Method of Stabilizing Heavily Spalted Big Leaf Maple as a Decorative Coating Veneer Layer for Engineered Wood Flooring

Abstract

:1. Introduction

2. Materials and Methods

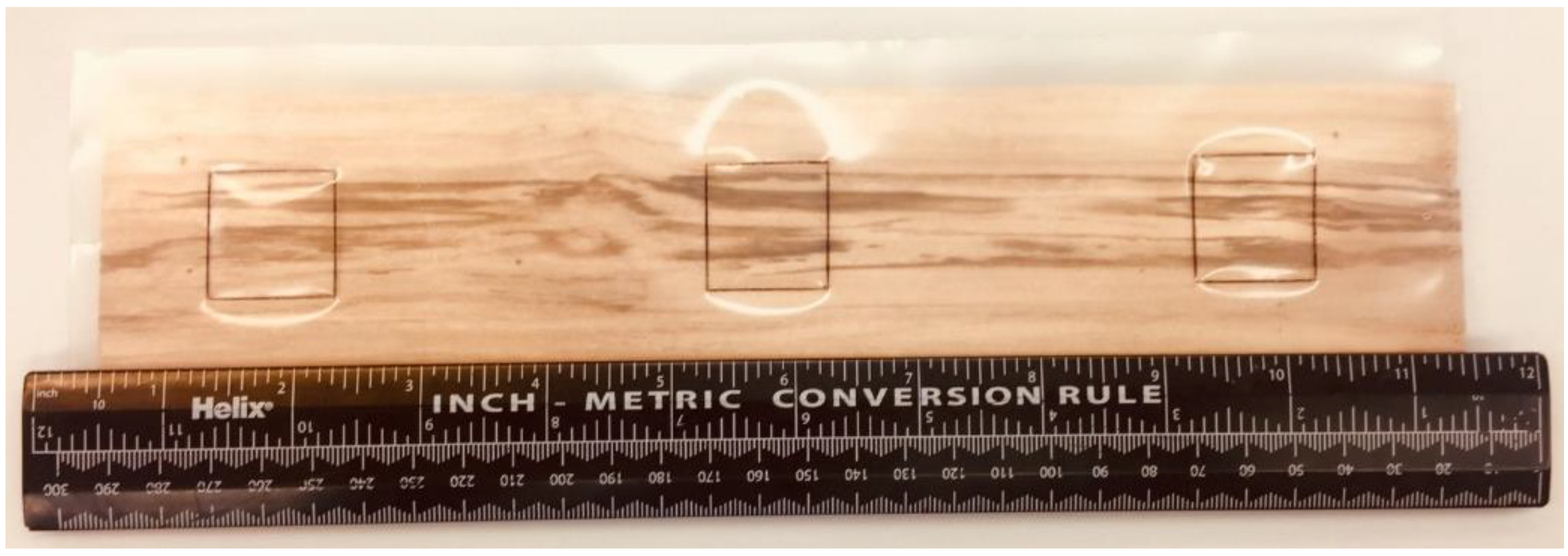

2.1. Specimen Selection

2.2. The VTC Process

2.3. Color Test

2.4. Hardness Test

2.5. Set Recovery Test

2.6. FTIR Test

3. Data Analysis

- Density = Wood | Treatment

- Hardness = Wood | Treatment

- Color = Wood | Treatment

4. Results

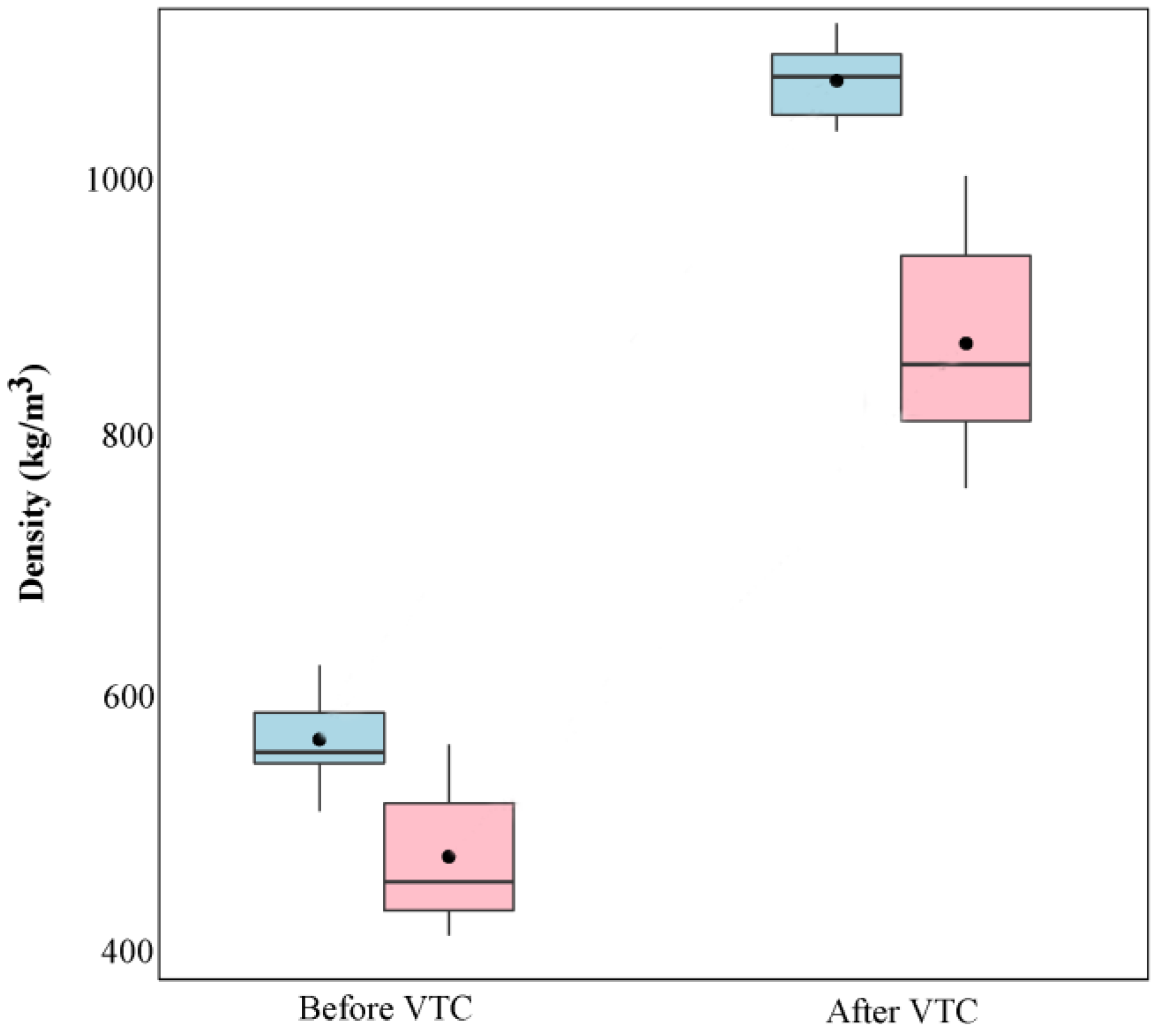

4.1. Density

4.2. Color Test

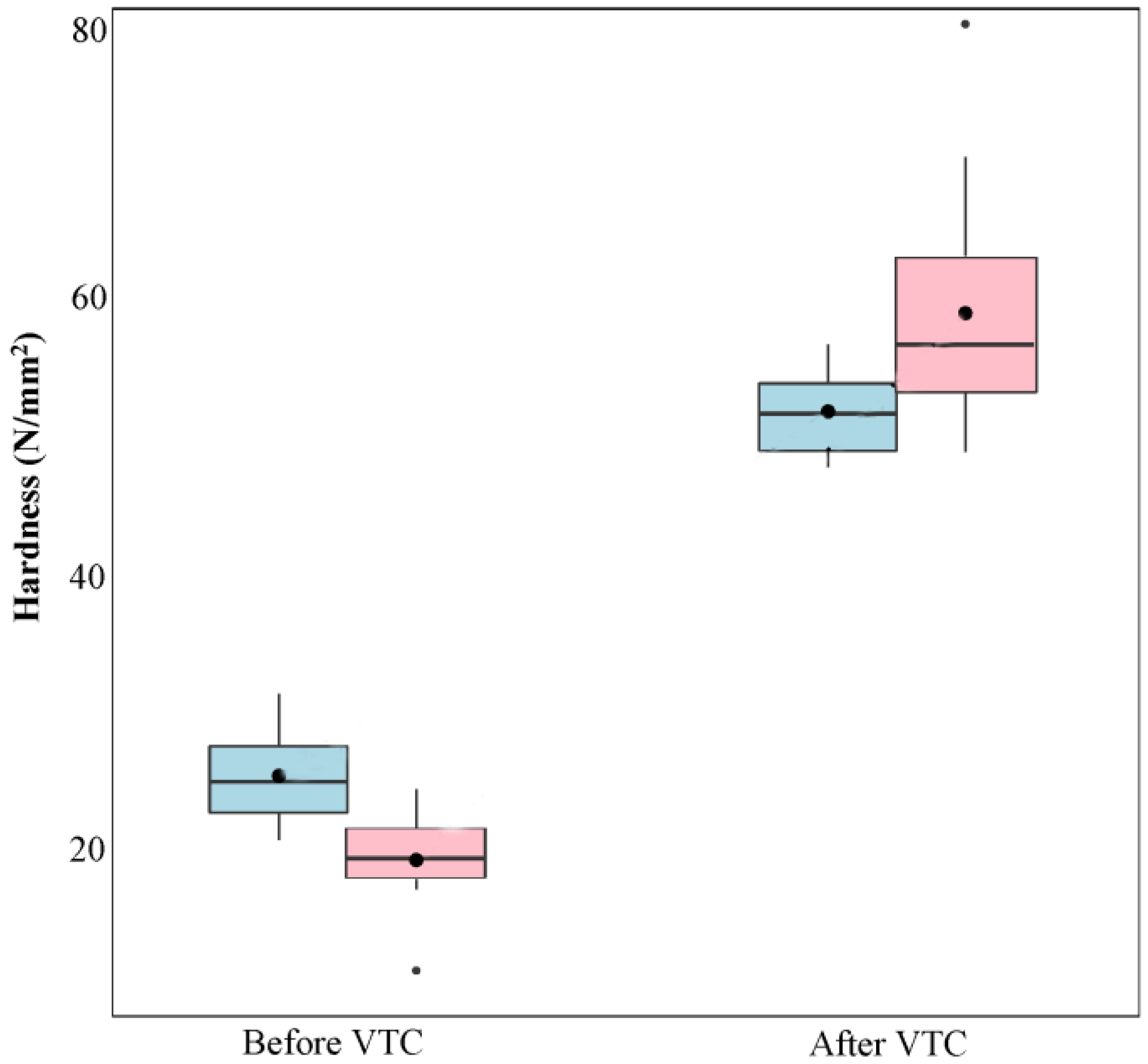

4.3. Hardness Test

4.4. Set Recovery Test

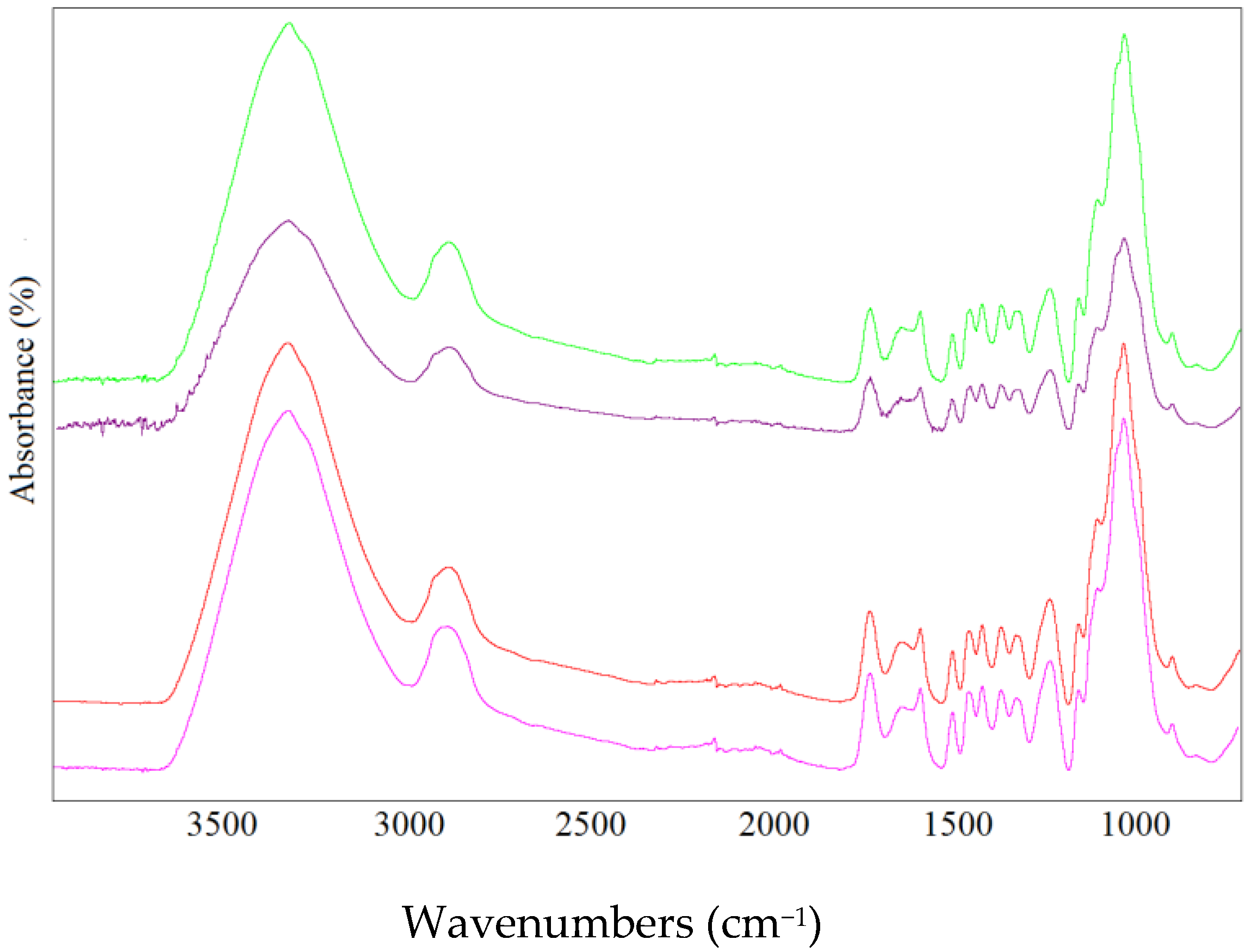

4.5. FTIR Test

5. Discussion

