Green Growth or Gray Growth: Measuring Green Growth Efficiency of the Manufacturing Industry in China

Abstract

:1. Introduction

2. Literature Review

2.1. Green Growth Theory

2.2. Scale Effect and Technological Effect in EKC

2.3. Green Growth in Manufacturing Industry

3. Methodology

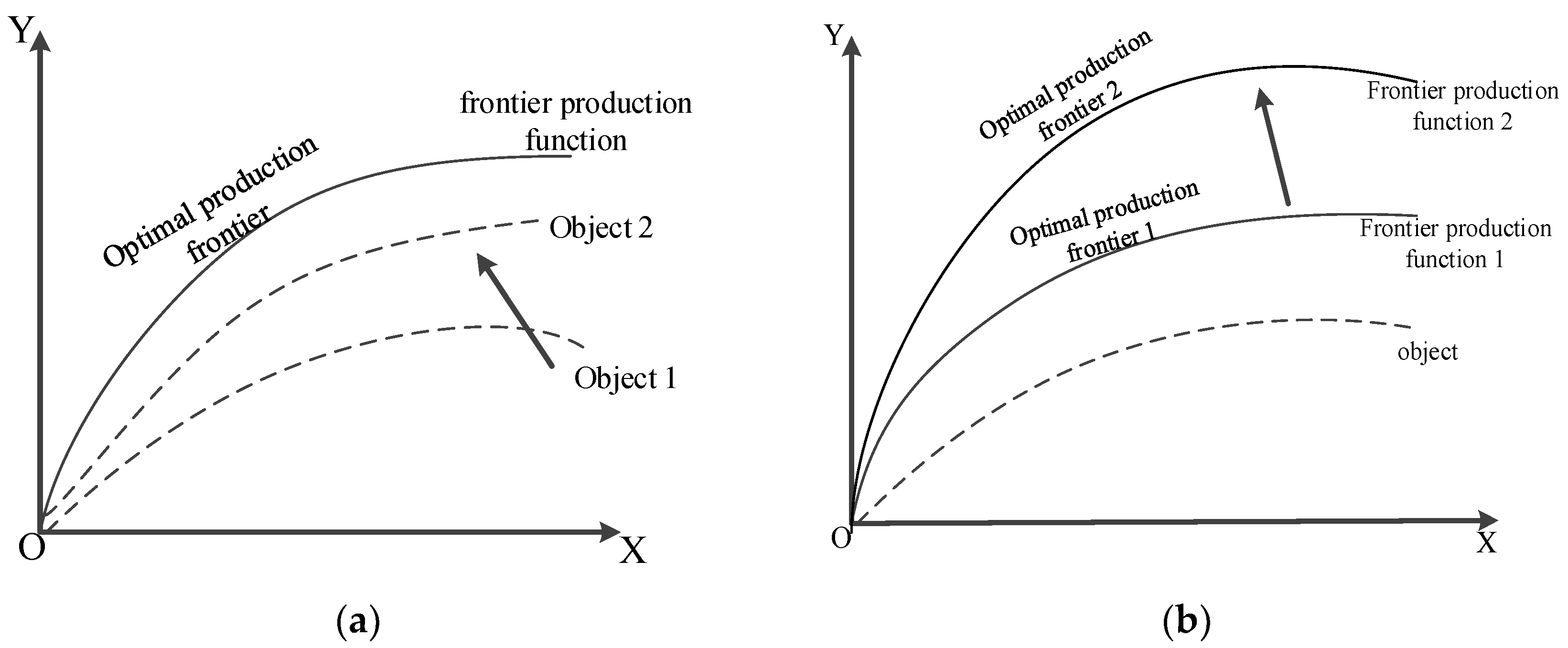

3.1. Production Possibility Set

- 1.

- “Zero Combination” Axiom. If and , . It means that if there is an industry without undesirable output, there is undesirable output. Or it can be understood that when there is a desirable output, there must be undesirable outputs, such as resource consumption and pollution emissions. So, we can put the element of resources and environment into the analytical framework.

- 2.

- Weakly Disposable Axiom. If and , It shows that the balance between desired and undesirable production changes, which suggests that, in the industrial sector, if we want to lessen environmental pollution or eliminate undesirable output, we must invest a certain amount of money and resources.

- , at least one industry produces each undesirable output.

- , each industry produces at least one undesirable output.

3.2. Super-Efficient SBM Model

3.3. Luenberger Productivity Index

3.4. Research Object and Index Selection

3.4.1. Research Context: Green Growth in the Manufacturing Industry

3.4.2. Research Object

3.4.3. Industry Classification

3.4.4. Index Selection

- 1.

- Input index

- Labor input: when measuring labor input, it is necessary to obtain the labor input of various industries. Since it is impossible to obtain statistical indexes including labor time and labor efficiency, the average number of employees in the manufacturing industry is selected as the index of labor input in this paper.

- Capital input: the estimation of capital stock is calculated by the value of fixed assets in the perpetual inventory method. In this paper, the annual average balance of net fixed assets of industrial enterprises above designated size is selected to approximately replace the investment in fixed assets, and the missing data of net fixed assets are approximately estimated by the average value.

