An Analysis of Effect of CO2 Laser Treatment on Carbon Fibre Fabric

Abstract

1. Introduction

2. Experimental

2.1. Materials

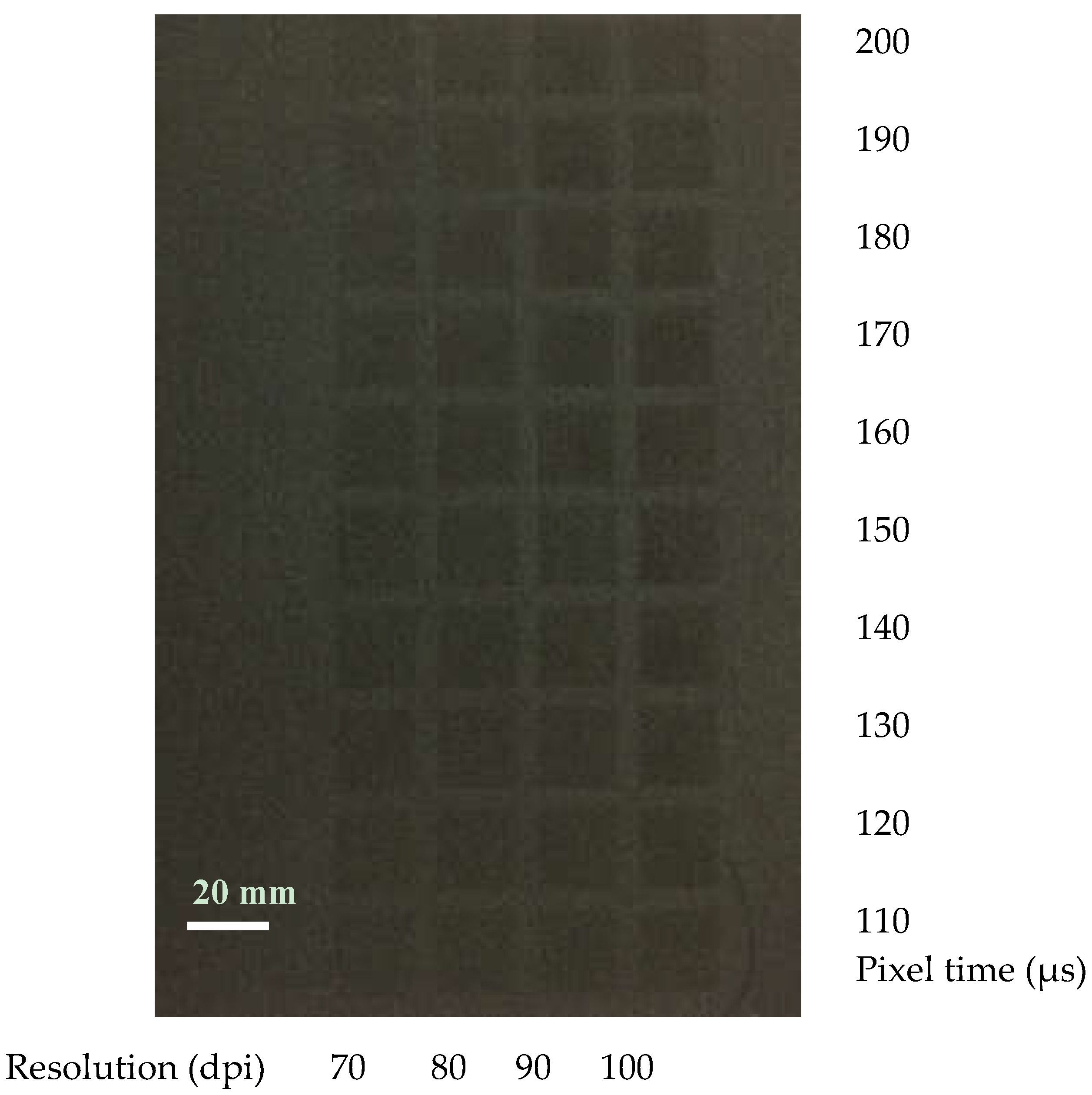

2.2. Laser Treatment

2.3. Contact Angle Measurement

