Comparative Evaluation of Sisal and Polypropylene Fiber Reinforced Concrete Properties

Abstract

:1. Introduction

2. Materials and Methods

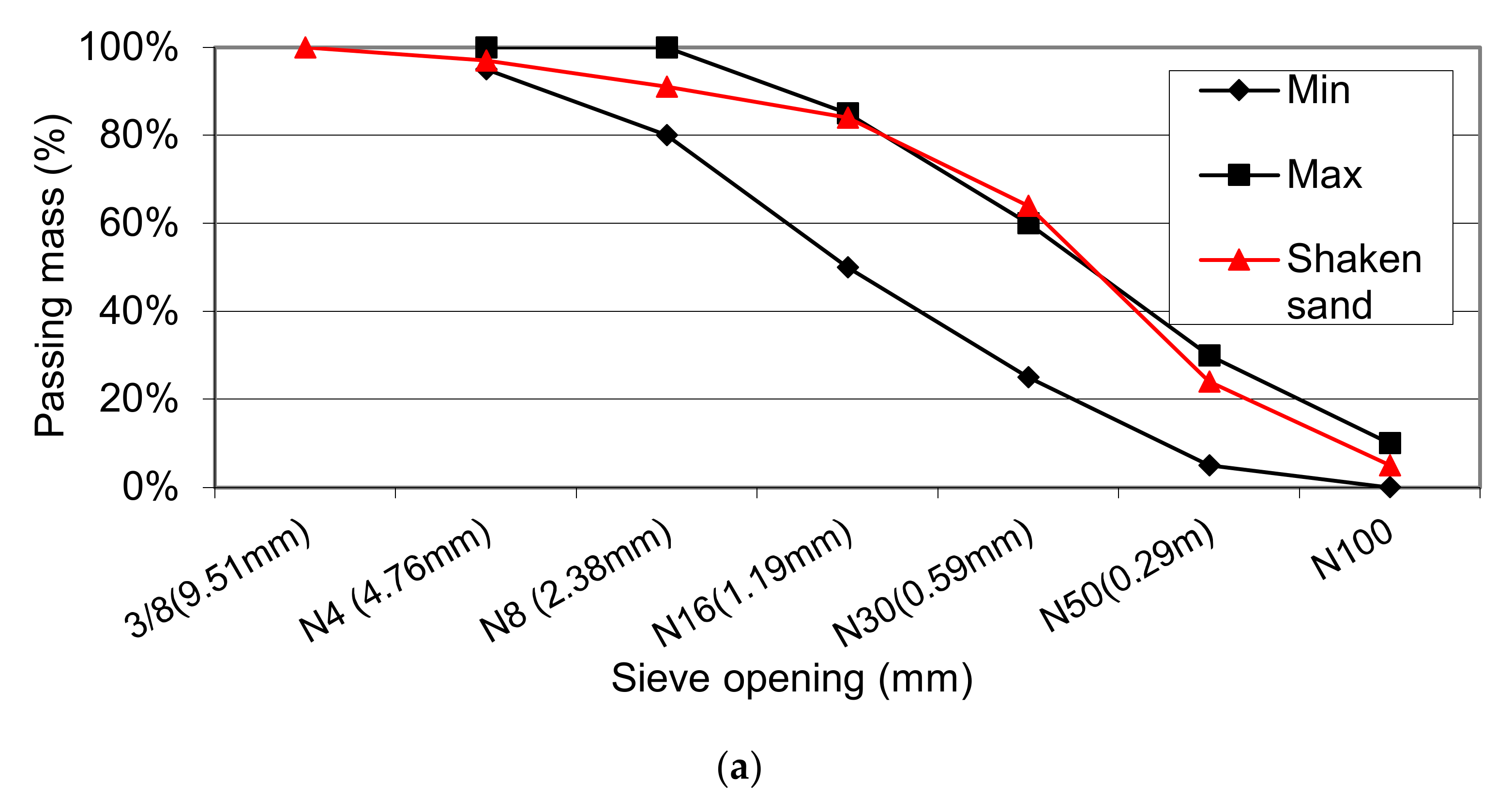

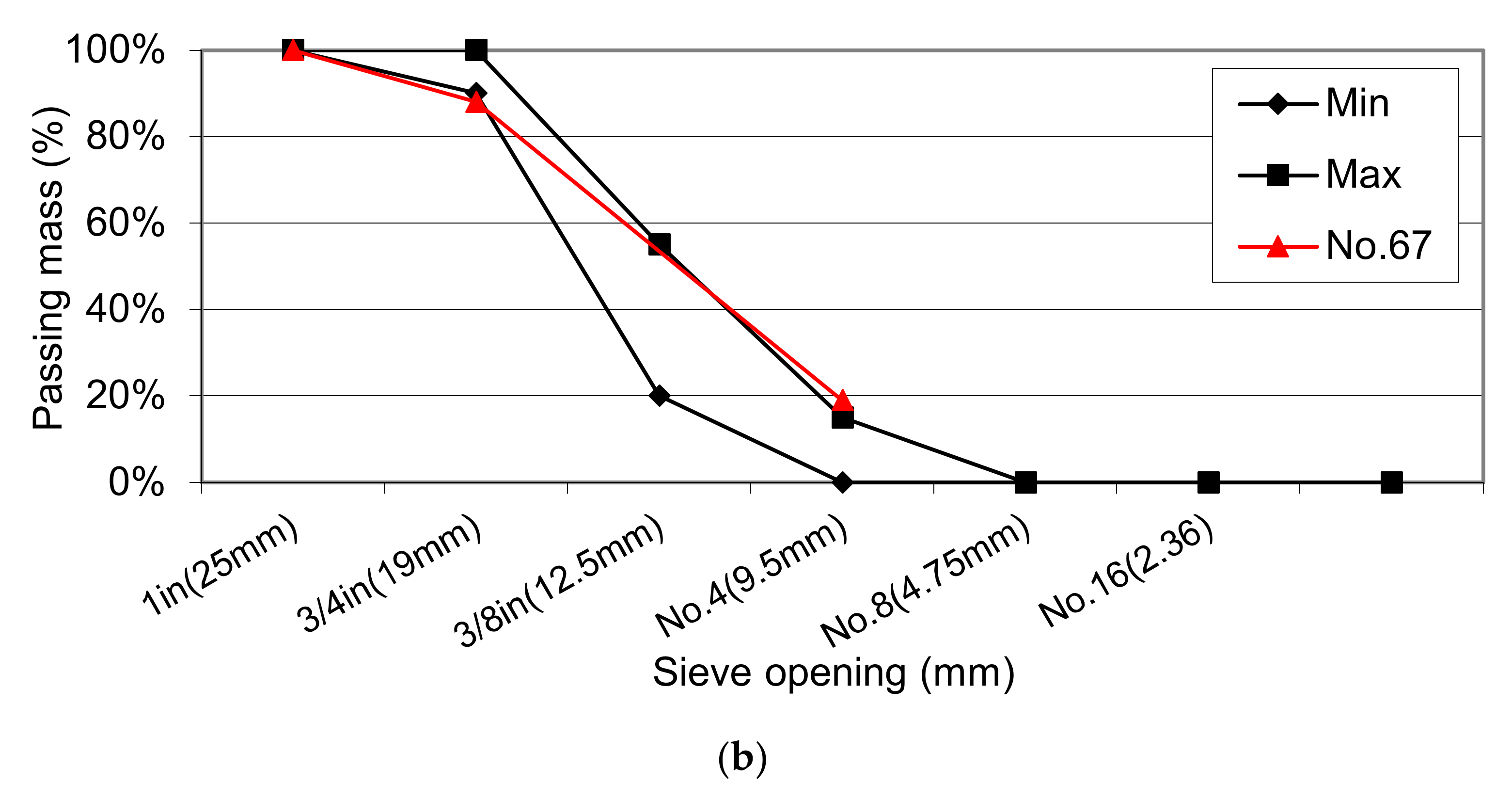

Materials

3. Results and Discussion

3.1. Workability

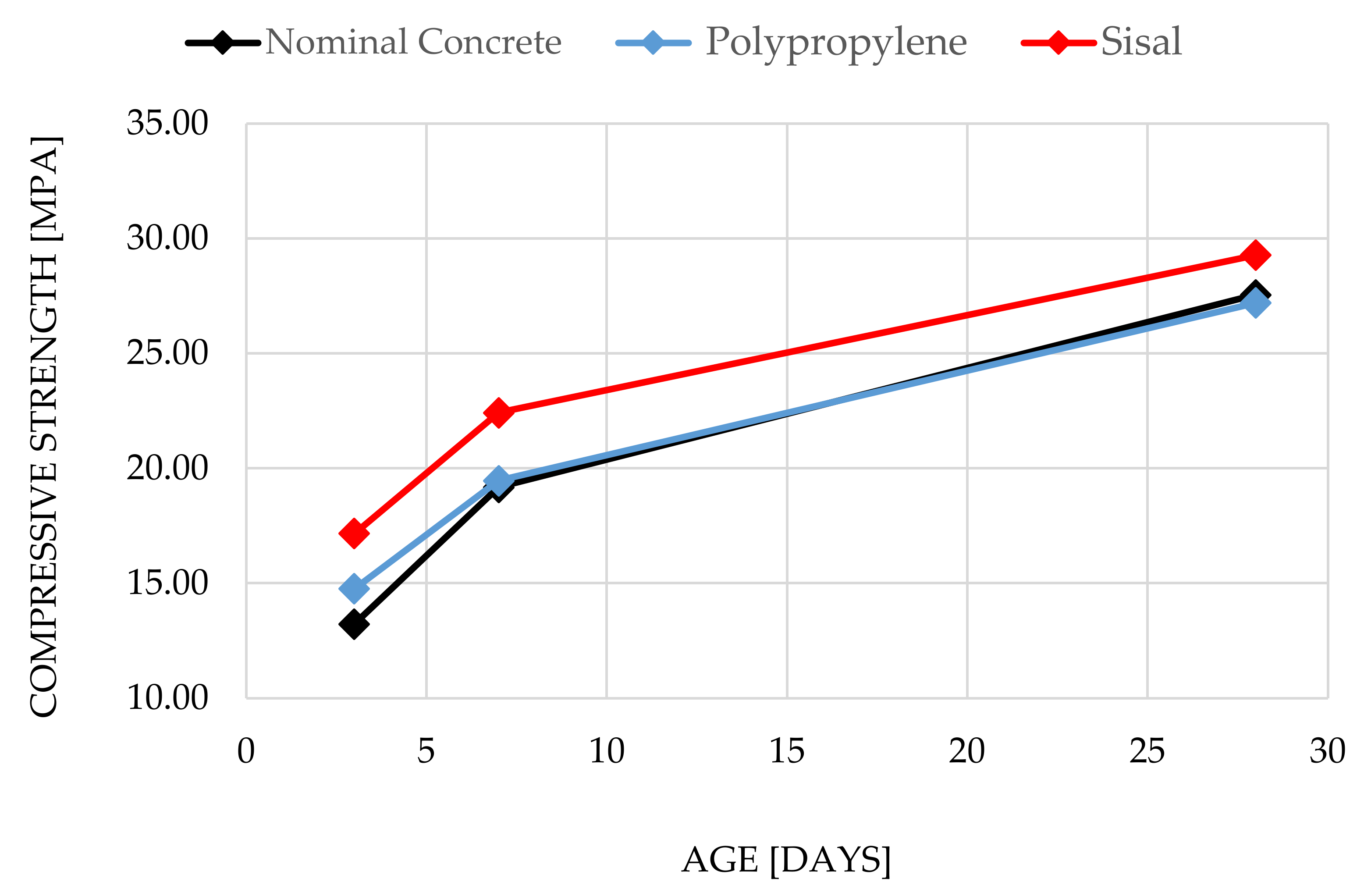

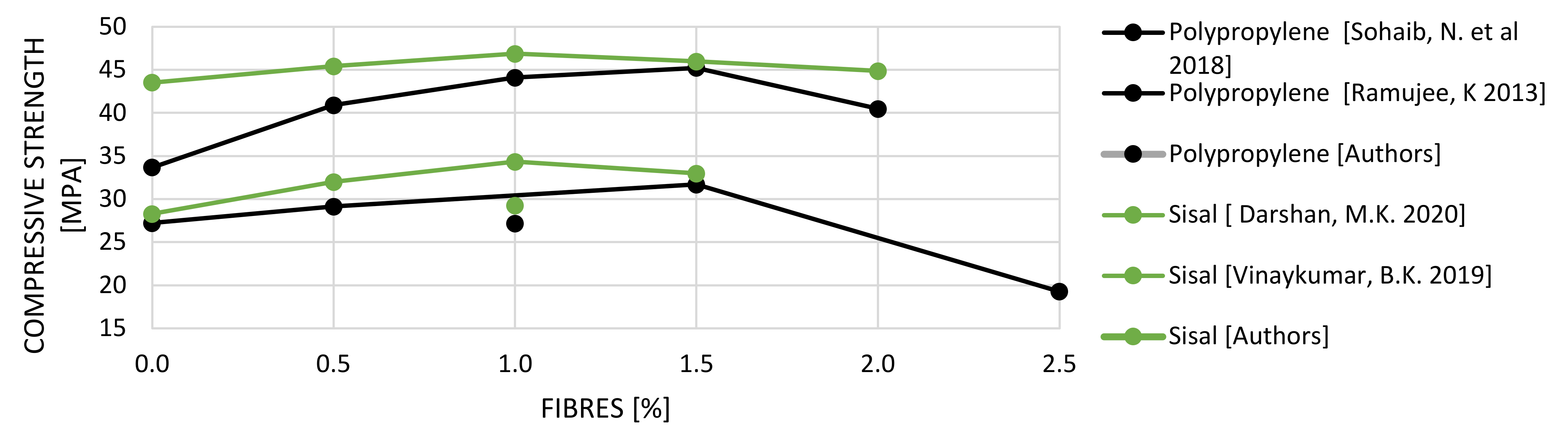

3.2. Compressive Strength

3.3. Flexural Strength

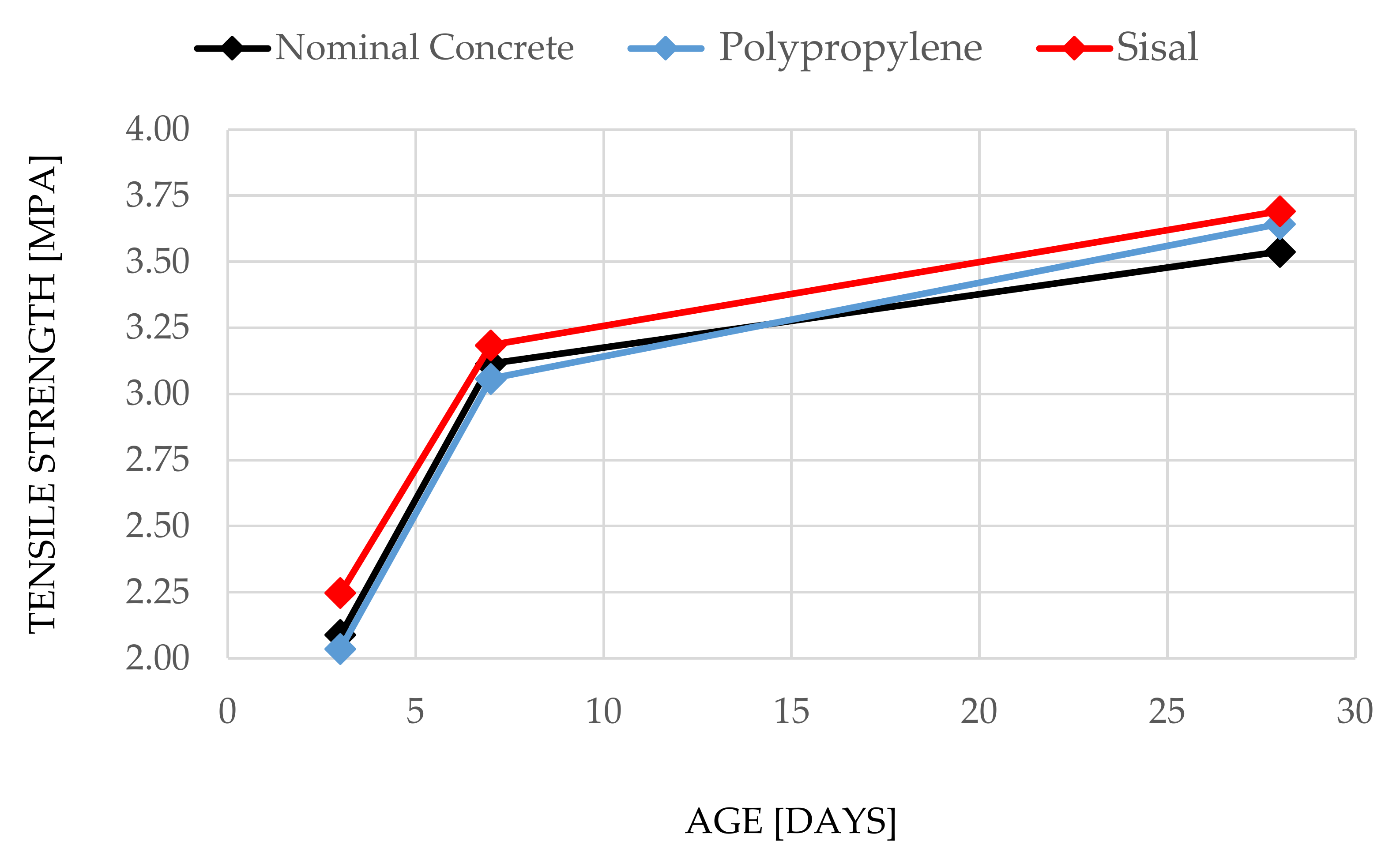

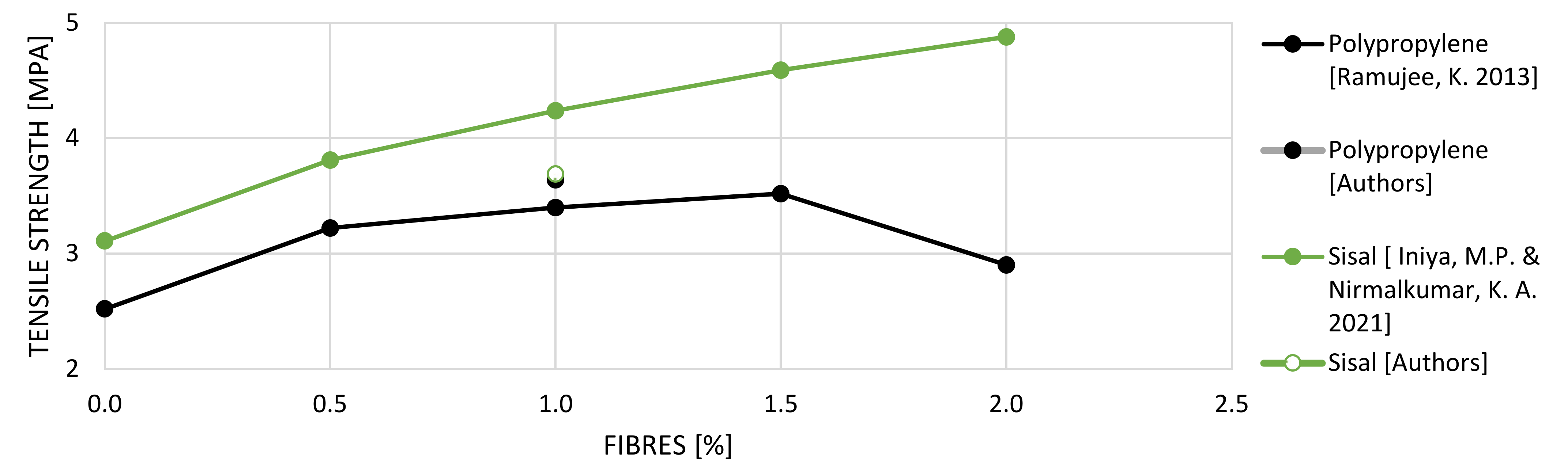

3.4. Tensile Strength

3.5. Pulse Velocity

3.6. Rebound Number

4. Environmental Aspects

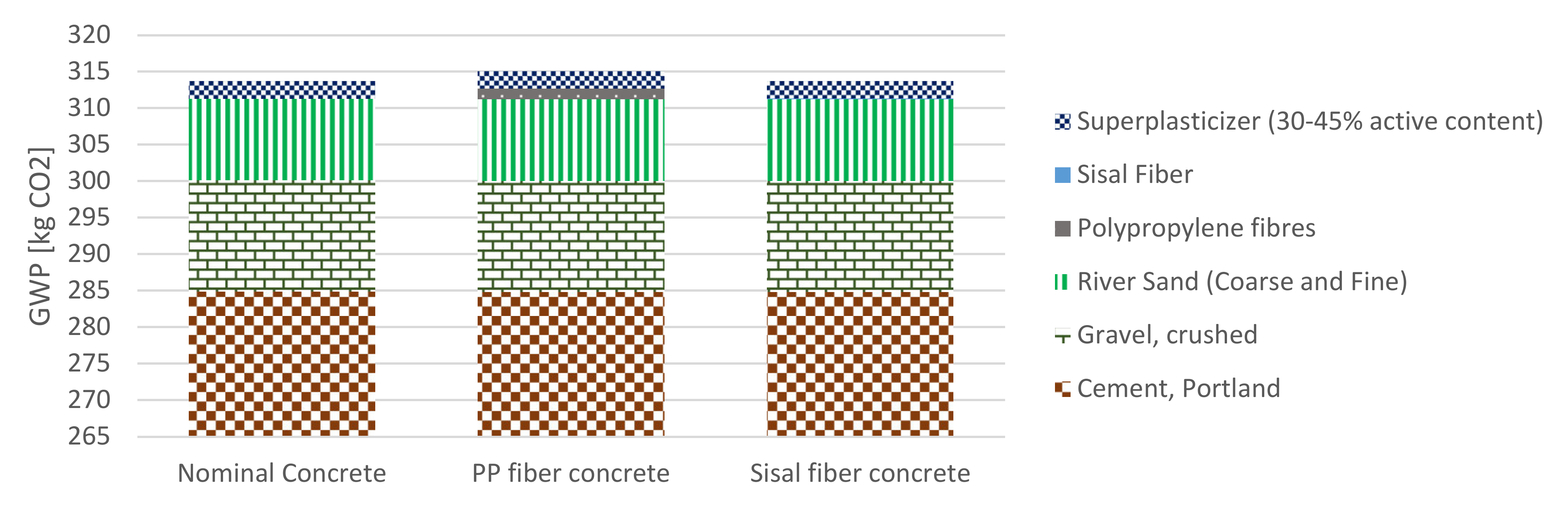

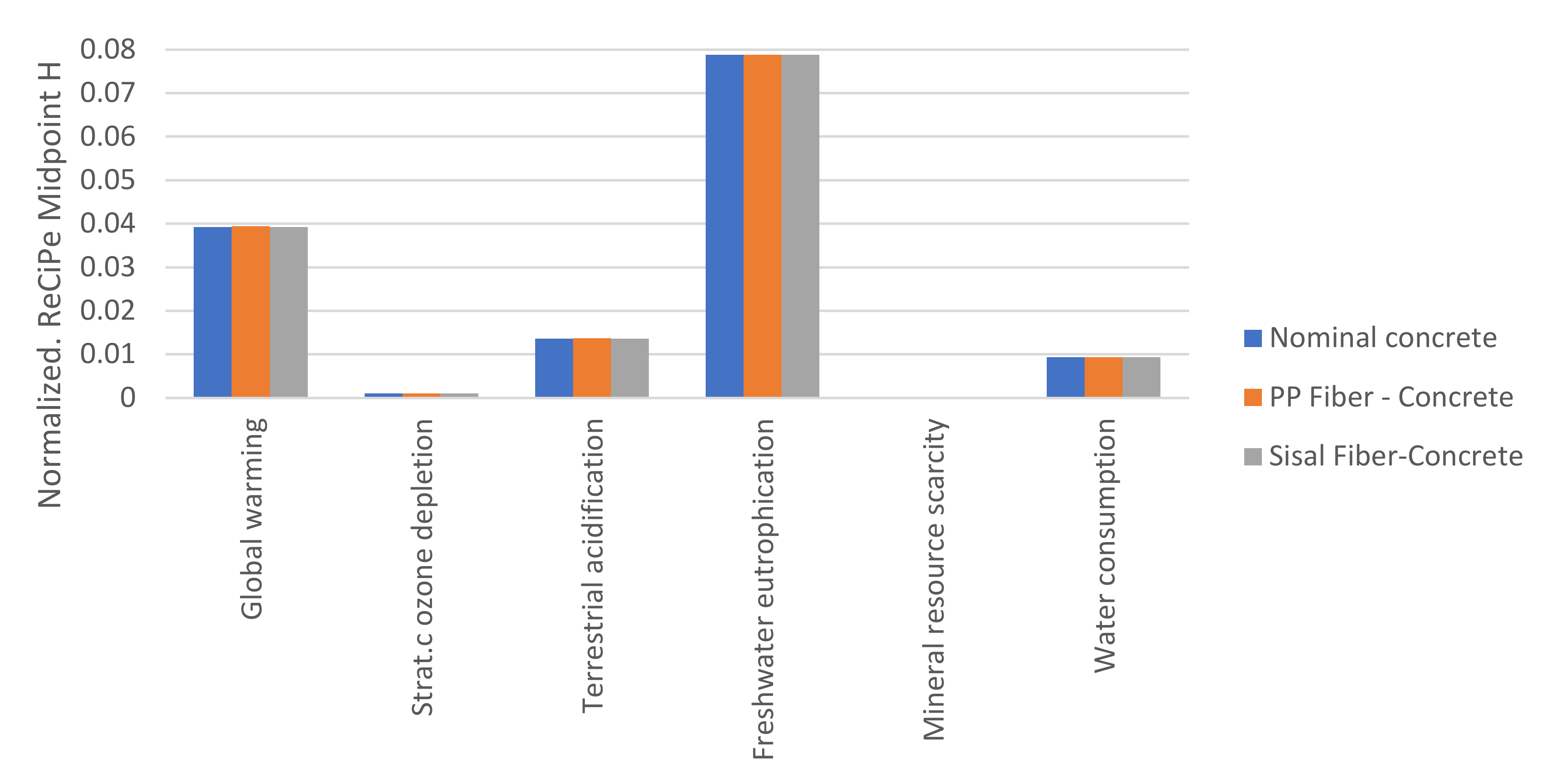

Life Cycle Assessment (LCA)

5. Conclusions

