1. Introduction

The new round of information technology and industrial upgrading is accelerating the transformation of the international scientific and technological competition pattern, especially the development of the digital economy, which has become the main driving force for national economic growth. Given the continuous development and application of digital technology, the production and operation methods of enterprises are also changing [

1]. Given the opportunity for digital transformation, enterprises use digital technology to reshape enterprise strategy, organizational structure, adaptability, production processes, and other links to adapt to the changing digital economic environment [

2]. Gradually updating digital technology in industrial production has improved production efficiency and has become an important choice for major economies globally to accelerate economic and industrial transformation and upgrading. The “Global Digital Economy White Paper (2022)” released by the China Academy of Information and Communications shows that China, the United States, and Europe have formed a tripolar pattern of global digital economy development. In 2021, the scale of the US digital economy reached

$15.3 trillion, accounting for over 65% of GDP and ranking first globally. During the same period, the scale of China’s digital economy was 7.1 trillion US dollars, ranking second globally but accounting for only 39.8% of GDP

1. In 2020, the digital transformation of the manufacturing market was

$263.93 billion and is expected to reach

$767.82 billion by 2026, for a compound annual growth rate of 19.48% in the 2021–2026 forecast period

2. The arrival of Manufacturing Industry 4.0 has accelerated the cultivation, development, and application of enterprise digital technology, making the production process more intelligent and modern. In this mode, traditional industry boundaries will gradually disappear, and various new industrial forms and models will emerge. The process of creating new value is changing, and the industrial chain, supply chain, and value chain are also restructured.

Digital transformation is a major technological revolution [

3] and the beginning of a new economic paradigm, affecting industrial structure, consumer demand, and competition rules [

4]. The digital transformation and the consequent innovation of business models have significantly altered consumer expectations and behaviors [

5]. As a response, both individuals and organizations now strive to integrate diverse resources to achieve innovation [

6]. The breakthrough development and comprehensive penetration of technologies, such as cloud computing, big data, the Internet of Things, and artificial intelligence, have led to drastic changes in enterprises’ technological environment [

7]. Sensors collect and analyze data in real time from production and organizational environments [

8,

9]. Enterprises enhance their information processing capabilities by adopting digital technologies related to Industry 4.0 [

10,

11,

12,

13], expand and utilize resources in company processes [

14], and improve the performance of manufacturing enterprises [

15]. The new generation of information network technology is deeply integrated with the manufacturing industry, and advanced sensing technology, digital design and manufacturing, robots, and intelligent control systems are increasingly widely used, promoting profound changes in manufacturing research and development design, production processes, and enterprise management models. The form of the manufacturing industry is undergoing significant changes. Personalized customization has increasingly become an important manufacturing paradigm, leading to the transformation of production organizations and the social division of labor toward networking, flattening, and platformization. The boundaries of enterprises are also becoming increasingly blurred, presenting many new features.

Faced with increasingly fierce international competition and organizational change, enterprises face an increasingly complex external environment, with a significant increase in uncertainty [

16]. Digital technology has become an important means for enterprises to establish strategic advantages [

17]. Using digital technology to achieve the digital transformation of data acquisition, transmission, and value creation is an important way for enterprises to create competitive advantages in the digital era [

18,

19]. When enterprises face profound environmental disturbances, the market environment is relatively complex, technology iterates rapidly, and potential demands constantly change. On the one hand, digitalization drives improvements in total factor productivity through innovation [

20]. On the other hand, digitization enriches the composition of innovation ecosystem elements, improves the collaborative and symbiotic relationship between innovation elements, and promotes enterprises to leverage their technological innovation advantages and engage in breakthrough innovation, ultimately leading to an increase in innovation efficiency [

21]. Some manufacturing firms have enhanced the connection between investing in innovation, controlling costs, and safeguarding profits through digital transformation, resulting in substantial advancements in their innovation capabilities [

22]. Similarly, digital transformation has accelerated the integration of innovation and sustainable development, optimizing business models and performance [

23].

Digital technology has accelerated the change in business models in many industries and plays an important role in the resource-matching stage [

24]. Given the arrival of the digital economy, digital technology has gradually penetrated all aspects of enterprise production and operations [

25]. Within the enterprise, the digitization and intelligence of production processes have promoted the matching of digital resources with various existing resources, optimized production and manufacturing processes, and further reduced internal costs [

26]. In addition, an improvement in digital capabilities promotes the corporate identity to identify and acquire valuable external digital resources to meet market policies and partner and customer needs and the matching and utilization of resources [

27]. Therefore, digital resource identification is the foundation and guarantee of resource integration. The stronger the ability of enterprises to apply digital resources is, the more diverse the matching combination between digital and other types of resources is [

28]. This advantage is more evident in manufacturing enterprises, where digital innovation makes them more agile and flexible [

29,

30].

In the context of the growing popularity of digital technology, high-end equipment manufacturing enterprises are willing to implement digital transformation and upgrading because of their power to improve production efficiency and enhance enterprise competitiveness. However, due to the uncertainty of cost inputs, income, and other factors, many high-end equipment manufacturing enterprises have different choices regarding whether to implement digital transformation and upgrading [

31]. Therefore, the power of enterprises’ digital transformation is affected by many aspects, such as enterprise development strategy, technological adaptability, transformation benefits, government policies, etc. Among them, as an effective regulatory mechanism, government subsidies can significantly improve the enthusiasm of enterprises for digital transformation [

32], and subsidy policies can guide enterprises to take positive actions that are beneficial to their interests and sustainable social development [

33].

Researchers from various countries and regions have carried out studies on the driving factors and mechanisms underlying enterprise digital transformation through various methods. Cyrielle Gaglio employed the Crepon-Duguet-Mairesse model to assess the correlation between digital technology and innovation performance as well as the productivity of small and micro enterprises in South Africa. The analysis revealed that exploiting digital technology was highly advantageous for small firms [

34]. Zhao [

35] utilized the difference-in-differences (DID) approach to assess the effects of low-carbon policies on the digital transformation of enterprises. The research implies that the government can enhance firms’ readiness for digital transformation by fortifying fiscal technology expenditures and loosening financing constraints. Similarly, Wu [

36] employed the multi-stage difference-in-differences methodology to ascertain that digital transformation has revolutionized the production methods of businesses, restructured their manufacturing processes, and decreased both energy consumption and pollutant emissions. Wang’s [

37] study revealed that increasing investment in digital transformation could facilitate the shift towards a service-oriented manufacturing sector and expedite the green transformation of the industry. This was achieved through the moderating effect of digital transformation. Ghobakhloo [

38] summarized 11 key factors for the success of digital transformation in small and medium-sized enterprises through a qualitative analysis of the literature. For instance, the investigation discovered that securing external assistance for digitalization is at the forefront of guaranteeing the accomplishment of the digital transformation.

