Abstract

Characterized by its resilience, connectivity, and real-time data processing capabilities, the fourth industrial revolution, referred to as Industry 4.0, is the main driver of today’s digital transformation. It is crucially important for manufacturing facilities to correctly identify the most suitable Industry 4.0 technologies that meet their operational schemes and production targets. Different technology selection frameworks were proposed to tackle this problem, several of which are complex, or require historic data from manufacturing facilities that might not always be available. The aim of this paper is to develop a novel Industry 4.0 selection framework that utilizes Fuzzy Analytical Hierarchy Process (FAHP) and Fuzzy Technique for Order of Preference by Similarity to Ideal Solution (FTOPSIS) to rank different Industry 4.0 technologies based on their economic, social, and environmental impact. The framework is also implemented on a real-life case study of a manufacturing firm to rank the different Industry 4.0 technologies required for its digital transformation based on their significance to the facility’s key performance indicators. The framework is utilized to select the top three Industry 4.0 technologies from a pool of eight technologies that are deemed important to the manufacturing firm. Results of the case study showed that Cyber-Physical Systems, Big Data analytics, and autonomous/industrial robots are the top three ranked technologies, having closeness coefficient scores of 0.964, 0.928, and 0.601, respectively. Moreover, the framework showed sensitivity towards weight changes. This is an advantage in the developed framework, since its main aim is to provide policymakers with a customized list of technologies based on their importance to the firm.

1. Introduction

Industries have been continuously determined to increase their production in an effort to meet fast-growing population demands, while maintaining minimum negative social and environmental impacts [1]. These ever-growing demands and different societal and environmental concerns have led to several industrial revolutions that began with the use of steam power for production mechanization, followed by the use of electric power for mass production, and information technology for the automation of production in the second and third industrial revolutions, respectively [2]. Currently, industries are shifting towards the fourth industrial revolution, named Industry 4.0. The term refers to the digitalization and automation of the industrial value chain using different Industry 4.0 technologies [3]. The main aim of incorporating these technologies into manufacturing firms is to achieve a resilient decentralized industrial value chain characterized by its automation, interconnectivity, productivity, and real-time data collection, integration, and processing capabilities [3,4,5,6]. Industry 4.0 technologies also showed promising contributions to the sustainability pillars, sustainable development goals, and different circular economy practices [4,7,8,9].

Several technologies have been linked to Industry 4.0. Originally, the term Industry 4.0 was introduced in Germany in 2011, referring to the use of Cyber-Physical Systems (CPSs) in industrial production systems [10]. In addition to CPSs, Industry 4.0 nowadays refers to several other technologies that include, but are not limited to, Cloud Computing, blockchain, Artificial Intelligence (AI) and machine learning, Big Data and analytics, cybersecurity, Digital Twin, Internet of Things (IoT), and additive manufacturing [11,12,13]. The unlimited capabilities and promising economic outcomes of these technologies are promoting their adoption and integration within manufacturing firms. Table 1 presents how the adoption of some of the most common Industry 4.0 technologies can help improve several industrial aspects, such as product design and modeling, production methodologies, raw material traceability, and product deliveries, enhancing the firm’s overall performance.

Table 1.

Selected Industry 4.0 technologies considered in the framework developed and their possible impact on manufacturing firms.

This work aims to propose an Industry 4.0 technology selection framework by utilizing some existing tools for manufacturing facilities. This framework aims to provide firms, especially small- and medium-sized enterprises (SMEs), with low-cost methods of determining the required Industry 4.0 technologies that would positively impact their industrial value chain and support its path towards digitalization. The framework also helps with the selection, collection, and preparation of the different key performance indicators that cover the production, environmental, economic, and social aspects associated with the manufacturing facility.

2. Literature Review

Currently, the literature addressing the development of an Industry 4.0 technology selection framework for manufacturing firms is limited. It is nonetheless worthwhile to consider the frameworks that are available. Firstly, Hamzeh et al. designed an Industry 4.0 technology selection framework for manufacturing firms which consists of six steps. The steps include an evaluation of the current situation, determining critical strategic factors for the implementation of Industry 4.0, planning the range/time horizon, identifying the manufacturing technology, evaluating the technology, and conducting risk assessment of technology alternatives [23]. Another study proposed an Industry 4.0 technology selection model that uses Mixed Integer Programming (MIP), Quality Function Deployment (QFD), and the Analytical Hierarchy Process (AHP) [24]. The MIP model in the proposed framework requires an algebraic modeling software to generate results. Moreover, another framework suggests which Industry 4.0 technologies to be implemented on the current assembly line within a manufacturing firm [25]. The model requires firms to implement Industry 4.0 technologies one at a time on the assembly line, which might not be a feasible approach for firms with limited financial resources and strict time constraints. Also, assessing criteria weights in this framework are pre-defined and are not based on experts’ opinions.

As mentioned earlier, very few frameworks are directly intended for Industry 4.0 technology selection. Hamzeh and Xu (2019) have performed a literature review on general technology selection methods and concluded that AHP, Data Envelopment Analysis (DEA), fuzzy logic, Financial Analysis Techniques, Mathematical Programming (MP), and Hybrid methods are the most frequently used methods for technology selection [26]. For instance, Armayor et al. (2011) proposed a decision support model which uses the fuzzy approach to select the suitable technologies for a given supply chain by calculating coefficients of satisfaction and necessity based on the integration requirements [27]. While Nath and Sarkar (2017) developed a method which utilizes fuzzy MCDM methods of Complex Proportional Assessment with Grey Relations (COPRAS-G) and Evaluation of Mixed Data (EVAMIX) to select AMTs for a given industry [28]. Similarly, Evans et al. (2013) used a fuzzy-decision-tree approach to calculate the certainty index for different technologies. This certainty later determines the rankings of technologies and shows the technology that is most suitable for implementation [29]. Lastly, Yurdakul (2003) proposed a hybrid technology selection approach, in which a combination of AHP and Goal Programming (GP) methods are used to select between Computer-Integrated Manufacturing (CIM) technology alternatives [30].