- Energy input: energy element represents the degree of resource consumption in the development of manufacturing industry. In this paper, the total energy consumption of the manufacturing industry is selected as the index of energy input.

- 2.

- Output index

- Desirable output: since resource consumption and environmental pollution exists in all aspects of the production process, the total output value of the industry contains the energy factor of the nature of intermediate inputs, including both the production part of added value and the intermediate input part. Therefore, the total industrial output value is selected as the index of desirable output in this paper.

- Undesirable output: the entropy method is used to synthesize the environmental pollution index to calculate the undesirable output. The environmental pollution index is composed of three indicators: wastewater discharge, exhaust gas discharge, and solid waste discharge. It is used to quantify the harm that pollutants released during manufacturing activities have on the environment.

4. Results and Discussion

4.1. Efficiency Analysis

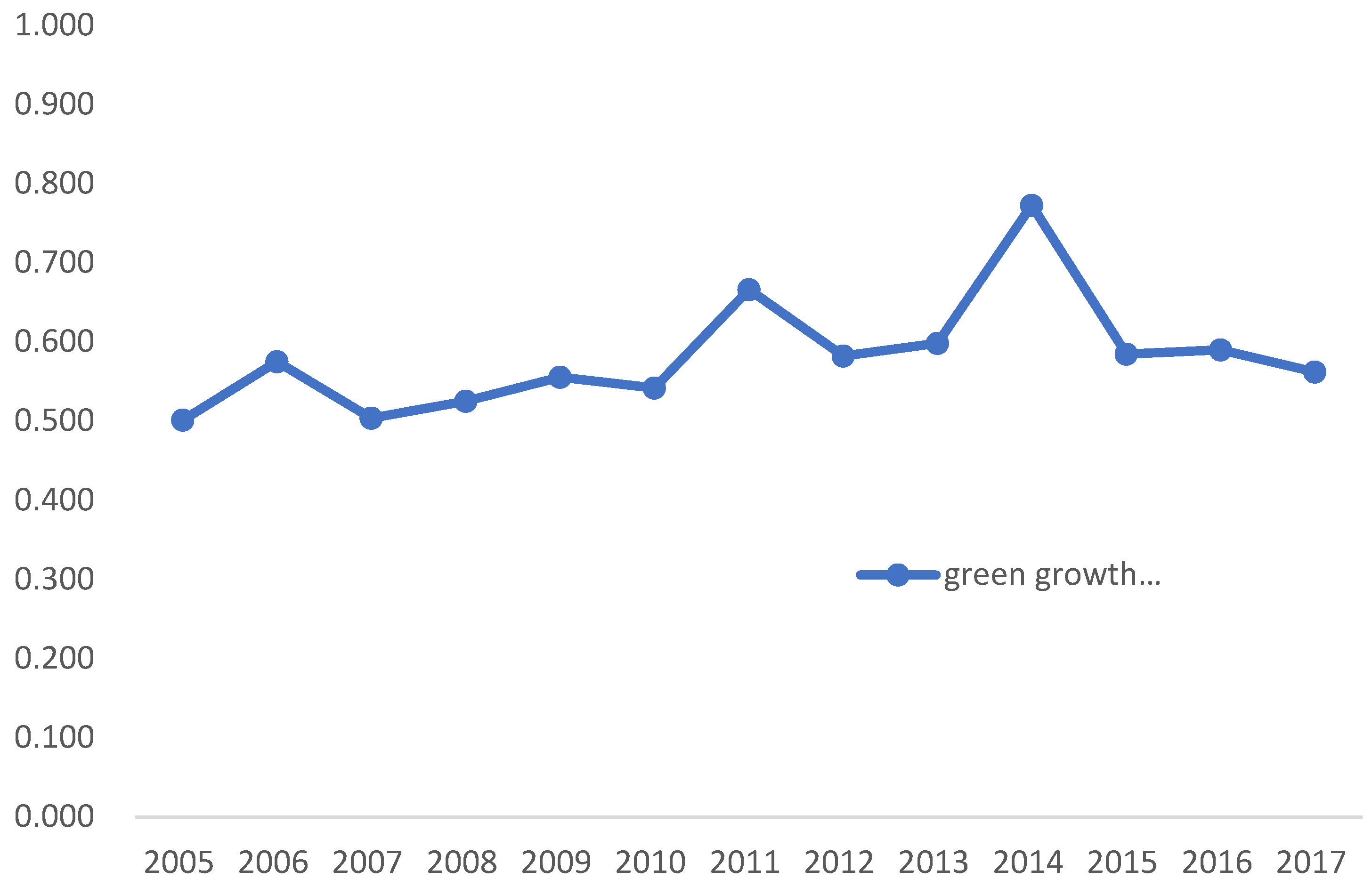

4.1.1. Fluctuation State and Unstable Upward Trend

4.1.2. Growth State

- Deep green growth: these six industries are clustered as deep green growth, and all of their efficiencies are above 1. They are TP (2.861), FM (1.591), CCE (1.473), Instrument (1.212), CACSE (1.155), and PR (1.066). These industries consume few resources and generate relatively less pollution, according to the previous statistics.

