Feasibility Analysis of a Mobile Microgrid Design to Support DoD Energy Resilience Goals

Abstract

:1. Introduction

- Can mobile microgrids (one size fits all) effectively meet an average 10 kW critical load while reducing the reliance on diesel fuel for power generation?

- What are the trade-offs between a mobile microgrid and a single load-specific microgrid (e.g., resilience, time, over or under utilization, load shedding)?

1.1. Motivation and Need

1.2. Specific Contribution

2. Background and Related Research

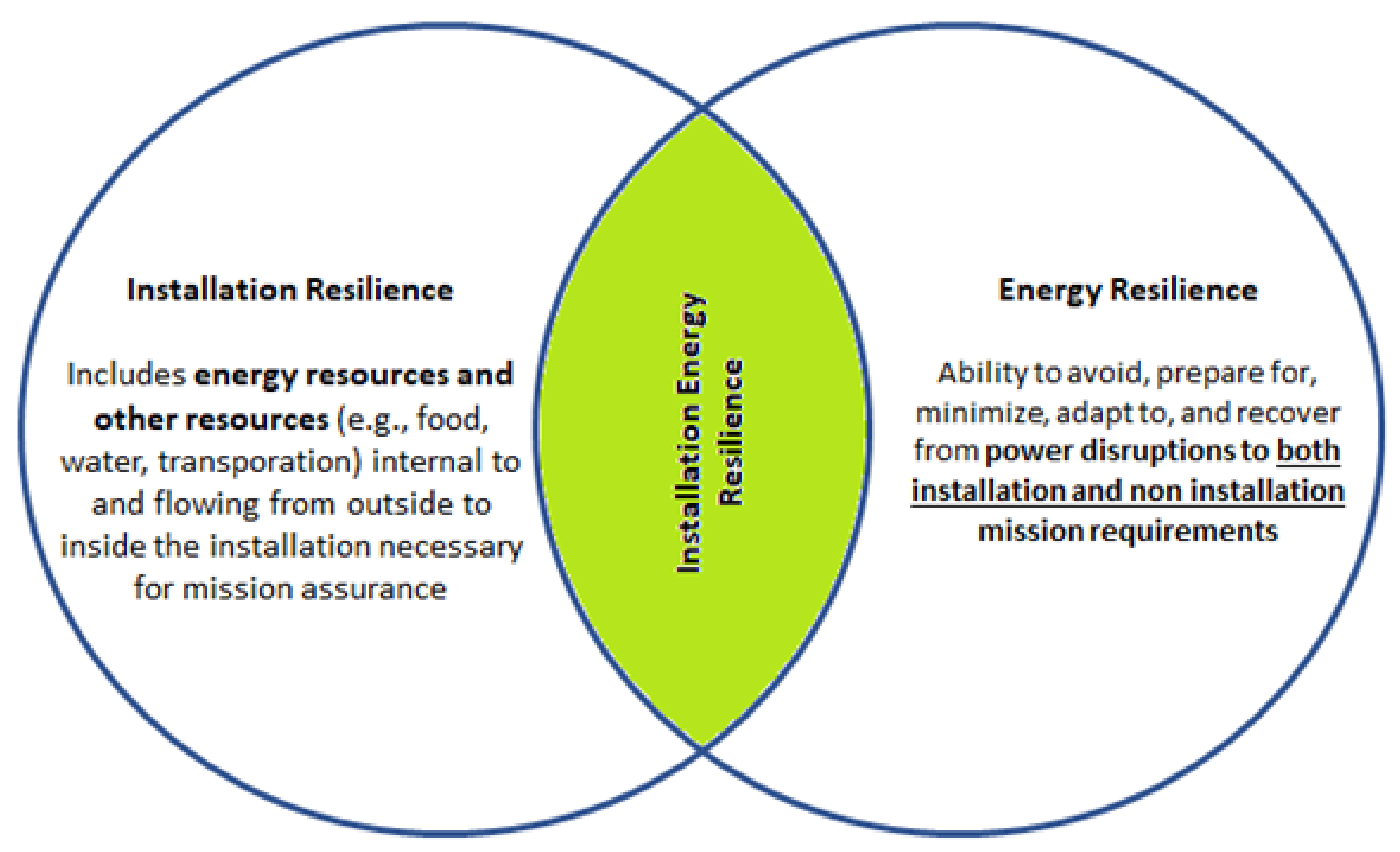

2.1. DoD Installation Energy Resilience

2.2. Why Does the DoD Care about Energy Resilience?

2.3. DoD Installation Microgrids

2.4. Single Load Microgrids

2.5. Mobile Microgrids

2.6. Related Research/Gap

3. Mission Sets

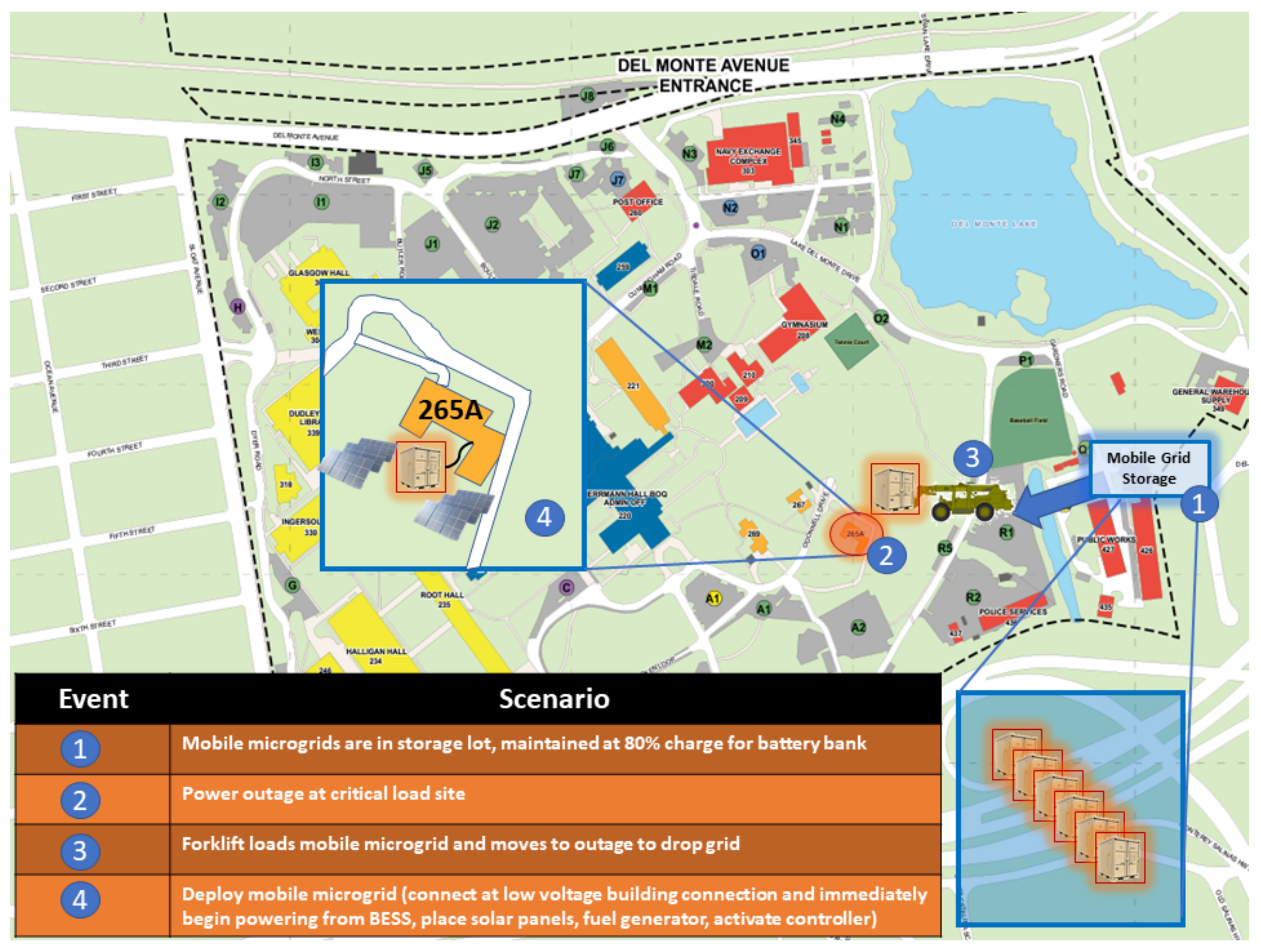

3.1. Backup Power for DoD Installation Critical Loads

3.2. Contingency Operations

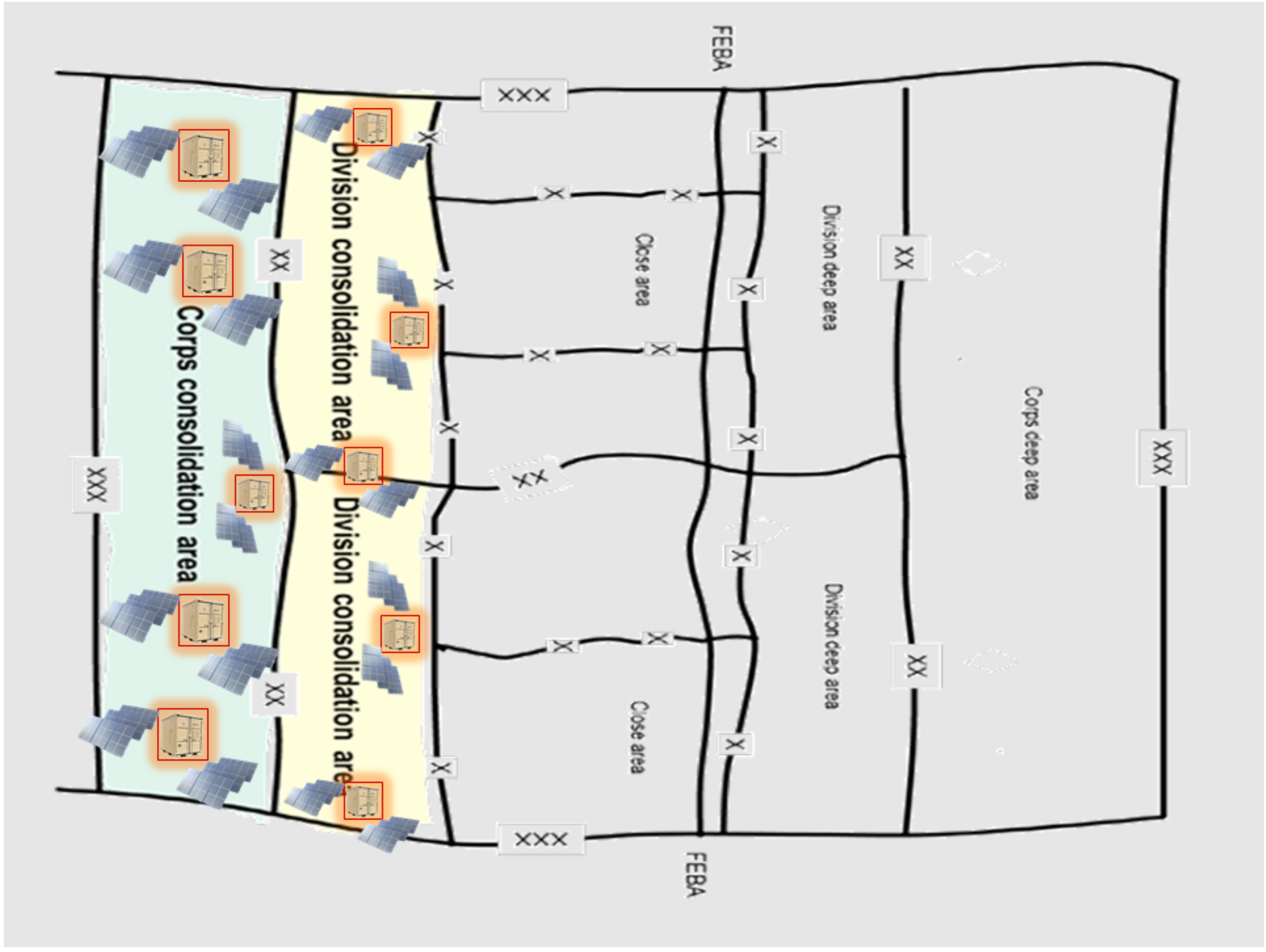