The Industry 4.0 technology selection procedure can be categorized as a Multi Criteria Decision-Making (MCDM) problem, since technologies (alternatives) are ranked based on a given criterion. MCDM analyses are often used to obtain an optimum solution when a range of similar options are available [31]. The most prominent advantage of MCDM analysis is the ability to analyze different forms of data that have high uncertainty [32]. The Analytical Hierarchy Process (AHP), Technique for Order Preference by Similarity to an Ideal Solution (TOPSIS), Complex Proportional Assessment (COPRAS), and Elimination and Choice Translating Reality (ELECTRE) methods are a few examples of available MCDM methods [33].

In general, the AHP method uses a 1–9 scale, which needs precise judgments by experts to set priorities in a hierarchical manner [34]. However, some limitations to the AHP method are the ambiguity associated in converting an expert’s judgment to crisp numbers and the great influence of subjective judgements on AHP results [35]. As a solution, fuzzy AHP was developed. Fuzzy AHP uses fuzzy numbers in calculations, which accounts for the uncertainty associated with an expert’s opinion [34]. Another MCDM method is the TOPSIS method. The TOPSIS method selects alternatives that have the least distance from the positive ideal solution and the largest distance from the negative ideal solution. Integration of fuzzy logic into the TOPSIS method removes vagueness from the results [36]. Efficiency and simplicity in computations and capability of handling uncertainty are some of the important traits of the fuzzy TOPSIS method [37]. Fuzzy AHP and fuzzy TOPSIS methods have been implemented in a variety of engineering applications. For example, Pythagorean fuzzy AHP and fuzzy TOPSIS were used to select a green supplier for an Industry 4.0-based firm [38]. Also, fuzzy AHP and fuzzy TOPSIS methods were used to rank the barriers in the development of photovoltaic energy production [37]. The methods were also used to select the best procedure for plastic recycling [39].

The three main concepts used in this work are indicator selection, multi-criteria decision-making (MCDM) methods, and fuzzy logic theory. Industries face the burden of selecting the most suitable indicators set to correctly capture their activities in an effective manner that would allow for a fair assessment of their digitalization pathway. Thus, the study presents a guide on how to select the correct set of indicators. As several indicators are better, or more exclusively described in linguistic terms, fuzzy logic theory is utilized in the proposed framework. Fuzzy logic models logical reasoning with linguistic terms or imprecise statements, such as “short, tall, big, small”. By utilizing fuzzy logic in the technology selection framework, users can easily describe the indicators using linguistic terms. Hence, this allows for the inclusion of qualitative indicators, rather than relying on quantitative ones only. Lastly, to allow for any number of indicators and technologies, MCDM methods are used. MCDM methods analyses are used to obtain an optimum solution when a range of similar options are available. The aforementioned three aspects are integrated together in a customized way, as it is described in the text, to achieve an optimum technology selection procedure.

As transforming to Industry 4.0 is now becoming a necessity for each firm to maintain its market competitiveness, manufacturing firms now face the burden of selecting the correct Industry 4.0 technologies that are to be used to positively enhance their industrial value chain. Small- and medium-sized enterprises (SMEs) are mostly affected by this problem. Several studies revealed the low adoption rate of Industry 4.0 technologies among SMEs. This is mainly due to the major challenge SMEs face when transitioning to Industry 4.0, which lies within initial adoption decisions [13,40,41]. This, along with the variation of industrial activities of each firm, calls for an Industry 4.0 technology selection framework. Such a framework would present a low-cost method of determining the required Industry 4.0 technologies that would positively impact the firm’s industrial value chain and support its path towards digitalization.

The aim of this paper is to develop an Industry 4.0 technology selection framework that can be used by manufacturers of all sizes and types to digitalize their industrial value chain. The developed framework will facilitate the decision-making process of selecting the most appropriate Industry 4.0 technologies that would enhance the firm’s different economic, social, environmental, and production aspects. Given the capabilities of fuzzy AHP and fuzzy TOPSIS, the two methods were utilized in the developed framework to rank the alternatives based on the firm’s key performance indicators. The following sections of the paper present the framework development methodology, where the selection process of key performance indicators (KPI), and the procedures of implementing fuzzy AHP and fuzzy TOPSIS, are stated. The paper also presents a case study conducted on a real manufacturing firm to implement the developed Industry 4.0 technology selection framework. Lastly, sensitivity analysis is performed to visualize the sensitivity of the developed framework to changes in indicators’ global weights.

3. Methods

This section presents the development of the technology selection framework. It also presents the procedure of selecting KPIs and explains how fuzzy sets, fuzzy AHP, and fuzzy TOPSIS are utilized to obtain the results. Afterwards, the developed framework will be implemented on a real-life example of an aluminum extrusion firm in Section 3.

The construction of the subsections is as follows: firstly, Section 3.1 introduces the technology selection framework. Section 3.2 presents the suggested key performance indicators (KPIs) selection procedure. Section 3.3 presents the fuzzy logic theory, while Section 3.4 and Section 3.5 present fuzzy AHP and fuzzy TOPSIS theories, respectively.

