1. Introduction

The Global Status Report on Road Safety 2018, launched by the World Health Organization (WHO) in December 2018, highlights that the number of annual road traffic deaths has reached 1.35 million [

1]. To put this in context, that is almost 4000 per day or 154 per hour or 2.5 lives lost every minute. Between 20 and 50 million more people suffer non-fatal injuries, with many incurring a disability because of their injury. The WHO further reported that, globally, traffic collisions cost most governments 3% of their gross domestic product.

High friction surfacing (HFS) saves lives. HFS, sometimes referred to as anti-skid, is a skid resistant surfacing system bonded to a pavement surface in areas where the risk of a vehicle skidding out of control is high. Examples would be approaches to traffic lights, pedestrian crossings, roundabouts, steep inclines and dangerous bends where sudden or excessive braking or cornering may be required. HFS systems give superior performance over other road surfacing materials in terms of skidding resistance (i.e., grip) and, as a result, increase road safety to the road user at high risk locations. Research has shown that the number of fatalities and serious injuries can be substantially reduced when HFS systems are installed at high risk locations [

2,

3,

4].

The aggregate specified for use in HFS systems, calcined bauxite, is available in few locations throughout the world. Calcined bauxite has unique properties which gives it excellent performance in terms of skidding resistance. Geologically, the grade of bauxite suitable for use in HFS systems is not available in parts of the world such as Europe or North America where demand is greatest. The two main sources are China and Guyana, in South America. As a result, calcined bauxite is expensive and has negative environmental impacts due to the processes involved, in mining the raw bauxite, in the calcination process involved in altering the bauxite properties to give it unique skid resistance properties, and in the shipping and other transport costs involved to get to its desired locations around the world.

The HFS industry in the UK, USA and Ireland use refractory grade calcined bauxite imported predominantly from China. Other sources include Guyana and India. It is estimated that China produces 95% of the globe’s refractory bauxite for various industries [

5]. In recent years the calcined bauxite industry in China has undergone considerable change due to a range of political, environmental and economic factors. As part of Chinese government policy to clean up the environment and build a moderately prosperous society by 2020 [

6], a new environmental tax law has been implemented. The new law has resulted in a series of strict environmental inspections on mineral producing facilities to reduce industrial pollution levels and crack down on illegal mining operations. Throughout 2017 and 2018 environmental inspections led to many calcined bauxite production facilities being either temporarily or permanently shut down [

7].

The closures were related to the requirements for the industry to upgrade its calcining facilities, at a considerable cost. The costs associated with the Government’s drive to upgrade production plants from coal to natural gas fired kilns has led to many producers being forced to close their businesses [

8]. Furthermore, the crackdown on illegal businesses and the stricter controls on the use of explosives have further compounded the industry. All these factors have inevitably led to supply shortages which have resulted in price rises within the market. Calcined bauxite is predicted to experience continued tight supply and high prices throughout 2019. Although refractory bauxite is currently excluded from US trade tariffs, there is the risk over the coming years that the implementation of such tariffs, due to a US-China trade war, could lead to further price increases and volatility within the bauxite market [

5].

Several studies in the US have investigated the potential use of alternative aggregates in HFS systems by comparing each aggregate’s performance to that of calcined bauxite. The general conclusions from these studies show that calcined bauxite maintains higher levels of friction for longer periods of time than all other alternative aggregates investigated. The Texas A and M Transportation Institute undertook a laboratory study to compare the performance of a sandstone aggregate as a potential alternative to calcined bauxite [

9]. Although the sandstone had good frictional properties, it did not perform as good as calcined bauxite. The authors also highlighted the high micro-deval mass loss as a concern for the performance of the softer sandstone. A research study sponsored by the Indiana Department of Transportation compared the laboratory and field performance of steel slag as a potential alternative to calcined bauxite [

10]. After completion of cyclical polishing, the laboratory findings showed that friction was reduced by 8% and 4% for steel slag and calcined bauxite, respectively. The field data showed that, after nine months of service, the steel slag reduced friction by 45% and the calcined bauxite reduced in friction by 20%.

The National Center for Asphalt Technology (NCAT) at Auburn University conducted two studies into alternative aggregates for use in HFS systems. The first study compared the laboratory and field performance of seven alternative aggregates including: granite, flint, basalt, silica sand, steel slag, emery, and taconite [

11]. The laboratory data showed that all seven aggregates performed worse than calcined bauxite. The field data found that calcined bauxite maintained higher friction levels over a 24-month period. Calcined bauxite friction values decreased from 70 to 64. Flint friction values decreased from 55 to 43. Granite friction values decreased from 55 to 40. The second study compared the laboratory performance of ten alternative aggregates including: basalt, copper slag, flint, feldspar, three samples of calcined kaolin and three samples of quartz [

12]. The laboratory data showed that calcined bauxite maintained higher friction values than all other alternative aggregates during testing.

A review of 50 years of UK road trial data and laboratory investigations also found that calcined bauxite is the only aggregate to consistently offer the highest levels of performance for the longest period [

13]. Natural aggregates with very good resistance to wear will polish and become slippery over time. Conversely, natural aggregates with very good resistance to polishing will abrade and wear away over time [

14,

15].

In 2017, the authors considered how in-service performance of HFS could be predicted in the laboratory and investigated the 100% replacement of calcined bauxite with a range of natural aggregates. The data showed that calcined bauxite outperformed all the natural aggregates with only one natural aggregate (sandstone) just meeting the British Board of Agrément (BBA) Type 1 specification requirements required in the UK. That paper also reviewed the use and certification of HFS in the UK. The work reported in 2017 led to the data reported in this paper which investigates whether there is a natural aggregate that could be blended with calcined bauxite for use in HFS systems and still be able to meet specification requirements.