- The workability of the polypropylene fiber reinforced concrete was virtually identical to that of the nominal non-reinforced materials. On the other hand, the presence of sisal fibers reduces the workability by about 20% due to this fiber absorbing the added water, leaving less water in the mixture.

- The presence of sisal fibers in the concrete tends to improve the compression by around 6% compared with the nominal concrete, whilst the polypropylene fibers had minimal or no influence. Ultrasonic pulse velocity and rebound hammer tests largely confirm these results.

- For the flexural strength, the three mixes follow the same trend, but some improvement is obtained for both sisal and polypropylene fiber reinforced concrete. The increase in strength is likely to be associated with enhanced fracture toughness, providing ductility in tension, making these materials feasible for avoiding spalling under extreme loading.

- Based on the assessments from this paper, overall, from the two fibers investigated, the sisal fiber showed more promising results, indicating that natural fibers can be a more sustainable alternative to plastic fibers, providing a good balance between workability and strengths.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cha, S.L.; Jin, S.S.; An, G.H.; Kim, J.K. A prediction approach of concrete properties at early ages by using a thermal stress device. Constr. Build. Mater. 2018, 178, 120–134. [Google Scholar] [CrossRef]

- Zollo, R.F. Fiber-reinforced concrete: An overview after 30 years of development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Banthia, N. Fiber Reinforced Concrete; ACI SP-142; ACI: Detroit, MI, USA, 1994; Volume 91, p. 119. [Google Scholar]

