Soft body armor (e.g., bullet-proof vests) typically consists of stacked, fabric layers often having a tight plain weave construction to keep the yarns from separating during ballistic impact. More rigid, flat composite panels (e.g., cockpit doors) and shells (e.g., helmets) often consist of many alternating layers of parallel yarns, stacked orthogonally, and impregnated with a flexible polymer matrix at 15 to 20% volume fraction to provide dimensional stability and fill voids between fibers. The constituent yarns in these biaxial structures often consist of ultra-high molecular weight polyethylene (UHMWPE) fiber, under trade names such as Dyneema® and Spectra®, or aramid fiber under trade names such as Twaron® or Kevlar®. Such yarns are available in a wide variety of linear densities (deniers), and materials processing history, which affects their axial stiffness and tensile strength.

1.1. Fundamental Parameters Governing the Ballistic Resistance of Fibrous Systems

Depending on the shape and hardness of an impacting projectile, many geometric and mechanical parameters and their interactions affect the ballistic performance of multilayer fibrous systems. In practice, optimizing the geometry and performance of an initial prototype involves trial-and error ballistic testing, irrespective of the sophistication of the software used in its initial design. Nonetheless, once reasonably optimized in overall structure, the seminal work of Cunniff [

5] has shown that the most important material properties governing ballistic performance are the yarn tensile strength, Young’s modulus, and density (which also determine the tensile wave speed and failure strain). To demonstrate this, Cunniff [

5] applied dimensional analysis to data on the critical or threshold velocity for full penetration, called V

50, as obtained from an extensive set of controlled, laboratory ballistic experiments on multi-ply fabric and panel systems. The projectiles used were standardized, right circular cylindrical (RCC) projectiles of various weights and dimensions.

In his work, Cunniff [

5] uncovered certain dimensionless ratios that appeared to govern

V50 ballistic performance through a two-parameter function,

, having overall mathematical structure

The parameters in the dimensionless ratios appearing in this function are

and

where

,

,

and

are, respectively, the yarn’s tensile strength, strain-to-failure, Young’s modulus and density. Also

is the effective depth of fiber in the fabric system (the depth measured if all voids are compressed out leaving fully dense fiber material), and

and

are the projectile’s mass and cylindrical radius, respectively. The parameter,

, is referred to as the areal density ratio, that is, the total mass of the fabric lying within the circle (of radius,

) of projectile impact, divided by the projectile areal density (mass over projectile presented area,

). The velocity,

, is the median value (at 50% probability) of the critical or threshold velocity for full penetration (so-named to reflect statistical variation from sample to sample). Lastly,

is the product of two quantities:

, the maximum elastic energy that can be stored in the yarn per unit mass (i.e., specific stored elastic energy), and

, the tensile wave-speed.

The involvement of

indicates that the fabric system must store a lot of elastic energy per unit mass, as well as transport that energy away from the impact region as quickly as possible. The normalizing quantity in Equation (1), was viewed by Cunniff [

5] as a characteristic velocity,

, and using Equation (2) and the relationship,

, this velocity can be written in the form

where,

, defined in the square parenthesis is a critical impact velocity for failure arising later.

Cunniff’s extensive laboratory experiments [

5] involved firing RCC projectiles of various masses and diameters into multi-ply fabric systems, widely ranging in the numbers of layers, and made from different fiber materials including the polymers UHMWPE, two aramids, poly(

p-phenylene-2,6-benzobisoxazole (PBO) and nylon, as well as more brittle carbon and E-glass fibers. Composite panels were also tested, where it was found that their ballistic resistance followed remarkably well the same dimensional rules, provided the added resin was mathematically absorbed by defining effective fiber properties to account for the added resin mass and cross-sectional area. Apart from the benefit of holding yarns in place and filling voids, the results showed that for a given areal density ratio,

, the replacement of fiber material with resin tends to reduce the

performance of the composite panel by lowering both the tensile wave-speed and the elastic energy storage ability per unit mass.

Cunniff [

5] also uncovered certain anomalies in the predictions, whereby glass and carbon fiber composite panels do not perform as well as predicted, largely because of their previously noted brittle response to sudden transverse loads. Also, based on his assumed mechanical properties for Spectra

® 1000 UHMWPE yarns, Cunniff [

5] found the associated UHMWPE fabrics and composites performed below expectations in that the critical value,

, had to be artificially reduced by 16% in order for Equation (1) to be able to resolve the data. Cunniff proposed that an effective strength reduction (by about 23%) may be the result of strength loss from thermal softening connected to the relatively low melting point of UHMWPE fibers compared to the higher thermal stability of other polymeric fibers, such as aramids and virgin PBO.

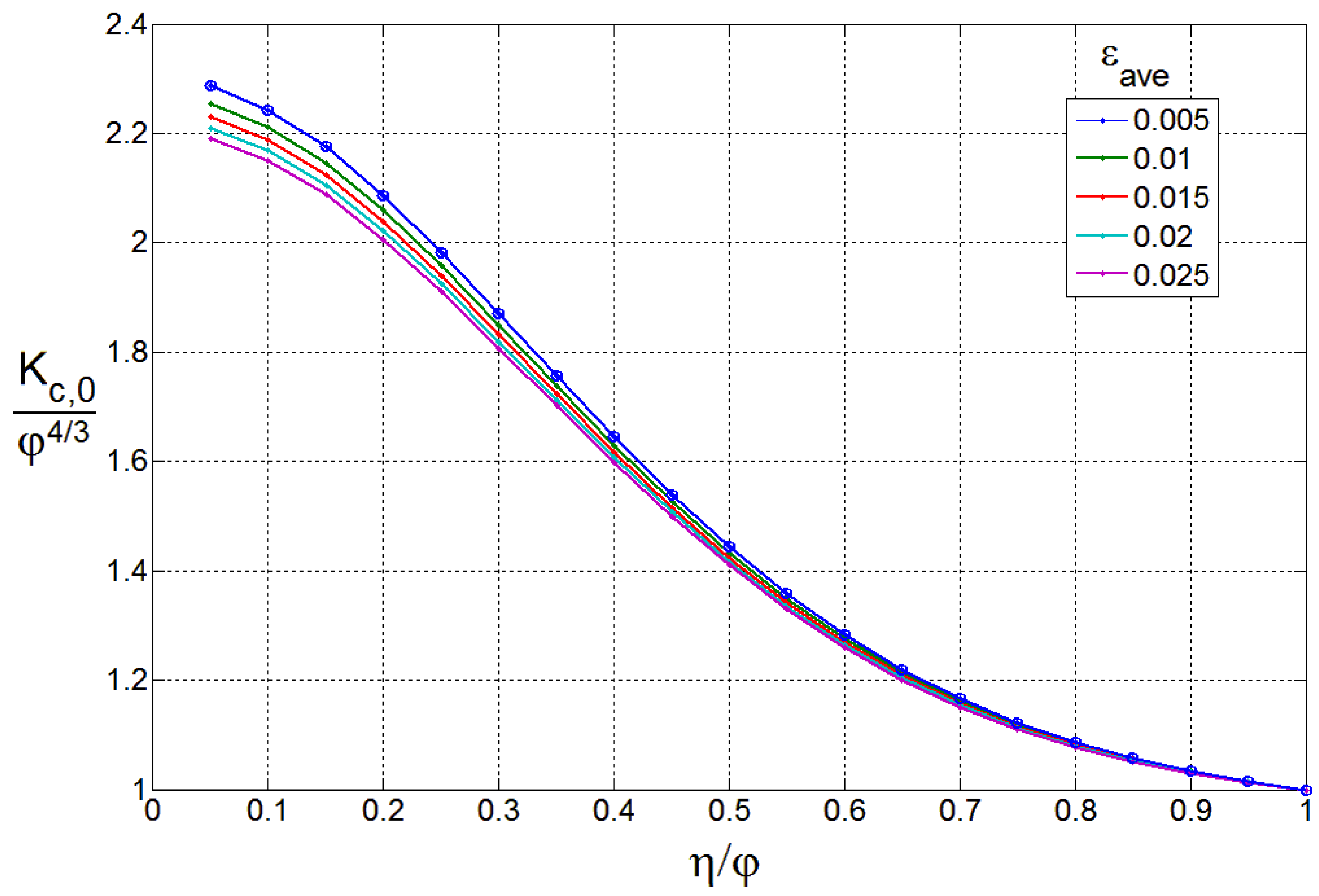

In more recent theoretical work on RCC impact into a 2D isotropic membrane, Phoenix and Porwal [

6] largely confirmed the role of Cunniff’s dimensionless parameters,

and

, although there emerged a small, additional, dimensionless multiplier,

, on

, as indicated in Equation (4) above. Apart from this difference, these authors derived a specific mathematical expression for the function

, again finding it to be virtually material independent. Another important aspect of their work [

6] was to focus specifically on the inherent feature of build-up of tensile stress in a 2D membrane system that intensifies within a few diameters of the projectile axis, and especially in and around the projectile contact circle. This feature is nominally absent in idealized models of transverse projectile impact into 1D geometries (e.g., a single fiber, yarn, or narrow unidirectional tape) due to Rakhmatulin [

7,

8], Cole et al. [

9], Ringleb [

10] and Smith et al. [

11].

In later work, Porwal and Phoenix [

12] studied the performance reducing effect on

of significant cumulative air gaps between layers, relative to the projectile radius,

. In a multi-ply fabric system or composite panel with 2D membrane layers, the rapid stress build-up under and around the projectile means that defeating the projectile requires decelerating the projectile sufficiently quickly to limit the maximum occurring stress over time to less than the critical strength values of the material. At higher projectile velocities, this typically must occur very quickly before the transverse wave or ‘pyramid’ has grown more than one or two projectile diameters at its base. Air gaps reduce the ability of layers to work together in engaging and decelerating the projectile as the first few layers may fail before subsequent layers are even engaged. (Once a layer fails, its ability to contribute to projectile deceleration vanishes.) Although not directly studied, their analysis also suggests that similar performance reductions would result from having voids between fibers and low transverse compressive stiffness of an armor system.

