Electrophoretic Deposition of Graphene Oxide on Laser-Ablated Copper Mesh for Enhanced Oil/Water Separation

Abstract

1. Introduction

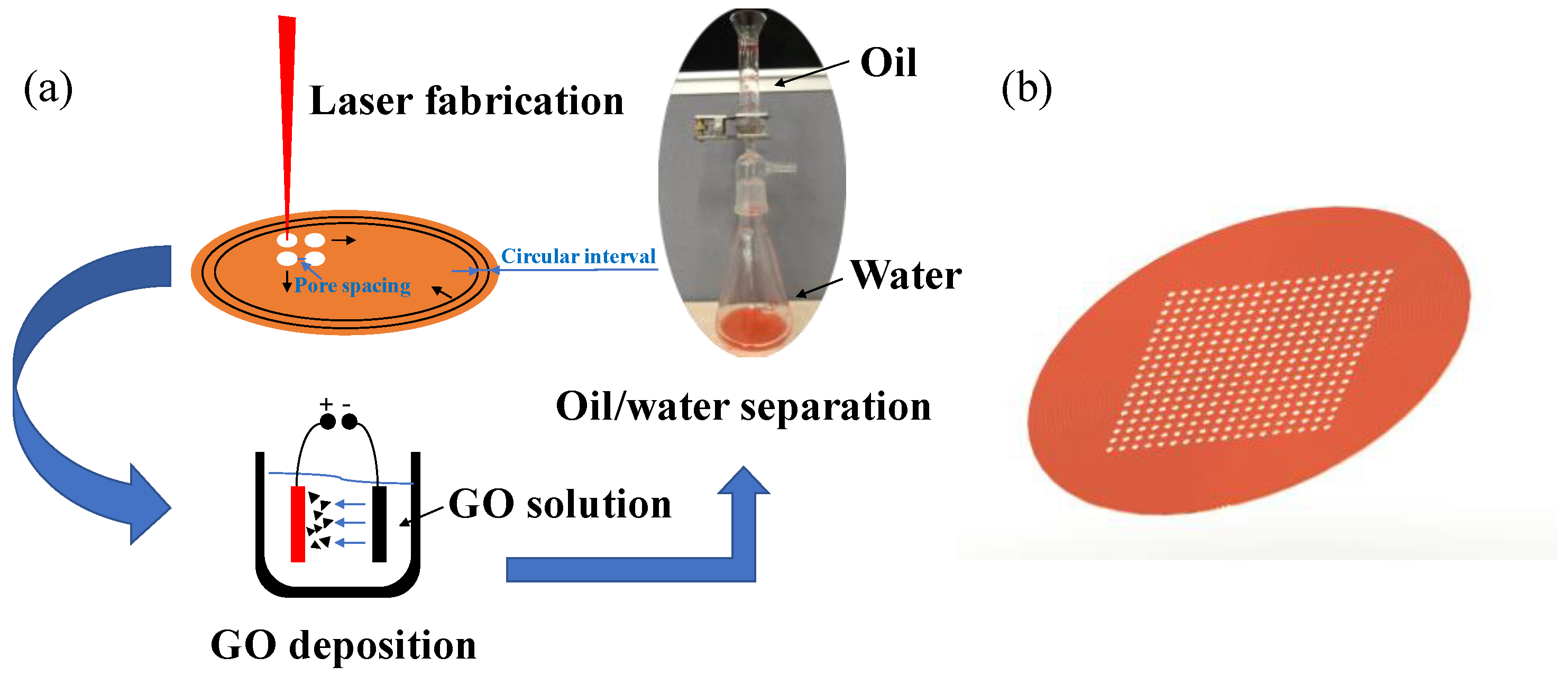

2. Materials and Methods

2.1. Laser Nanostructuring of Copper Sheet

2.2. Graphene Oxide Deposition

2.3. Contact Angle Measurement

2.4. Oil/Water Separation and Durability

3. Results and Discussion