Although there are many literature studies on digital transformation of enterprises through qualitative and quantitative methods, regression analysis [

39] and case studies [

40] are mainly used, and there is a lack of analyses on the driving factors of the digital transformation of enterprises by different stakeholders. Moreover, from the perspective of research objects, it includes large text companies [

41], multinational enterprises [

42], listed companies [

43], and so on. However, equipment manufacturing enterprises are seldom analyzed from an evolutionary game perspective, despite being a significant aspect of digital transformation. This paper aims to explore the mechanism of stakeholders within the digital transformation of equipment manufacturing enterprises. To achieve this, a stakeholder-based game analysis model utilizing an evolutionary game model was constructed. The following contributions have been made:

(1) The manuscript establishes an evolutionary game model for the digital transformation of manufacturing enterprises. It examines the equilibrium points in multipart games based on the level of government subsidies and consumer preferences, extending the scope of research on the digital transformation of manufacturing firms.

(2) The study employed numerical simulation analysis to examine the impact of government subsidy intensity and consumer preference on the evolution of the system. It revealed a complex interactive relationship between equipment manufacturing enterprises, the government, and consumers.

(3) Based on the findings of an evolutionary game analysis, in conjunction with XCMG’s digital transformation process—which is a leading enterprise in the Chinese construction machinery industry—this study verified the mechanism of stakeholders in the digital transformation and put forth policy recommendations accordingly.

The rest of the paper is organized as follows:

Section 2 introduces the research methods, including establishing a payment matrix for both parties in the manufacturing enterprise game, setting parameters, and analyzing the stability of equilibrium points.