This feature of stress build-up is absent in classical 1D ballistic impact models and experiments on yarns. Even when is very small, and projectile deceleration is negligible, failure in 1D yarns occurs either immediately, or much later (if at all) when statistical flaws in fibers, and associated length effects, result in a lower apparent yarn strength as the tension wave progresses along it.

In applying Cunniff’s framework [

5], a crucial issue is to determine appropriate yarn strength and Young’s modulus values to use in the dimensionless framework of Equations (1) and (2). Cunniff used properties obtained from quasi-static tension tests at strain rates resulting in failure in a few seconds. However, at lower strain rates UHMWPE and aramid yarns both exhibit strain-rate effects in apparent modulus or strength (or both) depending on the material version. Furthermore, the inherent strain rate in ballistic impact experiments is of order 10

4/s, and thus, is 6 to 7 orders of magnitude larger than typical values of 10

−2/s to 10

−3/s used in quasi-static tension tests. Various methods have been used to determine Young’s modulus and sometimes the strength of such materials at high strain rates. Lim et al. [

13] used a miniature Kolsky bar, and others have used a split Hopkinson bar, as discussed by Wang [

14], who points out that the results take considerable experimental sophistication to interpret. The method we use involves ‘yarn shooting experiments’ whereby a single yarn, under a prescribed level of initial tension, is subjected to transverse impact by a projectile. The yarn strength and Young’s modulus are calculated from the evolving transverse and tension waves using results from classical theory for impact into a 1D string, as discussed below.

1.3. Experiments on Ballistically Measured Yarn Modulus and Strength in the Literature

Among the many investigators who have conducted and interpreted yarn shooting experiments and in some cases developed specific models, are Rakhmatulin [

7,

8], Smith and colleagues [

11,

17,

18,

19], Prevorsek et al. [

20], Wang et al. [

16], Carr [

21], Bazhenov et al. [

22] and Utomo and colleagues [

23,

24,

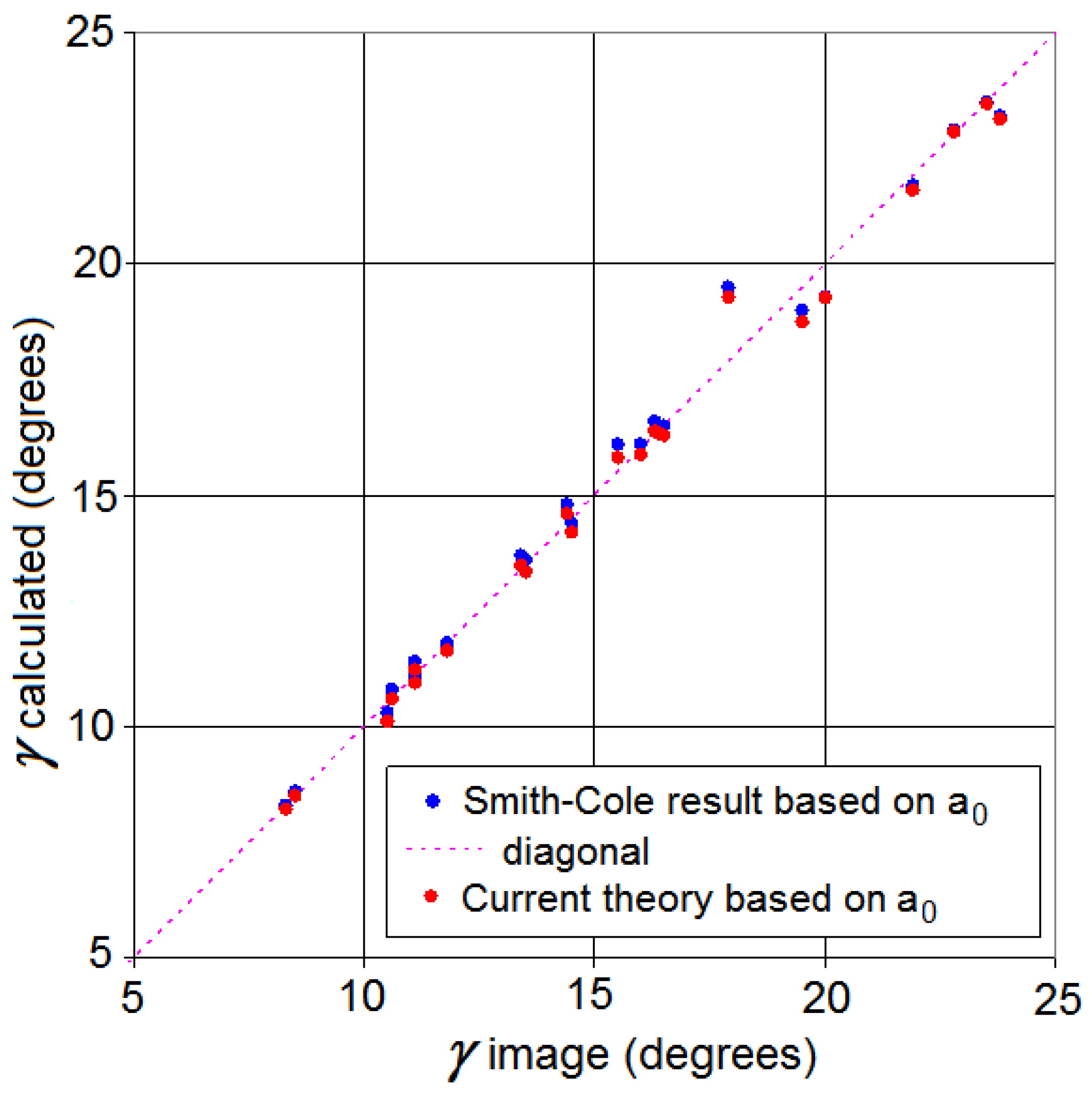

25]. The yarn model and theory used by Prevorsek et al. [

20] and Wang et al. [

16] has components credited to Cole [

9], and Smith [

11,

18], including the incorporation of initial tension prior to impact. Bazhenov et al. [

22] refers to the theoretical model used as the Rakhmatulin-Smith theory, and that of Utomo and colleagues [

23,

24,

25] is essentially the same as used by Prevorsek et al. [

20]. Parga-Landa and Hernandez-Olivares [

26] implemented a numerical model for yarn impact, involving discrete time steps, but the governing equations are consistent with those of the above authors.

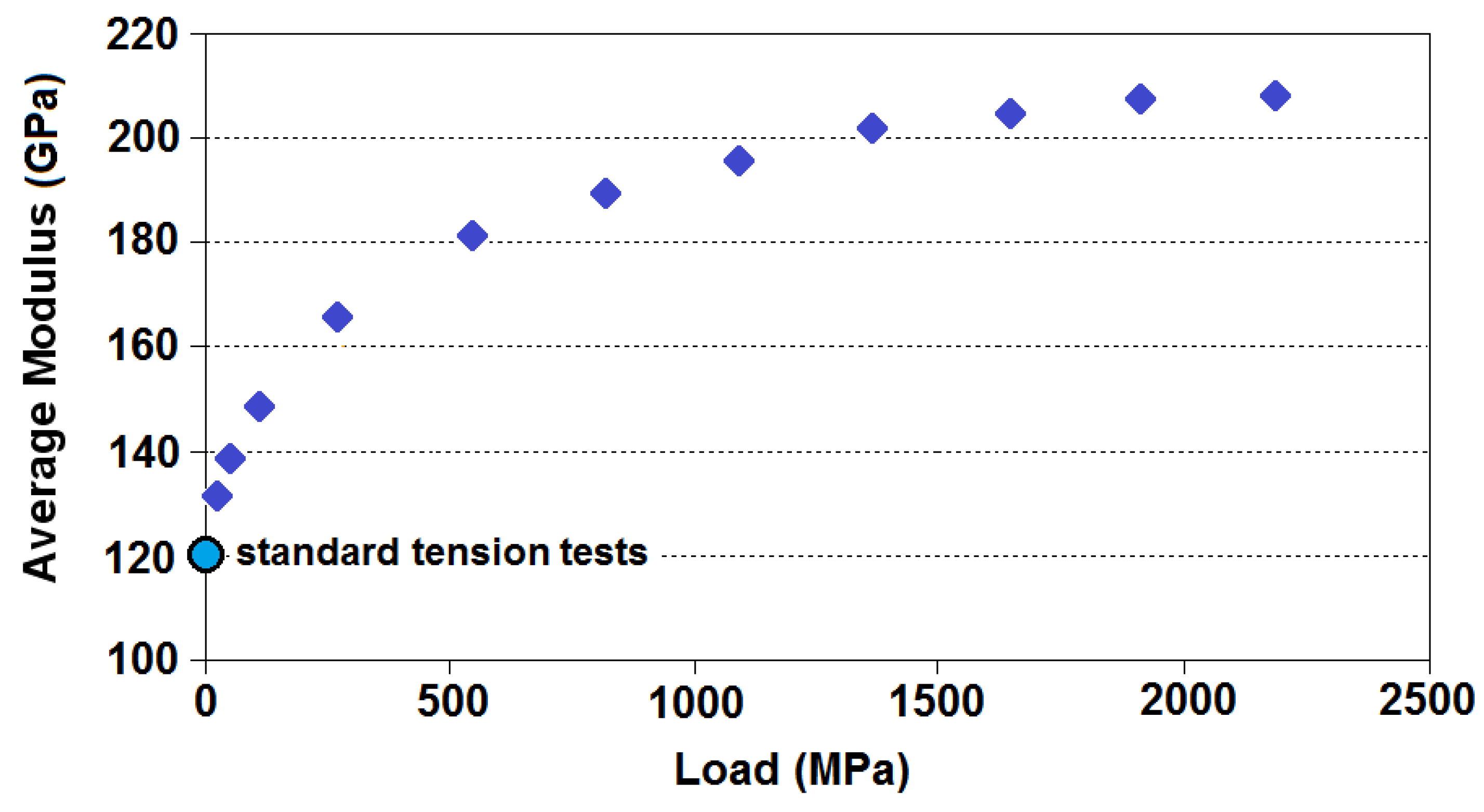

Ideally one would expect published yarn shooting experiments on UHMWPE and aramid yarns to have provided values of yarn modulus and strength that are not only an improvement over the quasi-static values used in Cunniff’s dimensionless framework, but also are consistent across the various investigators. Unfortunately, this is not the case, since similar (in some cases identical) materials have appeared to yield quite different properties. Nonetheless, certain important features have emerged. It has generally been found that Young’s modulus determined from yarn shooting experiments, is considerably larger than measured in quasi-static tension tests and in one case [

20], the increase approached a factor of three. Furthermore, in another case, impact into a yarn under a large initial tension, resulted in higher calculated Young’s modulus values than into a low or un-tensioned yarn. Additionally, when such measurements have been attempted, the yarn strength inferred from yarn shooting experiments is typically much lower than obtained in quasi-static tension tests, irrespective of fiber type.

