Investigation of the Performance of ATH Powders in Organic Powder Coatings

Abstract

1. Introduction

2. Experimental

2.1. Preparation of the Samples

2.2. Measurements of the Samples

2.2.1. Characterization of Powder Paints

2.2.2. Characterization of Finished Films

3. Results

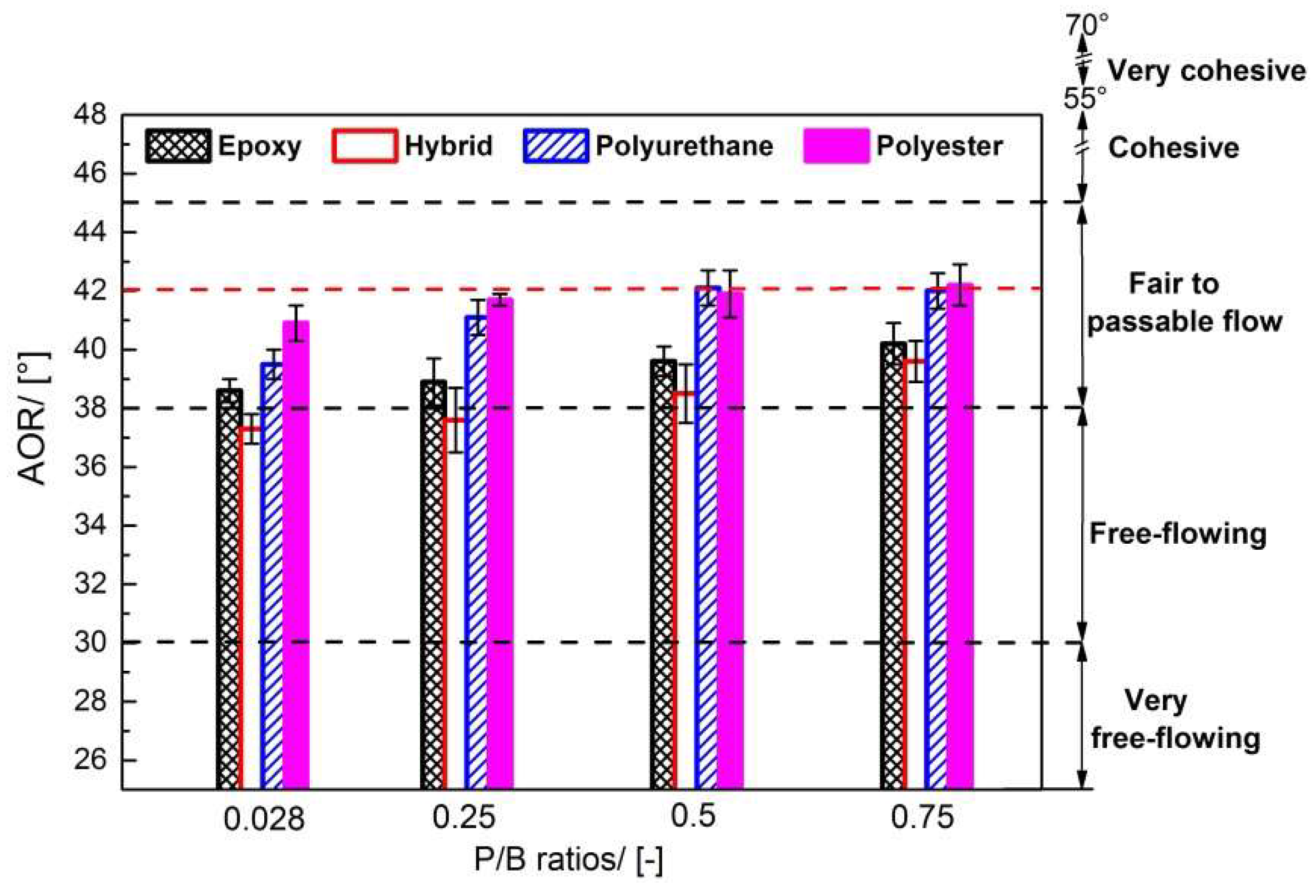

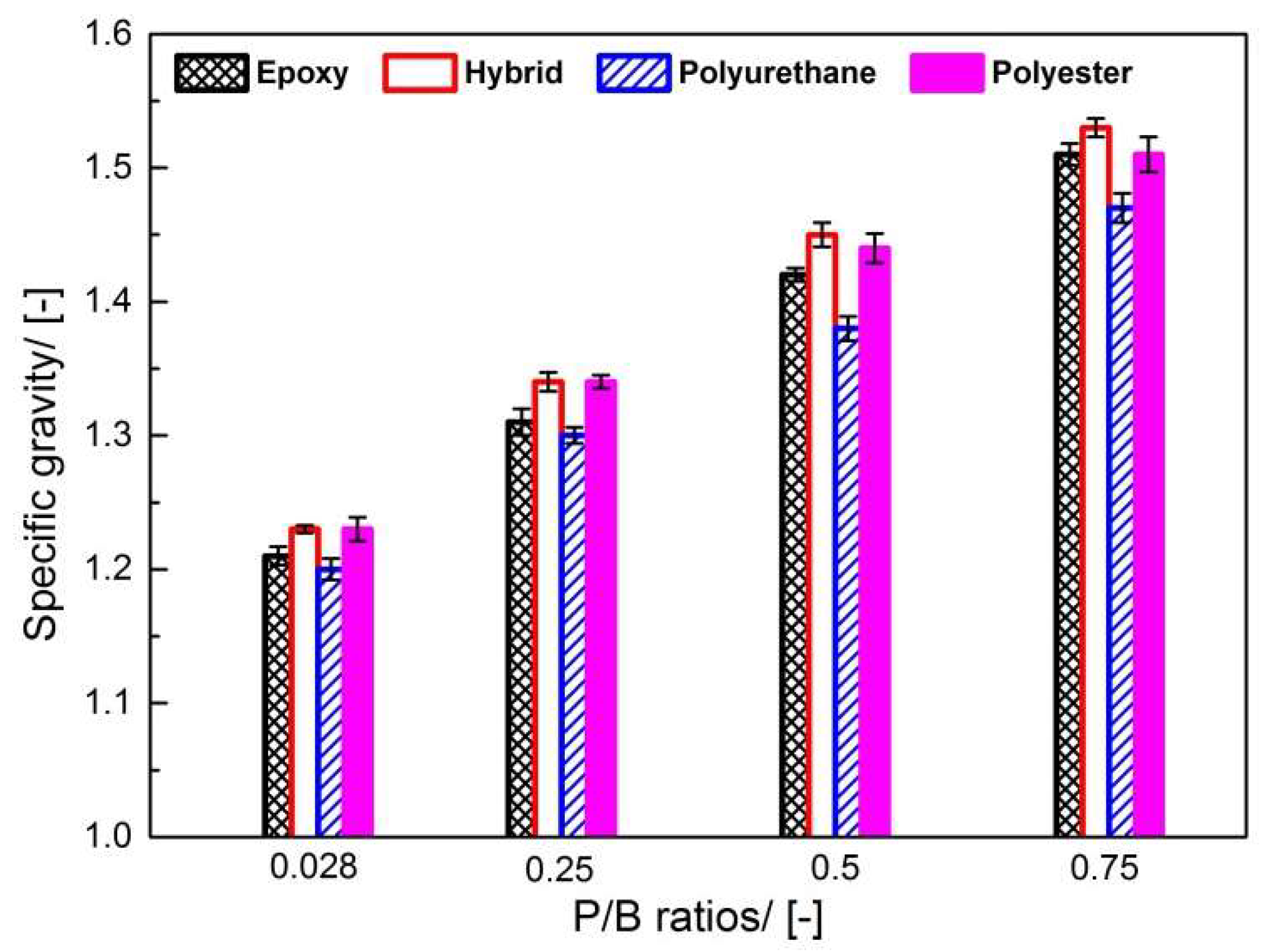

3.1. Powder Properties-Angle of Repose and Specific Gravity

3.2. Film Properties-Mechanical, Physical, UV and Corrosion Resistance Performances

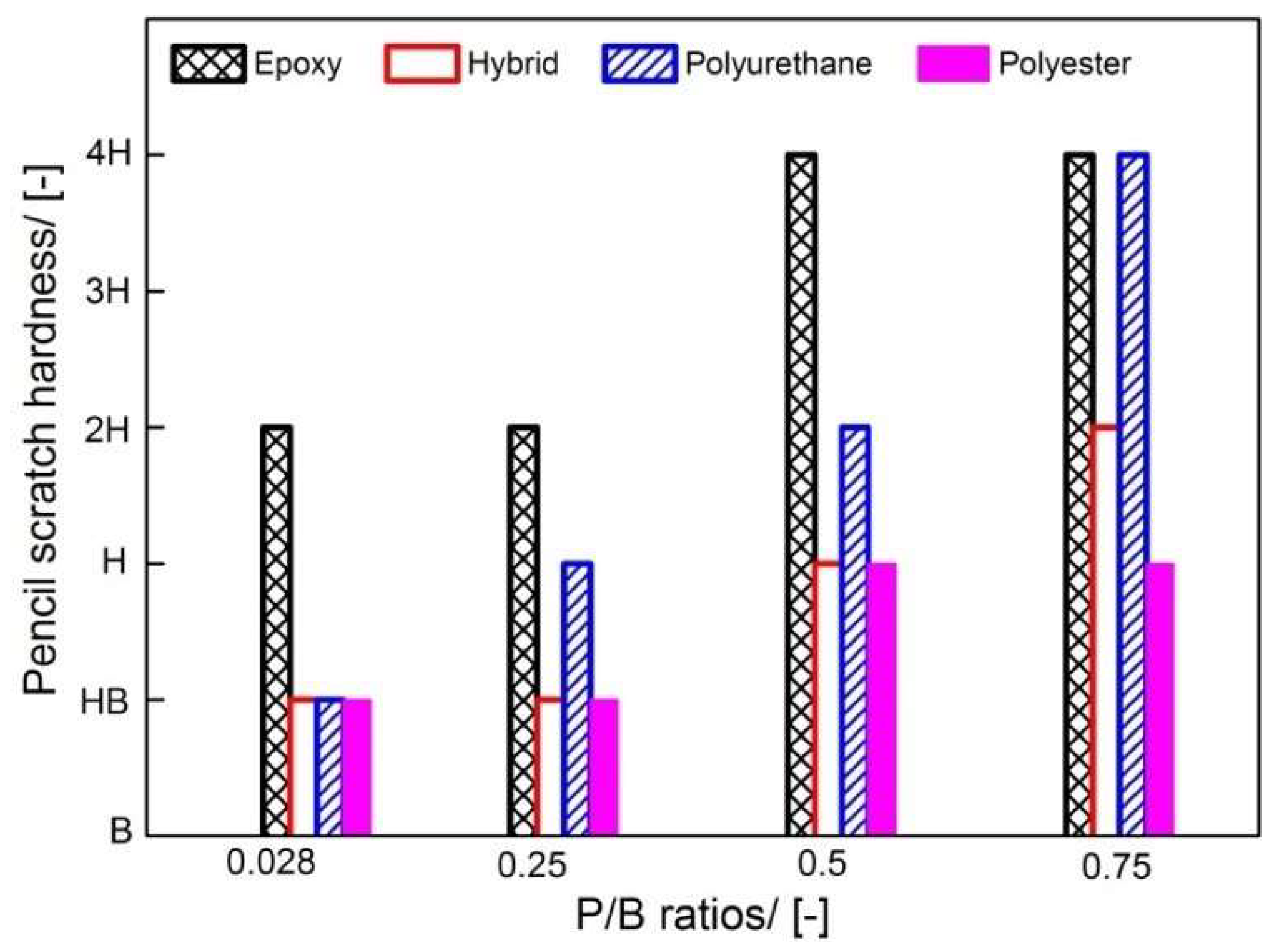

3.2.1. Effect of ATH on the Pencil Scratch Hardness, Flexibility and Impact Resistance of the Films