5.1. In General

5.2. Density

5.3. Color Test

5.4. Hardness Test

5.5. Set Recovery Test

5.6. FTIR Test

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Donovan, G.H.; Nicholls, D.L. Consumer preferences and willingness to pay for character-marked cabinets from alaska birch. For. Prod. J. 2003, 53, 27–32. [Google Scholar]

- Lindquist, M. Spalted wood. Rare jewels from death and decay. Fine Woodwork. 1977, 7, 50–53. [Google Scholar]

- Robinson, S.C.; Michaelsen, H.; Robinson, J.C. Spalted Wood: The History, Science and Art of a Unique Material, 1st ed.; Schiffer Publishing: Atglen, PA, USA, 2016; p. 287. [Google Scholar]

- Robinson, S.C.; Tudor, D.; MacDonald, G.; Mansourian, Y.; Cooper, P.A. Repurposing mountain pine beetle blue wood for art through additional fungal colonization. Int. Biodeterior. Biodegrad. 2013, 85, 372–374. [Google Scholar] [CrossRef]

- Robinson, S.C. Developing fungal pigments for “painting” vascular plants. Appl. Microbiol. Biotechnol. 2012, 93, 1389–1394. [Google Scholar] [CrossRef] [PubMed]

- Vega Gutierrez, S.M.; Kramer, O.E.; Andersen, C.C.; Vega Gutierrez, P.T.; Robinson, S.C. A method for citizen scientists to catalogue worldwide Chlorociboria spp. Distribution. Challenges 2018, 9, 11. [Google Scholar] [CrossRef]

- Christensen, K.W. Improving the Working Properties of Spalted Woods through Impregnation with Methyl Methacrylate; Brigham Young University, Department of Industrial Education: Provo, UT, USA, 1982. [Google Scholar]

- Robinson, S.C.; Vega Gutierrez, S.M.; Cespedes Garcia, R.A.; Iroume, N.; Vorland, N.R.; Andersen, C.; de Oliveira Xaxa, I.D.; Kramer, O.E.; Huber, M.E. Potential for fungal dyes as colorants in oil and acrylic paints. J. Coat. Technol. Res. 2018, 15, 1–5. [Google Scholar] [CrossRef]

- Kamke, F.A. Densified radiata pine for structural composites. Maderas. Ciencia y Tecnologia 2006, 8, 83–92. [Google Scholar]

- Kutnar, A.; Kamke, F.A.; Nairn, J.A.; Sernek, M. Mode II fracture behavior of bonded viscoelastic thermal compressed wood. Wood Fiber Sci. 2008, 40, 362–373. [Google Scholar]