The aim of this paper is to investigate the use of locally available natural aggregates found in the UK with calcined bauxite in HFS systems. This paper considers how the results from three separate laboratory experiments could potentially impact society, the economy and the environment. The three experiments are as follows:

Experiment 1: Subject cold-applied HFS specimens of calcined bauxite, granite, sandstone and volcanic tuff, at various blend ratios, to simulated trafficking and test for skid resistance, texture depth and mass loss.

Experiment 2: Subject hot-applied HFS specimens of calcined bauxite and high PSV sandstone, at various blend ratios, to simulated trafficking and test for skid resistance, texture depth and mass loss.

Experiment 3: Subject cold-applied HFS specimens of calcined bauxite and high PSV sandstone, at various blend ratios, to simulated trafficking and test for skid resistance, texture depth and mass loss.

2. Materials and Methods

2.1. Aggregates Used in Experiments

The natural aggregates used in the experiments were sandstone from three separate sources (A, B and C), granite and volcanic tuff. There were three sources of calcined bauxite used in the experiments: buff colored Chinese calcined bauxite, grey colored Chinese calcined bauxite and grey colored Guyanese calcined bauxite. Each aggregate type was tested for loose bulk density [

16], particle density and water absorption [

17] prior to manufacture of test specimens. The polished stone value (PSV) [

18] and aggregate abrasion value (AAV) [

19] were declared values by the suppliers.

Table 1 shows the PSV, AAV, bulk density, particle density and water absorption data for the aggregates used in the experiments.

Local authorities often select HFS systems to be aesthetically pleasing as well as for the obvious safety reasons. For this reason, the natural aggregates selected to be blended with each source of calcined bauxite were chosen based on predicted performance and for aesthetic reasons. For example, in Experiment 1, sandstone A was dark in colour and was blended with grey Chinese bauxite. Each aggregate blend was compared against a reference specimen which was 100% of the calcined bauxite used in the experiment.

2.2. Specimen Manufacture

Thermosetting, more commonly known as cold-applied HFS systems, comprise a resin binder that is applied to a road surface and acts as an adhesive to hold 1–3 mm aggregates in place which provide high levels of friction. Binder systems include epoxy resin, polyurethane, polyurea or methyl methacrylate (MMA). After the resin binder is applied, an excess of the 1–3 mm aggregates are spread over the binder. After the resin is cured the excess or loose aggregates are removed by sweeping. For Experiment 1, test plates were supplied by Aetec Laboratories, Madrid, Spain. For Experiments 2 and 3, test slabs were supplied by Ulster University, Newtownabbey, UK. The test plates/slabs were brushed clean and taped off to provide adequate formwork to hold the binder in place. The binder component, used for each specimen in investigations 1 and 3, was a two-part epoxy resin.

The two components (A and B) of the epoxy system were thoroughly mixed at a ratio of 50:50 until homogenous. The epoxy binder was then spread evenly over the test plates/slabs using a serrated edged squeegee at a coverage rate of 1.8 kg/m

2. Aggregates of various blend ratios were then spread over each test plate/slab to excess. After initial curing over-night the excess was removed by brushing. The specimens were then left to fully cure.

Figure 1a shows a newly laid HFS system on an approach to a roundabout in Ireland whilst

Figure 1b shows a cold applied HFS specimen prior to simulated traffic testing in Experiment 1.

Thermoplastic, more commonly known as hot-applied HFS systems, comprise a pre-mixed rosin ester binder and aggregate thermoplastic system. The mixture is heated to high temperatures in truck mounted boilers before being discharged into buckets and applied to a road surface in strips using a screed box. For Experiment 2 the test slabs were brushed clean and taped off to provide a neat edged finish. The mixture was heated in appropriate size pans in the laboratory to the recommended laying temperatures whilst being continuously and thoroughly mixed. The heated material was then transferred to a heated screed box and spread over the slab. The screed box was combed over the material several times to ensure even distribution of aggregate and a well textured finish. The tape was removed before the specimens were left to fully cure over-night.

2.3. Simulated Trafficking and Testing

2.3.1. Wear Simulator Turntable

The wear simulator turntable located at Aetec Laboratories is primarily used to assess the performance of road marking materials [

20]. The Turntable consists of a 6.4 m external diameter table that can rotate up to a maximum speed of 120 km/h. Up to eighteen test plate specimens can be mounted on the table. Four vertically mounted approved commercial tires with pressures of 0.25 ± 0.02 MPa run freely on the table at a steering angle of 1° ± 10′, applying a load of 3000 ± 300 N on the test specimens from each tire.

The wear simulator has a water dispenser to apply water over the test plates and a cleaning system to keep the specimens and tires clean. The turntable is enclosed in a temperature-controlled room where testing is carried out at 7.5 ± 2.5 °C. The agreed test intervals were: 0 wheel-passes (WP), 5000 WP, 40,000 WP, 100,000 WP, 200,000 WP, 500,000 WP, 1 million WP, and 1.5 million WP. For the first 500,000 WP a steering angle of 1° ± 10′ was used with the remainder of testing carried out at a steering angle of 1.5° ± 10′. For every hour of simulated trafficking on the turntable the following test conditions were maintained: 15 min of wet trafficking at 15 km/h followed by 45 min of dry trafficking at 60 km/h. The wear simulator Turntable is shown in

Figure 2a.

2.3.2. Road Test Machine

Appendix H of the Transport Research Laboratory (TRL) Report 176 contains a generic description of the test equipment used to perform the wear test [

21]. There is only one device available for use in the UK. This is known as the Road Test Machine 1 (RTM) and is shown in

Figure 2b. This equipment was identified as being suitable to simulate trafficking and so predict wear resistance. The RTM is now located at Ulster University where it is used in the UK BBA process of HFS certification. The equipment is used to test other types of asphalt and concrete products under conditions of simulated wear. This allows direct comparison of HFS data with other types of asphalt or concrete products used as a road surfacing.

