Abstract

Background: The Industry 4.0 wave is leading the changes in existing manufacturing and industrial processes across the world. This is especially important in the formulation of the smart-factory concept with an outlook to energy sustainable processes. In viewing and identifying the foundational elements of such a transformation, the initial conditions and current practices in a cross-sectoral manner is considered a first, yet crucial step in the EU-funded project EnerMan. Methods: In this paper, we identify and analyse the key common features and characteristics of industrial practices set in a perspective of similar and identical functions with a focus to three key energy areas: sustainability, management, and footprint. The examination of different industrial sector cases is performed via distributed questionnaires and then viewed under the prism of the equifinality state via a text-mining analysis approach. Results: identification of common themes and benchmarking of current practices in a cross-industry manner led to the creation of a common systemic framework within energy management related aspects, which is hereby presented. Conclusions: use of an equifinality approach in energy management practices should be further pursued to open up new methods of ideation and innovation and communicate systems’ design in tandem with each industrial set goals.

1. Introduction

The advent of the age of big-data and Internet-of-things (IoT) [1] supports an evidence-based approach towards minimising the energy footprint and better monitoring the energy management within a factory. Therefore, the organization, interaction and interdependence in a systems-oriented approach in the industrial domain is receiving more attention and shifts the interest to a holistic and dynamic point-of-view of the smart-factory layers and interpretations [2] including the cyber-physical [3] and maintenance [4] perspective. As most of the Industry 4.0 studies deal with technological or infrastructural aspects, with a few noticing the importance of social and human aspects [5,6,7], one of the main objectives towards the implementation and realization of the smart factory concept [8] is the resource productivity and efficiency of existing industrial setups in terms of energy. The existing practices and principles, as well as the importance of considering relationships and interactions both among the energy components of the factory [9] as a system within its environment, is becoming a crucial issue over the last years for the smart-factory layout [10].

The main outcome of this paper focuses on cracking specific challenges with respect to linking efficient energy management in smart manufacturing environments, in relation to energy consumption and costs minimization, as well as monitoring the environmental footprint of the relevant products. By developing an open equifinality-based framework, this study prioritizes strengthening open sharing of knowledge and cross-fertilization with other industries and their best practices and policies. This aims to produce new knowledge and advance existing one, ensuring a sustainable growth for the technological advancements that will be delivered by linking similar concepts and identifying commonalities in energy management themes in a cross-industry ecosystem.

2. The EnerMan Project

In an effort to homogenize the approach and provide an additional insight as far as energy sustainability aspects are concerned, the launch of the EU-funded project EnerMan (https://enerman-h2020.eu/ (accessed on 17 November 2021)(GA no. 958478) explores the energy sustainability concept as a three-aspect combination: energy consumption, energy cost due to the power grid electricity price and the environmental impact due to the production process of the consumed energy. By introducing an energy sustainability management system, the project aims to achieve a holistic and data-based view of the energy efficiency, energy use and consumption within the factory. The evaluation and demonstration of the EnerMan solution will take place across Europe in three different pilot categories with eight different use cases that focus on different, energy consuming industrial manufacturing sectors (food, metal processing, automotive manufacturing). In more detail, the pilots will showcase:

- The appliances and industrial components manufacturing industry:

- ○

- Automotive manufacturing represented by Centro Ricerche Fiat in Italy;

- ○

- Automotive manufacturing represented by AVL List GMBH in Austria.

- Food industry, represented by Yiotis Anonimos Emporiki and Viomixaniki Etaireia in Greece and

- Metal manufacturing and processing industry:

- ○

- Aluminium industry represented by ASAS Aluminyum Sanayi Ve Ticaret Anonim Sirketi in Turkey;

- ○

- Titanium manufacturing for medical devices industry represented by Depuy Unlimited in Ireland;

- ○

- Iron and steel manufacturing industry represented by Stomana Industry SA in Bulgaria, and;

- ○

- Additive manufacturing for processing metal component, represented by Prima Electro S.p.A. (Società per Azioni) and 3D New Technologies S.r.l. (Società a responsabilità limitata) in Italy.

Further details about the expected pilots are shown in Table 1, provided hereinafter.

Table 1.

Description of the to-be-deployed EnerMan Pilots.

These factories can be viewed as different systems, based on their geographical and application fields, however their components in terms of energy factors may exhibit similar characteristics, therefore they can be viewed as “general systems”. This term belong to the general systems theory approach and research, a discipline whose subject matter is “the formulation and derivation of those principles which are valid for ‘systems’ in general” [11]. To address the dimensions of energy consumption, sustainability, and footprint comparison of similar and identical functions across the different sites participating in the EnerMan project will provide an initial benchmarking framework. This will allow an insight of where and how performance gaps related to energy management have been addressed and current practices conducted within the organisations participating. Moreover, it will provide a baseline of energy management actions set in the general and not specific context, that can be used as a guideline for future transitional efforts of existing practices within factories and their transcendence into smart ones.

3. Energy Investigation Areas and Current Practices

3.1. Energy Consumption

It is critical from the energy management coordination aspects point-of-view to have a view of the “pulse of energy consumption” [12]. This is best achieved through an effective and efficient system of energy monitoring and reporting [13,14]. Such a system should have the capacity to monitor energy consumption measurements and provide comparison metrics related to either the company goals or to some energy consumption related standard [15]. At a hypothetical level, this should cover each operation or production cost centre in the plant, but most facilities lack the required devices for metering purposes [16]. Most plants only meter energy consumption at a single point, where the various sources enter the plant. However, there are already remedy actions performed towards this end by installing additional metering devices (e.g., when steam system shutdowns or vacation downtime occurs). This and any future reporting scheme need to be reviewed on a periodical basis to ensure that only necessary material is being produced, that all required data are available, and that the system is overall efficient and effective.

