not to be insulated enough to generate the amount of energy required, the solution should be dropped, and is prohibitive. Each solution appears to come with its own set of requirements.

- Principle: A solution principle consists of describing the use case of a technology or a practice and is essential to understand how the solution will contribute to the decarbonization on a daily basis. While all the different characteristics brought up so far could be defined by a couple of words or figures, this principle is ideally expressed via prose text that is supposed to “tell the story” behind the usage of the technology/practice, as declared by Colette and Ben Achour [58].

- Performance: Information regarding the solution implementation cost, duration (factual or estimation), and environmental and financial impact.

For reasons that are similar to the ones explained earlier (Section 4.2), solutions shall also be ranked and prioritized in order to allow APPs to choose among them. In fact, the rising pressure that is placed on the automotive companies’ shoulders to decarbonate their plants will most likely generate an augmentation of DM creation in the following years, which means that plants should choose between different DMs that answer the same needs, suggesting different approaches, and establish an action plan that relies on the evaluation of the most relevant DMs to implement, given a certain budget.

Therefore, solution performance shall be analyzed according to the three points of view: environmental, financial, and social. Environmental performance should be, at least, evaluated through the amount of CO2 emission reduction (in-plant and off-plant) and energy consumption reduction, whereas financial performance can be measured through KPIs such as Capex, Opex, return on investment (ROI), autonomy (proportion of energy that can be produced by a plant thanks to a DM compared to a plant’s energy needs), implementation cost, etc. The social impact of a solution is hard, and as a first attempt, the satisfaction of both the company employees and the product users will be monitored. By contributing to the decarbonization of plants, these solutions will generate a positive impact on the environment by lowering the impact of vehicle production on global warming and its consequences. It will also help end users satisfy their moving needs with cars that are not only low-GHG emitting, but also produced in a more sustainable way. In the end, stakeholders’ environmental requirements will be progressively met.

4.4. Plant Characteristics

The solution provided to answer the decarbonization needs related to a context takes place in a plant having its own set of characteristics. Automotive plants are, in most cases, old and not standardized. APPs are different from one another in many different ways:

- Plants location, age, and buildings: Automotive plants do not share the same design even though they more or less have the same purpose. The facilities and their components are different, and so are their age and weather conditions, which implies, for example, the fact that plants’ thermic conditions and models are unique.

- Plants production process: Three different types of plants exist. Foundry plants are plants that are dedicated to the production of separate pieces that compose the car, powertrain plants are plants that take care of the production of the automotive parts that are responsible for its ability to move, and vehicle manufacturing plants are plants that essentially assemble the different parts of the car, paint it, and test it before it is placed on the market. Considering this categorization, it comes clear that major process differences exist between APP types. However, the reality is more complex since APPs belonging to the same type may have different methods of accomplishing the same tasks, which represents a smaller yet important potential difference.

- Production volume: APPs do not produce the same number of cars; there are definitely bigger and smaller producers, which implies, for example, the fact that the energy needs and the plant size could highly differ.

- Digitalization: Plants’ digitalization mainly consists of this context of the installation of Internet of Things (IoT) sensors and meters that provide reliable energy consumption data to a dedicated and exploitable database. Digitalization process is ongoing in APPs, and what is sure is that APPs’ status on this is quite heterogeneous, which means that there are, on the one hand, plants that are quite advanced on this topic having multiple sensors implemented, and, on the other hand, plants that have just started to work on this subject.

- Regulatory context: Norms and regulations that define the rules to respect in industrial production may vary from one country/region to another, which could potentially imply the regulatory scalability of DMs.

These are some examples of the plant characteristics that can be considered in order to compare plants. These pieces of information can also find their utility in the existence of the support needed for solution implementation in the considered plant.