The RTM equipment consists of a 2.1 m diameter table that rotates at 10 RPM or 1.1 m/s. The table has spaces for mounting ten 305 mm × 305 mm × 50 mm test specimens. These are typically asphalt slabs made using a roller compacter unto which the HFS is applied. Two vertically mounted full size 195/70R14 tires run freely on the table each applying a load of approximately 5 kN. Tire inflation pressure is maintained at 2 bar or 30 psi. During testing the tires track back and forth across the width of the test specimen generating additional stress. The RTM is enclosed in a temperature-controlled room with testing carried out at 10 ± 2 °C to avoid deformation of the test specimen. The wear test was carried out in a dry condition with no abrasive.

The Appendix H wear test method requires initial test values and after 100,000 wheel-passes, i.e., 50,000 rotations of the table. However, test values at the start and finish of accelerated testing do not adequately show what happens during the whole period of simulated trafficking. Understanding what happens during testing offers improved insight into time related changes which relate to in-service trafficking conditions. Simulated RTM trafficking is typically stopped at regular intervals to measure changes in HFS properties.

2.3.3. Test Methods

Each test specimen was photographed and weighed to assess erosion loss and assessed for wet skid resistance value (SRV) and texture depth using the British pendulum [

22] and volumetric patch technique [

23] methods respectively.

