Maintenance Service Configuration Optimization for Complex Equipment

Abstract

1. Introduction

2. Problem Description and Model Construction

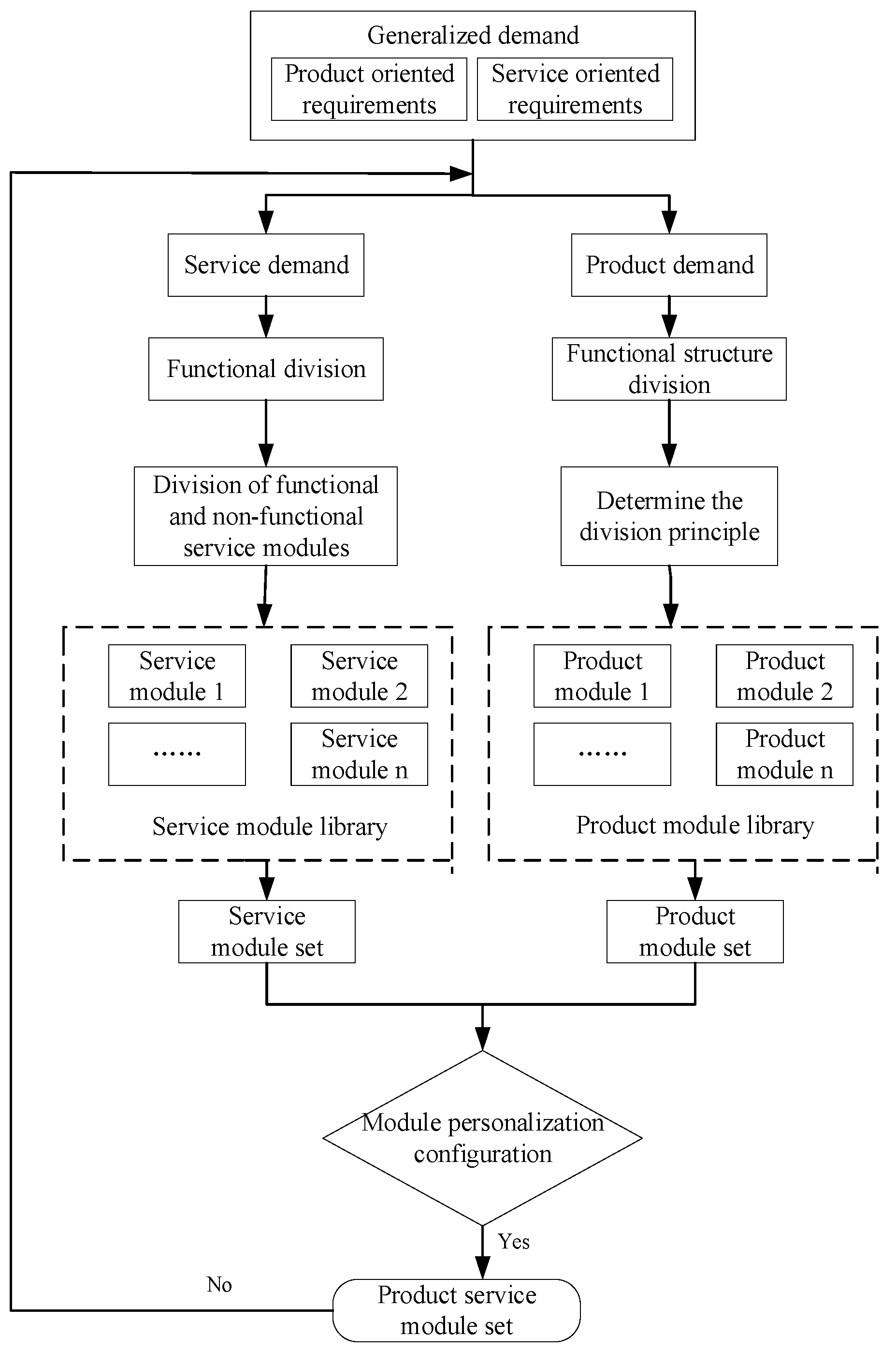

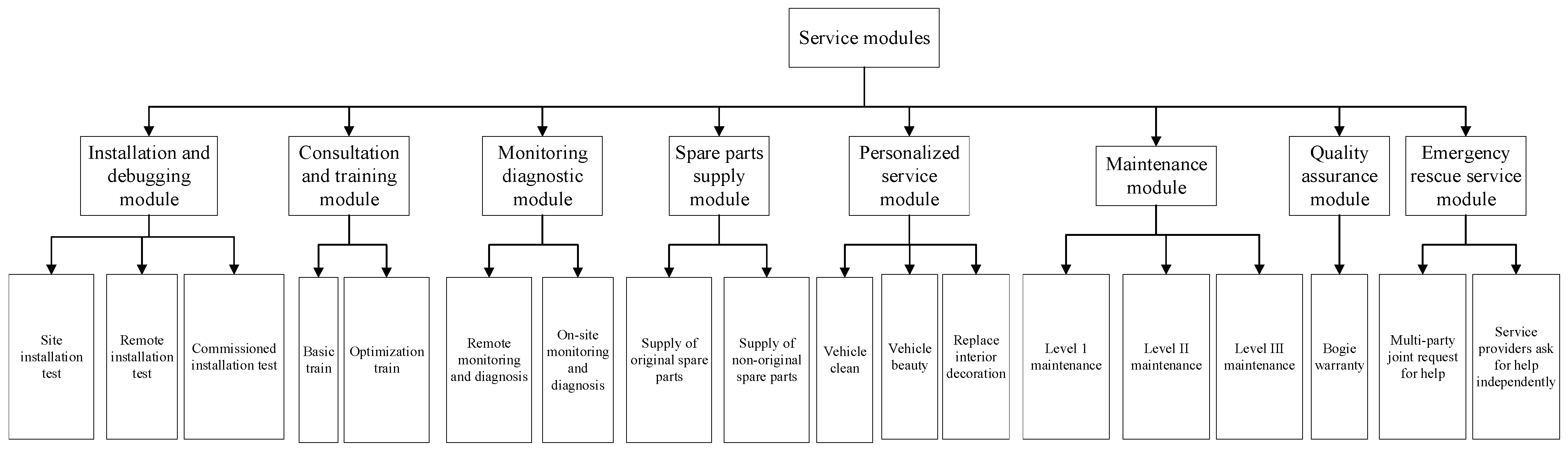

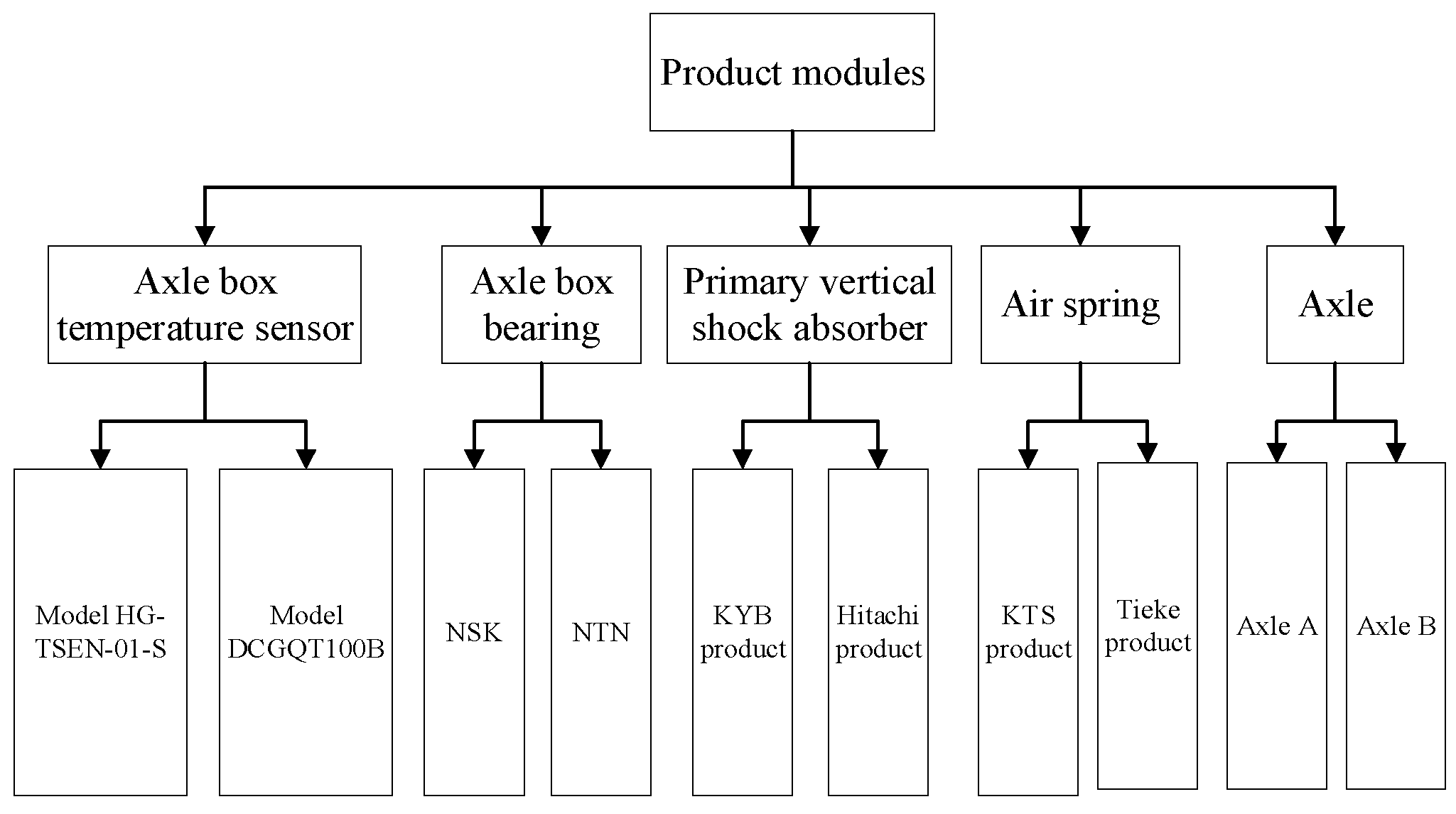

2.1. Product and Service Modularization

2.2. Customer Requirements Mapping

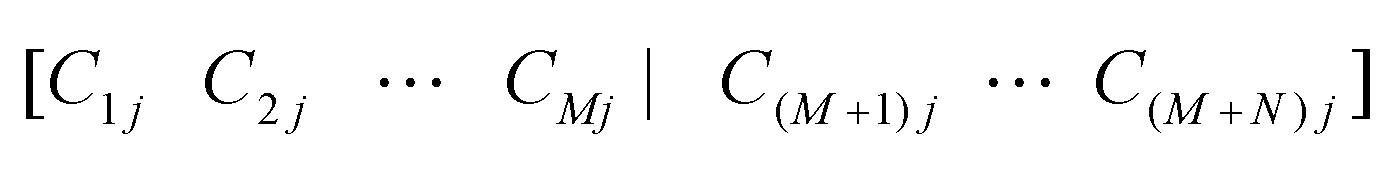

2.3. Parameter and Set Description

2.4. Decision Variables

2.5. Model Establishment

3. Case Analysis and Solution

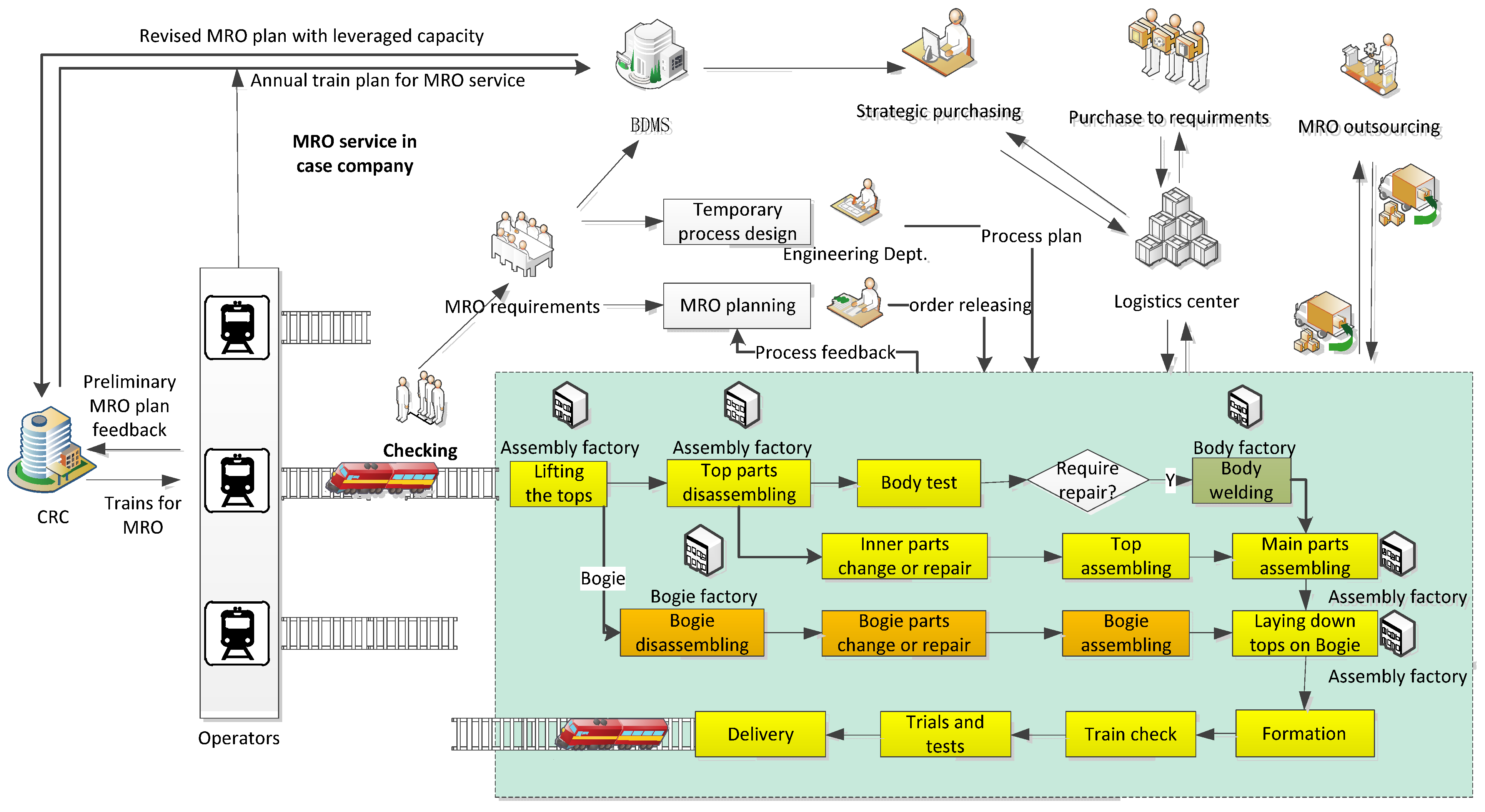

3.1. Case Description

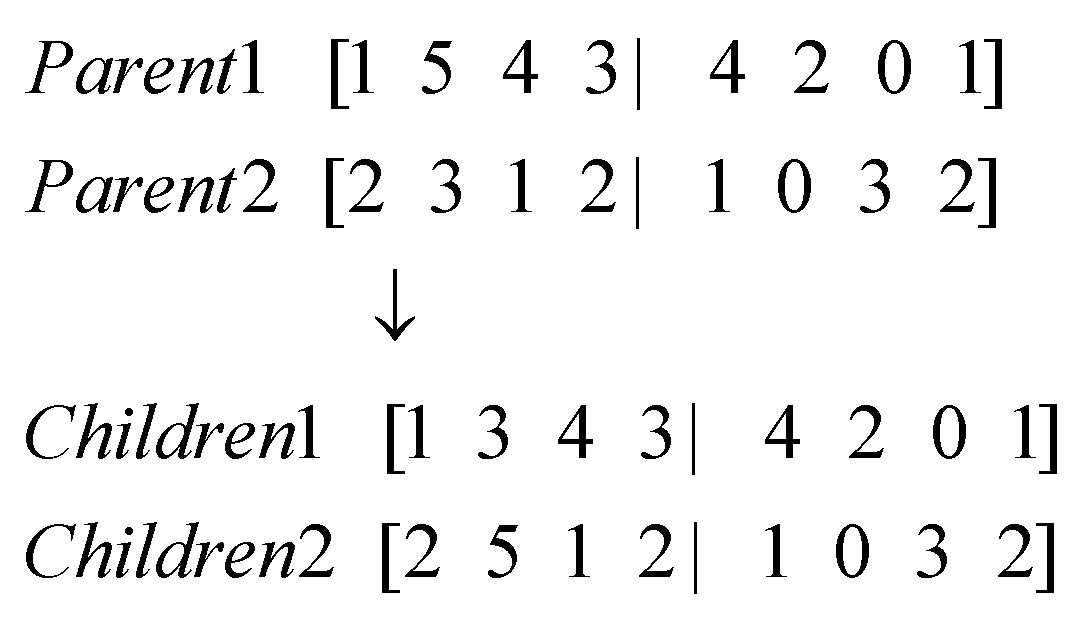