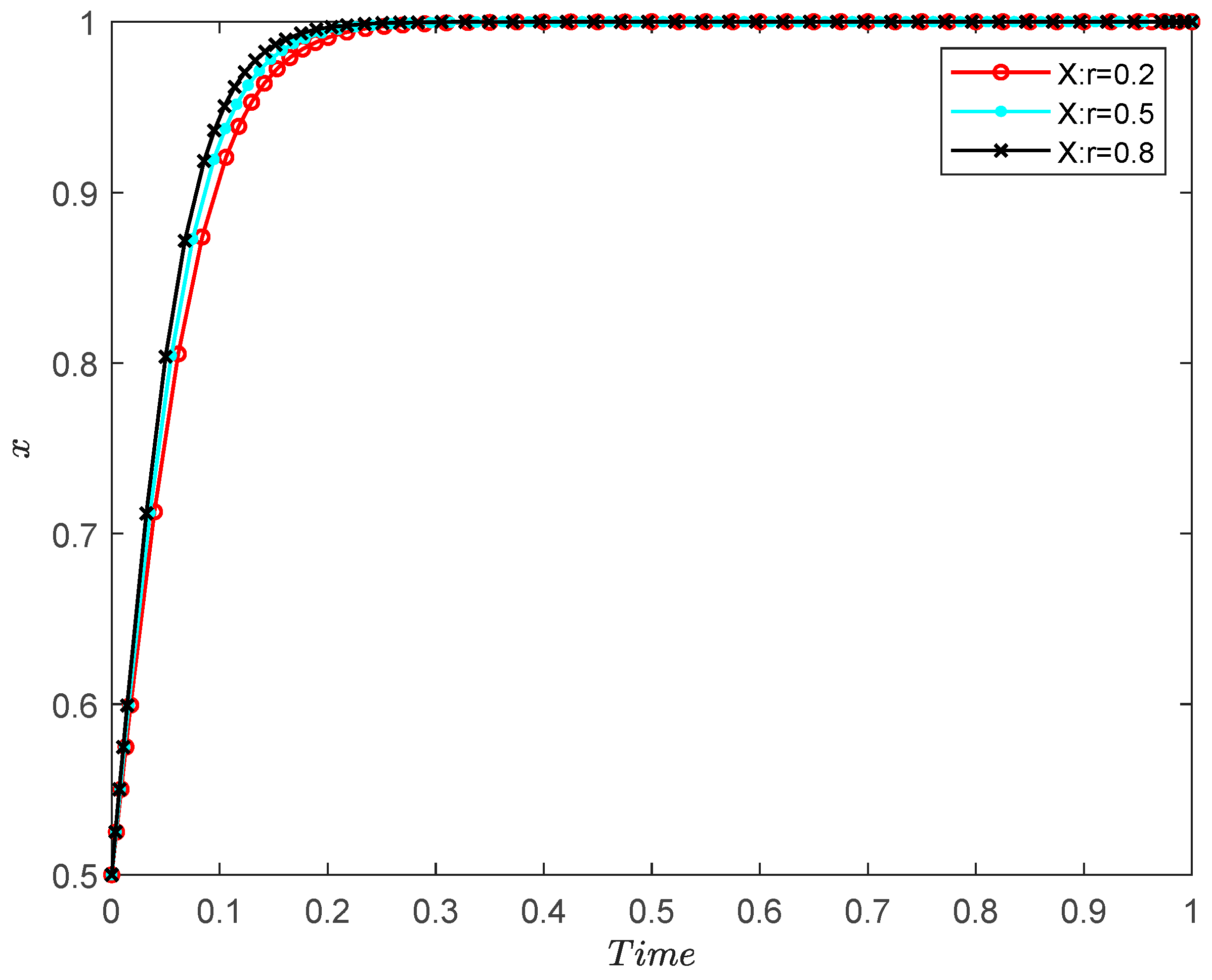

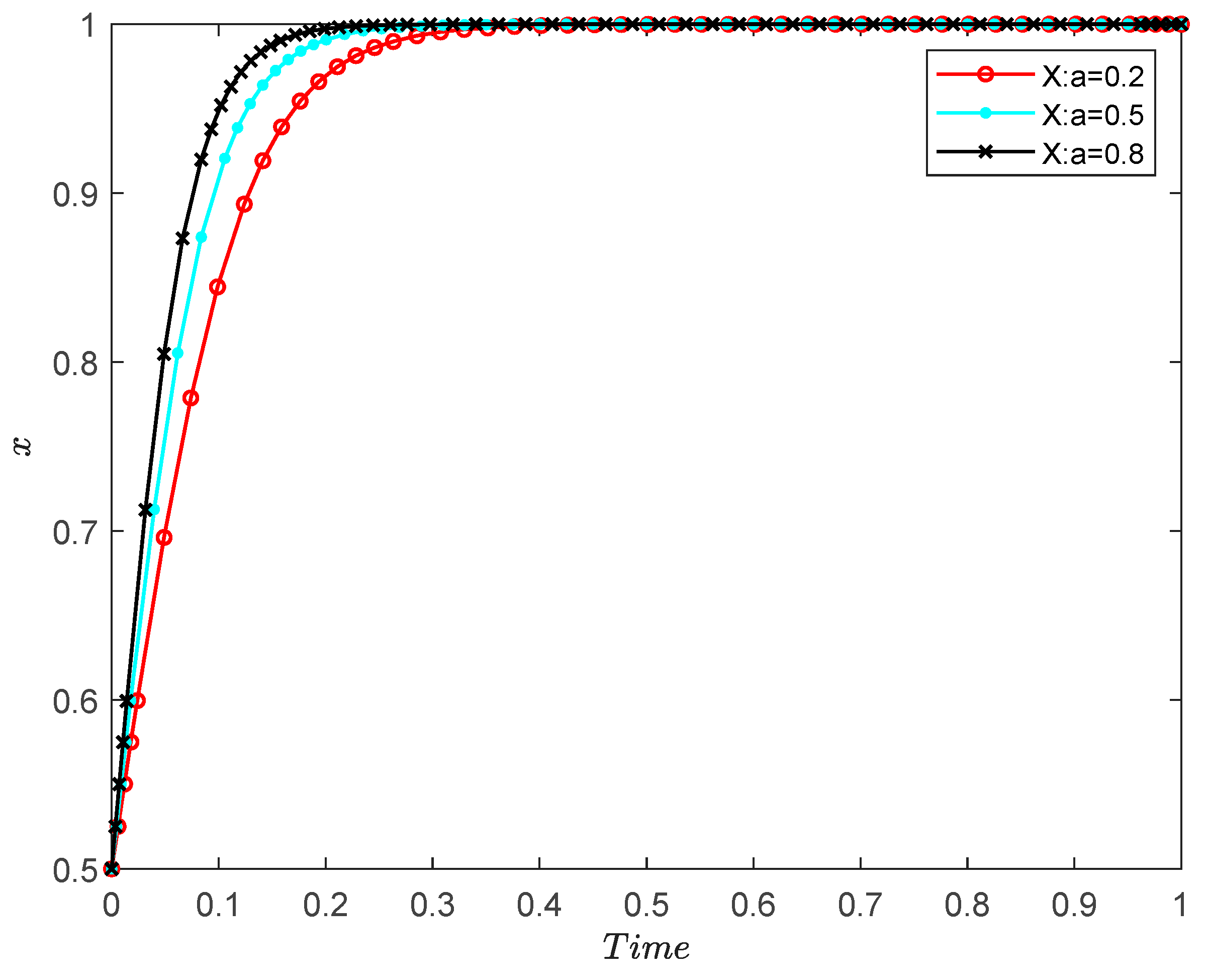

Section 3 simulated the impact of government subsidy intensity on system evolution under different coefficients and the impact of consumer preference on system evolution through numerical simulation analysis.

Section 4 examines the effect of government subsidies and consumers on the digital transformation of China’s leading construction machinery production enterprise. The Xuzhou Construction Machinery Group (XCMG) performs case studies to investigate the driving mechanism of digital transformation in equipment manufacturing enterprises.

Section 5 summarizes the research findings, identifies deficiencies in the research, and recommends policies based on the analysis results.

2. Research Methods

2.1. Research Framework

Contingency theory suggests that a company’s strategic choices are related to its internal and external environment [

44]. To improve production processes, increase product market competitiveness, and respond to external environmental uncertainties, enterprises are actively adopting digital technology to accelerate their digital transformation [

22]. The implementation of digital technology has the potential to increase the trustworthiness of technology for decision makers [

45], and when the benefits obtained by enterprises are greater than or equal to the cost of implementing this behavior, digital transformation will be chosen [

46]. Digital transformation is also the key to promoting the rapid growth of enterprises [

47] and ensuring long-term competitive advantages [

48].