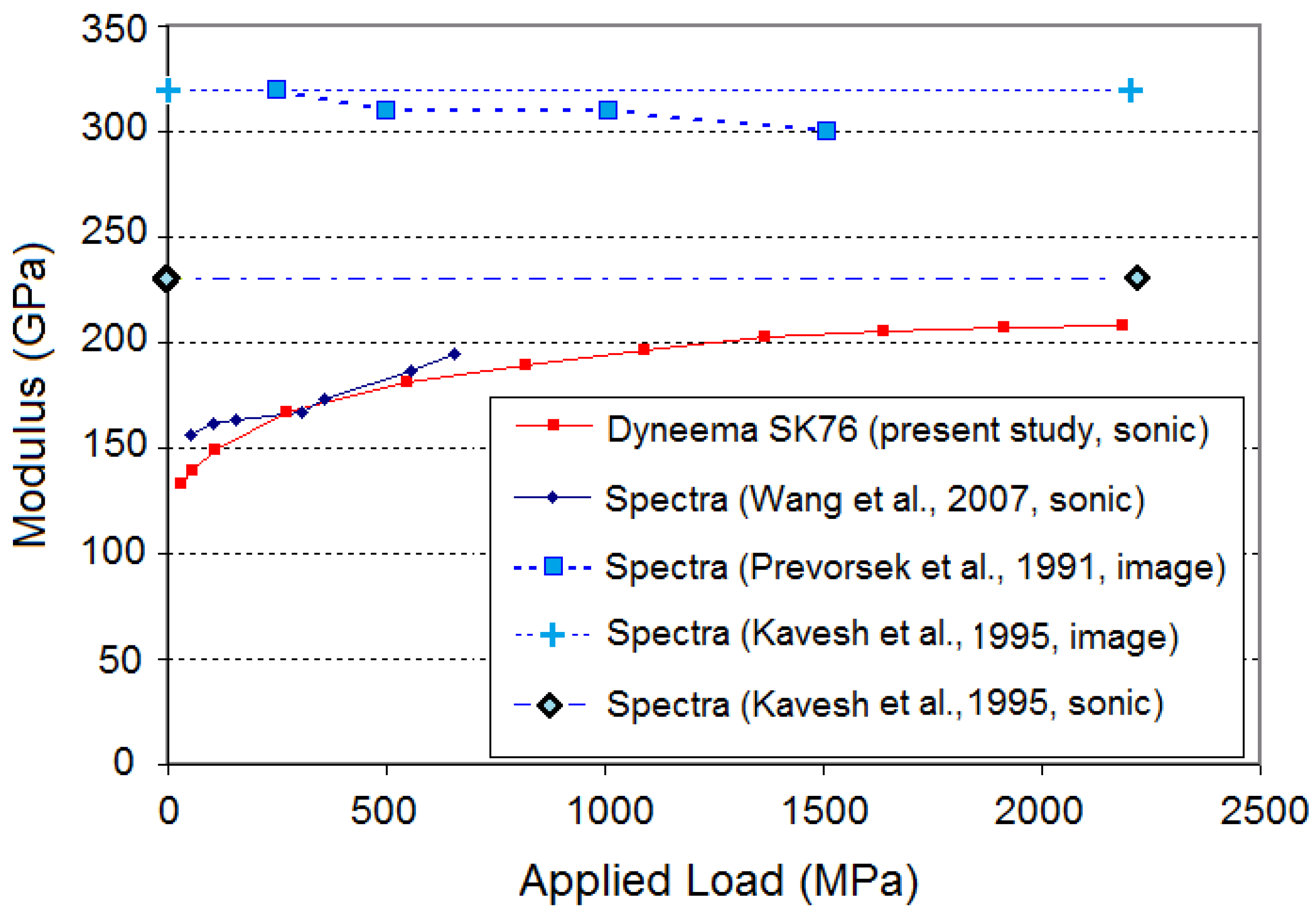

The first yarn shooting experiments we discuss are those of Prevorsek et al. [

20], who shot a plastic PMMA projectile with a curved profile at both single Spectra

® 1000 yarns of 195 dtex and density 1000 kg/m

3, and Kevlar

® yarns of 938 dtex (844 denier) and density 1470 kg/m

3. The tensile wave-speed in the yarn was calculated from the transverse wave-speed and the projectile velocity measured from high-speed photographs and interpreted using the Cole-Smith equations. They calculated a tensile modulus of

for the Spectra

® 1000 and a value

for Kevlar

®. In their experiments, Prevorsek et al. [

20] used various values of pretension, which in the case of Spectra

® 1000, ranged from 250 MPa to 1500 MPa, however, little if any effect was observed on Young’s modulus, and the same was true for Kevlar

®. Many of the results in Prevorsek et al. [

20] were also reported in paper by Field and Sun [

27], who provided additional details.

Pevorsek et al. [

20] mentioned that quasi-static modulus values for Spectra

® 1000 are about 110 GPa in quasi-static tension tests (other sources give values in the 120 GPa range), so the reported value of 310 GPa represented an increase by almost a factor of 3. Unfortunately, they did not mention the particular Kevlar

® version used, nor was a quasi-static Young’s modulus value given (although Field and Sun [

27] did indicate the use of Kevlar

® 29 at one point, but not elsewhere in the paper). Kevlar

® 129 is available as an 840 denier yarn and quasi-static modulus values of 95 GPa can be found in DuPont product literature. Their use of Kevlar

® KM2 cannot be ruled out, however, since this yarn is available as an 850 denier yarn, and Cheng et al. [

2] obtained a Young’s modulus value of about 85 GPa. Nonetheless, from the yarn shooting experiments of Prevorsek et al., the measured modulus of the Kevlar

® fibers used exceeds these quasi-static values by a factor of at least 2.3. Indeed, the values obtained by Prevorsek et al. [

20] are much higher than the high strain-rate values, 112 to 143 GPa, developed by Lim et al. [

13] for Kevlar

® 129, using a miniature Kolsky bar (where the values vary depending on whether one assumes a tangent or secant modulus).

Wang et al. [

16] performed yarn shooting experiments on both Spectra

® 1000 yarn and what was said in the paper to be Kevlar

® 29 yarn, but using a very different projectile, namely a sabot with a razor edge attached. Interestingly, the same linear densities were quoted as those used by Prevorsek et al. [

20] (one co-author appeared on both works). Perhaps there was a typographical error and the fiber used was Kevlar

® 129 as we have conjectured above in the Prevorsek et al. experiments, since Kevlar

® 29 does not appear to be available in 840 denier form. Based on results using pre-stress values ranging from about 30 MPa to 700 MPa, the projected modulus values at zero tension for Spectra

® 1000 and their Kevlar

® were, respectively, 159 GPa and 122 GPa, which are about half the values reported by Prevorsek et al. [

20] and Field and Sun [

27]. Wang et al. [

16] also noted a corresponding 23% and 17% increase, respectively, in these modulus values when preloads were increased from 54 to 658 MPa and 32 to 478 MPa, respectively. These authors interpreted this modulus increase with pretension as implying that the fiber has a non-linear stress-strain curve, yet the effect of impact velocity on modulus (i.e., through the tensile wave-speed) appeared to be negligible, which seems contradictory.

For the razor-edge impact experiments of Wang et al. [

16], the extent to which the results yielded the strength of the two types of yarns is unclear, but the values quoted for Spectra

® 1000 and Kevlar

® were 715 MPa and 555 MPa, respectively, or about 1/5th the values found from quasi-static tension tests. At ballistic loading rates the fiber modulus values obtained were about half those obtained by Prevorsek et al. [

20] and Field and Sun [

27], though were consistent with the high strain-rate values obtained by Lim et al. [

13]. Later on, Kavesh and Prevorsek [

28] referred to an unpublished report wherein a Young’s modulus of 230 GPa was calculated from a directly measured, tensile wave-speed in Spectra

® fiber, though the exact version and level of pre-tension was not specified.

Carr [

21] performed yarn shooting experiments on UHMWPE yarns (440 and 880 dtex Dyneema

® SK66) and aramid yarns (930 dtex Kevlar

® 129, 940 dtex Kevlar

® KM2, as well as 930 dtex Twaron CT yarns) where the main purpose was to investigate the failure modes during impact failure, rather than the critical velocity and yarn failure stresses. The projectile used was a steel sphere of mass 0.68 g and diameter 5.50 mm, and impact velocities ranged from 346 to 720 m/s. Note that the fully dense yarn diameters (viewed as one large cylindrical fiber without air spaces) were approximately 0.239 mm and 0.338 mm for the Dyneema

® SK66 yarns and 0.286 mm for the Kevlar

® and Twaron

® yarns, so accounting for roughly 80% packing of their filaments, these diameters would inflate by about 12% to 0.268, 0.378 and 0.320. These diameters are still more than an order of magnitude smaller than the projectile diameter.

Carr [

21] characterized what she considered to be two distinct failure modes, the first being a transmitted stress wave (TSW) mode and the second being a shear failure mode, and the transition between the two modes was said to occur at impact energies (projectile kinetic energies) of 160 J and 130 J for UHMWPE and aramid yarns, respectively. Using the kinetic energy formula,

, such energies imply transition projectile velocities of 686 m/s for the Dyneema

® SK66 yarns and generally 618 m/s for the aramid yarns. An interesting feature associated with the so-called, high velocity shear mode was that a “shear plug” consisting of a finite length of yarn would be severed and then carried along by the projectile after failure. In the lower velocity TSW mode, the usual transverse triangle wave would be observed for a short time before yarn failure, which presumably was more distributed in nature, though not stated specifically beyond mentioning “gross permanent disruption of the yarn structure in all specimens for a distance of about 40 mm”, which is about 7 projectile diameters. The appearance of these two types of failure modes will be the subject of further discussion, but here it suffices to note that the existence of a severed shear plug counters the notion that a strain concentration naturally occurs at the midpoint of spherical contact.