Some of the operational efficiency aspects examined among the eight pilot sites include existence of energy audit on a regular basis, the availability of energy consumption data, use of automated energy anomaly detection features, temperature or other metric-dependent loads, site performance and existence of energy consumption information.

3.2. Energy Sustainability and Smart Manufacturing

Smart manufacturing offers new production advantages that come from the flexibility and productivity alignment offered by digital technology enablers. Smart manufacturing describes fully-integrated, collaborative manufacturing systems that respond in real-time to meet changing demands and conditions in tomorrow’s smart factory [17]. The principles behind this concept concentrate on embracing the data revolution, using technology to increase sustainable practices and upgrading the potential for people-driven processes through smart manufacturing strategies [18]. Smart manufacturing ultimately leads to sustainable manufacturing. This concept refers to all industrial activities from the factory (plant) to the customer including all in-between steps (i.e., resources and services that are connected to the manufacturing chain) [19].

The most consuming part in terms of energy and resources in the supply chain is the manufacturing stage. Therefore, implementation of the “design of manufacturing” approach is an important key to achieve sustainability goals [20]. To this point, sustainable manufacturing should be part of an organization’s strategy to promote better financial performance and at the same time fulfil any social, environmental and policy/regulations objectives set [19,21]. Therefore, in examining energy sustainability aspects in industrial manufacturing processes, we investigated the existence of data collection mechanisms, participation in energy efficiency networks and sustainability reporting features among the eight pilot sites.

3.3. Energy Footprint

Based on the fourth assessment report by the Intergovernmental Panel on Climate Change (https://www.ipcc.ch/site/assets/uploads/2018/03/ar4_wg2_full_report.pdf (accessed on 17 December 2021)), and increasing requirements from retailers and shareholders, firms around the world are considering the extent of their carbon footprint, and the means to reduce these emissions (https://ec.europa.eu/environment/industry/retail/pdf/Issue%20Paper%206.pdf (accessed on 17 December 2021)). Energy management activities in general are gentler to the environment than large-scale energy production, especially when this is coupled with extreme events, such as the COVID-19 pandemic [22], and they certainly lead to less consumption of scarce and valuable resources. Time and energy management mechanisms have shown that they can substantially reduce energy costs and energy consumption. In parallel with an increased uptake of ISO 50001 certifications [23,24], tools and key performance indicators [25] have been developed to assess the overall quality of energy management systems. However, the current approaches often fail to consider the multi-perspectives of structural design, such as safety, environmental issues, and cost in a comprehensive way.

Commitments in environmental protection can be shown through the adoption of environmental legislation [26], promotion of energy projects [27] and software features to streamline utility-related processes and identification of billing and metering errors leading to early-stage decision-making [28], which critically influences the overall cost and environmental performance at the manufacturing stage [29].

3.4. Review of Existing Energy Management Solutions

In the framework of the preliminary analysis towards full commercial exploitation of EnerMan, a preliminary analysis of the competitors of the EnerMan’s solution, are hereby briefly presented.

The solution provided by Integrated Technologies Australia (ITA (https://integratedtechnologiesaustralia.com.au/energy-management/our-markets/energy-management-for-industrial-plants-and-factories (accessed on 18 November 2021))) involves three steps: (i) analysis and audit (analysing energy patterns and identifying areas to improve efficiency; (ii) implementing tailor-made solutions; and (iii) monitoring and improving (based on changing energy usage patterns). However, this solution is not in line with EU-based standards and regulations, does not provide environmental footprint mechanisms and does not include the deployment of a full simulation environment (e.g., digital twin) of the manufacturing system.

Advantech (https://www.advantech.com/industrial-automation/industry4.0/fems#my_cen (accessed on 18 November 2021)) delivers a factory energy management system (EMS). Through IoT technology, the factory EMS system provides the optimisation of energy supply and consumption to reduce CO2 emission and factory operation costs. The specific solution includes: (i) energy consumption visualisation system (air conditioning, lighting, power consumption); (ii) air compressor equipment and heat recovery ventilation system; and (iii) renewable energy and natural gas energy monitoring system. This solution, compared to the vision set by EnerMan, does not include any ‘intelligence’ in terms of proposing specific activities and applying predictive analytics to improve energy efficiency; it is mainly used as a monitoring tool.

In the specific field of digital twins, a handful of solutions is already available in the market: General Electric (https://www.ge.com/digital/applications/digital-twin (accessed on 18 November 2021)) has developed such systems for power plants; SIEMENS (https://new.siemens.com/global/en/company/stories/industry/the-digital-twin.html (accessed on 18 November 2021)) and BOSCH (https://blog.bosch-si.com/developer/how-digital-twins-boost-development-in-the-iot/ (accessed on 18 November 2021)) see that as a baseline for Industry 4.0; IBM (https://www.ibm.com/topics/what-is-a-digital-twin (accessed on 18 November 2021)) and ORACLE (https://docs.oracle.com/en/cloud/paas/iot-cloud/iotgs/oracle-iot-digital-twin-implementation.html (accessed on 18 November 2021)) have already started deploying such solutions for any IoT-based environment. However, none of these approaches have a special focus on energy management of manufacturing environments. Therefore, the EnerMan project aims to provide a thorough solution that will comprise efficient energy management mechanism; minimisation of the environmental footprint and AI-based predictive analytics to facilitate an accurate decision support system and the deployment of accurate digital twin-enabled environments that will enable the realisation of its services.