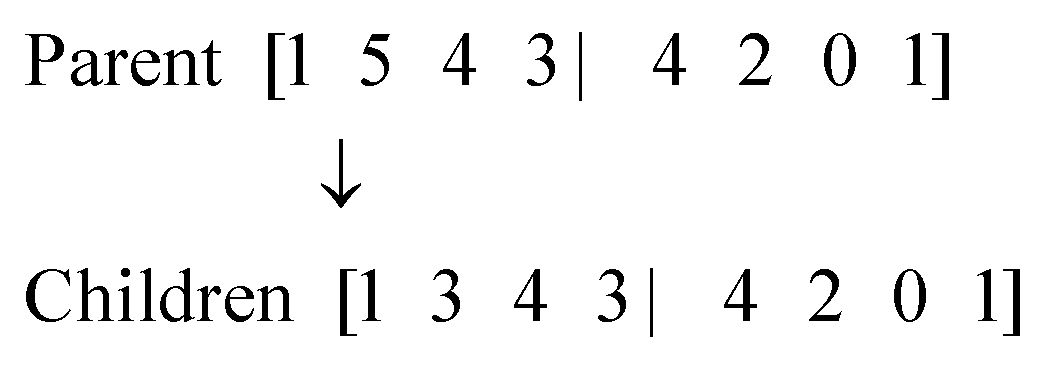

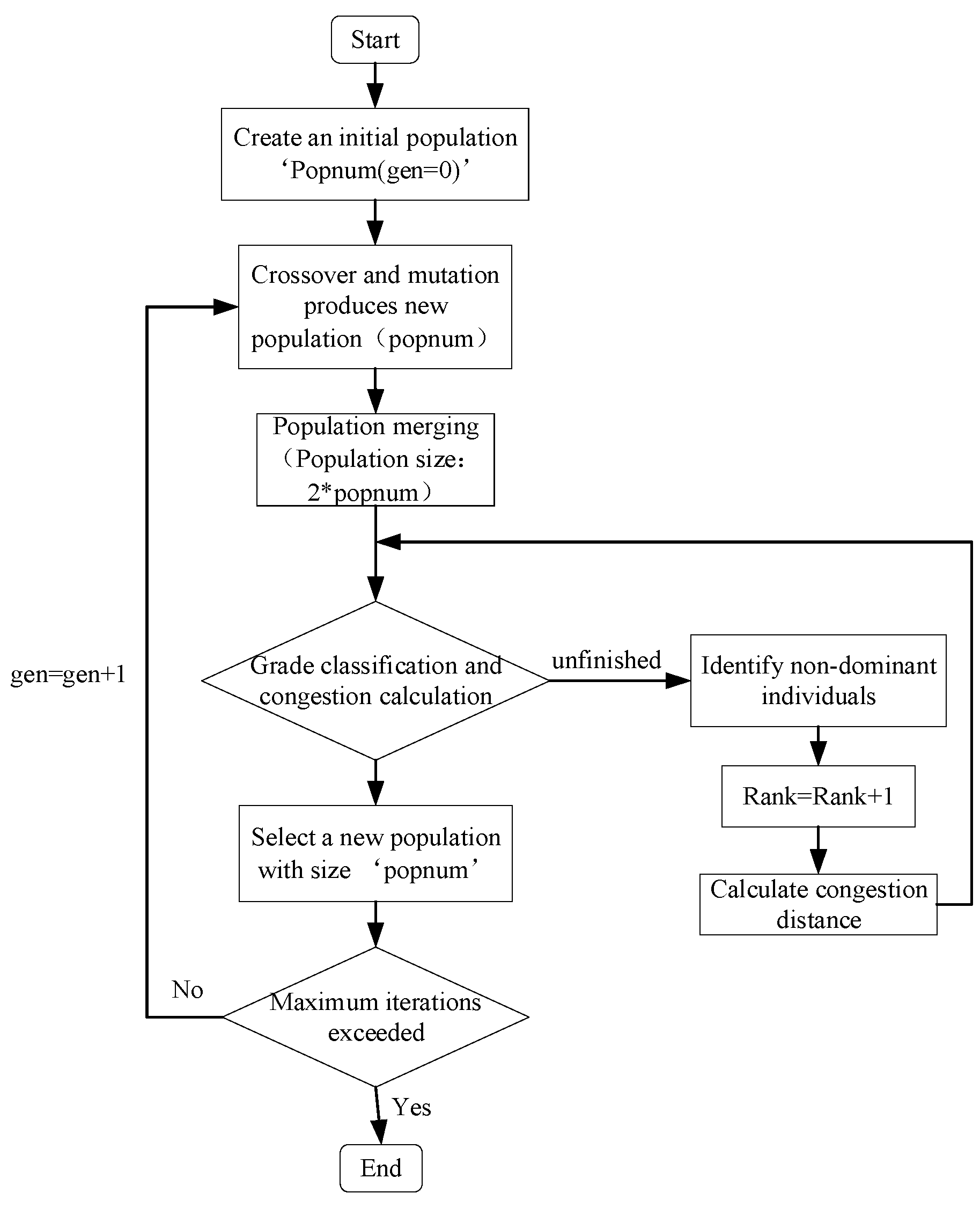

3.2. Solution Method

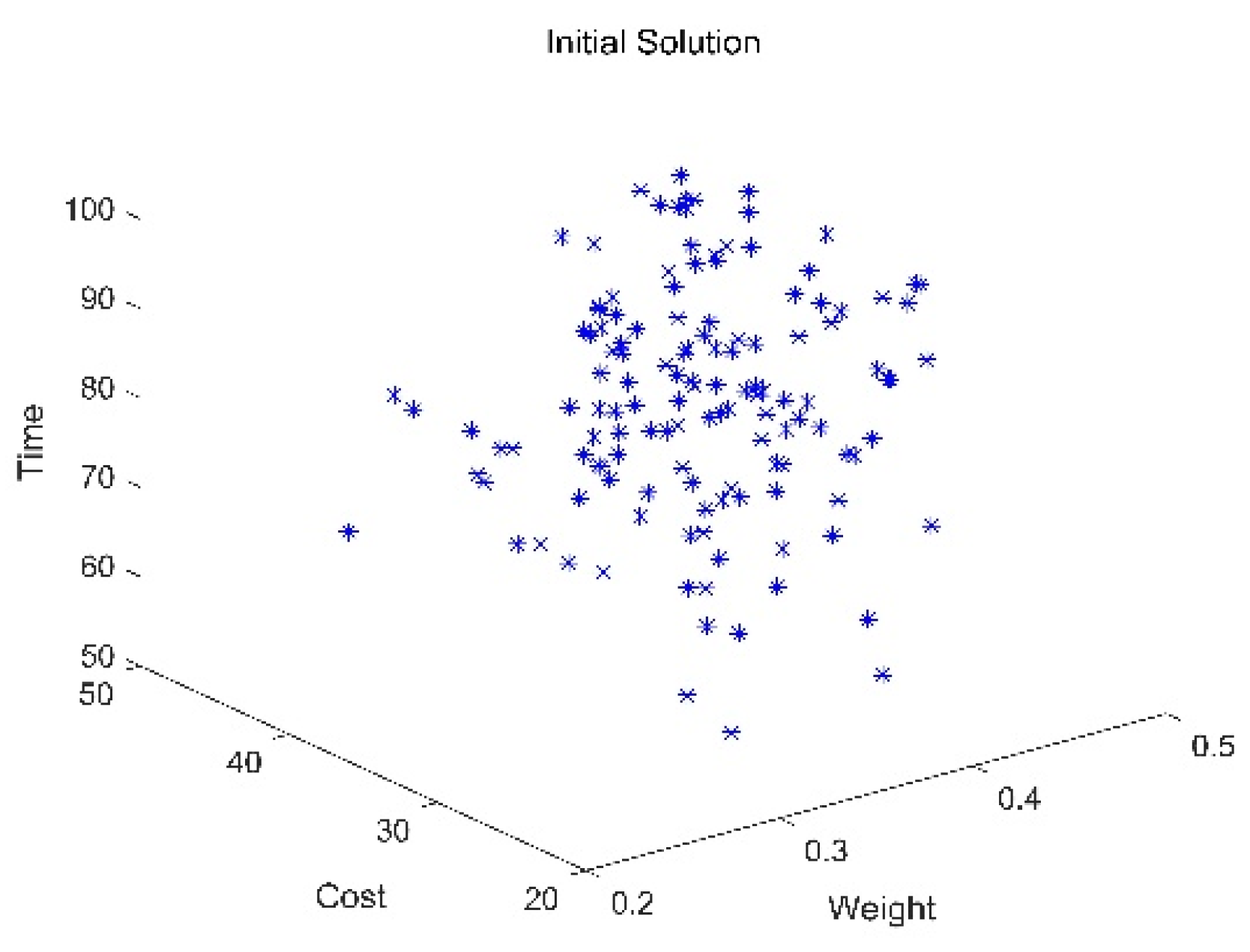

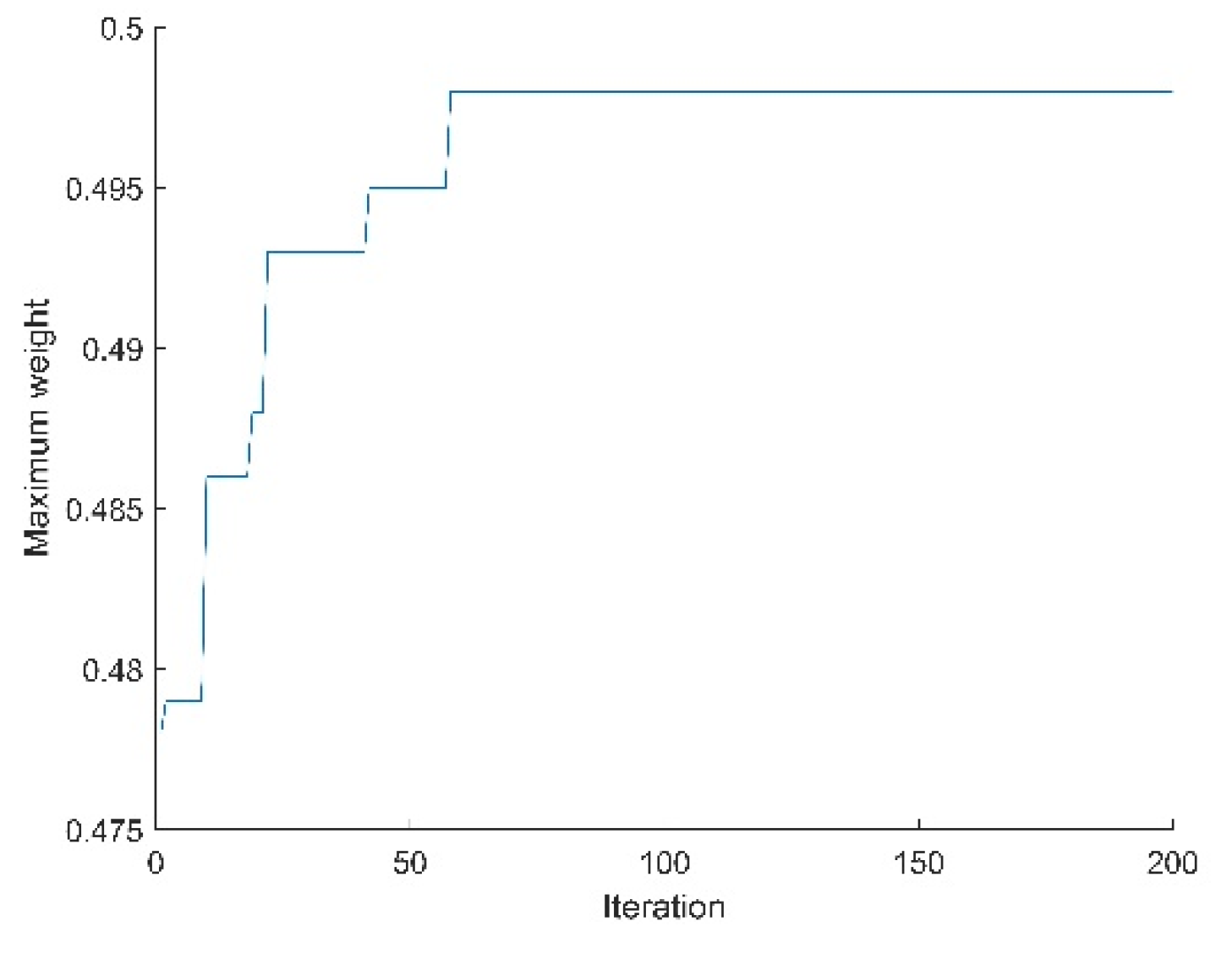

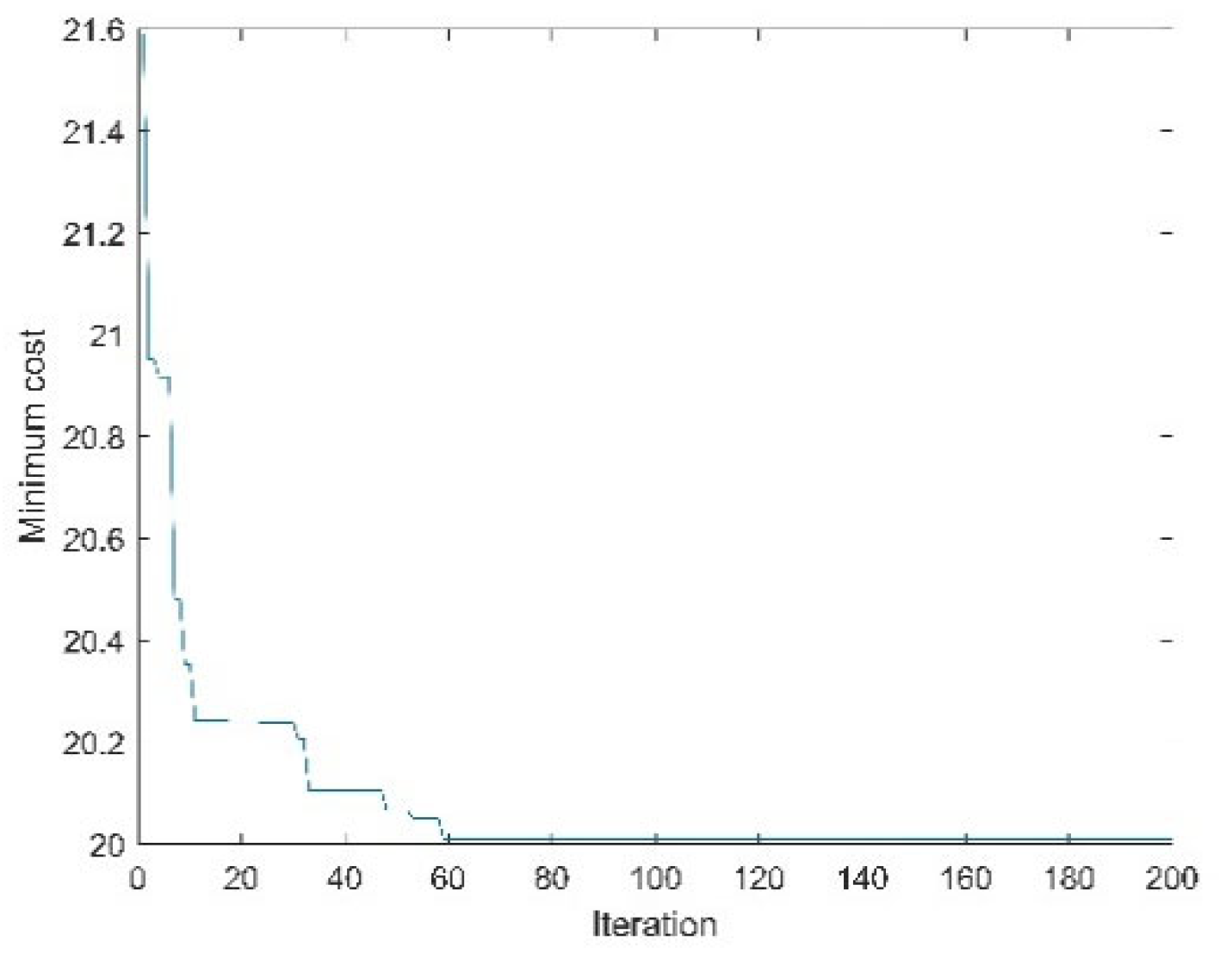

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dou, R.; Huang, R.; Nan, G.; Liu, J. Less diversity but higher satisfaction: An intelligent product configuration method for type-decreased mass customization. Comput. Ind. Eng. 2020, 142, 106336.1–106336.13. [Google Scholar] [CrossRef]

