Effect of Heat Treatment on the Cavitation Erosion Performance of WC–12Co Coatings

Abstract

1. Introduction

2. Experimental

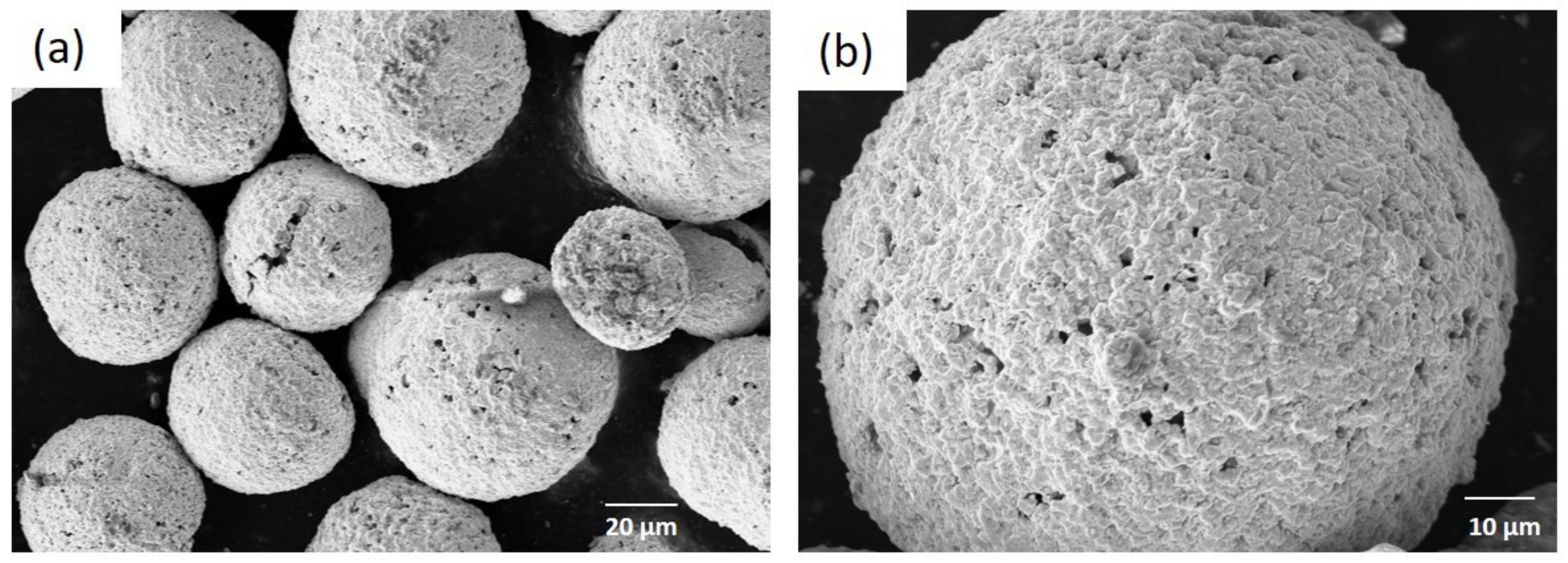

2.1. Materials

2.2. Coating Preparation

2.3. Heat-Treatment

2.4. Coating Characterization

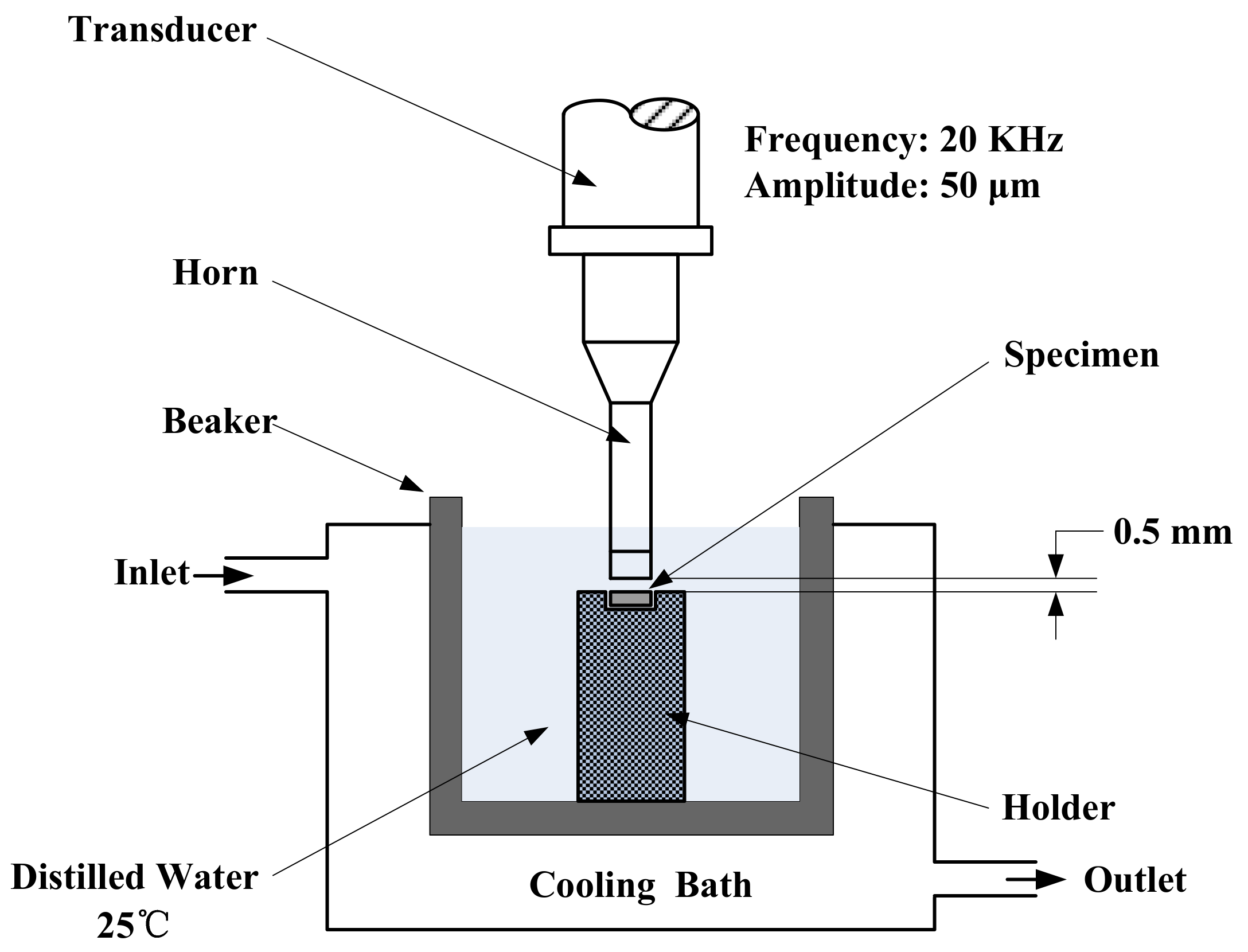

2.5. Cavitation Erosion Test

3. Results and Discussions

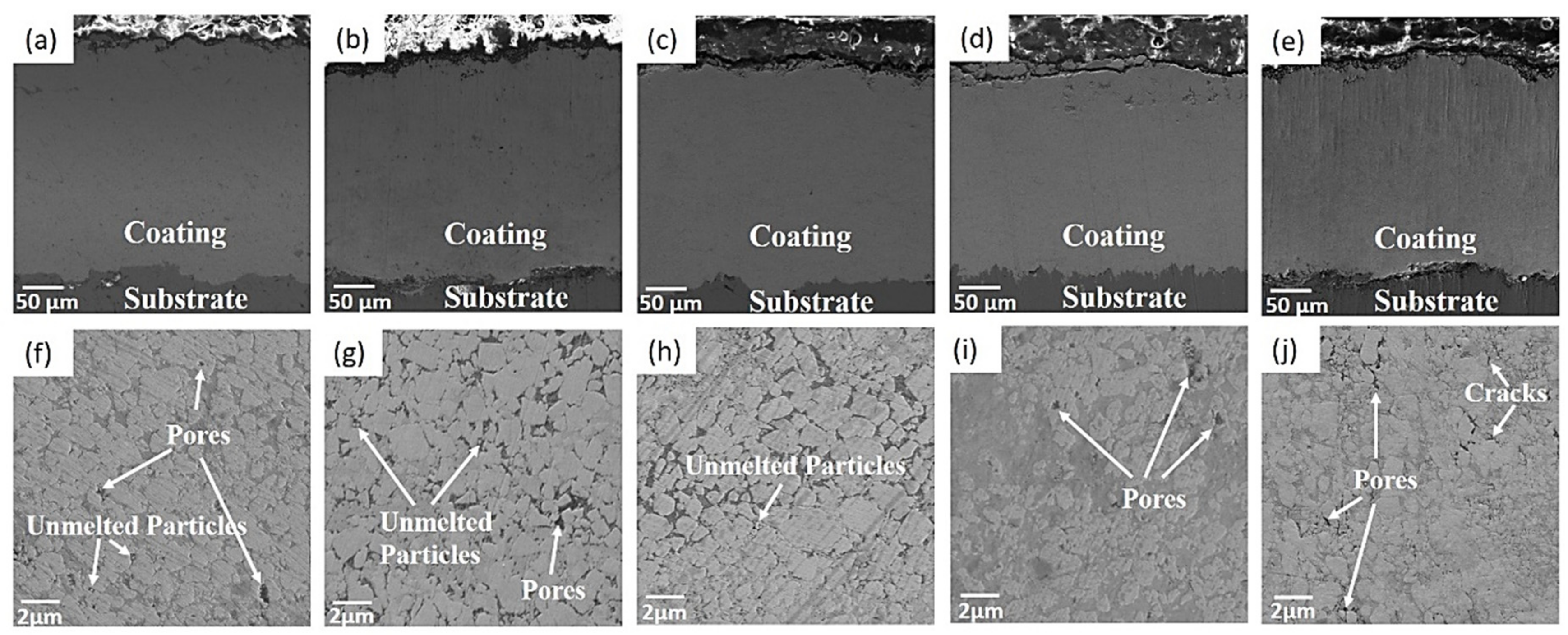

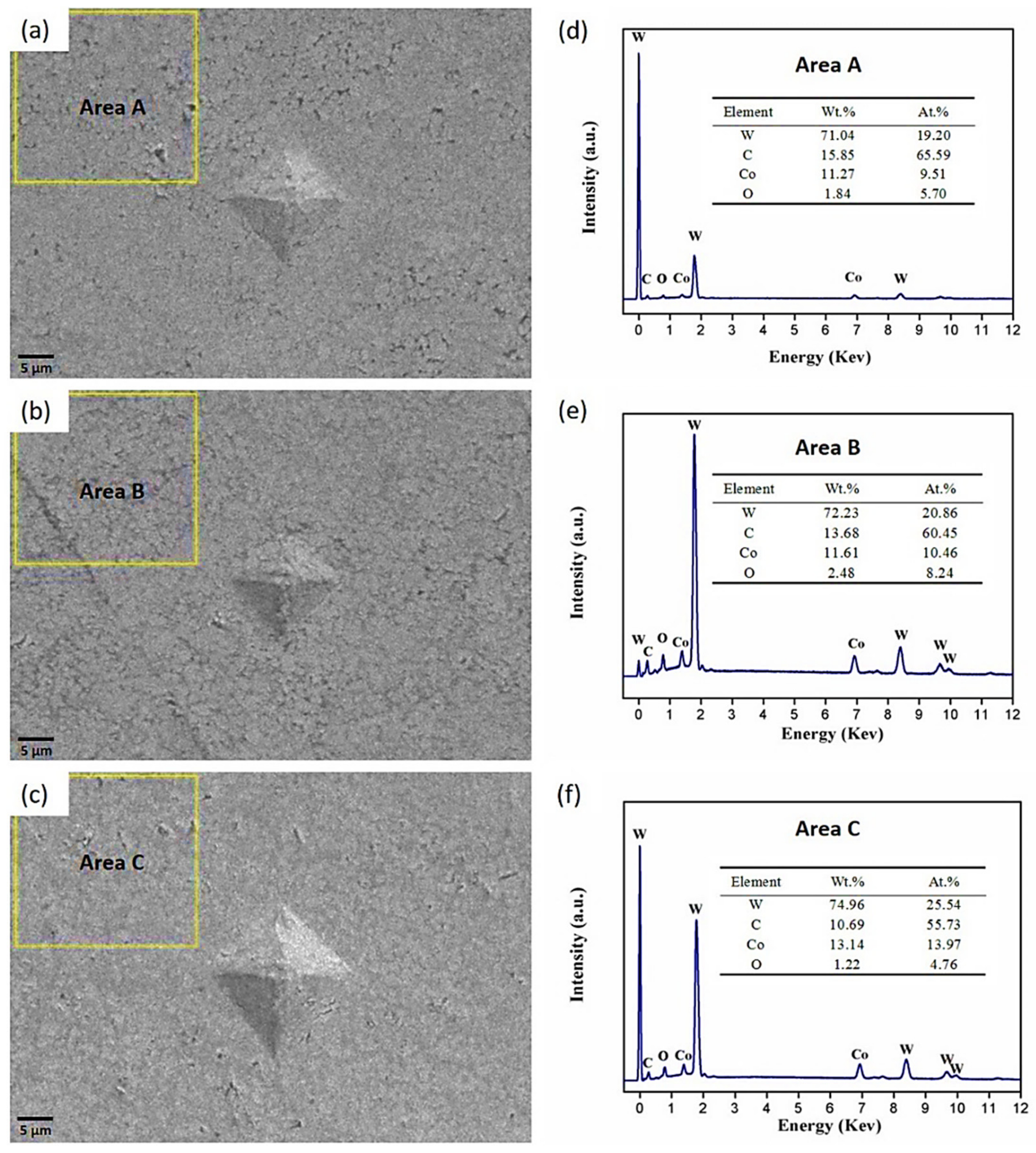