3.5. Equifinality in a Cross-Industry Framework: A State-Of-The-Art Investigation

Equifinality as a concept is gaining attention over the last years. A relevant search in electronic bibliographical databases (i.e., Scopus and IEEEXplore) yields specific examples including the correlation of the equifinality in open source software development [30] as well as knowledge sourcing in foreign-owned subsidiaries [31,32] and open innovation in the biotechnological cluster [33,34]. Restaurant firms, [35], circular economy industries [36] and apparel manufacturing [37] have also been examined Identification of the need for equifinal configurations in high technology industrial cluster [38,39,40], including dynamic configurations in the chemical industry [41], high performance in agribusinesses [42] and the specification of them in the airline industry [43].

However, narrowing down the search and analysis of results set in a cross-industry framework, we found out that there is minimal application of equifinality in a cross-industry setting apart from three studies which explored hypothesis theory within the equifinality concept. The first one was set to understand the IT capability configuration-innovation performance relationship with IT-fit capabilities in a large number of different industrial sectors [44]. In [45], business model innovation in manufacturing and service firms was explored under an equifinality approach and in [46] mineral, non-mineral and technological cluster industries were explored under an equifinality approach. While these three examples provide a foundation towards the research direction set in this study, they also highlight a research gap in identifying commonalities among different types of industries under a common equifinality approach framework, and more specifically one related to energy management practices. Table 2 summarises the findings of these results.

Table 2.

Identified Studies Exploring Equifinality in Industrial Sectors.

4. Methodology

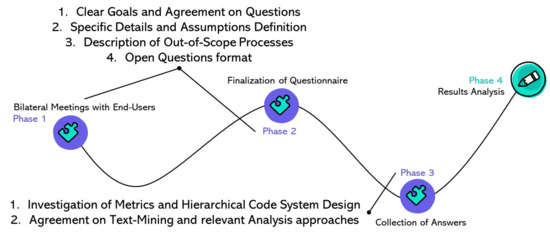

A strategic benchmarking type of action [47] is considered to be of the most constructive nature for identifying such actions. Figure 1 shows the timeplan of the phases identified, along with the key goals related to each phase, which are hereinafter described in more detail.

Figure 1.

Timeplan of phases related to information acquisition for the study.

In this study, a semi-structured questionnaire [48] was conducted from February to May 2020, comprised of three open-ended questions about benchmarking practices within industrial manufacturing premises, so as to guide the end-users towards describing the aimed themes (Table 3). Phase 1 and Phase 2 (Figure 1) concerned the definition and clarity on the goals set, as well as the nature of the questions, specific details, and assumptions as well out-of-scope processes.

Table 3.

Open-ended Questions Related to Benchmarking Practices.

The answers received were then qualitatively analysed and a hierarchical code system was designed in which higher level categories describe the answers in general terms (Phase 3 in Figure 1). This system approach was designed based on an iterative methodology where we revisited and refined the answers given: the most important answered were highlighted; those that were unclear or that were not considered relevant were ignored; some answers and/or concepts with similar meaning were merged. We then thoroughly analysed the answers by indicating their relevance, variations, dimensions and parameters [49]. Finally, to go beyond a simplistic descriptions level, we comparatively and relationally analysed the content to reveal the existence and strength of patterns of associations between the data elements. The results of this exercise are provided in Table 4, Table 5 and Table 6:

Table 4.

Energy Consumption Related Practices.

Table 5.

Energy Sustainability Related Practices.

Table 6.

Energy Footprint Related Practices.

The Equifinality Aspect

The idea of equifinality suggests that similar results may be achieved with different initial conditions and in many different ways [50]. Given the difference in character among the investigated industries, an additional approach would be to check if and how they may establish similar competitive advantages based on substantially different competencies [51]. Moreover, it is suggested that “the social, economic, and environmental impacts of each process must be determined to identify the optimal course of action” [51]. To check the equifinality aspect of the industries involved in the EnerMan project, identification of commonalities in sustainable mission-driven goals (namely the energy consumption, sustainability and footprint practices deployed within their floors) under an unknown future (be it that of the project outcomes in terms of its expectations), should provide an indication of whether this is true or not across a multi-system approach.

As part of the use cases analysis questionnaire deployed for identifying the requirements and specifications of the EnerMan pilots, an additional section was also included to explore the aspect of equifinality via a set of open-ended questions set to address the expectations from each pilot site regarding the EnerMan project outcomes (parts of Phase 1 and Phase 2 in Figure 1). These questions were based on bilateral teleconference meetings held for these purposes. The agreed list of questions is shown in Table 7.

Table 7.

Questions related to EnerMan expectations.

5. Results and Discussion

5.1. Results

Given the open format of the answers, a preliminary text-mining analysis was performed to identify qualitative context stemming out of the answers (Phase 3 in Figure 1). The main research item from these questions was to see if there are common themes pursued among the end-users and identification of common issues envisioned by them to address the issue of equifinality among different industrial environments.