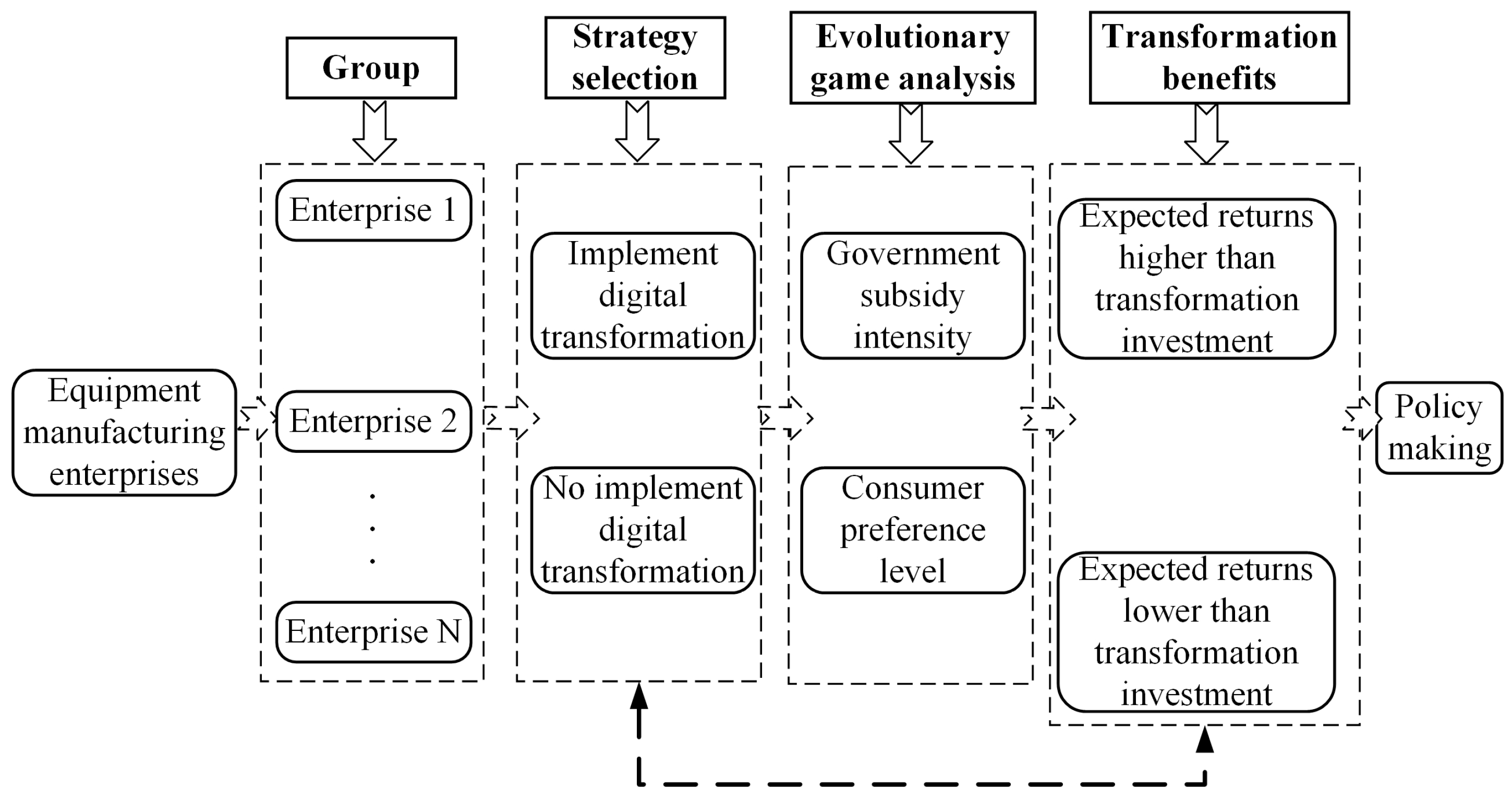

Among equipment manufacturing enterprises, some have developed clear digital transformation strategies or require the use of digital technology in certain production processes or management methods, which may create motivation for digital transformation. However, not all equipment manufacturing companies are actively taking measures to accelerate the application of digital technologies. For example, after considering the costs of digital transformation, some enterprises may find that the expected benefits are lower than the transformation costs, which may result in a negative response to digital technology. However, due to the strong promotion of digital transformation by government departments, a series of financial subsidy policies, tax reduction policies, and digital talent training subsidies have been introduced to guide equipment manufacturing enterprises in digital transformation from multiple aspects. In this situation, some equipment manufacturing enterprises that did not consider digital transformation before have also undergone digital transformation due to the emergence of government subsidies, taking into account production costs and the prospects of digital transformation. In addition, consumers’ preferences for highly digitized equipment manufacturing products have also had a significant impact on companies’ digital transformation strategies. They prefer products that can monitor equipment performance and operation in real time, so leading equipment manufacturing enterprises are more actively engaged in digital transformation practices. Under the influence of factors such as the cost of digital transformation, government subsidy policies, and consumer preferences, a comprehensive consideration of the expected benefits of digital transformation is made to decide whether or not to transform. In addition, government departments introduce relevant policies based on the transformation stage of enterprises to guide them to actively transform. The research framework is shown in

Figure 1.

2.2. Parameter Setting

(1) In the “natural” environment, without considering other constraints, the manufacturing enterprises producing the same product are regarded as a system, which has two different types of bounded rationality, and they are divided into Group 1 and Group 2.

(2) Enterprises from Group 1 and Group 2 are randomly selected multiple times for a game. The enterprises selected from Group 1 are called Enterprise 1, and the enterprises selected from Group 2 are called Enterprise 2. In the game process, the enterprises in Group 1 and Group 2 choose to either implement or not implement the digital transformation.

(3) The government provides certain subsidies to enterprises that choose to implement digital transformation, and the subsidy intensity is (). Consumers have a certain preference for enterprises that can provide digital and personalized services, with a preference level of ().

(4) The income of enterprises choosing to implement digital transformation is (i = 1,2 represents Enterprise 1 or Enterprise 2); the benefit of enterprises not implementing digital transformation is (i = 1,2), . The investments in enterprises when implementing digital transformation is (i = 1,2). If all enterprises choose digital transformation, the system produces a certain synergistic effect. At this time, the investment amount (i = 1,2) is smaller than that of independent digital transformation, that is, . The government’s subsidy amount for enterprises is (i = 1,2) (or ). If consumers have a certain preference for digital enterprises, then when one enterprise chooses to implement a digital transformation and another enterprise does not, the change in revenue caused by the change in sales volume is (i = 1,2). represents the benefits of Enterprise 1 under different strategies and represents the benefits of Enterprise 2 under different strategies.

2.3. Evolutionary Game Equilibrium Point

As assumed above, the payment matrix under the two strategies of implementing and not implementing a digital transformation for manufacturing enterprises 1 and 2 under government supervision is shown in

Table 1.

Assuming that in Group 1, the proportion of enterprises implementing a digital transformation is

, the proportion of enterprises not implementing a digital transformation is

. The proportion of enterprises implementing a digital transformation in Group 2 is

, and the proportion of enterprises not implementing a digital transformation is

. From the game payment matrix, we calculate the expected return

of Enterprise 1 when it chooses the digital transformation but not the expected return

of the digital transformation and the average return

of Enterprise 1, namely:

In the same way, it can be calculated that Enterprise 2 chooses the expected return

of digital transformation, not the expected return

of digital transformation and the average return

of Enterprise 2, namely:

According to the dynamic replication equation, we assume that Enterprises 1 and 2 choose the growth rate of digital transformation technology in the overall proportion as

and

, respectively. Then, the Malthusian equation is:

If , it can be concluded that , , and . If , it can be concluded that , , and . For the convenience of analyzing problems, we set and .

