1. Introduction

Supply chain resilience (SCR) is a study topic of increasing importance, particularly in developing countries [

1,

2], and it is a crucial aspect of operational strategy with far-reaching implications for supply chain performance [

3,

4]. In the real world, the COVID-19 pandemic has resulted in significant disruptions to supply chains, forcing many enterprises to temporarily halt operations and to face difficulties in restarting their operations [

5,

6]. As a result, the heightened interest in understanding and improving supply chain resilience stems from the highly unpredictable business landscape [

7]. Meanwhile, one area that has received relatively little attention in the SCR discussions is small and medium-size enterprises (SMEs) [

8,

9] even though they play critical roles in the national economy. SMEs are often vulnerable and face challenges in managing risks and adapting to changing supply chain requirements [

8,

10,

11]. Aman and Seuring (2021) stressed that the tipping points for resilience ideas in recent years were the financial crisis and the COVID-19 pandemic [

1].

Notably, SMEs struggle to be resilient in the supply chain, and two main factors require attention: enterprise capacity and collaborative resources to help firms connect to the supply chain [

8]. Consequently, SCR research is receiving the attention of academics and industry professionals. Managers can anticipate difficulties and disruptions by lifting obstacles and immediately restoring business operations [

12]. However, they were concerned about future threats and forced to consider alternate approaches to prevent and manage multiple disruptions [

8,

13]. Disruptions to the flow of materials or information caused by such issues can negatively affect enterprises’ financial, production, and operational performance [

14,

15]. Hence, Naghshineh and Carvalho (2021) have suggested that future research trends may include investigating adoption barriers and supply chain vulnerabilities [

16]. Identifying barriers to supply chain resilience enables managers to anticipate potential problems and interruptions, and they could adopt appropriate solutions early on [

13,

16]. Moreover, the growth of any organization depends on its managing ability and overcoming a crisis [

17,

18]. Recent studies have revealed that SMEs struggle with response problems regarding human, material, and financial resources because they lack the capacity for operational contingencies [

10]. More importantly, SMEs face challenges involving external and internal stakeholders. Some barriers have been found: a lack of policy, guidance, and support from the government [

19]; a lack of financial resources to obtain urgent loans [

20]; and a lack of noncommitment from senior management, who plays a crucial role in guiding the organization’s direction [

21,

22,

23]. Therefore, to survive in an uncertain environment, enterprises must eliminate these barriers to supply chain resilience; in addition, it could help SMEs quickly adapt to crises [

4,

24].

In the context of a transitional economy, the Vietnamese supply chain is attempting to integrate with the global chain thanks to the significant contributions of SMEs, which play vital roles in this economy’s integrated global supply chain process [

25,

26]. However, some barriers could restrict firms from quickly exploiting the benefits of resilience in the face of increased uncertainty and risk [

27]. Thus, the research and the analysis of potential obstacles affecting the resilience of Vietnamese SMEs become crucial. Nonetheless, the authors found a few articles on SMEs in the Vietnamese supply chain, though also a lack of studies that have considered resilience barriers, which can help SMEs quickly improvise and deal with challenges after recent disruptions. Hence, the main objective of this study attempts to answer related research questions:

To formulate flexible long-term decision-making strategies, it is imperative to identify the most significant barriers to supply chain resilience, which will inform recommendations on the effective deployment of stability [

3,

28,

29]. Therefore, the following section includes a literature review, which provides a deeper understanding of the SCR, the research technique that will be conducted, a discussion and interpretation of study results, and strategies for SMEs to build sustainable supply chains.

2. Literature Review

The definitions of SCR remain controversial among scholars [

21]. According to Hohenstein et al., (2015), SCR definitions include four phases: preparedness, response, restoration, and development [

30]. Several authors have defined “resilience” as the capacity of a system to recover, either completely or partially, to its original state or a better state after being subjected to a disturbance [

31,

32]. While many existing definitions cover the reaction and recovery stages, only a minority of research includes the adaptation and growth stages [

32]. However, most of them agree that SCR refers to an organization’s ability to deal with unforeseen disruptions in the supply chain [

21,

28,

33], and the SCR is no longer regarded in terms of stability but rather in terms of adaptation and transformation [

34]. Moreover, some scholars have identified three primary constructs that contribute to SCR, including the stages of resilience, strategies for resilience, and the competencies required to be resilient [

35,

36]. Hence, SCR can provide an advantage by decreasing the effect of supply chain disruptions or enabling quick recovery [

37,

38,

39].