4. Discussion

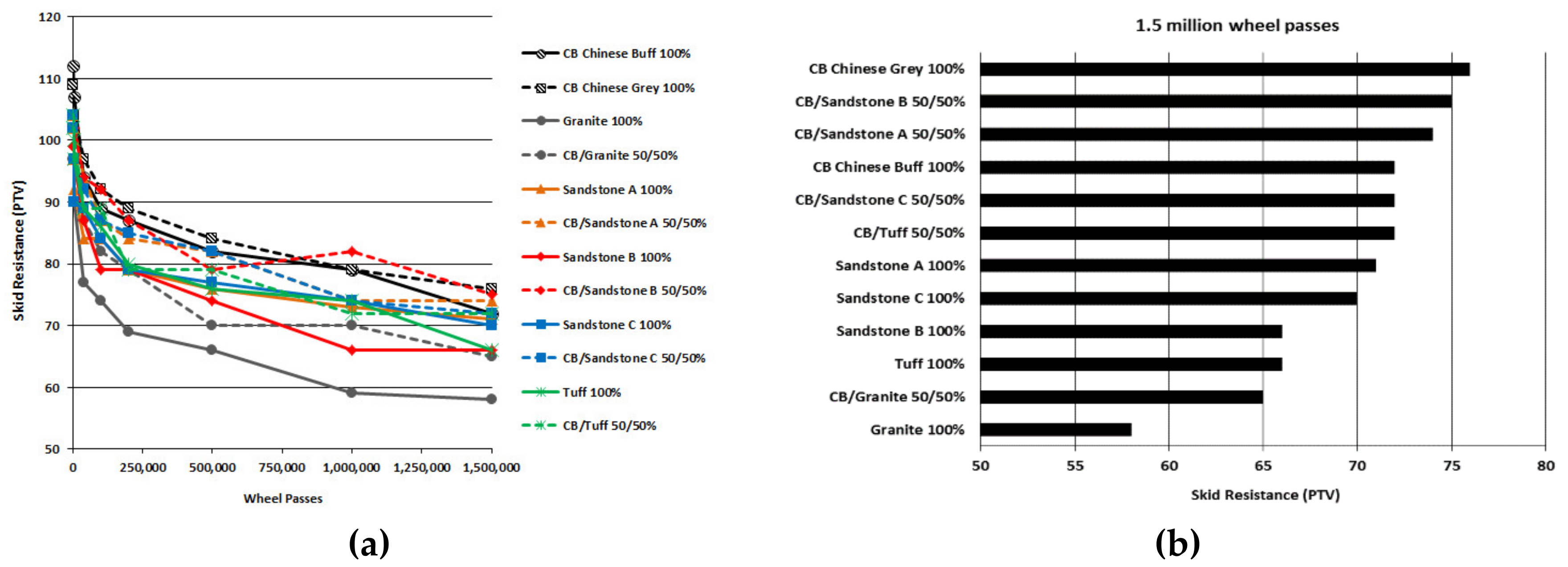

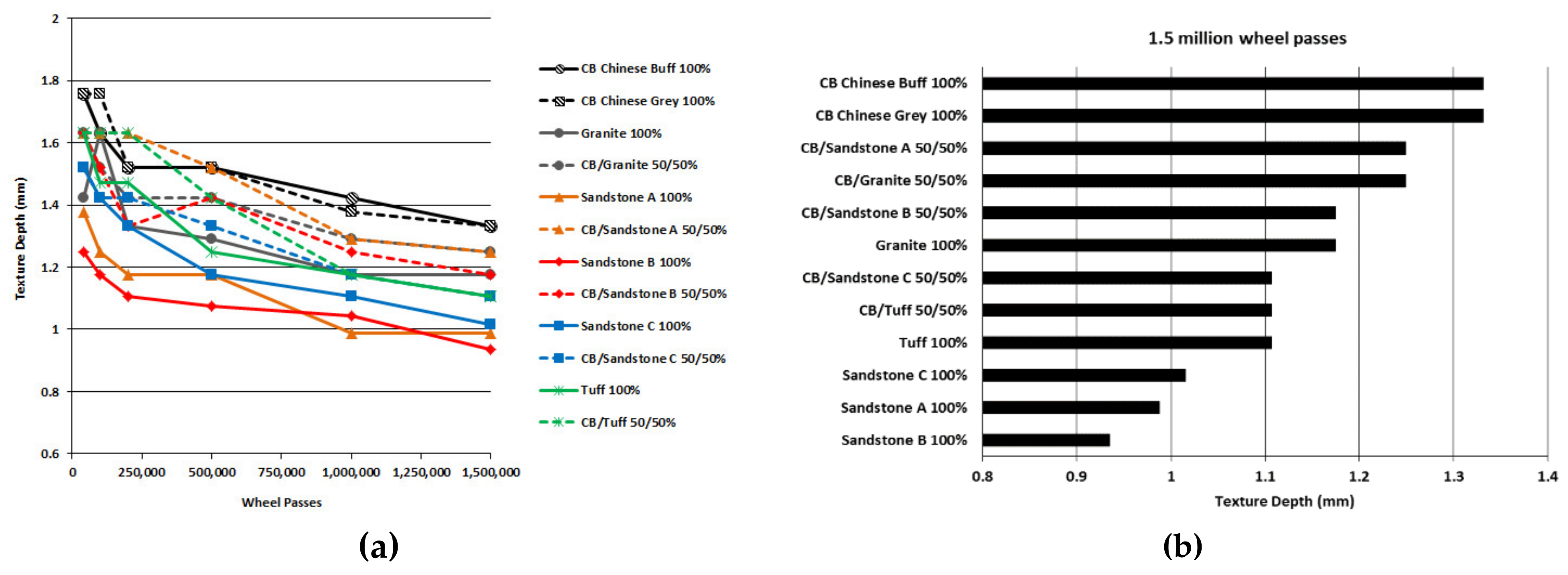

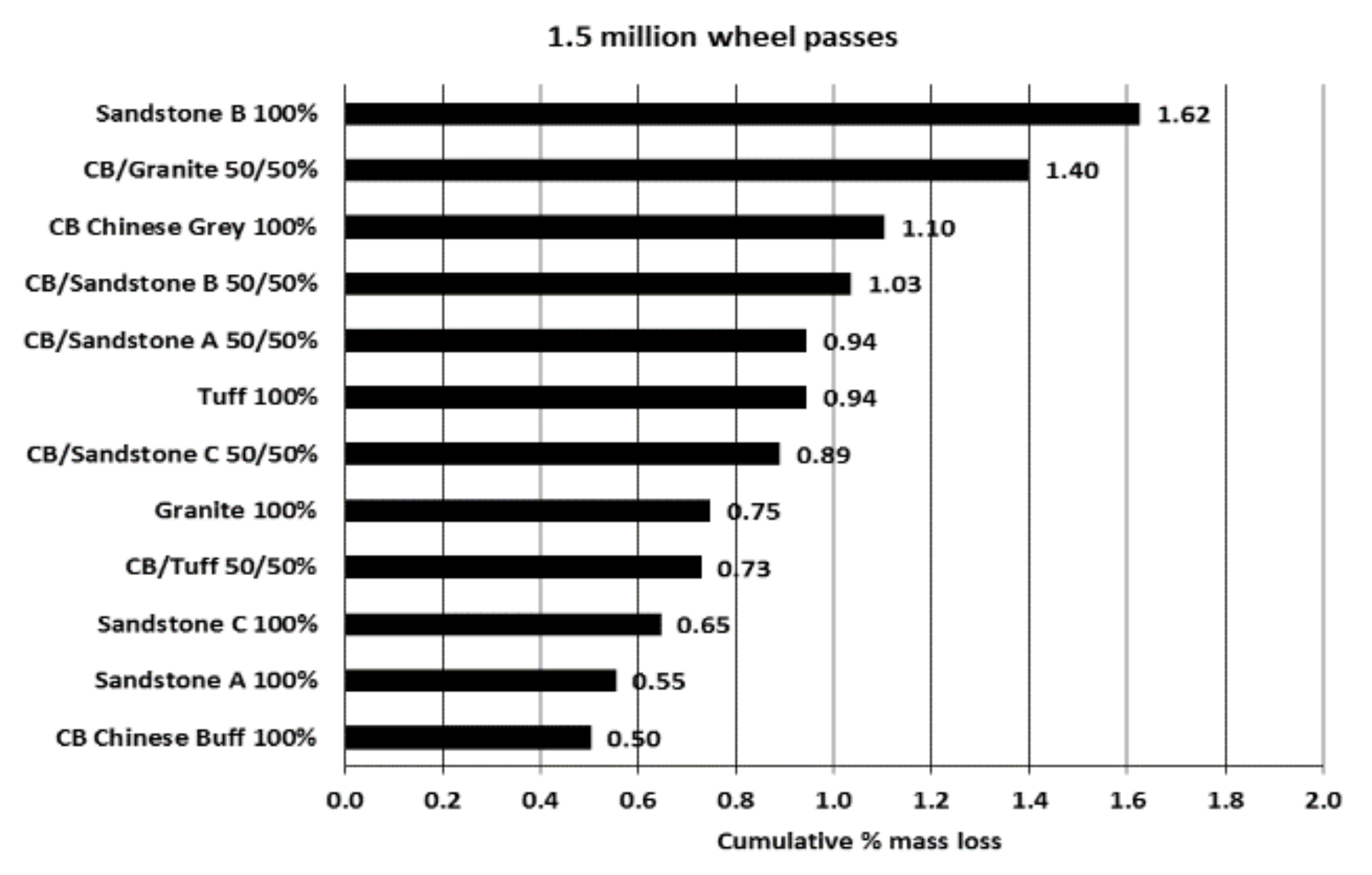

The results reported in this paper clearly show that there are natural aggregates available that can be blended with calcined bauxite and meet national laboratory performance requirements for HFS systems such as those that have been used in the UK. For many years researchers have tried to come up with alternatives to calcined bauxite in HFS systems. The approach (or mistake) was to look for 100% replacement using natural aggregates. For example, using 100% granite will not work because it will polish prematurely and become slippery to the road user over time. Using 100% sandstone will not work because it will wear prematurely over time because it is not durable enough to withstand the enormous stresses exerted on the material at high stress/risk locations where HFS systems are used. The same can be used to account for why other natural rock types do not perform in HFS. This can be seen from the results of Experiment 1, where the specimen containing 100% granite was the worst performer in terms of skid resistance. The next worst performer was the specimen containing a blend of granite and calcined bauxite. Even though 50% of the granite was replaced with 50% calcined bauxite, it was still the second worst performer. This illustrates the susceptibility of granite and other similar rock types to polishing and the risk that their use in HFS could pose to the road user.