- Ţibea, C.; Bompa, D.V. Ultimate shear response of ultra-high-performance steel fibre-reinforced concrete elements. Arch. Civ. Mech. Eng. 2020, 20, 49. [Google Scholar] [CrossRef] [Green Version]

- Bompa, D.V.; Xu, B.; Elghazouli, A.Y. Constitutive modelling and mechanical properties of cementitious composites incorporating recycled vinyl banner plastics. Constr. Build. Mater. 2021, 275, 122159. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Awal, A.A.; Yatim, J.B.M. The impact resistance and mechanical properties of concrete reinforced with waste polypropylene carpet fibres. Constr. Build. Mater. 2017, 143, 147–157. [Google Scholar] [CrossRef]

- Rubio-de Hita, P.; Pérez-Gálvez, F.; Morales-Conde, M.J.; Pedreño-Rojas, M.A. Reuse of plastic waste of mixed polypropylene as aggregate in mortars for the manufacture of pieces for restoring jack arch floors with timber beams. J. Clean. Prod. 2018, 198, 1515–1525. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Dolati-Milehsara, S.; Lotfi-Omran, O.; Sadeghi-Nik, A. The combined effects of waste Polyethylene Terephthalate (PET) particles and pozzolanic materials on the properties of self-compacting concrete. J. Clean. Prod. 2016, 112, 2363–2373. [Google Scholar] [CrossRef]

- Pereira, E.L.; de Oliveira Junior, A.L.; Fineza, A.G. Optimization of mechanical properties in concrete reinforced with fibers from solid urban wastes (PET bottles) for the production of ecological concrete. Constr. Build. Mater. 2017, 149, 837–848. [Google Scholar] [CrossRef]

- Bhavi, B.K.; Reddy, V.V.; Ullagaddi, P.B. Effect of different percentages of waste high density polyethylene (HDPE) fibres on the properties of fibre reinforced concrete. Nat. Environ. Pollut. Technol. 2012, 11, 461. [Google Scholar]