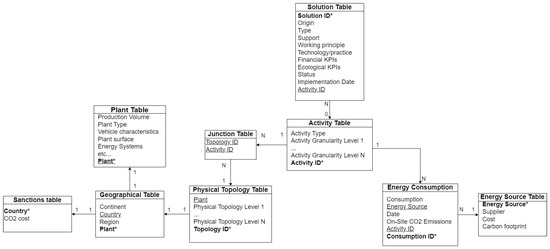

5. Data Model

5.1. Model Presentation

The understanding and breakdown of both DM context and solutions allowed the conception of the data model shown in Figure 7. This data model is meant to unite in one concept all the data and information required to understand DMs and study their plant-to-plant transferability. It will serve the purpose of creating a structured database (DB) that will allow the collection, centralization, and retrieval of data related to DMs. This DB could then be used for the design of a specific KMS that would use these data for the study of DM transferability and application. The design of this model fully relies on the DM context and solutions analysis performed in part 4 and aims to logically link all their subelements with each other. This structure will allow any user to clearly understand the decarbonization needs and solutions of any given plant.

Figure 7.

DM data model.

Energy consumption input data have the potential to be delivered automatically from the plants thanks to their sensors and energy meters in case their digitalization is sufficient. Plant structure, location, activities, and available solutions will have to be humanly handled.

This model can be divided into two parts: the bottom (all tables except for solution table) part will help define the context justifying the needs for a solution and the upper part will stock the solution concepts and key information of DMs that are implemented or to be implemented.

Primary keys are written in bold characters with a star (*), and external keys are underlined.

5.2. Tables’ Content

This data model is made from eight main tables:

- Activity table: This is meant to bring up all the activities performed in a plant that could trigger decarbonization opportunities; it is made from three principal types of features:

- ○

- Activity type: Could be whether building management or process management.

- ○

- Activity granularity level 1 to N: These features have to split each of the building management or process management activities through different levels of granularity (Appendix A). As an example, painting a car is a process made from different subprocesses, which could also be divided into further subprocesses, and so forth. The number of granularity levels, N, is to be defined, and the number of levels is likely to differ from a process to another.

- ○

- ID: Unique ID for each activity.

- Physical topology table: This is meant to progressively divide a plant into progressively smaller parts until the machine/tools scale, and it is made from four principal features (Appendix A):

- ○

- Plant: Unique plant ID.

- ○

- Physical topology level 1 to N: Each feature represents a granularity level and contains the considered element/area (see Appendix B). The number of granularity levels is not consistent from an area to another.

- ○

- ID: Unique ID for each area/tool.

- Geographical table: Contains information that is required to locate a plant.

- Plant table: Many different variables can be considered to compare plants, such as plant types, plant surfaces, production volumes, heat degree days, working days, the number of shifts, characteristics of the vehicles produced, HVAC system characteristics, energy systems, etc. However, the goal would be to select the ones that are key to implement DMs, and this will occur through the analysis of the support of each DM. The exact content of this table is yet to be adapted and will surely keep on evolving through the years as new solutions provided with new support will emerge.

- Sanctions table: A table that is meant to contain the information required for taxes and sanctions financial impact calculation. In that case, it contains, per country, the price of a CO2 ton, but other kinds of sanctions could be considered in the future.

- Energy Consumption table: Aims to associate each activity with the amount of energy consumed, the type of energy consumed, and the onsite emissions related to this consumption. This table will play the role of energy consumption history, retrieving the consumption every X minutes, hours, or days, depending on the plants’ needs.

- Energy Source table: Aims to link each energy source with its supplier and provide the offsite carbon footprint generated by energy suppliers.

- Solution table: Contains all the elements that are relevant to describe and classify solutions as explained in the previous part, and the status column in order to know whether the solution is implemented or not.

5.3. Relationships among Tables

The following aspects will justify the relationships among the tables shown in Figure 7:

- Relationships involving the activity table and:

- ○

- Location table: In one single area, multiple activities (e.g., in a shop, building management, and process activities) can be performed, and one activity can be performed in multiple areas (e.g., heating). An n–n relationship exists between these tables, which justifies the creation of the junction table between them, dividing one n–n into two 1–n relationships.

- ○

- Solution table: CO2 emissions caused by an activity can be reduced by the implementation of one or many different solutions. However, one solution is specifically designed for a given activity. In addition, one activity could be lacking a solution, justifying the 0–n relationship between these tables.