3.1. Technology Selection Framework

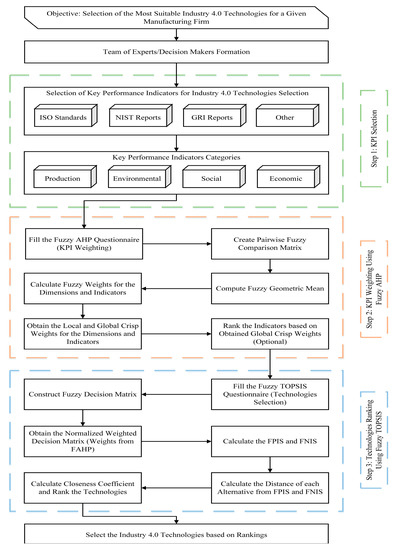

Figure 1 represents the technology selection framework. Firstly, a team of experts/decision makers is formed. The role of this team is to define a set of KPIs that best suits the firm’s goals and objectives (i.e., aspects that are needed to be optimized). The selected KPIs should be able to represent the firm’s production, economic, environmental, and social implications. After selecting the appropriate KPIs, a fuzzy AHP survey is created and filled by the decision makers. This step avoids randomness in weight assignment and ensures that proper weights are assigned to each KPI. During this step, a pairwise fuzzy comparison matrix is created, which leads to calculating the geometric mean values. Fuzzy geometric mean values will help in calculating the fuzzy weights for each dimension and indicator. Fuzzy weights are converted to crisp weights so that they can be used later. Next, the fuzzy TOPSIS questionnaire is filled, and the fuzzy TOPSIS decision matrix is obtained. The decision matrix is normalized, and weights obtained from the fuzzy AHP analysis are multiplied into the normalized decision matrix. Using the normalized weighted decision matrix, Fuzzy Positive Ideal Solution (FPIS) and Fuzzy Negative Ideal Solution (FNIS) values are calculated for each indicator. Using FPIS and FNIS, the positive and negative distance values are calculated. Aggregated positive and negative distance values for each technology will help in calculating the closeness coefficient values for the technologies. Finally, the technologies are ranked based on the value of the closeness coefficient obtained. Closeness coefficient values vary between zero and one. Technologies with higher closeness coefficients will have better rankings. The higher the rank of a technology is, the more important it is to the firm’s goals and objectives.

Figure 1.

The developed Industry 4.0 technology selection framework.

3.2. Key Performance Indicators (KPI) Selection

In this paper, KPIs are divided into different categories that are of importance to any manufacturing firm. The first category is production. KPIs used in this category are taken from the International Organization for Standardization (ISO22400), which includes 34 KPIs for manufacturing operations management. KPIs defined in ISO standards are derived from different supporting elements [42]. For example, Availability (A) KPI is derived by dividing the Actual Production Time (APT) and Planned Busy Time (PBT) from one another and multiplying the result by 100 to obtain the percentage value [42]. The second, third, and fourth categories of KPIs are the environmental, social, and economic categories. These categories are the main dimensions covering different aspects of sustainable manufacturing. Joung et al. have performed a literature review on publicly available indicator sets for measuring sustainability in manufacturing firms. The Global Report Initiative (GRI) sustainability report indicator set, Dow Jones Sustainability Indexes (DJSI), and the Ford Product Sustainability Index (Ford PSI) are a few examples of sustainability indicator sets reported [43]. Moreover, Accounting-based Financial Performance (AFP) and Value-based Financial Performance (VFP) measures can be used to evaluate the economic performance of the manufacturing firm. Yalcin et al. (2012) included some of the commonly used financial performance measures in their paper that can be used to evaluate the financial performance of manufacturing firms [44]. In this framework, KPIs have been chosen from a pool of ISO22400, GRI Sustainability Reporting Standards (2021), and other sources, so that all of the dimensions that are important to manufacturing firms are covered. Table 2 gathers and defines some important KPIs that are recommended to be used in the Industry 4.0 technology selection framework to achieve a comprehensive coverage of the manufacturing firms’ operations. These KPIs are collected from different sources, such as the ISO22400, GRI Sustainability Reporting Standards, and from the literature [42,44,45,46]. Since not all manufacturing firms operate in the same manner, KPIs can be customized by industrial value chain experts to match the firms’ operations and targets.

Table 2.

Examples of Key Performance Indicators that can be Used for Industry 4.0 Technology Selection.

3.3. Fuzzy Theory

Experts and decision makers often use linguistic terms to evaluate a given problem. In 1965, Zadeh introduced the fuzzy set theory to accommodate for the ambiguity and imprecision in humans’ criteria definitions and judgements [47]. Fuzzy set Ã, which has universe of discourse X, is described by membership function shown as below [48]:

For every x in the universe of discourse X, this membership function can have a real number in the interval [0, 1] [49]. The membership functions used in this paper are in the form of triangular membership functions. Each triangular membership function can be described by three numbers. The triangular fuzzy set à is defined by (a1, a2, a3), and the mathematical form of its membership function is defined as below [50]:

The mathematical operations between two fuzzy sets à and are described as follows [50]:

The inverse of a fuzzy set can be also defined as the following:

3.4. Fuzzy AHP

The fuzzy AHP method is a modification of the AHP method, which uses fuzzy sets to determine the weight of the given criteria. This method can be approached in two different ways. The first approach is by finding the geometric mean proposed by Buckley in 1985 [51]. The second approach is introduced by Chang, and is based on an extent analysis method to perform the fuzzy AHP analysis [48]. For simplicity in calculation, the geometric mean approach is utilized in this framework. After defining the triangular membership functions for criteria weighting, the fuzzy number is defined as (lij, mij, uij), where lij, mij, and uij are the lower, middle, and upper bound values for the fuzzy number [52]. The following steps are then followed to obtain criteria weights [52,53].

Step 1: The pairwise comparison matrix, which relates the preference of the ith criterion (row) over the jth criterion (column) is constructed as:

Step 2: The fuzzy geometric mean is calculated for each row using Equation (6) and implementing fuzzy multiplication rules, as shown in Equation (3).

where n is the total number of criteria and i = 1, 2, 3, …, n.

Step 3: After calculating the fuzzy geometric value for each row, Equation (7) is used to calculate the fuzzy weights. Fuzzy geometric values are added using the summation operation for fuzzy numbers, as shown in Equation (3), and the inverse of the summation is obtained using Equation (4).

Step 4: The above calculated weight is still a fuzzy number, hence the Centre of Area (COA) defuzzification method is utilized to convert the fuzzy number into a crisp value using Equation (8). This crisp weight is then normalized using Equation (9).

Step 5: Since multiple experts can be considered for determining criteria weights, Equation (10) is used to obtain the final weights, where y is the total number of experts.