- Light green growth: these four businesses are categorized as being in a light green growth state, since their green growth efficiency values range from 0.581 to 1. What these industries have in common is the high level of technology required, but, at the same time, the industry’s resource and energy consumption is also relatively high.

- Gray growth: this contains 17 industries that we classify as being in a gray growth condition because their mean green growth efficiency values are significantly below the industry average, ranging from 0.076 to 0.334. The number of industries in gray growth accounted for more than 60%. This indicates that most of the manufacturing industries have not achieved green growth and are still in a state of gray growth. There is still much room for improvement in the green road of China’s manufacturing industry, and most industries still have not eliminated the production dilemma of high emissions.

4.1.3. Industry Heterogeneity

- Labor-intensive industry: this includes eight industries, including AS, WBR, TP, Textile, and some others. From 2005 to 2012, it showed a rather steady increasing trend; starting in 2012, the trend began to turn downward. The labor-intensive industry has a lower level of technical innovation and is highly reliant on the need for labor resources. For the implementation of green growth in labor-intensive industries, the development model of population dividends as a source of competitive advantage is no longer appropriate.

- Capital-intensive industry: this include 10 industries, such as FM, PP, PR, metal, transportation, iron, steel, and other basic industries. A typical industry is the heavy chemical industry. Capital-intensive industry has a lower rate of green growth than labor-intensive industries. With the exception of 2006, 2011, and 2014, most of them are in a condition of gray growth, with an average green growth efficiency of less than 0.5. Producing requires a substantial investment of capital. Capital-intensive sectors exhibit glaring green development disadvantages since they rely on investment-driven industry growth models, such as capital advantages and processing trade.

- Technology-intensive industry: this includes nine industries, such as CC, CF, GE, an SE, which belong to high-tech industrial sectors. Its technical knowledge accounts for a large proportion, and scientific research funds, labor education, and product added value are all significant contributors. Technology-intensive industries have shown a clear increase trend in green growth efficiency from 2005 to 2017. Among the three different types of industries, this is the only one to generate green growth. This further illustrates the significance of technological innovation in the green growth of the manufacturing industry. Technology dominance is the most efficient approach to increase the value of businesses, and it is also the primary driving force to increase the efficiency of green growth.

