Environmental Supply Chain Risk Management for Industry 4.0: A Data Mining Framework and Research Agenda

Abstract

1. Introduction

2. Theoretical Framework of Industry 4.0 and Environmental Supply Chain Risk Management

2.1. Industry 4.0 Conceptualization

- (1)

- The Smart Manufacturing (SM) concept which is presented as an adaptable manufacturing system where flexible lines automatically adjust production processes for various types of products in various industrial settings [28,29,30]. Smart manufacturing in a smart factory improves quality, productivity, and flexibility, which results in mass customization and efficient resource consumption [23,28];

- (2)

- The Smart Supply Chain (SSC) concept that relates to integrating supply chain processes and partners through the exchange of information and coordination to mitigate undesirable bullwhip effects [16]. SSC aims to render resource use for supply chain members to be more efficient by sharing resources and coordinating activities [31,32];

- (3)

- The Smart Products (SP) concept that provides data feedback for new product development [23] as well as new services and solutions to customers through embedded technologies [33]. Smart products allow new business models such as product-service systems, which create new opportunities for manufacturers and service providers [29,34].

- (1)

- ‘Smart technologies’ aiming to achieve radical transformation of the manufacturing activities based on emerging technologies (Smart Manufacturing) and the way products are designed and marketed (Smart Products) [23]. Those technologies relate to the way raw materials and products are delivered (Smart Supply Chain) [29,35] and the new ways workers perform their activities based on the support of emerging technologies (Smart Working) [36,37]. The combination of these smart technologies creates an integrated network or supply chain that processes various types of flows to address operational and market needs [17,23];

- (2)

- ‘Base technologies’ which include technologies providing connectivity and real-time data for front-end technologies, thus enabling the complete integration of the manufacturing system [38,39,40]. These technologies constitute the foundations of Industry 4.0 dimensions by making interconnectivity possible between manufacturing systems and other processes [40]. The deployment of such technologies is what constitutes the peculiarity of Industry 4.0, differentiating the latter from previous industrial revolutions [38].

- (i).

- IoT resulting from wireless communication between sensors and computing through the internet [41]. Technological advancement made the implementation of IoT possible. Thus, the decreasing cost of sensors along with the expansion of internet networks have allowed the use of this technology to spread among companies [30,42];

- (ii).

- (iii).

- Both cloud and IoT technologies can be combined with different types of equipment to share data, which results in a huge amount of data called Big Data [29,44,45]. The big data collected from equipment, objects, and systems necessitates processing tools/analytics such as data mining and machine learning [33,46]. It is expected that the combination of big data with analytics can make industrial plants and warehouses self-managed and able to optimize their capacity by identifying glitches in the system before their occurrence [30,40,47];

- (iv).

- Additive manufacturing and 3D printing constitute a different approach to manufacturing by generating successive layers of materials through a digital model that contributes to the creation of the final product [48], thus avoiding the need for parts and component assembly. Additive manufacturing and 3D printing techniques can help companies to produce small batches of customized products with complex, lightweight designs [49] which will reduce transport costs and stock on hand [50];

- (v).

- Robotic systems in a smart factory can take charge of various tasks without needing reprogramming [40,51]. Robotic systems can reduce costs, provide a wide range of capabilities (surpassing traditional assembly lines or existing automated guided vehicle) and perform several operations in smart factories [52,53] including tasks too dangerous for human operators;

- (vi).

- Simulations and prototyping can allow organizations to study CPS dynamic behavior through real-time data on machine operations, manufacturing cost, connectivity, and movements [54,55]. In that way, firms can test machine settings to increase quality, reduce setup times, and mitigate risks such as cyber threats [43]. Moreover, simulation and prototyping techniques are used for real-time tracking of manufacturing cost [56], and advanced optimization for planning and scheduling [47].

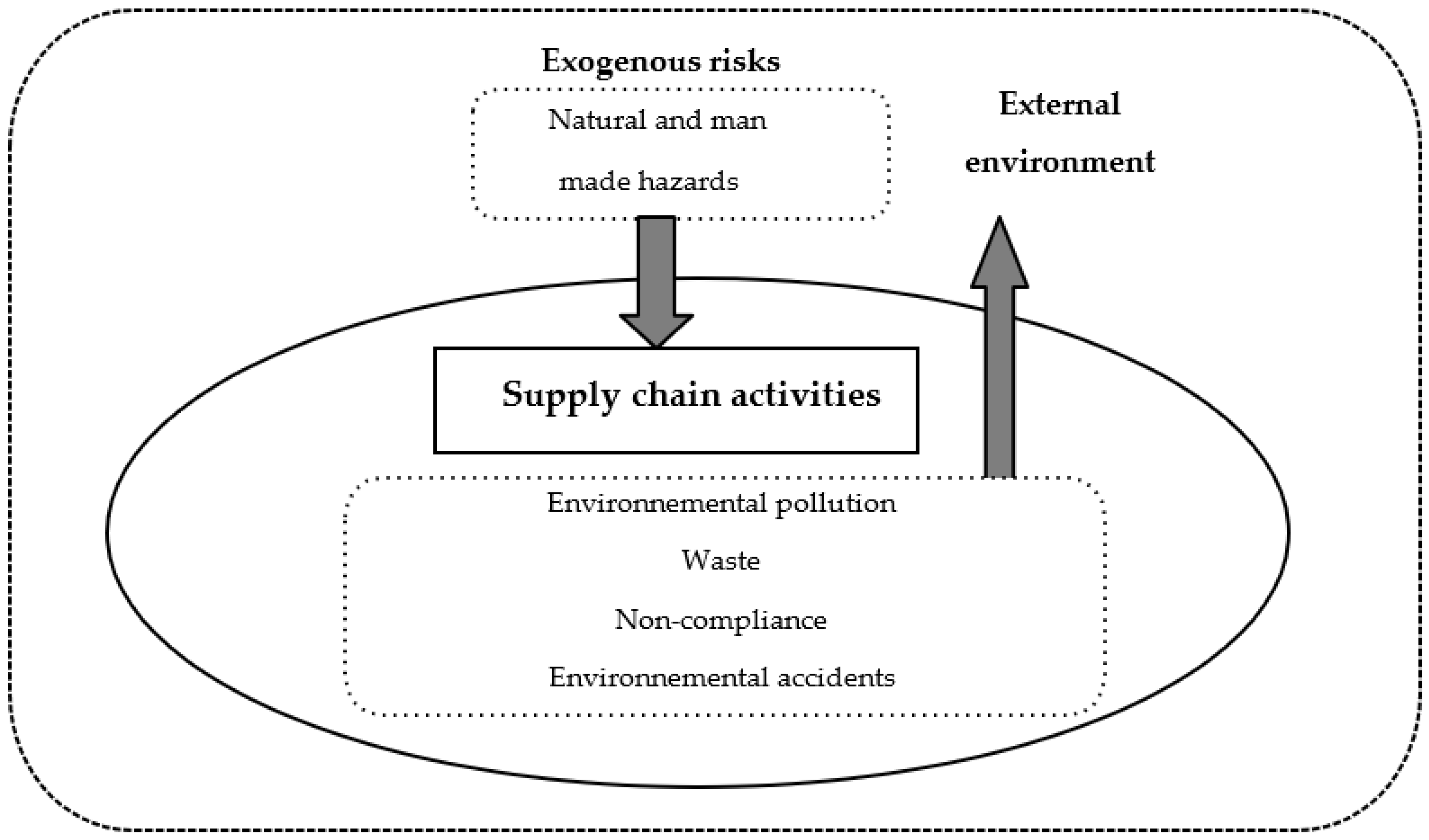

2.2. Environmental Supply Chain Risk Management

- (i)

- Endogenous risks which result from company supply chain operations including pollution and harmful emissions, as well as accidents caused by the firm’s staff, operations, and machines [57]. Endogenous risks include inefficient resource consumption, waste, and scrap generation [58]. Further, other scholars consider non-compliance with regulations related to personnel safety, ecology, and social responsibility as an endogenous risk [6];

- (ii)

- Exogenous risks which emerge from the interaction of firms with their external environment [6,59]. Thus, exogenous environmental risks relate to natural disasters (e.g., earthquakes, hurricanes, and pandemics) and man-made disasters such as terrorist attacks, wars, and military conflicts [60,61]. Numerous scholars [6,10], have prioritized endogenous risks over exogenous risks since the latter are mostly unpredictable and hard to control. In contrast, endogenous risks result from the actions of firms and their supply chain partners, hence the possibility to assign responsibility of mitigating these risks [62].