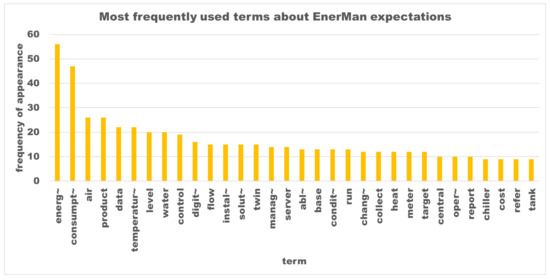

For these purposes, a bag-of-words model approach [52] was followed for feature generation out of the answers given by each end-user. The most common type of features (or characteristics) calculated from the bag-of-words model is the frequency, namely the number of times a term appears in the text. Julia v1.4 [53] was used for programming a script (a link to the Julia notebook is provided as a footnote (https://nextjournal.com/EnerManD12textMining/enerman-d12-text-mining-analysis-for-expectations-related-answers (accessed on 18 November 2021))) (Phase 4 in Figure 1). The results are shown in Table 8. Figure 2 provides the diagrammatical representation of the same results.

Table 8.

Bag-of-Words Results.

Figure 2.

Most Frequently Used Terms from End Users Related to EnerMan Expectations.

As shown in Figure 2, the main terms reflecting the end-users’ opinion have to do with manufacturing related issues (e.g., “consumption”, “production”, “flow”), energy sources (e.g., “energy”, “air”, “water”) and data related characteristics (e.g., “real-time”, “data”, “digital”, “server”). However, and in order to obtain a better view of the end-users’ perspective, an n-gram analysis was performed to highlight the most commonly used bi-/tri- and quadra-grams (i.e., number of consecutive words found together in a sentence) to extract a meaningful interpretation of common trends. Table A1, Table A2 and Table A3 in the Appendix A show the first 15 results coming from that analysis. Terms highlighted with green colour confirm the trends appearing among partners as far the EnerMan application is concerned, with characteristic examples the need for “a central server” and “ML and AI algorithms”, while “flow rate measures”, “of the building” and “end-node meters” are of high importance as well.

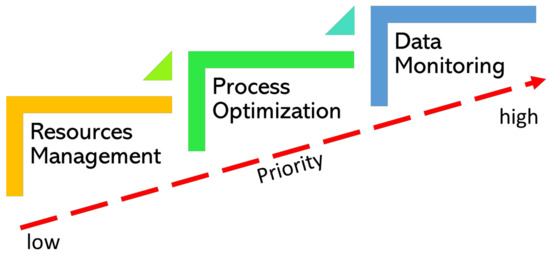

Based on the previous results, a diagrammatic representation of the context level desired to be achieved by the EnerMan approach was drawn (Figure 3), as far as the end-users are concerned. Based on the text-mining analysis, data monitoring issues are of outmost importance and are highlighted by the context of the answers provided, followed by manufacturing processes optimization and improvements on existing resources management and allocation.

Figure 3.

Context-related Expectation Levels regarding EnerMan.

This is also aligned with the answers given in the specific question number 5 in Table 7 related to the KPIs. Table 9 shows a redacted version of the total answers given by the end-users in non-specific order and by removing partners’ identifiable information. As it is evident, data monitoring and measurements issues dominate the answers given in terms of Key Performance Indicators, thus serving as a driver for the upcoming build-up of the EnerMan system.

Table 9.

Redacted Answers to Question #5.

5.2. Discussion

In this point it should be highlighted that specific key and data metrics related to the practices followed by the pilot sites were not given respecting the terms of confidentiality imposed by them. However, this is not restrictive in terms of sharing several important insights into how organisations can employ energy-related information for energy management strategies at different stages of their present or future energy management strategy planning. These insights are hereinafter described.

Organisations in all levels of energy management positioning give a significant focus from an energy efficiency perspective, e.g., by using available and newly gathered information. This information is used for performing efficiency improvement decisions, evaluation of the plant performance and participation in sustainability projects. Despite the differences shown in how intensively the organisation use this information, they also intend to obtain other sustainability benefits such as mitigation of any environmental impacts, industrial energy usage, and carbon emissions. For example, adoption of the ISO 50001 standard is pretty common and provides a constant variable in terms of energy management practices.

However, due to the unavailability of systematic environmental monitoring data and recent use of energy management systems and their associated information collection and management mechanisms, the investigated organisations following reactive and preventive strategies do not exploit the full potential of energy efficiency strategies. For example, the option of using renewable energy sources is limited among the pilot sites, and such environmental management initiatives should be extended and promoted among both internal stakeholders and external stakeholders.

On the other hand, all organisations are found to actively pursue reactive and preventive strategies and have included this focal aspect in managing existing information. The investigated organisations follow a proactive strategy and attempt to be as transparent as possible in terms of energy information management and provision. However, even these organisations seem to lack a proper mechanism to integrate multi-tier suppliers into their network of energy management and related activities. Non consideration of AI- and ML-enabling technologies along with related strategies, would deny these organisations opportunities to further achieve low energy and low-carbon operations.