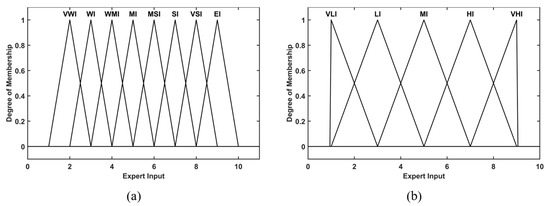

The membership functions defined for the fuzzy AHP process are defined in Table 3 and shown in Figure 2a.

Table 3.

Membership Functions Defined for the Fuzzy AHP Process.

Figure 2.

Triangular Fuzzy Membership Functions Defined for (a) Dimensions and Indicators Weighting (b) Technology Alternatives Selection.

3.5. Fuzzy TOPSIS

The fuzzy TOPSIS method was first introduced by Chen, in which fuzzy numbers replaced crisp number sets [54]. In this framework, fuzzy TOPSIS is implemented to rank Industry 4.0 technologies, based on given criterions. The steps for the fuzzy TOPSIS approach used in this framework are shown below [50,54,55].

Step 1: Fuzzy decision matrix is constructed, such that the ith rows correspond to alternatives (technologies), and jth columns correspond to the criterion. Each input in the matrix is a fuzzy number defined as .

where and .

Step 2: If multiple Decision Makers (DM) are considered to fill the survey, the fuzzy decision matrices obtained from Equation (11) are all combined into a single decision matrix, using the following formulas, to compute each component in the combined matrix.

where the kth DM has decision matrix components of and k is the total number of DMs.

Step 3: The normalized fuzzy decision matrix is then constructed by:

in which Equations (13) and (14) are used when they have benefit and cost criterions, respectively.

Step 4: Fuzzy weights, or crisp weights, calculated from the fuzzy AHP approach, are used to calculate the weighted normalized fuzzy decision matrix .

Step 5: The Fuzzy Positive Ideal Solution (FPIS, A*), and Fuzzy Negative Ideal Solution (FNIS, A−), are defined as:

Step 6: The distance of each alternative from A* and A− are next calculated by:

where the distance between two fuzzy numbers can be calculated by:

Step 7: The Closeness Coefficient (CCi) of each alternative is calculated as below:

Industry 4.0 technologies are finally ranked based on the CCi obtained for each technology, such that the technology with the highest value for CCi will be ranked first, etc. Triangular fuzzy membership functions used for technology selection are described in Table 4 and shown in Figure 2b.

Table 4.

Membership Function for Alternative Rankings in Fuzzy TOPSIS Process [55].

4. Case Study

In this section, the proposed framework is implemented on an aluminum extrusion firm located in Jordan to select the most important Industry 4.0 technologies for the firm as an example of the implementation of this framework. The decision matrices for fuzzy AHP and fuzzy TOPSIS methods have been obtained through consensus decision-making between multiple experts within the firm. In other words, multiple decision makers of the facility have met and filled a single decision survey. This survey is used to generate the decision matrices.

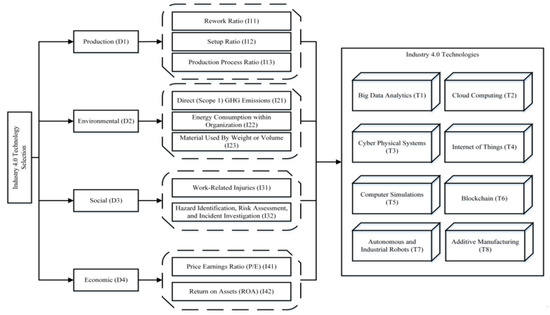

4.1. Defining the Dimensions and Indicators

From the list of KPIs provided in Table 2, decision makers have selected a certain number of KPIs that align with the firm’s goals and objectives to be considered as indicators for this framework. Users of the framework are encouraged to consult an expert to customize a set of indicators that would correctly capture the activities and the impact of the manufacturing facility. Any sets of indicators can be used, given that they effectively cover the environmental, social, economic, and production categories. For this case study, the indicators have been grouped into four main dimensions of production, environmental, social, and economic. Each dimension contains several indicators. Figure 3 shows the proposed dimensions and indicators chosen. These dimensions and indicators can be modified further if the manufacturing firm have certain goals and objectives to follow that have not been considered in this framework. It is noted that all these indicators are considered as beneficial indicators. As an example, when decision makers are making a decision on how important an Industry 4.0 technology to sub-criterion Direct (Scope 1) GHG Emissions is, the importance is considered with respect to reducing the GHG emissions. Table 5 discusses the assessment methodology for the indicators selected, which are all being considered as beneficial indicators.

Figure 3.

The Structure of the Industry 4.0 Technology Selection Framework for the Given Case Study.

Table 5.

Membership Function for Alternative Rankings in Fuzzy TOPSIS Process [55].

4.2. Assigning Weights to the Dimensions and Indicators

After defining the dimensions and indicators, the AHP survey is filled to construct the decision matrix for KPI weighting. Table 6 summarizes the obtained fuzzy values, and Table 7 provides the calculation of the fuzzy geometry mean. Fuzzy and crisp weights obtained from the survey for the dimensions are tabulated in Table 8. The same procedure as above is repeated to obtain the indicator weightings based on DMs’ inputs, as shown in Table 9, Table 10, Table 11 and Table 12.

Table 6.

Dimension Weights Assigned by the Firm.

Table 7.

Calculation of Fuzzy Geometry Mean.

Table 8.

Fuzzy and Crisp Calculated Weights for the Dimensions.

Table 9.

Production Dimension Decision Matrix.

Table 10.

Environmental Dimension Decision Matrix.

Table 11.

Social Dimension Decision Matrix.

Table 12.

Economic Dimension Decision Matrix.