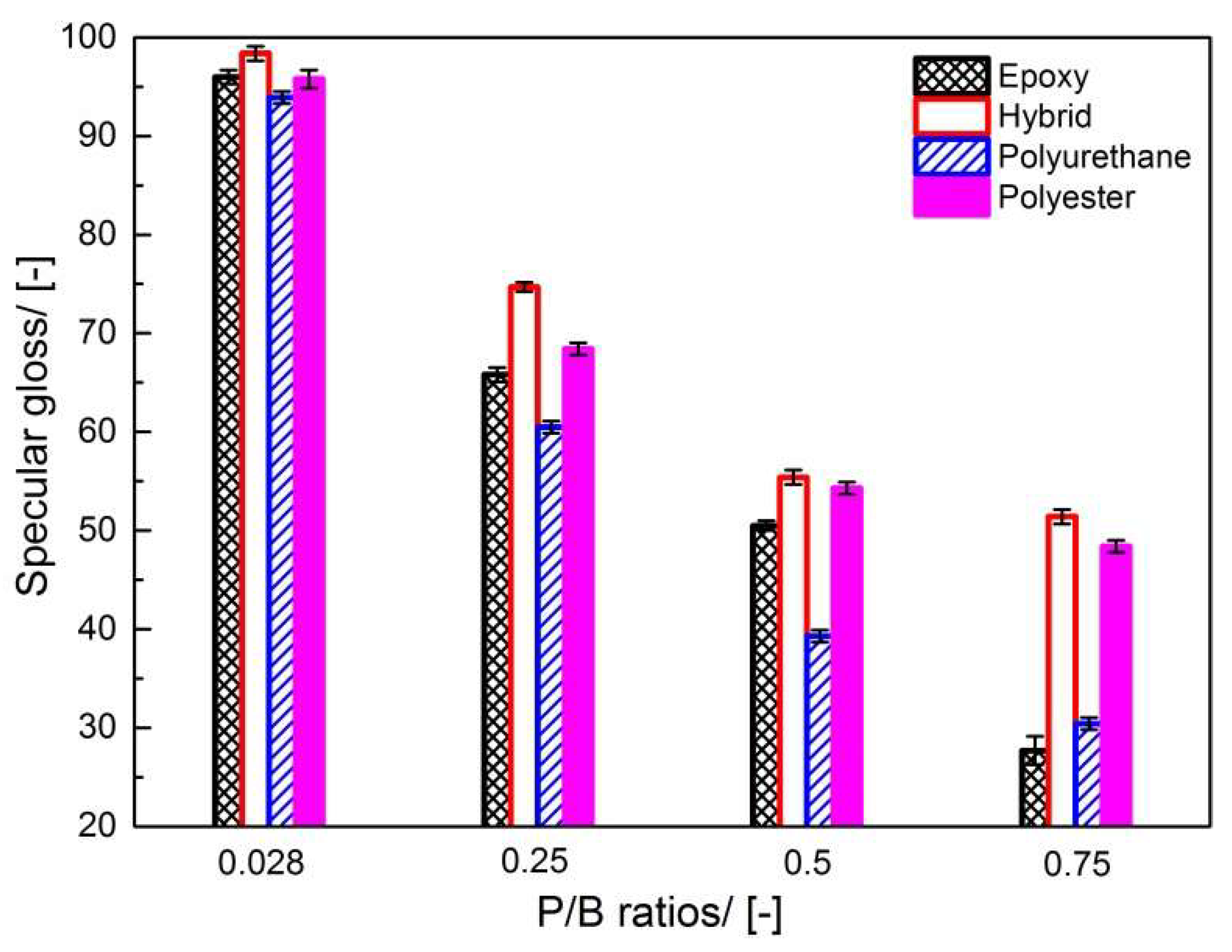

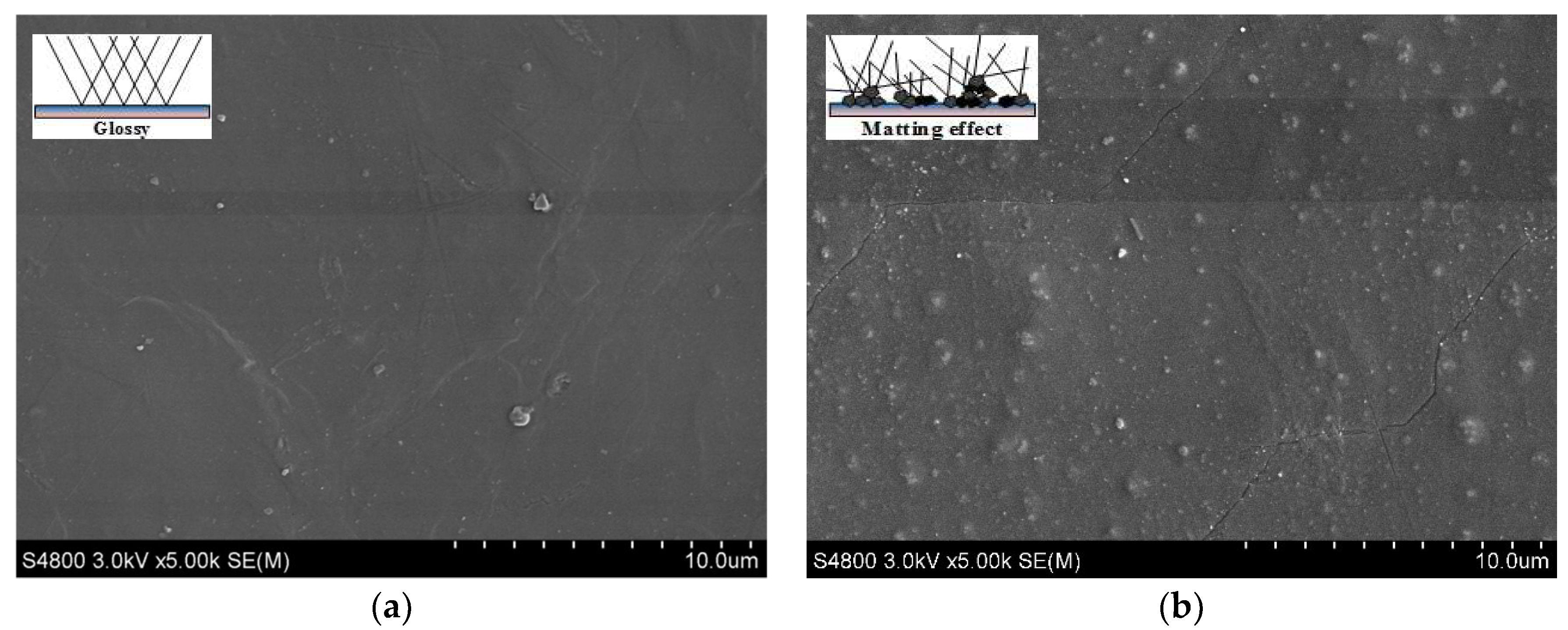

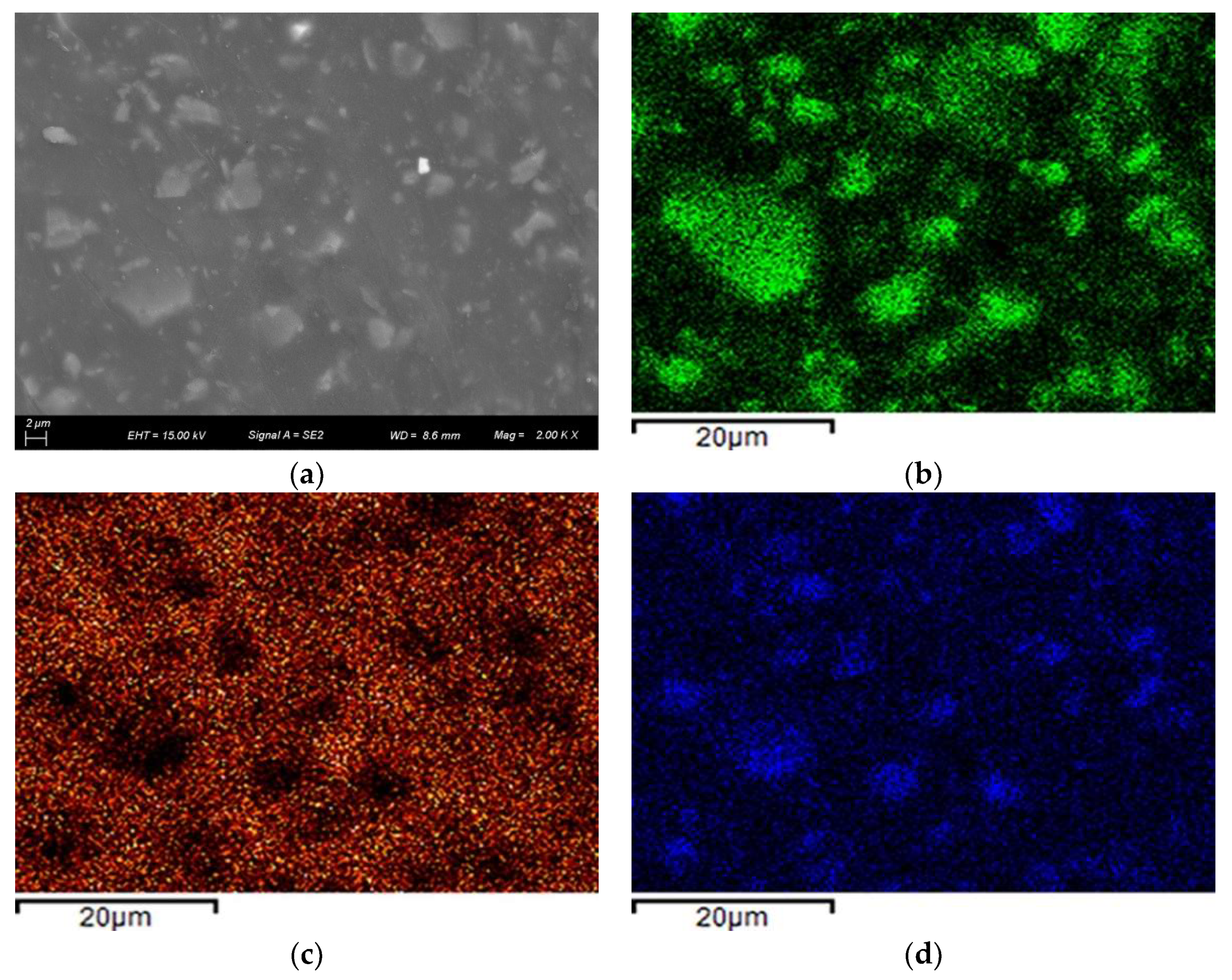

3.2.2. Effect of ATH on the Specular Gloss of the Films

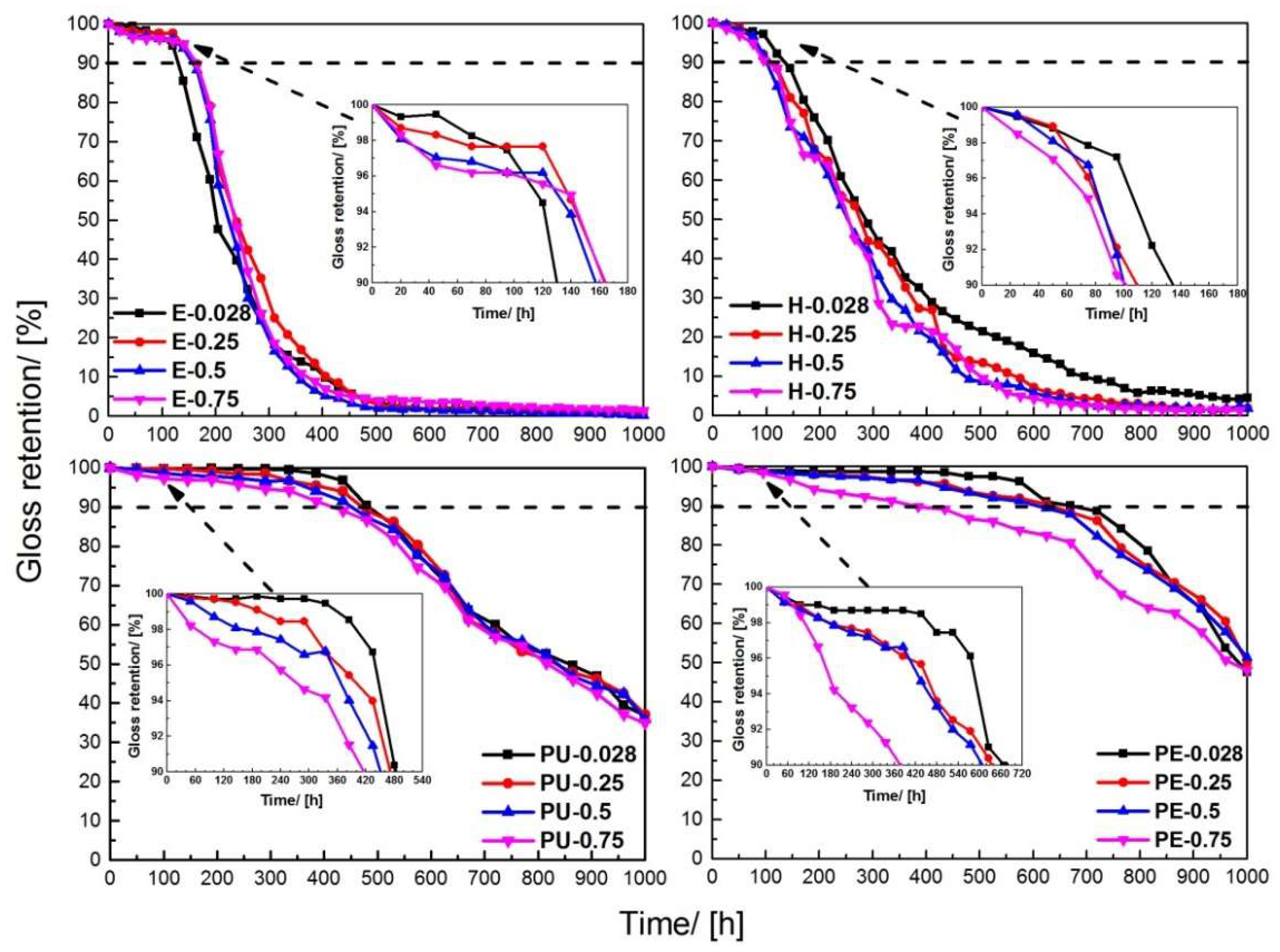

3.2.3. Effect of ATH on the UV Resistance of the Films

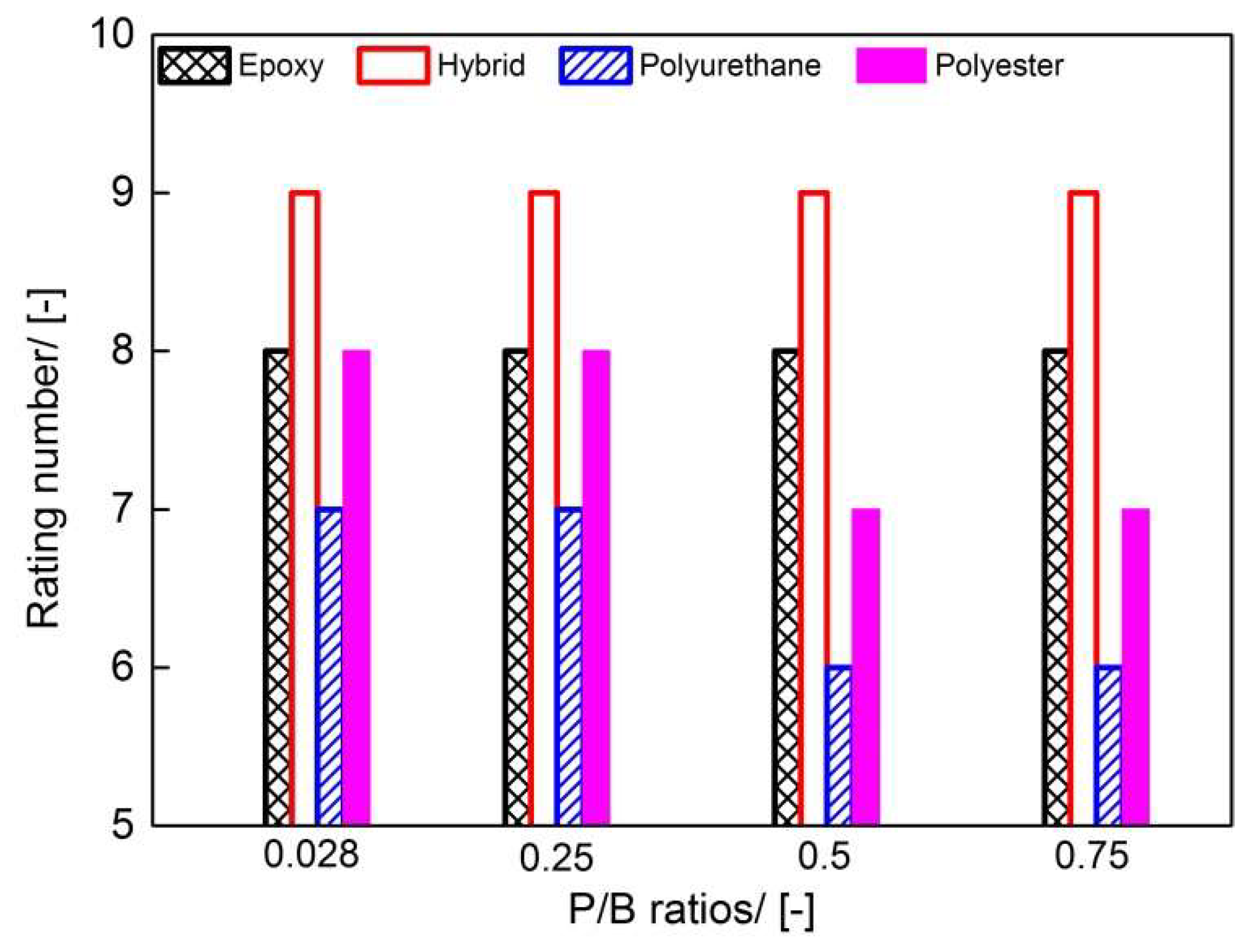

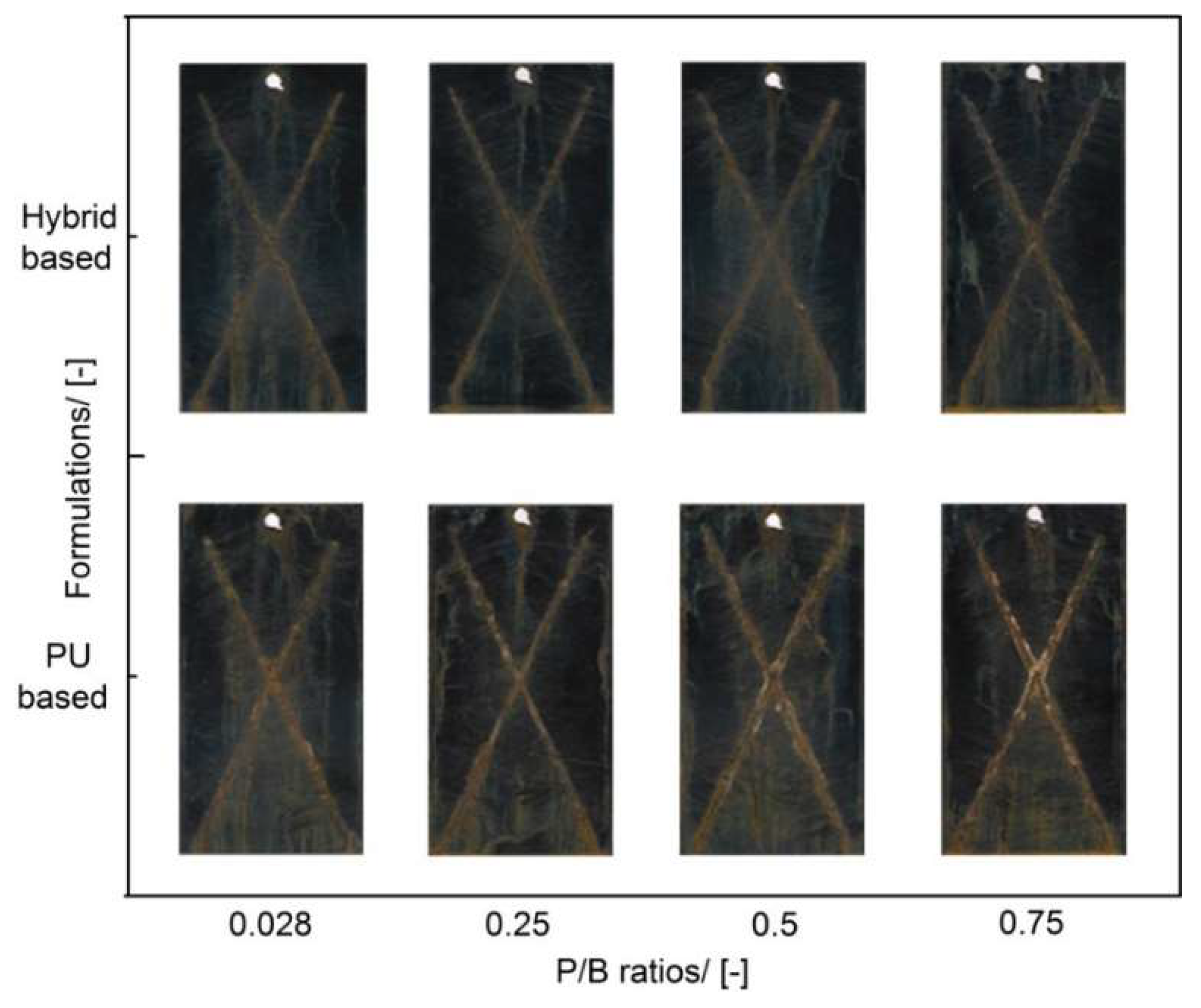

3.2.4. Effect of ATH on Corrosion Resistance of the Film

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Notations

| D50 | Median particle diameter (50 vol.% of the powder smaller than the diameter) [μm] |

| Initial gloss [-] | |

| Gloss value at a general time “x” [-] |

References