- –

- –

- –

- –

- Elaborating environmental management programs to address issues related to waste, resources management, recycling, and reuse of materials [68]. Green practices entail managing pollution, emissions, and hazardous substance storage, handling and disposal [10]. Environmental management systems can be developed to ensure the monitoring, tracking, and treatment of greenhouse gas (GHG) emissions [69];

- –

- Developing cooperative initiatives with suppliers and customers. Focal firms can help their suppliers adopt environmental practices through ISO 14000 certification, environmental audits of suppliers’ environmental management system, and providing assistance to suppliers implementing environmental practices [69]. Likewise, firms can be aided by their customers to develop environmental management based on their clients’ requirements;

- –

- Ensuring compliance with legislation related to environmental, safety, and health issues;

- –

- Developing contingency plans in cases of disruption, emergency, and unexpected events related to exogenous risks.

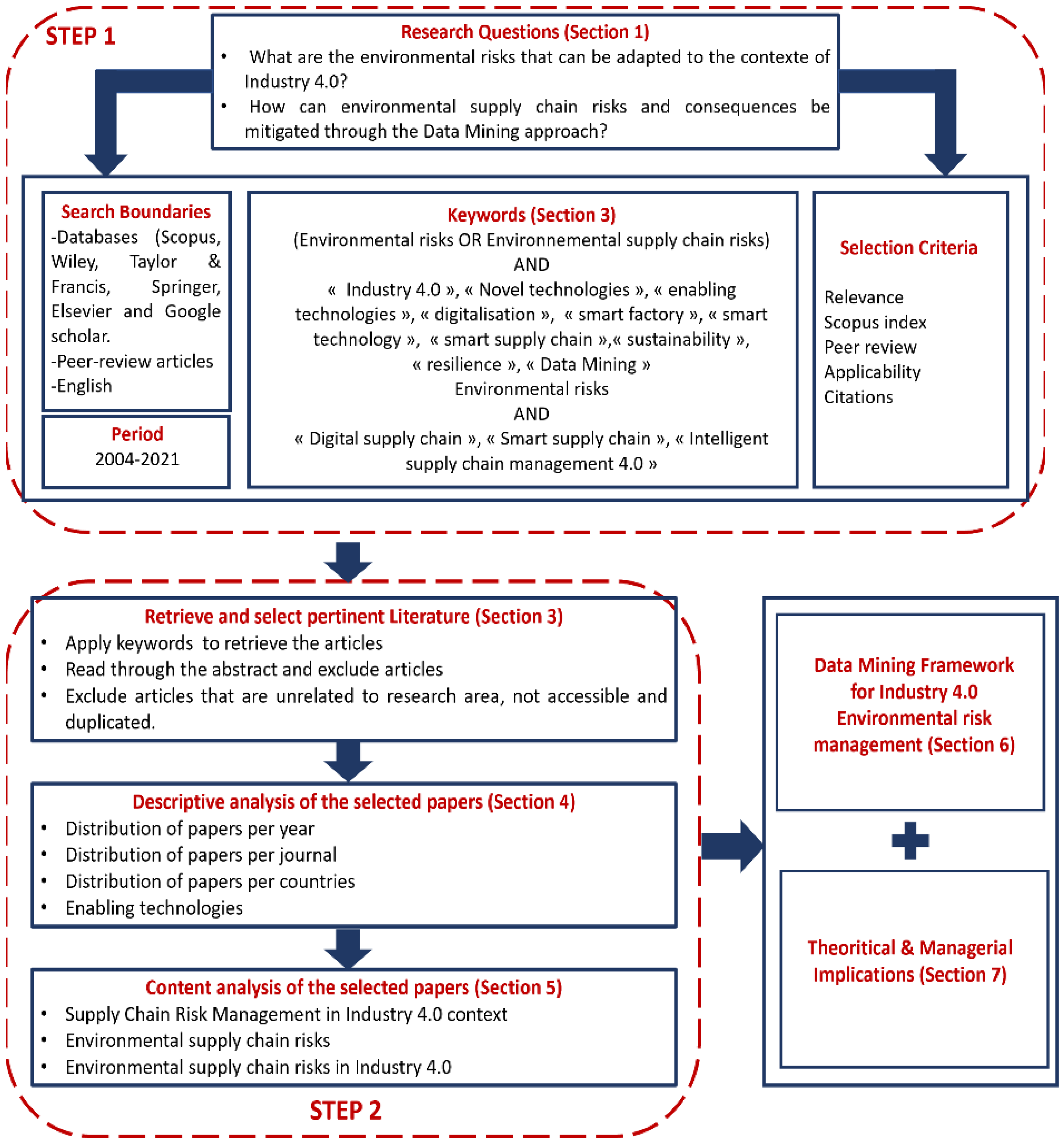

3. Research Methodology

3.1. The Selection and Retrieval Phase

- (1)

- A search was conducted in several databases (SCOPUS, EMERALD, Taylor & Francis, Springer, Elsevier, and Google Scholar) in order to generate a comprehensive set of papers [76];

- (2)

- The review was limited to peer-reviewed publications to guarantee quality [77]. Articles published in peer-reviewed journals are subject to a rigorous process of evaluation prior to publication [76]. Consequently, chapters in books, conference proceedings, and trade journals were excluded from the search;

- (3)

- Conceptual and empirical research was considered in gathering as many publications as possible. The articles identified are from 2004 to 2021;

- (4)

- Only publications in English were considered, to facilitate data analysis;

- (5)

- Subject terms related to ESCRM and Industry 4.0 were used in screening the papers’ titles, abstracts, and keywords to assess their relevance.