- ○

- Energy consumption table: One activity can correspond to one or more consumptions defined mainly by the energy source consumed and its timing. For example, painting a car involves roughly two types of consumption: electricity (production line) and fuel consumption (ovens).

- Relationships involving the energy consumption table and:

- ○

- Energy source table: Each consumption is here considered using one unique energy source, in order to allow a consumption breakdown. In that case, the relationship is 1–1.

- Relationships involving the physical topology table and:

- ○

- Geographical table: the physical topology is linked to a plant, having a unique geographical location: 1–1 relationship.

- Relationships involving the geographical table and:

- ○

- Sanctions table: Each country/region has its own set of rules that potentially generates financial sanctions: 1–1 relationship,

- ○

- Plant table: Each plant is unique and has its own set of characteristics, implying a 1–1 relationship.

5.4. Model Dynamic and Maintenance

DM implementation will generate changes in APPs’ industrial activity. First of all, it could modify the amount and the type of energy consumed by a specific production area (energy consumption and source tables). Second of all, APPs’ physical topology and characteristics (plant and physical topology tables) could be changed depending on DM support: new machines/systems/processes could be deployed and replace the existing ones. This could also result in the replacement or addition of activities performed in the considered area (activity table). Sanctions and regulations surrounding the context of APP production are also likely to evolve.

What becomes clear is the fact that this model is not frozen in time. On the contrary, these tables are meant to be updated frequently for it to keep up with the consequences that decarbonization has on APPs.

6. Case Study for the Construction of the Proposed Model

The suggested data model is the core of the KMS that aims to give a concrete solution to the decarbonization issues met by automotive companies. A concrete application is needed to test this model and verify its relevance. The Stellantis company, partner of this work, will therefore be the basis for a case study.

6.1. Stellantis Case Presentation

Stellantis is one of the world leaders in the automotive market, possessing more than 100 automotive production plants (APPs) dispatched on five different continents. This company’s situation in terms of KM application for sustainability has the same issues as the ones specified earlier (Section 2.2 and Section 2.3) in a general case.

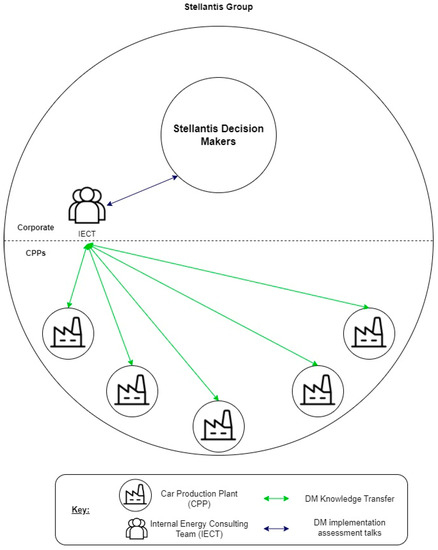

6.1.1. DM Implementation and Actors

Similarly to the policies introduced at the beginning of the article, Stellantis aims to implement DMs in its APPs to meet the stakeholders’ requirements.

Three main entities are responsible for the creation and implementation of DMs (see Figure 8 below):

Figure 8.

Stellantis knowledge management organization for DMs.

- The first entity is the energy team: each plant from the Stellantis group has its own energy team. Lead by an energy manager (EM), its purpose consists of reporting, monitoring, and optimizing their plant’s energy consumption. These tasks are complex and hardly achievable by the EM alone, considering APPs complexity. The EM relies on his team members that are usually specialized in the energy analysis of specific areas. In the context of decarbonization, this team serves many purposes. First, energy team members have to look for DM needs inside their plant and suggest DMs to Stellantis Corporate for approval. The other way around is also possible: Corporate may come with DM suggestions, and it is up to them to analyze their feasibility and relevancy inside their plant. Second, they have to follow DM implementation. Third, they have to measure the results after deployment. Finally, they need to constantly check for new legislation in order to evaluate the new norms and their impact on DM feasibility assessment. This team’s knowledge and the range of its action are local, strictly limited to the plant they work in.