- O’Connor, J.P. Improving Wood Strength and Stiffness through Viscoelastic Thermal Compression. Master’s Thesis, Oregon State University, Corvallis, OR, USA, June 2007. [Google Scholar]

- Rautkari, L.; Kamke, F.A.; Hughes, M. Density profile relation to hardness of viscoelastic thermal compressed (VTC) wood composite. Wood Sci. Technol. 2011, 45, 693–705. [Google Scholar] [CrossRef]

- Robinson, S.C.; Laks, P.E.; Richter, D.L.; Pickens, J.B. Evaluating loss of machinability in spalted sugar maple. For. Prod. J. 2007, 57, 33–37. [Google Scholar]

- Kutnar, A.; Kamke, F.A. Compression of wood under saturated steam, superheated steam, and transient conditions at 150 °C, 160 °C, and 170 °C. Wood Sci. Technol. 2012, 46, 73–88. [Google Scholar] [CrossRef]

- Kutnar, A.; Humar, M.; Kamke, F.A.; Sernek, M. Fungal decay of viscoelastic thermal compressed (VTC) wood. Eur. J. Wood Wood Prod. 2011, 69, 325–328. [Google Scholar] [CrossRef]

- BS EN 1534:2000: Wood and Parquet Flooring—Determination of Resistance to Indentation (Brinell)—Test Method; BSI Group: London, UK, 2000.

- Laine, K.; Rautkari, L.; Hughes, M.; Kutnar, A. Reducing the set-recovery of surface densified solid scots pine wood by hydrothermal post-treatment. Eur. J. Wood Wood Prod. 2013, 71, 17–23. [Google Scholar] [CrossRef]

- Militz, H. Thermal treatment of wood: European processes and their background. IRG/WP 2002, 2002, 02-40241. [Google Scholar]

- Schwarze, F.W.; Spycher, M. Resistance of thermo-hydro-mechanically densified wood to colonization and degradation by brown-rot fungi. Holzforschung 2005, 59, 358–363. [Google Scholar] [CrossRef]

- Bhuiyan, T.R.; Hirai, N.; Sobue, N. Change of crystallinity in wood cellulose by heat-treatment under dried and moist conditions. J. Wood Sci. 2000, 46, 431–436. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood: Chemistry Ultrastructure Reactions; Walter de Gruyter & Co.: Berlin, Germany, 1989; pp. 319–336. [Google Scholar]

- Esteves, B.; Marques, A.V.; Domingos, I.; Pereira, H. Heat-induced colour changes of pine (Pinus pinaster) and eucalyptus (Eucalyptus globulus) wood. Wood Sci. Technol. 2008, 42, 369–384. [Google Scholar] [CrossRef]

- Bowyer, J.L.; Shmulski, R.; Haygreen, J.G. Forest Products and Wood Science: An Introduction, 4th ed.; Iowa State University Press: Ames, IA, USA, 2003; pp. 3–23. [Google Scholar]

- Heger, F.; Groux, M.; Girardet, F.; Welzback, C.; Rapp, A.O.; Navi, P. Mechanical and durability performance of THM-densified wood. Proceedings of Environmental Optimization of Wood Protection Workshop, Lisboa, Portugal, 22–23 March 2004. [Google Scholar]

- Kamke, F.A.; Rautkari, L. Modified wood veneer for structural applications. In Proceedings of the 4th International Symposium on Veneer Processing and Products (ISVPP), Espoo, Finland, 24–27 May 2009; pp. 207–212. [Google Scholar]

- Kutnar, A.; Kamke, F.A.; Sernek, M. Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci. Technol. 2009, 43, 57. [Google Scholar] [CrossRef]

- Kutnar, A.; Kamke, F.A. The influence of heat treatment on the set recovery of compressive deformation. In Proceedings of the 1st International Conference on Processing Technologies for the Forest and Biobased Products Industries (PTF BPI), Salzburg University of Applied Sciences, Kuchl, Austria, 7–8 October 2010. [Google Scholar]

- Bekhta, P.; Proszyk, S.; Krystofiak, T.; Sedliacik, J.; Novak, I.; Mamonova, M. Effects of short-term thermomechanical densification on the structure and properties of wood veneers. Wood Mater. Sci. Eng. 2015, 12, 40–54. [Google Scholar] [CrossRef]