3.2. Descriptive and Content Analysis of the Selected Papers

4. The Main Findings of the Literature Review

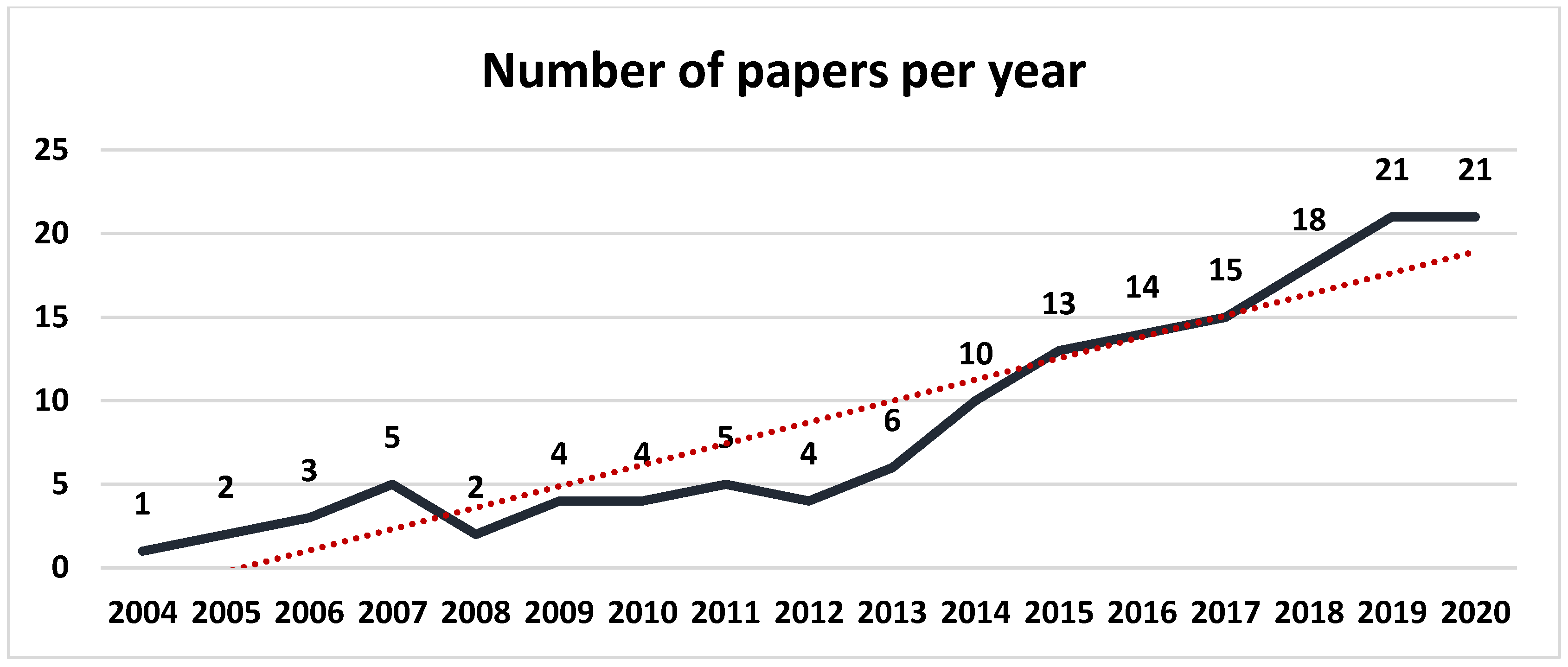

4.1. Chronological Evolution of Papers

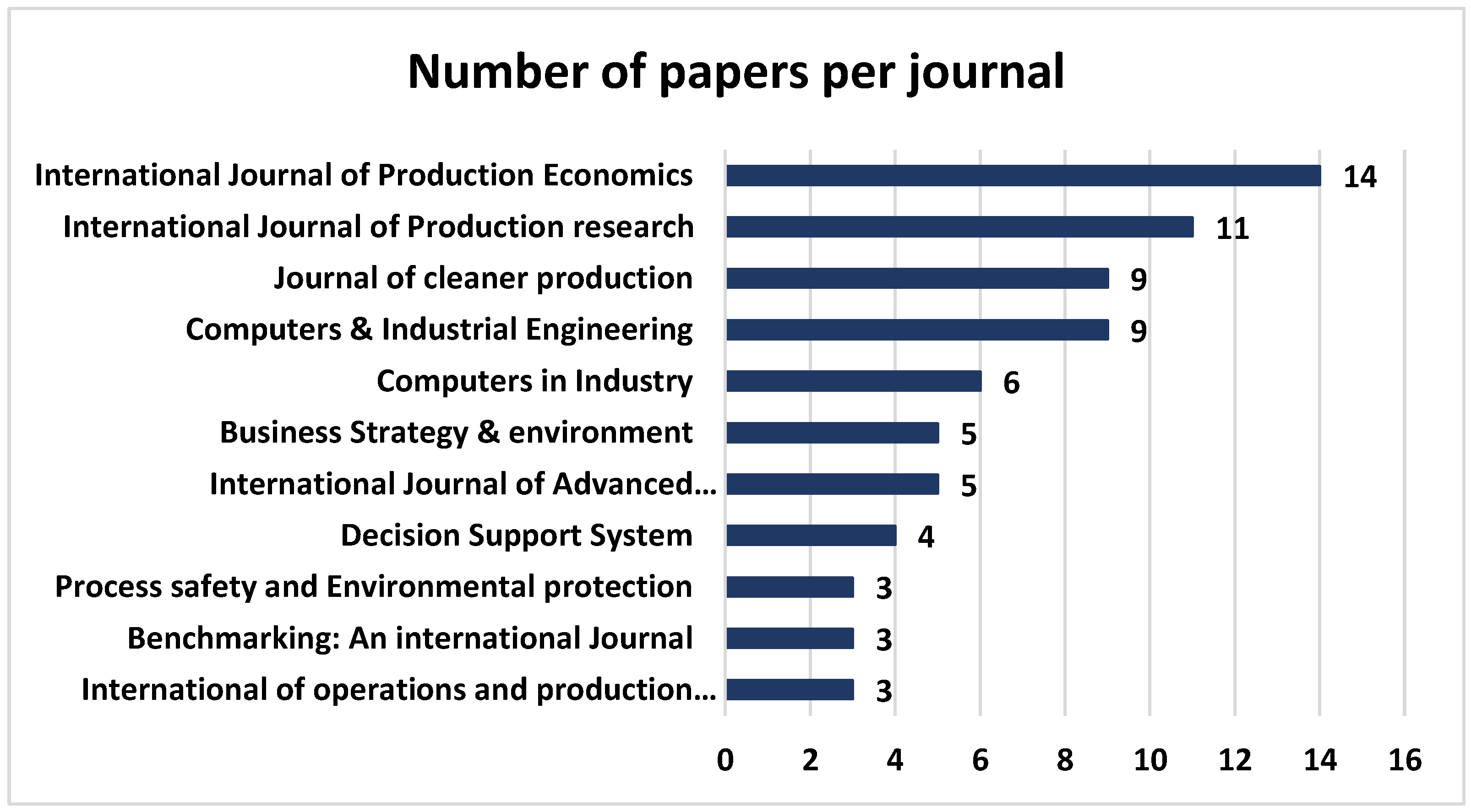

4.2. Most Contributing Journals

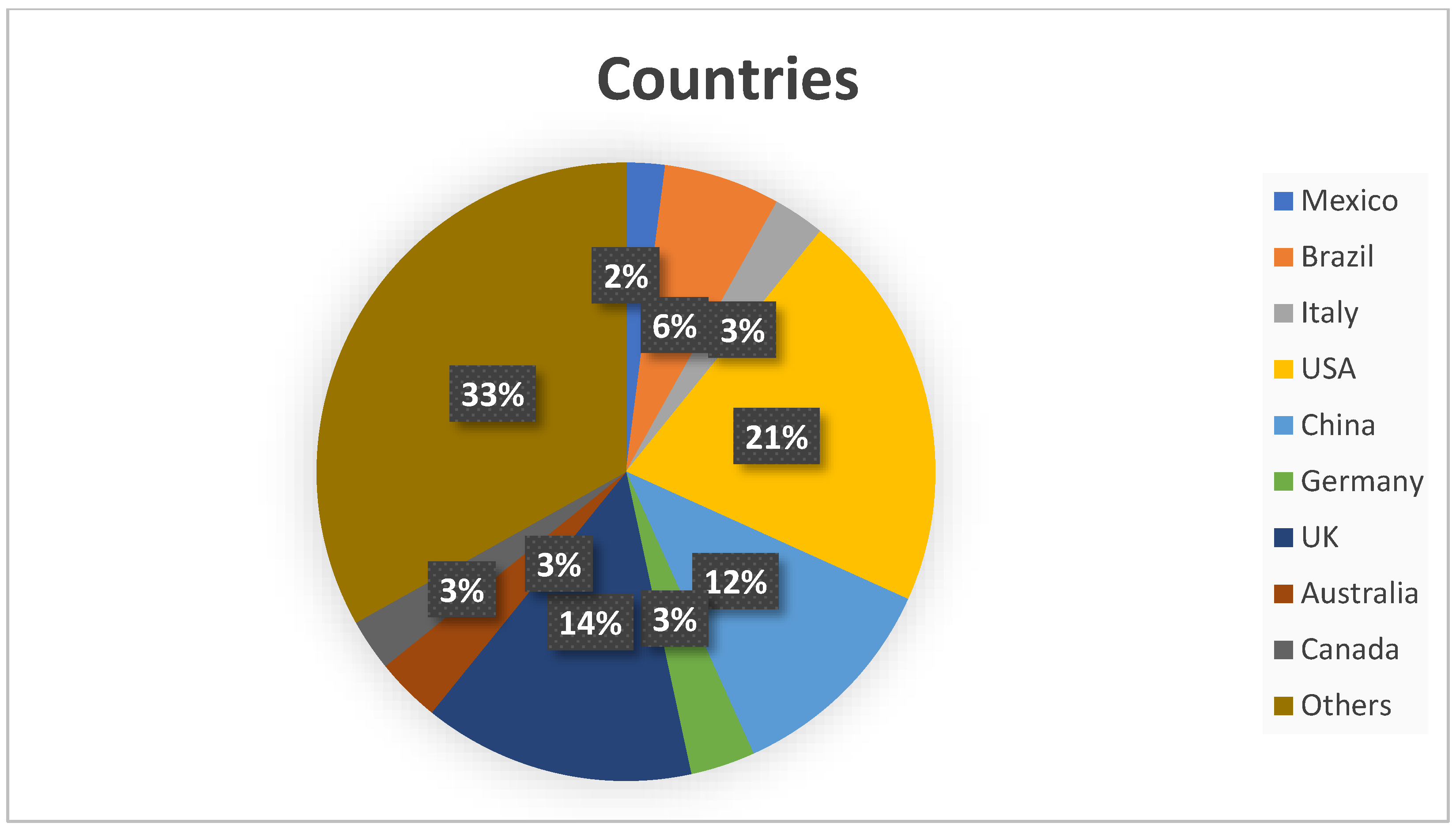

4.3. Distribution of Papers by Country

4.4. The Most Frequently Investigated Industry 4.0 Technologies

4.5. Content Analysis and Main Topical Areas

- –

- Research highlighting supply chain risk management (SCRM) in Industry 4.0 context;

- –

- Studies with an environmental supply chain risk management focus in Industry 4.0.

4.5.1. Supply Chain Risk Management in Industry 4.0 Context

4.5.2. Environmental Supply Chain Risk Management in Industry 4.0

4.5.3. Identified Gaps and the Necessity of a Holistic Approach to Supply Chain Risk Management in Industry 4.0

5. Environmental Risk Management of Industry 4.0: A Data Mining Framework

5.1. Data Mining Relevance for Managing Supply Chain Risks in Industry 4.0 Context

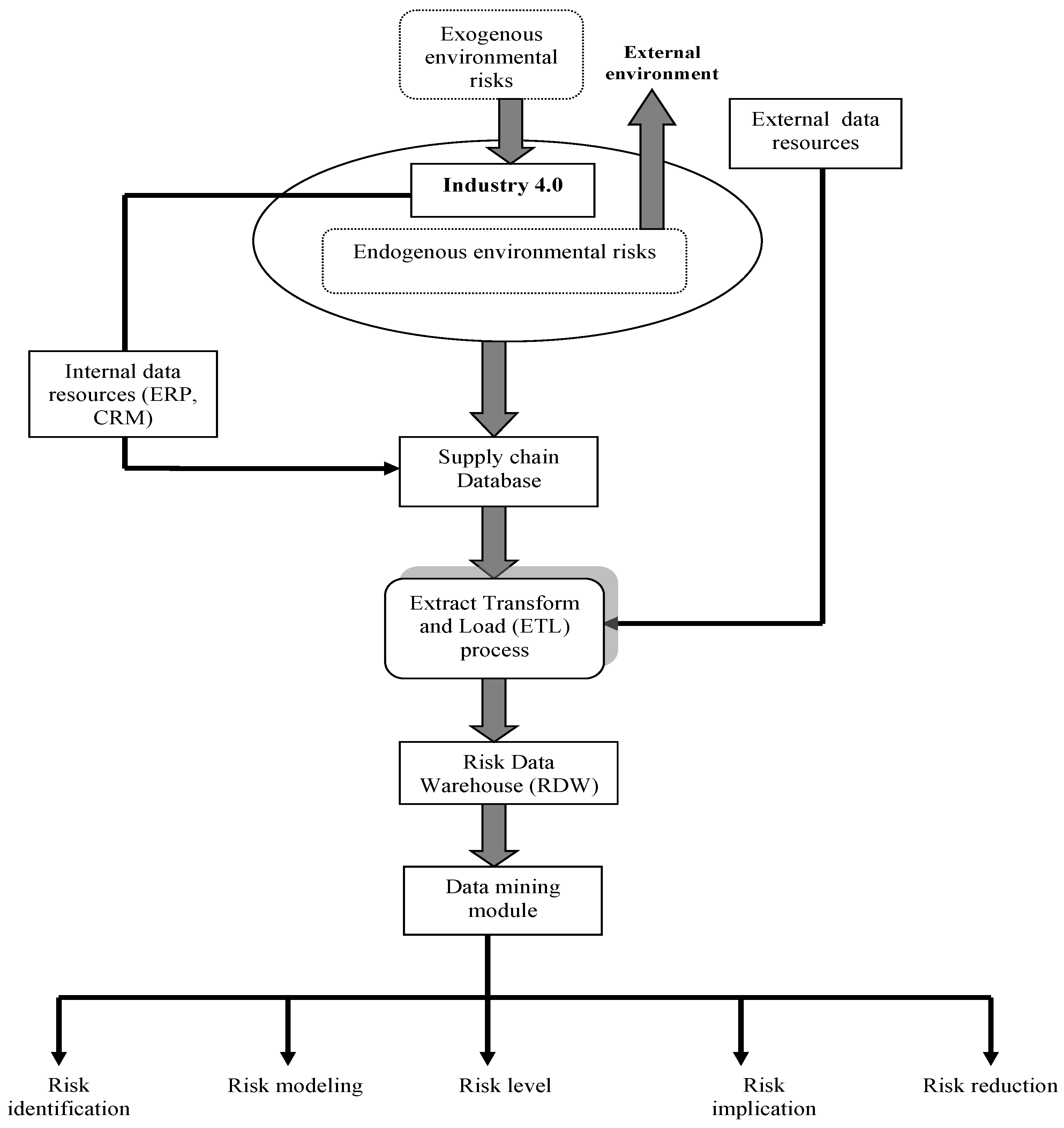

5.2. Data Mining Approach for Managing Industry 4.0 Environmental Risks

- (i)

- Identifying environmental risks indicators. Using various metrics, measurements and indicators, organizations can identify the risk exposure of their activities [4]. Risk indicators can be obtained from internal data sources such as the organization’s internal databases [128]. External sources of risk indicators are governmental and international agency reports, consultants/experts opinions, social media data, and insurance company recommendations [129,130,131]. Using such data, simulation models might be employed to quantify the externalities of environmental risks and their impact [132,133,134]. Using Industry 4.0 technologies, such as real time monitoring devices can help collect data about environmental risks [135]. For instance, using sensors, RFID tags, motion sensors, and energy monitoring systems, firms can ensure better control of cold chain products shipments and prevent waste or threats of natural or man-made disruptions. Firms can benefit from such an approach in providing better control of logistics and SC operations [129];

- (ii)