In Experiment 1, one would expect the two control specimens containing 100% calcined bauxite to have the highest skid resistance. This was not the case. The best performer was the specimen containing 100% Chinese grey calcined bauxite with a skid resistance of 76. The next two best performers were the specimens containing blends of Chinese grey calcined bauxite and sandstone B and sandstone A with skid resistance values of 75 and 74 respectively. The 100% Chinese buff calcined bauxite specimen had the same skid resistance value as the specimens containing blends of calcined bauxite with sandstone A and volcanic tuff. In terms of texture depth, the two best performers were the two specimens containing 100% calcined bauxite. The three worst performers were the three specimens containing 100% sandstone. This illustrates the susceptibility of softer sandstone to wear and loss of texture. All the other specimens fell between these two groups.

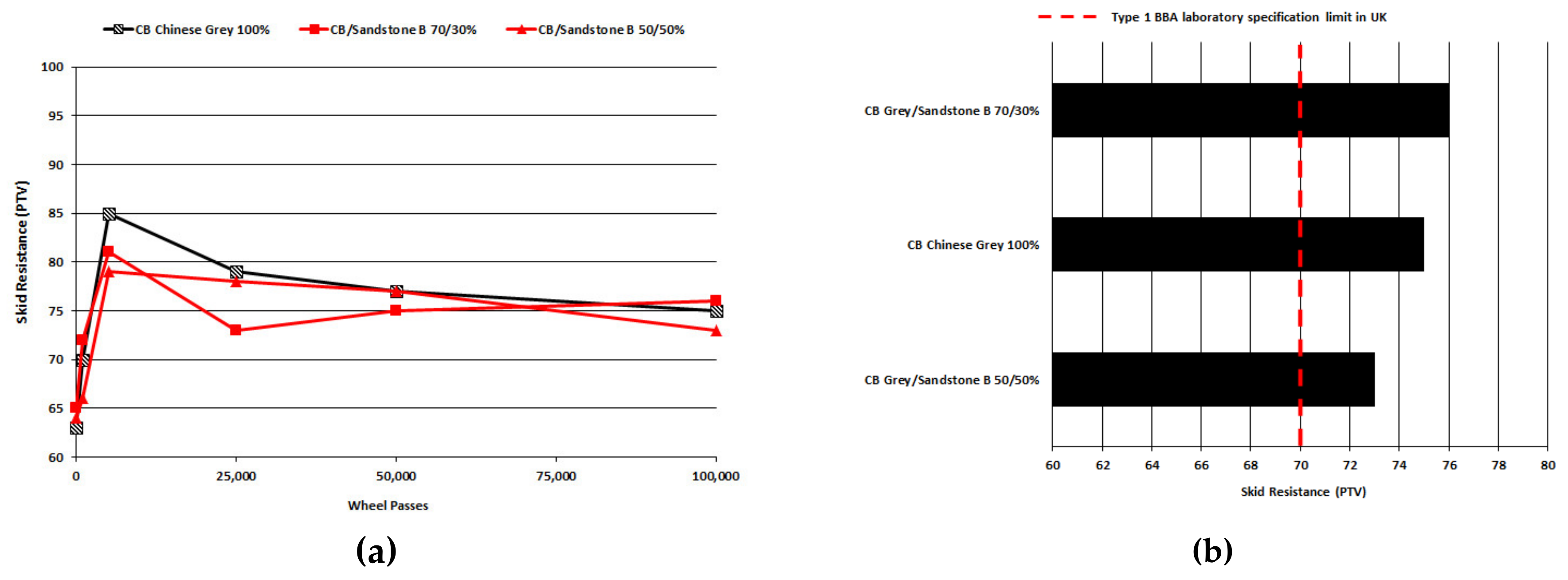

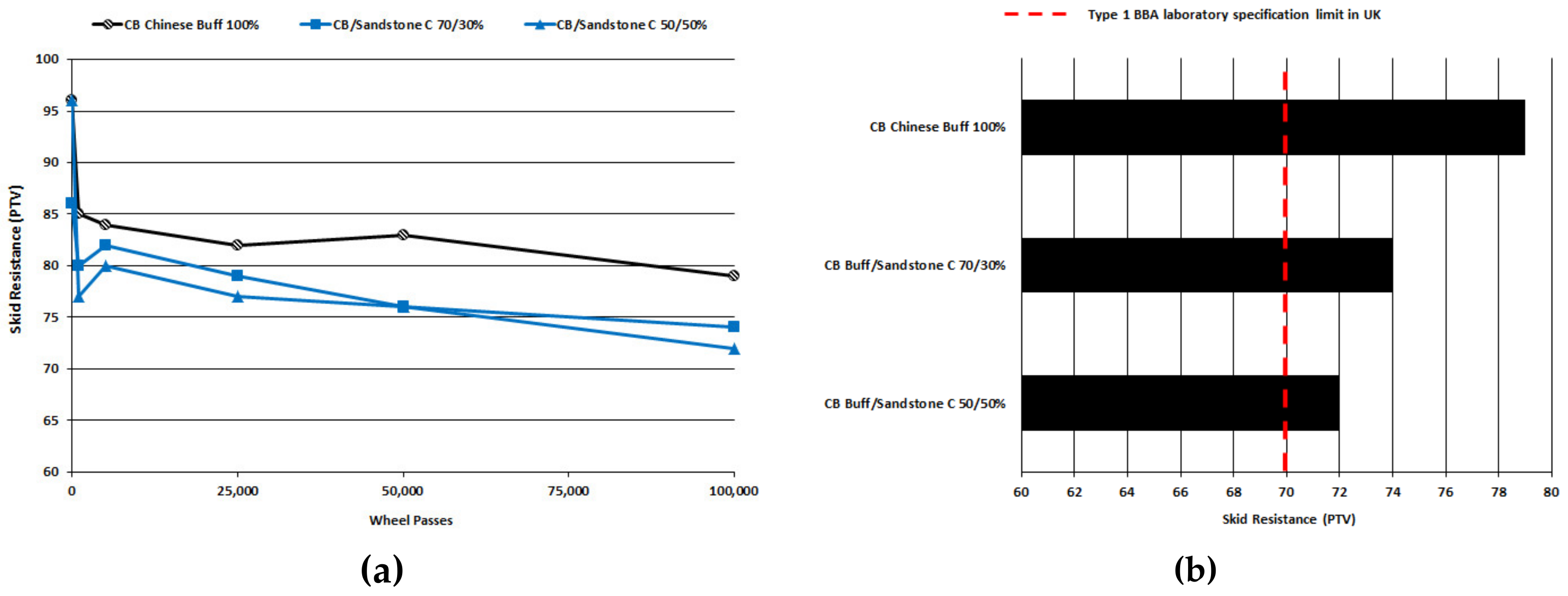

In Experiment 2,

Figure 6b shows that the specimen containing 70% Chinese grey calcined bauxite and 30% sandstone B outperformed the 100% calcined bauxite specimen by one point. The specimen containing 50% calcined bauxite and 50% sandstone B had a skid resistance of 73.

Figure 7b shows the specimens ranked in order as would be expected. The 100% Chinese buff calcined bauxite specimen was the best performer with a skid resistance of 79. This was followed by the specimens containing 70% and 50% Chinese buff calcined bauxite with skid resistance values of 74 and 72 respectively. The early life friction development differs for both sets of specimens in

Figure 6a and

Figure 7a.

Figure 6a shows friction development increasing from 0 to 5000 wheel-passes before entering a downward cyclical trend of friction development.

Figure 7a shows friction development decreasing in a downward cyclical trend throughout testing.