The reaction of the supply chain to environmental instability can be examined in terms of SMEs. The vast majority of SMEs around the globe are struggling to identify vulnerabilities in their supply chains [

18,

19]. According to various studies, SMEs are among more-vulnerable entities in the supply chain, compared with big firms, when it comes to unexpected adverse events [

8,

40]. The dependence on the requirements and orientation of large enterprises and a few suppliers has significantly impacted the sustainability of SMEs [

8]. Notably, they have been unprepared to deal with COVID-19 disruptions in recent years [

5]. The COVID-19 epidemic has extraordinarily impacted global supply chains in the real world [

41]. As a result, while some enterprises have remained resilient, others have lagged [

42]. Therefore, SMEs should focus on stability to overcome resource limitations and enhance competitiveness [

9]. In addition, the complicated resilience process requires SMEs to evaluate operation strategies and to identify and remove different obstacles that impede their limited capacity [

9,

40].

According to Ali et al., (2017), three major SCR hurdles for SMEs include a lack of management autonomy; limited IT adoption ability; and insufficient R&D spending. In addition, they emphasized the necessity for large firms to assist SMEs in promptly resuming normal business operations [

8]. Agarwal et al., (2022) mentioned that agile capabilities, collaborative capabilities, a lack of top management support, and a lack of empowerment are the barriers that can impede resilience [

21]. Banerjee et al., (2022) determined that a lack of agile capabilities is one of the causal barriers to resilient operations; in addition, a lack of financial capabilities and government support is a barrier to the operation management of SMEs [

20]. Bak et al., (2020) argued that SMEs need the help of both scholars and specialists to precisely identify barriers and evaluate the critical elements contributing to the supply chain resilience process. Moreover, the supply chain resilience in SMEs is determined by internal elements such as resources, finances, and organization and external factors such as political institutions, geopolitical and supply chain interrelationships, and information flow [

43]. Hence, some authors have suggested that supply chain resilience in SMEs should focus on the following three clusters: resilience phases, strategies, and competencies [

35,

36]. Much literature on supply chain resilience has evolved, but many academics in various sectors still believe it is in its infancy, particularly in SMEs [

10,

33,

44]. Overall, the existing literature makes it amply clear that SCR is still receiving attention and needs deeper understanding in both theoretical and real-world contexts; thus, this work attempts to bridge some of the following research gaps.

First, the existing literature on supply chain resilience barriers has shown that SMEs pay exceptional attention to approaches, which some practical evidence from various countries has demonstrated, such as India [

12,

20,

45], Brazil [

46], Australia [

8,

36], and Bangladesh [

40]. In addition, some scholars have suggested ranking barriers and suggested that the most effective solutions are for senior managers to understand the problems [

43,

47]. However, we have found that no research has reported resilience barriers to the Vietnamese supply chain context; meanwhile, Vietnam is an emerging economy trying to recover after the COVID-19 pandemic. Therefore, this is the first study on the Vietnam supply chain to determine what prevents SMEs from recovering after the pandemic.

Second, Vietnamese SMEs substantially impact the stability and sustainability of the supply chain [

15], but they struggle to remove barriers to the resilient processes, particularly struggling to identify the critical factors. Hence, the findings from research on such topics would provide some worthy novel insights for Vietnamese SMEs managers and other scholars into supply chain resilience and related barriers.

Finally, in terms of research technique, the authors have noticed that several approaches have been used to determine the importance of elements, such as AHP, TOPSIS [

26,

48,

49], VIKOR [

12,

50], and DEMATEL [

20,

40,

51]. Moreover, some authors have even suggested to conduct fuzzy set theories to evaluate the best option from experts’ perspectives [

52,

53]. Hence, this work applies the fuzzy VIKOR approach, which helps increase the understanding of the multicriteria decision-making (MCDM) method in ranking the crucial factors.