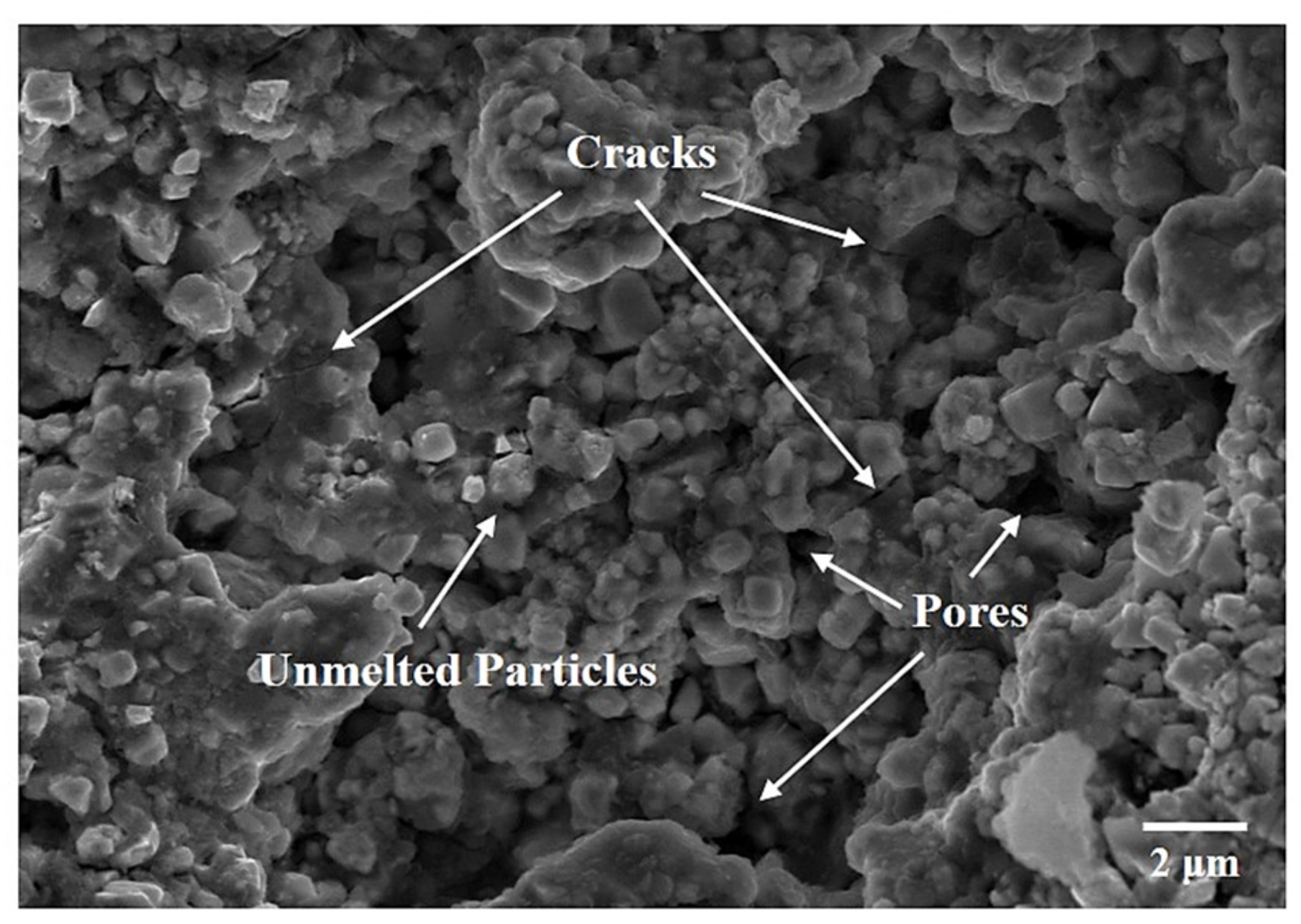

3.1. Microstructure and Phase Composition of the Coatings

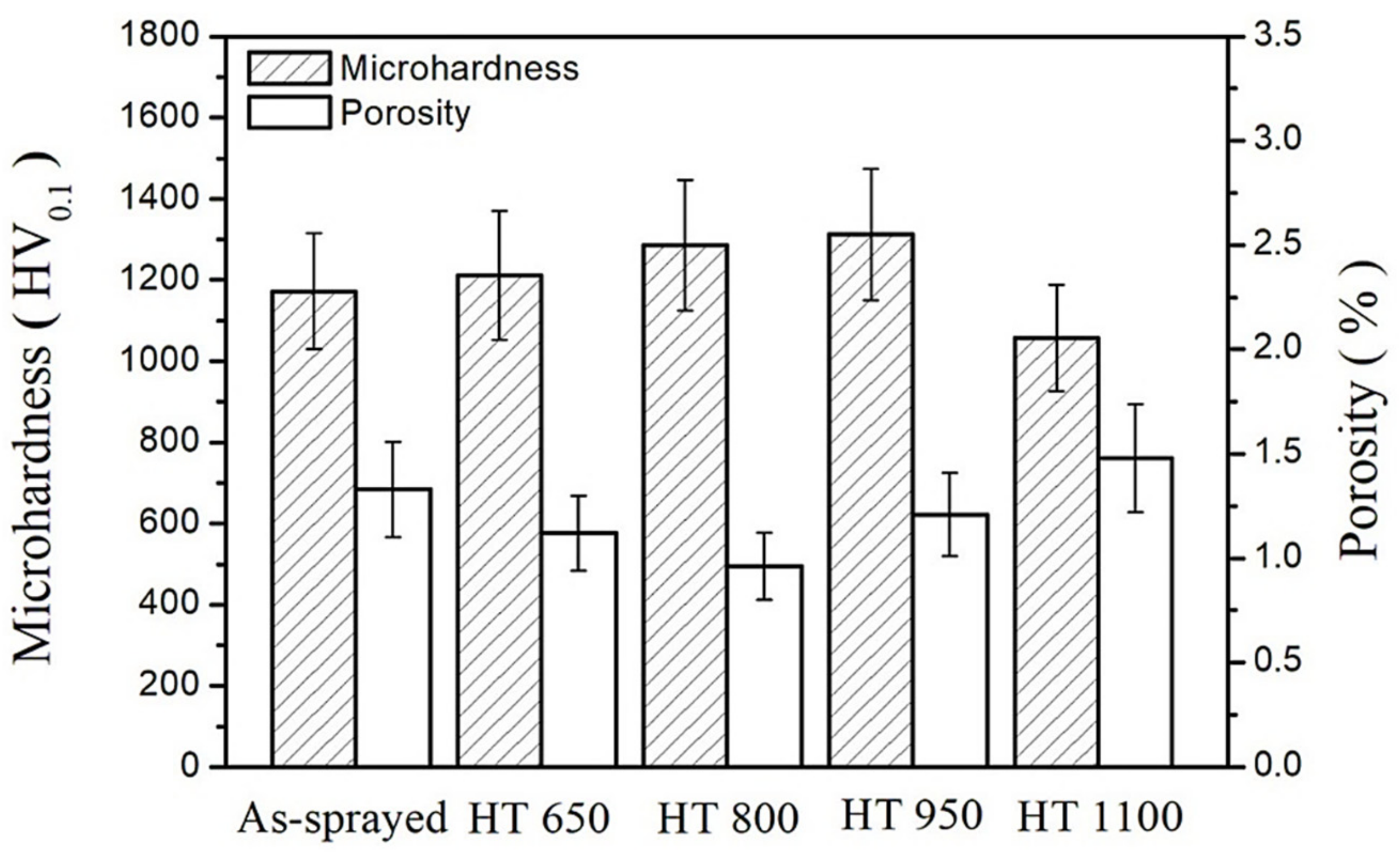

3.2. Porosity and Microhardness

3.3. Volume Loss and Cavitation Erosion Rate

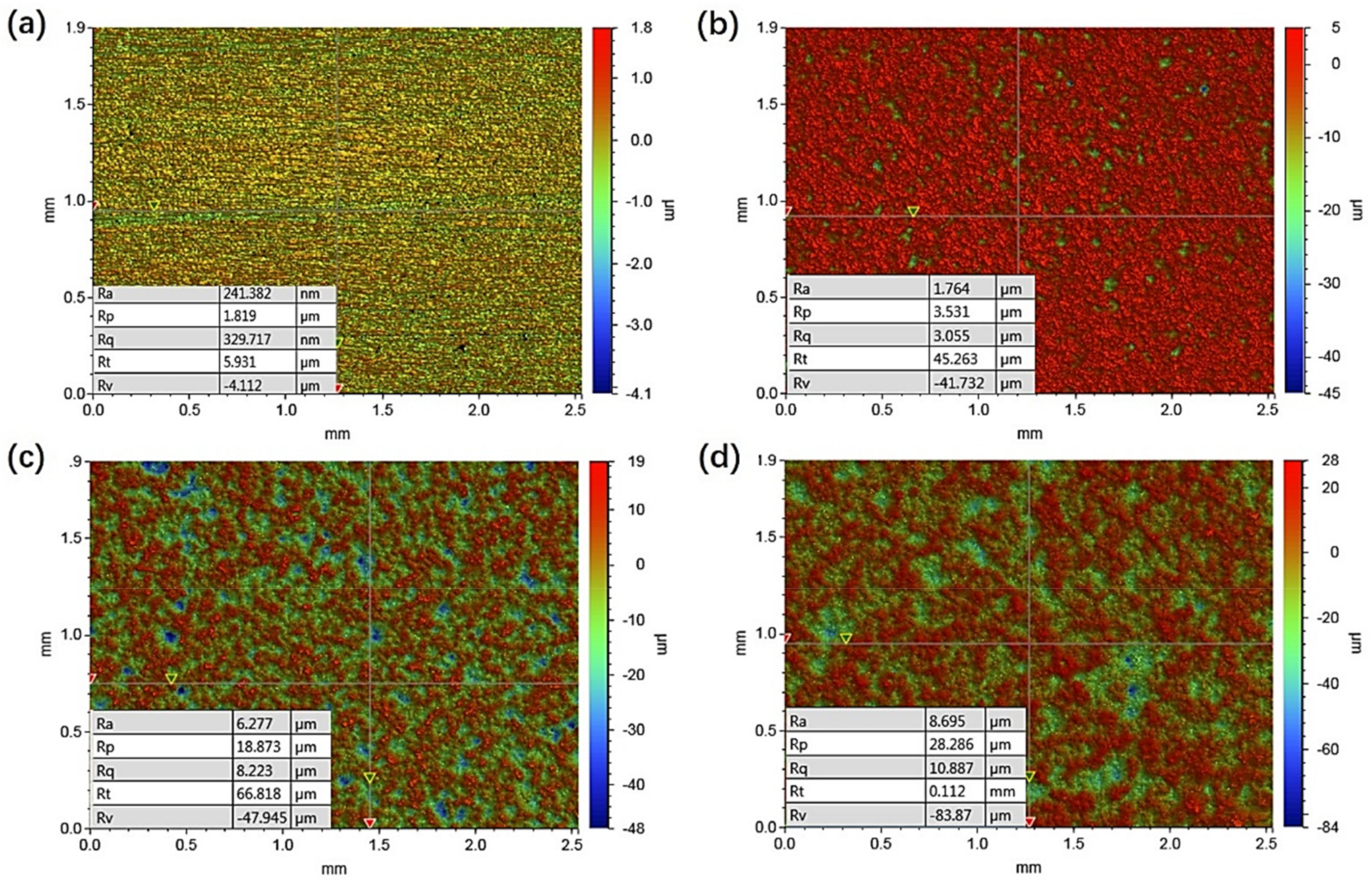

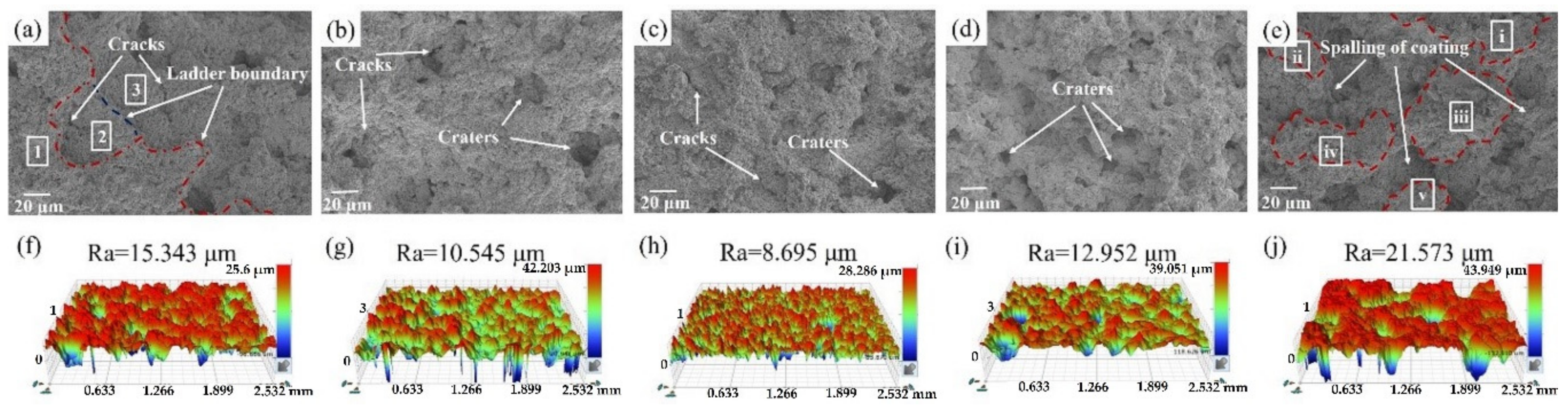

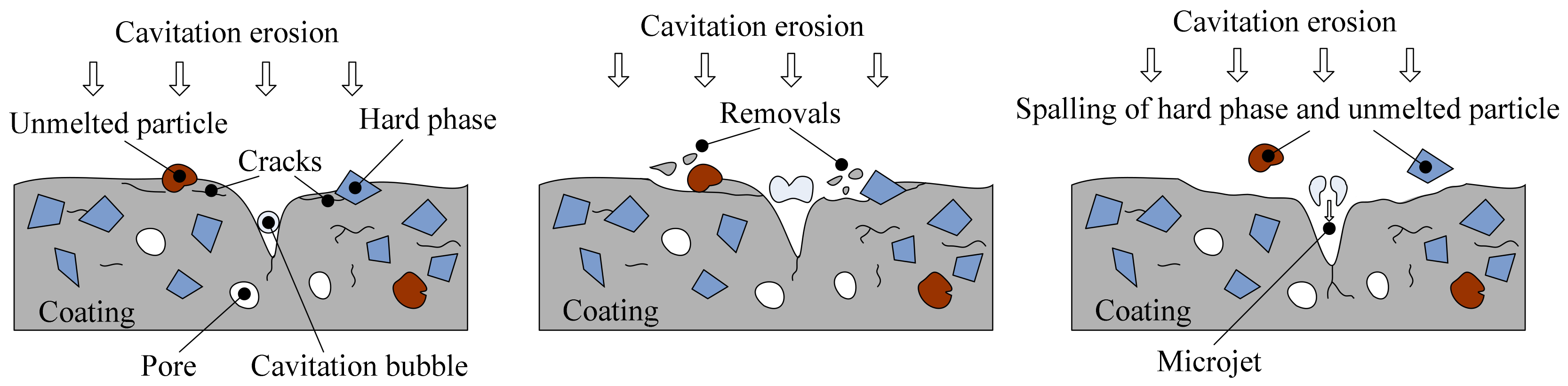

3.4. Cavitation Erosion Mechanism

4. Conclusions