Carr [

21] noted another interesting phenomenon, namely that the energy absorbed during failure (measured from the decrease in projectile kinetic energy) versus impact velocity, had different trends in the two different fiber types. In the case of UHMWPE yarns, the specific energy absorbed in Joules/tex increased roughly linearly with projectile velocity, with no discernable jump or slope change at the transition velocity separating the failure modes. Exactly the opposite trend was noted for aramid yarns, namely a progressive decrease in absorbed specific energy with increasing impact velocity. This decrease accompanied reduced tendencies for both fibrillation and longitudinal splitting commonly observed in single aramid fibers, in favor of transverse fiber failure at higher velocities. In contrast, UHMWPE fibers exhibited no longitudinal splitting, but rather, the failure was said to be shear failure accompanied by shear bands in adjacent regions, as well as what was characterized in some cases as melt damage seen as a bulb of increased cross-sectional area over a fiber length of about three or four fiber diameters.

Bazhenov et al. [

22] performed yarn shooting experiments on yarns of an aramid fiber called SVM (580 dtex) using a 3 cm diameter, hard spherical projectile, so about 100 times the yarn diameter. Experimentally, the critical velocity for yarn failure was reported to be 670 m/s. This was said to correspond to failure occurring nearly instantaneously but long enough after impact to establish a measurable deflection angle for the transverse wave of

. Using the Rakhmatulin-Smith theory led to a predicted fiber strength value of 2.394 GPa. From their plot of quasi-static yarn stress-strain response, we confirm their Young’s modulus value of 114 GPa at strains below 1.5%, but also a tangent value of 80 GPa at strains approaching the failure strain (ignoring late stress roll-off in bundles due to load loss from random, Weibull-distributed, fiber failure strains). Bazhenov et al. [

22] did not calculate a modulus value corresponding to the inferred tensile wave-speed from their tests. However, since the preload was small (said only to be enough to straighten the yarn), the Cole-Smith formulas in Prevorsek et al. [

20] together with his V

0 value, 670 m/s, as well as the deflection angle,

, results in a modulus value 115 GPa, so virtually identical to their 114 GPa quasi-static value.

Using arguments based on the effects of strain rate as predicted by the formula of Zhurkov [

29], Bazhenov et al. [

22] proposed that the relevant fiber strength in ballistic experiments should be at least 2.8 GPa (and based on single-filament composite tests a value as large as 3.3 GPa was even suggested). Accounting for nonlinear, finite strain effects, they used this value in their Rakhmatulin-Smith theory to predict a critical velocity of 770 m/s. This then led to attempts to explain the difference between the 670 m/s they observed, versus the 770 m/s they predicted.

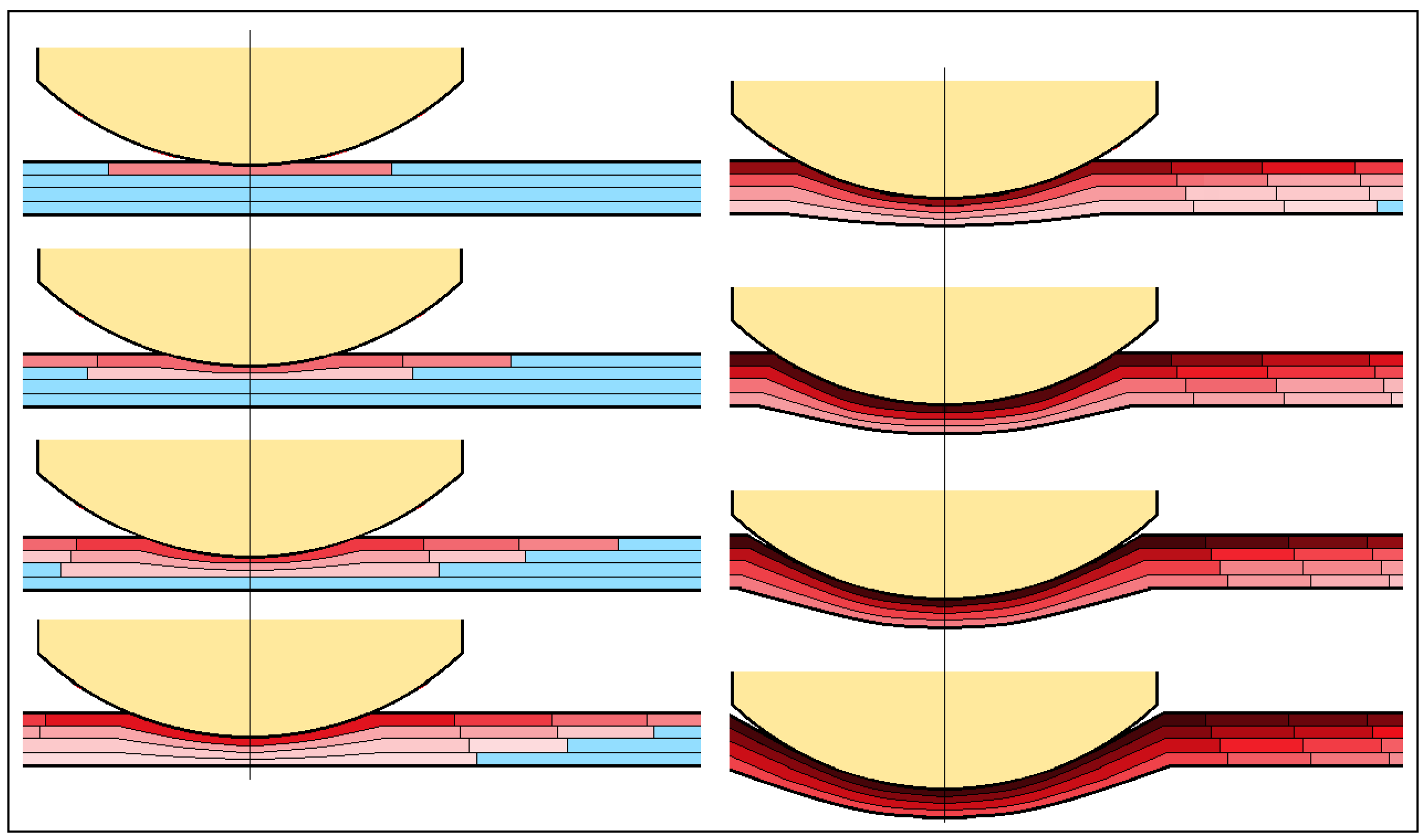

In their first effort to explain this velocity difference, Bazhenov et al. [

22] considered the influence of the observed nonlinearities in the stress-strain behavior of the fiber, but the resulting difference proved trivial. They then attempted an explanation in terms of a possible strain concentration generated by the spherical projectile shape during the growing contact and assuming a no-slip condition between the projectile and the yarn. Their initial analysis, based on discrete steps, led to a strain concentration of 2.62, obviously far larger than experimentally observed, and with further refinement of the steps, the stress concentration grew unbounded implying failure no matter how low the velocity of impact. This result obviously contradicted all published experimental data. Their result also contradicted theoretical results obtained by Rakhmatulin [

8] for a similar geometry under frictionless slip (which would further increase the strain) whereby a spherical shape would begin with zero strain on first contact, followed by a progressive build up to the steady state value. Bhazhenov et al. [

22] then attempted to revise their estimate of the strain concentration by invoking further non-linear effects, but still ended up with a significant stress concentration equivalent to

, which would reduce the critical velocity by the factor 1.26. Even this factor is considerably larger than their theoretical to experimental ratio 770/670 = 1.15.