4.2. The Discussion of Driving Force

4.2.1. The Discussion of Growth Rate

4.2.2. The Discussion of TE and TP

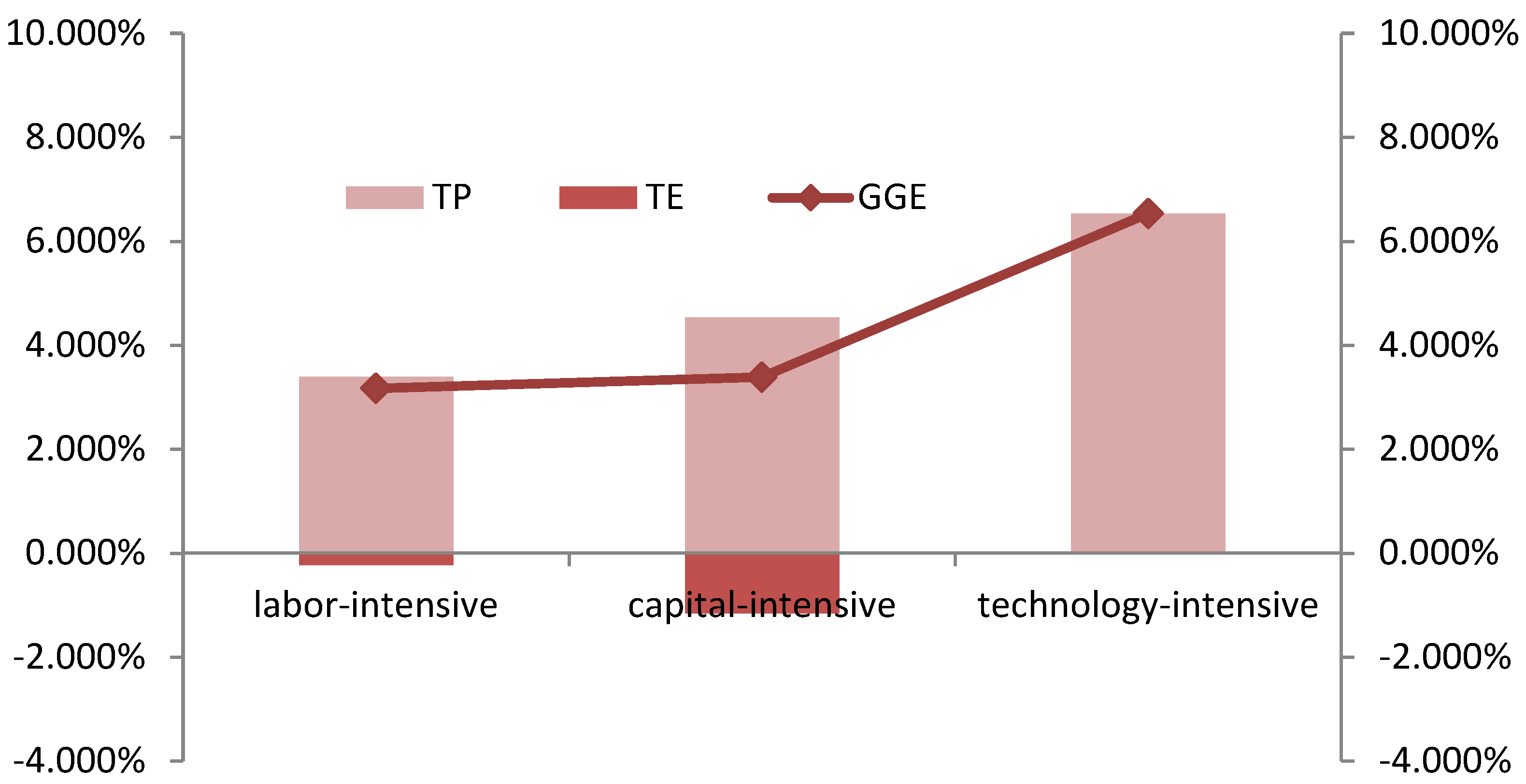

4.2.3. The Discussion of Industry Heterogeneity

- (1)

- The green growth efficiency of the three types of manufacturing has achieved positive growth, and the technology-intensive component still dominates in the process of the manufacturing industry.The growth rates of the three types of industries are higher than zero when viewed in terms of the total manufacturing green growth efficiency growth rate. The manufacturing industry is growing consistently. Technology-intensive industries have the fastest growth rate (6.535%), followed by capital-intensive industries (3.382%), and labor-intensive industries (3.169%) have the slowest growth rate. Table 3 demonstrates that industries that rely heavily on technology have the highest rates of green growth efficiency. All of this suggests that technologically advanced industries hold a significant place in China’s manufacturing industry.

- (2)

- The TE in labor-intensive and capital-intensive industries is deteriorating, but it is improving in the technology-intensive industries.Labor-intensive industries (−0.228%) and capital-intensive industries (−1.159%) are less than 0 in TE dimension, which is reflected in the deterioration of technical efficiency. Labor-intensive industries (3.397%), capital-intensive industries (4.541%), and technology intensive industries (6.539%) are all greater than 0 in the TP dimension, and technological progress is the core driving force. Based on the changes of TE and TP indexes, it was found that the industry heterogeneity is obvious. The greening process of technology-intensive industries includes both the improvement of technical efficiency and the role of technological progress. However, the green growth of labor-intensive and capital-intensive industries is more driven by the core of technological progress, and innovation is the main source of its future development.

5. Conclusions and Suggestion

5.1. Conclusions

5.2. Suggestion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, H.; Hao, Y.; Ren, S. How do environmental regulation and environmental decentralization affect green total factor energy efficiency: Evidence from China. Energy Econ. 2020, 91, 104880. [Google Scholar] [CrossRef]

- Zhang, X.; Li, R.; Zhang, J. Understanding the Green Total Factor Productivity of Manufacturing Industry in China: Analysis Based on the Super-SBM Model with Undesirable Outputs. Sustainability 2022, 14, 9310. [Google Scholar] [CrossRef]

- Lin, B.; Wu, W.; Song, M. Industry 4.0: Driving factors and impacts on firm’s performance: An empirical study on China’s manufacturing industry. Ann. Oper. Res. 2019, 1–21. [Google Scholar] [CrossRef]

- Bansal, P.; Kumar, S.; Mehra, A.; Gulati, R. Developing two dynamic Malmquist-Luenberger productivity indices: An illustrated application for assessing productivity performance of Indian banks. Omega 2022, 107, 102538. [Google Scholar] [CrossRef]

- Jiahuey, Y.; Liu, Y.; Yu, Y. Measuring green growth performance of China’s chemical industry. Resour. Conserv. Recycl. 2019, 149, 160–167. [Google Scholar] [CrossRef]

- Qian, Y.; Liu, J.; Cheng, Z.; Forrest, J.Y.-L. Does the smart city policy promote the green growth of the urban economy? Evidence from China. Environ. Sci. Pollut. Res. 2021, 28, 66709–66723. [Google Scholar] [CrossRef]

- Alhassan, I.; Katharine, B.; Ehsan, S. Green infrastructure needs green governance: Lessons from Australia’s largest integrated stormwater management project, the River Torrens Linear Park. J. Clean Prod. 2020, 261, 121202. [Google Scholar]

- Galinato, G.I.; Chouinard, H.H. Strategic interaction and institutional quality determinants of environmental regulations. Resour. Energy Econ. 2018, 53, 114–132. [Google Scholar] [CrossRef]

- Bowen, A.; Hepburn, C. Green growth: An assessment. Oxf. Rev. Econ. Policy 2014, 30, 407–422. [Google Scholar] [CrossRef]

- Balsalobre-Lorente, D.; Driha, O.M.; Leitão, N.C.; Murshed, M. The carbon dioxide neutralizing effect of energy innovation on international tourism in EU-5 countries under the prism of the EKC hypothesis. J. Environ. Manag. 2021, 298, 113513. [Google Scholar] [CrossRef]

