Measurement of Equivalent BRDF on the Surface of Solar Panel with Periodic Structure

Abstract

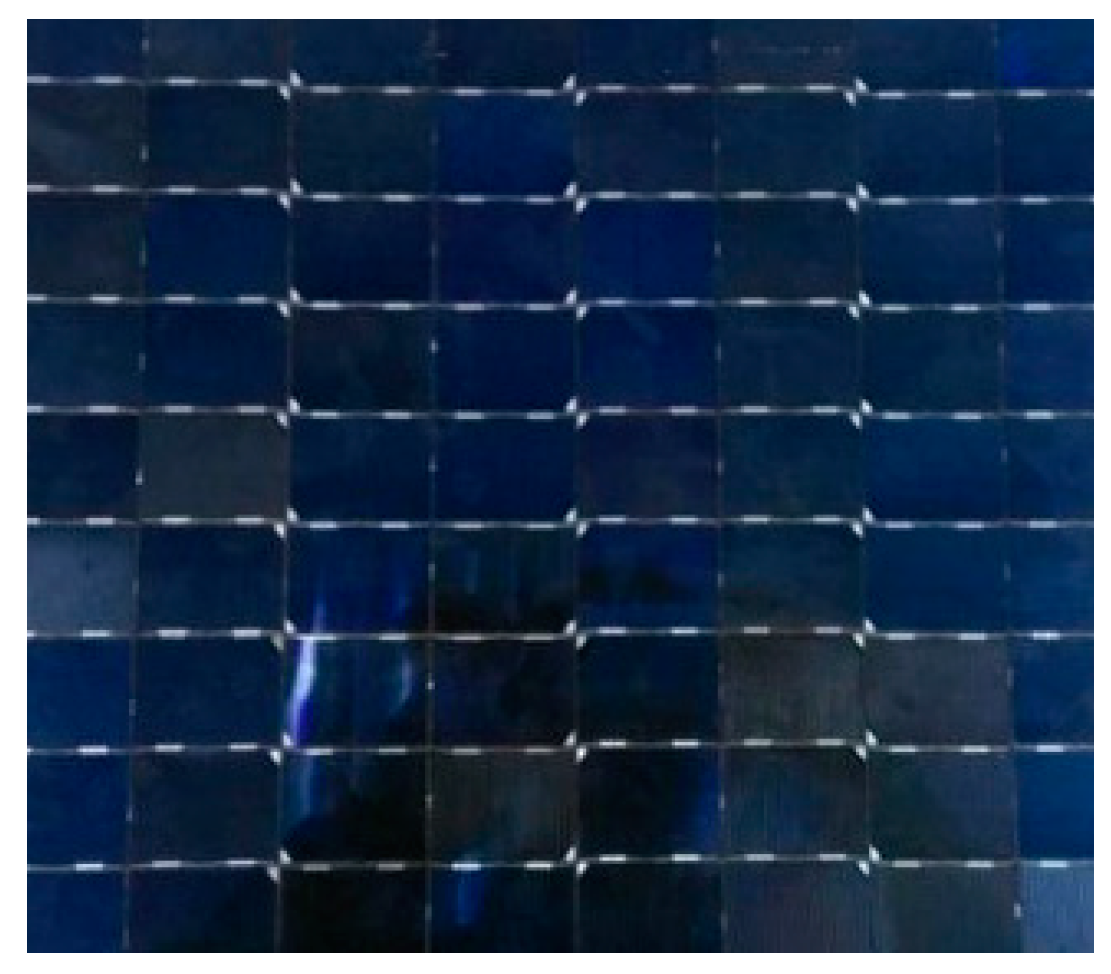

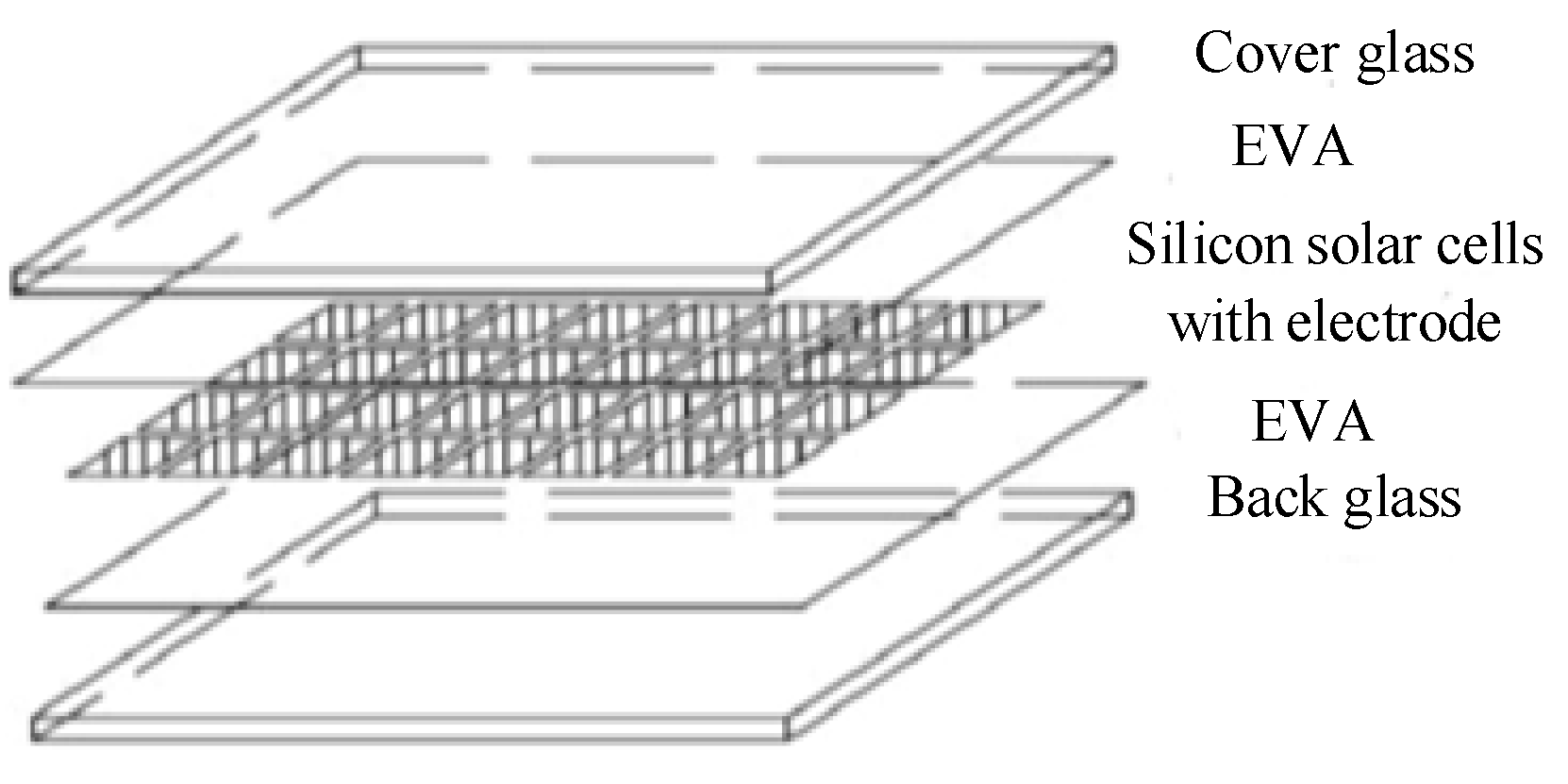

:1. Introduction

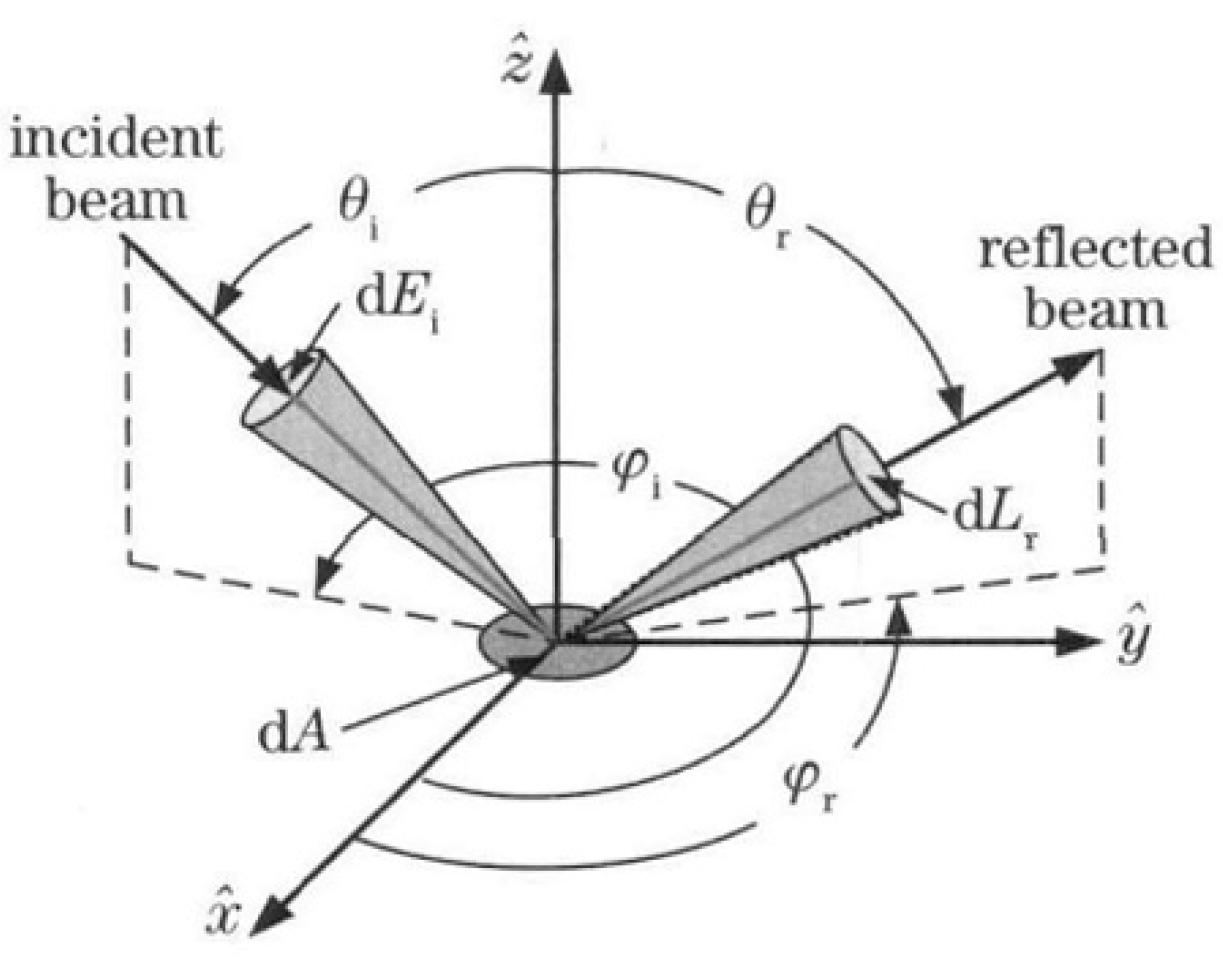

2. Equivalent BRDF of Complex Material Surface

2.1. BRDF of Uniform Material Surface

2.2. Definition of Equivalent BRDF

3. Measuring Principle and Precision Improvement Strategy