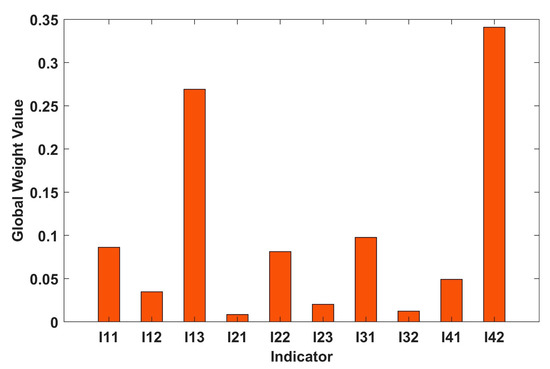

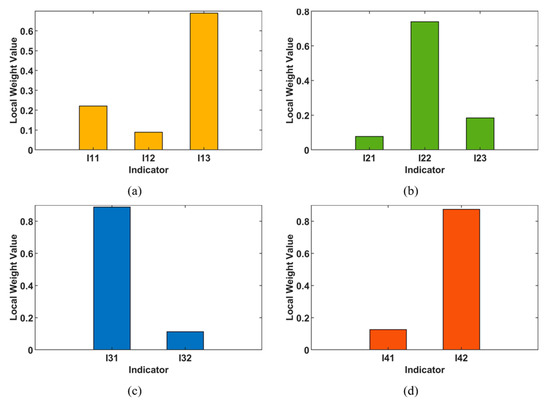

Table 13 tabulates the results obtained for the normalized local and global crisp weights for the indicators. Figure 4 and Figure 5 graphically represent the global and local weights obtained for the indicators, respectively.

Table 13.

Indicators Normalized Local and Global Crisp Weights.

Figure 4.

Indicators’ Global Weight Plot.

Figure 5.

Indicators’ Local Weights Plot for (a) Production, (b) Environmental, (c) Social, and (d) Economic Dimensions.

4.3. Normalization and Ranking of Technologies

The fuzzy TOPSIS method is implemented to rank the Industry 4.0 technology alternatives after obtaining the dimensions and indicators weights through fuzzy AHP. Experts are asked to fill a fuzzy TOPSIS survey and make judgments based on fuzzy linguistic terms, as shown in Table 4. Results obtained from the consensus decision-making between decision makers in the firm are tabulated in Table 14.

Table 14.

Fuzzy TOPSIS Decision Matrix (Fuzzy Linguistic Value).

The fuzzy linguistic values tabulated in Table 14 are converted into fuzzy numerical values. These values are normalized using Equation (13) as all the defined indicators are beneficial. The normalized fuzzy decision matrix is then multiplied by the crisp indicators’ global weights to obtain the weighted decision matrix. Table 15 shows the weighted decision matrix obtained.

Table 15.

Weighted fuzzy TOPSIS Decision Matrix.

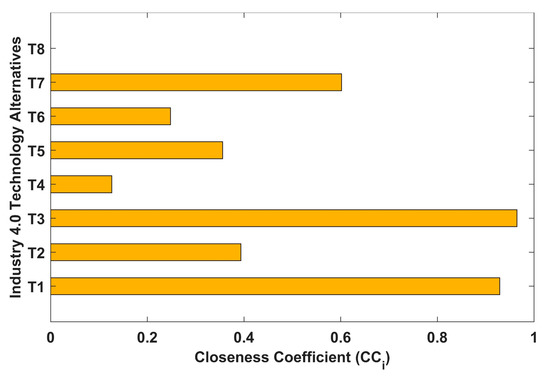

Using Equations (16) and (17), the FPIS (A*), and FNIS (A−) are obtained. Using Equations (18)–(21), the positive and negative distances for each component in the matrix is calculated to obtain the closeness coefficient for technology ranking. Table 16 and Figure 6 tabulate and illustrate the results obtained.

Table 16.

The Obtained Technologies Rankings.

Figure 6.

Closeness Coefficient Values Obtained for Technology Alternatives.

For the aluminum extrusion firm studied, Cyber-Physical Systems technologies obtained the highest closeness coefficient, which depicts that this technology is the most impactful technology for the firm. On the other hand, Additive Manufacturing obtained the lowest closeness coefficient, which portrays that this technology is the least impactful technology for the firm, based on the given indicators. With the help of the results obtained, the manufacturing firm’s decision makers will have a better idea on which Industry 4.0 technologies have the most impact on their firm and, hence, are the most useful to be implemented.

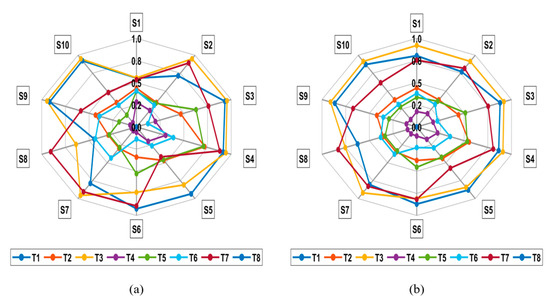

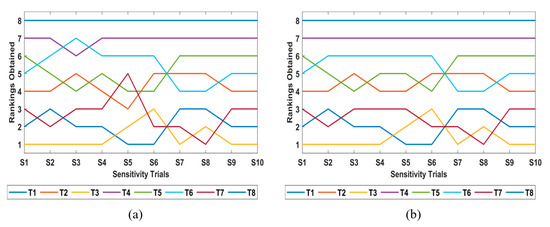

4.4. Sensitivity Analysis

A sensitivity analysis is performed to visualize the robustness of a given framework to changes in indicators’ global weights. Two sets of experiments have been performed. The number of trials in both experiments are equal to ten. In the first experiment, for each trial, one indicator weight has been assigned to 0.64, and other indicators’ weights are assumed to be same and equal to 0.04. In the second set of the experiment, for each trial, the weight of one indicator was assigned as 0.37, while other indicators have an equal weight of 0.07. Figure 7 and Figure 8 present the results of the conducted sensitivity analysis.

Figure 7.

Radar Chart Obtained Showcasing Closeness Coefficient Values from Sensitivity Analysis in (a) Experiment 1 and (b) Experiment 2.

Figure 8.

Technology Rankings Obtained from Sensitivity Analysis in (a) Experiment 1 and (b) Experiment 2.