- Zabel, R.A.; Morrell, J.J. Wood Microbiology: Decay and Its Prevention; Harcourt Brace Jovanovich, Academic Press, Inc.: New York, NY, USA, 1992. [Google Scholar]

- Hoadley, R.A. Identifying Wood: Accurate Results with Simple Tools; Tauton Press: Newtown, CT, USA, 1990. [Google Scholar]

- Koch, G.; Puls, J.; Bauch, J. Topochemical characterisation of phenolic extractives in discoloured beechwood (Fagus sylvatica L.). Holzforschung 2003, 54, 339–345. [Google Scholar] [CrossRef]

- Sundqvist, B.; Karlsson, O.; Westermark, U. Determination of formic-acid and acetic acid concentrations formed during hydrothermal treatment of birch wood and its relation to colour, strength and hardness. Wood Sci. Technol. 2006, 40, 549. [Google Scholar] [CrossRef]

- Tjeerdsma, B.F.; Boonstra, M.; Tekely, P.; Militz, H. Characterisation of thermally modified wood: Molecular reasons for wood performance improvement. Holz als Roh- und Werkstoff 1998, 56, 149. [Google Scholar] [CrossRef]

- Varga, D.; van der Zee, M.E. Influence of steaming on selected wood properties of four hardwood species. Holz als Roh- und Werkstoff 2008, 66, 11. [Google Scholar] [CrossRef]

- Welzbacher, C.R. Tmt-interlab-test to establish suitable quality control techniques-structure and first results. Proceedings of 41st Annual Meeting of the International Research Group on Wood Protection, Biarritz, France, 9–13 May 2010. [Google Scholar]

- Lesar, B.; Humar, M.; Kamke, F.A.; Kutnar, A. Influence of the thermo-hydro-mechanical treatments of wood on the performance against wood-degrading fungi. Wood Sci. Technol. 2013, 47, 977–992. [Google Scholar] [CrossRef]

- Bekhta, P.; Niemz, P. Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 2005, 57, 539–546. [Google Scholar] [CrossRef]

- Curling, S.F.; Clausen, C.A.; Winandy, J.E. Relationships between mechanical properties, weight loss, and chemical composition of wood during incipient brown-rot decay. For. Prod. J. 2002, 52, 34. [Google Scholar]

- Humar, M.; Amartey, S.A.; Pohleven, F. Influence of corn steep liquor and glucose on colonization of control and CCB (Cu/Cr/B)-treated wood by brown rot fungi. Waste Manag. 2006, 25, 459–469. [Google Scholar] [CrossRef]

- Mayer, I.; Koch, G. Element content and pH value in American black cherry (Prunus serotina) with regard to colour changes during heartwood formation and hot water treatment. Wood Sci. Technol. 2007, 41, 537. [Google Scholar] [CrossRef]

- Sundqvist, B.; Morén, T. The influence of wood polymers and extractives on wood colour induced by hydrothermal treatment. Holz als Roh- und Werkstoff 2002, 60, 375–376. [Google Scholar] [CrossRef]

- Sundqvist, B. Colour Changes and Acid Formation in Wood during Heating. Ph.D. Thesis, Luleå University of Technology, Godkänd, Sweden, January 2004. [Google Scholar]

- Bekhta, P.; Proszyk, S.; Krystofiak, T. Colour in short-term thermo-mechanically densified veneer of various wood species. Eur. J. Wood Wood Prod. 2014, 72, 785–797. [Google Scholar] [CrossRef]

- Bekhta, P.; Proszyk, S.; Lis, B.; Krystofiak, T. Gloss of thermally densified alder (Alnus glutinosa Goertn.), beech (Fagus sylvatica L.), birch (Betula verrucosa Ehrh.), and pine (Pinus sylvestris L.) wood veneers. Eur. J. Wood Wood Prod. 2014, 72, 799–808. [Google Scholar] [CrossRef]

- Diouf, P.N.; Stevanovic, T.; Cloutier, A.; Fang, C.-H.; Blanchet, P.; Koubaa, A.; Mariotti, N. Effects of thermo-hygro-mechanical densification on the surface characteristics of trembling aspen and hybrid poplar wood veneers. Appl. Surf. Sci. 2011, 257, 3558–3564. [Google Scholar] [CrossRef]

- Arruda, L.M.; Del Menezzi, C.H.S. Effect of thermomechanical treatment on physical properties of wood veneers. Int. Wood Prod. J. 2013, 4, 217–224. [Google Scholar] [CrossRef]