3.1. Measuring Principle

3.2. Measurement Accuracy Improvement Strategy

3.2.1. Spot Size Optimization

3.2.2. Measurement Radius Optimization

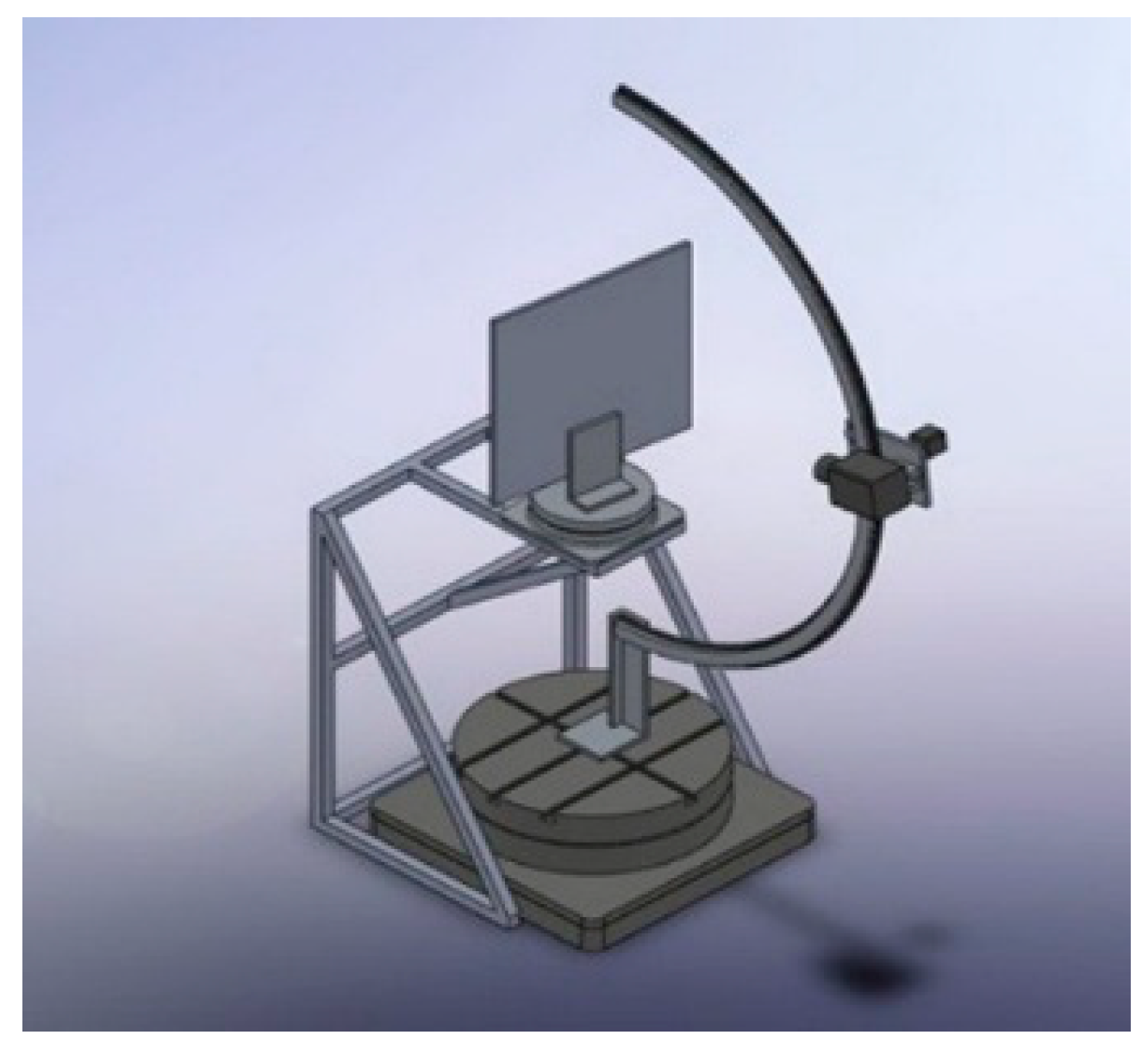

4. Measurement Equipment and Measurement Process

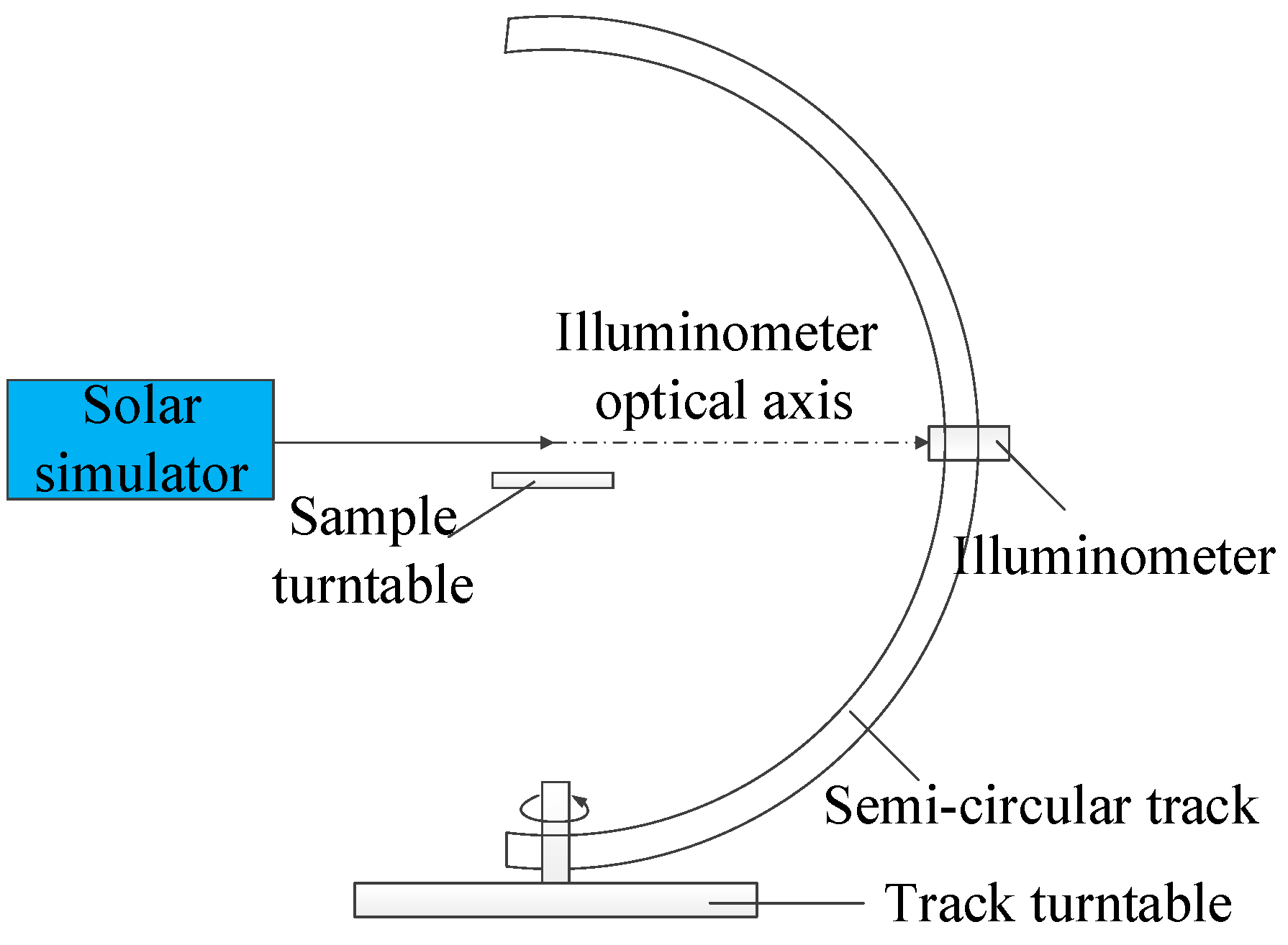

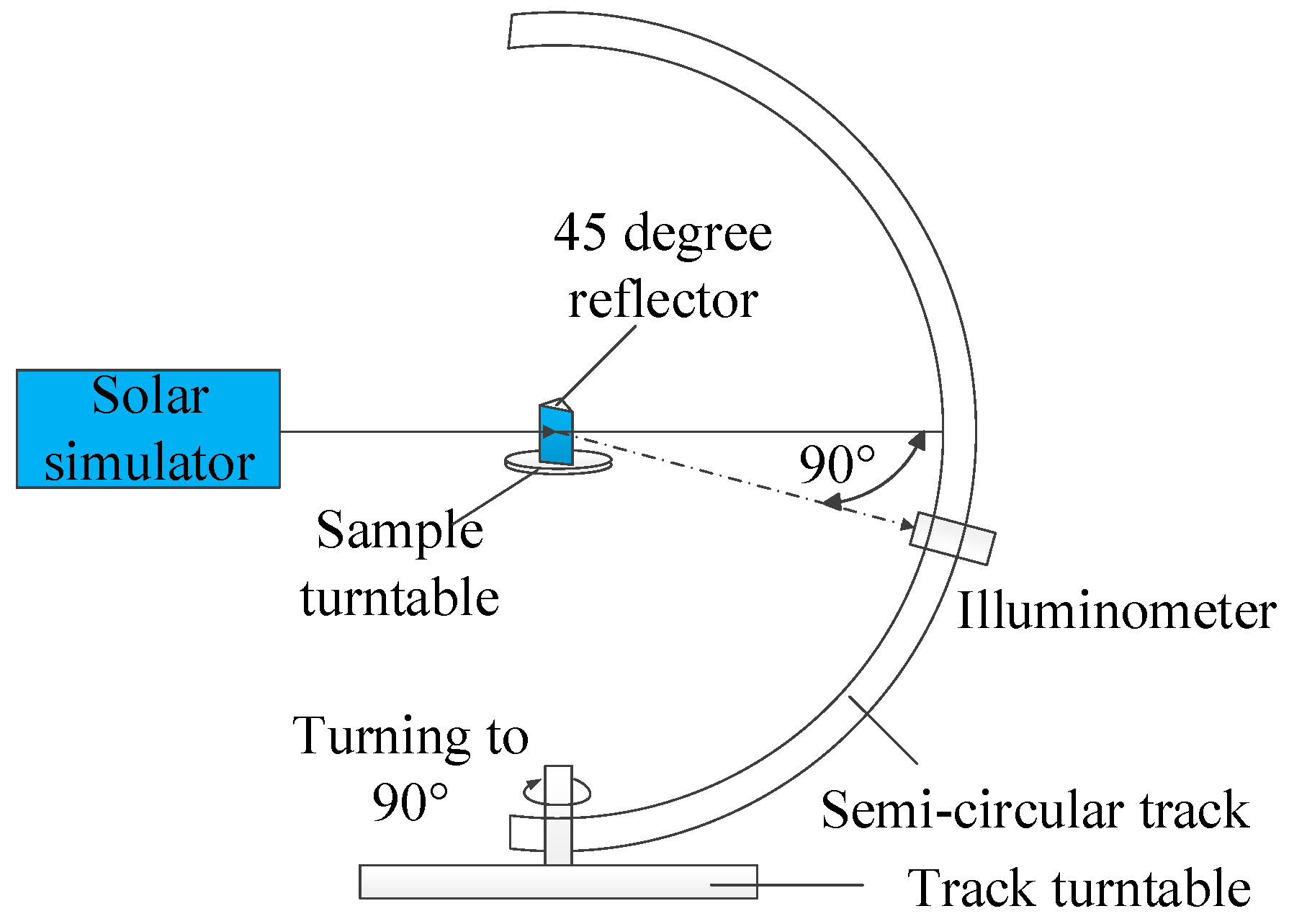

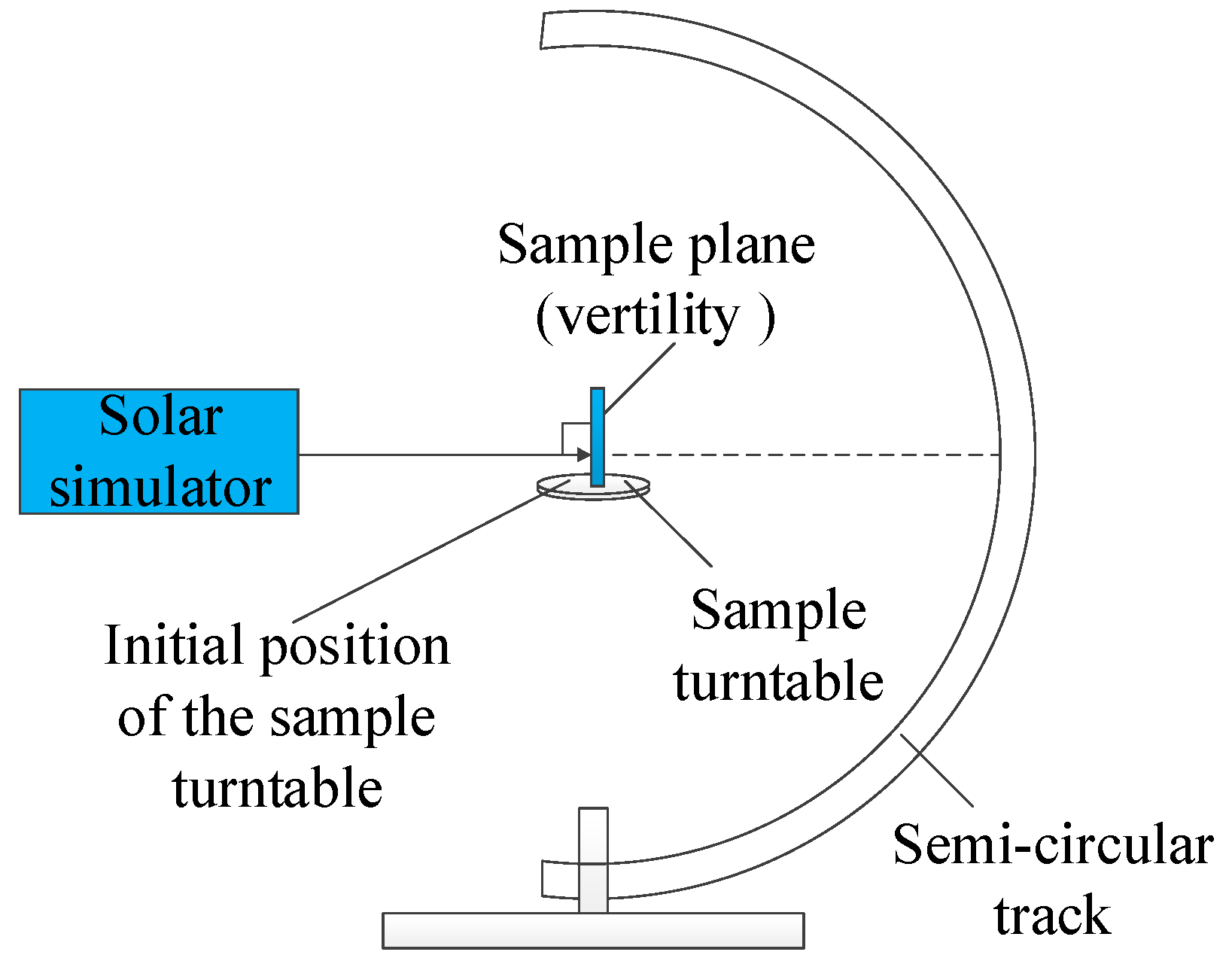

4.1. Measurement Equipment