- Developing an environmental risks data warehouse to collect risk data. RDW are built using data extracted from internal and external sources—also called supply chain database—to make data accessible [103]. Initially, a conceptual risk data model has to be elaborated to structure the data generated from the various entities/sources and their interaction. Data processing is needed to develop the appropriate format for a data warehouse [136]. A process of data cleaning, reduction, and integration is necessary [120] through smoothing, normalization, discretization, aggregation, and generalization [128]. As a result, risk metrics and indicators can be obtained by type and activity [69]. After that, risk data can be subjected to an extract transform and load (ETL) process which generates RDW by source, type, attributes, and relationships. Converted data by ETL is transformed into an analytical structure containing the risk metadata [136]. The metadata layer of the DM-based ESCRM model consists of risk indicators, metrics, sources, factors, and location in terms of activity (e.g., manufacturing, shipping) or SC network (supplier, vendor, etc.) and data collection methods [45,137]. RDW is the key to access risk data in the DM framework. Firms can specify what kind of technology can be employed according to the data and available resources. Issues related to the type of database server, software employed, ETL server, storage needs, user interface, and network type have to be discussed and clarified in detail [138]. Once a decision is made regarding such elements, the RDW can be operationalized by connecting its components (internal and external databases);

- (iii)

- Elaborating a DM module for assessing environmental risk management. The DM module seeks to provide useful information for intelligent decision making in ESCRM. Without assessment, risk data are merely worthless information. The DM module creates risk data mart (RDM) from the RDW. RDM—also called risk problem database—is obtained through synthesizing, processing, and assessing data of the RDW according to the requirements of the DM application. Firms can assign several tasks to DM such as prediction, association, clustering, categorization, and aggregation of risk [121,127]. In such a manner, decision makers might use DM for different aims such as identifying risk triggers, predicting the impact of risks, detecting their root causes, prioritizing risks by degree, and modeling future trends [115,124].