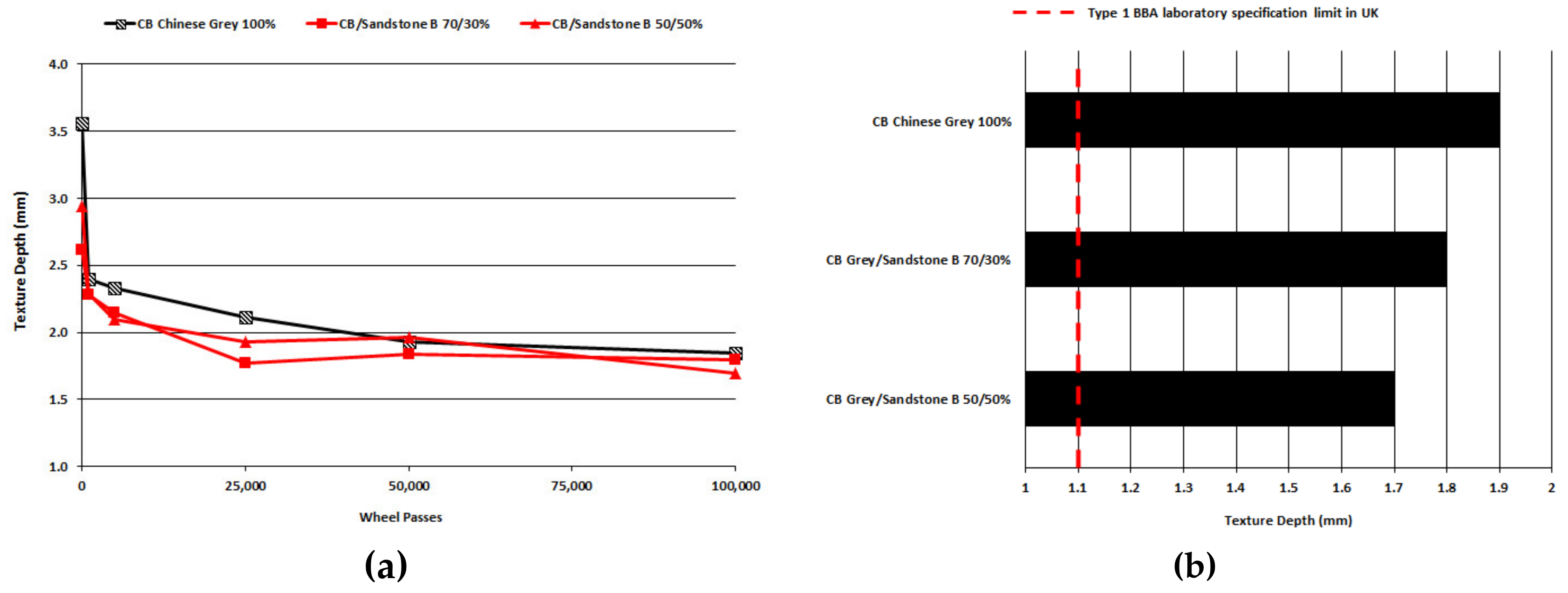

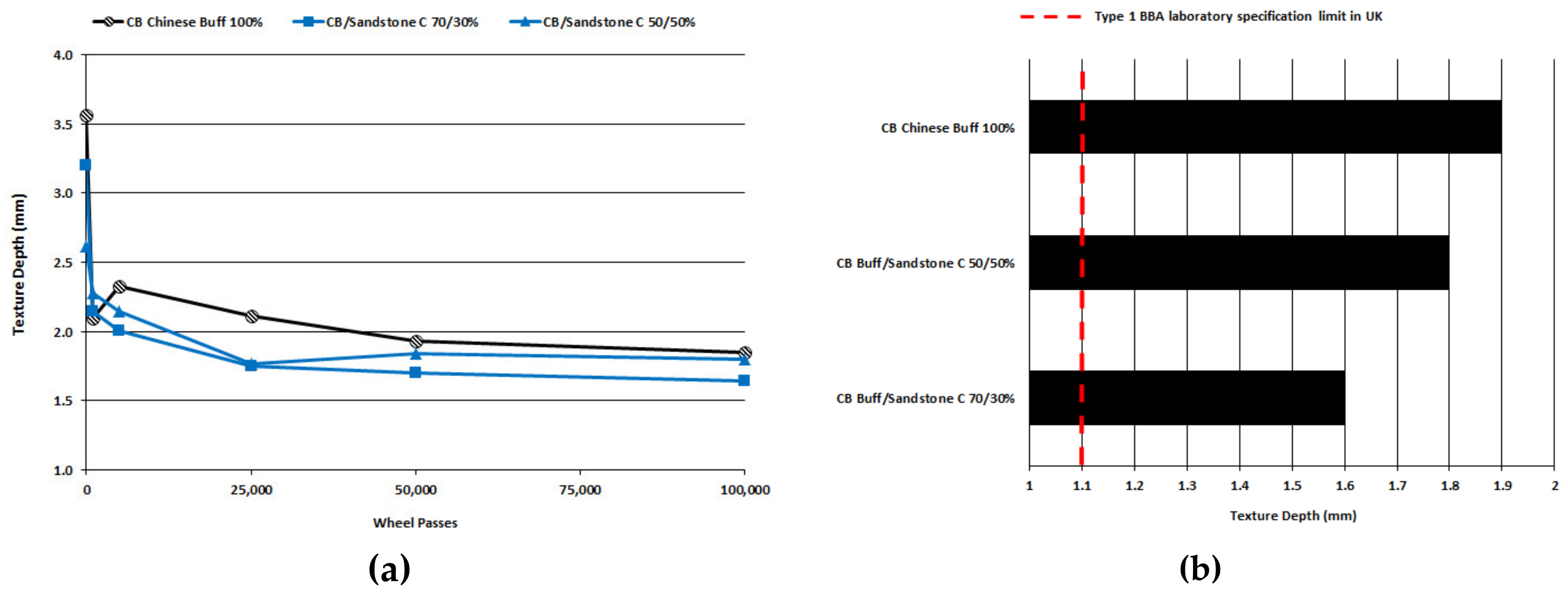

Figure 8a and

Figure 9a shows both sets of specimens having similar trends of texture development. Both sets of data show that texture depth development stabilized after 25,000 wheel-passes and underwent minimal texture change for the remainder of testing.