- The second entity is the Internal Energy Consulting Team (IECT), which is part of Stellantis Corporate. IECT’s main role is to help APPs deploy DMs, which consists of two different tasks. The first task is to learn from the completed or ongoing DM implementations in pilot plants and to spread the related knowledge to other plants in need of decarbonization. This team can also suggest the usage of technologies and practices that are not yet available in the group since they are constantly in contact with external suppliers.

The second task is to gather sufficient data related to financial and financial aspects of DM concepts to share them with the third entity: the corporate decision makers. They are the ones in charge to study the relevancy of DMs and to give, or not, the go-ahead for implementation.

Despite being part of the corporate, the IECT is the closest corporate entity to APPs (justifying their proximity to the APP/corporate frontier in Figure 8).

6.1.2. DM Implementation Challenges

In addition to the policy drawbacks highlighted in Section 2, the Stellantis case analysis adds some more details to them. In fact, one of the major drawbacks lies behind the organizational aspect of APPs industrial activity. In Stellantis, APPs of the same type are defined as mutually independent, meaning that the production of one plant does not have any influence on the production of other plants belonging to the same type. Furthermore, each plant is provided with its own budget and takes care of its own issues, and never intervenes in other plants’ projects. Direct plant-to-plant communication is almost nonexistent, and this phenomenon could be explained by other causes than a simple lack of interplant interest. According to the feedback from energy mangers, fulfilling the tasks related to their plant which they have to take care of in priority is already challenging and difficult enough. A clear lack of time to spend on learning from other plants has been expressed.

The rare opportunities where plants directly communicate with each other are meetings scheduled by the IECT in order to share the ideas and best practices emerging from DM projects. However, these communications are not sufficient to answer the complex problem of DM implementation and knowledge transfer. In fact, memorizing every single key aspect of the 100+ plants dispatched all around the world and confronting them with the huge quantity of DMs suggested by potentially each one of them is humanly impossible. Suggesting DMs to a specific and unique context is a complex task that implies the consideration of several elements that will be explained later in this article.

A clear conclusion to the different arguments stated is the fact that the IECT seems to be theoretically and logically overwhelmed by the amount of work they have to provide, and the complexity of their task.

It is important to mention that communication between IECT and plants could be sometimes difficult, because of the fact that IECT is part of the corporate and is not directly implied in the activity of APPs. As IECTs are somewhat external to every plant, they are not considered by plants as the ideal means to carry out their priorities. A sort of schism exists between these entities, making both of their jobs more difficult, not to mention the urgent decarbonization.

6.2. How the Data Model Would Be Tested on Stellantis and How DM Implementation Would Be Monitored

6.2.1. Data Model Usefulness for Users

The data model designed represents the core of an interplant, centralized, and unique information system that would serve the purpose of optimizing the decarbonization-related knowledge sharing between APPs. In the case of Stellantis, this tool would help three different actors: Ems (energy managers), IEC (the internal energy consultant), and decision makers.

From an EM point of view, this information system would be helpful at two scales: intraplant and interplant. Concerning the intraplant usefulness, this tool would help Ems analyze their plants’ structured energy consumption data on a centralized tool, producing standardized reports. It would also allow them to measure the impact (mainly environmental and financial) of their plant’s activity on different granularity levels and prioritize the decarbonization targets following their interpretation of the results provided. This would also serve the purpose of conserving and sharing the DM-related knowledge they have produced in their APP.

Concerning the interplant objective, this information system would represent a platform of DM data sharing between plants. EMs are struggling to find time considering the DMs implemented in other APPs. In fact, DMs are numerous, belonging to a unique context and potentially not scalable to other plants. Thanks to this tool, EMs will be able to filter DMs by selecting a specific area, activity, or energy source, reducing the number of DMs they have to deal with. The fact that these pieces of information are available all the time and are constantly updated will help plants indirectly communicate with each other, since the analysis of a DM is related to each plant situation. The differences between factories will never change; however, this tool will allow similarities to be found between them and simplification of their description in a unified form.