- Zhu, J.X.; Zhang, H. Ultrafine powder coatings: An innovation. Powder Coat. 2005, 16, 39–47. [Google Scholar]

- Misev, T.A.; Van der Linde, R. Powder coatings technology: New developments at the turn of the century. Prog. Org. Coat. 1998, 34, 160–168. [Google Scholar] [CrossRef]

- Huang, Q.; Zhang, H.; Zhu, J. Flow properties of fine powders in powder coating. Particuology 2010, 8, 19–27. [Google Scholar] [CrossRef]

- Wei, H.; Liang, H.; Zou, J.; Shi, W. UV-curable powder coatings based on dendritic poly(ether-amide). Prog. Org. Coat. 2003, 90, 287–291. [Google Scholar] [CrossRef]

- Stojanović, I.; Šimunović, V.; Alar, V.; Kapor, F. Experimental evaluation of polyester and epoxy–polyester powder coatings in aggressive media. Coatings 2018, 8, 98. [Google Scholar] [CrossRef]

- Zhu, D.; Luo, F.; Xiong, L.; Zhou, W. Preparation and properties of glass coats containing SiCN nano powder as filler. Mater. Sci. Eng. A 2006, 431, 311–314. [Google Scholar] [CrossRef]

- Luo, S.; Zheng, Y.; Li, J.; Ke, W. Effect of curing degree and fillers on slurry erosion behavior of fusion-bonded epoxy powder coatings. Wear 2003, 254, 292–297. [Google Scholar] [CrossRef]

- Tang, Q.; Zhang, Y.M.; Zhang, P.G.; Shi, J.J.; Tian, W.B.; Sun, Z.M. Preparation and properties of thermal insulation coatings with a sodium stearate-modified shell powder as a filler. Int. J. Miner. Metall. Mater. 2017, 24, 1192–1199. [Google Scholar] [CrossRef]