3.3. Large Scale Combat Operations

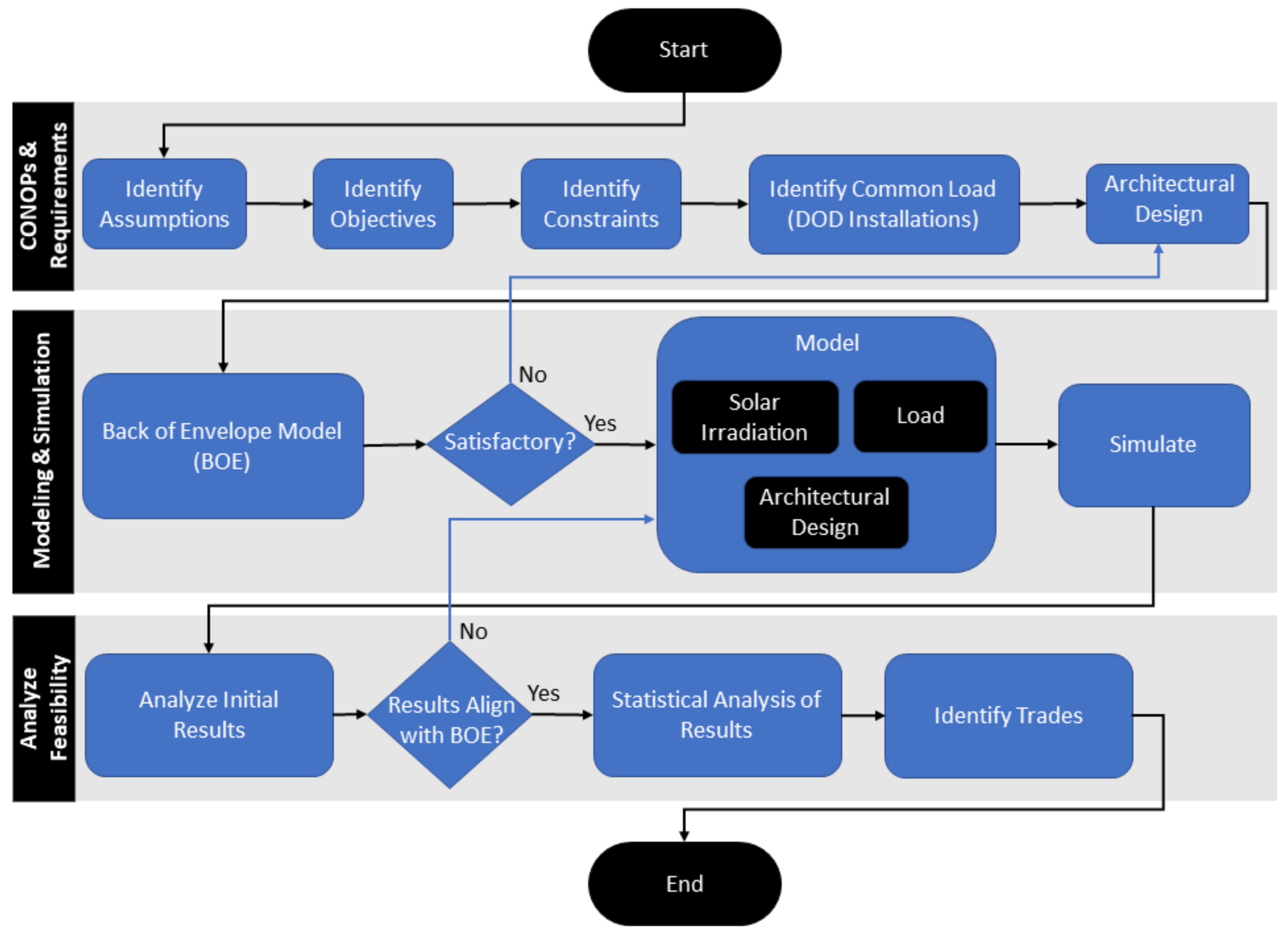

4. Methodology

4.1. CONOPS and Requirements

4.1.1. Framing Assumptions

- Power outages will likely be accompanied by a fuel-constrained environment such as a natural disaster that restricts fuel transportation due to road damage, damage to nearby supply stores and pipelines, or enemy-targeted SCNs.

- Risk/Reward Relationship: The risk of an outage of both the host domestic grid and installation microgrid does not warrant each individual critical load on the installation having a designated backup power redundancy such as a single load microgrid.

4.1.2. Indentifying Objectives

- Provide an “Off-the-Shelf” solution that allows installation energy managers to treat a mobile microgrid as an equipment purchase rather than going through the design and construction process associated with load-specific implementations for single load microgrids [1].