- Sabin, D.; Weigel, R. Product configuration frameworks—A survey. IEEE Intell. Syst. Appl. 1998, 13, 42–49. [Google Scholar] [CrossRef]

- Forza, C.; Salvador, F. Managing for variety in the order acquisition and fulfilment process: The contribution of product configuration systems. Int. J. Prod. Econ. 2002, 76, 87–98. [Google Scholar] [CrossRef]

- Shao, X.Y.; Wang, Z.H.; Li, P.G.; Feng, C.X.J. Integrating data mining and rough set for customer group-based discovery of product configuration rules. Int. J. Prod. Res. 2006, 44, 2789–2811. [Google Scholar] [CrossRef]

- Hapsari, S.N.; Rosyidi, C.N. A goal programming optimization model for the allocation og liquid steel production. IOP Conf. 2018, 319, 012021. [Google Scholar]

- Malekimajd, M.; Ardagna, D.; Ciavotta, M.; Gianniti, E.; Passacantando, M.; Rizzi, A.M. An optimization framework for the capacity allocation and admission control of MapReduce jobs in cloud systems. J. Supercomput. 2018, 74, 5314–5348. [Google Scholar] [CrossRef]

- Badurdeen, F.; Aydin, R.; Brown, A. A multiple lifecycle-based approach to sustainable product configuration design. J. Clean. Prod. 2018, 200, 756–769. [Google Scholar] [CrossRef]