From the IECT department point of view, this tool would simplify its IEC’s task regarding plant decarbonization assistance as the plant EMs would have a better understanding and overview of DMs implemented in the group. Centralized energy consumption data and related impacts would also help them understand the context of plants they are assisting without having to ask them directly, which would help deal with the IEC–plants communication issues. They will also be able to track APPs energy performance evolution and compare them to the fixed objectives. The DM database will also provide them a solid and centralized data source to understand, analyze, and suggest DMs to plants, and ultimately work with them on structured plant-scale decarbonization plans (DM implementation through time considering environmental, financial, and social factors).

Considering the effects of the information system’s application on both EMs and IECs, strong foundations are built to help DM transferability assessment.

From the decision makers’ perspective, the implementation of this tool would contribute to reliable, constant, and robust plant energy performance analysis, but also the input of data that would help them build group-scale decarbonization plants.

6.2.2. Information System Requirements

In order to harness this data model to its full potential, important requirements must be respected. To begin with, this tool needs to be centralized to all the production plants. This implies the necessity for this tool to be connected, but also the need for an interplant consensus. In fact, physical topology and activities of plants belonging to the same sector will certainly differ after reaching a certain topology level, which is not compromising the interplant comparison unless the first physical topology levels are not the same. A common model shall therefore be created by the plants to make the data model consistent.

Moreover, DM implementations will generate some changes to the activities and the physical topology of a given plant, installing somewhat of a dynamic that needs to be kept up with. The data model therefore needs to be updated as soon as a change in these domains is implied, and the same applies to the cost of energy sources and the sanctions related to CO2 emissions, which are constantly varying. The creation of new solutions will also require some new support that will need to appear both in the solution table and linked to a plant characteristic.

6.2.3. Information System Limits and Open Points

Although the information system based on the suggested data model is able to answer some questions related to the transferability study of DMs, it does not answer all of them, and represents a solution that needs to be completed.

This system would never be able to confirm with absolute certainty the physical feasibility of a DM on a given plant, despite the support and plant information data present in the database. This aspect of feasibility is likely to be handled by humans, unless a plant-aware intelligence is produced.

Despite being able to provide context and solution rankings that will allow evaluation of the relevancy of DMs in terms of environmental concerns or finance, this tool is not yet able to evaluate their social impact, which would be essential considering the pressure coming from stakeholders. Furthermore, this system is not able to provide indicators mixing all three impact factors (financial, environmental, and social), which would be ideal to evaluate DMs between each other.

The system would provide functionalities that would allow its user to filter DMs thanks to the data model; however, this feature is not entirely sufficient for EMs and IECs to know which DM could fit their needs. Some kind of “intelligence” shall be developed to suggest DMs to plants following their energy consumption and environmental data.

Suggesting entire decarbonization action plans would also be a must for each of the three actors mentioned earlier (Section 6.1.1). This would suggest a series of DM implementation for each plant on a large timescale, and not consider DMs one by one.

The proposal of a concrete action plan with limited budget consideration on a plant scale and on a group scale is mandatory to validate the financial feasibility of DMs, which is yet to be dealt with.

In conclusion, this data model will represent the structure upon which further studies should be carried out in order to achieve cross-site DM transferability evaluation.

7. Conclusions

This article introduced the concept of a knowledge management system aiming to help the automotive industry find ways to accelerate the decarbonization of their car production plants by collecting, processing, and sharing site information. After automotive decarbonization context and policy understanding [1,2,3,4,7,8], this article studied the feasibility of this transition through EM and IECT feedback. Four challenges for decarbonization were assessed, the main one being overcoming the lack of communication between plants, making DMs systematically local. Locality of DMs represent missed opportunities to spread knowledge to a maximum of plants and potentially accelerate the decarbonization process of APPs. These observations led to the conclusion that further investigations on DM knowledge management in the automotive industry should be carried out in order to help automotive groups reach their environmental goals more efficiently.