- Xu, B.; Bompa, D.V.; Elghazouli, A.Y.; Ruiz-Teran, A.M.; Stafford, P.J. Behaviour of rubberised concrete members in asymmetric shear tests. Constr. Build. Mater. 2018, 159, 361–375. [Google Scholar] [CrossRef]

- Kang, T.H.K.; Kim, W.; Kwak, Y.K.; Hong, S.G. Shear Testing of Steel Fiber-Reinforced Lightweight Concrete Beams without Web Reinforcement. ACI Struct. J. 2011, 108, 553–561. [Google Scholar]

- Di Prisco, M.; Plizzari, G.; Vandewalle, L. Fibre reinforced concrete: New design perspectives. Mater. Struct. 2009, 42, 1261–1281. [Google Scholar] [CrossRef]

- Hassan, A.M.T.; Jones, S.W.; Mahmud, G.H. Experimental test methods to determine the uniaxial tensile and compressive behaviour of ultra high performance fibre reinforced concrete (UHPFRC). Constr. Build. Mater. 2012, 37, 874–882. [Google Scholar] [CrossRef]

- ACI Committee 544.4-18; Guide to Design with Fiber-Reinforced Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2018.

- EPA. Plastics: Material-Specific Data; United States Environmental Protection Agency: Washington, DC, USA, 2018. [Google Scholar]

- PlasticsEurope. Plastics—The Facts 2019; PlasticsEurope: Brussels, Belgium, 2019. [Google Scholar]

- Yin, S.; Tuladhar, R.; Collister, T.; Combe, M.; Sivakugan, N.; Deng, Z. Post-cracking performance of recycled polypropylene fibre in concrete. Constr. Build. Mater. 2015, 101, 1069–1077. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Alavi Nia, A.; Hedayatian, M.; Nili, M.; Afrough Sabet, V. An experimental and numerical study on how steel and polypropylene fibers affect the impact resistance in fiber-reinforced concrete. Int. J. Impact Eng. 2012, 46, 62–73. [Google Scholar]

- Rokbi, M.; Baali, B.; Rahmouni, Z.E.A.; Latelli, H. Mechanical properties of polymer concrete made with jute fabric and waste marble powder at various woven orientations. Int. J. Environ. Sci. Technol. 2019, 16, 5087–5094. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.W.; Ye, L. Sisal fibre and its composites: A review of recent developments. Compos. Sci. Technol. 2000, 60, 2037–2055. [Google Scholar] [CrossRef]

- Ramalingam, S.; Murugasan, R.; Nagabhushana, M.N. Laboratory performance evaluation of environmentally sustainable sisal fibre reinforced bituminous mixes. Constr. Build. Mater. 2017, 148, 22–29. [Google Scholar] [CrossRef]

- Hari, R.; Mini, K.M. Mechanical and durability properties of sisal-Nylon 6 hybrid fibre reinforced high strength SCC. Constr. Build. Mater. 2019, 204, 479–491. [Google Scholar] [CrossRef]

- Sika. Sika CarboHeater; Sika: Baar, Switzerland, 2001; Available online: www.sika.com (accessed on 20 August 2021).

- Okeola, A.A.; Abuodha, S.O.; Mwero, J. Experimental investigation of the physical and mechanical properties of sisal fiber-reinforced concrete. Fibers 2018, 6, 53. [Google Scholar] [CrossRef] [Green Version]

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C.; Divyah, N. Mechanical characterisation of sustainable fibre-reinforced lightweight concrete incorporating waste coconut shell as coarse aggregate and sisal fibre. Int. J. Environ. Sci. Technol. 2021, 18, 1579–1590. [Google Scholar] [CrossRef]

- De Klerk, M.D.; Kayondo, M.; Moelich, G.M.; de Villiers, W.I.; Combrinck, R.; Boshoff, W.P. Durability of chemically modified sisal fibre in cement-based composites. Constr. Build. Mater. 2020, 241, 117835. [Google Scholar] [CrossRef]

- Sen, T.; Reddy, H.N.J. Flexural Strengthening of RC Beams Using Natural Sisal and Artificial Carbon and Glass Fabric Reinforced Composite System. Sustain. Cities Soc. 2014, 10, 195–206. [Google Scholar] [CrossRef]

- Holcim. HE Cement. Available online: https://www.holcim.com.ec/sites/ecuador/files/atoms/files/holcim_premiun.pdf (accessed on 15 August 2021).

- ASTM C1157; Standard Performance Specification for Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2020.

- Sika. Sika Sikament® N-100; Sika: Baar, Switzerland, 2001; Available online: www.ecu.sika.com (accessed on 29 July 2021).

- ACI PRC-211.1-91; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2009.

- Sohaib, N.; Seemab, F.; Sana, G.; Mamoon, R. Using Polypropylene Fibers in Concrete to achieve maximum strength. In Eighth International Conference on Advances in Civil and Structural Engineering—CSE 2018; Institute of Research Engineers and Doctors: New York, NY, USA, 2018. [Google Scholar]

- Ramujee, K. Strength properties of polypropylene fiber reinforced concrete. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 3409–3413. [Google Scholar]

- Iniya, M.P.; Nirmalkumar, K. A Review on Fiber Reinforced Concrete using sisal fiber. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1055, 012027. [Google Scholar] [CrossRef]

- Darshan, M.K.; Abhishek, I.; Gowda, J.P.; Mahadeva, C.G. Strength and analysis of sisal fibre in concrete. Int. Res. J. Eng. Technol. 2020, 7, 2581–2589. [Google Scholar]

- Jitendra, D.; Uttam, B.; Pallavi, P. Effect of fibre length and percentage of sisal on strength of concrete. Multidiscip. J. Res. Eng. Technol. 2016, 3, 923–932. [Google Scholar]

- Vinaykumar, B.K.; Prathap, D.; Varsha, P.; Pavan, K.J.; Supriya, C.L. Study on the Strength of Sisal Fiber Reinforced Concrete. Int. J. Innov. Res. Sci. Eng. Technol. 2019, 8, 5383–5389. [Google Scholar]

- León, M.P.; Ramírez, F. Morphological Characterization of Concrete Aggregates through Image Analysis. Rev. Ing. Constr. 2010, 25, 215–240. [Google Scholar] [CrossRef] [Green Version]

- ASTM C566-19; Standard Test Method for Total Evaporable Moisture Content of Aggregate by Drying. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C127-12; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C143; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C31; Standard Practice for Making and Curing Concrete Test Specimens in the Field. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C192; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C1231; Standard Practice for Use of Unbonded Caps in Determination of Compressive Strength of Hardened Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C78; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C597; Standard Test Method for Pulse Velocity through Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C805; Standard Test Method for Rebound Number of Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2018.