- Costa, N.; Patricio, L.; Morelli, N.; Magee; Christopher, L. Bringing service design to manufacturing companies: Integrating PSS and service design approaches. Des. Stud. 2018, 55, 112–145. [Google Scholar]

- Cao, Y.; Wang, S.; Kang, L.; Gao, Y. A TQCS-based service selection and scheduling strategy in cloud manufacturing. Int. J. Adv. Manuf. Technol. 2016, 82, 235–251. [Google Scholar] [CrossRef]

- Piran, F.A.S.; Lacerda, D.P.; Camargo, L.F.R.; Viero, C.F.; Teixeira, R.; Dresch, A. Product modularity and its effects on the production process: An analysis in a bus manufacturer. Int. J. Adv. Manuf. Technol. 2017, 88, 2331–2343. [Google Scholar] [CrossRef]

- Tang, M.; Qi, Y.; Zhang, M. Impact of product modularity on mass customization capability: An exploratory study of contextual factors. Int. J. Inf. Technol. Decis. Mak. 2017, 16, 939–959. [Google Scholar] [CrossRef]

- Kim, S.; Moon, S.K. Eco-modular product architecture identification and assessment for product recovery. J. Intell. Manuf. 2019, 30, 383–403. [Google Scholar] [CrossRef]

- Li, Z.; Wang, S.; Yin, W. Determining optimal granularity level of modular product with hierarchical clustering and modularity assessment. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 1–14. [Google Scholar] [CrossRef]