A lack of knowledge sharing was assessed, and finding a way to improve this knowledge management situation, both on an organizational and a technical way, was thought to be an interesting opportunity to accelerate decarbonization. Research of the literature in the field of knowledge management led to the conclusion that knowledge management systems would be the best-suited technology to address this issue [13,42,55], since it would answer automotive companies’ needs without overloading their already highly requested knowledgeable employees. Since knowledge could only be recreated under the transfer of explicit information and data, knowledge management systems were considered to be a special kind of information system, specifically designed for the learning and knowledge recreation process of the end users [25,31]. A data model was then designed to provide the core of the information system that would contribute to decarbonization acceleration. This model relies on the concept of decarbonization measure, and provides structured data that would help any end user understand the context of each DM and evaluate its performances (both financial and environmental). Although the implementation of such a system in automotive companies such as Stellantis would help them in their decarbonization duty, the features suggested by it are not sufficient: some further “layers” should be added to this information system to intelligently and efficiently guide its users that would have lots of information to process. Some further work shall be carried out on the automated assessment of DM transferability and relevancy considering plant characteristics and financial resources to help end users deal with a database that is already large and will keep increasing in the following years as the deadline approaches. Further concrete investigation shall also be performed with energy managers in order to specify the different uses cases surrounding the usage of the KMS. Since the decarbonization of plants essentially relies on their work and input, designing the features of the platforms according to their expectations and needs is mandatory to provide solid, reliable, and relevant content to all parties.

Author Contributions

S.A.S.: Conceptualization, formal analysis, writing—original draft preparation. D.B.: Visualization, writing—reviewing and editing, supervision. D.E.: Visualization, writing—reviewing and editing, supervision. D.F.: Supervision. D.D.l.F.: Writing—reviewing and supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This work is part of a French public-funded CIFRE Ph.D. held by the ANRT (n° 2021/1400) involving Stellantis and the Grenoble Alpes University.

Data Availability Statement

Restrictions apply to the availability of these data. Data was obtained from Stellantis and are available from the authors Dominik FLICK and Damien De la FONTAINE with the permission of Stellantis.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Activity Table.

Table A1.

Activity Table.

| Activity Table | ||||||

|---|---|---|---|---|---|---|

| Activity Type | Plant Type | Activity Granularity Level 1 | Activity Granularity Level 2 | Activity Granularity Level 3 | Activity Granularity Level 4 | ID |

| Building Management | All | Comfort Heating | Power Up | #### | ||

| Building Management | All | Comfort Heating | Regulation | #### | ||

| Building Management | All | Comfort Heating | Power Down | #### | ||

| Building Management | All | Comfort Cooling | Power Up | #### | ||

| Building Management | All | Comfort Cooling | Regulation | #### | ||

| Building Management | All | Comfort Cooling | Power Down | #### | ||

| Building Management | All | Ventilation | #### | |||

| Building Management | All | Air Quality Management | #### | |||

| Building Management | All | Energy Supply | #### | |||

| Building Management | All | Lighting | #### | |||

| Process Management | VM | Painting | #### | |||

| Process Management | VM | Welding | #### | |||

| Process Management | VM | Stamping | #### | |||

| Process Management | VM | Assembling | #### | |||

| Process Management | VM | Testing | #### | |||

| Process Management | VM | Painting | Pretreatment | #### | ||

| Process Management | VM | Painting | Electrocoating | #### | ||

| Process Management | VM | Painting | Sealing and underbody coating | #### | ||

| Process Management | VM | Painting | Primer | #### | ||

| Process Management | VM | Painting | Top Coat | #### | ||

| Process Management | VM | Painting | Finalization | #### | ||

| Process Management | VM | Painting | Pretreatment | Washing | #### | |

| Process Management | VM | Painting | Pretreatment | Activation | #### | |

| Process Management | VM | Painting | Pretreatment | Phosphating | #### | |

| Process Management | VM | Painting | Pretreatment | Final Rinsing | #### | |

Appendix B

Table A2.

Physical Topology Table.

Table A2.