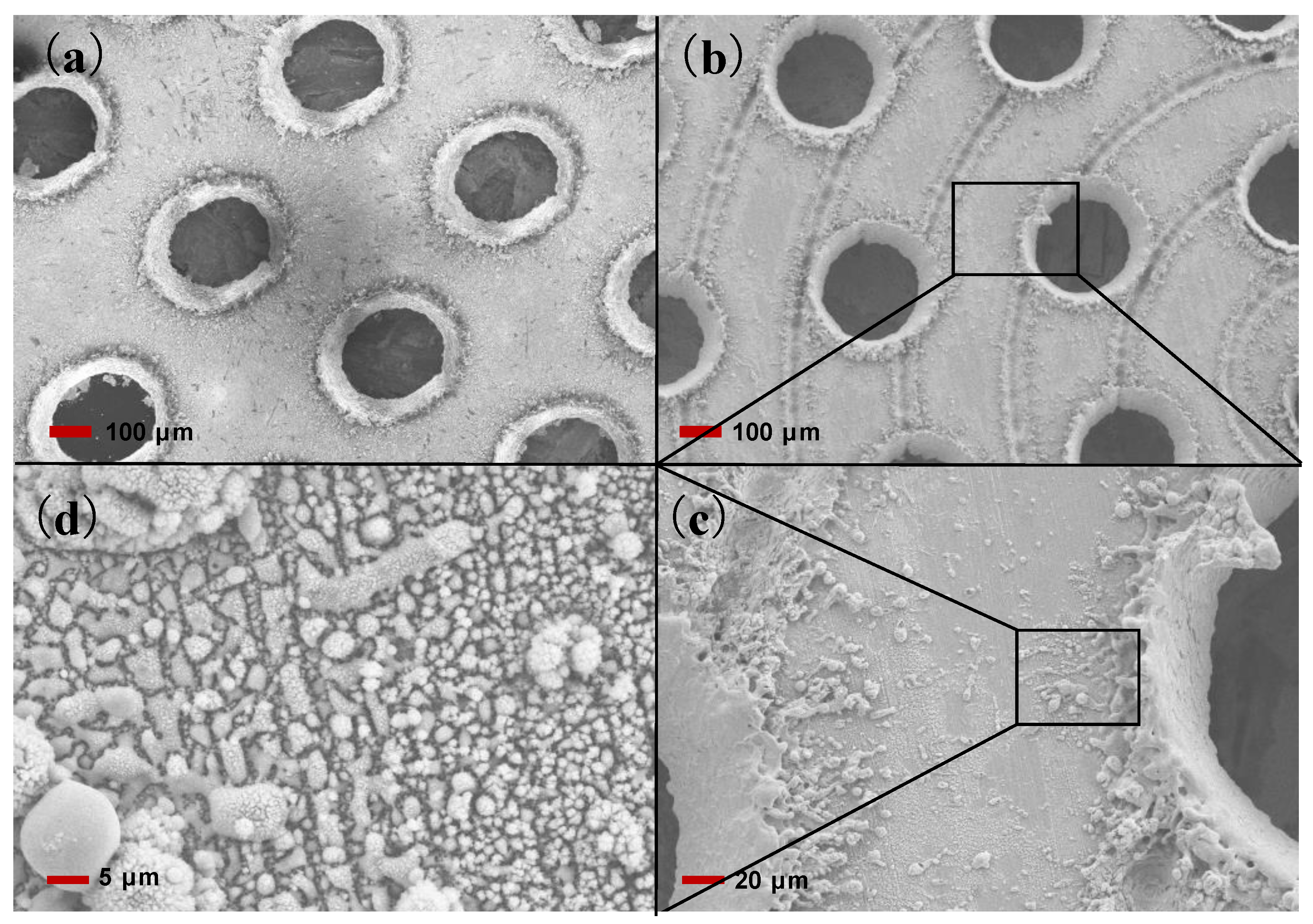

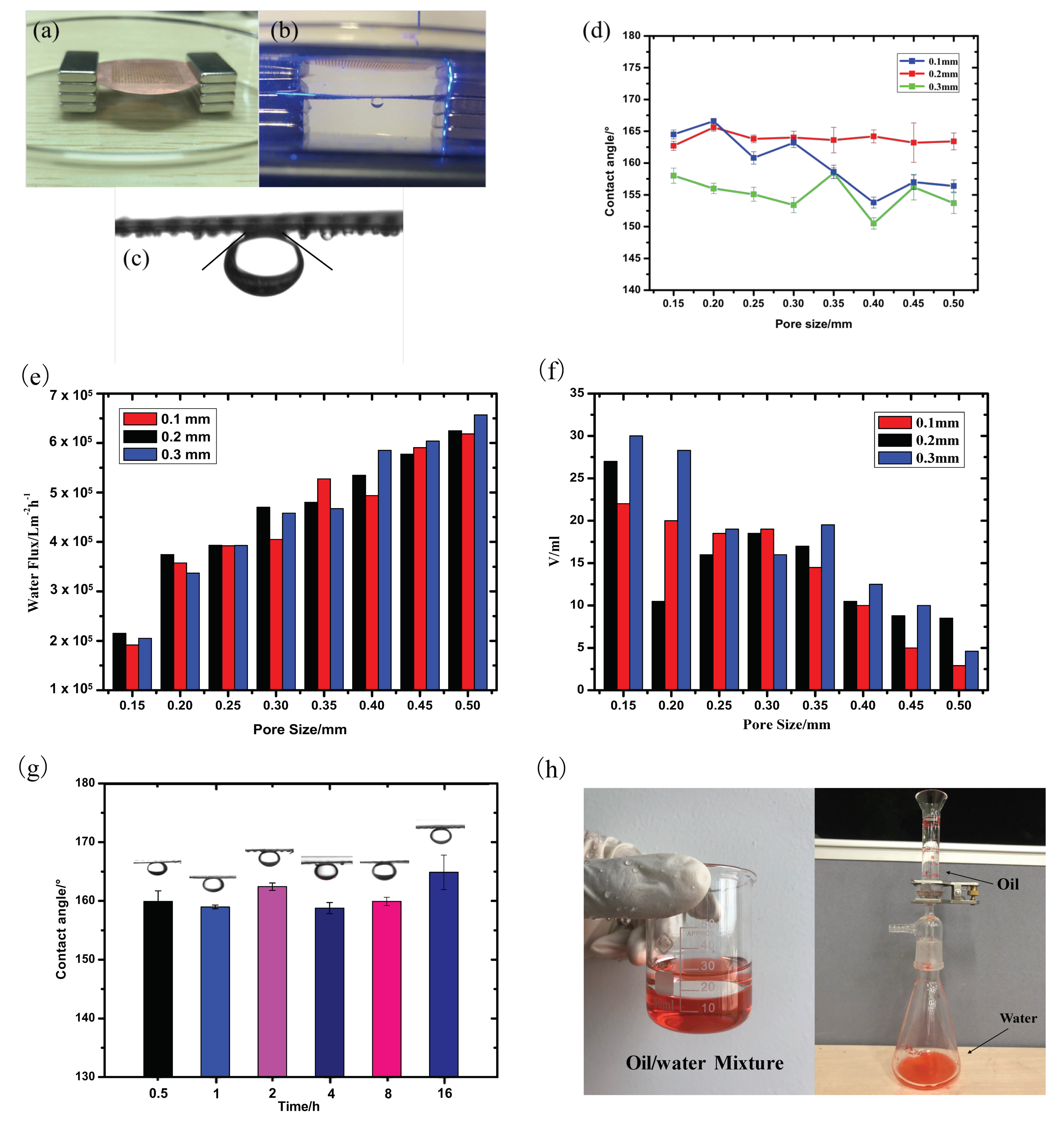

3.1. Laser-Ablated Copper Mesh without GO Deposition

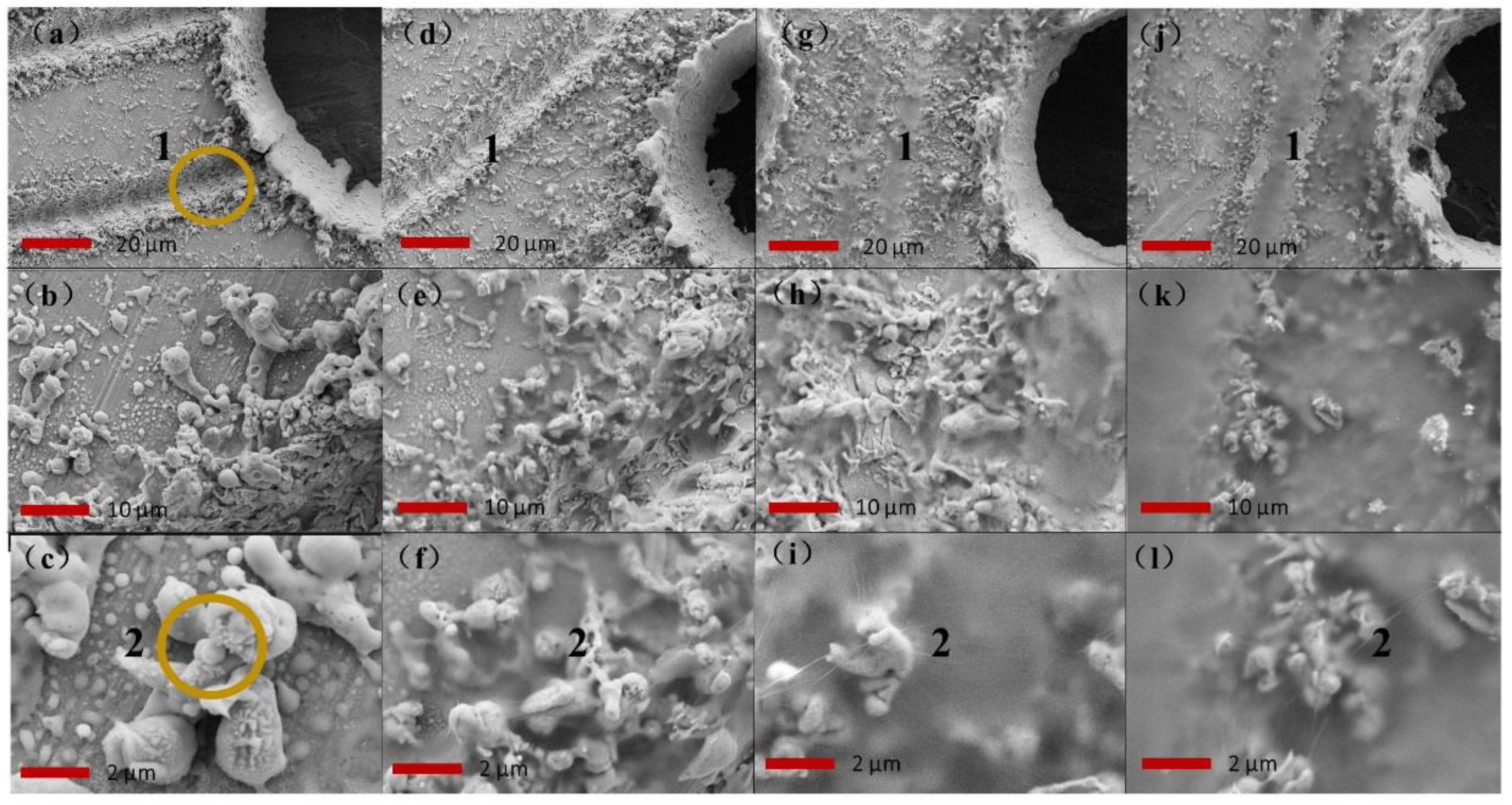

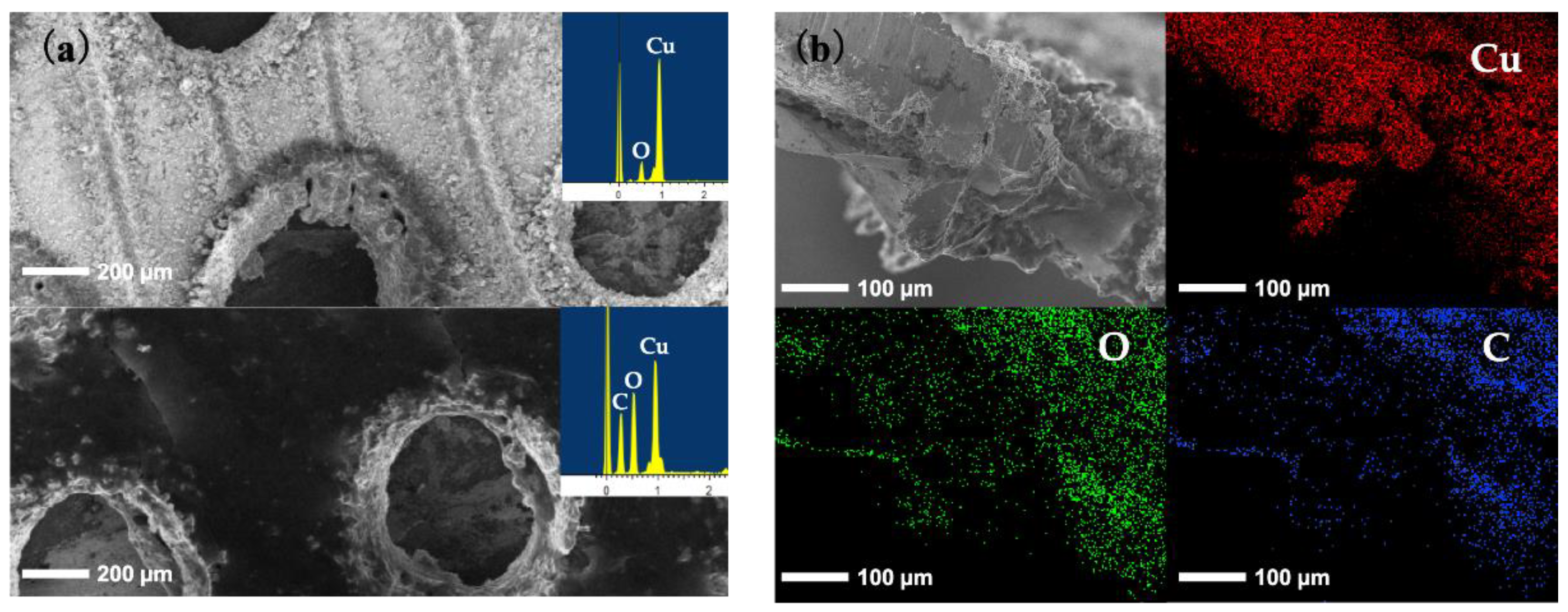

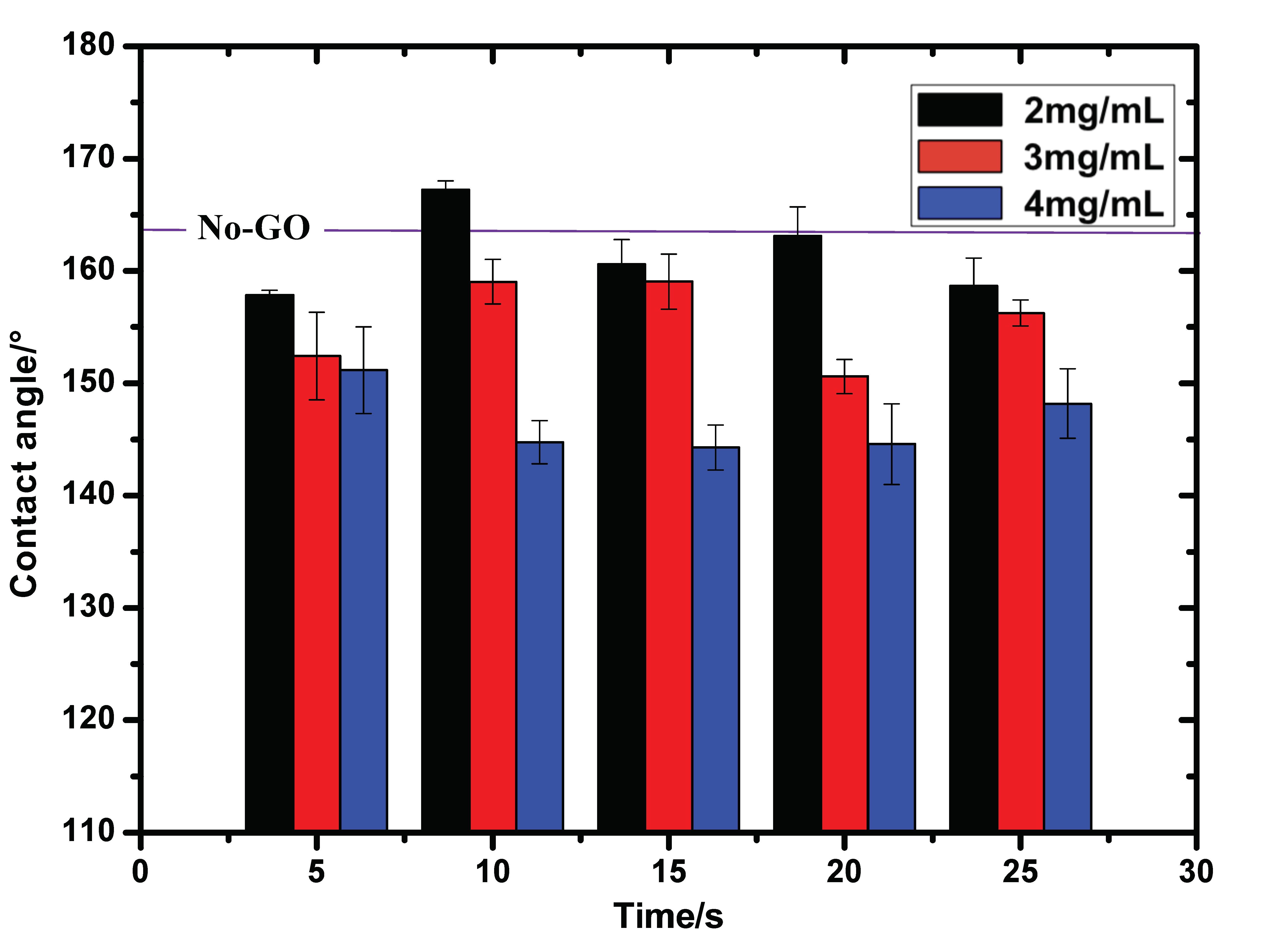

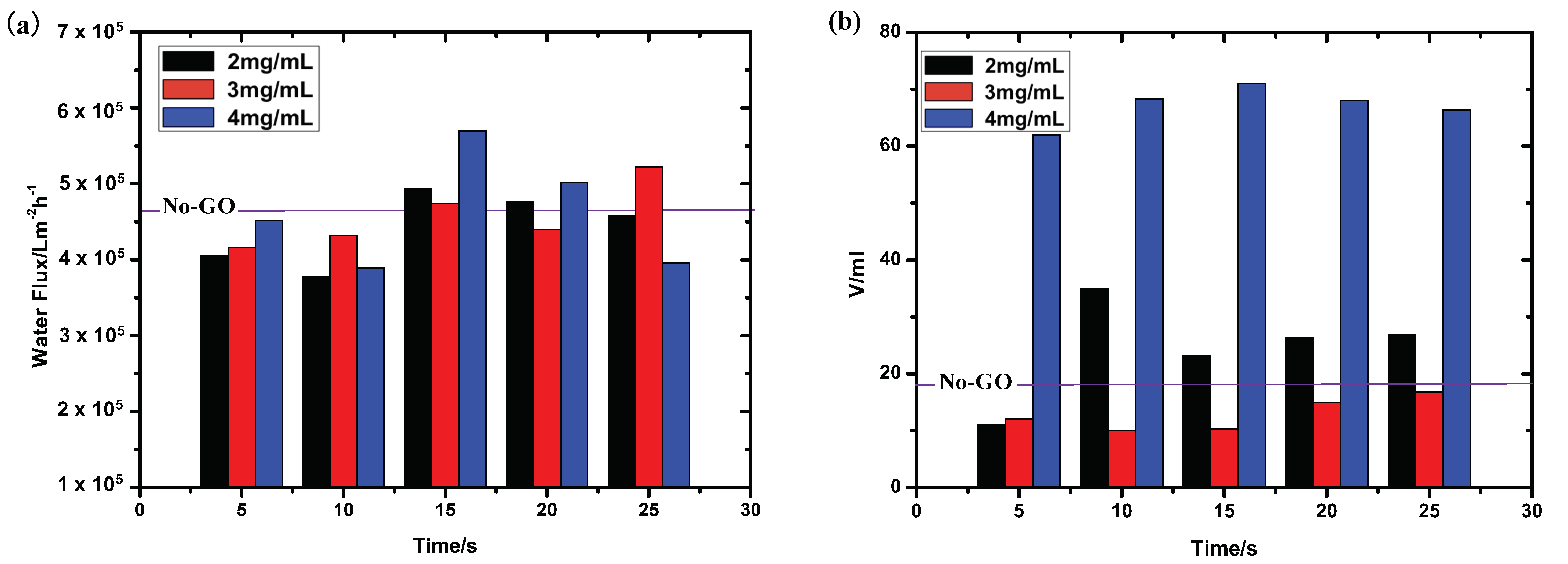

3.2. Electrophoretic Deposition of GO on the Laser-Ablated Copper Mesh