- The volume loss of as-sprayed HT 650, HT 800, HT 950, and HT 1100 coating after 6 h of cavitation erosion tests was 4.87, 2.71, 1.72, 3.67, and 6.01 mm3, respectively, which means that the coating heat-treated at 800 °C exhibits the best cavitation erosion resistance.

- The cavitation rate of the coating is closely related to the micro defects of the coatings, such as pores, cracks, unmelted or semi-melted particles, and phase transitions that occurred during the heat treatment process.

- The surface roughness values, Ra, of as-sprayed HT 650, HT 800, HT 950, and HT 1100 coatings after 6 h cavitation erosion were 15.343, 10.545, 8.695, 12.952, and 21.573 μm, respectively. The surface roughness is positively correlated with the cavitation erosion rate, which indicates that the surface roughness can be used to quantitatively evaluate the cavitation erosion behavior of the materials.

- The existence of debris, unmelted particles, and hard phases, as well as the propagation and connection of cracks and pores in the coatings are the dominant cavitation erosion mechanisms.

Author Contributions

Funding

Conflicts of Interest

References

- Caupin, F.; Herbert, E. Cavitation in water: A review. Comptes Rendus Physique 2006, 7, 1000–1017. [Google Scholar] [CrossRef]

- Dorji, U.; Ghomashchi, R. Hydro turbine failure mechanisms: An overview. Eng. Fail. Anal. 2014, 44, 136–147. [Google Scholar] [CrossRef]

- Gohil, P.P.; Saini, R.P. Coalesced effect of cavitation and silt erosion in hydro turbines—A review. Renew. Sustain. Energy Rev. 2014, 33, 280–289. [Google Scholar] [CrossRef]

- Okada, T.; Iwai, Y.; Awazu, K. A study of cavitation bubble collapse pressure sand erosion part 1: A method for measurement of collapse pressures. Wear 1989, 133, 219–232. [Google Scholar] [CrossRef]