- Provide a highly mobile design that supports movement with common DoD installation assets (e.g., 10K forklift, flatbed trucks, and trailers).

- Support air transportation using common fixed wing military airlift assets (e.g., C-130 or C-17) and rotary wing airlift assets (e.g., CH-47 or CH-53) to support contingency operations, LSCO, and organic military asset long and short-range air transportation.

- Align with DoD common shipping infrastructure such as flatbed truck, railroad, cargo plane, and cargo ship movement.

- Provide a solution that offers the potential to support DoD installations, contingency operations, and secure rear-echelon power demands in LSCO.

- Restore power to critical loads within 30 min of being collocated with the load.

- Meet an average 10 kW load 12 h a day over 14 days of continuous operation.

- Reduce the need for fossil fuels and resources external to the DoD installation.

4.1.3. Identify Constraints

- The housing for the mobile microgrid in this feasibility study is an International Organization for Standardization (ISO) Triple Container (TriCon).

- -

- The ISO TriCon is a shipping container used heavily by DoD, and is easily transported by both ground and air assets common to DoD and commercial shipping infrastructure. This container constraint was chosen because many DoD forklift assets can move TriCon containers without requiring extensive balancing of the internal load because of the container dimension’s minimal overlap on fork width. This reduces risk in all envisioned operations, requiring only standard training of transportation asset operators.

- The mobile microgrid must be forklift transportable to allow for quicker reaction to emergent power requirements during an outage of the domestic host grid or microgrid.

- -

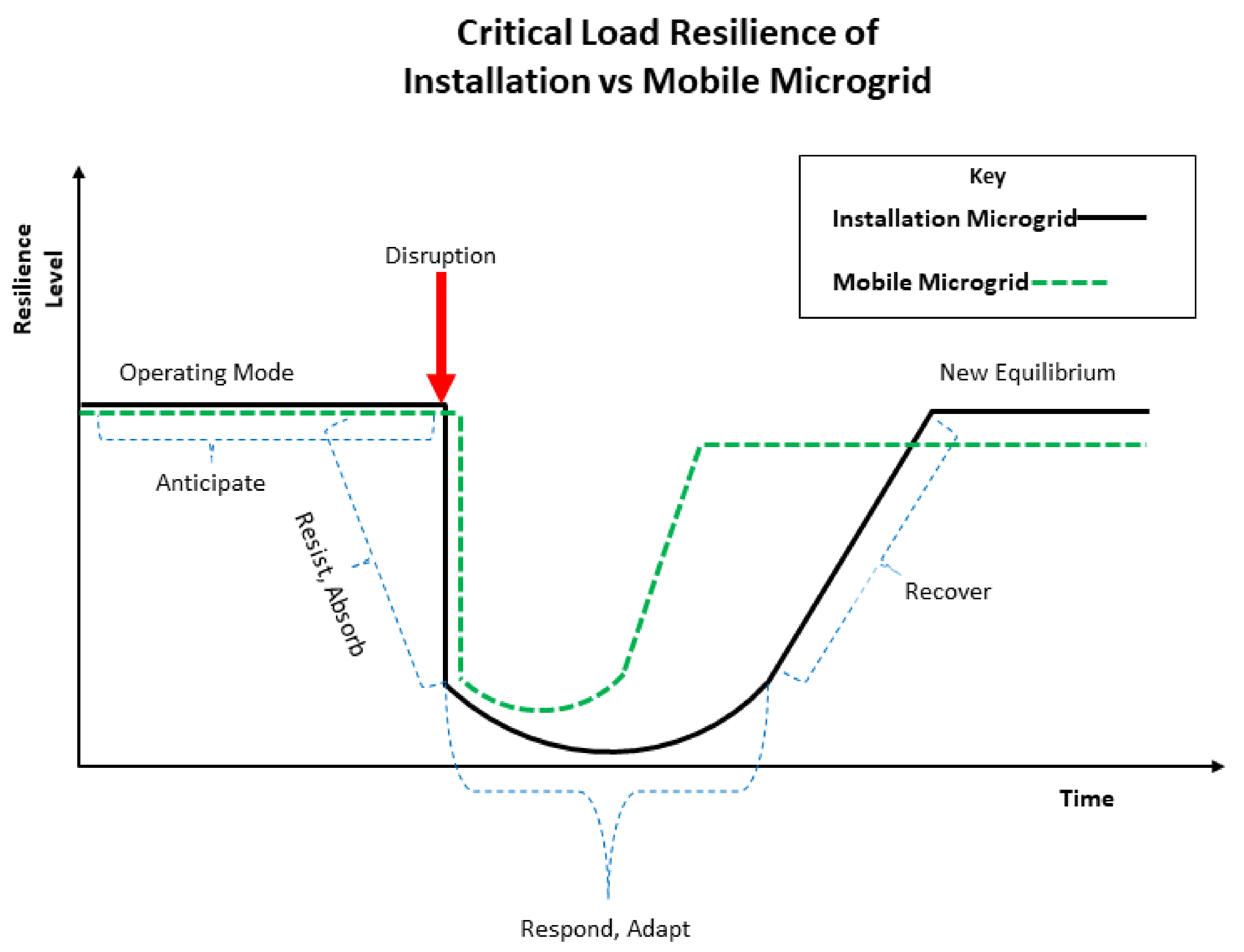

- The concept is to be able to use internal DoD installation assets to quickly relocate a mobile microgrid to the point of need without the use of special assets which may delay responding to the outage (focused on reducing the “Respond, Adapt” and “Recover” phases of the resilience curve in Figure 2). The forklift-compatible constraint primarily constrains the weight of the mobile microgrid, which for this research, is limited to less than 10,000 lbs (approximately 4535 kg) based on an assumption that DoD installations have Rough Terrain Military Forklifts or similar capabilities.

- The mobile microgrid must be air-transportable.

- -

- For this constraint, both DoD fixed wing and helicopter assets were analyzed. The previous weight restriction of 10,000 lbs (approximately 4535 kg) is more restrictive than the limitations of larger heavy lift rotary wing assets. The other constraint is hazmat considerations associated with the BESS for fixed wing airlift. Helicopter airlift is assumed to be external load only.

4.1.4. Identify Common Load Level (DoD Installations)

4.1.5. Architectural Design

4.2. Modeling and Simulation

4.2.1. Model

- EDG Usage: Calculated as a percent of time compared to running the load only from an EDG.

- Average Load per Day: The load is randomized using a normal distribution and standard deviation around a mean of the threshold average load.

- Load Shed: Calculated as the ratio of the amount of unserved load by the mobile microgrid to the total load demanded.

- Average Sun Hours: The average peak sun hours over the period of operation provides a more widely used and simplified metric to understand the level of conservatism of the model’s renewable power generation.