- Prasad, A.R.; Rao, K.M. Mechanical properties of natural fibre reinforced polyester composites: Jowar, sisal and bamboo. Mater. Des. 2011, 32, 4658–4663. [Google Scholar] [CrossRef]

- Mashrei, M.A.; Sultan, A.A.; Mahdi, A.M. Effects of polypropylene fibers on compressive and flexural strength of concrete material. Int. Res. J. Eng. Technol. 2018, 9, 2208–2217. [Google Scholar]

- Wu, Y. Flexural strength and behavior of polypropylene fiber reinforced concrete beams. J. Wuhan Univ. Technol. (Mater. Sci. Ed.) 2002, 17, 54–57. [Google Scholar] [CrossRef]

- Dhanasekar, K.; Manikandan, R.; Ancil, R.; Raman, V.; Selva Surender, P. Strength and durability evaluation of sisal fibre reinforced concrete. Int. Res. J. Eng. Technol. 2017, 8, 741–748. [Google Scholar]

- Garcia-Troncoso, N.; Crespo-Leon, K. Correlaciones Entre Ensayos no Destructivos y Destructivos para Hormigon de alta Resistencia Usando Agregados Calcareos. Master’s Thesis, Escuela Superior Politecnica del Litoral, Guayaquil, Ecuador, 2009. Available online: http://www.dspace.espol.edu.ec/handle/123456789/7961 (accessed on 20 May 2021).

- Yahya, Z.; Abdullah, M.M.A.B.; Mohd Ramli, N.; Burduhos-Nergis, D.D.; Abd Razak, R. Influence of Kaolin in Fly Ash Based Geopolymer Concrete: Destructive and Non-Destructive Testing. IOP Conf. Ser. Mater. Sci. Eng. 2018, 374, 012068. [Google Scholar]

- Morel, J.C.; Mesbah, A.; Oggero, M.; Walker, P. Building Houses with Local Materials: Means to Drastically Reduce the Environmental Impact of Construction. Build. Environ. 2001, 36, 1119–1126. [Google Scholar]

- De Andrade Silva, F.; Toledo Filho, R.D.; de Almeida Melo Filho, J.; de Moraes RegoFairbairn, E. Physical and Mechanical Properties of Durable Sisal Fiber–Cement Composites. Constr. Build. Mater. 2010, 24, 777–785. [Google Scholar]

- Arriagada Acuña, R. Estudio de la Oxidación Catalítica, en Fase Gaseosa de Propileno a Acroleina; Universidad Complutense de Madrid: Madrid, Spain, 1977. [Google Scholar]

- Meyer, C. The Greening of the Concrete Industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Oikonomou, N.D. Recycled Concrete Aggregates. Cem. Concr. Compos. 2005, 27, 315–318. [Google Scholar]

- Limbachiya, M.C.; Leelawat, T.; Dhir, R.K. Use of Recycled Concrete Aggregate in High-Strength Concrete. Mater. Struct. 2000, 33, 574–580. [Google Scholar]

- Sadati, S.; Khayat, K.H. Field Performance of Concrete Pavement Incorporating Recycled Concrete Aggregate. Constr. Build. Mater. 2016, 126, 691–700. [Google Scholar]

- Arutchelvi, J.; Sudhakar, M.; Arkatkar, A.; Doble, M.; Bhaduri, S.; Uppara, P.V. Biodegradation of Polyethylene and Polypropylene. Available online: http://nopr.niscair.res.in/bitstream/123456789/7326/4/IJBT%207%281%29%209-22.pdf (accessed on 5 December 2021).

- Badia, J.D.; Strömberg, E.; Kittikorn, T.; Ek, M.; Karlsson, S.; Ribes-Greus, A. Relevant Factors for the Eco-Design of Polylactide/Sisal Biocomposites to Control Biodegradation in Soil in an End-of-Life Scenario. Polym. Degrad. Stab. 2017, 143, 9–19. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- European Federation of Concrete Admixture Associations Ltd. (EFCA). Environmental Product Declaration: Concrete Admixtures—Plasticizers and Superplasticizers; Institut Bauen und Umwelt e.V.: Berlin, Germany, 2015. [Google Scholar]

- Broeren, M.L.M.; Dellaert, S.N.C.; Cok, B.; Patel, M.K.; Worrell, E.; Shen, L. Life cycle assessment of sisal fibre—Exploring how local practices can influence environmental performance. J. Clean. Prod. 2017, 149, 818–827. [Google Scholar] [CrossRef]

- Stoiber, N.; Hammerl, M.; Kromoser, B. Cradle-to-gate life cycle assessment of CFRP reinforcement for concrete structures: Calculation basis and exemplary application|Elsevier Enhanced Reader. J. Clean. Prod. 2021, 280, 124300. [Google Scholar] [CrossRef]

- Pillai, R.G.; Gettu, R.; Santhanam, M.; Rengaraju, S.; Dhandapani, Y.; Rathnarajan, S.; Basavaraj, A.S. Service life and life cycle assessment of reinforced concrete systems with limestone calcined clay cement (LC3). Cem. Concr. Res. 2019, 118, 111–119. [Google Scholar] [CrossRef]

- Yang, K.-H.; Song, J.-K.; Song, K.-I. Assessment of CO2 reduction of alkali-activated concrete|Elsevier Enhanced Reader. J. Clean. Prod. 2013, 39, 265–272. [Google Scholar]

- Sjunnesson, J. Life Cycle Assessment of Concrete. 2005. Available online: www.miljo.lth.se (accessed on 28 August 2021).