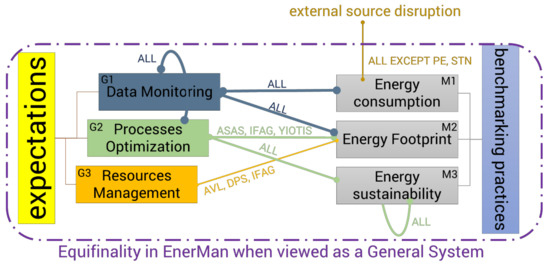

Thus, in terms of equifinality, a suggested framework within energy-related aspects, inspired by the means-end-chain model approach [54] covering both the states of expectations (as goals) and existing practices (as means) (Figure 4). The inter-systemic interactions are hereby highlighted with interlinks of varying thickness, so as to open up new methods of ideation and innovation and communicate a systems’ design in tandem with industrial set goals. As shown in the figure, G1: data monitoring was found to be of the outmost importance (depicted with the thicker drawn interlinks) to achieve the required status of energy consumption (M1) and footprint (M2) metrics within an industrial environment, while G2: process optimization comes second towards the fulfilment of both the energy footprint and sustainability (M3) profile to be achieved. G3: resources management is shown to affect only the energy footprint status, and that in specific cases (depicted with thinner drawn interlink), while an external source disruption (namely that of external audits) seems also to affect a number of industries within the energy consumption framework.

Figure 4.

Approaching of Equifinality within the EnerMan project.

Although real-time implementation of data monitoring/management strategies is requested and/or expected by all industries, this is shown not to be actually taking place in terms of realizing them in terms of energy sustainability, consumption and footprint. To request or require such services (in terms of real-time monitoring). Therefore, the suggested framework acts as a scaffold on which they should base current and future activities especially in terms of all the aforementioned concepts, so as to interlink and recognize the impact of their energy-related activities with environmental metrics in real-time and in an evidence-based manner.

6. Conclusions and Future Work

The innovation delta offered by depicting energy related expectations and practices under a commonly understood framework, such as the one presented in the current study aims to provide the push to all energy management activities of the EnerMan partners but to external stakeholders as well. Identifying common themes and common-goal priorities under the same umbrella terms, intends to allow the effective and meaningful use of energy management information, which plays a crucial role in monitoring, measuring, and evaluating progress towards the achievement of sustainability and energy management goals not only on a corporate level, but on a decision-making and multi-stakeholder level as well.

The innovation value chain in the context of AI-based energy management solutions for Industry 4.0 environments is enacted by an open ecosystem of small and large industries, individual inventors, research institutes and universities. Large industries are experimenting with a variety of schemes to stimulate and benefit from entrepreneurial activities outside their organizations. Information gathering, and analysis is still in progress, but it appears that while the general philosophy of open innovation is shared, there is considerable variation in how it is interpreted and applied, and a consensus on best practice has yet to emerge, as highlighted in similar approaches (e.g., in [55,56]).

The EnerMan project aims to empower AΙ and digital twins to drive efficient energy management in smart manufacturing. The framework is very rich in innovative features. The envisioned operations incorporate (i) a novel self-learning distributed approach; (ii) a data- and knowledge-driven approach for digital twin manufacturing towards intelligent energy management in manufacturing; (iii) novelty in modelling algorithms and finally (iv) a novel, thorough industrial model-based management system to help humans to resolve unforeseen critical situations in smart factories towards (1) efficient production planning to reduce energy consumption, costs, and the relevant environmental footprints, (2) effective analysis and improvement of production processes towards the same direction. Environmental barriers affect organizational factors, which in turn have an impact on system integration, system and data security, and data quality [57].

With its associated companies, EnerMan will reinforce the power to innovate and the competitiveness of local businesses in particular by means of applied research of the suggested framework. At the same time, mutual exchange of experience and knowledge, cooperation in interdisciplinary teams and shared use of infrastructure creates a market-oriented and science-based process of innovation that benefits all the project partners involved. Interdisciplinary exchange improves competitiveness in an international context and guarantees that the very latest research findings are constantly incorporated into the framework. This gives a decisive edge to the project.

As far as future work is concerned and as far as the project progresses, a more elaborate insight on the framework relations will be explored, so as to indicate the variables and parameters on a micro-, and meso-scale the implementation activities on both an expectational and practical level. By fulfilling the goals set by the EnerMan project, a better glimpse will be given on the existing and future energy landscape at various industrial sectors, towards the realization and the transformation motions set by Industry 4.0.

Author Contributions

Conceptualization, P.K.; methodology, P.K.; software: P.K.; resources, M.C., F.M., L.M., A.I., E.B., H.B.T., Z.T.Ö., İ.A.S., K.P., J.B., S.P., G.P., R.P., R.d.F., F.F.; writing—original draft preparation, P.K.; writing—review and editing, M.C., F.M., L.M., A.I., E.B., H.B.T., Z.T.Ö., İ.A.S., K.P., J.B., S.P., G.P., R.P., R.d.F., F.F.; The co-authors named in the resources, represent the end users of the EnerMan project and have provided input regarding the current practices followed within their industrial manufacturing premises and input for the definition and clarity of the goals set for the EnerMan project. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Union’s Horizon 2020 Research and Innovation Programme under Grant Agreement No. 958478.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Bigram Analysis: First 15 Results.

Table A1.