4.2.2. Simulate

4.3. Analyze Feasibility

4.3.1. Analyze Initial Results

4.3.2. Statistical Analysis of Results

4.3.3. Identify Trade-Offs

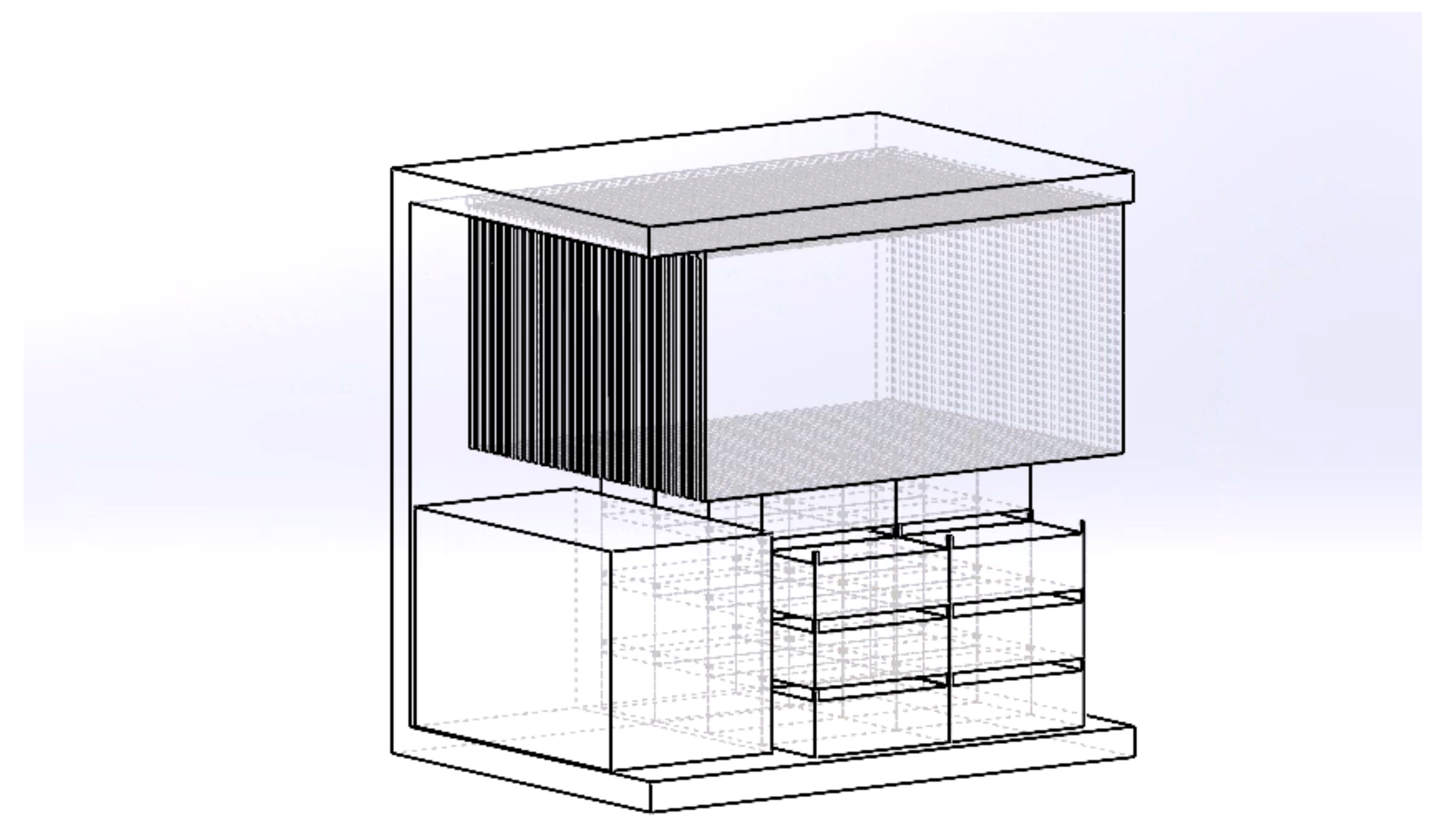

5. Preliminary Proposed Design

5.1. Sizing

5.2. Load Analysis

- Average threshold load = 10 kw

- Operating hours per day = 8 h

- Inverter/Charger efficiency = 0.85

- Peak Sun Hours in Worst Month = 3 h/day@1-sun

5.3. PV Sizing

- Rated panel current = 10.92 A

- Nominal panel voltage = 50.01 V

- Coulomb Efficiency = 0.9

- De-rating factor of the panel = 0.9

5.4. BESS Sizing

- Usable days of storage = 1.5 days

- Using Lithium Iron Phosphate (LiFePO4) Batteries with a maximum depth of discharge (MDOD) of 98%

- A temperature correction factor (TCF) at Celcius for LiFePO4 Battery, TCF = 0.90

- Nominal battery voltage = 48 V

- Single battery capacity = 100 Ah

5.5. Generator Sizing

- The system required a charge time of 20 h.

- The charger efficiency is 80%.

6. Mission Engineering Analysis

- The average threshold load is set using a normal distribution with mean of 10 kW and standard deviation of 2 kW.

- The number of PV panel strings in parallel is set using a uniform discreet distribution with minimum of 27 and maximum of 30 panels. This assumes that there may be up to three panels (10% of the proposed PV array) not working in our system at any one time from occurrences such as damage due to transportation, mishandling, or poor connections.

- The Coulomb efficiency for PV panels uses a triangular distribution with a minimum of 0.80, a likeliest of 0.9 and maximum of 0.93. This provided more conservative results from the model’s solar power generation than using a fixed Coulomb efficiency of 0.90 which some simplified solar models recommend [79].

- The panel De-rating Factor, essentially a parameter of panel efficiency, is a triangular distribution with a minimum of 0.85, likeliest of 0.9, and maximum of 0.93. This also provides more conservative results from the model’s solar power generation than using a fixed De-rating Factor of 0.90 which some basic solar models recommend [79].

- The generator set uses a triangular distribution with max at 10 kW and likeliest at 9 kW and minimum at 8.5 kW for short duration run times to correlate to the model timestep of 30 min. This accounts for the generator running at outputs that align with its continuous output power specifications. This ensures the mobile microgrid can support more stressing scenarios where solar irradiance is lower or when work hours are extended outside of normal business hours during contingency and emergency operations.

- Panel rated current uses a uniform distribution from 10 A to 10.88 A to account for variations in panel reliability from panel to panel and other factors such as dust.