Figure 8b and

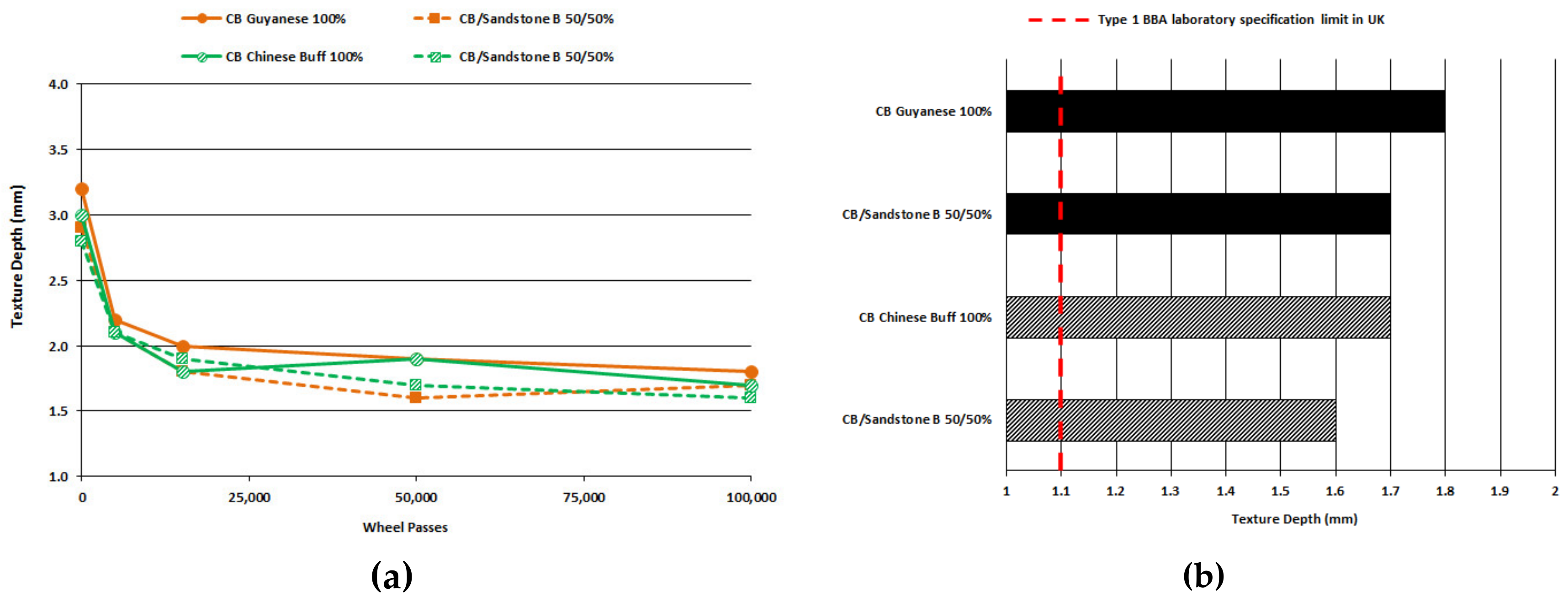

Figure 9b show that after 100,000 wheel-passes texture depths ranged from 1.9 to 1.6 mm. Both specimens containing 100% calcined bauxite had the highest texture depths. The experiment shows that all specimens would meet the laboratory wear test specification requirements for Type 1 HFS in the UK.

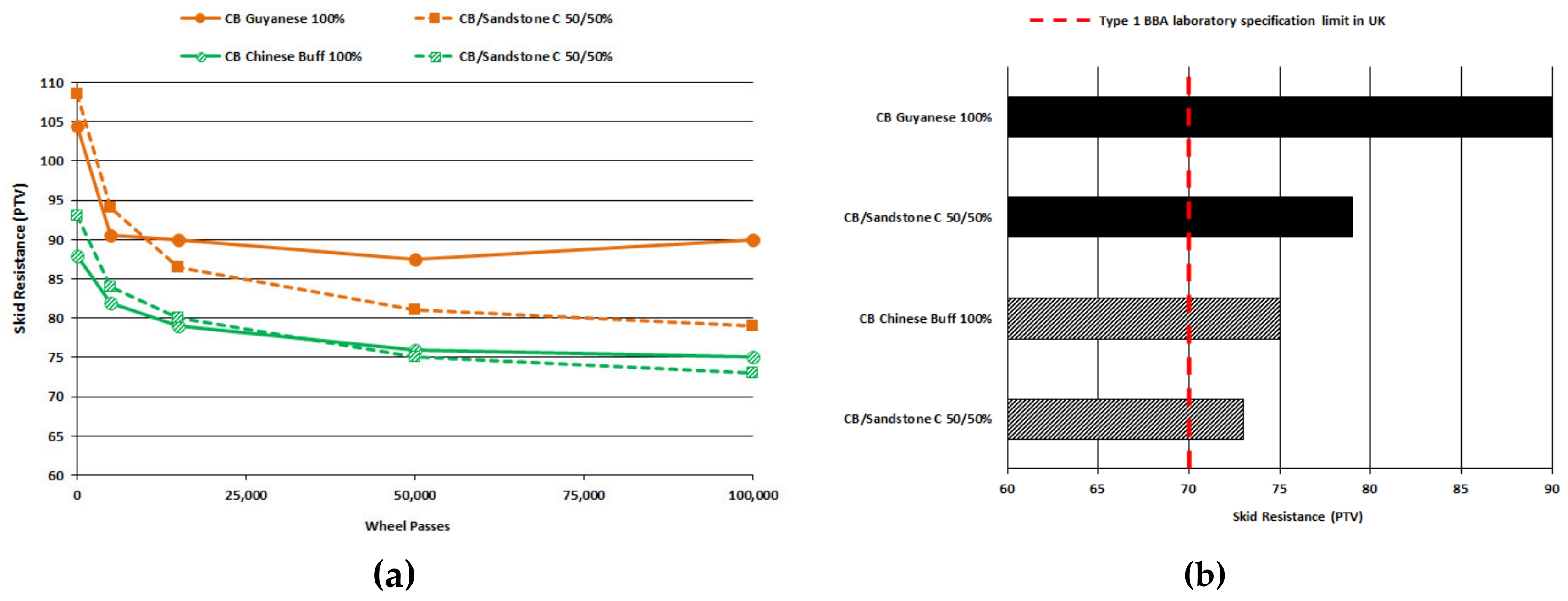

In experiment 3,

Figure 10a shows both sets of specimens to have a similar trend of friction development with equilibrium being reached after 50,000 wheel-passes.

Figure 10b shows the Guyanese calcined bauxite to be superior in performance to all the other specimens including the Chinese buff calcined bauxite. The specimen containing 50% Guyanese calcined bauxite and 50% sandstone C had a skid resistance four points higher than the 100% Chinese buff calcined bauxite. This illustrates potentially significant cost savings whilst ensuring performance.

Figure 11a shows texture development to be similar for both sets of specimens during testing.

Figure 11b shows texture depths ranging from 1.8 to 1.6 mm. The experiment shows that all specimens would meet the laboratory wear test specification requirements for Type 1 HFS in the UK.

The concept of blending calcined bauxite with high PSV sandstone or volcanic tuff compensates for the lack of resistance to wear in the sandstone or tuff by ensuring there is enough calcined bauxite in the blend to absorb most of the impact energy exerted on to the HFS by vehicle tires at high stress locations. As the tire rubber envelopes are essentially point contacts, compared to a typical asphalt or concrete road surface, the presence of calcined bauxite protects the blended particles around them. Optimizing the blend, both in terms of ratio and complimentary natural aggregate wear characteristics, ensures the longer-term survival of point contacts to maximize interfacial contact at a high stress site or during high vehicle demand driving maneuver. The correct combination of aggregates in the blend work in unison to achieve high levels of skid resistance, whilst the extremely hard calcined bauxite protects the softer sandstone or tuff particles from wearing away prematurely. These findings have potential major implications for road safety, the environment and industry supply chains.