5.3. Further Research Directions

- −

- Further research might attempt empirical and/or experimental testing of our DM framework in specific industrial contexts. Such endeavor might pinpoint possible shortcomings or barriers hindering the adoption of DM. Such a line of research might also clarify the limits of what DM might offer to firms in terms of predictive and modeling capacity;

- −

- Following the recent outbreak of the COVID-19 pandemic, it would be insightful to assess the potential of the DM framework regarding risk identification, risk assessment, and risk control. The disruptive nature of the pandemic can help evaluate the capacity of firms to adapt quickly to the threats of a volatile environment. Therefore, COVID-19 can constitute an adequate setting to assess the potential of the DM approach to help decision making, elaborate reactive measures, and learn from the disruption;

- −

- A potential line of research could be related to studies connecting ESCRM and Industry 4.0 through conceptual or empirical research seeking to provide further assessment of how both concepts interact. Such a line of research would delineate how ESCRM might benefit from adopting Industry 4.0 such as IoT, CC, BDA, and others. In addition, there is merit in elaborating further on the how Industry 4.0 implementation would require taking into consideration risk management including environmental risks.

6. Conclusions

6.1. Theoretical Contributions

6.2. Managerial Contributions

6.3. Research Limitations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Brusset, X.; Teller, C. Supply chain capabilities, risks, and resilience. Int. J. Prod. Econ. 2017, 184, 59–68. [Google Scholar] [CrossRef]

- Gurtu, A.; Johny, J. Supply Chain Risk Management: Literature Review. Risks 2021, 9, 16. [Google Scholar] [CrossRef]

- Norrman, A.; Jansson, U. Ericsson’s proactive supply chain risk management approach after a serious sub-supplier accident. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 434–456. [Google Scholar] [CrossRef]

- Fan, Y.; Stevenson, M. A review of supply chain risk management: Definition, theory, and research agenda. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 205–230. [Google Scholar] [CrossRef]

- Hofmann, H.; Busse, C.; Bode, C.; Henke, M. Sustainability-related supply chain risks: Conceptualization and management. Bus. Strategy Environ. 2014, 23, 160–172. [Google Scholar] [CrossRef]

- Giannakis, M.; Papadopoulos, T. Supply chain sustainability: A risk management approach. Int. J. Prod. Econ. 2016, 171, 455–470. [Google Scholar] [CrossRef]

- Munir, M.; Jajja, M.S.S.; Chatha, K.A.; Farooq, S. Supply chain risk management and operational performance: The enabling role of supply chain integration. Int. J. Prod. Econ. 2020, 227, 107667. [Google Scholar] [CrossRef]

- Yiannakoulias, N.; Gordon, J.N.; Darlington, J.C. The decision game: A serious game approach to understanding environmental risk management decisions. J. Risk Res. 2020, 23, 81–94. [Google Scholar] [CrossRef]

- Levner, E.; Ptuskin, A. Entropy-based model for the ripple effect: Managing environmental risks in supply chains. Int. J. Prod. Res. 2018, 56, 2539–2551. [Google Scholar] [CrossRef]

- Torres-Ruiz, A.; Ravi-Ravindran, A. Multiple criteria framework for the sustainability risk assessment of a supplier portfolio. J. Clean. Prod. 2018, 172, 4478–4493. [Google Scholar] [CrossRef]

- Freise, M.; Seuring, S. Social and environmental risk management in supply chains: A survey in the clothing industry. Logist. Res. 2015, 8, 2. [Google Scholar] [CrossRef]

- Rebs, T.; Brandenburg, M.; Seuring, S. System dynamics modelling for sustainable supply chain management: A literature review and systems thinking approach. J. Clean. Prod. 2018, 208, 1265–1280. [Google Scholar] [CrossRef]

- Reefke, H.; Sundaram, D. Key themes and research opportunities in sustainable supply chain management identification and evaluation. Omega 2017, 66, 195–211. [Google Scholar] [CrossRef]

- Addo-Tenkorang, R.; Helo, P.T. Big data applications in operations/supply-chain management: A literature review. Comput. Ind. Eng. 2016, 101, 528–543. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2018, 57, 829–846. [Google Scholar] [CrossRef]

- Ivanov, D.; Tang, C.; Dolgui, A.; Battini, D.; Das, A. Researchers’ Perspectives on Industry 4.0: Multi-Disciplinary Analysis and Opportunities for Operations Management. Int. J. Prod. Res. 2020, 59, 2055–2078. [Google Scholar] [CrossRef]

- Wu, L.; Yue, X.; Jin, A.; Yen, D.C. Smart supply chain management: A review and implications for future research. Int. J. Logist. Manag. 2016, 27, 395–417. [Google Scholar] [CrossRef]

- Kara, M.E.; Fırat, S.Ü.O.; Ghadge, A. A data mining-based framework for supply chain risk management. Comput. Ind. Eng. 2020, 139, 105570. [Google Scholar] [CrossRef]

- Ruiz-Torres, A.J.; Mahmoodi, F.; Zeng, A.Z. Supplier selection model with contingency planning for supplier failures. Comput. Ind. Eng. 2013, 66, 374–382. [Google Scholar] [CrossRef]

- da Silva, J.B.N.; Senna, P.; Chousa, A.; Coelho, O. Data mining and operations research techniques in Supply Chain Risk Management: A bibliometric study. Braz. J. Oper. Prod. Manag. 2020, 17, 1–14. [Google Scholar] [CrossRef]

- Olson, D.L. A review of supply chain data mining publications. J. Supply Chain. Manag. Sci. 2020, 1, 15–26. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.; Ayala, N. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.A. Digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plan. Control 2020, 32, 775–788. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; Loures, E.; Ramos, L. Past, present and future of Industry 4.0-a systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Xu, L.; Xu, E.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Godinho Filho, M. When titans meet—Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Fragapane, G.; Peron, M.; Sgarbossa, F.; Strandhagen, J.O.; Ivanov, D. Increasing flexibility and productivity in Industry 4.0 production networks with autonomous mobile robots and smart intralogistics. Ann. Oper. Res. 2020, 308, 125–143. [Google Scholar] [CrossRef]

- Schuh, G.; Anderi, R.; Gausemeier, J.; ten Hompel, M.; Wahlster, W. Industry 4.0 Maturity Index. Managing the Digital Transformation of Companies (Acatech Study); Herbert Utz Verlag: Munich, Germany, 2017. [Google Scholar]

- Gawer, A.; Cusumano, M. Industry platforms and ecosystem innovation. J. Prod. Innov. Manag. 2014, 31, 417–433. [Google Scholar] [CrossRef]

- Chen, T.; Tsai, H. Ubiquitous manufacturing: Current practices, challenges, and opportunities. Robot. Comput.-Integr. Manuf. 2017, 45, 126–132. [Google Scholar] [CrossRef]

- Porter, M.E.; Heppelmann, J. How smart, connected products are transforming competition. Harv. Bus. Rev. 2014, 92, 64–88. [Google Scholar]