6.1. Feasibility Use Case NSA Monterey

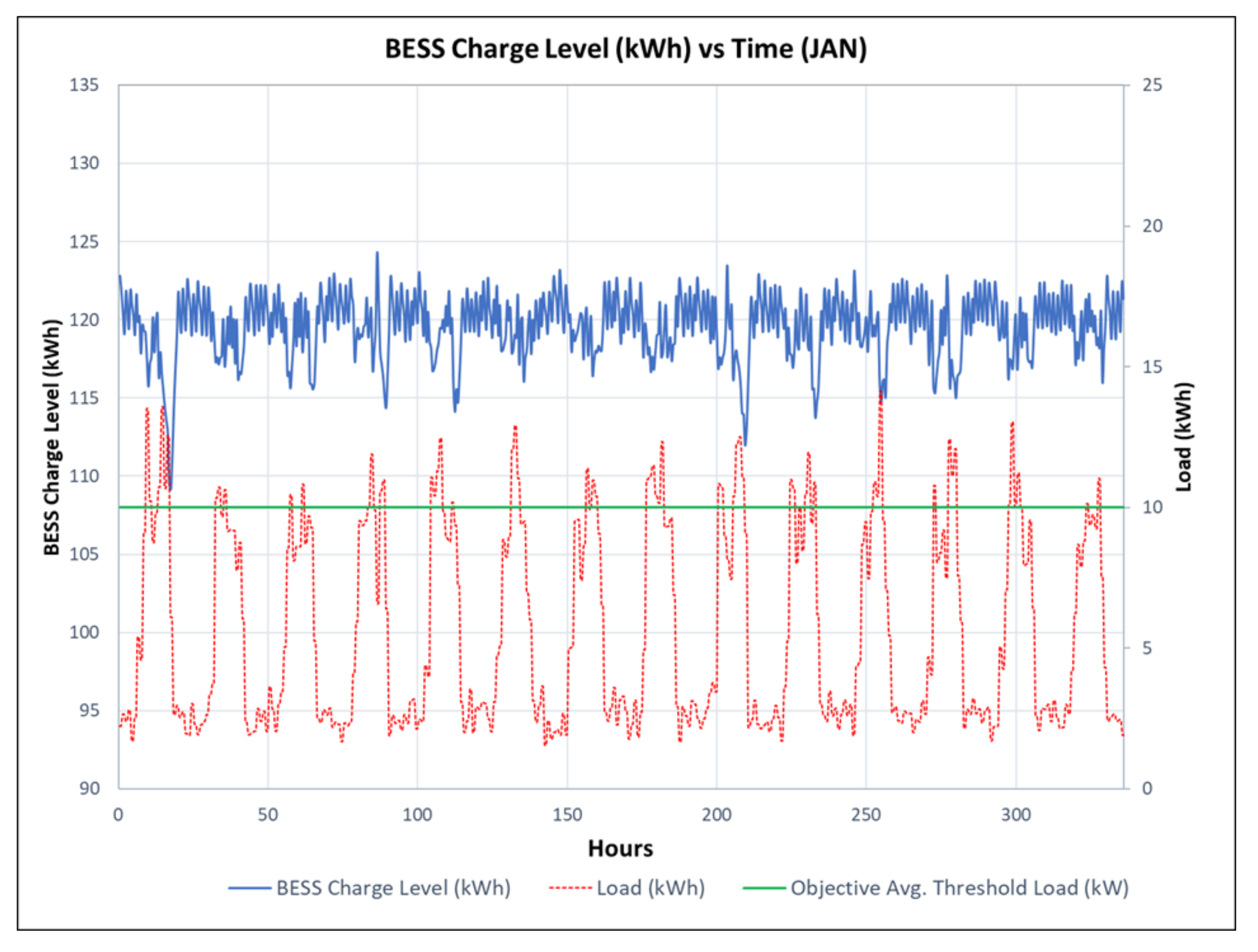

6.1.1. January Analysis

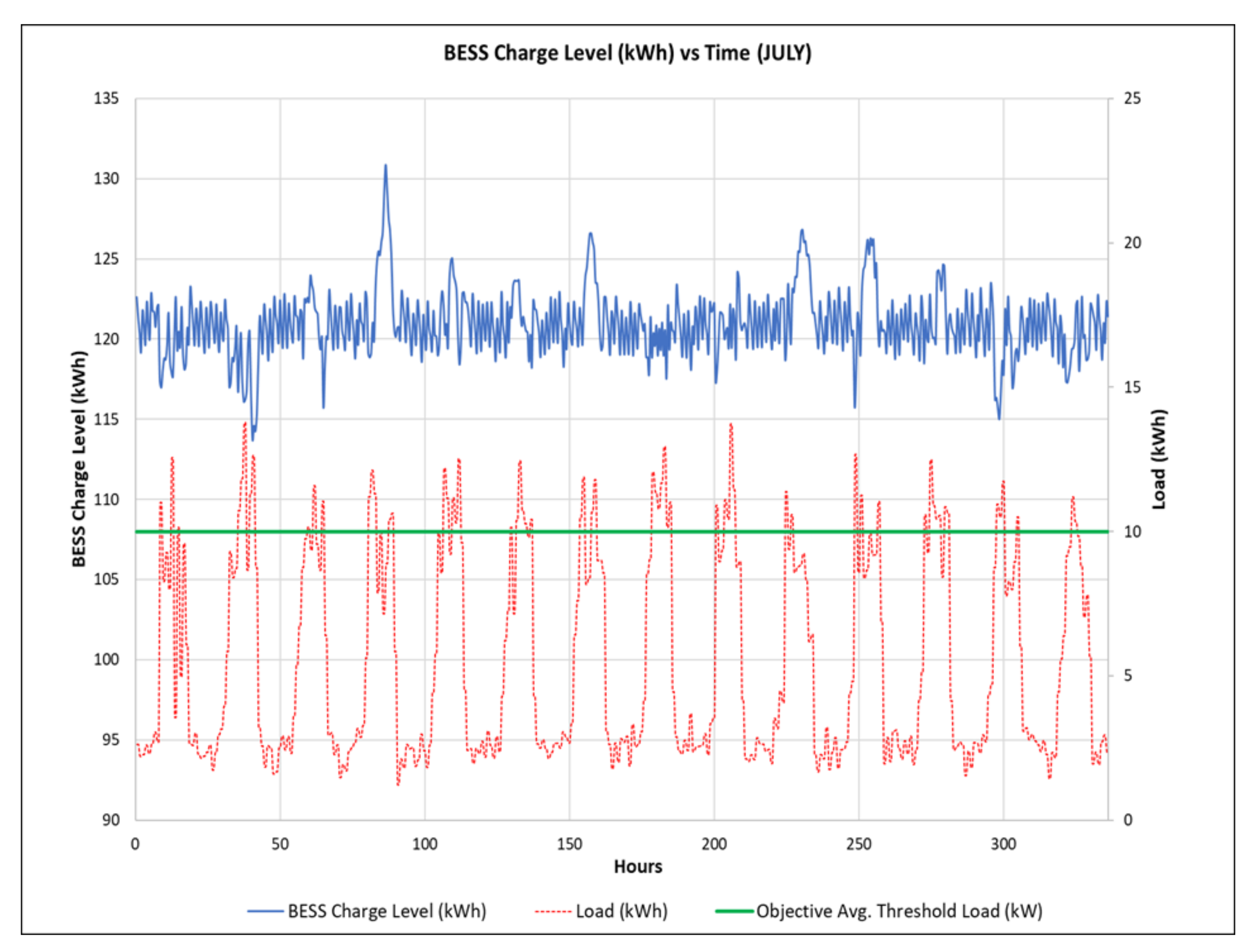

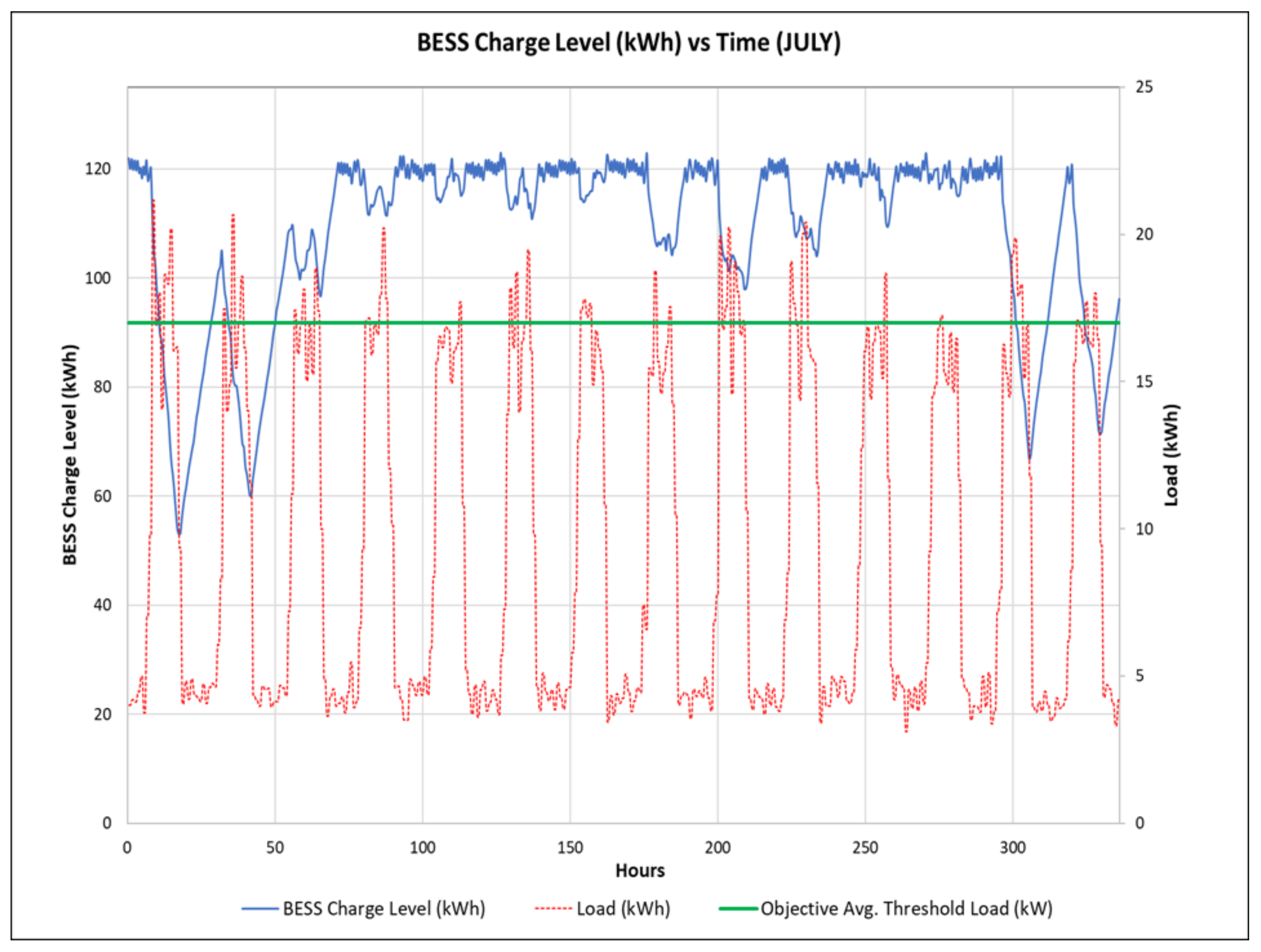

6.1.2. July Analysis

6.2. Stressing Scenarios

6.2.1. Stressing Scenario Using January GHI Data

6.2.2. Stressing Scenario Using July GHI Data

7. Discussion and Future Work

7.1. Design Objectives

7.2. Load Size

7.3. Trade-Offs between a Mobile Microgrid and a Static Customized Single Load Microgrid

7.4. Future Work

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Piluso, A.; Defense Energy Manager, Sicily, Italy. Personal communication, March 2022.