- Leong, C.K.; Chung, D.D.L. Improving the electrical and mechanical behavior of electrically conductive paint by partial replacement of silver by carbon black. J. Electron. Mater. 2006, 35, 118–122. [Google Scholar] [CrossRef]

- Shang, Q.; Hao, S.; Wang, W.; Fu, D.; Ma, T. Preparation and characterization of antistatic coatings with modified BaTiO3 powders as conductive fillers. J. Adhes. Sci. Technol. 2013, 27, 2642–2652. [Google Scholar] [CrossRef]

- Howell, D.M. Powder Coatings. In the Technology, Formulation and Application of Powder Coatings; John Wiley and Sons Ltd.: Hoboken, NJ, USA, 2000. [Google Scholar]

- Liberto, N. User’s Guide to Powder Coating, 4th ed.; Society of Manufacturing Engineers: Dearborn, MI, USA, 2003. [Google Scholar]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.M.; Veleva, L. Mineral filler influence on the photo-oxidation of high density polyethylene: I. Accelerated UV chamber exposure test. Polym. Degrad. Stab. 1999, 63, 253–260. [Google Scholar] [CrossRef]

- Wei, W.; Guo, J. The investigation of blended conductive coating of graphite/carbon-black. J. Xi’an Jiaotong Univ. 1994, 28, 98–103. (In Chinese) [Google Scholar]

- Wypych, G. Handbook of Fillers, 4th ed.; ChemTec Publishing: Toronto, ON, Canada, 2016. [Google Scholar]

- Qiu, F.; Wang, M.; Hao, Y.; Guo, S. The effect of talc orientation and transcrystallization on mechanical properties and thermal stability of the polypropylene/talc composites. Compos. Part A 2014, 58, 7–15. [Google Scholar] [CrossRef]

- Shafiq, M.; Yasin, T.; Aftab Rafiq, M. Structural, thermal and antibacterial properties of chitosan/ZnO composites. Polym. Compos. 2014, 35, 79–85. [Google Scholar] [CrossRef]

- Seyedmehdi, S.A.; Zhang, H.; Zhu, J. Superhydrophobic RTV silicone rubber insulator coatings. Appl. Surf. Sci. 2014, 258, 2972–2976. [Google Scholar] [CrossRef]

- Xanthos, M. Functional fillers for plastics; Wiley-VCH: Weinheim, Germany, 2005. [Google Scholar]