Sensitivity analysis show that the framework is relatively sensitive to changes in indicators’ weightings. In the first experiment, where a relatively larger weight is assigned to a single indicator, the analysis shows that the framework is not robust, since the technology’s rankings vary, going from one trial to another. In the second experiment, where a lower weight is assigned to a single indicator at each trial, the framework showed more robustness to weight changes. As can be seen in Figure 8b, the top three ranked technologies always stayed the top three rankings. The same observation can be made for the middle three ranked technologies, in which the corresponding technologies always stayed in the middle three rankings. Having a relative sensitivity to changes in indicators’ weights is acceptable in this framework, since the rankings of technologies must depend on manufacturing firm’s requirements and KPIs weight assignments.

5. Conclusions

An Industry 4.0 technology selection framework is developed to facilitate the Industry 4.0 technology selection decision-making process. The following points summarize the contributions of this work by highlighting the main advantages of the developed technology selection framework and the findings of the case study:

- The developed framework helps decision makers, especially at the SMEs level, to decide on the most suitable Industry 4.0 technology needed in a timely and cost-effective manner.

- The framework utilizes fuzzy AHP and fuzzy TOPSIS, which are capable of eliminating any uncertainties that are associated with expert’s opinions and linguistic terms.

- This work also proposed a comprehensive set of indicators that are capable of capturing the environmental, economic, and social dimensions, as well as the production performance of the assessed manufacturing firm.

- Nevertheless, the framework is flexible, which makes it easy to select and use other sets of indicators that best suits the firm’s goals and functionalities.

- A case study was carried out on an aluminum extrusion firm. The framework detected several Industry 4.0 technologies that, if adopted and implemented, would enhance the firm’s overall environmental, economic, social, and production performances.

- The technologies, in order of their importance, were Cyber-Physical systems, Big Data, and autonomous/industrial robots, respectively.

- The framework showed sensitivity towards weight changes. This is an advantage in the developed framework, since its main aim is to provide policymakers with a customized list of technologies, based on their importance to the firm.

- Several specialized industries could benefit from the utilization of this framework, such as the sustainability of the healthcare industry [56], the fashion industry [57], and waste management [58].

One limitation of the framework lies within the length of the surveys presented to the manufacturing facility. If a large number of indicators are used, the surveys and the calculations will become lengthy and time-consuming. Thus, it is recommended to use a computer program to assist in carrying out the computational steps involved in the fuzzy AHP and fuzzy TOPSIS methods. This would ease the technology selection process and would eliminate any unforced errors that may occur while following the calculation steps. Furthermore, experts of their respected areas are encouraged to collect and prepare standard sets of indicators to be used by firms that perform similar activities. This would enhance the technology selection procedure and would further reduce subjectivity. Also, a standard set of indicators will enable investors to compare between different firms, allowing them to make informed decisions about their future investments. As of future work, the framework can be compared with other MCDM methods. Furthermore, inclusive indicators, such as the Internet of People can be added to enhance the coverage of the framework. Due to its flexibility, the presented framework can be easily implemented for Industry 4.0 technology selection in other sectors, such as healthcare and education, rather than being solely focused on manufacturing industries.

Author Contributions

Conceptualization, P.D.P., M.A.N. and B.M.D.; methodology, P.D.P., A.A.A., M.A.N. and B.M.D.; validation, P.D.P., A.A.A., M.A.N. and B.M.D.; formal analysis, P.D.P.; investigation, P.D.P., A.A.A., M.A.N. and B.M.D.; writing—original draft preparation, P.D.P.; writing—review and editing, P.D.P., A.A.A., M.A.N. and B.M.D.; visualization, P.D.P.; supervision, A.A.A., M.A.N. and B.M.D.; project administration, M.A.N. and B.M.D.; funding acquisition, M.A.N. and B.M.D. All authors have read and agreed to the published version of the manuscript.

Funding

The work in this paper was supported, in part, by the Open Access Program from the American University of Sharjah. This research was funded by the American University of Sharjah under grant numbers FRG21-M-91 and FRG21-M-90. This paper represents the opinions of the author(s) and does not mean to represent the position or opinions of the American University of Sharjah.

Data Availability Statement

All data used is presented in the manuscript.

Acknowledgments

The authors would like to acknowledge the American University of Sharjah for funding this work through its Open Access Program.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution: What It Means, How to Respond. 14 January 2016. Available online: https://www.weforum.org/agenda/2016/01/the-fourth-industrial-revolution-what-it-means-and-how-torespond/#:∼:text=The%20First%20Industrial%20Revolution%20used,information%20technology%20to%20automate%20production (accessed on 25 August 2022).

- Shah, K.; Patel, N.; Thakkar, J.; Patel, C. Exploring applications of blockchain technology for Industry 4.0. Mater. Today Proc. 2022, 62, 7238–7242. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Silvestri, C.; Aquilani, B.; Silvestri, L. Is this a new story of the ‘Two Giants’? A systematic literature review of the relationship between industry 4.0, sustainability and its pillars. Technol. Forecast. Soc. Chang. 2022, 177, 121511. [Google Scholar] [CrossRef]

- Dubey, G.; Gupta, R.K.; Kumar, S.; Kumar, M. Study of industry 4.0 pillars and their uses in increasing productivity and reducing logistics defects. Mater. Today Proc. 2022, 63, 85–91. [Google Scholar] [CrossRef]

- Pour, P.D.; Nazzal, M.A.; Darras, B.M. The role of industry 4.0 technologies in overcoming pandemic challenges for the manufacturing sector. Concurr. Eng. 2022, 30, 190–205. [Google Scholar] [CrossRef]

- Ching, N.T.; Ghobakhloo, M.; Iranmanesh, M.; Maroufkhani, P.; Asadi, S. Industry 4.0 applications for sustainable manufacturing: A systematic literature review and a roadmap to sustainable development. J. Clean. Prod. 2022, 334, 130133. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Nazzal, M.A.; Darras, B.M. Cyber-Physical Systems as an Enabler of Circular Economy to Achieve Sustainable Development Goals: A Comprehensive Review. Int. J. Precis. Eng. Manuf. Technol. 2021, 9, 955–975. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Gonzalez, E.S. Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability. Sustain. Oper. Comput. 2022, 3, 203–217. [Google Scholar] [CrossRef]

- Drath, R.; Horch, A. Industrie 4.0: Hit or Hype? IEEE Ind. Electron. Mag. 2014, 8, 56–58. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- IBM. What Is Industry 4.0? Available online: https://www.ibm.com/ae-en/topics/industry-4-0 (accessed on 10 January 2022).