- Gillis, W. Memorandum of Understanding Between U.S. Department of Defense, Office of the Assistant Secretary of Defense for Susainment and U.S. Department of Energy, Office of the Assistant Secretary for the Office of Electricity; Official Memorandum, Department of Defense: Washington, DC, USA, 2020; Available online: https://www.acq.osd.mil/eie/Downloads/IE/DoD%20DOE%20MOU%20for%20Energy%20Resilience.pdf (accessed on 5 January 2022).

- NAVFAC P-601 Microgrid Design Guide; Naval Facilities Engineering Command: Washington, DC, USA, 2016.

- Anderson, K.H.; Di Orio, N.A.; Cutler, D.S.; Butt, R.S. Increasing resiliency through renewable energy microgrids. Int. J. Energy Sect. Manag. 2017, 2, 1–17. [Google Scholar]

- Sagunsky, D.L. Risk on the Horizon, Rig for Dark: Solutions to Mitigate DoD’s Reliance on the Fragile Electric Grid. Master’s Thesis, Joint Forces Staff College National Defense University, Norfolk, VA, USA, 2013. Available online: https://apps.dtic.mil/sti/pdfs/ADA581121.pdf (accessed on 5 January 2022).

- Anuat, E.; Van Bossuyt, D.L.; Pollman, A. Energy Resilience Impact of Supply Chain Network Disruption to Military Microgrids. Infrastructures 2021, 7, 4. [Google Scholar] [CrossRef]

- Kain, A.; Van Bossuyt, D.L.; Pollman, A. Investigation of Nanogrids for Improved Navy Installation Energy Resilience. Appl. Sci. 2021, 11, 4298. [Google Scholar] [CrossRef]

- Mallery, J.; Van Bossuyt, D.L.; Pollman, A. Defense Installation Energy Resilience for Changing Operational Requirements. Designs 2022, 6, 28. [Google Scholar] [CrossRef]

- Neimeyer, L. Installation Energy Plans: Energy Resilience and Cybersecurity Update and Expansion of the Requirements to All DoD Installations; Official Memorandum, Department of Defense: Washington, DC, USA, 2018; Available online: https://www.acq.osd.mil/eie/Downloads/IE/IEP%20Policy_May302018.pdf (accessed on 5 January 2022).

- Yodo, N.; Wang, P. Engineering resilience quantification and system design implications: A literature survey. J. Mech. Des. 2016, 138, 111408. [Google Scholar] [CrossRef] [Green Version]

- Hosseini, S.; Barker, K.; Ramirez-Marquez, J.E. A review of definitions and measures of system resilience. Reliab. Eng. Syst. Saf. 2016, 145, 47–61. [Google Scholar] [CrossRef]

- Hamilton, M.C.; Lambert, J.H.; Connelly, E.B.; Barker, K. Resilience analytics with disruption of preferences and lifecycle cost analysis for energy microgrids. Reliab. Eng. Syst. Saf. 2016, 150, 11–21. [Google Scholar] [CrossRef]

- Roege, P.E.; Collier, Z.A.; Mancillas, J.; McDonagh, J.A.; Linkov, I. Metrics for energy resilience. Energy Policy 2014, 72, 249–256. [Google Scholar] [CrossRef]

- Armed Forces: 10 U.S.C. § 101(e)(6); Public Law U.S. Code; Government Printing Office: Washington, DC, USA, 3 January 2012.

- Armed Forces: 10 U.S.C. § 101(e)(7); Public Law U.S. Code; Government Printing Office: Washington, DC, USA, 3 January 2012.

- Armed Forces: 10 U.S.C. § 2911; Public Law U.S. Code; Government Printing Office: Washington, DC, USA, 3 January 2012.

- Reintjes, C.M. Energy Resiliency—How DoD Can Become Energy Resilient and Still Meet Its Renewable Energy Goals. Master’s Thesis, LLM Vermot Law School, South Royalton, VT, USA, 2019. Available online: https://apps.dtic.mil/sti/pdfs/AD1080509.pdf (accessed on 5 January 2022).

- Mishra, S.; Anderson, K.; Miller, B.; Boyer, K.; Warren, A. Microgrid resilience: A holistic approach for assessing threats, identifying vulnerabilities, and designing corresponding mitigation strategies. Appl. Energy 2020, 264, 114726. [Google Scholar] [CrossRef] [Green Version]

- Robyn, D.; Marqusee, J. Clean Power From the Pentagon. Issues Sci. Technol. 2019, 35, 63–68. [Google Scholar]

- Slattery, M. Energy Security in the United States Department of Defense: How and Why the U.S. Army and Navy Are Reducing Their Reliance on Fossil Fuels and the Electrical Grid, and What It Could Mean for the Rest of Us. Master’s Thesis, Vassar College, Poughkeepsie, NY, USA, 2015. [Google Scholar]

- Ton, D.T.; Smith, M.A. The US department of energy’s microgrid initiative. Electr. J. 2012, 25, 84–94. [Google Scholar] [CrossRef]

- Giachetti, R.E.; Peterson, C.J.; Van Bossuyt, D.L.; Parker, G.W. Systems engineering issues in microgrids for military installations. In Proceedings of the INCOSE International Symposium, Virtual Event, 20–22 July 2020; Volume 30, pp. 731–746. [Google Scholar]

- Hirsch, A.; Parag, Y.; Guerrero, J. Microgrids: A review of technologies, key drivers, and outstanding issues. Renew. Sustain. Energy Rev. 2018, 90, 402–411. [Google Scholar] [CrossRef]

- Hernandez-Aramburo, C.A.; Green, T.C.; Mugniot, N. Fuel consumption minimization of a microgrid. IEEE Trans. Ind. Appl. 2005, 41, 673–681. [Google Scholar] [CrossRef] [Green Version]

- Lasseter, R.H.; Paigi, P. Microgrid: A conceptual solution. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference (IEEE Cat. No. 04CH37551), Aachen, Germany, 20–25 June 2004; Volume 6, pp. 4285–4290. [Google Scholar]

- Judson, N.; Pina, A.L.; Dydek, E.; Van Broekhoven, S.B.; Castillo, A. Application of a Resilience Framework to Military Installations: A Methodology for Energy Resilience Business Case Decisions; Technical Report; MIT Lincoln Laboratory: Lexington, MA, USA, 2016. [Google Scholar]

- Dileep, G. A survey on smart grid technologies and applications. Renew. Energy 2020, 146, 2589–2625. [Google Scholar] [CrossRef]

- Teymouri, F.; Amraee, T.; Saberi, H.; Capitanescu, F. Toward controlled islanding for enhancing power grid resilience considering frequency stability constraints. IEEE Trans. Smart Grid 2017, 10, 1735–1746. [Google Scholar] [CrossRef]

- Peterson, C.J.; Van Bossuyt, D.L.; Giachetti, R.E.; Oriti, G. Analyzing mission impact of military installations microgrid for resilience. Systems 2021, 9, 69. [Google Scholar] [CrossRef]

- McCarthy, R. Army Directive 2020-03 (Installation Energy and Water Resilience Policy); Official Memorandum, Department of Defense: Washington, DC, USA, 2020; Available online: https://www.asaie.army.mil/Public/ES/doc/ARN21644_AD2020-03_Web_Final.pdf (accessed on 6 January 2022).

- Coglianese, V. Installation neXt Hawaii Resilience Symposium Report; Technical Report; Marine Corps Installations Command, Marine Corps Base Hawaii: Oahu, HI, USA, 2019. [Google Scholar]

- Department of Defense, Washington, DC, USA. Unified Facilities Criteria: Engine-Driven Generator Systems for Prime and Standby Power Applications, Change 2, 5 November 2019. Available online: https://www.wbdg.org/ffc/dod/unified-facilities-criteria-ufc/ufc-3-540-01 (accessed on 10 February 2022).