Lemma 1: The equilibrium points of the system are (0,0), (0,1), (1,0), and (1,1). When and , is also the equilibrium point of the system.

2.4. Stability Analysis of Equilibrium Points

According to Friedman’s method, the local stability of the evolutionary game equilibrium point is determined by constructing the Jacobian matrix of the system. The evolution game Jacobian matrix of enterprises’ choice of digital transformation can be obtained by successively solving the partial derivative

and

of the differential equation with respect to the sum:

If the trace condition of the Jacobian matrix (the sum of the elements on the diagonal of the Jacobian matrix is less than 0) and the Jacobian determinant condition (the determinant is greater than 0) are met, they are denoted as

and

, respectively. The equilibrium point of replicating dynamic equations is the local stable point, which is an evolutionary game stability strategy (

Table 2).

Setting and indicate the difference in revenue when enterprises choose to implement and not implement a digital transformation when the government implements subsidies and consumers prefer digital services.

Proposition 1. When the range of the income difference between the enterprises that choose and do not choose the digital transformation changes, the stable evolution strategy of the game between the two sides also changes. (1) If , the evolutionary stability strategy (ESS) of the system is . (2) If , the evolutionary stability strategy (ESS) of the system is . (3) If , the evolutionary stability strategy (ESS) of the system is . (4) If and , the evolutionary stability strategy (ESS) of the system is . (5) If and , the evolutionary stability strategy (ESS) of the system is or .

Proposition 1 indicates that in the game of enterprises implementing a digital transformation, the game’s evolution and stability strategy are mainly affected by the initial states and relevant parameters of both sides of the game. Different states and parameters drive the game results of enterprises to evolve in different directions. Next, a specific analysis is conducted on the above five situations, and the following conclusions are drawn.

Conclusion 1. When , for Enterprises 1 and 2, the difference between the income transfer generated by consumer preferences and the income when enterprises choose or do not choose digital transformation is greater than the investment required by enterprises to implement digital transformation alone after government subsidies. At this point, (1,1) is the evolutionary stability point, (0,1) and (1,0) are the saddle points, and (0,0) is the unstable point. After a long period of repeated games, both Enterprises 1 and 2 tend to choose to implement the digital transformation and finally achieve the stable ideal state of digital transformation for all manufacturing enterprise groups.

Conclusion 2. When , the profit margin of Enterprise 1 was greater than that of individual investments, while Enterprise 2’s profit margin was smaller than that of individual investments. At this time, (1,0) is the evolutionary stability point, (0,0) and (1,1) are the saddle points, and (0,1) is the unstable point. After a long and repeated game between Enterprises 1 and 2, Enterprise 1 chooses to implement digital transformation, and Enterprise 2 chooses not to implement digital transformation.

Conclusion 3. When , the profit margin of Enterprise 1 is smaller than that of individual investments, while Enterprise 2 has a profit margin greater than that of individual investments. At this time, (0,1) is the evolutionary stability point, (0,0) and (1,1) are the saddle points, and (1,0) is the unstable point. After a long and repeated game between Enterprises 1 and 2, Enterprise 1 chooses not to implement digital transformation, and Enterprise 2 chooses to implement digital transformation.

Conclusion 4. When and , Enterprise 1′s return difference is less than that of individual and collaborative investments, as is Enterprise 2’s return difference. At this time, (0,0) is the evolutionary stability point, (1,0) and (0,1) are the saddle points, and (1,1) is the unstable point. After long-term repeated games, both Enterprises 1 and 2 tend to choose not to implement a digital transformation.

Conclusion 5. When and , the return difference of Enterprise 1 is smaller than that of individual investments but greater than that of collaborative investments, and the return difference of Enterprise 2 is smaller than that of individual investments but less than that of collaborative investments. At this time, (0,0) and (1,1) are evolutionary stability points, (1,0) and (0,1) are unstable points and are saddle points. After long-term repeated games, Enterprises 1 and 2 tend to choose to jointly or jointly not implement digital transformation.

The above conclusions show that the appropriate adjustment in the intensity of government subsidies and the degree of consumer preference can enable both sides of the game to implement the digital transformation strategy with a higher probability and keep this strategy in an evolutionary and stable state. The government’s subsidy policy for enterprises to implement digital transformation can reduce related costs, improve the probability that enterprises engage in digital transformation, and encourage enterprises to actively carry out reform. Consumers’ preference for digital services can also improve the income of enterprises after implementing the digital transformation and further improving their enthusiasm. Therefore, the government’s introduction of a standardized and reasonable compensation mechanism and greater efforts to publicize the advantages of digital services, improve the efficiency of service consumers, and optimize the service experience can improve the probability of enterprises’ digital transformation and the benefits after transformation, thus achieving the goal of promoting the overall transformation and upgrading of the manufacturing industry.

4. Case Analysis—XCMG

4.1. Typical Case Selection

Established in 1989, XCMG is currently ranked first in the Chinese construction machinery industry, third globally in the industry, and 395th among Fortune 500 Global Brands, and is a leading player in the Chinese construction machinery industry. XCMG has a batch of products that represent the advanced nature of China and even the world: 2000-ton all-terrain cranes, 4000-ton crawler cranes, 700-ton hydraulic excavators, and so on. XCMG’s product sales network covers 187 countries and regions and has established over 300 overseas branches worldwide to provide users with comprehensive marketing services. Its annual exports exceed 2 billion US dollars, maintaining the top export volume in the industry for 30 consecutive years. XCMG has gradually begun to carry out business digitalization since 2008 and has implemented the digital transformation process with manufacturing and service digitalization as the core. Therefore, the case study of XCMG is typical of the digital transformation of equipment manufacturing enterprises.

Case study materials are collected through channels such as enterprise official websites and annual reports of listed companies and through on-site interviews. Between May 2021 and April 2022, 5 on-site interviews were conducted with 26 members of management, digital department executives, frontline production personnel, and machinery purchasing personnel. The case text information is organized and compiled into segments that can be encoded.

4.2. The Course of XCMG’s Digital Transformation

XCMG’s digital transformation is mainly divided into the following three stages.