- Chen, H.-S.; Liu, S.-H. Inelastic damages by stress wave on steel surface at the incubation stage of vibration cavitation erosion. Wear 2009, 266, 69–75. [Google Scholar] [CrossRef]

- Liu, J.; Bai, X.-Q.; Chen, T.-Z.; Yuan, C.-Q. Effects of cobalt content on the microstructure, mechanical properties and cavitation erosion resistance of HVOF sprayed coatings. Coatings 2019, 9, 534. [Google Scholar] [CrossRef]

- Shi, Z.-P.; Wang, J.-Q.; Wang, Z.-B.; Qiao, Y.-X.; Xiong, T.-Y.; Zheng, Y.-G. Cavitation erosion and jet impingement erosion behavior of the NiTi coating produced by air plasma spraying. Coatings 2018, 8, 346. [Google Scholar] [CrossRef]

- Vashishtha, N.; Khatirkar, R.K.; Sapate, S.G. Tribological behavior of HVOF sprayed WC–12Co, WC–10Co–4Cr and Cr3C2-25NiCr coatings. Tribol. Int. 2017, 105, 55–68. [Google Scholar] [CrossRef]

- Peat, T.; Galloway, A.; Toumpis, A.; Harvey, D.; Yang, W.-H. Performance evaluation of HVOF deposited cermet coatings under dry and slurry erosion. Surf. Coat. Technol. 2016, 300, 118–127. [Google Scholar] [CrossRef]

- García-Rodríguez, S.; Torres, B.; López, A.J.; Otero, E.; Rams, J. Characterization and mechanical properties of stainless steel coatings deposited by HVOF on ZE41 magnesium alloy. Surf. Coat. Technol. 2019, 359, 73–84. [Google Scholar] [CrossRef]

- Milanti, A.; Koivuluoto, H.; Vuoristo, P.; Bolelli, G.; Bozza, F.; Lusvarghi, L. Microstructural characteristics and tribological behavior of HVOF-sprayed novel Fe-based alloy coatings. Coatings 2014, 4, 98–120. [Google Scholar] [CrossRef]

- Tillmann, W.; Hagen, L.; Stangier, D.; Paulus, M.; Tolan, M.; Sakrowski, R.; Biermann, D.; Freiburg, D. Microstructural characteristics of high-feed milled HVOF sprayed WC–Co coatings. Surf. Coat. Technol. 2019, 374, 448–459. [Google Scholar] [CrossRef]

- Ahmed, R.; Ali, O.; Faisal, N.H.; Al-Anazi, N.M.; Al-Mutairi, S.; Toma, F.L.; Berger, L.M.; Potthoff, A.; Goosen, M.F.A. Sliding wear investigation of suspension sprayed WC–Co nanocomposite coatings. Wear 2015, 322, 133–150. [Google Scholar] [CrossRef]

- Zafar, S.; Sharma, A.K. Dry sliding wear performance of nanostructured WC–12Co deposited through microwave cladding. Tribol. Int. 2015, 91, 14–22. [Google Scholar] [CrossRef]

- Gao, P.-H.; Chen, B.-Y.; Wang, W.; Jia, H.; Li, J.-P.; Yang, Z.; Guo, Y.-C. Simultaneous increase of friction coefficient and wear resistance through HVOF sprayed WC-(nano WC–Co). Surf. Coat. Technol. 2019, 363, 379–389. [Google Scholar] [CrossRef]

- Ding, X.; Ke, D.; Yuan, C.-Q.; Ding, Z.-X.; Cheng, X.-D. Microstructure and cavitation erosion resistance of HVOF deposited WC–Co coatings with different sized WC. Coatings 2018, 8, 307. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.-P.; Zhang, J.-F.; Zheng, Y.-G.; Qin, Y.-J.; Lin, J.-R. Ultrasonic cavitation erosion of high-velocity oxygen-fuel (HVOF) sprayed near-nanostructured WC–10Co–4Cr coating in NaCl solution. Ultrason. Sonochem. 2015, 26, 87–92. [Google Scholar] [CrossRef]

- Liu, X.-M.; He, D.-Y.; Zhou, Z.; Wang, G.-H.; Wang, Z.-J.; Guo, X.-Y. Effect of post-heat-treatment on the microstructure of micro-plasma sprayed hydroxyapatite coatings. Surf. Coat. Technol. 2019, 367, 225–230. [Google Scholar] [CrossRef]

- González, M.A.; Rodríguez, E.; Mojardín, E.; Jiménez, O.; Guillen, H.; Ibarra, J. Study of the erosive wear behaviour of cryogenically and tempered WC–CoCr coating deposited by HVOF. Wear 2017, 376, 595–607. [Google Scholar] [CrossRef]

- Stewart, D.A.; Shipway, P.H.; McCartney, D.G. Influence of heat treatment on the abrasive wear behavior of HVOF sprayed WC–Co coatings. Surf. Coat. Technol. 1998, 105, 13–24. [Google Scholar] [CrossRef]

- Lima, M.M.; Godoy, C.; Modenesi, P.J.; Avelar-Batista, J.C.; Davison, A.; Matthews, A. Coating fracture toughness determined by Vickers indentation: An important parameter in cavitation erosion resistance of WC–Co thermally sprayed coatings. Surf. Coat. Technol. 2004, 177, 489–496. [Google Scholar] [CrossRef]

- ASTM G32-16. Standard Test Method for Cavitation Erosion Using Vibratory Apparatus; ASTM International: West Conshohocken, PA, USA, 2016.