4.2. Measurement Process

5. Measurement Results and Analysis

5.1. Spot Size Optimization Results

5.2. Measurement Results

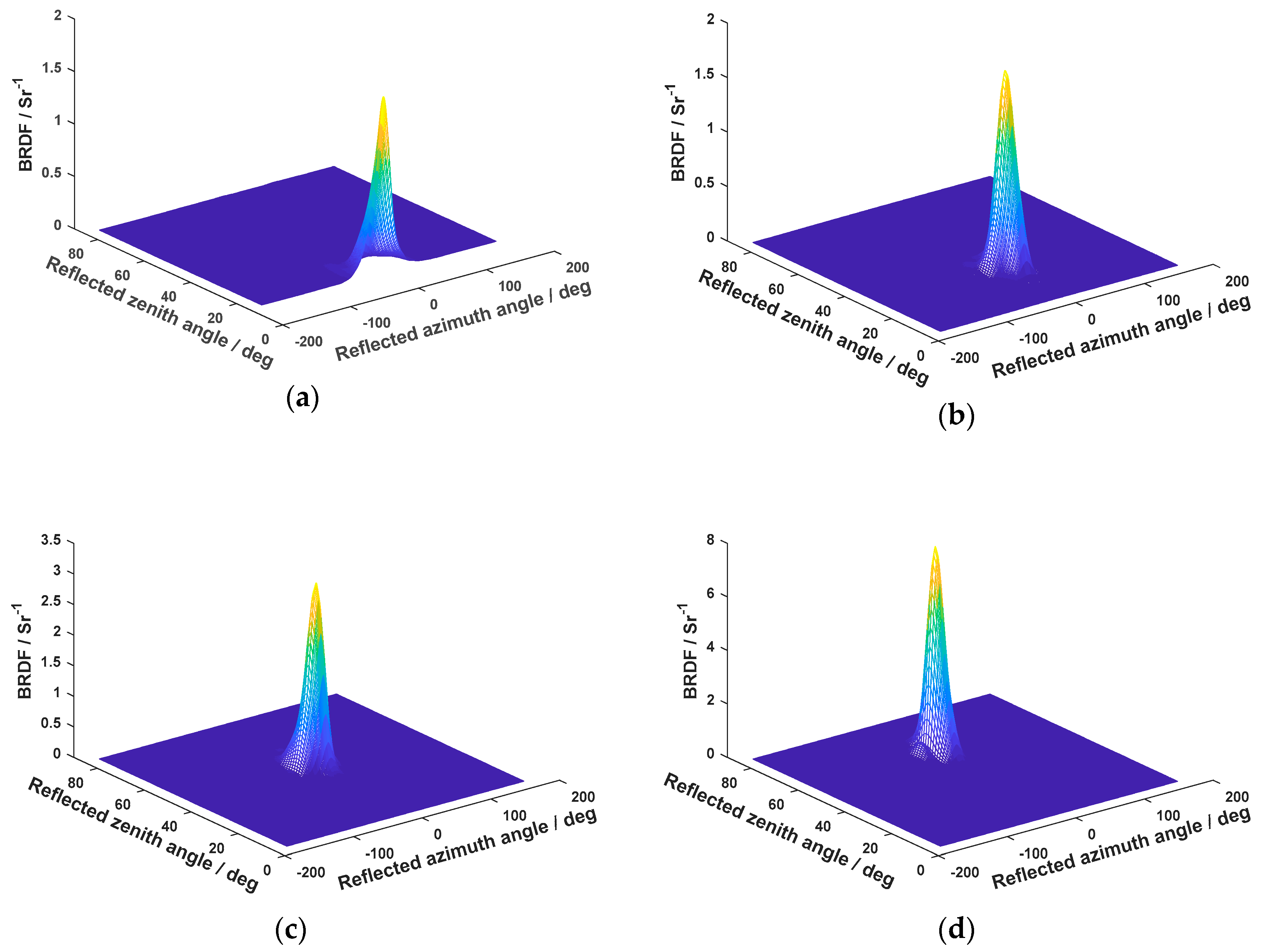

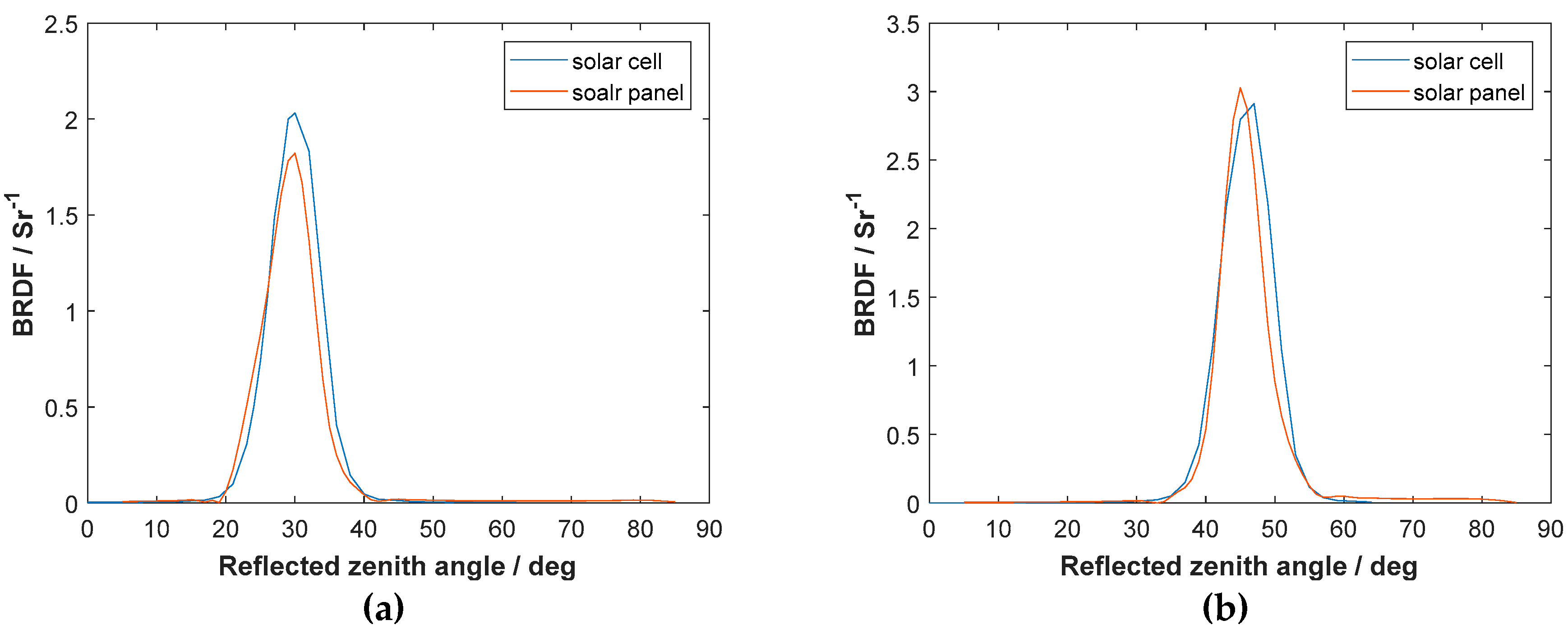

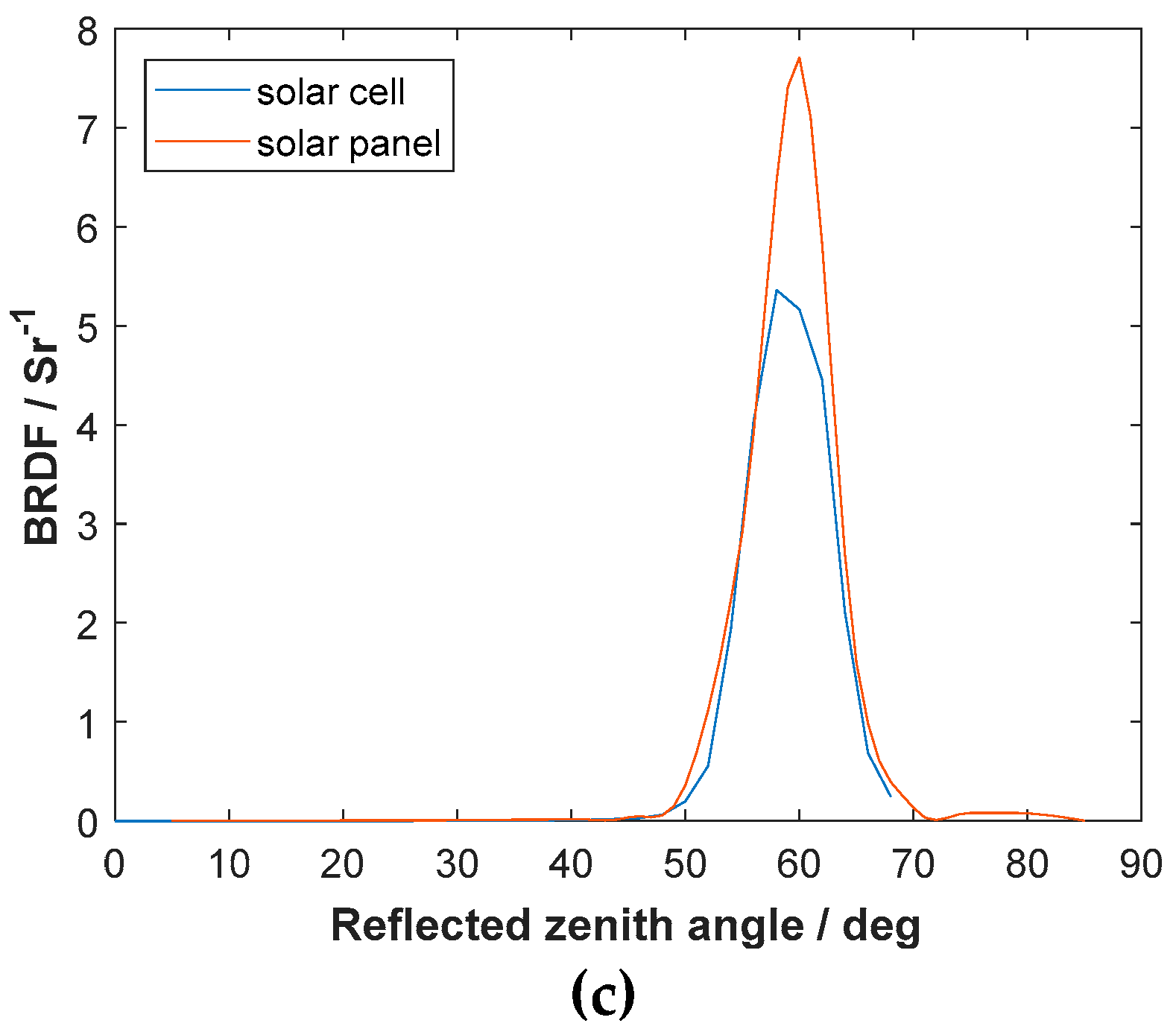

5.2.1. Measurement Results of Solar Panel

5.2.2. Comparison of BRDF Measurements Results

5.3. Measurement Error Analysis

5.3.1. The Mechanical System Error