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, W.; Shi, Z.; Zhang, F.; Liu, X.; Jin, J.; Jiang, L. Superhydrophobic and Superoleophilic PVDF Membranes for Effective Separation of Water-in-Oil Emulsions with High Flux. Adv. Mater. 2013, 25, 2071–2076. [Google Scholar] [CrossRef] [PubMed]

- Yong, J.; Chen, F.; Fang, Y.; Huo, J.; Yang, Q.; Zhang, J.; Bian, H.; Hou, X. Bioinspired Design of Underwater Superaerophobic and Superaerophilic Surfaces by Femtosecond Laser Ablation for Anti- or Capturing Bubbles. ACS Appl. Mater. Interfaces 2017, 9, 39863–39871. [Google Scholar] [CrossRef] [PubMed]

- Marmur, A. The Lotus effect: Superhydrophobicity and metastability. Langmuir 2004, 20, 3517–3519. [Google Scholar] [CrossRef] [PubMed]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of Solid Surfaces to Wetting by Water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Xue, Z.; Wang, S.; Lin, L.; Chen, L.; Liu, M.; Feng, L.; Jiang, L. A novel superhydrophilic and underwater superoleophobic hydrogel-coated mesh for oil/water separation. Adv. Mater. 2011, 23, 4270–4273. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Zhang, W.B.; Shi, Z.; Wang, D.; Jin, J.; Jiang, L. Nanowire-haired inorganic membranes with superhydrophilicity and underwater ultralow adhesive superoleophobicity for high-efficiency oil/water separation. Adv. Mater. 2013, 25, 4192–4198. [Google Scholar] [CrossRef] [PubMed]

- Yong, J.; Chen, F.; Yang, Q.; Bian, H.; Du, G.; Shan, C.; Huo, J.; Fang, Y.; Hou, X. Oil-Water Separation: A Gift from the Desert. Adv. Mater. Int. 2016, 3, 1500650–1500656. [Google Scholar] [CrossRef]