- Candan, Z.; Hiziroglu, S.; McDonald, A.G. Surface quality of thermally compressed douglas-fir veneer. Mater. Des. 2010, 31, 3574–3577. [Google Scholar] [CrossRef]

- Fang, C.-H.; Mariotti, N.; Cloutier, A.; Koubaa, A.; Blanchet, P. Densification of wood veneers by compression combined with heat and steam. Eur. J. Wood Wood Prod. 2012, 70, 155–163. [Google Scholar] [CrossRef]

- Kariz, M.; Kuzman, M.K.; Sernek, M.; Hughes, M.; Rautkari, L.; Kamke, F.A.; Kutnar, A. Influence of temperature of thermal treatment on surface densification of spruce. Eur. J. Wood Wood Prod. 2017, 75, 113–123. [Google Scholar] [CrossRef]

- Rautkari, L.; Properzi, M.; Pichelin, F.; Hughes, M. Properties and set-recovery of surface densified Norway spruce and European beech. Wood Sci. Technol. 2010, 44, 679–691. [Google Scholar] [CrossRef]

- Rautkari, L.; Laine, K.; Kutnar, A.; Medved, S.; Hughes, M. Hardness and density profile of surface densified and thermally modified scots pine in relation to degree of densification. J. Mater. Sci. 2013, 48, 2370–2375. [Google Scholar] [CrossRef]

- Gong, M.; Lamason, C.; Li, L. Interactive effect of surface densification and post-heat-treatment on aspen wood. J. Mater. Proc. Technol. 2010, 210, 293–296. [Google Scholar] [CrossRef]

- Antikainen, T.; Paajanen, O.; Rautkari, L.; Kutnar, A.; Kamke, F.A.; Hughes, M. Simultaneous drying and densification of silver birch (Betula pendula L.) veneers: Analysis of morphology, thickness swelling, and density profile. Wood Sci. Technol. 2014, 48, 325–336. [Google Scholar] [CrossRef]

- Navi, P.; Heger, F. Combined densification and thermo-hydro-mechanical processing of wood. MRS Bull. 2004, 29, 332–336. [Google Scholar] [CrossRef]

- Welzbacher, C.R.; Wehsener, J.; Rapp, A.O.; Haller, P. Thermo-mechanical densification combined with thermal modification of norway spruce (Picea abies Karst) in industrial scale—Dimensional stability and durability aspects. Holz als Roh- und Werkstoff 2008, 66, 39. [Google Scholar] [CrossRef]

- Hsu, W.E.; Schwald, W.; Scwald, J.; Shields, J.A. Chemical and physical changes required for producing dimensionally stable wood-based composites. Wood Sci. Technol. 1988, 22, 281–289. [Google Scholar] [CrossRef]

- Shams, M.I.; Kagemori, N.; Yano, H. Compressive deformation of wood impregnated with low molecular weight phenol formaldehyde (pf) resin iv: Species dependency. J. Wood Sci. 2006, 52, 179–183. [Google Scholar] [CrossRef]

- Wolcott, M.P.; Shutler, E.L. Temperature and moisture influence on compression-recovery behavior of wood. Wood Fiber Sci. 2007, 35, 540–552. [Google Scholar]

- Bodig, J.; Jayne, B.A. Mechanics of Wood and Wood Composites; Van Nostrand Reinhold Company: New York, NY, USA, 1982. [Google Scholar]

- Morsing, N.; Hoffmeyer, P. Densification of wood: The influence of hygrothermal treatment on compression of beech perpendicular to gain. Ph.D. Thesis, Danmarks Tekniske Universitet, Copenhagen, Denmark, 1998. [Google Scholar]

- Navi, P.; Sandberg, D. Thermo-Hydro-Mechanical Wood Processing; EPFL Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Inoue, M.; Norimoto, M.; Tanahashi, M.; Rowell, R.M. Steam or heat fixation of compressed wood. Wood Fiber Sci. 1993, 25, 224–235. [Google Scholar]

- Inoue, M.; Sekino, N.; Morooka, T.; Rowell, R.M.; Norimoto, M. Fixation of compressive deformation in wood by pre-steaming. Trop. For. Sci. 2008, 20, 273–281. [Google Scholar]

- Reynolds, M.S. Hydro-Thermal Stabilization of Wood-Based Materials. Master’s Thesis, Virginia Tech, Blacksburg, VA, USA, 2004. [Google Scholar]