5.3.2. The illumination System Error

5.3.3. The Detection System Error

5.3.4. The Artificial Error

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, B.; Liu, W.; Wei, Q.; Gao, M.; Lian, C.; Hu, J.; Wang, S. Analysis of scattering characteristic of the sample based on BRDF experiment measurements. Opt. Tech. 2006, 32, 180–182. [Google Scholar]

- Xue, Q.; Wang, S.; Yang, X.; Zhang, Z.; Li, F. Spectral radiance responsivities calibration of limb imaging spectrometer. J. Optoelectron. Laser 2010, 21, 406–410. [Google Scholar]

- Yu, T.; Wei, W.; Zhang, Y.; Zhang, Y.; Li, X.; Zheng, X.; Sun, L. Analysis of the BRDF Characteristics of Dunhuang Radiometric Calibration Site in the Spring. Acta Photonica Sin. 2018, 47, 0612004. [Google Scholar]

- Wang, A.; Zhang, H.; Wu, Z.; Feng, J.; Zeng, Z. Experiment measurements and optimal modeling of goal surface’s visible spectrum BRDF. Opt. Tech. 2008, 34, 655–658. [Google Scholar]

- Yuan, Y.; Sun, C.; Zhang, X. Measuring and Modeling the Spectral Bidirectional Reflection Distribution Function of Space Target’s Surface Material. Acta Photonica Sin. 2010, 59, 2097–2103. [Google Scholar]

- Zhang, W.; Wang, H.; Wang, Z. Measurement of Bidirectional Reflection Distribution Function on Material Surface. Chin. Opt. Lett. 2009, 7, 88–91. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, F.; Wang, Z.; Wang, H. Measuring of spectral BRDF using fiber optic spectrometer. In Proceedings of the 5th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Optoelectronic Materials and Devices for Detector, Imager, Display, and Energy Conversion Technology, Dalian, China, 26–29 April 2010. [Google Scholar]