- Nordman, B.; Christensen, K.; Meier, A. Think globally, distribute power locally: The promise of nanogrids. Computer 2012, 45, 89–91. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.R.; Brown, E.D. DC nanogrids: A low cost PV based solution for livelihood enhancement for rural Bangladesh. In Proceedings of the 2014 3rd International Conference on the Developments in Renewable Energy Technology (ICDRET), Dhaka, Bangladesh, 29–31 May 2014; pp. 1–5. [Google Scholar]

- Ghasemi-Nejhad, M.N.; Menendez, M.; Minei, B.; Wong, K.; Gabrick, C.; Thornton, M.; Ghorbani, R. Smart nanogrid systems for disaster mitigation employing deployable renewable energy harvesting devices. In Proceedings of the Active and Passive Smart Structures and Integrated Systems 2016, Las Vegas, NV, USA, 21–24 March 2016; Volume 9799, pp. 756–765. [Google Scholar]

- Pollman, A.; Gannon, A. Multi–physics energy approach and demonstration facility. In Proceedings of the ASME 2015 9th International Conference on Energy Sustainability, San Diego, CA, USA, 28 June–2 July 2015. [Google Scholar] [CrossRef]

- Bouchekara, H.R.A.H.; Shahriar, M.S.; Javaid, M.S.; Sha’aban, Y.A.; Ramli, M.A.M. Multi-Objective Optimization of a Hybrid Nanogrid/Microgrid: Application to Desert Camps in Hafr Al-Batin. Energies 2021, 14, 1245. [Google Scholar] [CrossRef]

- Zhou, Q.; Shahidehpour, M.; Li, Z.; Che, L.; Alabdulwahab, A.; Abusorrah, A. Compartmentalization strategy for the optimal economic operation of a hybrid ac/dc microgrid. IEEE Trans. Power Syst. 2019, 35, 1294–1304. [Google Scholar] [CrossRef]

- Sandgani, M.R.; Sirouspour, S. Energy management in a network of grid-connected microgrids/nanogrids using compromise programming. IEEE Trans. Smart Grid 2016, 9, 2180–2191. [Google Scholar]

- Berardi, U.; Tomassoni, E.; Khaled, K. A Smart Hybrid Energy System Grid for Energy Efficiency in Remote Areas for the Army. Energies 2020, 13, 2279. [Google Scholar] [CrossRef]

- Firefly Hybrid Power. Firefly PowerPlus Hybrid Power Generator. Available online: https://www.fireflyhybridpower.com/products/powerplus (accessed on 23 May 2022).

- Hakaienergysolutions. Container Box Systems. Available online: https://hakaienergysolutions.com/commercial-solar/container-systems/ (accessed on 23 May 2022).

- Boxpower. BoxPower SolarContainer. Available online: https://boxpower.io/products/solar-container/ (accessed on 23 May 2022).

- Boxpower. BoxPower MiniBox. Available online: https://boxpower.io/products/mini-box-solar-power-system/ (accessed on 23 May 2022).

- Škanata, D. Improving Cyber Security with Resilience. Ann. Disaster Risk Sci. ADRS 2020, 3. [Google Scholar] [CrossRef]

- Francis, R.; Bekera, B. A metric and frameworks for resilience analysis of engineered and infrastructure systems. Reliab. Eng. Syst. Saf. 2014, 121, 90–103. [Google Scholar] [CrossRef]

- Abimbola, M.; Khan, F. Resilience modeling of engineering systems using dynamic object-oriented Bayesian network approach. Comput. Ind. Eng. 2019, 130, 108–118. [Google Scholar] [CrossRef]

- Headquarters, Department of the Army. FM 3-0 Operations; Department of the Army: Washington, DC, USA, 2017. Available online: https://armypubs.army.mil/epubs/DR_pubs/DR_a/pdf/web/ARN6687_FM%203-0%20C1%20Inc%20FINAL%20WEB.pdf (accessed on 10 April 2022).

- Global Horizontal Solar Irradiance Map National Solar Radiation Database Physical Solar Model. Available online: https://www.nrel.gov/gis/assets/images/solar-annual-ghi-2018-usa-scale-01.jpg (accessed on 25 March 2022).

- Global Horizontal Solar Irradiance in January National Solar Radiation Database Physical Solar Model. Available online: https://www.nrel.gov/gis/assets/images/solar-january-ghi-2018-usa-scale-01.jpg (accessed on 25 March 2022).

- Global Horizontal Solar Irradiance in July National Solar Radiation Database Physical Solar Model. Available online: https://www.nrel.gov/gis/assets/images/solar-july-ghi-2018-usa-scale-01.jpg (accessed on 25 March 2022).

- Fish, R. Design and Modeling of Hybrid Microgrids in Arctic Environments. Master’s Thesis, Department of Electrical Engineering, NPS, Monterey, CA, USA, 2020. [Google Scholar]

- Anglani, N.; Oriti, G.; Fish, R.; Van Bossuyt, D.L. Design and Optimization Strategy to Size Resilient Stand-Alone Hybrid Microgrids in Various Climatic Conditions. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Virtual, 10–14 October 2021; pp. 210–217. [Google Scholar]

- Canadiansolar. HiKu Super High Power PERC Module. Available online: https://www.canadiansolar.com/wp-content/uploads/2019/12/Canadian_Solar-Datasheet-HiKu_CS3W-MS_EN.pdf (accessed on 4 April 2022).

- JAsolar. JAM72S20 445-470/MR Series Modules. Available online: https://www.jasolar.com/uploadfile/2021/0602/20210602105327260.pdf (accessed on 4 April 2022).

- Renvu. LONGi Solar 450W 144 Half-Cell Mono PERC Tier 1 Solar Panel. Available online: https://www.renvu.com/LONGi-Solar-450W-144-Half-Cell-Mono-PERC-Tier-1-Solar-Panel (accessed on 4 April 2022).

- Sunwatts. 450 watt Phono Solar Mono XL M4 Solar Panel. Available online: https://sunwatts.com/450-watt-phono-solar-mono-xl-m4-solar-panel/ (accessed on 4 April 2022).

- Trinasolar. TALLMAX M DE17M(II) Half-cut, MBB, 430-450W Modules. Available online: https://www.trinasolar.com/en-glb/product/Tianjing72-de17mII (accessed on 4 April 2022).

- Ecodirect. Canadian Solar CS6X-320P, 320 Watt Solar Panel. Available online: https://www.ecodirect.com/Canadian-Solar-CS6X-320P-320W-36-8-V-PV-Panel-p/canadian-solar-cs6x-320ppallet.htm (accessed on 4 April 2022).

- JAsolar. 320 W PERC Smart Module. Available online: https://www.jasolar.com/uploadfile/2018/1215/20181215014401325.pdf (accessed on 4 April 2022).

- Renogy. 320 Watt Monocrystalline Solar Panel. Available online: https://www.renogy.com/320-watt-monocrystalline-solar-panel/ (accessed on 4 April 2022).

- Renvu. SOLARIA PowerXT 320 W High Power ALL BLACK 60 Cell Mono PERC. Available online: https://www.renvu.com/SOLARIA-PowerXT-320R-BX-320W (accessed on 4 April 2022).

- Battlebornbatteries. 100 Ah 12V LiFePO4 Deep Cycle Battery. Available online: https://battlebornbatteries.com/product/12v-lifepo4-deep-cycle-battery/ (accessed on 4 April 2022).

- Renogy. 12V 100Ah Smart Lithium Iron Phosphate Battery. Available online: https://www.renogy.com/12v-100ah-smart-lithium-iron-phosphate-battery/ (accessed on 4 April 2022).

- Dakotalithium. Dakota Lithium 12V 100AH Deep Cycle LIFEPO4 Battery. Available online: https://dakotalithium.com/product/dakota-lithium-12v-100ah-deep-cyle-lifepo4-marine-solar-battery/ (accessed on 4 April 2022).

- Richsolar. 12V 100Ah LiFePO4 Lithium Iron Phosphate Battery. Available online: https://richsolar.com/products/12v-100ah-lifepo4-lithium-iron-phosphate-battery (accessed on 4 April 2022).

- Renogy. Deep Cycle AGM Battery 12 Volt 100Ah. Available online: https://www.renogy.com/deep-cycle-agm-battery-12-volt-100ah/ (accessed on 4 April 2022).

- Eco-worthy. 100Ah 12V AGM Deep Cycle Battery. Available online: https://www.eco-worthy.com/products/100ah-12v-agm-deep-cycle-battery (accessed on 4 April 2022).

- Amazon. WindyNation 100 amp-Hour 100AH 12V 12 Volt AGM Deep Cycle Sealed Lead Acid Battery. Available online: https://www.amazon.com/WindyNation-amp-Hour-100AH-Sealed-Battery/dp/B07BS1ZB15?th=1 (accessed on 4 April 2022).

- Amazon. ExpertPower 12V 100Ah Deep Cycle Sealed Lead Acid Battery for Solar Wind Power (AGM). Available online: https://www.amazon.com/ExpertPower-100Ah-Solar-Sealed-Battery/dp/B01GSZMEU4?th=1 (accessed on 4 April 2022).

- Lithiumbatterypower. 48 V 100 Ah Lithium Battery. Available online: https://www.lithiumbatterypower.com/products/48v-100ah-lithium-ion-battery-steel-case (accessed on 4 April 2022).