(1) The initial period of digitization (2008–2013) was mainly focused on business digitization. After the 2008 financial crisis, the Chinese government introduced a “Four-Trillion-Yuan Economic Stimulus Plan”, cyclical industries, such as infrastructure, rapidly recovered. The market demand for construction machinery products increased rapidly, and sales continued to reach new highs. XCMG also seized the opportunity to increase its development and technological transformation efforts, accelerating the pace of internationalization. Against the background of a rapid increase in business volume, XCMG leaders awakened the awareness of digital transformation and began with business digitalization, turning the original information generated in the business process into data. Due to the emergence of digital control requirements, XCMG has gradually applied digital management systems and platforms to integrate collected data and optimize operations and decision making.

(2) The digital development period (2014–2017) mainly focuses on the digitalization of production. At this stage, due to the significant reduction in industry demand, XCMG’s revenues have decreased. To withstand the impact and enhance its competitiveness, XCMG has continuously increased its Research and Development (R&D) investments during the industry’s downward cycle, improved its ability to engage in independent innovation, accelerated digital transformation and upgrading, and started to build information platforms, such as global collaborative R&D, budget management, and business intelligence. At this stage, XCMG continuously adopts and applies new technologies and equipment through independent R&D and technology introduction, digitizes its production lines, and on this basis, has created a digital smart factory and a new digital industrial park.

(3) The digital maturity period (2018–present) mainly focuses on digitizing services. In 2018, China’s macroeconomic situation gradually improved, and the increase in public infrastructure investments has brought new demand to the construction machinery industry. In this market environment, XCMG’s advantages in digital transformation and digital factory construction during the digital development period have continued to emerge. The construction machinery industry has ushered in new growth, and the overall revenue and profitability level of the XCMG has significantly improved. At this stage, we are building a new base for investments in intelligent manufacturing and constructing an intelligent supply chain system. In 2018, XCMG started a new phase of digital transformation in an all-around way, promoting the comprehensive digitalization of the R&D process and services. The coding results of this stage are shown in

Table 3.

4.3. Impact of Government Subsidies on XCMG’s Digital Transformation

XCMG has established a system that runs through digital research and development, manufacturing, service, and management, achieving data connection and integration throughout the entire management process and reducing management costs. Senior management personnel A of the group stated, “Given XCMG’s active R&D investment and government support, the enterprise has constantly made new breakthroughs in the field of science and technology and has actively applied the results to digital transformation”. In recent years, XCMG has made independent innovations and has developed the world’s first crawler crane, all-terrain cranes, and tower cranes with the largest lifting capacity; the world’s first electric dump truck with the largest load capacity; the world’s first rotary drilling rig with the largest tonnage and the world’s first horizontal directional drilling machine; the world’s first high-altitude jet fire truck; and China’s first largest tonnage hydraulic excavator. At the end of 2022, XCMG Machinery has a total of 9742 valid authorized patents, including 2458 invention patents and 183 international patents.

Table 4 lists some government subsidies related to digital transformation obtained by XCMG in recent years. The government has given some support to enterprises in digital technology application, digital product, R&D, digital platform construction, etc., which has stimulated their willingness to pursue digital transformation and improve its efficiency.

4.4. Impact of Consumers on XCMG’s Digital Transformation

The improvement in XCMG’s product digitization level has enhanced its competitiveness in product design capabilities, marketing channels, understanding of customer needs, and product supply chain management. By creating a convenient and efficient customer relationship management system for customers, all processes such as procurement, contracts, product pricing, and financial settlement are digitized and online, improving the customer’s purchasing experience. In addition, customers can use the digital platform of XCMG to query the operational status of machinery in real time on both computer terminals and mobile apps. Enterprises also provide early warnings for potential problems with machinery based on data from mechanical sensors and equipment. Customer A stated, “Currently, we only choose highly digitized construction machinery products because we can monitor the operation of the machines at any time, and the back end will remind us of maintenance based on sensor data in a timely manner, solving our worries.” Customer B said, “XCMG has sold large-scale machinery and equipment online and has solved the logistics service problem. Even the financial service business is online, which greatly facilitates purchases by our consumers.” The Hanyun Industrial Internet platform developed by XCMG has accumulated 680,000 devices connected to the network and has connected users in more than 20 countries along “the Belt and Road.” The assets managed on the platform have exceeded 550 billion yuan. The Hanyun platform not only connect and collect data from all products but also achieve the interconnection of service personnel, service vehicles, spare parts outlets, and platforms, truly controlling the distribution and utilization of resources in real time, resolving the problem of imbalanced and uneven service resources, and improving service quality and efficiency.