Bigram Analysis: First 15 Results.

| Bigram | Count | Log Likelihood |

|---|---|---|

| of the | 78 | 230.7207 |

| should be | 26 | 166.5386 |

| EnerMan solution | 14 | 134.299 |

| central server | 10 | 121.5994 |

| in order | 13 | 107.1364 |

| digital twins | 8 | 93.51045 |

| energy consumption | 17 | 91.33639 |

| order to | 13 | 89.84082 |

| able to | 13 | 89.84082 |

| no answer | 7 | 77.76522 |

| flow rate | 6 | 75.66086 |

| target processes | 7 | 63.61579 |

| based on | 7 | 63.20992 |

| AI algorithms | 4 | 62.65131 |

| from the | 20 | 59.0126 |

Table A2.

Trigram Analysis: First 15 Results.

Table A2.

Trigram Analysis: First 15 Results.

| 3 g | Count | Frequency |

|---|---|---|

| in order to | 13 | 0.351351 |

| be able to | 9 | 0.243243 |

| of the target | 8 | 0.216216 |

| of the process | 7 | 0.189189 |

| the target processes | 7 | 0.189189 |

| should be installed | 6 | 0.162162 |

| the central server | 6 | 0.162162 |

| the EnerMan solution | 6 | 0.162162 |

| it should be | 6 | 0.162162 |

| be installed in | 6 | 0.162162 |

| EnerMan solution should | 6 | 0.162162 |

| of the production | 5 | 0.135135 |

| the temperature and | 5 | 0.135135 |

| of the system | 5 | 0.135135 |

| no answer energy | 5 | 0.135135 |

Table A3.

The Four-gram Analysis: First 15 results.

Table A3.

The Four-gram Analysis: First 15 results.

| 4 g | Count | Frequency |

|---|---|---|

| of the target processes | 5 | 0.135135 |

| process in order to | 4 | 0.108108 |

| should be able to | 4 | 0.108108 |

| no no answer energy | 4 | 0.108108 |

| ML and AI algorithms | 4 | 0.108108 |

| should be installed in | 4 | 0.108108 |

| on a central server | 4 | 0.108108 |

| Bodyshop environmental air conditioning | 3 | 0.081081 |

| environmental air conditioning system | 3 | 0.081081 |

| to minimize energy consumption | 3 | 0.081081 |

| of the target process | 3 | 0.081081 |

| acquired from the field | 3 | 0.081081 |

| dynamic parameters that are | 3 | 0.081081 |

| parameters that are important | 3 | 0.081081 |

| that are important to | 3 | 0.081081 |

References

- Renugadevi, N.; Saravanan, S.; Naga Sudha, C.M. IoT based smart energy grid for sustainable cites. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Osterrieder, P.; Budde, L.; Friedli, T. The smart factory as a key construct of industry 4.0: A systematic literature review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- Napoleone, A.; Macchi, M.; Pozzetti, A. A review on the characteristics of cyber-physical systems for the future smart factories. J. Manuf. Syst. 2020, 54, 305–335. [Google Scholar] [CrossRef]

- Forcina, A.; Introna, V.; Silvestri, A. Enabling technology for maintenance in a smart factory: A literature review. Proced. Comput. Sci. 2021, 180, 430–435. [Google Scholar] [CrossRef]

- Matt, D.T.; Orzes, G.; Rauch, E.; Dallasega, P. Urban production—A socially sustainable factory concept to overcome shortcomings of qualified workers in smart SMEs. Comput. Ind. Eng. 2020, 139, 105384. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Industry 4.0 integration with socio-technical systems theory: A systematic review and proposed theoretical model. Technol. Soc. 2020, 61, 101248. [Google Scholar] [CrossRef]

- Neumann, W.P.; Winkelhaus, S.; Grosse, E.H.; Glock, C.H. Industry 4.0 and the human factor—A systems framework and analysis methodology for successful development. Int. J. Prod. Econ. 2021, 233, 107992. [Google Scholar] [CrossRef]

- Resman, M.; Turk, M.; Herakovič, N. Methodology for planning smart factory. Proced. CIRP 2021, 97, 401–406. [Google Scholar] [CrossRef]

- Cugno, M.; Castagnoli, R.; Büchi, G. Openness to Industry 4.0 and performance: The impact of barriers and incentives. Technol. Forecast. Soc. Chang. 2021, 168, 120756. [Google Scholar] [CrossRef]

- Soares, N.; Monteiro, P.; Duarte, F.J.; Machado, R.J. Extending the scope of reference models for smart factories. Proced. Comput. Sci. 2021, 180, 102–111. [Google Scholar] [CrossRef]

- Rousseau, D. Systems Research and the Quest for Scientific Systems Principles. Systems 2017, 5, 25. [Google Scholar] [CrossRef] [Green Version]

- Xie, F.; Zhang, B.; Wang, N. Non-linear relationship between energy consumption transition and Green Total Factor Productivity: A perspective on different technology paths. Sustain. Prod. Consum. 2021, 28, 91–104. [Google Scholar] [CrossRef]

- Wang, D.; Zhong, D.; Souri, A. Energy management solutions in the Internet of Things applications: Technical analysis and new research directions. Cogn. Syst. Res. 2021, 67, 33–49. [Google Scholar] [CrossRef]

- Singh, J.; Kaur, R.; Singh, D. A survey and taxonomy on energy management schemes in wireless sensor networks. J. Syst. Archit. 2020, 111, 101782. [Google Scholar] [CrossRef]

- Bagdadee, A.H.; Aurangzeb, M.; Ali, S.; Zhang, L. Energy management for the industrial sector in smart grid system. Energy Rep. 2020, 6, 1432–1442. [Google Scholar] [CrossRef]