- Kwon, G.; Kota, A.K.; Li, Y.; Sohani, A.; Mabry, J.M.; Tuteja, A. On-Demand Separation of Oil-Water Mixtures. Adv. Mater. 2012, 24, 3666–3671. [Google Scholar] [CrossRef] [PubMed]

- Long, Y.; Hui, J.-F.; Wang, P.-P.; Xiang, G.-L.; Xu, B.; Hu, S.; Zhu, W.-C.; Lü, X.-Q.; Zhuang, J.; Wang, X. Hydrogen Bond Nanoscale Networks Showing Switchable Transport Performance. Sci. Rep. 2012, 2, 612–617. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Johnson, N.; Drelich, J.; Yap, Y.K. The performance of superhydrophobic and superoleophilic carbon nanotube meshes in water–oil filtration. Carbon 2011, 49, 669–676. [Google Scholar] [CrossRef]

- Feng, L.; Zhang, Z.; Mai, Z.; Ma, Y.; Liu, B.; Jiang, L.; Zhu, D. A super-hydrophobic and super-oleophilic coating mesh film for the separation of oil and water. Angew. Chem. 2004, 43, 2012–2014. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yan, L.; Li, H.; Li, W.; Zha, F.; Lei, Z.Q. Underwater superoleophobic palygorskite coated meshes for efficient oil/water separation. J. Mater. Chem. 2015, 3, 14696–14702. [Google Scholar] [CrossRef]

- Huo, J.; Yang, Q.; Feng, C.; Yong, J.; Yao, F.; Zhang, J.; Lin, L.; Xun, H. Underwater transparent miniature “mechanical hand” based on femtosecond laser-induced controllable oil-adhesive patterned glass for oil droplet manipulation. Langmuir 2017, 33, 3659–3665. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Guan, P.; Zhang, Y.; Xiang, B.; Tang, X.; She, H. A diatomite coated mesh with switchable wettability for on-demand oil/water separation and methylene blue adsorption. Sep. Sci. Technol. 2017, 174, 275–281. [Google Scholar] [CrossRef]

- Lo, Y.-H.; Yang, C.-Y.; Chang, H.-K.; Hung, W.-C.; Chen, P.-Y. Bioinspired Diatomite Membrane with Selective Superwettability for Oil/Water Separation. Sci. Rep. 2017, 7, 13422–13429. [Google Scholar] [CrossRef] [PubMed]

- Yan, H.; Rashid, M.R.B.A.; Si, Y.K.; Li, F.; Hong, M. Wettability Transition of Laser Textured Brass Surfaces inside Different Mediums. Appl. Surf. Sci. 2017, 369–375. [Google Scholar] [CrossRef]

- Wang, G.; Wang, B.; Park, J.; Yang, J.; Shen, X.; Yao, J. Synthesis of enhanced hydrophilic and hydrophobic graphene oxide nanosheets by a solvothermal method. Carbon 2009, 47, 68–72. [Google Scholar] [CrossRef]

- Wei, N.; Lv, C.; Xu, Z. Wetting of Graphene Oxide: A Molecular Dynamics Study. Langmuir 2014, 30, 3572–3578. [Google Scholar] [CrossRef] [PubMed]

- Guiyuan, C.; Xiaosong, G.; Han, L.; Baohua, J. An accurate design of graphene oxide ultrathin flat lens based on Rayleigh-Sommerfeld theory. Opto. Electron. Adv. 2018, 1, 180012. [Google Scholar] [CrossRef]

- Huang, Y.; Li, H.; Wang, L.; Qiao, Y.; Tang, C.; Jung, C.; Yoon, Y.; Li, S.; Yu, M. Ultrafiltration Membranes with Structure-Optimized Graphene-Oxide Coatings for Antifouling Oil/Water Separation. Adv. Mater. Int. 2015, 2, 1400433–1400439. [Google Scholar] [CrossRef]

- Xu, Y.; Li, J.; Huang, W. Porous Graphene Oxide Prepared on Nickel Foam by Electrophoretic Deposition and Thermal Reduction as High-Performance Supercapacitor Electrodes. Materials 2017, 10, 936. [Google Scholar]

- Saba, N.; Chang-Mou, W.; Ting-Zhen, X.; Chiu-Chun, L.; Syang-Peng, R. Oil-Water Separation of Electrospun Cellulose Triacetate Nanofiber Membranes Modified by Electrophoretically Deposited TiO2/Graphene Oxide. Polymers 2018, 10, 746. [Google Scholar]