- Alola, A.A.; Ozturk, I. Mirroring risk to investment within the EKC hypothesis in the United States. J. Environ. Manag. 2021, 293, 112890. [Google Scholar] [CrossRef]

- Román-Collado, R.; Economidou, M. The role of energy efficiency in assessing the progress towards the EU energy efficiency targets of 2020: Evidence from the European productive sectors. Energy Policy 2021, 156, 112441. [Google Scholar] [CrossRef]

- Tang, H.-L.; Liu, J.-M.; Wu, J.-G. The impact of command-and-control environmental regulation on enterprise total factor productivity: A quasi-natural experiment based on China’s “Two Control Zone” policy. J. Clean. Prod. 2020, 254, 120011. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Z.; Saydaliev, H.B.; Abu Hatab, A.; Fang, W. Measuring Energy Efficiency Performance in China: Do Technological and Environmental Concerns Matter for Energy Efficiency? Front. Energy Res. 2021, 9, 758. [Google Scholar] [CrossRef]

- Luukkanen, J.; Kaivo-oja, J.; Vähäkari, N.; O’Mahony, T.; Korkeakoski, M.; Panula-Ontto, J.; Phonhalath, K.; Nanthavong, K.; Reincke, K.; Vehmas, J.; et al. Green economic development in Lao PDR: A sustainability window analysis of Green Growth Productivity and the Efficiency Gap. J. Clean. Prod. 2019, 211, 818–829. [Google Scholar] [CrossRef]

- Loewen, B. Coal, green growth and crises: Exploring three European Union policy responses to regional energy transitions. Energy Res. Soc. Sci. 2022, 93, 102849. [Google Scholar] [CrossRef]

- Ofori, I.K.; Gbolonyo, E.Y.; Ojong, N. Towards inclusive green growth in Africa: Critical energy efficiency synergies and governance thresholds. J. Clean. Prod. 2022, 369, 132917. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, J.; She, S.; Liu, W. Green growth, natural resources and sustainable development: Evidence from BRICS economies. Resour. Policy 2022, 79, 103032. [Google Scholar] [CrossRef]

- Peng, B.; Zheng, C.; Wei, G.; Elahi, E. The cultivation mechanism of green technology innovation in manufacturing industry: From the perspective of ecological niche. J. Clean. Prod. 2019, 252, 119711. [Google Scholar] [CrossRef]

- Arbona, A.; Giménez, V.; López-Estrada, S.; Prior, D. Efficiency and quality in Colombian education: An application of the metafrontier Malmquist-Luenberger productivity index. Socio-Econ. Plan. Sci. 2021, 79, 101122. [Google Scholar] [CrossRef]

- Sandberg, M.; Klockars, K.; Wilén, K. Green growth or degrowth? Assessing the normative justifications for environmental sustainability and economic growth through critical social theory. J. Clean. Prod. 2018, 206, 133–141. [Google Scholar] [CrossRef]

- Cao, J.; Law, S.H.; Samad, A.R.B.A.; Mohamad, W.N.B.W.; Wang, J.; Yang, X. Impact of financial development and technological innovation on the volatility of green growth—Evidence from China. Environ. Sci. Pollut. Res. 2021, 28, 48053–48069. [Google Scholar] [CrossRef] [PubMed]

- Chien, F.; Ananzeh, M.; Mirza, F.; Bakar, A.; Vu, H.M.; Ngo, T.Q. The effects of green growth, environmental-related tax, and eco-innovation towards carbon neutrality target in the US economy. J. Environ. Manag. 2021, 299, 113633. [Google Scholar] [CrossRef] [PubMed]

- Belmonte-Ureña, L.J.; Plaza-Úbeda, J.A.; Vazquez-Brust, D.; Yakovleva, N. Circular economy, degrowth and green growth as pathways for research on sustainable development goals: A global analysis and future agenda. Ecol Econ 2021, 185, 107050. [Google Scholar] [CrossRef]

- Tawiah, V.; Zakari, A.; Adedoyin, F.F. Determinants of green growth in developed and developing countries. Environ. Sci. Pollut. Res. 2021, 28, 39227–39242. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, L.; Liu, J. Natural resource abundance, resource industry dependence and economic green growth in China. Resour. Policy 2020, 68, 101734. [Google Scholar] [CrossRef]

- Roh, T.; Noh, J.; Oh, Y.; Park, K. Structural relationships of a firm’s green strategies for environmental performance: The roles of green supply chain management and green marketing innovation. J. Clean. Prod. 2022, 356, 131877. [Google Scholar] [CrossRef]

- Jiakui, C.; Abbas, J.; Najam, H.; Liu, J.; Abbas, J. Green technological innovation, green finance, and financial development and their role in green total factor productivity: Empirical insights from China. J. Clean. Prod. 2023, 382, 135131. [Google Scholar] [CrossRef]

- Song, M.; Zhu, S.; Wang, J.; Zhao, J. Share green growth: Regional evaluation of green output performance in China. Int. J. Prod. Econ. 2020, 219, 152–163. [Google Scholar] [CrossRef]