- Gellert, A.; Florea, A.; Fiore, U.; Palmieri, F.; Zanetti, P. A study on forecasting electricity production and consumption in smart cities and factories. Int. J. Inf. Manag. 2019, 49, 546–556. [Google Scholar] [CrossRef]

- Zenisek, J.; Wild, N.; Wolfartsberger, J. Investigating the Potential of Smart Manufacturing Technologies. Proced. Comput. Sci. 2021, 180, 507–516. [Google Scholar] [CrossRef]

- Lu, Y.; Witherell, P.; Jones, A. Standard connections for IIoT empowered smart manufacturing. Manuf. Lett. 2020, 26, 17–20. [Google Scholar] [CrossRef]

- Enyoghasi, C.; Badurdeen, F. Industry 4.0 for sustainable manufacturing: Opportunities at the product, process, and system levels. Resour. Conserv. Recycl. 2021, 166, 105362. [Google Scholar] [CrossRef]

- Zhang, X.; Ming, X. An implementation for Smart Manufacturing Information System (SMIS) from an industrial practice survey. Comput. Ind. Eng. 2021, 151, 106938. [Google Scholar] [CrossRef]

- Awasthi, A.; Saxena, K.K.; Arun, V. Chapter eleven—Sustainability and survivability in manufacturing sector. In Modern Manufacturing Processes; Kumar, K., Davim, J.P., Eds.; Woodhead Publishing Reviews: Mechanical Engineering Series; Woodhead Publishing: Cambridge, UK, 2020; pp. 205–219. ISBN 978-0-12-819496-6. [Google Scholar]

- Chofreh, A.G.; Goni, F.A.; Klemeš, J.J.; Seyed Moosavi, S.M.; Davoudi, M.; Zeinalnezhad, M. Covid-19 shock: Development of strategic management framework for global energy. Renew. Sustain. Energy Rev. 2021, 139, 110643. [Google Scholar] [CrossRef]

- António da Silva Gonçalves, V.; Mil-Homens dos Santos, F.J. Energy management system ISO 50001:2011 and energy management for sustainable development. Energy Policy 2019, 133, 110868. [Google Scholar] [CrossRef]

- Fuchs, H.; Aghajanzadeh, A.; Therkelsen, P. Identification of drivers, benefits, and challenges of ISO 50001 through case study content analysis. Energy Policy 2020, 142, 111443. [Google Scholar] [CrossRef]

- Andersson, E.; Dernegård, H.; Wallén, M.; Thollander, P. Decarbonization of industry: Implementation of energy performance indicators for successful energy management practices in kraft pulp mills. Energy Rep. 2021, 7, 1808–1817. [Google Scholar] [CrossRef]

- Caglar, A.E.; Mert, M.; Boluk, G. Testing the role of information and communication technologies and renewable energy consumption in ecological footprint quality: Evidence from world top 10 pollutant footprint countries. J. Clean. Prod. 2021, 298, 126784. [Google Scholar] [CrossRef]

- Yao, X.; Yasmeen, R.; Hussain, J.; Hassan Shah, W.U. The repercussions of financial development and corruption on energy efficiency and ecological footprint: Evidence from BRICS and next 11 countries. Energy 2021, 223, 120063. [Google Scholar] [CrossRef]

- Patterson, M.; McDonald, G.; Hardy, D. Is there more in common than we think? Convergence of ecological footprinting, emergy analysis, life cycle assessment and other methods of environmental accounting. Ecol. Model. 2017, 362, 19–36. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q. Environmental sustainability and production: Taking the road less travelled. Int. J. Prod. Res. 2018, 56, 743–759. [Google Scholar] [CrossRef]

- Poba-Nzaou, P.; Uwizeyemungu, S. Worries of open source projects’ contributors: Patterns, structures and engagement implications. Comput. Hum. Behav. 2019, 96, 174–185. [Google Scholar] [CrossRef]

- Dahms, S. Foreign-owned subsidiary knowledge sourcing: The role of location and expatriates. J. Bus. Res. 2019, 105, 178–188. [Google Scholar] [CrossRef]

- Andrews, D.S.; Fainshmidt, S.; Gaur, A.; Parente, R. Configuring knowledge connectivity and strategy conditions for foreign subsidiary innovation. Long Range Plann. 2021, 102089. [Google Scholar] [CrossRef]

- Carmona-Lavado, A.; Cuevas-Rodríguez, G.; Cabello-Medina, C.; Fedriani, E.M. Does open innovation always work? The role of complementary assets. Technol. Forecast. Soc. Chang. 2021, 162, 120316. [Google Scholar] [CrossRef]

- Vlaisavljevic, V.; Medina, C.C.; Van Looy, B. The role of policies and the contribution of cluster agency in the development of biotech open innovation ecosystem. Technol. Forecast. Soc. Chang. 2020, 155, 119987. [Google Scholar] [CrossRef]

- Madanoglu, M.; Kizildag, M.; Ozdemir, O. Which bundles of corporate governance provisions lead to high firm performance among restaurant firms? Int. J. Hosp. Manag. 2018, 72, 98–108. [Google Scholar] [CrossRef]

- Tate, W.L.; Bals, L.; Bals, C.; Foerstl, K. Seeing the forest and not the trees: Learning from nature’s circular economy. Resour. Conserv. Recycl. 2019, 149, 115–129. [Google Scholar] [CrossRef]