- Alparslan, E.B.; Arianne, X.C.; Panos, Y.P.; Bogdan, I.E. Multiobjective optimization of modular design concepts for a collection of interacting systems. Struct. Multidiscip. Optim. 2018, 57, 83–94. [Google Scholar]

- Sheng, Z.; Xu, T.; Song, J. Configuration design of product service system for CNC machine tools. Adv. Mech. Eng. 2015, 7, 971720. [Google Scholar] [CrossRef]

- Shen, J.; Erkoyuncu, J.A.; Roy, R.; Wu, B. A framework for cost evaluation in product service system configuration. Int. J. Prod. Res. 2017, 55, 6120–6144. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Mazzoldi, L.; Reboldi, R. Product-service System for Sustainable EAF Transformers: Real Operation Conditions and Maintenance Impacts on the Life-cycle Cost. Procedia CIRP 2016, 47, 72–77. [Google Scholar] [CrossRef]

- Sirbiladze, G.; Garg, H.; Ghvaberidze, B.; Matsaberidze, B.; Khutsishvili, I.; Midodashvili, B. Uncertainty modeling in multi-objective vehicle routing problem under extreme environment. Artif. Intell. Rev. 2022, 55, 6673–6707. [Google Scholar] [CrossRef]

- Harish, G.; Sultan, S.A.; Hamiden, A. Study on multi-objective nonlinear programming problem with rough parameters. J. Intell. Fuzzy Syst. 2021, 42, 3591–3604. [Google Scholar]

- Modu, B.; Umar, M.M. Multiobjective Mathematical Optimization Model for Municipal Solid Waste Management with Economic Analysis of Reuse/Recycling Recovered Waste Materials. J. Comput. Cogn. Eng. 2022, 1, 1–16. [Google Scholar]

- Harish, G.; Rizk, M.R. A novel approach for solving rough multi-objective transportation problem: Development and prospects. Comput. Appl. Math. 2021, 40, 149. [Google Scholar]

- Sun, H.; Liu, Y.; Sakao, T.; Wang, Z. Configuring use-oriented aero-engine overhaul service with multi-objective optimization for environmental sustainability. J. Clean. Prod. 2016, 162, S94–S106. [Google Scholar] [CrossRef]

- Zhu, Q. Maintenance Optimization for Multi-Component Systems under Condition Monitoring. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2015. [Google Scholar]

- Arts, J.; Basten, R. Design of multi-component periodic maintenance programs with single-component models. IISE Trans. 2018, 50, 606–615. [Google Scholar] [CrossRef]

- Tversky, A.; Kahneman, D. Advances in prospect theory: Cumulative representation of uncertainty. J. Risk Uncertain. 1992, 5, 297–323. [Google Scholar] [CrossRef]

| Model Name | Instance Name | Module Instance Code | Cost (Ten Thousand Yuan) | Maintenance Time (h) | Module Attribute | |

|---|---|---|---|---|---|---|

| Service modules | Installation and debugging service module | Site installation test | 1 | 1.50 | 18.4 | ▲ |

| Remote installation test | 2 | 0.80 | 22.6 | |||

| Commissioned installation test | 3 | 2.20 | 18.5 | |||

| Consultation and training module | Basic train | 1 | 0.56 | 8.6 | ▲ | |

| Optimization train | 2 | 1.20 | 17.2 | |||

| Monitoring diagnostic module | Remote monitoring and diagnosis | 1 | 4.58 | 2.4 | △ | |

| On-site monitoring and diagnosis | 2 | 6.23 | 5.8 | |||

| Spare parts supply module | Supply of original spare parts | 1 | 5.45 | 4.5 | ▲ | |

| Supply of non-original spare parts | 2 | 3.55 | 5.0 | |||

| Personalized service | Vehicle clean | 1 | 0.12 | 4.55 | △ | |

| Vehicle beauty | 2 | 0.25 | 5.6 | |||

| Replace interior decoration | 3 | 0.89 | 6.98 | |||

| Maintenance service module | Level 1 maintenance | 1 | 8.70 | 5.2 | ▲ | |

| Level II maintenance | 2 | 15.60 | 5.4 | |||

| Level III maintenance | 3 | 18.90 | 5.1 | |||

| Quality assurance module | Bogie warranty | 1 | 5.20 | 7.6 | △ | |

| Emergency rescue service module | Multi-party joint request for help | 1 | 8.60 | 9.5 | ▲ | |

| Service providers ask for help independently | 2 | 6.40 | 10.0 | |||

| Product modules | Axle box temperature sensor | Model HG-TSEN-01-S | 1 | 0.0354 | 2.1 | △ |

| Model DCGQT100B | 2 | 0.0368 | 1.9 | |||

| Axle box bearing | NSK | 1 | 0.0450 | 2.04 | △ | |

| NTN | 2 | 0.0420 | 1.83 | |||

| Primary vertical shock absorber | KYB product | 1 | 0.135 | 6.3 | △ | |

| Hitachi product | 2 | 0.129 | 6.7 | |||

| Air spring | KTS product | 1 | 0.0150 | 0.8 | △ | |

| Tieke product | 2 | 0.0185 | 0.75 | |||

| Axle | Axle A | 1 | 0.68 | 2.5 | △ | |

| Axle B | 2 | 0.60 | 2.95 | |||

| Number | Rule Types | Meaning |

|---|---|---|

| 1 | Mutually exclusive rule | KYB products are incompatible with Hitachi products, and choose one to install |

| 2 | Dependency rule | If the reducer type is KYB, NSK must be selected |

| If you choose to seek help from multiple parties, you must decide to use the optimization train | ||

| 3 | Personalization rule | Parts that must be selected or not selected as specified by the customers |

| Technical Characteristics | Energy Saving Performance | Timeliness | Adaptability | Reliability | Security | Availability | Specialty | Experience | Environmental Performance | Instance Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| Preference | 6 | 9 | 7 | 1 | 2 | 4 | 5 | 3 | 8 | |

| Technical characteristics weight | 0.0907 | 0.0369 | 0.074 | 0.2021 | 0.1645 | 0.1246 | 0.1074 | 0.1431 | 0.0566 | 0 |