- Huang, H.; Mo, R.; Chen, X. New patterns in China’s regional green development: An interval Malmquist–Luenberger productivity analysis. Struct. Change Econ. D 2021, 58, 161–173. [Google Scholar] [CrossRef]

- Yang, M.; Hou, Y.; Fang, C.; Duan, H. Constructing energy-consuming right trading system for China’s manufacturing industry in 2025. Energy Policy 2020, 144, 111602. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, Y. How biased technological progress sustainably improve the energy efficiency: An empirical research of manufacturing industry in China. Energy 2021, 230, 120823. [Google Scholar] [CrossRef]

- Zhai, X.; An, Y. Analyzing influencing factors of green transformation in China’s manufacturing industry under environmental regulation: A structural equation model. J. Clean. Prod. 2019, 251, 119760. [Google Scholar] [CrossRef]

- Gutiérrez, E.; Lozano, S. Efficiency performance of Current Account-BoP flows in advanced world economies considering GHG emissions. J. Clean Prod. 2020, 254, 120139. [Google Scholar] [CrossRef]

- Sun, Y.; Ding, W.; Yang, Z.; Yang, G.; Du, J. Measuring China’s regional inclusive green growth. Sci. Total Environ. 2020, 713, 136367. [Google Scholar] [CrossRef]

- Song, M.; Wang, J.; Zhao, J.; Baležentis, T.; Shen, Z. Production and safety efficiency evaluation in Chinese coal mines: Accident deaths as undesirable output. Ann. Oper. Res. 2018, 291, 827–845. [Google Scholar] [CrossRef]

- Zhong, K.; Wang, Y.; Pei, J.; Tang, S.; Han, Z. Super efficiency SBM-DEA and neural network for performance evaluation. Inf. Process. Manag. 2021, 58, 102728. [Google Scholar] [CrossRef]

- Eya Jebali, H.E. Total Factor Environmental Productivity in the Mediterranean Counries: A Malmquist-Luenberger Index Approach. Int. J. Appl. Manag. Technol. 2020, 19, 62–76. [Google Scholar]

- Cao, J.; Law, S.H.; Bin Abdul Samad, A.R.; Binti, W.; Mohamad, W.N.; Wang, J.; Yang, X. Effect of financial development and technological innovation on green growth—Analysis based on spatial Durbin model. J. Clean. Prod. 2022, 365, 132865. [Google Scholar] [CrossRef]

- Roh, T.; Lee, K.; Yang, J.Y. How do intellectual property rights and government support drive a firm’s green innovation? The mediating role of open innovation. J. Clean. Prod. 2021, 317, 128422. [Google Scholar] [CrossRef]

- Wang, Y.; Ye, G.; Zhang, Y.; Mu, P.; Wang, H. Is the Chinese construction industry moving towards a knowledge- and technology-intensive industry? J. Clean. Prod. 2020, 259, 120964. [Google Scholar] [CrossRef]

- Mensah, C.N.; Long, X.; Dauda, L.; Boamah, K.B.; Salman, M.; Appiah-Twum, F.; Tachie, A.K. Technological innovation and green growth in the Organization for Economic Cooperation and Development economies. J. Clean. Prod. 2019, 240, 118204. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, M.; Feng, C.; Zhou, H.; Wang, K. Total factor energy efficiency in Chinese manufacturing industry under industry and regional heterogeneities. Resour. Conserv. Recycl. 2020, 168, 105255. [Google Scholar] [CrossRef]

| Labor-Intensive | Capital-Intensive | Technology-Intensive |

|---|---|---|

| Agricultural and sideline food processing (AS) | Furniture (FM) | Chemical raw materials and chemical products (CC) |

| Food | Paper making and paper products (PP) | Pharmaceutical |

| Wine, beverage, and refined tea (WBR) | Printing and recording media reproduction (PR) | Chemical fiber (CF) |

| Tobacco products (TP) | Culture and education, arts and crafts, sports, and entertainment products (CACSE) | General equipment (GE) |

| Textile | Petroleum processing, smelting, and nuclear fuel processing (PSN) | Special equipment (SE) |

| Textile and clothing (TC) | Rubber and plastic products (RP) | Railway, ship, aerospace, and other transportation (RSAT) |

| Leather, fur, feathers, and their products and footwear (LFFF) | Non-Metallic mineral products (NMM) | Electrical machinery and equipment (EME) |

| Wood processing and wood, bamboo, rattan, palm, and grass products (WWBRPG) | Ferrous metal smelting and rolling processing (FMSR) | Computer, communication, and other electronic equipment (CCE) |

| Non-Ferrous metal smelting and rolling processing (NFMSR) | Instrument | |

| Metal products (MP) |

| Index | Avg. | S.D. | Min. | Max. | |

|---|---|---|---|---|---|

| Input index | Capital Stock | 3974.271 | 4287.587 | 59.0448 | 24,825.4 |

| Average number of employees | 253.8858 | 184.1726 | 15 | 909.26 | |

| Total energy consumption | 4737.796 | 10,422.49 | 65.8392 | 67,051.67 | |

| Desirable output | Total industrial output value | 4204.416 | 5703.454 | 117.354 | 44,897.7 |