- Ayala, N.F.; Paslauski, C.A.; Ghezzi, A.; Frank, A.G. Knowledge sharing dynamics in service suppliers’ involvement for servitization of manufacturing companies. Int. J. Prod. Econ. 2017, 193, 538–553. [Google Scholar] [CrossRef]

- Angeles, R. Anticipated IT infrastructure and supply chain integration capabilities for RFID and their associated deployment outcomes. Int. J. Inf. Manag. 2009, 29, 219–231. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Comput. Ind. Eng. 2017, 113, 144–159. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Thoben, K.D.; Wiesner, S.; Wuest, T. Industry 4.0 and smart manufacturing–a review of research issues and application examples. Int. J. Autom. Technol. 2017, 11, 4–19. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for Industry 4.0: A self-organized multi-agent system with big data based feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- Boyes, H.; Hallaq, B.; Cunningham, J.; Watson, T. The industrial internet of things (IIoT): An analysis framework. Comput. Ind. 2018, 101, 1–12. [Google Scholar] [CrossRef]

- Yu, C.; Xu, X.; Lu, Y. Computer-integrated manufacturing, cyber-physical systems and cloud manufacturing—Concepts and relationships. Manuf. Lett. 2015, 6, 5–9. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Liu, H. Big data drives cloud adoption in enterprise. IEEE Internet Comput. 2013, 17, 68–71. [Google Scholar] [CrossRef]

- Ahuett-Garza, H.; Kurfess, T. A brief discussion on the trends of habilitating technologies for Industry 4.0 and Smart manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Rossit, D.A.; Tohmé, F.; Frutos, M. Industry 4.0: Smart Scheduling. Int. J. Prod. Res. 2019, 57, 3802–3813. [Google Scholar] [CrossRef]

- Chen, T.; Lin, Y.C. Feasibility evaluation and optimization of a smart manufacturing system based on 3D printing: A review. Int. J. Intell. Syst. 2017, 32, 394–413. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of sustainable manufacturing in industry 4.0. Procedia Cirp 2016, 40, 536–541. [Google Scholar] [CrossRef]

- Strange, R.; Zucchella, A. Industry 4.0 global value chains and international business. Multinatl. Bus. Rev. 2017, 25. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of Industry 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 1–10. [Google Scholar] [CrossRef]

- Pei, F.Q.; Tong, Y.F.; He, F.; Li, D.B. Research on design of the smart factory for forging enterprise in the Industry 4.0 environment. Mechanika 2017, 23. [Google Scholar] [CrossRef]

- Mueller, E.; Chen, X.L.; Riedel, R. Challenges and requirements for the application of Industry 4.0: A special insight with the usage of cyber-physical system. Chin. J. Mech. Eng. 2017, 30, 9. [Google Scholar] [CrossRef]

- Bahrin, M.A.K.; Othman, M.F.; Azli, N.H.N.; Talib, M.F. Industry 4.0: A review on industrial automation and robotic. J. Teknol. 2016, 78, 6–13. [Google Scholar] [CrossRef]

- Moreno, A.; Velez, G.; Ardanza, A.; Barandiaran, I.; de Infante, A.R.; Chopitea, R. Virtualisation process of a sheet metal punching machine within the Industry4.0 vision. Int. J. Interact. Des. Manuf. 2017, 11, 365–373. [Google Scholar] [CrossRef]

- Sokolov, B.; Ivanov, D.; Dolgui, A. (Eds.) Scheduling in Industry 4.0 and Cloud Manufacturing; Springer: New York, NY, USA, 2020; ISBN 978-3-030-43176-1. [Google Scholar]

- Blackburn, W.R. The Sustainability Handbook: The Complete Management Guide to Achieving 29 Social, Economic, and Environmental Responsibility; Environmental Law Institute; Routledge: New York, NY, USA, 2007; ISBN 1138990094. [Google Scholar]

- Dües, M.; Kim, C.; Tan, H.; Ming, L. Green as the new Lean: How to use Lean practices as a catalyst to greening your supply chain. J. Clean. Prod. 2013, 40, 93–100. [Google Scholar] [CrossRef]

- Faisal, M.N. Prioritization of Risks in Supply Chains. In Managing Supply Chain Risk and Vulnerability; Wu, T., Blackhurst, J., Eds.; Springer: New York, NY, USA, 2009; Volume 41–66. [Google Scholar]

- Prakash, S.; Soni, G.; Singh, R.; Ajay, P.; Singh, S. Risk analysis and mitigation for perishable food supply chain: A case of dairy industry. Benchmarking Int. J. 2017, 24, 2–23. [Google Scholar] [CrossRef]

- Jüttner, U.; Peck, H.; Christopher, M. Supply chain risk management: Outlining an agenda for future research. Int. J. Logist. Res. Appl. 2003, 6, 197–210. [Google Scholar] [CrossRef]

- Sinha, P.; Whitman, L.; Malzahn, D. Methodology to mitigate supplier risk in an aerospace supply chain. Supply Chain. Manag. Int. J. 2004, 9, 154–168. [Google Scholar] [CrossRef]

- Christopher, M.; Mena, C.; Khan, O.; Yurt, O. Approaches to managing global sourcing risk. Supply Chain. Manag. Int. J. 2011, 16, 67–81. [Google Scholar] [CrossRef]

- Kamalahmadi, M.; Mellat-Parast, M. Developing a resilient supply chain through supplier flexibility and reliability assessment. Int. J. Prod. Res. 2016, 54, 302–321. [Google Scholar] [CrossRef]

- Chen, A.; Hsieh, Y.; Wee, H.M. A resilient global supplier selection strategy: A case study of an automotive company. Int. J. Advanced. Manuf. Technol. 2016, 87, 1475–1490. [Google Scholar] [CrossRef]

- Cousins, P.D.; Lamming, R.C.; Bowen, F. The role of risk in environment-related supplier initiatives. Int. J. Oper. Prod. Manag. 2004, 24, 554–565. [Google Scholar] [CrossRef]

- Shankar, R.; Choudhary, D.; Jharkharia, S. An integrated risk assessment model: A case of sustainable freight transportation systems. Transp. Res. Transp. Environ. 2018, 63, 662–676. [Google Scholar] [CrossRef]

- Kuo, T.; Hsu, C.W.; Li, J.-Y. Developing a green supplier selection model by using the DANP with VIKOR. Sustainability 2015, 7, 1661–1689. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Examining the effects of green supply chain management practices and their mediations on performance improvements. Int. J. Prod. Res. 2012, 50, 1377–1394. [Google Scholar] [CrossRef]

- Wieland, A.; Wallenburg, C.M. Dealing with supply chain risks: Linking risk management practices and strategies to performance. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 887–905. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M. Supply chain resilience: Conceptualization and scale development using dynamic capability theory. Int. J. Prod. Econ. 2017, 188, 185–204. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Rousseau, D.M.; Manning, J.; Denyer, D. 11 Evidence in management and organizational science: Assembling the field’s full weight of scientific knowledge through syntheses. Acad. Manag. Ann. 2008, 2, 475–515. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a Systematic Review. In The SAGE Handbook of Organizational Research Methods; Buchanan, D.A., Bryman, A., Eds.; Sage Publications Ltd.: London, UK, 2009; pp. 671–689. [Google Scholar]

- Durach, C.F.; Kembro, J.; Wieland, A. A new paradigm for systematic literature reviews in supply chain management. J. Supply Chain. Manag. 2017, 53, 67–85. [Google Scholar] [CrossRef]

- Colicchia, C.; Strozzi, F. Supply chain risk management: A new methodology for a systematic literature review. Supply Chain. Manag. Int. J. 2012, 17, 403–418. [Google Scholar] [CrossRef]

- Frandsen, T. Evolution of modularity literature: A 25-year bibliometric analysis. Int. J. Oper. Prod. Manag. 2017, 37, 703–747. [Google Scholar] [CrossRef]