- SAP. What Is industry 4.0? Available online: sap.com/insights/what-is-industry-4-0.html (accessed on 10 January 2022).

- Wang, J.; Xu, C.; Zhang, J.; Zhong, R. Big data analytics for intelligent manufacturing systems: A review. J. Manuf. Syst. 2022, 62, 738–752. [Google Scholar] [CrossRef]

- Ooi, K.-B.; Lee, V.-H.; Tan, G.W.-H.; Hew, T.-S.; Hew, J.-J. Cloud computing in manufacturing: The next industrial revolution in Malaysia? Expert Syst. Appl. 2018, 93, 376–394. [Google Scholar] [CrossRef]

- Schleinkofer, U.; Klöpfer, K.; Schneider, M.; Bauernhansl, T. Cyber-physical Systems as Part of Frugal Manufacturing Systems. Procedia CIRP 2019, 81, 264–269. [Google Scholar] [CrossRef]

- Cui, X. Cyber-Physical System (CPS) architecture for real-time water sustainability management in manufacturing industry. Procedia CIRP 2021, 99, 543–548. [Google Scholar] [CrossRef]

- Garg, K.; Goswami, C.; Chhatrawat, R.; Dhakar, S.K.; Kumar, G. Internet of things in manufacturing: A review. Mater. Today Proc. 2022, 51, 286–288. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Mani, V.; Belhadi, A.; Sharma, R. Digital twin for sustainable manufacturing supply chains: Current trends, future perspectives, and an implementation framework. Technol. Forecast. Soc. Chang. 2022, 176, 121448. [Google Scholar] [CrossRef]

- Leng, J.; Ruan, G.; Jiang, P.; Xu, K.; Liu, Q.; Zhou, X.; Liu, C. Blockchain-empowered sustainable manufacturing and product lifecycle management in industry 4.0: A survey. Renew. Sustain. Energy Rev. 2020, 132, 110112. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Substantial capabilities of robotics in enhancing industry 4.0 implementation. Cogn. Robot. 2021, 1, 58–75. [Google Scholar] [CrossRef]

- Lacroix, R.; Seifert, R.W.; Timonina-Farkas, A. Benefiting from additive manufacturing for mass customization across the product life cycle. Oper. Res. Perspect. 2021, 8, 100201. [Google Scholar] [CrossRef]

- Hamzeh, R.; Zhong, R.; Xu, X.; Kajati, E.; Zolotova, I. A Technology Selection Framework for Manufacturing Companies in the Context of Industry 4.0. In Proceedings of the 1st IEEE World Symposium on Digital Intelligence for Systems and Machines, DISA, Kosice, Slovakia, 23–25 August 2018; pp. 267–276. [Google Scholar] [CrossRef]

- Erbay, H.; Yıldırım, N. Technology Selection for Industry 4.0 Digital Transformation: A Decision-Making Model Combining AHP, QFD and MIP; Springer: Cham, Switzerland, 2019; pp. 143–157. [Google Scholar]

- Aljinović, A.; Gjeldum, N.; Bilić, B.; Mladineo, M. Optimization of Industry 4.0 Implementation Selection Process towards Enhancement of a Manual Assembly Line. Energies 2022, 15, 30. [Google Scholar] [CrossRef]

- Hamzeh, R.; Xu, X. Technology selection methods and applications in manufacturing: A review from 1990 to 2017. Comput. Ind. Eng. 2019, 138, 106123. [Google Scholar] [CrossRef]

- Armayor, D.P.; Batista, J.A.D.; Gómez, J.M. Toward an Integration Technology Selection Model for Information Systems Integration in Supply Chains; Springer: Berlin/Heidelberg, Germany, 2011; pp. 187–194. [Google Scholar]

- Nath, S.; Sarkar, B. An Exploratory Analysis for the Selection and Implementation of Advanced Manufacturing Technology by Fuzzy Multi-criteria Decision Making Methods: A Comparative Study. J. Inst. Eng. (India) Ser. C 2017, 98, 493–506. [Google Scholar] [CrossRef]

- Evans, L.; Lohse, N.; Summers, M. A fuzzy-decision-tree approach for manufacturing technology selection exploiting experience-based information. Expert Syst. Appl. 2013, 40, 6412–6426. [Google Scholar] [CrossRef]

- Yurdakul, M. Selection of computer-integrated manufacturing technologies using a combined analytic hierarchy process and goal programming model. Robot. Comput. Manuf. 2004, 20, 329–340. [Google Scholar] [CrossRef]

- Singh, A.; Malik, S.K. Major MCDM Techniques and their application-A Review. IOSR J. Eng. 2014, 4, 15–25. [Google Scholar] [CrossRef]

- Wang, J.-J.; Jing, Y.-Y.; Zhang, C.-F.; Zhao, J.-H. Review on multi-criteria decision analysis aid in sustainable energy decision-making. Renew. Sustain. Energy Rev. 2009, 13, 2263–2278. [Google Scholar] [CrossRef]

- Emovon, I.; Oghenenyerovwho, O.S. Application of MCDM method in material selection for optimal design: A review. Results Mater. 2020, 7, 100115. [Google Scholar] [CrossRef]

- Kaewfak, K.; Huynh, V.-N.; Ammarapala, V.; Charoensiriwath, C. A Fuzzy AHP-TOPSIS Approach for Selecting the Multimodal Freight Transportation Routes; Springer: Singapore, 2019; pp. 28–46. [Google Scholar]

- Patil, S.K.; Kant, R. A fuzzy AHP-TOPSIS framework for ranking the solutions of Knowledge Management adoption in Supply Chain to overcome its barriers. Expert Syst. Appl. 2014, 41, 679–693. [Google Scholar] [CrossRef]