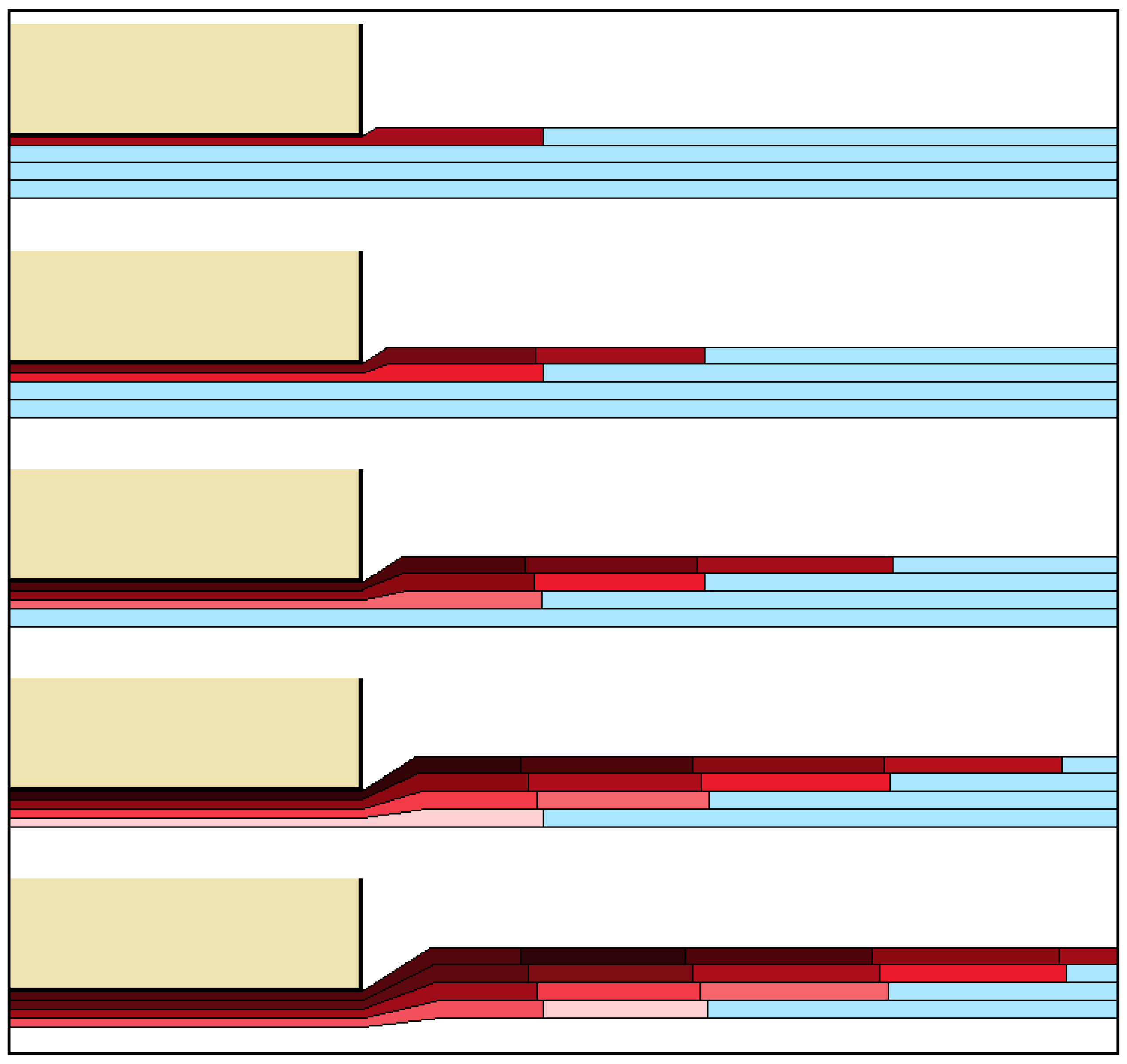

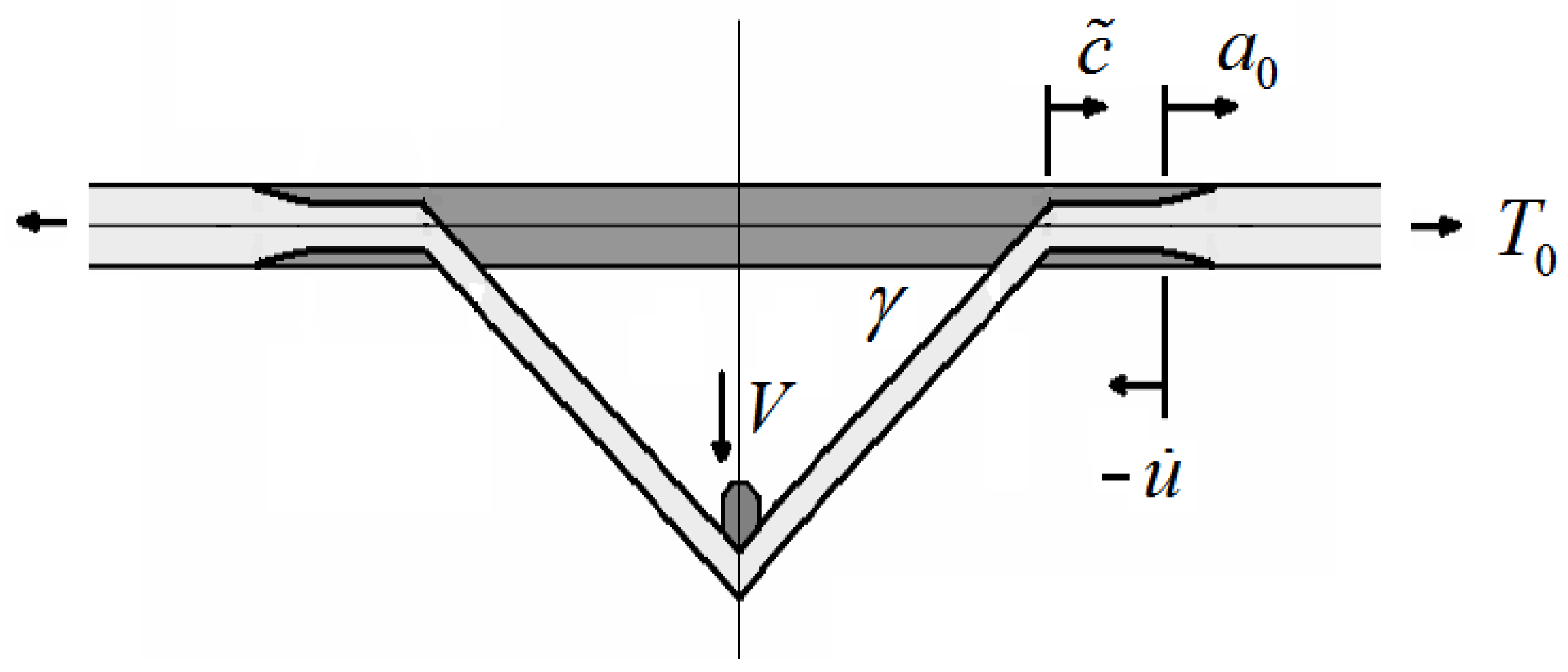

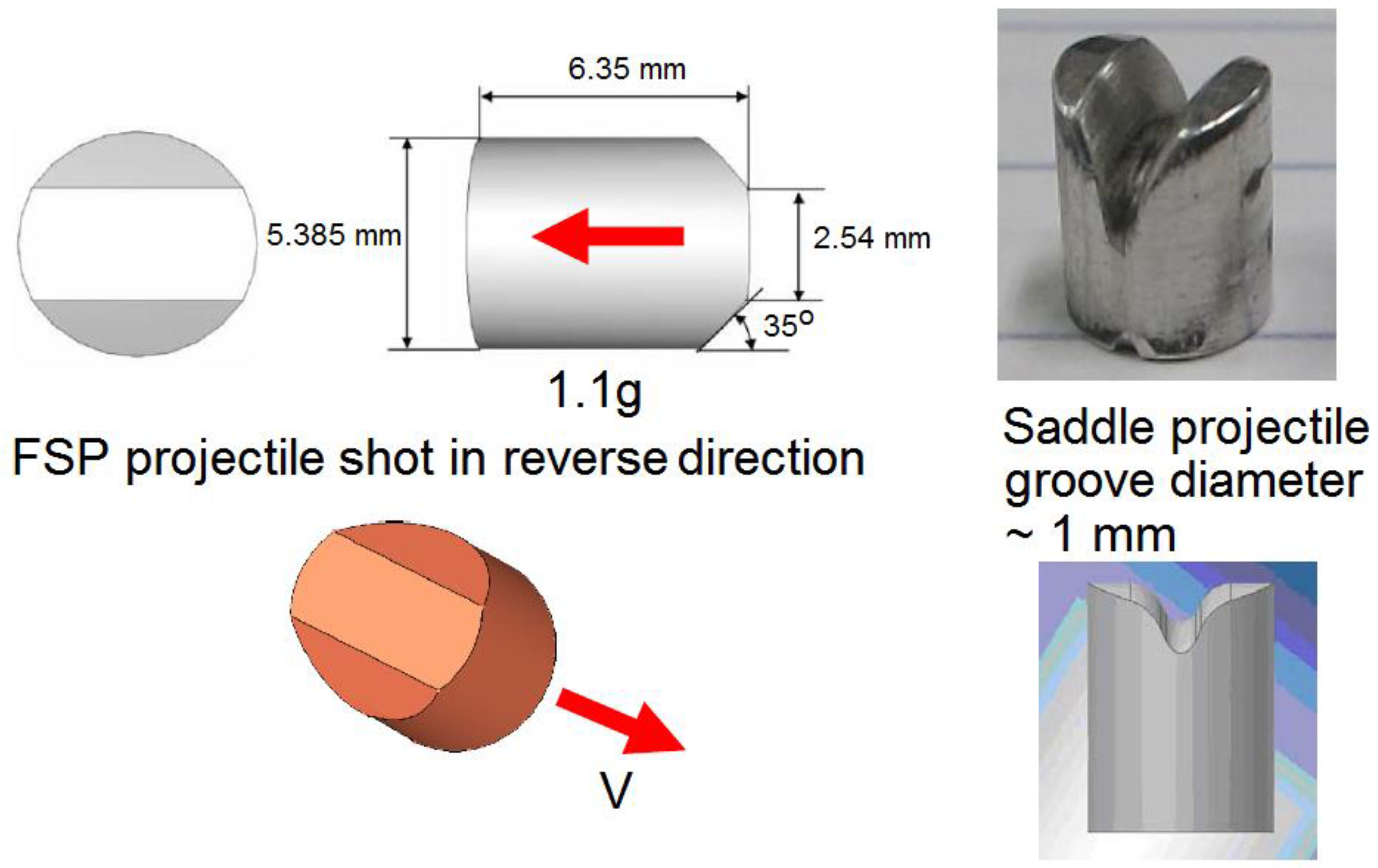

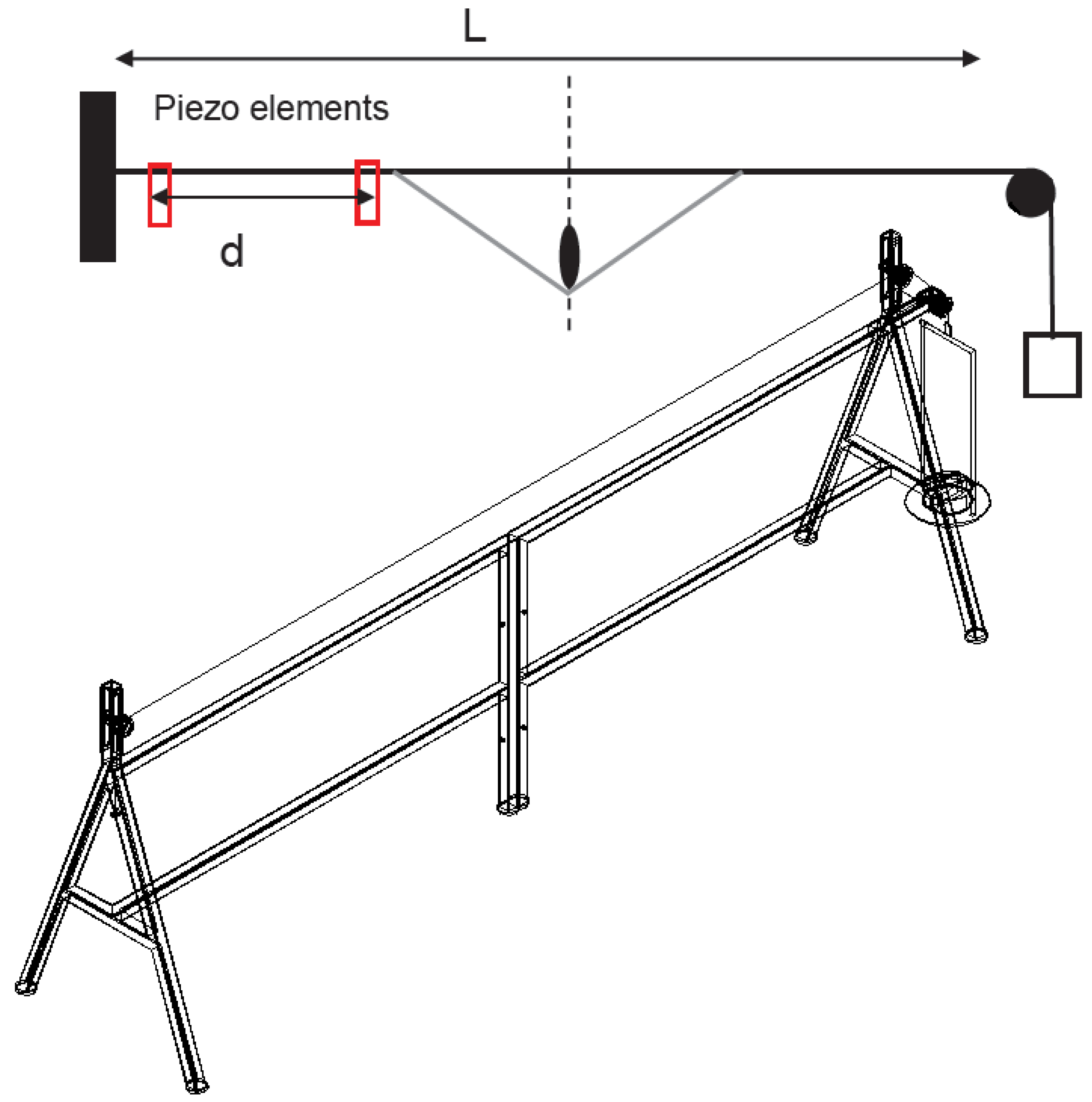

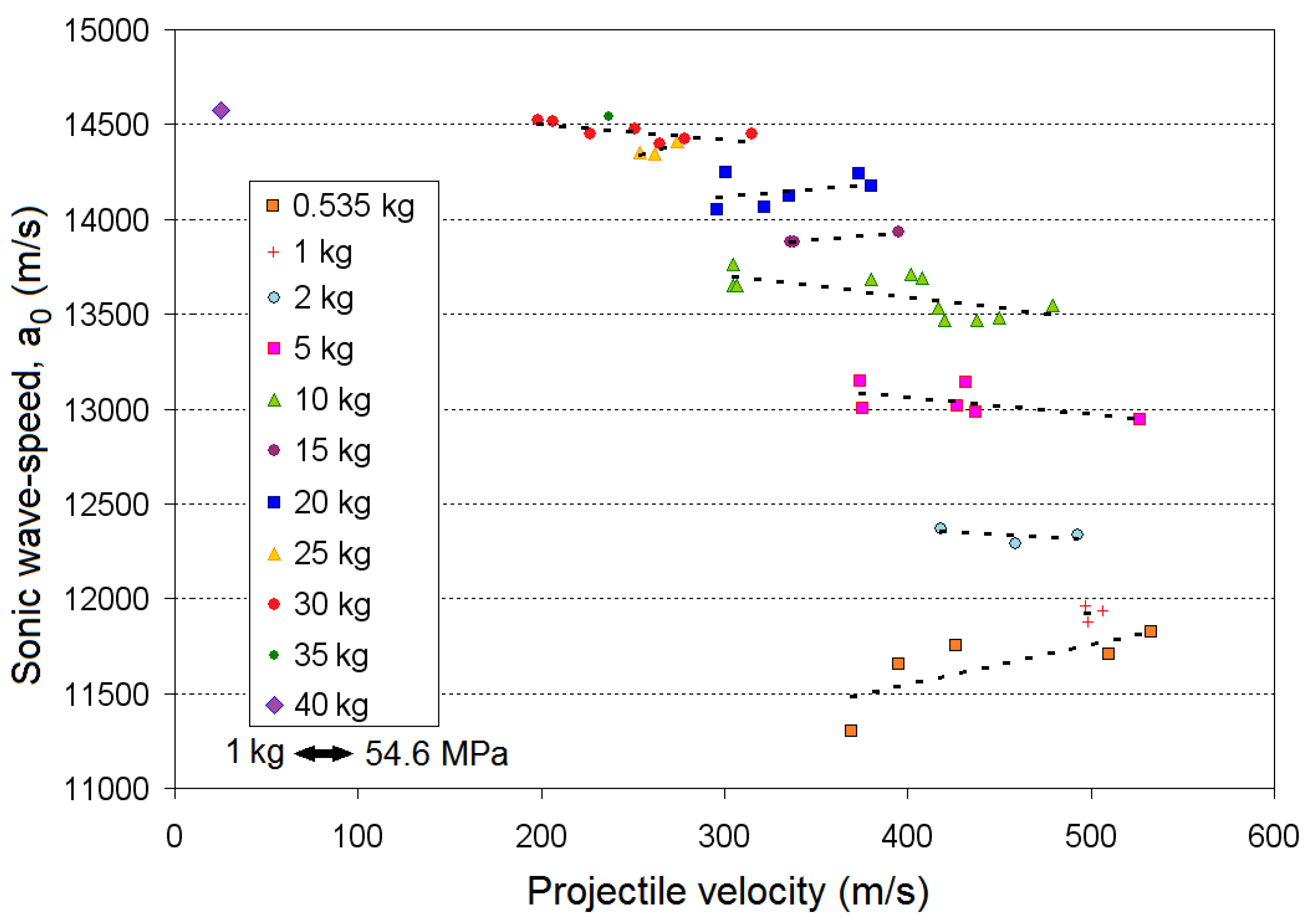

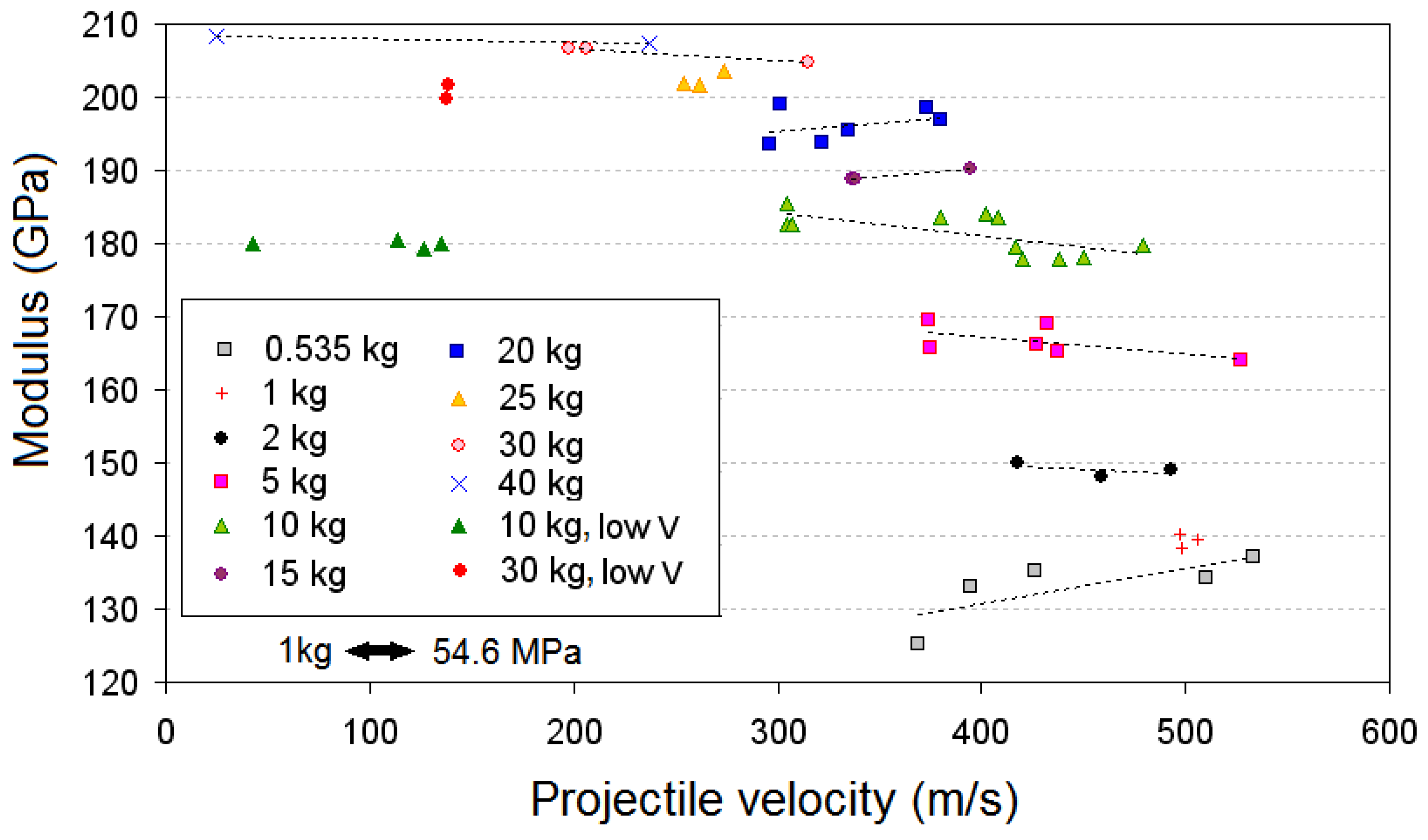

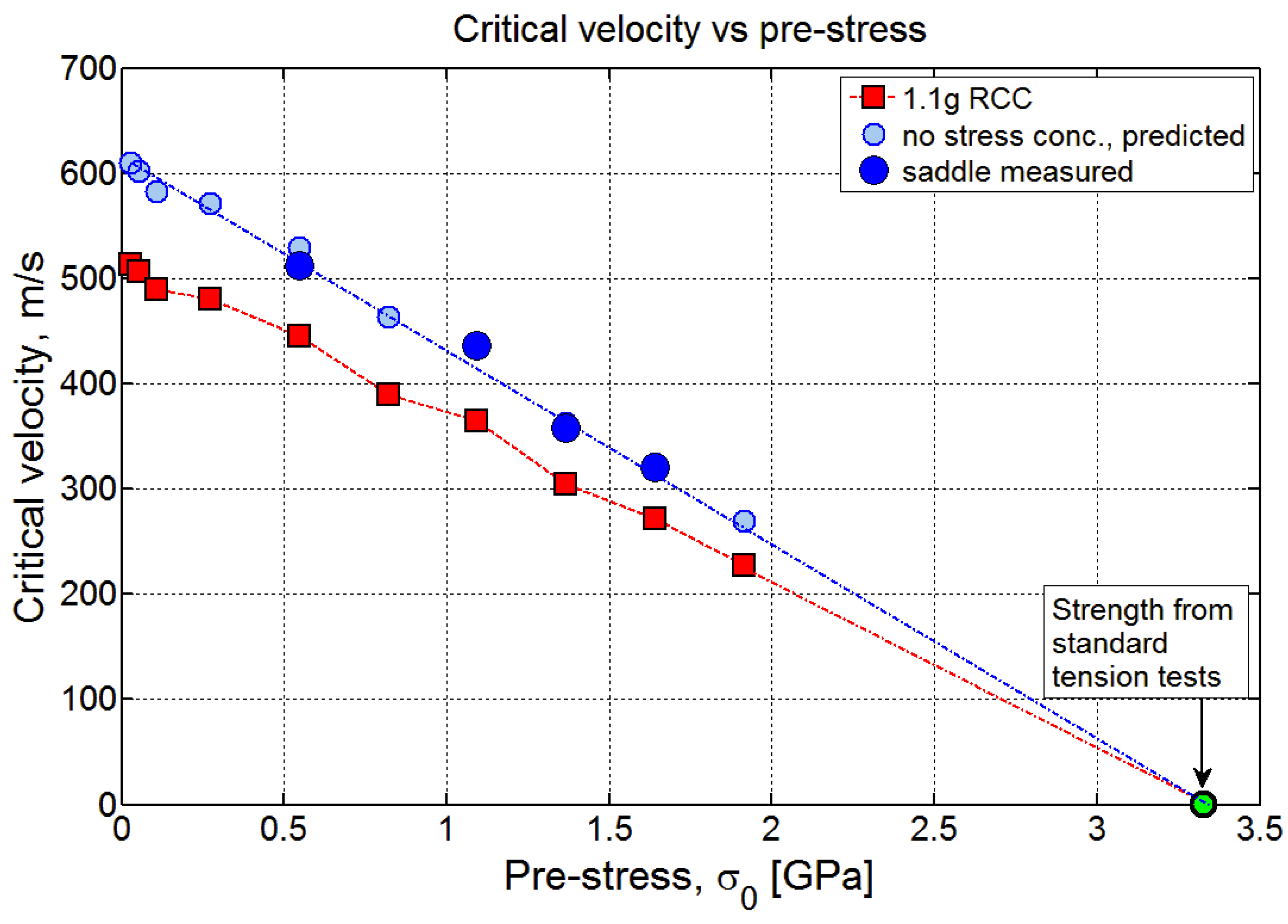