- Bryman, A.; Bell, E. Business Research Methods, 2nd ed.; Oxford University Press: New York, NY, USA, 2007; pp. 226–238. [Google Scholar]

- Seuring, S.; Gold, S. Conducting content-analysis based literature reviews in supply chain management. Supply Chain. Manag. Int. J. 2012, 17, 544–555. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Mohamed, R. A novel plithogenic TOPSIS-CRITIC model for sustainable supply chain risk management. J. Clean. Prod. 2020, 247, 119586. [Google Scholar] [CrossRef]

- Kolberg, D.; Zühlke, D. Lean Automation enabled by Industry 4.0 Technologies. IFAC-Pap. 2015, 48, 1870–1875. [Google Scholar] [CrossRef]

- Kersten, W.; Blecker, T.; Ringle, C.M. Sustainability in Logistics and Supply Chain Management: New Designs and Strategies; Epubli GmbH: Berlin, Germany, 2015. [Google Scholar]

- Tupa, J.; Simota, J.; Steiner, F. Aspects of risk management implementation for Industry 4.0. Procedia Manuf. 2017, 11, 1223–1230. [Google Scholar] [CrossRef]

- Baryannis, G.; Validi, S.; Dani, S.; Antoniou, G. Supply chain risk management and artificial intelligence: State of the art and future research directions. Int. J. Prod. Res. 2019, 57, 2179–2202. [Google Scholar] [CrossRef]

- Vishnu, C.R.; Sridharan, R.; Kumar, P.R. Supply chain risk management: Models and methods. Int. J. Manag. Decis. Mak. 2019, 18, 31–75. [Google Scholar] [CrossRef]

- Chu, C.-Y.; Park, K.; Kremer, G.E. A global supply chain risk management framework: An application of text-mining to identify region-specific supply chain risks. Adv. Eng. Inform. 2020, 45, 101053. [Google Scholar] [CrossRef]

- Wang, L.; Ranjan, R. Processing distributed internet of things data in clouds. IEEE Cloud Comput. 2015, 2, 76–80. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B.; Ivanova, M. Literature review on disruption recovery in the supply chain. Int. J. Prod. Res. 2017, 55, 6158–6174. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B.; Werner, F.; Ivanova, M. A dynamic model and an algorithm for short-term supply chain scheduling in the smart factory industry 4.0. Int. J. Prod. Res. 2016, 54, 386–402. [Google Scholar] [CrossRef]

- Scheibe, K.P.; Blackhurst, J. Supply chain disruption propagation: A systemic risk and normal accident theory perspective. Int. J. Prod. Res. 2018, 56, 43–59. [Google Scholar] [CrossRef]

- Marconi, M.; Marilungo, E.; Papetti, A.; Germani, M. Traceability as a means to investigate supply chain sustainability: The real case of a leather shoe supply chain. Int. J. Prod. Res. 2017, 55, 6638–6652. [Google Scholar] [CrossRef]

- Babu, H.; Bhardwaj, P.; Agrawal, A.K. Modelling the supply chain risk variables using ISM: A case study on Indian manufacturing SMEs. J. Model. Manag. 2020, 16, 215–239. [Google Scholar] [CrossRef]

- Birkel, H.S.; Veile, J.W.; Müller, J.M.; Hartmann, E.; Voigt, K.-I. Development of a risk framework for Industry 4.0 in the context of sustainability for established manufacturers. Sustainability 2019, 11, 384. [Google Scholar] [CrossRef]

- Hirman, M.; Benesova, A.; Steiner, F.; Tupa, J. Project management during the industry 4.0 implementation with risk factor analysis. Procedia Manuf. 2019, 38, 1181–1188. [Google Scholar] [CrossRef]

- Junior, A.N.; de Oliveira, M.C.; Helleno, A.L. Sustainability evaluation model for manufacturing systems based on the correlation between triple bottom line dimensions and balanced scorecard perspectives. J. Clean. Prod. 2018, 190, 84–93. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Ali, S.M.; Kusi-Sarpong, S.; Shaikh, M.A.A. Assessing challenges for implementing Industry 4.0: Implications for process safety and environmental protection. Process Saf. Environ. Prot. 2018, 117, 730–741. [Google Scholar] [CrossRef]

- Potrich, L.; Cortimiglia, M.N.; de Medeiros, J.F. A systematic literature review on firm-level proactive environmental management. J. Environ. Manag. 2019, 243, 273–286. [Google Scholar] [CrossRef]

- Bonilla, S.H.; Silva, H.R.; Terra da Silva, M.; Gonçalves, R.; Sacomano, J.B. Industry 4.0 and sustainability implications: A scenario-based analysis of the impacts and challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef]

- Oliveira, J.B.; Jin, M.; Lima, R.S.; Kobza, J.E.; Montevechi, J.A.B. The role of simulation and optimization methods in supply chain risk management: Performance and review standpoints. Simul. Model. Pract. Theory 2019, 92, 17–44. [Google Scholar] [CrossRef]

- Li, Y.; Dai, J.; Cui, L. The impact of digital technologies on economic and environmental performance in the context of industry 4.0: A moderated mediation model. Int. J. Prod. Econ. 2020, 229, 107777. [Google Scholar] [CrossRef]

- Shojaei, P.; Haeri, S.A.S. Development of supply chain risk management approaches for construction projects: A grounded theory approach. Comput. Ind. Eng. 2019, 128, 837–850. [Google Scholar] [CrossRef]

- Fagundes, M.V.C.; Teles, E.O.; de Melo, S.A.V.; Freires, F.G.M. Decision-making models and support systems for supply chain risk: Literature mapping and future research agenda. Eur. Res. Manag. Bus. Econ. 2020, 26, 63–70. [Google Scholar] [CrossRef]

- Erol, S.; Jäger, A.; Hold, P.; Ott, K.; Sihn, W. Tangible Industry 4.0: A Scenario-Based Approach to Learning for the Future of Production. Procedia CIRP 2016, 54, 13–18. [Google Scholar] [CrossRef]

- Kumar, M.; Graham, G.; Hennelly, P.; Srai, J. How Will Smart City Production Systems Transform Supply Chain Design: A Product-level Investigation. Int. J. Prod. Res. 2016, 54, 7181–7192. [Google Scholar] [CrossRef]

- Zhuge, H. Semantic Linking through Spaces for Cyber-physical-socio Intelligence: A Methodology. Artif. Intell. 2011, 175, 988–1019. [Google Scholar] [CrossRef]

- Linoff, G.S.; Berry, M.J. Data Mining Techniques: For Marketing, Sales, and Customer Relationship Management, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Ranjan, J.; Bhatnagar, V. Role of knowledge management and analytical CRM in business: Data mining based framework. Learn. Organ. 2011, 18, 131–148. [Google Scholar] [CrossRef]

- Lee, E.B.; Kim, J.; Lee, S.G. Predicting customer churn in mobile industry using data mining technology. Ind. Manag. Data Syst. 2017, 117, 90–109. [Google Scholar] [CrossRef]

- Neef, D. Managing corporate risk through better knowledge management. Learn. Organ. 2005, 12, 112–124. [Google Scholar] [CrossRef]

- Haksöz, Ç. Risk Intelligent Supply Chains: How Leading Turkish Companies Thrive in the Age of Fragility, 1st ed.; Taylor and Francis Group/CRC Press: New York, NY, USA, 2013. [Google Scholar]

- Wu, D.D.; Chen, S.H.; Olson, D.L. Business intelligence in risk management: Some recent progresses. Inf. Sci. 2014, 256, 1–7. [Google Scholar] [CrossRef]

- Saradhi, V.V.; Palshikar, G.K. Employee churns prediction. Expert Syst. Appl. 2011, 38, 1999–2006. [Google Scholar] [CrossRef]

- Ngai, E.W.T.; Hu, Y.; Wong, Y.H.; Chen, Y.; Sun, X. The application of data mining techniques in financial fraud detection: A classification framework and an academic review of literature. Decis. Support Syst. 2011, 50, 559–569. [Google Scholar] [CrossRef]