| Undesirable output: | Wastewater discharge | 60,008.19 | 89,417.85 | 298 | 424,597 |

| Exhaust emissions | 10,390.23 | 27,486.46 | 20.64 | 185,327.9 | |

| Solid waste emissions | 2568.632 | 7016.641 | 2 | 44076 | |

| environmental pollution index | 0.111962 | 0.19453 | 1.28 × 10−5 | 0.896436 | |

| Industry | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | Average | Growth State |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TP | 2.035 | 2.244 | 2.637 | 2.843 | 3.073 | 3.302 | 3.315 | 3.338 | 2.834 | 3.135 | 2.897 | 2.764 | 2.780 | 2.861 | Dark Green Growth |

| FM | 1.359 | 1.457 | 1.279 | 1.116 | 1.050 | 1.011 | 1.036 | 0.627 | 1.778 | 6.012 | 1.046 | 1.616 | 1.293 | 1.591 | |

| CCE | 1.438 | 1.489 | 1.498 | 1.506 | 1.459 | 1.459 | 1.427 | 1.439 | 1.475 | 1.492 | 1.494 | 1.480 | 1.491 | 1.473 | |

| Instrument | 1.511 | 1.351 | 1.243 | 1.178 | 1.103 | 1.018 | 1.012 | 0.529 | 1.182 | 1.109 | 1.762 | 1.339 | 1.422 | 1.212 | |

| CACSE | 1.000 | 3.105 | 1.000 | 1.000 | 1.000 | 1.000 | 3.000 | 1.000 | 1.203 | 0.512 | 0.362 | 0.487 | 0.340 | 1.155 | |

| PR | 1.008 | 1.186 | 1.145 | 1.243 | 1.121 | 1.139 | 1.145 | 1.098 | 1.088 | 1.050 | 1.036 | 1.055 | 0.544 | 1.066 | |

| EME | 0.421 | 0.409 | 0.462 | 1.030 | 1.078 | 1.073 | 1.135 | 1.148 | 1.041 | 1.008 | 0.698 | 0.733 | 0.748 | 0.845 | Light Green Growth |

| Textile | 0.272 | 0.284 | 0.304 | 0.288 | 1.032 | 1.037 | 1.042 | 1.040 | 0.271 | 1.019 | 1.014 | 1.005 | 1.007 | 0.740 | |

| NFSR | 0.161 | 0.174 | 0.195 | 0.206 | 0.231 | 0.185 | 1.192 | 1.162 | 1.108 | 1.130 | 1.118 | 1.145 | 1.258 | 0.713 | |

| RSAT | 0.289 | 0.267 | 0.273 | 0.287 | 0.379 | 0.362 | 0.389 | 0.438 | 1.056 | 1.107 | 1.149 | 1.169 | 1.154 | 0.640 | |

| CF | 0.317 | 0.276 | 0.245 | 0.241 | 0.241 | 0.261 | 0.351 | 1.002 | 0.272 | 0.284 | 0.255 | 0.302 | 0.295 | 0.334 | Gray Growth |

| LFFF | 0.473 | 0.384 | 0.394 | 0.369 | 0.354 | 0.325 | 0.332 | 0.321 | 0.333 | 0.257 | 0.242 | 0.239 | 0.236 | 0.328 | |

| WWBRPG | 0.366 | 0.335 | 0.359 | 0.359 | 0.314 | 0.242 | 0.245 | 0.232 | 0.237 | 0.239 | 0.225 | 0.216 | 0.215 | 0.276 | |

| GE | 0.182 | 0.175 | 0.185 | 0.202 | 0.236 | 0.199 | 0.206 | 0.226 | 0.255 | 0.437 | 0.488 | 0.381 | 0.350 | 0.271 | |

| SE | 0.244 | 0.225 | 0.237 | 0.250 | 0.280 | 0.239 | 0.225 | 0.257 | 0.272 | 0.307 | 0.292 | 0.284 | 0.270 | 0.260 | |

| Pharmaccutical | 0.261 | 0.248 | 0.247 | 0.241 | 0.252 | 0.243 | 0.258 | 0.259 | 0.254 | 0.277 | 0.268 | 0.260 | 0.250 | 0.255 | |

| TC | 0.391 | 0.304 | 0.316 | 0.275 | 0.253 | 0.217 | 0.226 | 0.224 | 0.232 | 0.199 | 0.189 | 0.186 | 0.179 | 0.245 | |

| MP | 0.234 | 0.201 | 0.200 | 0.196 | 0.201 | 0.166 | 0.172 | 0.180 | 0.178 | 0.167 | 0.164 | 0.160 | 0.173 | 0.184 | |

| NFMSR | 0.184 | 0.167 | 0.165 | 0.184 | 0.175 | 0.154 | 0.234 | 0.179 | 0.144 | 0.169 | 0.189 | 0.204 | 0.240 | 0.184 | |