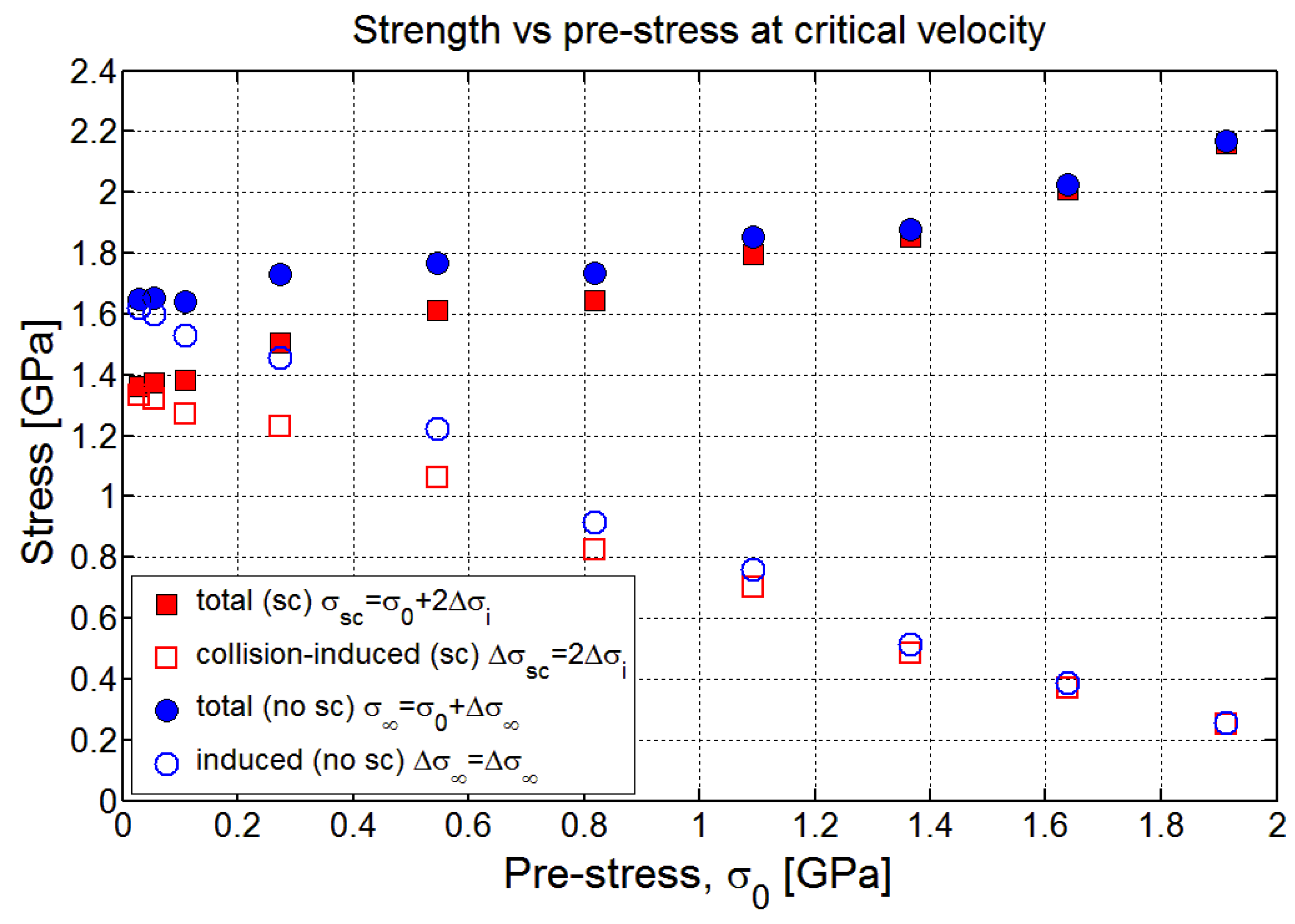

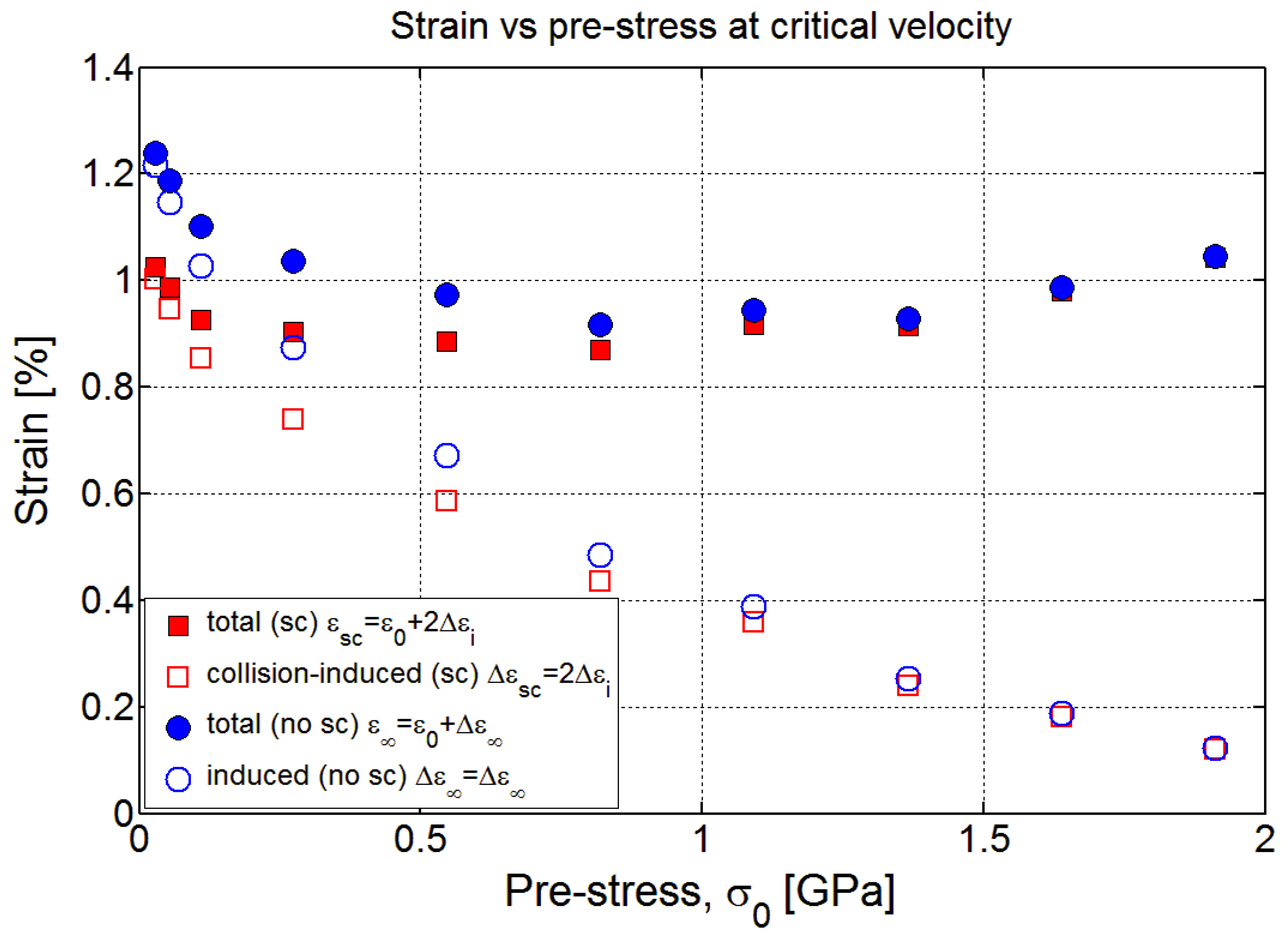

Utomo and colleagues [

23,

24,

25] performed yarn shooting experiments on Dyneema

® SK76 UHMWPE (1760 dtex) and Twaron

® (1760 dtex) yarns, and used a fixed 2.0 Kg weight to apply tension to the specimens. They used both an RCC flat-faced cylindrical projectile as well as a specially designed “saddle” projectile designed to capture the yarn (so it does not slide off the projectile nose) and to induce curvature in the yarn in the impact region, similar to that generated by a spherical projectile. They used the same theory as Prevorsek et al. [