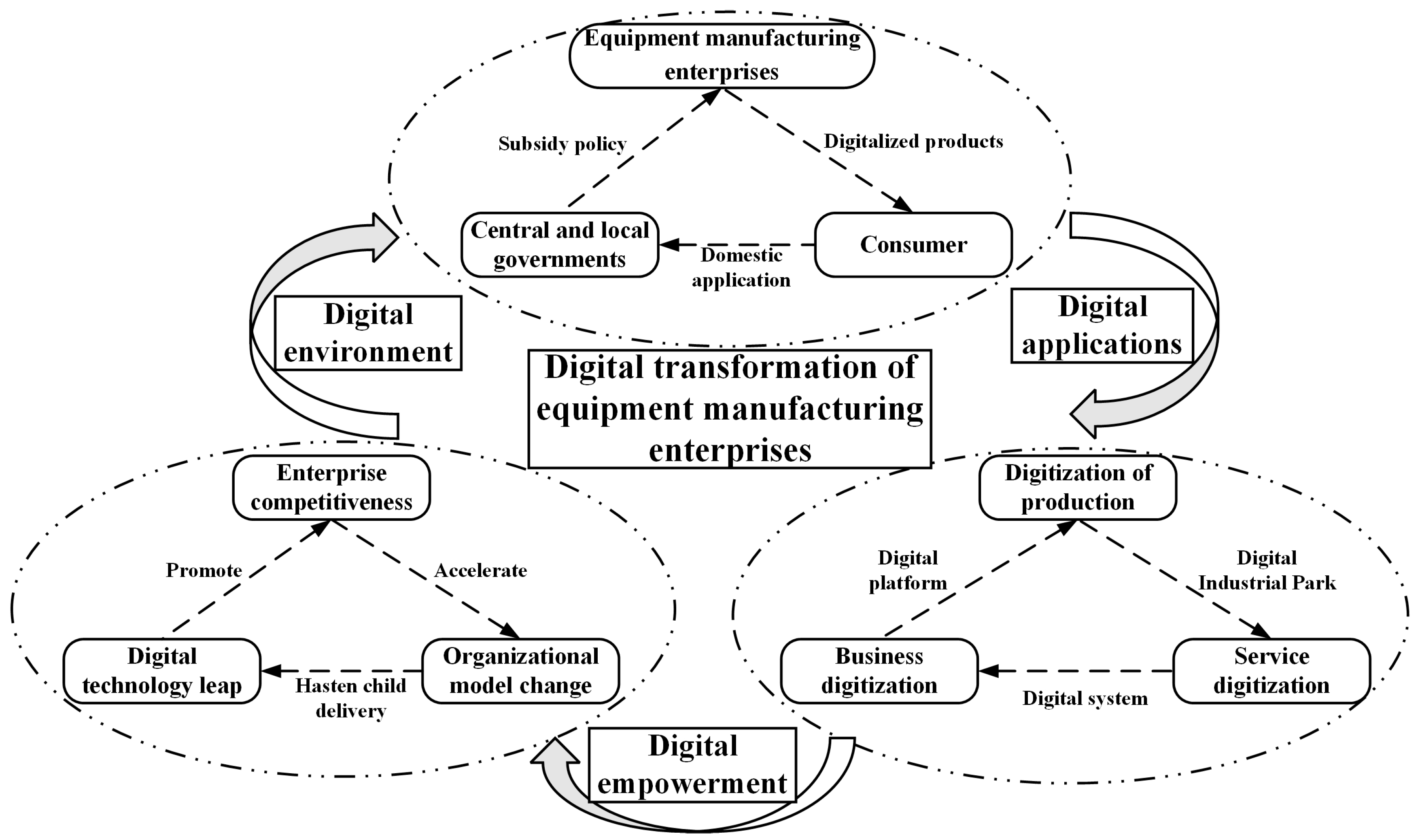

4.5. Dynamic Mechanism of XCMG’s Digital Transformation

The digital transformation of equipment manufacturing enterprises is affected by multiple factors. First, the development level of the enterprise’s industry is an important external factor for the digital transformation of equipment manufacturing enterprises. To improve their competitiveness, enterprises need to compete with their peers in R&D, production, sales, and other aspects. Therefore, they need to optimize their organizational structure. In addition to the continuous breakthroughs in digital technology, the cost of enterprises adopting digital technology is gradually reduced, so a good environment for digital transformation has been formed. Second, the digital transformation of the equipment manufacturing industry is the main pillar that promotes the high-quality development of the digital economy. Central and local governments have introduced a series of subsidy policies to stimulate the willingness of equipment manufacturing enterprises to accelerate the digital transformation process. After receiving subsidies, enterprises increase their investments in digital transformation on the one hand, reduce R&D costs on the other hand, and constantly optimize products with digital technology, forming a benign digital application process. Finally, improvements in production processes, the leap in digital technology, and the transformation of management models have laid a solid foundation for the digital empowerment of equipment manufacturing enterprises in production. Business digitization is a prerequisite for production digitization, and digitally transformed production lines, digital workshops, and parks are key factors to improving product quality and optimizing services (

Figure 4).

5. Conclusions, Policy Recommendations, Limitations, and Future Research

5.1. Conclusions

The rapid evolution of digital technology has provided enterprises with diverse information and services. Jin used a game theory model to discover that market environments such as technology costs, brand power, information asymmetry, and market uncertainty have a profound impact on corporate digital transformation decisions [

49]. In addition, through digital transformation, enterprises have improved their product development processes and generated new digital business models [

50]. On the one hand, the power of the digital transformation of equipment manufacturing enterprises comes from their development strategies. On the other hand, it is related to government subsidy policies and consumer preferences. For example, through an evolutionary game analysis, Yang [

51] found that the government’s fiscal incentive policy significantly promoted firms’ willingness to share knowledge, accelerated their digital transformation, and increased their economic benefits. Equipment manufacturing enterprises are the main executors of digital transformation, and their digital transformation intentions affect the progress and final results of digital transformation. Ensuring efficiency, reducing collaboration costs, and improving collaboration efficiency are conducive to better serving the digital transformation of enterprises [

52]. The government is the policy-maker of equipment manufacturing enterprises and the intervener in digital transformation. The game with enterprises uses information and institutional advantages to influence the effect of digital transformation. Therefore, factors such as the intensity of government governance, the cooperation efficiency, and the input costs of participants have become important drivers for the digital development [

53]. In addition, the choice of consumers is also an important factor in the enterprise’s digital transformation. Equipment with a higher digital degree can respond more quickly to user needs, which is a positive driving factor for the enterprise’s digital transformation. To maximize the benefits of the digital transformation of equipment manufacturing enterprises, it is necessary to rely on the institutional arrangement of combining government support and consumer applications.

Based on the analysis of evolutionary game models and the simulation results of system dynamics, the following conclusions can be drawn.

(1) The intensity of government subsidies significantly affects the transformation progress of equipment manufacturing enterprises. Equipment manufacturing enterprises are mostly traditional industries, so the optimization and upgrading of enterprise production technology is urgent, while digital transformation requires a substantial capital investment for production line transformation, system upgrading, talent training, etc. Therefore, the government subsidy policy accelerates the speed of the evolution of enterprises’ choice to implement a digital transformation strategy. On the one hand, government subsidies reduce the financial burden and stimulate enthusiasm for the digital transformation of enterprises. On the other hand, after the successful digital transformation of enterprises, improvements in product competitiveness increase R&D investments and provide additional benefits for local taxes, employment, etc.

(2) The increase in consumer preferences accelerates the speed of the evolution of enterprises’ choice of implementing digital transformation strategies. Equipment manufacturing enterprises with higher digitalization also respond to an increase in the level of intelligence of their products. Consumers are more convenient in equipment customization, financial services, user experience, and post-maintenance. Digital production and digital services reduce the cost of equipment usage for consumers, improve economic efficiency, and therefore tend to choose products from enterprises with higher digitalization. This consumption preference encourages enterprises to accelerate the implementation of digital transformation.