- Wang, Q.; Li, L.-X.; Yang, G.-B.; Zhao, X.-Q.; Ding, Z.-X. Influence of heat treatment on the microstructure and performance of high-velocity oxy-fuel sprayed WC–12Co coatings. Surf. Coat. Technol. 2012, 206, 4000–4010. [Google Scholar] [CrossRef]

- Ghadami, F.; Sohi, M.H.; Ghadami, S. Effect of bond coat and post-heat treatment on the adhesion of air plasma sprayed WC–Co coatings. Surf. Coat. Technol. 2015, 261, 289–294. [Google Scholar] [CrossRef]

- Vashishtha, N.; Sapate, S.G.; Bagde, P.; Rathod, A.B. Effect of heat treatment on friction and abrasive wear behaviour of WC–12Co and Cr3C2-25NiCr coatings. Tribol. Int. 2018, 118, 381–399. [Google Scholar] [CrossRef]

- Spencer, K.; Zhang, M.-X. The use of kinetic metallization to form intermetallic reinforced composite coatings by post-spray heat treatment. Surf. Coat. Technol. 2009, 20, 3019–3025. [Google Scholar] [CrossRef]

- Yost, A.R.; Erdeniz, D.; Ashley, E.; Puente, P.; Dunand, D.C. Effect of diffusion distance on evolution of Kirkendall pores in titanium-coated nickel wires. Intermetallics 2019, 104, 124–132. [Google Scholar] [CrossRef]

- Lamana, M.S.; Pukasiewicz, A.G.M.; Sampath, S. Influence of cobalt content and HVOF deposition process on the cavitation erosion resistance of WC–Co coatings. Wear 2018, 398, 209–219. [Google Scholar] [CrossRef]

- Espitia, L.A.; Toro, A. Cavitation resistance, microstructure and surface topography of materials used for hydraulic components. Tribol. Int. 2010, 43, 2037–2045. [Google Scholar] [CrossRef]

- Kishor, B.; Chaudhari, G.P.; Nath, S.K. Cavitation erosion of thermomechanically processed 13/4 martensitic stainless steel. Wear 2014, 319, 150–159. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, J.-W.; Kang, N.; Darut, G.; Poirier, T.; Stella, J.; Liao, H.-L.; Planche, M.P. Cavitation erosion of plasma-sprayed CoMoCrSi coatings. Tribol. Int. 2016, 102, 429–435. [Google Scholar] [CrossRef]

- Qin, C.-P.; Zheng, Y.-G.; Wei, R. Cavitation erosion behavior of nanocomposite Ti–Si–C–N and Ti/Ti–Si–C–N coatings deposited on 2Cr13 stainless steel using a plasma enhanced magnetron sputtering process. Surf. Coat. Technol. 2010, 204, 3530–3538. [Google Scholar] [CrossRef]

- Ma, D.; Harvey, T.J.; Wellman, R.G.; Ehiasarian, A.P.; Hovsepian, P.E.; Sugumaran, A.A.; Purandare, Y.P.; Wood, R.J.K. Cavitation erosion performance of CrAlYN/CrN nanoscale multilayer coatings deposited on Ti6Al4V by HIPIMS. J. Alloy. Compd. 2019, 788, 719–728. [Google Scholar] [CrossRef]

- Szala, M.; Hejwowski, T. Cavitation erosion resistance and wear mechanism model of flame-sprayed Al2O3-40%TiO2/NiMoAl cermet coatings. Coatings 2018, 8, 254. [Google Scholar] [CrossRef]

- Chiu, K.Y.; Cheng, F.T.; Man, H.C. Evolution of surface roughness of some metallic materials in cavitation erosion. Ultrasonics 2005, 43, 713–716. [Google Scholar] [CrossRef]

- Kumar, R.K.; Seetharamu, S.; Kamaraj, M. Quantitative evaluation of 3D surface roughness parameters during cavitation exposure of 16Cr–5Ni hydro turbine steel. Wear 2014, 320, 16–24. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Oxygen flow rate (m3/h) | 55 |

| Powder feed rate (g/min) | 95 |

| Fuel flow rate (L/h) | 24 |

| Spray distance (mm) | 280 |

| Spray angle (°) | 90 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, J.; Zhang, J.; Zhang, C. Effect of Heat Treatment on the Cavitation Erosion Performance of WC–12Co Coatings. Coatings 2019, 9, 690. https://doi.org/10.3390/coatings9100690

Du J, Zhang J, Zhang C. Effect of Heat Treatment on the Cavitation Erosion Performance of WC–12Co Coatings. Coatings. 2019; 9(10):690. https://doi.org/10.3390/coatings9100690

Chicago/Turabian StyleDu, Jin, Jianfeng Zhang, and Chao Zhang. 2019. "Effect of Heat Treatment on the Cavitation Erosion Performance of WC–12Co Coatings" Coatings 9, no. 10: 690. https://doi.org/10.3390/coatings9100690

APA StyleDu, J., Zhang, J., & Zhang, C. (2019). Effect of Heat Treatment on the Cavitation Erosion Performance of WC–12Co Coatings. Coatings, 9(10), 690. https://doi.org/10.3390/coatings9100690