20] and calculated Young’s moduli of about 198 GPa and 135 GPa for their Dyneema

® SK76 and Twaron

® yarns, respectively, with limiting impact velocities said to be 485 m/s and 380 m/s, respectively. They did not, however, attempt to report yarn tensile strength results, possibly because of the obscuring effects of yarn fraying associated with having untwisted yarns. The moduli they calculated were said to be higher than the quasi-static values by factors of 1.5 and 1.3, respectively, but again, are much lower than those obtained by Prevorsek et al. [

20] for materials of similar type.

Chocron et al. [

30] have reported data from yarn shooting experiments involving 0.3 caliber, FSP projectiles impacting Kevlar

® S5705, Dyneema

® SK65 and Zylon

® PBO yarns. For a range of incremental impact velocities, it was determined whether or not yarns fail immediately by evaluating frames from high speed video. This gave ‘bracket’ values for the so-called critical threshold velocities causing yarn failure, which were lower than expected. Regarding the transverse wave speed, Smith’s theoretical predictions were compared with both experimental values and numerical values generated using LS-Dyna software using orthotropic continuum elements to model the yarn. A good match was found between the transverse wave speeds obtained by the three methods. The ability to accurately predict the transverse wave speed in impacted yarns is critical to being able to model impact into complex single and multi-layer woven systems for comparison to experiments.

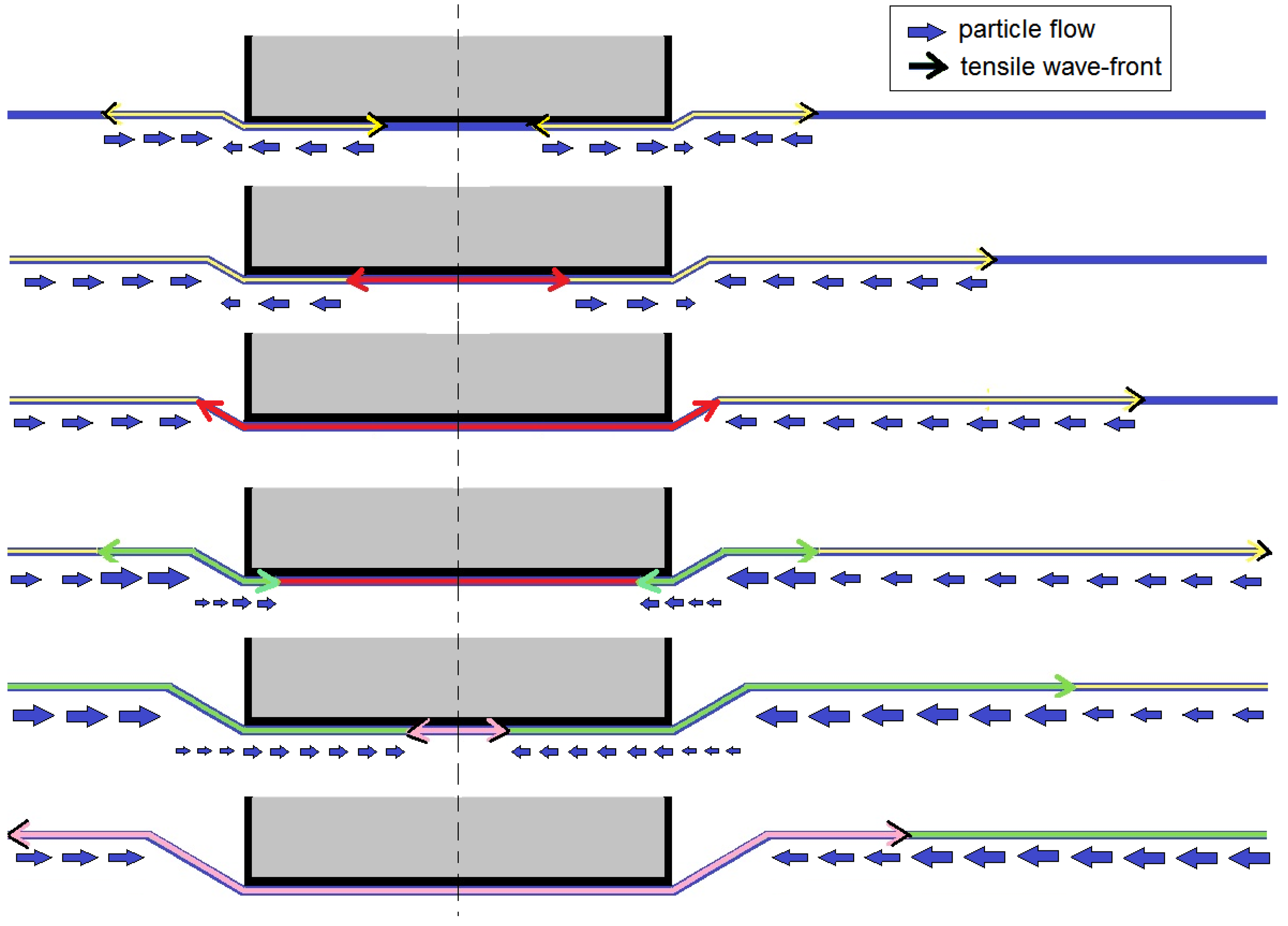

Reasons for their lower-than-expected, transverse critical impact velocities causing yarn failure were discussed in a companion paper by Walker and Chocron [

31]. (The paper acknowledges that this discrepancy was originally pointed out to the authors by van der Werff and Phoenix in 2010 including some discussion of the effect of strain doubling below a flat projectile having right-angle corners.) Walker and Chocron recast the classical theory in a rigorous form to derive that the strain in the yarn is uniform throughout the affected length also when the transverse wave passes. When a flat faced projectile strikes a yarn, they showed that the critical velocity is at least 11% lower than the classical solution predicts, when accounting for the effects of strain waves launched from the edges of the projectile that travel along the yarn inward and meet below the center of the projectile to double the strain. They proposed that, in addition, if the yarn were to ‘bounce off’ the projectile, the particle velocity would be doubled in the elastic case, and a potential 40% reduction of the critical impact velocity for yarn failure could be attributed to this effect. Such a bounce was seen in numerical modelling using the code, LS-Dyna, and was also experimentally reported by Field and Sun [

27] in the case of a nylon sphere striking a rubber band. Additional details on yarn modeling can be found in Chocron et al. [

32] who used four continuum elements for the yarn cross section and assumed a linear elastic, orthotropic constitutive model.

Advances in high speed photography have subsequently allowed very detailed observation of the yarn impact event as for instance in work by Song et al [

33,

34] for 450 denier Kevlar KM2 yarn where a Hopkinson bar was used for transverse impact testing. It is clearly visible that no bounce occurs, and additionally, non-uniform through-thickness compression of the yarn occurs before the back of the yarn begins to move. Further experimental observations by Hudspeth et al. [

35], in the form of video footage of impacted Kevlar KM2 yarns, also showed yarns being squashed without bounce. Results presented by Hudspeth et al. in a series of papers [

36,

37,

38], demonstrate that even in quasi-static transverse loading, an initial V-shaped angle causes a reduction in maximum transverse load for sharp indenters (razor blade and FSPs with small edge radius of curvature). This is attributed to a multi-axial, non-uniform stress state in the yarn, not accounted for in one-dimensional classical theory and variants. These works set the stage for involving non-homogenous, multi-axial stress states and wave interference effects to account for the reduction in critical velocity in yarn shooting experiments, as we later discuss and elaborate on in

Appendix A.

Advances in numerical modeling have also resulted from specifically resolving a yarn into individual filaments, as was done by Nilakantan [

39] who obtained a non-uniform stress state through the thickness and along the yarn under transverse impact. Sockalingam et al. [

40] modeled the transverse impact of a single Kevlar

® KM2 fiber using a sufficient number of elements over the cross section to resolve a non-uniform stress state using a linear, orthotropic material model. A sensitivity study of the effect of the longitudinal shear moduli indicated that flexural waves next to the projectile are observed for increasing shear stiffness. Sockalingam et al. also showed that to model the quasi-static transverse compression of Kevlar

® KM2 [

41,

42] and Dyneema

® SK76 [

43], it is crucial to include nonlinear inelastic behavior. If this approach is applied to transverse impact on 600 denier KM2 yarn with 400 individually modelled fibers (84 three-dimensional solid elements in the fiber cross section), a multi-axial stress state occurs with progressive loading through the thickness, as well as fiber squashing [

44]. From the model, the predicted critical impact velocity (causing yarn failure) is about 500 m/s, while the classical value is over 900 m/s. The critical velocity is also sensitive to the longitudinal shear modulus where higher moduli result in lower velocities. In this case failure starts at the back of the curved fiber bundle.