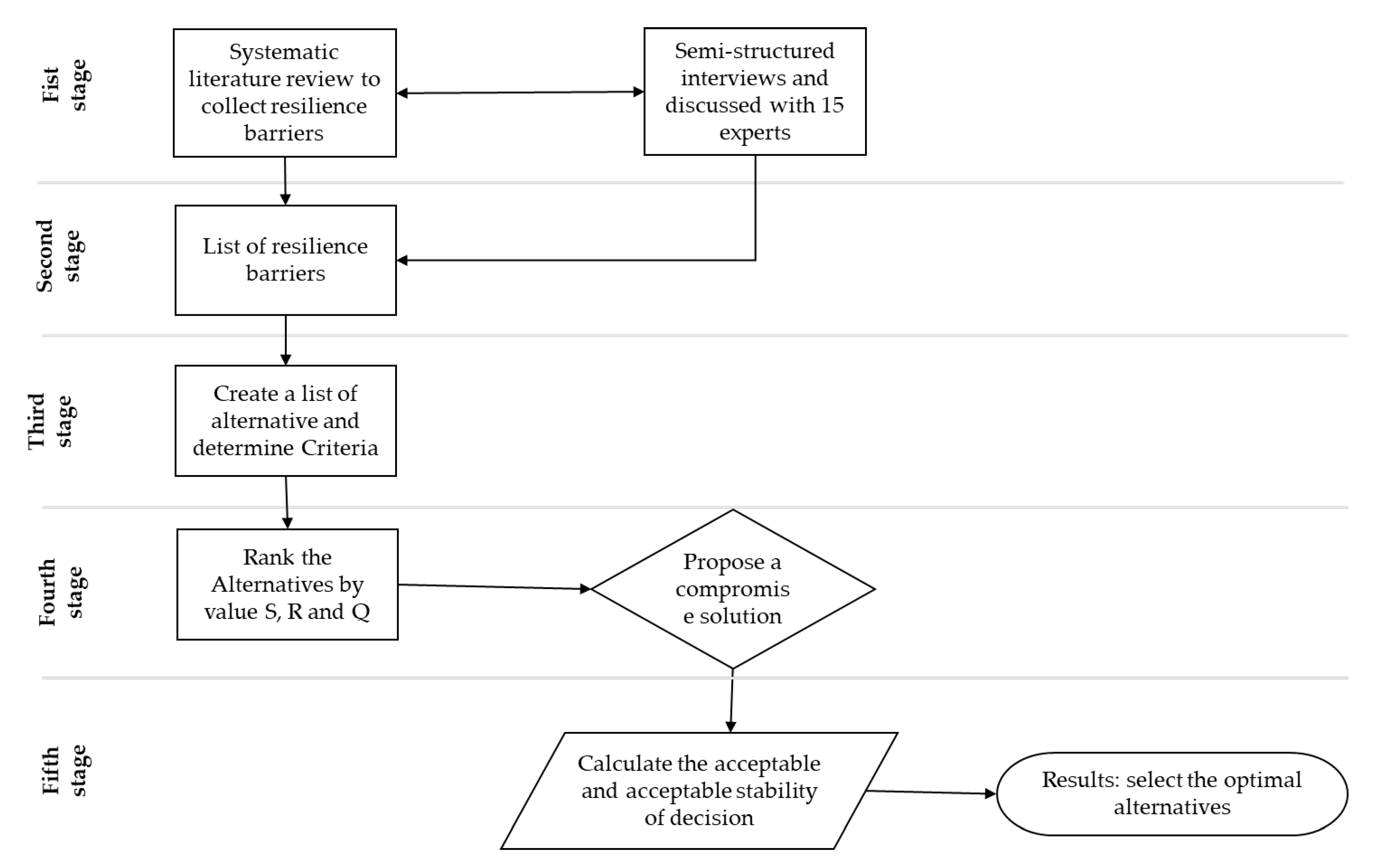

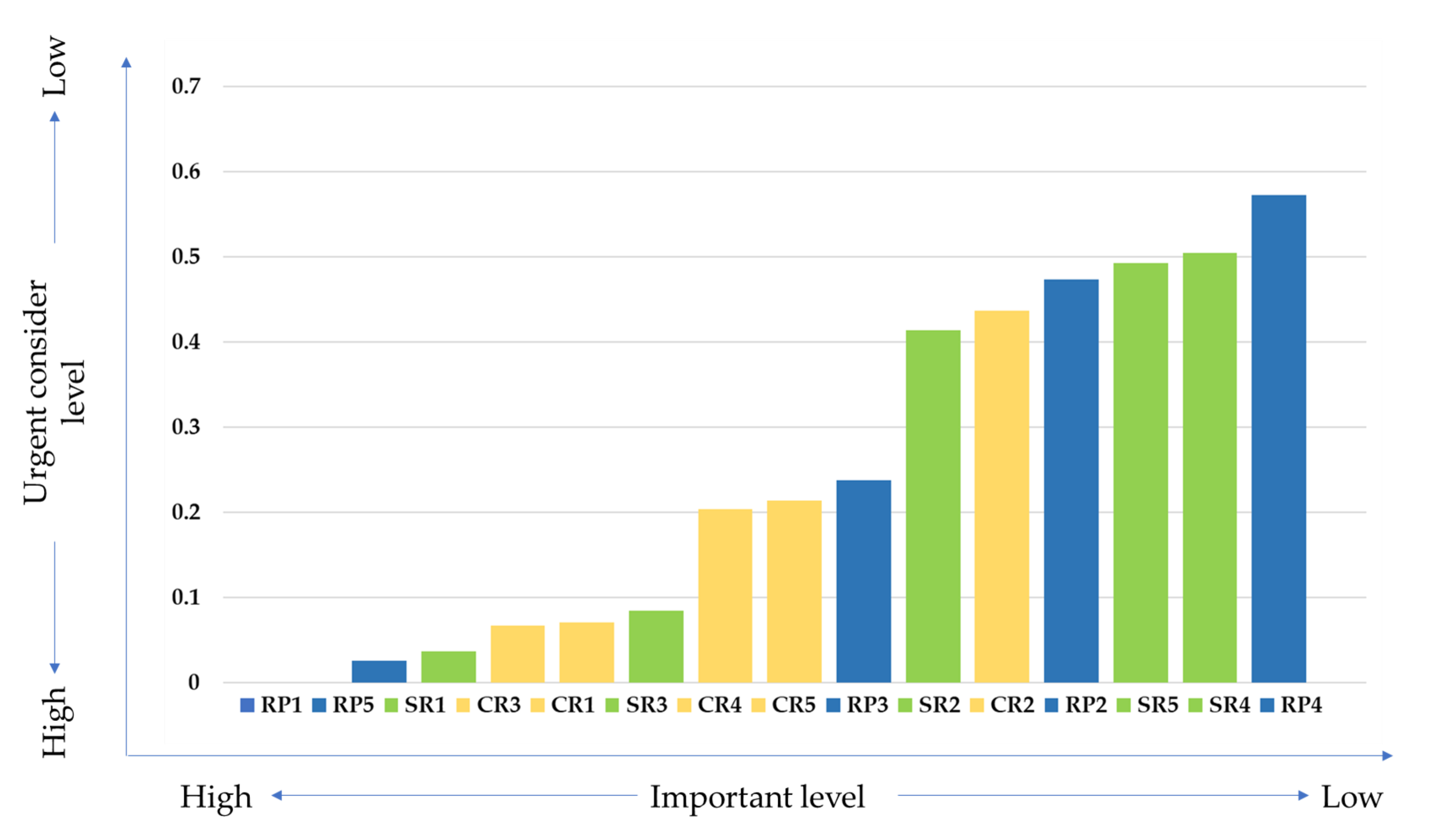

5. Research Implications

The findings of this research provide three important additions to the existing literature. First, this paper introduces 15 SCR barriers for SMEs across three categories: the resilience phase (RP), strategy resilience (SR), and resilience competencies (CR). Second, the study identifies and ranks these barriers, shedding light on how SMEs perceive their ability to follow blueprints in a volatile environment. Finally, the paper significantly contributes to the SCR literature by critically ranking the identified barriers on the basis of evidence from the Vietnam supply chain. More importantly, the authors introduce an exciting new topic for discussing the elements that hinder SMEs’ resilience. They also highlight the varying sub-barriers within each construct of the resilience concept. Moreover, the study offers several theoretical insights into the SCR literature by comparing its findings to previous studies.

This article provides valuable insights for SMEs operating in the Vietnam supply chain, an article whose approach could be taken for use in another context. First, this research investigated the various elements contributing to the SCR management of SMEs in Vietnam. As a part of a complicated supply chain, which necessitates that managers of SMEs have a firm grasp of SCR knowledge because of the interdependence of the SMEs in the entire supply chain. Hence, the article aims to equip SMEs with a resilient mindset to help them identify potential risks, devise contingency plans, and swiftly respond to any disruptions. Second, this study sheds light on the resilience of the Vietnamese supply chain through SMEs