- Mathew, M.; Chakrabortty, R.K.; Ryan, M.J. A novel approach integrating AHP and TOPSIS under spherical fuzzy sets for advanced manufacturing system selection. Eng. Appl. Artif. Intell. 2020, 96, 103988. [Google Scholar] [CrossRef]

- Sadat, S.A.; Fini, M.V.; Hashemi-Dezaki, H.; Nazififard, M. Barrier analysis of solar PV energy development in the context of Iran using fuzzy AHP-TOPSIS method. Sustain. Energy Technol. Assess. 2021, 47, 101549. [Google Scholar] [CrossRef]

- Çalık, A. A novel Pythagorean fuzzy AHP and fuzzy TOPSIS methodology for green supplier selection in the Industry 4.0 era. Soft Comput. 2021, 25, 2253–2265. [Google Scholar] [CrossRef]

- Vinodh, S.; Prasanna, M.; Prakash, N.H. Integrated Fuzzy AHP–TOPSIS for selecting the best plastic recycling method: A case study. Appl. Math. Model. 2014, 38, 4662–4672. [Google Scholar] [CrossRef]

- Hopkins, J.L. An investigation into emerging industry 4.0 technologies as drivers of supply chain innovation in Australia. Comput. Ind. 2021, 125, 103323. [Google Scholar] [CrossRef]

- Stentoft, J.; Jensen, K.W.; Philipsen, K.; Haug, A. Drivers and Barriers for Industry 4.0 Readiness and Practice: A SME Perspective with Empirical Evidence. In Proceedings of the 52nd Hawaii International Conference on System Sciences, Maui, HI, USA, 8–11 January 2019; pp. 5155–5164. [Google Scholar]

- Kang, N.; Zhao, C.; Li, J.; Horst, J.A. A Hierarchical structure of key performance indicators for operation management and continuous improvement in production systems. Int. J. Prod. Res. 2016, 54, 6333–6350. [Google Scholar] [CrossRef] [PubMed]

- Joung, C.B.; Carrell, J.; Sarkar, P.; Feng, S.C. Categorization of indicators for sustainable manufacturing. Ecol. Indic. 2013, 24, 148–157. [Google Scholar] [CrossRef]

- Yalcin, N.; Bayrakdaroglu, A.; Kahraman, C. Application of fuzzy multi-criteria decision making methods for financial performance evaluation of Turkish manufacturing industries. Expert Syst. Appl. 2012, 39, 350–364. [Google Scholar] [CrossRef]

- Johnsson, C. Key Performance Indicators Used as Measurement Parameter for Plant-Wide Feedback Loops; Springer: Berlin/Heidelberg, Germany, 2014; pp. 91–99. [Google Scholar]

- Consolidated Set of the GRI Standards 2021. GRI Standards. Available online: https://www.globalreporting.org/how-to-use-the-gri-standards/gri-standards-english-language/ (accessed on 5 November 2022).

- Zadeh, L.A. Fuzzy sets. In Fuzzy Sets, Fuzzy Logic, and Fuzzy Systems: Selected Papers; Zadeh, L.A., Ed.; World Scientific: Singapore, 1996; pp. 394–432. [Google Scholar]

- Junior, F.R.L.; Osiro, L.; Carpinetti, L.C.R. A comparison between Fuzzy AHP and Fuzzy TOPSIS methods to supplier selection. Appl. Soft Comput. 2014, 21, 194–209. [Google Scholar] [CrossRef]

- Torfi, F.; Farahani, R.Z.; Rezapour, S. Fuzzy AHP to determine the relative weights of evaluation criteria and Fuzzy TOPSIS to rank the alternatives. Appl. Soft Comput. 2010, 10, 520–528. [Google Scholar] [CrossRef]

- Kuo, R.J.; Hsu, C.W.; Chen, Y.L. Integration of fuzzy ANP and fuzzy TOPSIS for evaluating carbon performance of suppliers. Int. J. Environ. Sci. Technol. 2015, 12, 3863–3876. [Google Scholar] [CrossRef]

- Buckley, J.J. Fuzzy hierarchical analysis. Fuzzy Sets Syst. 1985, 17, 233–247. [Google Scholar] [CrossRef]

- Chandna, R.; Saini, S.; Kumar, S. Fuzzy AHP based performance evaluation of massive online courses provider for online learners. Mater. Today Proc. 2021, 46, 11103–11112. [Google Scholar] [CrossRef]

- Afolayan, A.H.; Ojokoh, B.A.; Adetunmbi, A.O. Performance analysis of fuzzy analytic hierarchy process multi-criteria decision support models for contractor selection. Sci. Afr. 2020, 9, e00471. [Google Scholar] [CrossRef]

- Chen, C.-T. Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst. 2000, 114, 1–9. [Google Scholar] [CrossRef]

- Kumar, S.; Barman, A.G. Fuzzy TOPSIS and fuzzy VIKOR in selecting green suppliers for sponge iron and steel manufacturing. Soft Comput. 2021, 25, 6505–6525. [Google Scholar] [CrossRef]

- Moldovan, F.; Blaga, P.; Moldovan, L.; Bataga, T. An Innovative Framework for Sustainable Development in Healthcare: The Human Rights Assessment. Int. J. Environ. Res. Public Health 2022, 19, 2222. [Google Scholar] [CrossRef]

- Grieco, A.; Caricato, P.; Gianfreda, D.; Pesce, M.; Rigon, V.; Tregnaghi, L.; Voglino, A. An Industry 4.0 Case Study in Fashion Manufacturing. Procedia Manuf. 2017, 11, 871–877. [Google Scholar] [CrossRef]

- Fatimah, Y.A.; Govindan, K.; Murniningsih, R.; Setiawan, A. Industry 4.0 based sustainable circular economy approach for smart waste management system to achieve sustainable development goals: A case study of Indonesia. J. Clean. Prod. 2020, 269, 122263. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).