- Relionlbattery. RB48V100 48 V 100 Ah LiFePO4 Battery. Available online: https://relionbattery.com/products/lithium/rb48v100 (accessed on 4 April 2022).

- Royalbattery. Constant Power Lithium 48 V-100 AH LiFePO4 Deep Cycle Solar RE. Available online: https://www.royalbattery.com/lbscpl48v-100 (accessed on 4 April 2022).

- Cummings. Rugged Mobile Power. Available online: https://www.cummins.com/generators/rugged-mobile-power (accessed on 4 April 2022).

- Marine Corps Systems Command. AMMPS 10 kW Generator Set. Available online: https://www.marcorsyscom.marines.mil/Portals/105/PfM/LCES/ES/Power%20Team/Mobile%20Power/Info%20Sheets/GENERATORSET10KW60HZAMMPSSKIDMOUNTED.pdf?ver=2018-11-13-150411-360 (accessed on 4 April 2022).

- Li, W.; Mou, X.; Zhou, Y.; Marnay, C. On voltage standards for DC home microgrids energized by distributed sources. In Proceedings of the 7th International Power Electronics and Motion Control Conference, Harbin, China, 2–5 June 2012; Volume 3, pp. 2282–2286. [Google Scholar]

- Rodriguez-Diaz, E.; Chen, F.; Vasquez, J.C.; Guerrero, J.M.; Burgos, R.; Boroyevich, D. Voltage-level selection of future two-level LVdc distribution grids: A compromise between grid compatibiliy, safety, and efficiency. IEEE Electrif. Mag. 2016, 4, 20–28. [Google Scholar] [CrossRef] [Green Version]

- Kumar, D.; Zare, F.; Ghosh, A. DC microgrid technology: System architectures, AC grid interfaces, grounding schemes, power quality, communication networks, applications, and standardizations aspects. IEEE Access 2017, 5, 12230–12256. [Google Scholar] [CrossRef]

- Masters, G.M. Renewable and Efficient Electric Power Systems; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Liu, M. Optimal Number of Trials for Monte Carlo Simulation; VRC–Valuation Research Report; VRC: Boston, MA, USA, 2017. [Google Scholar]

- National Solar Radition Data Base Data Viewer. Available online: https://maps.nrel.gov/nsrdb-viewer/?aL=IAvYSN%255Bv%255D%3Dt%26mcQtmw%255Bv%255D%3Dt%26mcQtmw%255Bd%255D%3D1&bL=clight&cE=0&lR=0&mC=4.740675384778373%2C22.8515625&zL=2 (accessed on 21 February 2022).

- Rahimi, T.; Ding, L.; Kheshti, M.; Faraji, R.; Guerrero, J.M.; Tinajero, G.D.A. Inertia response coordination strategy of wind generators and hybrid energy storage and operation cost-based multi-objective optimizing of frequency control parameters. IEEE Access 2021, 9, 74684–74702. [Google Scholar] [CrossRef]

| PV Panel Specifications (STC) | Sources | |||||||

|---|---|---|---|---|---|---|---|---|

| PV Panel Type by Advertised Size | Open Circuit Voltage (Vmp) [V] | Maximum Power Current (Imp) [A] | Rated Maximum Power (Pmax) [W] | Length (Inches) | Width (Inches) | Depth (Inches) | Weight (lbs) | |

| 450 W | 49.32 | 10.89 | 450 | 82.90 | 41.11 | 1.43 | 53.95 | [54,55,56,57,58] |

| 320 W | 42.07 | 9.20 | 320 | 67.82 | 39.68 | 1.48 | 43.08 | [59,60,61,62] |

| Battery Specifications | ||||||||

| Battery Type | Chemistry | Voltage | Storage Capacity [Ah] | Length (Inches) | Width (Inches) | Height (Inches) | Weight (lbs) | |

| LiFePO4 | LiFePO4 | 12 | 100 | 12.49 | 6.76 | 8.38 | 27.68 | [63,64,65,66] |

| Lead Acid | Lead Acid AGM Deep Cycle | 12 | 100 | 12.75 | 6.74 | 8.51 | 62.9 | [67,68,69,70] |

| LiFePO4 | LiFePO4 | 48 | 100 | 26.68 | 14.98 | 9.25 | 135.57 | [71,72,73] |

| Generator: DoD Advanced Medium Mobile Power Sources (AMMPS) | ||||||||

| Power Rating (kW) | Fuel Consumption: 100% Rated Load 60 Hz (400 Hz) [GPH] | Length (Inches) | Width (Inches) | Height (Inches) | Weight (Wet) [lbs] | |||

| 10 | 0.75 | 55 | 32 | 36 | 1060 | [74,75] | ||

| 15 | 1.06 | 65 | 36 | 53 | 1560 | [74] | ||

| Final Design COTS Component Specifications | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| PV Panel Specifications (STC) | Sources | ||||||||

| PV Panel Type by Advertised Size | Quantity | Open Circuit Voltage (Vmp) [V] | Maximum Power Current (Imp) [A] | Rated Maximum Power (Pmax) [W] | Length (Inches) | Width (Inches) | Depth (Inches) | Weight (lbs) | |

| 450 W | 30 | 49.32 | 10.89 | 450 | 82.90 | 41.11 | 1.43 | 53.95 | [54,55,56,57,58] |

| Battery Specifications | |||||||||

| Battery Type | Quantity | Chemistry | Voltage | Storage Capacity (Ah) | Length (Inches) | Width (Inches) | Height (Inches) | Weight (lbs) | |

| LiFePO4 | 30 | LiFePO4 | 48 | 100 | 26.68 | 14.98 | 9.25 | 135.57 | [71,72,73] |

| Generator: DoD Advanced Medium Mobile Power Sources (AMMPS) | |||||||||

| Power Rating (kW) | Quantity | Fuel Consumption: 100% Rated Load 60 Hz (400 Hz) [GPH] | Length (Inches) | Width (Inches) | Height (Inches) | Weight (Wet) [lbs] | |||

| 10 | 1 | 0.75 | 55 | 32 | 36 | 1060 | [74,75] | ||

| Summary of Results from Mission Engineering Analysis | ||||||||

|---|---|---|---|---|---|---|---|---|

| Use Case | Period of Analysis (Days) | Average Peak Solar/Day (hrs@1-sun/Day) | Average Load Input (kW) [Mean, Std] | Mean Load/Day (kWh/Day as 95% CI) | Mean Generator Usage (has 95% CI) [14 Days = 336 h] | Mean Generator Usage (% of Period of Analysis as 95% CI) | Load Shed (kWh) [Mean, Std] | Load Shed (% of Total Load Demand) [mean, std] |

| January at NSA Monterey | 14 | 2.83 | 10, 2 | 135.29 ± 0.53 | 207.03 ± 1.02 | 62 ± 0.29 | 0.49, 11.96 | 0.0, 0.4 |

| July at NSA Monterey | 14 | 7.01 | 10, 2 | 135.23 ± 0.54 | 136.65 ± 1.02 | 41 ± 0.31 | 0.00, 0.00 | 0.00, 0.00 |

| January Stressing at NSA Monterey | 14 | 2.83 | 17, 2 | 229.34 ± 0.53 | 328.64 ± 0.27 | 98 ± 0.08 | 374.06, 13.74 | 10.69, 8.74 |

| July Stressing at NSA Monterey | 14 | 7.01 | 17, 2 | 230.00 ± 0.53 | 297.82 ± 0.72 | 89 ± 0.22 | 72.94, 160.46 | 1.92, 4.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Varley, D.W.; Van Bossuyt, D.L.; Pollman, A. Feasibility Analysis of a Mobile Microgrid Design to Support DoD Energy Resilience Goals. Systems 2022, 10, 74. https://doi.org/10.3390/systems10030074

Varley DW, Van Bossuyt DL, Pollman A. Feasibility Analysis of a Mobile Microgrid Design to Support DoD Energy Resilience Goals. Systems. 2022; 10(3):74. https://doi.org/10.3390/systems10030074

Chicago/Turabian StyleVarley, Daniel W., Douglas L. Van Bossuyt, and Anthony Pollman. 2022. "Feasibility Analysis of a Mobile Microgrid Design to Support DoD Energy Resilience Goals" Systems 10, no. 3: 74. https://doi.org/10.3390/systems10030074

APA StyleVarley, D. W., Van Bossuyt, D. L., & Pollman, A. (2022). Feasibility Analysis of a Mobile Microgrid Design to Support DoD Energy Resilience Goals. Systems, 10(3), 74. https://doi.org/10.3390/systems10030074