and provides new evidence for top managers. In detail, financial resources and budgetary constraints were the most difficult of the barriers that SMEs faced. Moreover, this research stresses that government policy and support broadly impact SMEs’ resilience. Thus, the influence of SMEs on the economy’s resilience deserves more consideration from policymakers. Finally, the article recommends that SMEs adopt flexible resources to overcome human barriers in the SCR management process, such as top management commitment to a competent workforce.

This paper is a reference source for managers to examine their current circumstances to remove related barriers. Additionally, they should focus on building resilience within their organization to ensure their long-term sustainability and success in the supply chain.

6. Conclusions, Limitations, and Future Research

This contribution is an effort to distinguish and analyze significant barriers to adopting SCR concepts in the Vietnamese SMEs context. In this research, the authors reveal 15 barriers related to SCR adoption by using a literature survey and feedback received from experts. In addition, it establishes a hierarchy of SCR barriers that could help managers focus on overcoming obstacles in each cluster, which is crucial for increasing SCR success rates. According to the findings, the following is our ranking of the most critical barriers in SCR practices in the Vietnam context: a lack of financial resources (RP1); a lack of available alternatives for sources of supply (RP5); a lack of a skilled and competent workforce (SR1); the noncommitment of top management (SR3); a lack of policy, guidance, and support from the government (CR3); and a lack of collaboration across the