| CC | 0.166 | 0.178 | 0.178 | 0.173 | 0.211 | 0.179 | 0.205 | 0.197 | 0.175 | 0.179 | 0.179 | 0.179 | 0.190 | 0.184 | |

| AS | 0.238 | 0.218 | 0.229 | 0.230 | 0.213 | 0.158 | 0.167 | 0.159 | 0.133 | 0.134 | 0.120 | 0.115 | 0.116 | 0.172 | |

| Food | 0.236 | 0.204 | 0.198 | 0.182 | 0.169 | 0.148 | 0.144 | 0.140 | 0.140 | 0.137 | 0.125 | 0.125 | 0.119 | 0.159 | |

| WBR | 0.215 | 0.184 | 0.182 | 0.172 | 0.161 | 0.148 | 0.147 | 0.150 | 0.151 | 0.145 | 0.131 | 0.134 | 0.132 | 0.158 | |

| NMM | 0.093 | 0.095 | 0.104 | 0.114 | 0.136 | 0.126 | 0.128 | 0.139 | 0.130 | 0.132 | 0.130 | 0.125 | 0.126 | 0.121 | |

| PP | 0.158 | 0.139 | 0.127 | 0.119 | 0.113 | 0.102 | 0.106 | 0.104 | 0.104 | 0.107 | 0.105 | 0.114 | 0.116 | 0.117 | |

| PSN | 0.145 | 0.127 | 0.106 | 0.089 | 0.085 | 0.072 | 0.070 | 0.060 | 0.051 | 0.051 | 0.051 | 0.054 | 0.063 | 0.079 | |

| RP | 0.128 | 0.105 | 0.095 | 0.083 | 0.077 | 0.064 | 0.068 | 0.064 | 0.063 | 0.063 | 0.059 | 0.060 | 0.061 | 0.076 | |

| Average | 0.501 | 0.575 | 0.504 | 0.525 | 0.555 | 0.542 | 0.666 | 0.582 | 0.598 | 0.773 | 0.585 | 0.590 | 0.562 | 0.581 |

| Green Growth Efficiency | Growth State |

|---|---|

| ≥1 | Dark green growth |

| 0.581~1 | Light green growth |

| <0.581 | Gray growth |

| Number | Manufacturing Industry | GGE | TE | TP |

|---|---|---|---|---|

| 1 | AS | 0.0045 | −0.0119 | 0.0164 |

| 2 | FOOD | 0.0182 | −0.0048 | 0.0230 |

| 3 | WBR | 0.0226 | −0.0028 | 0.0254 |

| 4 | TP | 0.0176 | 0.0104 | 0.0072 |

| 5 | Textile | 0.0786 | 0.0049 | 0.0737 |

| 6 | TC | 0.0266 | −0.0075 | 0.0341 |

| 7 | LFFF | 0.0142 | −0.0086 | 0.0228 |

| 8 | WWBRPG | 0.0711 | 0.0020 | 0.0691 |

| 9 | FM | 0.1054 | 0.0087 | 0.0966 |

| 10 | PP | 0.0154 | −0.0003 | 0.0157 |

| 11 | PR | 0.1055 | 0.0051 | 0.1004 |

| 12 | CACSE | −0.0289 | −0.1156 | 0.0867 |

| 13 | PSN | 0.0002 | −0.0060 | 0.0062 |

| 14 | CC | 0.0114 | −0.0028 | 0.0142 |

| 15 | Pharmaceutical | 0.0410 | −0.0060 | 0.0470 |

| 16 | CF | 0.0729 | 0.0038 | 0.0691 |

| 17 | RP | 0.0052 | −0.0024 | 0.0076 |

| 18 | NMM | 0.0101 | −0.0003 | 0.0105 |

| 19 | FMSR | 0.0896 | 0.0087 | 0.0809 |

| 20 | NFMSR | 0.0199 | −0.0018 | 0.0217 |

| 21 | MP | 0.0247 | −0.0064 | 0.0311 |

| 22 | GE | 0.1044 | 0.0031 | 0.1013 |

| 23 | SE | 0.0983 | 0.0000 | 0.0984 |

| 24 | RSAT | 0.1091 | 0.0166 | 0.0925 |

| 25 | EME | 0.0935 | −0.0010 | 0.0945 |

| 26 | CCE | 0.0117 | −0.0258 | 0.0375 |

| 27 | Instrument | 0.0371 | 0.0063 | 0.0307 |

| Average | 0.04369 | −0.0049 | 0.0486 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, X.; Lu, X. Green Growth or Gray Growth: Measuring Green Growth Efficiency of the Manufacturing Industry in China. Systems 2022, 10, 255. https://doi.org/10.3390/systems10060255

Lv X, Lu X. Green Growth or Gray Growth: Measuring Green Growth Efficiency of the Manufacturing Industry in China. Systems. 2022; 10(6):255. https://doi.org/10.3390/systems10060255

Chicago/Turabian StyleLv, Xiaofei, and Xiaoli Lu. 2022. "Green Growth or Gray Growth: Measuring Green Growth Efficiency of the Manufacturing Industry in China" Systems 10, no. 6: 255. https://doi.org/10.3390/systems10060255

APA StyleLv, X., & Lu, X. (2022). Green Growth or Gray Growth: Measuring Green Growth Efficiency of the Manufacturing Industry in China. Systems, 10(6), 255. https://doi.org/10.3390/systems10060255