- Schlegel, G.L.; Trent, R.J. Supply Chain Risk Management: An Emerging Discipline, 1st ed.; Routledge CRC Press: New York, NY, USA, 2014. [Google Scholar]

- Lee, B.K.; Zhou, R.; Souza, R.; Park, J. Data-driven risk measurement of firm-to-firm relationships in a supply chain. Int. J. Prod. Econ. 2016, 180, 148–157. [Google Scholar] [CrossRef]

- Kang, S.; Kim, E.; Shim, J.; Cho, S.; Chang, W.; Kim, J. Mining the relationship between production and customer service data for failure analysis of industrial products. Comput. Ind. Eng. 2017, 106, 137–146. [Google Scholar] [CrossRef]

- Apgar, D. Risk Intelligence: Learning to Manage What We Don’t Know; Harvard Business School Press: Boston, MA, USA, 2006. [Google Scholar]

- Giudici, P.; Figini, S. Applied Data Mining for Business and Industry, 2nd ed.; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- Köksal, G.; Batmaz, I.; Testik, M. A review of data mining applications for quality improvement in manufacturing industry. Expert Syst. Appl. 2011, 38, 13448–13467. [Google Scholar] [CrossRef]

- Han, J.; Kamber, M.; Pei, J. Data Mining: Concepts and Techniques, 3rd ed.; Morgan Kaufmann: Boston, MA, USA, 2012. [Google Scholar]

- Witten, I.H.; Frank, E.; Hall, M.A.; Pal, C.J. Data Mining: Practical Machine Learning Tools and Techniques, 4th ed.; Morgan Kaufmann: Boston, MA, USA, 2014. [Google Scholar]

- Murray, P.W.; Agard, B.; Barajas, M.A. Market segmentation through data mining: A method to extract behaviors from a noisy data set. Comput. Ind. Eng. 2017, 109, 233–252. [Google Scholar] [CrossRef]

- Seng, J.; Chen, T. An analytic approach to select data mining for business decision. Expert Syst. Appl. 2010, 37, 8042–8057. [Google Scholar] [CrossRef]

- Carneiro, N.; Figueira, G.; Costa, M. A data mining based system for credit-card fraud detection in e-tail. Decis. Support Syst. 2017, 95, 91–101. [Google Scholar] [CrossRef]

- Basole, R.C.; Bellamy, M.A. Visual analysis of supply network risks: Insights from the electronics industry. Decis. Support Syst. 2014, 67, 109–120. [Google Scholar] [CrossRef]

- Heckmann, I.; Comes, T.; Nickel, S. A critical review on supply chain risk—Definition, measure and modelling. Omega 2015, 52, 119–132. [Google Scholar] [CrossRef]

- Jukic, N.; Vrbsky, S.; Nestorov, S. Database Systems: Introduction to Databases and Data Warehouses, 1st ed.; Prospect Press: Burlington, VT, USA, 2017. [Google Scholar]

- Robertson, D. Managing Operational Risk: Practical Strategies to Identify and Mitigate Operational Risk within Financial Institutions, 1st ed.; Palgrave Macmillan: New York, NY, USA, 2016. [Google Scholar]

- Knemeyer, A.M.; Zinn, W.; Eroglu, C. Proactive planning for catastrophic events in supply chains. J. Oper. Manag. 2009, 27, 141–153. [Google Scholar] [CrossRef]

- Franzetti, C. Operational Risk Modelling and Management, 1st ed.; Routledge Taylor & Francis Group: New York, NY, USA, 2011. [Google Scholar]

- Goh, R.S.M.; Wang, Z.; Yin, X.; Fu, X.; Ponnambalam, L.; Lu, S.; Li, X. RiskVis: Supply Chain Visualization with Risk Management and Real-time Monitoring. In Proceedings of the IEEE International Conference on Automation Science and Engineering (CASE), Madison, WI, USA, 17–20 August 2013; pp. 207–212. [Google Scholar] [CrossRef]

- Bandaly, D.; Satir, A.; Shanker, L. Impact of lead time variability in supply chain risk management. Int. J. Prod. Econ. 2016, 180, 88–100. [Google Scholar] [CrossRef]

- Rajagopal, V.; Venkatesan, S.P.; Goh, M. Decision-making models for supply chain risk mitigation: A review. Comput. Ind. Eng. 2017, 113, 646–682. [Google Scholar] [CrossRef]

- Ojha, R.; Ghadge, A.; Tiwari, M.K.; Bititci, U.S. Bayesian network modelling for supply chain risk propagation. Int. J. Prod. Res. 2018, 56, 5795–5819. [Google Scholar] [CrossRef]

- Kim, K.; Kim, H.; Kim, S.K.; Jung, J.Y. i-RM: An intelligent risk management framework for context-aware ubiquitous cold chain logistics. Expert Syst. Appl. 2016, 46, 463–473. [Google Scholar] [CrossRef]

- Vaisman, A.; Zimányi, E. Data Warehouse Systems: Design and Implementation, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Kayis, B.; Karningsih, P.D. SCRIS: A knowledge-based system tool for assisting manufacturing organizations in identifying supply chain risks. J. Manuf. Technol. 2012, 23, 834–852. [Google Scholar] [CrossRef]

- Coronel, C.; Morris, S. Database Systems: Design, Implementation, & Management, 12th ed.; Cengage Learning: Farmington Hills, MI, USA, 2017. [Google Scholar]

- Larose, D.T.; Larose, C.D. Data Mining and Predictive Analytics, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- El Baz, J.; Tiwari, S.; Akenroye, T.; Cherrafi, A.; Derrouiche, R. A framework of sustainability drivers and externalities for Industry 4.0 technologies using a Best-Worst Method. J. Clean. Prod. 2022, 344, 130909. [Google Scholar] [CrossRef]

- El Baz, J.; Ruel, S. Can supply chain risk management practices mitigate the disruption impacts on supply chains’ resilience and robustness? Evidence from an empirical survey in a COVID-19 outbreak era. Int. J. Prod. Econ. 2021, 233, 107972. [Google Scholar] [CrossRef]

- Ruel, S.; El Baz, J. Disaster readiness’ influence on the impact of supply chain resilience and robustness on firms’ financial performance: A COVID-19 empirical investigation. Int. J. Prod. Res. 2021. [Google Scholar] [CrossRef]

- Zouari, D.; Ruel, S.; Viale, L. Does digitalising the supply chain contribute to its resilience? Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 149–180. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Baz, J.; Cherrafi, A.; Benabdellah, A.C.; Zekhnini, K.; Beka Be Nguema, J.N.; Derrouiche, R. Environmental Supply Chain Risk Management for Industry 4.0: A Data Mining Framework and Research Agenda. Systems 2023, 11, 46. https://doi.org/10.3390/systems11010046

El Baz J, Cherrafi A, Benabdellah AC, Zekhnini K, Beka Be Nguema JN, Derrouiche R. Environmental Supply Chain Risk Management for Industry 4.0: A Data Mining Framework and Research Agenda. Systems. 2023; 11(1):46. https://doi.org/10.3390/systems11010046

Chicago/Turabian StyleEl Baz, Jamal, Anass Cherrafi, Abla Chaouni Benabdellah, Kamar Zekhnini, Jean Noel Beka Be Nguema, and Ridha Derrouiche. 2023. "Environmental Supply Chain Risk Management for Industry 4.0: A Data Mining Framework and Research Agenda" Systems 11, no. 1: 46. https://doi.org/10.3390/systems11010046

APA StyleEl Baz, J., Cherrafi, A., Benabdellah, A. C., Zekhnini, K., Beka Be Nguema, J. N., & Derrouiche, R. (2023). Environmental Supply Chain Risk Management for Industry 4.0: A Data Mining Framework and Research Agenda. Systems, 11(1), 46. https://doi.org/10.3390/systems11010046