- Wang, H.; Zhang, W.; Dong, A. Measurement and Modeling of Bidirectional Reflectance Distribution Function (BRDF) on Material Surface. Meas. J. Int. Meas. Confed. 2013, 46, 3654–3661. [Google Scholar] [CrossRef]

- Hou, Q.; Zhi, X.; Zhang, H.; Zhang, W. Modeling and Validation of Spectral BRDF on Material Surface of Space Target. In Proceedings of the International Society for Optical Engineering, Beijing, China, 8–11 October 2014. [Google Scholar]

- Wang, F.; Zhang, W.; Wang, H. Reflection Characteristics of On-orbit Satellite Based on Bidirectional Reflectance Distribution Function. Opto-Electron. Eng. 2011, 38, 6–12. [Google Scholar]

- Wang, H.; Zhang, W. Visible Imaging Characteristics of the Space Target Based on Bidirectional Reflection Distribution Function. J. Mod. Opt. 2012, 59, 547–554. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Dong, A. Modeling and Validation of Photometric Characteristics of Space Targets Oriented to Space-Based Observation. Appl. Opt. 2012, 51, 7810–7819. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Zhao, J.; Xu, L.; Liu, F.; Li, Z. BRDF Measurement of Matte Coating and Its Application. Opt. Precis. Eng. 2016, 24, 2627–2635. [Google Scholar] [CrossRef]

- Zhao, M.; Si, F.; Lu, Y.; Wang, S.; Jiang, Y.; Zhou, H.; Liu, W. Bidirectional Reflectance Distribution Function of Space-Borne Quartz Volume Diffuser. Spectrosc. Spectr. Anal. 2016, 36, 1565–1570. [Google Scholar]

- Han, G.; Lin, G.; Wang, L.; Li, B.; Cao, D. Measurement of Far-Ultraviolet BRDF for Solar Diffuser. Acta Photonica Sin. 2017, 46, 159–166. [Google Scholar]

- Li, M.; Zong, X. In-Lab System-Level BRDF Measurement Method of Calibration Diffuser. Infrared Laser Eng. 2017, 46, 0117004. [Google Scholar]

- Shi, W.; Zheng, J.; Li, Y.; Li, X.; An, Q. Measurement and Modeling of Bidirectional Reflectance Distribution Function on Cutting Surface. Acta Optica Sin. 2018, 38, 1029001. [Google Scholar]

- Nicodemus, F.E. Reflectance Nomenclature and Directional Reflectance and Emissivity. Appl. Opt. 1970, 9, 1474–1475. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Xie, L.; Li, Y.; Tapas K., M.; Wei, Q.; Hao, X.; He, B. Experimental and Theoretical Research on Bending Behavior of Photovoltaic Panels with a Special Boundary Condition. Energies 2018, 11, 3435. [Google Scholar] [CrossRef]

| Number | MAD | ||

|---|---|---|---|

| 1 | 0° | 0°~2.86° | 2.86° |

| 2 | 30° | 27.47°~32.43° | 2.53° |

| 3 | 60° | 58.50°~61.37° | 1.50° |

| Name | Type | Parameter and Specification |

|---|---|---|

| Solar simulator | 94123A | Collimated Angle: < 90° |

| The power of xenon lamp: 1600 W | ||

| Irradiated area:300 mm × 300 mm | ||

| High-intensity light illuminometer | TES1339 | Measurement range: 0.01~999900 lx |

| Measurement error: ≤ 3% | ||

| Low-intensity light illuminometer | PHOTO-2000m | Measurement range: 10−6 ~1.0 lx |

| Measurement error: ≤ 4% | ||

| Precise rotary platform | MRS102 | Angle Resolution: 0.00022° |

| Displacement Precision: <10 s of arc |

| Diameter: 240 mm | Diameter: 170 mm | Diameter: 120 mm | Diameter: 120 mm (Translate Half Silicon Wafer) | |

|---|---|---|---|---|

| Vertical projection area (m2) | 0.045 | 0.023 | 0.011 | 0.011 |

| Incident illuminance (lx) | 25,500 | 14,500 | 6500 | 6500 |

| 0.235019 | 0.222273 | 0.209133 | 0.208671 | |

| 0.052507 | 0.040240 | 0.033764 | 0.034827 | |

| 0.022246 | 0.019436 | 0.009998 | 0.009633 | |

| 0.464673 | 0.401097 | 0.374244 | 0.371373 | |

| 0.005353 | 0.005210 | 0.000872 | 0.000839 | |

| 1.325325 | 1.258932 | 1.145356 | 1.148140 |

| Solar Cells(°) | Solar Panels(°) | |

|---|---|---|

| 30° | 8.4108 | 8.1226 |

| 45° | 8.7396 | 6.7717 |

| 60° | 8.8016 | 7.3001 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Q.; Wang, Z.; Su, J.; Tan, F. Measurement of Equivalent BRDF on the Surface of Solar Panel with Periodic Structure. Coatings 2019, 9, 193. https://doi.org/10.3390/coatings9030193

Hou Q, Wang Z, Su J, Tan F. Measurement of Equivalent BRDF on the Surface of Solar Panel with Periodic Structure. Coatings. 2019; 9(3):193. https://doi.org/10.3390/coatings9030193

Chicago/Turabian StyleHou, Qingyu, Zhile Wang, Jinyu Su, and Fanjiao Tan. 2019. "Measurement of Equivalent BRDF on the Surface of Solar Panel with Periodic Structure" Coatings 9, no. 3: 193. https://doi.org/10.3390/coatings9030193

APA StyleHou, Q., Wang, Z., Su, J., & Tan, F. (2019). Measurement of Equivalent BRDF on the Surface of Solar Panel with Periodic Structure. Coatings, 9(3), 193. https://doi.org/10.3390/coatings9030193