- Sala, S.; Crenna, E.; Secchi, M.; Pant, R. Global Normalisation Factors for the Environmental Footprint and Life Cycle Assessment; Publications Office of the European Union: Luxembourg, 2017; pp. 1–16. [Google Scholar] [CrossRef]

| Chemical Composition * | Portland cement clinker up to 95% |

| Calcium sulphate 0–5% | |

| Calcium Carbonate 0–5% | |

| Calcium Oxide 0–4% | |

| Magnesium Oxide 0–5% | |

| Crystalline Silica < 0.1% | |

| Physical Properties | Change in length per autoclave: −0.04% |

| Setting time, Vicat method: 150 min | |

| Air content of the mortar: 3% | |

Minimum compressive strength

|

| Materials | |

|---|---|

| Cement | 300 |

| Coarse aggregate | 895 |

| Unified sand | 567 |

| Shaken sand | 384 |

| Water | 149 |

| Water reducer | 2.70 |

| Property (-) | Compressive Strength (MPa) | Splitting Tensile Strength (MPa) | Flexural Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|

| Age (days) | 3 | 7 | 28 | 3 | 7 | 28 | 28 |

| Nominal | 13.2 ± 0.1 | 19.2 ± 0.2 | 27.6 ± 0.8 | 2.1 ± 0.1 | 2.9 ± 0.6 | 3.5 ± 0.1 | 4.4 ± 0.1 |

| Sisal | 17.2 ± 0.1 | 22.4 ± 0.1 | 29.3 ± 1.1 | 2.2 ± 0.3 | 2.9 ± 0.2 | 3.7 ± 0.1 | 4.5 ± 0.4 |

| Polypropylene | 14.8 ± 0.2 | 19.5 ± 1.3 | 27.2 ± 0.8 | 2.0 ± 0.1 | 2.8 ± 0.1 | 3.6 ± 0.1 | 4.5 ± 0.3 |

| Property | Ultrasonic Pulse Velocity (m/s) | Compressive Strength (MPa) |

|---|---|---|

| Nominal | 4000 | 28.5 |

| Sisal | 4400 | 33.6 |

| Polypropylene | 4300 | 38.2 |

| Property | Rebound Number | Compressive Strength (MPa) |

|---|---|---|

| Nominal | 25.0 | 25.3 |

| Sisal | 27.7 | 28.2 |

| Polypropylene | 27.3 | 29.3 |

| Stage | Activities | Environment | Environ-Mental Factor | Environmental Impact Identification |

|---|---|---|---|---|

| Extraction | Polymer extraction | Natural | Ground | Soil contamination due to compound residues. |

| Atmosphere | Propylene is a combustible gas that arises from the thermal reaction between different fuels. | |||

| Human | Health | The harmful effects on the health of workers by toxic gases. | ||

| Application and use | Preparation of fiber reinforced concrete | Natural | Water | The consumption of drinking water is showed in the production of the concrete, in the curing of the structures and in the washing of machinery used in the construction process. |

| Ground | Surplus stone resources, including the used polymer similar to plastic, as well as liquid residues that remain in the preparation of the concrete that seep into the ground. | |||

| Atmosphere | Dust that is produced in construction from the concrete mixer, from the movement of materials and gases emitted from the machines. | |||

| End-of-life disposal | Construction demolition | Natural | Ground | The residues generated by the demolition of the concrete pollute the ground mostly because of the fiber polymer. |

| Human | Ground | Common waste sites can proliferate disease vectors. | ||

| Extraction | Sisal fiber extraction | Natural | Water | Exhaustive use of the resource for watering the plant. |

| Ground | The exploitation of the ground is common, due to the plant takes 2 to 7 years to produce the fiber. | |||

| Application and use | Fiber preparation | Natural | Water | The manufacture of commercial natural fiber is done through an industrial process that requires washing the fiber. |

| Atmosphere | The machinery for the processing, washing and combing of the fiber emits polluting gases. | |||

| End-of-life disposal | Construction demolition | Natural | Ground | Despite the existence of contamination in the ground because of the concrete, using natural fiber is a benefit, since it is biodegradable. |

| Mixes | GWP [kg CO2] | ODP [kg CFC11] | AP [kg SO2] | FE [kg P] | WC [m3] |

|---|---|---|---|---|---|

| Nominal Concrete | 313.717464 | 6.2375 × 105 | 0.55660589 | 0.05117901 | 2.47942288 |

| PP Fiber—Concrete | 315.08268 | 6.2712 × 105 | 0.56086763 | 0.05116763 | 2.48008645 |

| Sisal Fiber—Concrete | 313.736294 | 6.2444 × 105 | 0.55714865 | 0.05119341 | 2.4792952 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acosta-Calderon, S.; Gordillo-Silva, P.; García-Troncoso, N.; Bompa, D.V.; Flores-Rada, J. Comparative Evaluation of Sisal and Polypropylene Fiber Reinforced Concrete Properties. Fibers 2022, 10, 31. https://doi.org/10.3390/fib10040031

Acosta-Calderon S, Gordillo-Silva P, García-Troncoso N, Bompa DV, Flores-Rada J. Comparative Evaluation of Sisal and Polypropylene Fiber Reinforced Concrete Properties. Fibers. 2022; 10(4):31. https://doi.org/10.3390/fib10040031

Chicago/Turabian StyleAcosta-Calderon, Samantha, Pablo Gordillo-Silva, Natividad García-Troncoso, Dan V. Bompa, and Jorge Flores-Rada. 2022. "Comparative Evaluation of Sisal and Polypropylene Fiber Reinforced Concrete Properties" Fibers 10, no. 4: 31. https://doi.org/10.3390/fib10040031

APA StyleAcosta-Calderon, S., Gordillo-Silva, P., García-Troncoso, N., Bompa, D. V., & Flores-Rada, J. (2022). Comparative Evaluation of Sisal and Polypropylene Fiber Reinforced Concrete Properties. Fibers, 10(4), 31. https://doi.org/10.3390/fib10040031