Physical Topology Table.

| Physical Topology Table | |||||

|---|---|---|---|---|---|

| Plant | Physical Topology Level 1 | Physical Topology Level 2 | Physical Topology Level 3 | Physical Topology Level 4 | ID |

| Plant X | Paint Shop | #### | |||

| Plant X | Paint Shop | Paint Shop Area 1 | #### | ||

| Plant X | Paint Shop | Paint Shop Area 2 | #### | ||

| Plant X | Paint Shop | Paint Shop Area 3 | #### | ||

| Plant X | Paint Shop | Paint Shop Area 4 | #### | ||

| Plant X | Paint Shop | Paint Shop Area 1 | Paint Shop Subarea 1 | #### | |

| Plant X | Paint Shop | Paint Shop Area 1 | Paint Shop Subarea 2 | #### | |

| Plant X | Paint Shop | Paint Shop Area 1 | Paint Shop Subarea 3 | #### | |

| Plant X | Paint Shop | Paint Shop Area 1 | Paint Shop Subarea 4 | #### | |

| Plant X | Paint Shop | Paint Shop Area 1 | Paint Shop Subarea 5 | #### | |

| Plant X | Paint Shop | Paint Shop Area 1 | Paint Shop Subarea 6 | #### | |

| Plant X | Paint Shop | Paint Shop Area 1 | Paint Shop Subarea 7 | #### | |

| Plant X | Paint Shop | Paint Shop Area 1 | Paint Shop Subarea 8 | #### | |

| Plant X | Paint Shop | Paint Shop Area 1 | Paint Shop Subarea 1 | Oven | #### |

| Plant X | Paint Shop | Paint Shop Area 1 | Paint Shop Subarea 1 | Cataphoresis Cuve | #### |

References

- Rockström, J.; Gaffney, O.; Rogelj, J.; Meinshausen, M.; Nakicenovic, N.; Schellnhuber, H.J. A roadmap for rapid decarbonization. Science 2017, 355, 1269–1271. [Google Scholar] [CrossRef]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; De Vries, W.; De Wit, C.A.; et al. Planetary boundaries: Guiding human development on a changing planet. Science 2015, 347, 1259855. [Google Scholar] [CrossRef]

- IPCC. AR5 Climate Change 2014: Mitigation of Climate Change—IPCC. Available online: https://www.ipcc.ch/report/ar5/wg3/ (accessed on 5 June 2023).

- European Commission. Development of EU ETS (2005–2020). Available online: https://climate.ec.europa.eu/eu-action/eu-emissions-trading-system-eu-ets/development-eu-ets-2005-2020_en (accessed on 5 June 2023).

- Chen, J.; Jia, J.; Wang, L.; Zhong, C.; Wu, B. Carbon Reduction Countermeasure from a System Perspective for the Electricity Sector of Yangtze River Delta (China) by an Extended Logarithmic Mean Divisia Index (LMDI). Systems 2023, 11, 117. [Google Scholar] [CrossRef]

- Zheng, S.; Jin, S. Can Companies Reduce Carbon Emission Intensity to Enhance Sustainability? Systems 2023, 11, 249. [Google Scholar] [CrossRef]

- IPCC. Summary for Policymakers of IPCC Special Report on Global Warming of 1.5 °C Approved by Governments; IPCC: Geneva, Switzerland, 2018.

- Fong, W.K.; et Michael, D. (C40). Global Protocol for Community-Scale Greenhouse Gas Emission Inventories, 12 août 2014. Available online: https://www.wri.org/research/global-protocol-community-scale-greenhouse-gas-emission-inventories (accessed on 5 June 2023).

- Despeisse, M.; Ball, P.D.; Evans, S.; Levers, A. Industrial ecology at factory level—A conceptual model. J. Clean. Prod. 2012, 31, 30–39. [Google Scholar] [CrossRef]

- Ryu, C.; Do, S. A Method for Managing Software Assets in the Automotive Industry (Focusing on the Case of Hyundai Motor Company and Parts Makers). Appl. Sci. 2023, 13, 4174. [Google Scholar] [CrossRef]

- Rocchi, V.; Brissaud, D.; Steinwender, A.; Bocquillon, A. Technological and Organizational Factors to Succeed in Industry 4.0 Transition Implementation: An Empirical Study. Int. J. Manuf. Technol. Manag. 2023; In Press. Available online: https://hal.science/hal-04106417 (accessed on 5 June 2023).