- Hakkou, M.; Pétrissans, M.; Zoulalian, A.; Gérardin, P. Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym. Degrad. Stab. 2005, 89, 1–5. [Google Scholar] [CrossRef]

- Hakkou, M.; Pétrissans, M.; Gérardin, P.; Zoulalian, A. Investigations of the reasons for fungal durability of heat-treated beech wood. Polym. Degrad. Stab. 2006, 91, 393–397. [Google Scholar] [CrossRef]

- Tjeerdsma, B.F.; Militz, H. Chemical changes in hydrothermal treated wood: Ftir analysis of combined hydrothermal and dry heat-treated wood. Holz als Roh- und Werkstoff 2005, 63, 102–111. [Google Scholar] [CrossRef]

- Yildiz, S.; Yildiz, U.C.; Tomak, E.D. The effects of natural weathering on the properties of heat-treated alder wood. BioResources 2011, 6, 2504–2521. [Google Scholar]

- Liu, H.; Shang, J.; Chen, X.; Kamke, F.A.; Guo, K. The influence of thermal-hydro-mechanical processing on chemical characterization of tsuga heterophylla. Wood Sci. Technol. 2014, 48, 373–392. [Google Scholar] [CrossRef]

- Ma, M.-G.; Jia, N.; Zhu, J.-F.; Li, S.-M.; Peng, F.; Sun, R.-C. Isolation and characterization of hemicelluloses extracted by hydrothermal pretreatment. Bioresour. Technol. 2012, 114, 677–683. [Google Scholar] [CrossRef] [PubMed]

| Type of Wood | VTC Treatment | Density (kg/m3) | Standard Deviation | CV (%) |

|---|---|---|---|---|

| Spalted wood | before | 472 | 50 | 11 |

| after | 868 | 77 | 9 | |

| Sound wood | before | 562 | 30 | 5 |

| after | 1070 | 28 | 2 |

| Wood Type | VTC Treatment | L* | CV (%) | a* | CV (%) | b* | CV (%) |

|---|---|---|---|---|---|---|---|

| Spalted wood | Before | 74 (2) | 3 | 6 (1) | 16 | 20 (2) | 7 |

| After | 67 (3) | 4 | 7 (1) | 13 | 20 (1) | 7 | |

| Sound wood | Before | 75 (1) | 2 | 8 (1) | 10 | 19 (1) | 4 |

| After | 68 (2) | 2 | 9 (1) | 10 | 19 (1) | 3 |

| Type of Wood | VTC Treatment | Hardness (N/mm2) | Standard Deviation | CV (%) |

|---|---|---|---|---|

| Spalted wood | Before | 19 | 3 | 16 |

| After | 59 | 9 | 15 | |

| Sound wood | Before | 25 | 3 | 12 |

| After | 52 | 3 | 6 |

| Type of Wood | Set Recovery (%) | Standard Deviation | CV (%) |

|---|---|---|---|

| Spalted wood | 78 | 7 | 8 |

| Sound wood | 71 | 5 | 7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodrigues de Oliveira, D.; Andersen, C.C.; Vega Gutierrez, S.M.; Kamke, F.A.; Robinson, S.C. Method of Stabilizing Heavily Spalted Big Leaf Maple as a Decorative Coating Veneer Layer for Engineered Wood Flooring. Coatings 2019, 9, 132. https://doi.org/10.3390/coatings9020132

Rodrigues de Oliveira D, Andersen CC, Vega Gutierrez SM, Kamke FA, Robinson SC. Method of Stabilizing Heavily Spalted Big Leaf Maple as a Decorative Coating Veneer Layer for Engineered Wood Flooring. Coatings. 2019; 9(2):132. https://doi.org/10.3390/coatings9020132

Chicago/Turabian StyleRodrigues de Oliveira, Diego, Claudia C. Andersen, Sarath M. Vega Gutierrez, Frederick A. Kamke, and Seri C. Robinson. 2019. "Method of Stabilizing Heavily Spalted Big Leaf Maple as a Decorative Coating Veneer Layer for Engineered Wood Flooring" Coatings 9, no. 2: 132. https://doi.org/10.3390/coatings9020132

APA StyleRodrigues de Oliveira, D., Andersen, C. C., Vega Gutierrez, S. M., Kamke, F. A., & Robinson, S. C. (2019). Method of Stabilizing Heavily Spalted Big Leaf Maple as a Decorative Coating Veneer Layer for Engineered Wood Flooring. Coatings, 9(2), 132. https://doi.org/10.3390/coatings9020132