- Pipkin, S. Local Means in Value Chain Ends: Dynamics of Product and Social Upgrading in Apparel Manufacturing in Guatemala and Colombia. World Dev. 2011, 39, 2119–2131. [Google Scholar] [CrossRef]

- Fan, D.; Li, Y.; Chen, L. Configuring innovative societies: The crossvergent role of cultural and institutional varieties. Technovation 2017, 66–67, 43–56. [Google Scholar] [CrossRef]

- Poorkavoos, M.; Duan, Y.; Edwards, J.S.; Ramanathan, R. Identifying the configurational paths to innovation in SMEs: A fuzzy-set qualitative comparative analysis. J. Bus. Res. 2016, 69, 5843–5854. [Google Scholar] [CrossRef] [Green Version]

- Bouncken, R.B.; Fredrich, V. Good fences make good neighbors? Directions and safeguards in alliances on business model innovation. J. Bus. Res. 2016, 69, 5196–5202. [Google Scholar] [CrossRef]

- Gelhard, C.; von Delft, S.; Gudergan, S.P. Heterogeneity in dynamic capability configurations: Equifinality and strategic performance. J. Bus. Res. 2016, 69, 5272–5279. [Google Scholar] [CrossRef] [Green Version]

- Brenes, E.R.; Ciravegna, L.; Pichardo, C.A. Managing institutional voids: A configurational approach to understanding high performance antecedents. J. Bus. Res. 2019, 105, 345–358. [Google Scholar] [CrossRef]

- Greckhamer, T.; Gur, F.A. Disentangling combinations and contingencies of generic strategies: A set-theoretic configurational approach. Long Range Plann. 2021, 54, 101951. [Google Scholar] [CrossRef]

- Raymond, L.; Uwizeyemungu, S.; Fabi, B.; St-Pierre, J. IT Capability Configurations for Innovation: An Empirical Study of Industrial SMEs. In Proceedings of the 2014 47th Hawaii International Conference on System Sciences, Waikoloa, HI, USA, 6–9 January 2014; pp. 3939–3948. [Google Scholar] [CrossRef]

- Cheng, C.; Wang, L. How companies configure digital innovation attributes for business model innovation? A configurational view. Technovation 2021, 102398. [Google Scholar] [CrossRef]

- Vendrell-Herrero, F.; Bustinza, O.F.; Vaillant, Y. Adoption and optimal configuration of smart products: The role of firm internationalization and offer hybridization. Ind. Mark. Manag. 2021, 95, 41–53. [Google Scholar] [CrossRef]

- Ebner, K.; Mueller, B.; Ahlemann, F. Understanding the success of strategic IT benchmarking—Exploring the role of the individual level. Inf. Manag. 2019, 56, 640–656. [Google Scholar] [CrossRef]

- Sayeed, O.B. Questionnaire Design for Survey Research. In Essays on Research Methodology; Hegde, D.S., Ed.; Springer: New Delhi, India, 2015; pp. 185–211. ISBN 978-81-322-2214-9. [Google Scholar]

- Bazeley, P. Qualitative Data Analysis: Practical Strategies; SAGE Publications: Newbury Park, CA, USA, 2013. [Google Scholar]

- Von Bertalanffy, L. General System Theory: Foundations, Development, Applications, Revised ed.; George Braziller Inc.: New York, NY, USA, 1969. [Google Scholar]

- Dzombak, R.; Mehta, C.; Mehta, K.; Bilén, S.G. The Relevance of Systems Thinking in the Quest for Multifinal Social Enterprises. Syst. Pract. Action Res. 2014, 27, 593–606. [Google Scholar] [CrossRef]

- Zhang, Y.; Jin, R.; Zhou, Z.-H. Understanding bag-of-words model: A statistical framework. Int. J. Mach. Learn. Cybern. 2010, 1, 43–52. [Google Scholar] [CrossRef]

- Karpinski, S.; Shah, V.B.; Bezanson, J.W.; Edelman, A. Julia: A Fresh Approach to Numerical Computing. SIAM 2017, 59, 65–98. Available online: https://dspace.mit.edu/handle/1721.1/110125 (accessed on 18 June 2021).

- Gutman, J. A Means-End Chain Model Based on Consumer Categorization Processes. J. Mark. 1982, 46, 60–72. [Google Scholar] [CrossRef]

- Musbah, H.; Ali, G.; Aly, H.H.; Little, T.A. Energy management using multi-criteria decision making and machine learning classification algorithms for intelligent system. Electr. Power Syst. Res. 2022, 203, 107645. [Google Scholar] [CrossRef]

- Strengers, Y.; Dahlgren, K.; Pink, S.; Sadowski, J.; Nicholls, L. Digital technology and energy imaginaries of future home life: Comic-strip scenarios as a method to disrupt energy industry futures. Energy Res. Soc. Sci. 2022, 84, 102366. [Google Scholar] [CrossRef]

- Perno, M.; Hvam, L.; Haug, A. Implementation of digital twins in the process industry: A systematic literature review of enablers and barriers. Comput. Ind. 2022, 134, 103558. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the European Union. Licensee MDPI, Basel, Switzerland. This is an open access article distributed under the terms of the Creative Commons Attribution IGO License (http://creativecommons.org/licenses/by/3.0/igo/legalcode), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. In any reproduction of this article there should not be any suggestion that EU or this article endorse any specific organisation or products. The use of the EU logo is not permitted.