supply chain (CR1). Further, this paper identifies significant obstacles that need to be addressed and eliminated or prioritized in each phase to ensure the resilience of SMEs. This research minimizes the lack of literature on SCR by identifying and ranking barriers. This paper has contributed to the supply chain literature by addressing resilience and SMEs. This paper examines the capability of SMEs to explore 15 barriers to implementing resilience, and this study contributes to the current literature on SCR.

Supply chain resilience has been emphasized, and several barriers to bolstering resilience in SMEs have been outlined. Unfortunately, the study contains limitations, which are promising ideas for future works as follows. First, the collected data scope was restricted to 15 Vietnamese experts in the supply chain field, and this study took the fuzzy VIKOR approach. Thus, specific recommendations for other scholars that could attempt other methods of making decisions based on various SCR barriers, such as AHP and TOPSIS, are also utilized to rank the obstacles. In addition, the quantitative method could be suggested to solve the limitation related to sample size. Second, this work has identified 15 SCR barriers from consultations with Vietnamese experts’ and from the existing literature. In subsequent research, other scholars could explore more obstacles and investigate the importance of barriers preventing supply chain resilience for SMEs. Lastly, the authors focused only on Vietnamese SMEs and did not make comparisons or consider large enterprises. Hence, the authors suggest that other scholars compare these findings with other studies by choosing another context, such as a particular industry or a different economy.