| Site installation test | 3 | 3 | 3 | 9 | 9 | 3 | 3 | 5 | 1 | 0.037 |

| Remote installation test | 3 | 3 | 3 | 9 | 9 | 6 | 3 | 5 | 1 | 0.040 |

| Commissioned installation test | 3 | 3 | 3 | 9 | 9 | 8 | 3 | 5 | 1 | 0.042 |

| Basic train | 3 | 3 | 3 | 8 | 9 | 3 | 3 | 6 | 6 | 0.039 |

| Optimization train | 3 | 3 | 9 | 6 | 6 | 1 | 9 | 9 | 3 | 0.040 |

| Remote monitoring and diagnosis | 1 | 1 | 1 | 6 | 1 | 9 | 1 | 1 | 6 | 0.023 |

| On-site monitoring and diagnosis | 1 | 1 | 1 | 9 | 3 | 9 | 3 | 1 | 6 | 0.031 |

| Supply of original spare parts | 3 | 3 | 3 | 9 | 9 | 9 | 6 | 1 | 1 | 0.041 |

| Supply of non-original spare parts | 3 | 3 | 3 | 8 | 9 | 9 | 3 | 6 | 3 | 0.043 |

| Vehicle clean | 3 | 3 | 1 | 9 | 9 | 9 | 1 | 8 | 1 | 0.043 |

| Vehicle beauty | 1 | 1 | 3 | 9 | 9 | 9 | 1 | 6 | 3 | 0.041 |

| Replace interior decoration | 1 | 1 | 3 | 9 | 9 | 9 | 3 | 9 | 3 | 0.046 |

| Level 1 maintenance | 8 | 9 | 3 | 3 | 1 | 1 | 3 | 3 | 3 | 0.022 |

| Level II maintenance | 8 | 9 | 1 | 1 | 1 | 1 | 1 | 1 | 3 | 0.014 |

| Level III maintenance | 9 | 3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.013 |

| Bogie warranty | 1 | 3 | 3 | 9 | 6 | 9 | 9 | 3 | 1 | 0.040 |

| Multi-party joint request for help | 1 | 1 | 3 | 9 | 9 | 3 | 9 | 9 | 9 | 0.047 |

| Service providers ask for help independently | 3 | 3 | 3 | 6 | 8 | 3 | 8 | 8 | 3 | 0.040 |

| Model HG-TSEN-01-S | 3 | 3 | 1 | 3 | 3 | 3 | 9 | 9 | 3 | 0.030 |

| Model DCGQT100B | 3 | 1 | 1 | 3 | 3 | 3 | 9 | 9 | 3 | 0.030 |

| NSK | 1 | 3 | 3 | 9 | 9 | 9 | 3 | 3 | 3 | 0.040 |

| NTN | 1 | 3 | 9 | 8 | 3 | 9 | 3 | 3 | 3 | 0.035 |

| KYB product | 3 | 3 | 3 | 9 | 9 | 3 | 3 | 3 | 3 | 0.036 |

| Hitachi product | 3 | 3 | 3 | 6 | 9 | 3 | 3 | 3 | 3 | 0.032 |

| KTS product | 3 | 3 | 3 | 8 | 9 | 3 | 3 | 3 | 9 | 0.037 |

| Tieke product | 3 | 3 | 3 | 9 | 9 | 6 | 3 | 3 | 9 | 0.041 |

| Axle A | 1 | 3 | 1 | 9 | 9 | 3 | 9 | 3 | 3 | 0.038 |

| Axle B | 1 | 3 | 1 | 8 | 9 | 6 | 9 | 3 | 3 | 0.040 |

| Number | Scheme Code | [Weight Cost Time] |

|---|---|---|

| 1 | [2 2 2 1 2 2 3 1 1 1 1 2 2] | [0.488 33.8039 94.52] |

| 2 | [2 1 2 1 2 0 0 0 0 0 0 1 0] | [0.227 20.025 52.2] |

| 3 | [1 1 1 1 2 0 0 0 0 0 0 2 0] | [0.224 22.6285 47.45] |

| 4 | [3 2 2 1 1 2 3 1 2 1 1 2 2] | [0.496 37.4053 89.72] |

| 5 | [1 1 1 1 2 0 0 0 0 0 0 1 0] | [0.221 22.625 47.5] |

| 6 | [3 2 1 1 1 2 3 1 2 1 1 2 1] | [0.49 39.3853 88.77] |

| 7 | [1 1 1 1 2 1 0 0 2 2 0 1 0] | [0.316 27.2838 53.63] |

| 8 | [2 2 2 1 1 0 1 1 2 1 1 2 1] | [0.457 29.0853 85.14] |

| 9 | [1 1 1 3 2 0 0 0 2 0 0 1 0] | [0.24 32.8618 49.3] |

| 10 | [2 2 2 1 1 2 3 1 2 1 1 2 1] | [0.491 36.0853 93.37] |

| 11 | [1 1 2 1 2 0 1 0 2 2 1 2 0] | [0.368 21.0623 62.53] |

| 12 | [1 1 2 1 2 0 0 0 0 2 0 1 2] | [0.3 21.367 52.78] |

| 13 | [2 2 2 1 1 0 1 0 1 1 1 2 1] | [0.419 23.8839 77.74] |

| 14 | [2 1 2 1 2 0 0 0 0 0 0 1 2] | [0.265 20.625 55.15] |

| 15 | [1 1 2 1 2 0 1 0 2 2 1 2 1] | [0.403 21.7423 65.03] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, C.; Ye, S.; Wang, H.; Cao, J.; Gao, Z. Maintenance Service Configuration Optimization for Complex Equipment. Systems 2023, 11, 32. https://doi.org/10.3390/systems11010032

Zhou C, Ye S, Wang H, Cao J, Gao Z. Maintenance Service Configuration Optimization for Complex Equipment. Systems. 2023; 11(1):32. https://doi.org/10.3390/systems11010032

Chicago/Turabian StyleZhou, Chunliu, Shan Ye, Hongjun Wang, Jianhua Cao, and Zhenhua Gao. 2023. "Maintenance Service Configuration Optimization for Complex Equipment" Systems 11, no. 1: 32. https://doi.org/10.3390/systems11010032

APA StyleZhou, C., Ye, S., Wang, H., Cao, J., & Gao, Z. (2023). Maintenance Service Configuration Optimization for Complex Equipment. Systems, 11(1), 32. https://doi.org/10.3390/systems11010032