- Compan; Nathan, F.; Coutarel, D.; Brissaud, G. Les situations de collaboration capacitante (ECS): Intérêt pour l’analyse des collaborations humain-technologie de l’industrie contemporaine. In Le Travail Humain; Presses Universitaires de France: Paris, France, 2022; Volume 85, pp. 211–240. [Google Scholar]

- Liao, S.-H. Knowledge management technologies and applications—Literature review from 1995 to 2002. Expert Syst. Appl. 2003, 25, 155–164. [Google Scholar] [CrossRef]

- Chopra, M.; Saini, N.; Kumar, S.; Varma, A.; Mangla, S.K.; Lim, W.M. Past, present, and future of knowledge management for business sustainability. J. Clean. Prod. 2021, 328, 129592. [Google Scholar] [CrossRef]

- Boden, T.A.; Marland, G.; et Andres, R.J. Global, Regional, and National Fossil-Fuel CO2 Emissions (1751–2014); Environmental System Science Data Infrastructure for a Virtual Ecosystem (ESS-DIVE) (United States); Carbon Dioxide Information Analysis Center, Oak Ridge National Laboratory, U.S. Department of Energy: Oak Ridge, TN, USA, 2017. [CrossRef]

- IEA. CO2 Emissions in 2022; IEA: Paris, France, 2023. Available online: https://www.iea.org/reports/co2-emissions-in-2022 (accessed on 5 June 2023).

- Poschmann, J.; Bach, V.; Finkbeiner, M. Deriving decarbonization targets and pathways—A case study for the automotive industry. J. Clean. Prod. 2023, 409, 137256. [Google Scholar] [CrossRef]

- Adolfsen, J.F.; Kuik, F.; Lis, E.M.; Schuler, T. The Impact of the War in Ukraine on Euro Area Energy Markets. 2022. Available online: https://www.ecb.europa.eu/pub/economic-bulletin/focus/2022/html/ecb.ebbox202204_01~68ef3c3dc6.en.html (accessed on 29 August 2022).

- Shahzad, M.; Qu, Y.; Zafar, A.U.; Ding, X.; Rehman, S.U. Translating stakeholders’ pressure into environmental practices—The mediating role of knowledge management. J. Clean. Prod. 2020, 275, 124163. [Google Scholar] [CrossRef]

- Yu, W.; Ramanathan, R. An empirical examination of stakeholder pressures, green operations practices and environmental performance. Int. J. Prod. Res. 2015, 53, 6390–6407. [Google Scholar] [CrossRef]

- Gebler, M.; Cerdas, J.F.; Thiede, S.; Herrmann, C. Life cycle assessment of an automotive factory: Identifying challenges for the decarbonization of automotive production—A case study. J. Clean. Prod. 2020, 270, 122330. [Google Scholar] [CrossRef]

- Bonvoisin, J.; Thiede, S.; Brissaud, D.; Herrmann, C. An implemented framework to estimate manufacturing-related energy consumption in product design. Int. J. Comput. Integr. Manuf. 2013, 26, 866–880. [Google Scholar] [CrossRef]

- Evrard, D.; Brissaud, D.; Mathieux, F. Synergico: A method for systematic integration of energy efficiency into the design process of electr(on)ic equipment. Int. J. Sustain. Eng. 2013, 6, 225–238. [Google Scholar] [CrossRef]

- Keith, C. Making Local Knowledge Global. Harvard Business Review, 1 May 1996. Available online: https://hbr.org/1996/05/making-local-knowledge-global (accessed on 5 June 2023).

- Alavi, M.; Leidner, D.E. Knowledge Management and Knowledge Management Systems: Conceptual Foundations and Research Issues. MIS Q. 2001, 25, 107–136. [Google Scholar] [CrossRef]

- Hedlund, G. A model of knowledge management and the N-form corporation. Strat. Manag. J. 1994, 15, 73–90. [Google Scholar] [CrossRef]

- Dretske, F.I. Knowledge and the Flow of Information; MIT Press: Cambridge, MA, USA, 1981. [Google Scholar]