- Usha Kiran, N.; Dey, S.; Singh, B.P.; Besra, L. Graphene Coating on Copper by Electrophoretic Deposition for Corrosion Prevention. Coatings 2017, 7, 214. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Femtosecond laser nanostructuring of metals. Opt. Express 2006, 14, 2164–2169. [Google Scholar] [CrossRef] [PubMed]

- Reg, Y.; Kägeler, C.; Schmidt, M. Experimental studies on effects at micro-structuring of highly reflecting metals using nano- and picosecond-lasers. Phys. Procedia 2010, 5, 245–253. [Google Scholar] [CrossRef]

- Rui, Z.; Shengdong, L.; Ye, D.; Huan, Y.; Kenny Ong Yong, K.; Minghui, H. Enhancement of laser ablation via interacting spatial double-pulse effect. Opto. Electron. Adv. 2018, 1, 180014. [Google Scholar] [CrossRef]

- Khew, S.Y.; Tan, C.F.; Yan, H.; Lin, S.; Thian, E.S.; Zhou, R.; Hong, M. Nanosecond laser ablation for enhanced adhesion of CuO nanowires on copper substrate and its application for oil-water separation. Appl. Surf. Sci. 2019, 465, 995–1002. [Google Scholar] [CrossRef]

- Tian, X.; Jokinen, V.; Li, J.; Sainio, J.; Ras, R.H. Unusual Dual Superlyophobic Surfaces in Oil-Water Systems: The Design Principles. Adv. Mater. 2016, 28, 10652–10658. [Google Scholar] [CrossRef] [PubMed]

- Yong, J.; Chen, F.; Yang, Q.; Zhang, D.; Farooq, U.; Du, G.; Hou, X. Bioinspired underwater superoleophobic surface with ultralow oil-adhesion achieved by femtosecond laser microfabrication. J. Mater. Chem. 2014, 2, 8790–8795. [Google Scholar] [CrossRef]

- Wang, B.; Liang, W.X.; Guo, Z.G.; Liu, W.M. Biomimetic super-lyophobic and super-lyophilic materials applied for oil/water separation: A new strategy beyond nature. Chem. Soc. Rev. 2015, 44, 336–361. [Google Scholar] [CrossRef] [PubMed]

- Zhou, R.; Lin, S.; Shen, F.; Khew, S.Y.; Hong, M. A universal copper mesh with on-demand wettability fabricated by pulsed laser ablation for oil/water separation. Surf. Coat. Technol. 2018, 348, 73–80. [Google Scholar] [CrossRef]

- Liu, W.Y.; Sun, L.Y.; Wu, R.M.; Chen, Y.; Liu, Y.J. Effects of acid concentration on the superhydrophobic surface on aluminum alloy by etching and PP-coating. Adv. Mater. Res.-Switz. 2013, 763, 49–52. [Google Scholar] [CrossRef]

| Concentration | 5 s | 10 s | 15 s | 20 s | 25 s |

|---|---|---|---|---|---|

| 2 g/L | 1 mg | 3 mg | 21 mg | 64 mg | 71 mg |

| 3 g/L | 5 mg | 46 mg | 143 mg | 158 mg | 220 mg |

| 4 g/L | 3 mg | 54 mg | 128 mg | 157 mg | 155 mg |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, R.; Shen, F.; Cui, J.; Zhang, Y.; Yan, H.; Juan Carlos, S.S. Electrophoretic Deposition of Graphene Oxide on Laser-Ablated Copper Mesh for Enhanced Oil/Water Separation. Coatings 2019, 9, 157. https://doi.org/10.3390/coatings9030157

Zhou R, Shen F, Cui J, Zhang Y, Yan H, Juan Carlos SS. Electrophoretic Deposition of Graphene Oxide on Laser-Ablated Copper Mesh for Enhanced Oil/Water Separation. Coatings. 2019; 9(3):157. https://doi.org/10.3390/coatings9030157

Chicago/Turabian StyleZhou, Rui, Fei Shen, Jingqin Cui, Yonggang Zhang, Huangping Yan, and Segovia Sanchez Juan Carlos. 2019. "Electrophoretic Deposition of Graphene Oxide on Laser-Ablated Copper Mesh for Enhanced Oil/Water Separation" Coatings 9, no. 3: 157. https://doi.org/10.3390/coatings9030157

APA StyleZhou, R., Shen, F., Cui, J., Zhang, Y., Yan, H., & Juan Carlos, S. S. (2019). Electrophoretic Deposition of Graphene Oxide on Laser-Ablated Copper Mesh for Enhanced Oil/Water Separation. Coatings, 9(3), 157. https://doi.org/10.3390/coatings9030157