- Cárdenas, M.A.; García-López, D.; Gobernado-Mitre, I.; Merino, J.C.; Pastor, J.M.; Martínez, J.D.D.; Barbeta, J.; Calveras, D. Mechanical and fire retardant properties of EVA/clay/ATH nanocomposites—Effect of particle size and surface treatment of ATH filler. Polym. Degrad. Stab. 2008, 93, 2032–2037. [Google Scholar] [CrossRef]

- Khattab, M.A.; Feteha, F.A.H.; Sadik, W.A.; Abdel-Bary, E.M. Effect of aluminum trihydrate as flame retardant on properties of a thermoplastic rubber nanocomposite. Fire Mater. 2017, 41, 688–699. [Google Scholar] [CrossRef]

- Müller, B.; Poth, U. Paint formulation. In Coatings Formulation, 3rd ed.; Vincentz Network: Hanover, Germany, 2017; Part I; pp. 60–65. [Google Scholar]

- Cheremisinoff, N.P.; Cheremisinoff, P.N. Hydrodynamics of Gas-Solids Fluidization; Gulf Publishing Co.: Houston, UK, 1984. [Google Scholar]

- Visser, J. Van der Waals and other cohesive forces affecting powder fluidization. Powder Technol. 1989, 58, 1–10. [Google Scholar] [CrossRef]

- ASTM D5965-02(2013) Standard Test Methods for Specific Gravity of Coating Powders; ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D3363-05(2011) Standard Test Method for Film Hardness by Pencil Test; ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM D2794-93(2010) Standard Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact); ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D522/D522M-13 Standard Test Methods for Mandrel Bend Test of Attached Organic Coatings; ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D523-14(2018) Standard Test Method for Specular Gloss; ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM B117-11 Standard Practice for Operating Salt Spray (Fog) Apparatus; ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM D1654-08(2016) Standard Test Method for Evaluation of Painted or Coated Specimens Subjected to Corrosive Environments; ASTM International: West Conshohocken, PA, USA, 2016.

- Hess, M. The relationship between gloss and surface roughness of paint films. J. Oil Colour Chem. Assoc. 1956, 39, 185–192. [Google Scholar]

- Flectcher, T.E. A simple model to describe relationships between gloss behavior, matting agent concentration and the rheology of matted paints and coatings. Prog. Org. Coat. 2001, 44, 25–36. [Google Scholar] [CrossRef]

- Liu, G.H.; Zhou, B.H.; Li, Y.F.; Qi, T.G.; Li, X.B. Surface properties of superfine alumina trihydrate after surface modification with stearic acid. Int. J. Miner. Metall. Mater. 2015, 22, 537–542. [Google Scholar] [CrossRef]

| Materials | Epoxy (E) | Hybrid (H) | Polyurethane (PU) | Polyester (PE) |

|---|---|---|---|---|

| Resin | DER 663U | PE (Crylcoat 2440-2): E (DER 663U) = 7:3 wt.% | Albester 3220 | Crylcoat 2440-2 |

| Curing agent | DICY/Vestagon B31 | IPDI & ε-caprolactam/Alcure 4400 | TGIC/Araldite PT 810 | |

| Filler | Alumina trihydrate/Custom Grinders Polyfill 301 | |||

| Degassing agent | Benzoin/S602 | |||

| Pigment | Carbon black/Raven 5000 Ultra Π | |||

| Fluidization additive | Acrylic polymer/Lanco P10 | |||

| Filler | Shape | Particle Size (D50)/[μm] | Specific Gravity/[-] | Color | Refractive Index/[-] | Oil Absorption/[g oil/100 g] |

|---|---|---|---|---|---|---|

| Al (OH)3 | Irregular | 9 | 2.4 | White | 1.58 | 28 |

| Rust Creepage/mm | Rating Number | Rust Creepage/mm | Rating Number |

|---|---|---|---|

| Zero | 10 | 5.0 to 7.0 | 4 |

| 0 to 0.5 | 9 | 7.0 to 10.0 | 3 |

| 0.5 to 1.0 | 8 | 10.0 to 13.0 | 2 |

| 1.0 to 2.0 | 7 | 13.0 to 16.0 | 1 |

| 2.0 to 3.0 | 6 | 16.0 to more | 0 |

| 3.0 to 5.0 | 5 | – | – |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Franco, D.C.; Yang, M.S.; Zhu, X.; Zhang, H.; Shao, Y.; Zhang, H.; Zhu, J. Investigation of the Performance of ATH Powders in Organic Powder Coatings. Coatings 2019, 9, 110. https://doi.org/10.3390/coatings9020110

Li W, Franco DC, Yang MS, Zhu X, Zhang H, Shao Y, Zhang H, Zhu J. Investigation of the Performance of ATH Powders in Organic Powder Coatings. Coatings. 2019; 9(2):110. https://doi.org/10.3390/coatings9020110

Chicago/Turabian StyleLi, Weihong, Diego Cárdenas Franco, Marshall Shuai Yang, Xinping Zhu, Haiping Zhang, Yuanyuan Shao, Hui Zhang, and Jingxu Zhu. 2019. "Investigation of the Performance of ATH Powders in Organic Powder Coatings" Coatings 9, no. 2: 110. https://doi.org/10.3390/coatings9020110

APA StyleLi, W., Franco, D. C., Yang, M. S., Zhu, X., Zhang, H., Shao, Y., Zhang, H., & Zhu, J. (2019). Investigation of the Performance of ATH Powders in Organic Powder Coatings. Coatings, 9(2), 110. https://doi.org/10.3390/coatings9020110