(3) The case analysis results of XCMG’s digital transformation show that the equipment manufacturing industry is a typical discrete manufacturing industry that needs to improve its enterprises’ flexibility and adaptability through production, thus relying more on digital technology to enable production and management services. Therefore, business process digitalization, production digitalization, and service digitalization are the only ways for equipment manufacturing enterprises to achieve a digital transformation. Given the deep integration of the new generation of information technology and equipment manufacturing enterprises, digital technology penetrates the entire value chain of equipment manufacturing enterprises’ R&D, production, sales, finance, management, and services, improving their high-quality development.

5.2. Policy Recommendations

(1) Strengthen the construction of digital infrastructure and leverage the leading role of enterprises as the main body.

Digital infrastructure is the key to the digital transformation of equipment manufacturing enterprises and must be jointly promoted by governments, enterprises, and digital solution suppliers. First, the Chinese government is accelerating the construction of new infrastructure, such as 5G, the Internet of Things, cloud computing, artificial intelligence, the Industrial Internet, and data centers, which provide basic conditions for the digital transformation of equipment manufacturing enterprises. For example, Zhang Ping, an academician of the CAE (Chinese Academy of Engineering), believes that China’s 5G network construction scale is the world’s leader, which effectively supports the innovative development of the digital economy, forms a new technical route, product form, industrial links, etc., and builds a new 5G integrated technology industry system. In addition, Li Peigen, an academician of the CAE member, believes that an enterprise’s digital transformation should be based on the concept of deep integration of digital space and physical space, and digital twins are the best embodiment of this concept. Second, we should adhere to the principle of taking enterprises as the main body of digital transformation. Because manufacturing enterprises have different scales and are still in different stages of development, we should encourage digital transformation in stages. Especially for the vast majority of small, medium-sized, and microenterprises, it is necessary to explore a technological path suitable for their own digital transformation and upgrading in combination with the actual development of enterprises. For example, Tan Jianrong, an academician of the CAE member, believes that the digital transformation of the manufacturing industry should be through the innovative design of enterprises to develop new products and new functions, and innovative design should become the fundamental way to drive the development of the equipment manufacturing industry. Finally, we should actively play the role of digital solution suppliers, and effective external technology suppliers can actively drive the digital transformation of enterprises. The professional knowledge and experience of the digital transformation of suppliers can effectively guide enterprises to choose the path and mode of digital transformation and comprehensively improve the digital level of enterprises from the dimensions of collaborative research and development, personalized customization, digital production, and digital services.

(2) Establish a subsidy dynamic adjustment mechanism to encourage the high-quality digital transformation of equipment manufacturing enterprises.

Government subsidies can effectively encourage equipment manufacturing enterprises to carry out a digital transformation, and given an increase in government subsidies, the incentive effect is more obvious; however, government subsidies have a threshold effect. When subsidies are small, it is difficult to effectively encourage enterprises to carry out digital transformation. However, excessive subsidies put pressure on government finance, reduce the government’s willingness to support policies to encourage enterprises’ digital transformation, and hinder SMEs’ digital transformation process. For example, academician Zheng Jianhua of the CAE believes that in the process of enterprise digital transformation, it is necessary to help enterprises complete a digital transformation by optimizing the market environment and strengthening policy guidance. Considering the positive effect of government subsidies on the digital transformation of manufacturing enterprises, the government can set special funds for digital transformation to support the digital transformation of manufacturing enterprises. However, due to the threshold effect of subsidies, the government should subsidize equipment manufacturing enterprises’ digital transformation costs within a reasonable range to guide enterprises’ digital transformation. Therefore, the government should implement dynamically adjusted government subsidy policies in conjunction with the market competition environment. In a market with low competition intensity or in the early stage of digital transformation, equipment manufacturing enterprises should allocate more subsidy resources to accelerate the digital transformation of equipment manufacturing enterprises. In a highly competitive market, the effect of government subsidies is weakened. Direct subsidies to equipment manufacturing enterprises should be reduced, and enterprises should be encouraged to combine their own advantages to carry out digital transformation, reducing the inhibitory effect of homogeneous competition on the effect of government subsidies.

(3) Establish a digital sharing platform for equipment manufacturing enterprises and build a collaborative digital ecosystem for development.

The high initial investment cost of digital transformation will have a short-term impact on the economic benefits of enterprises, so some small and micro equipment manufacturing enterprises face a situation in which digital transformation is blocked. When an enterprise has formulated a clear goal of a digital transformation but digital resources are limited, it can choose to join the digital transformation sharing platform developed by equipment manufacturing industry leaders or “chain owner enterprises”, rely on the digital resources of the platform, open up business scenarios such as product design, production, service, and management, and encourage a digital transformation. Ding Han, an academician of the CAS member, established a research and public service platform. After the digital transformation of the manufacturing industry, he was able to solidify the complete process and design technology in industrial software, forming a whole ecological chain digital process of client, demand, design, manufacturing, and product post-maintenance. The leading enterprises benefitting from the advantages of digital transformation can actively build a digital platform, help enterprises that intend to engage in the transformation to participate in the platform, realize the integration and interconnection of industrial chain resources, upstream and downstream information sharing and collaborative cooperation, and drive the overall digital transformation of the equipment manufacturing industry. Through the digital reconstruction of the ecology of the equipment manufacturing industry, an efficient collaboration system including information and capital flows, logistics, and business and data flows will be built to create a new ecosystem of coordinated industrial development.

5.3. Limitations and Future Research

Although this paper studies the driving mechanism of digital transformation of equipment manufacturing enterprises from the perspective of game theory, there are still some shortcomings. Firstly, this article identifies the intensity of government subsidies and consumer preferences as the main driving forces for the digital transformation of equipment manufacturing enterprises. However, in reality, there may be other influencing factors. Secondly, although this article has analyzed the impact of government subsidies and consumer preferences on system evolution through simulation, due to limitations in data collection, there is not enough data to support the sensitivity analysis of this study in the case analysis section, which may lead to insufficient argumentation; and finally, in numerical simulation analysis, the determination of coefficients may affect the simulation results and may require more systematic analysis. Therefore, future research needs to consider more complex situations more comprehensively. For example, more stakeholders are involved in the digital transformation game of enterprises, and more multidimensional game models are constructed. In addition, can the determination of parameters in case-based simulation be based on actually collected data and studied in a more realistic way? The above interesting questions are worth exploring further.