2.4. Electrical Resistance Measurement

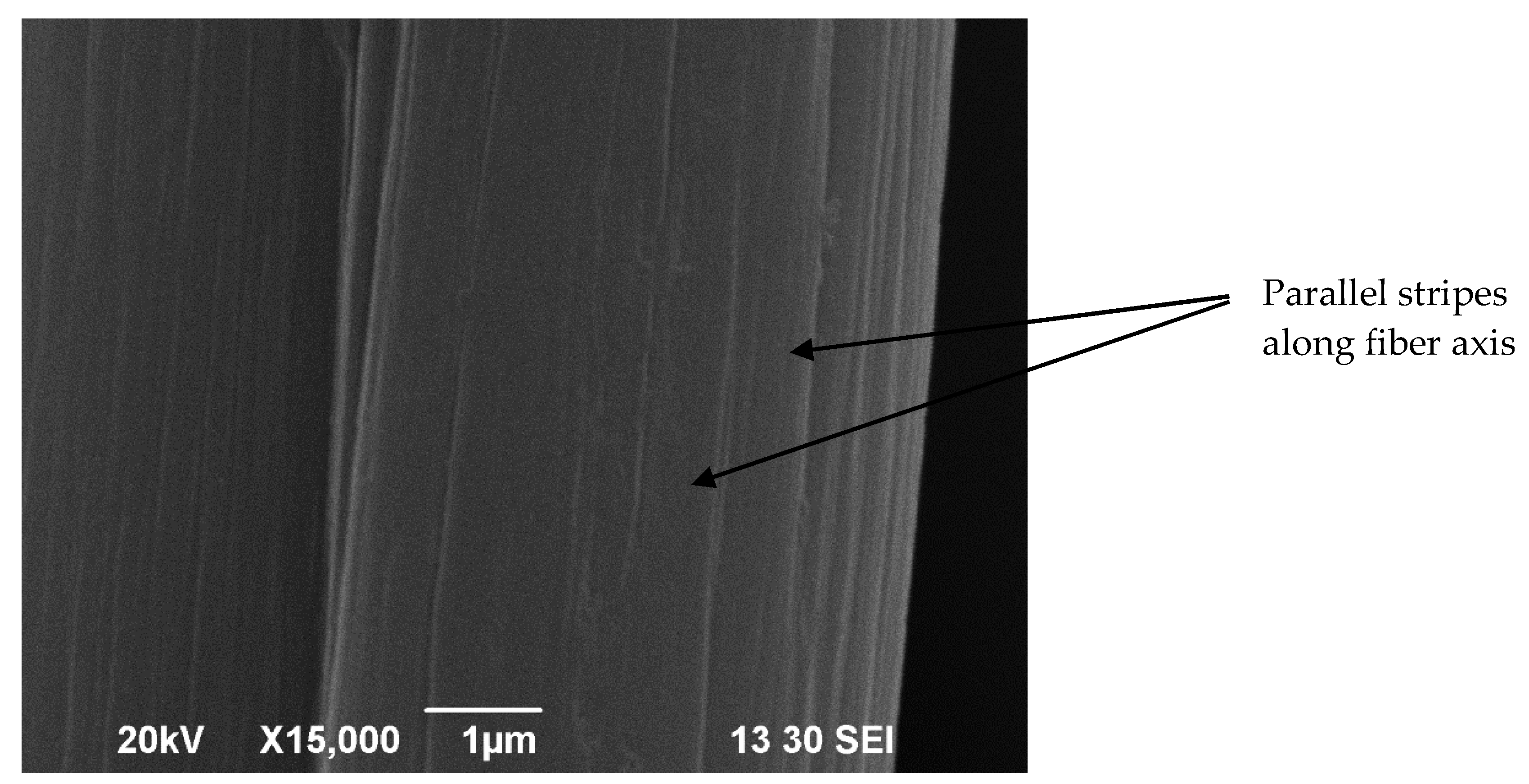

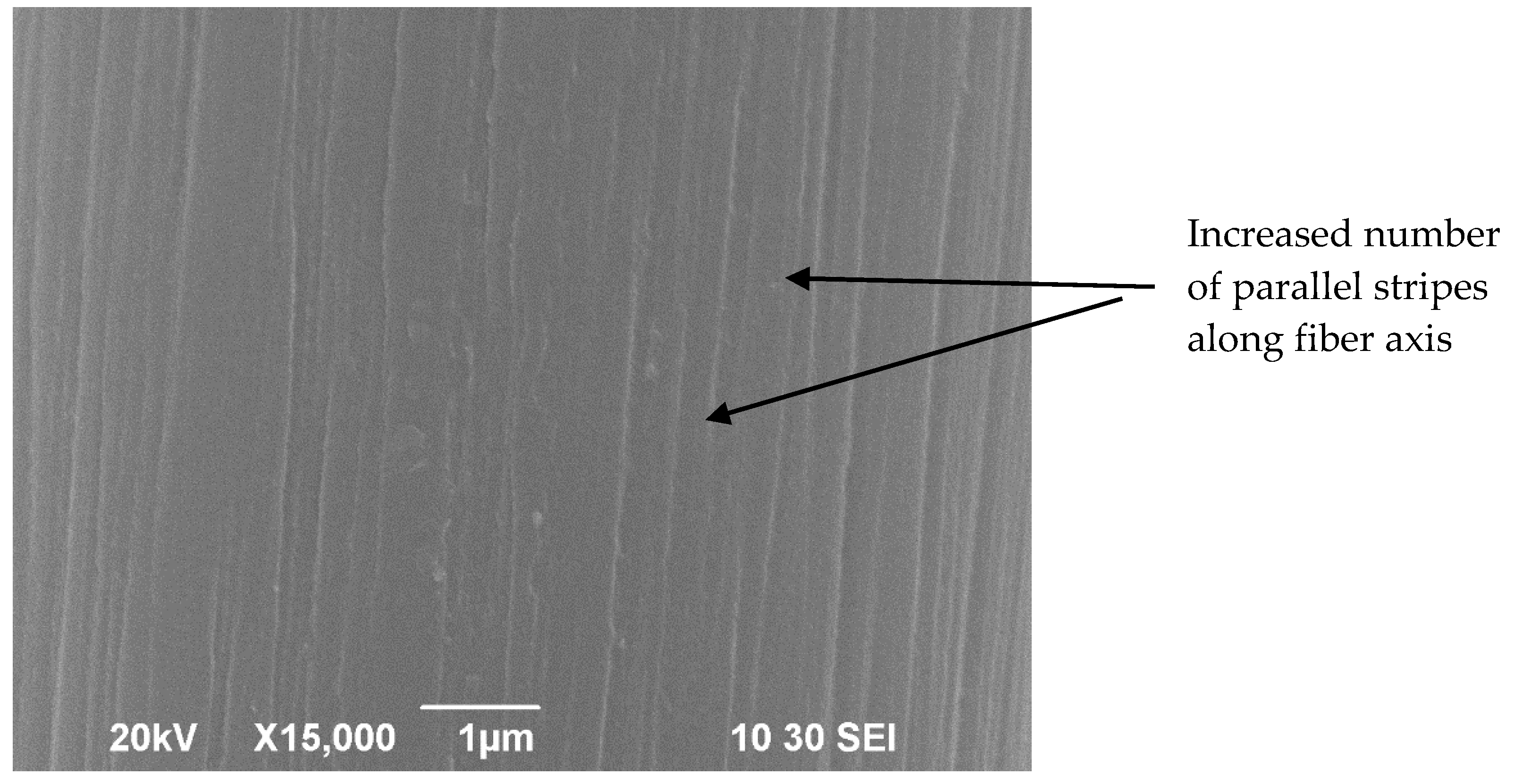

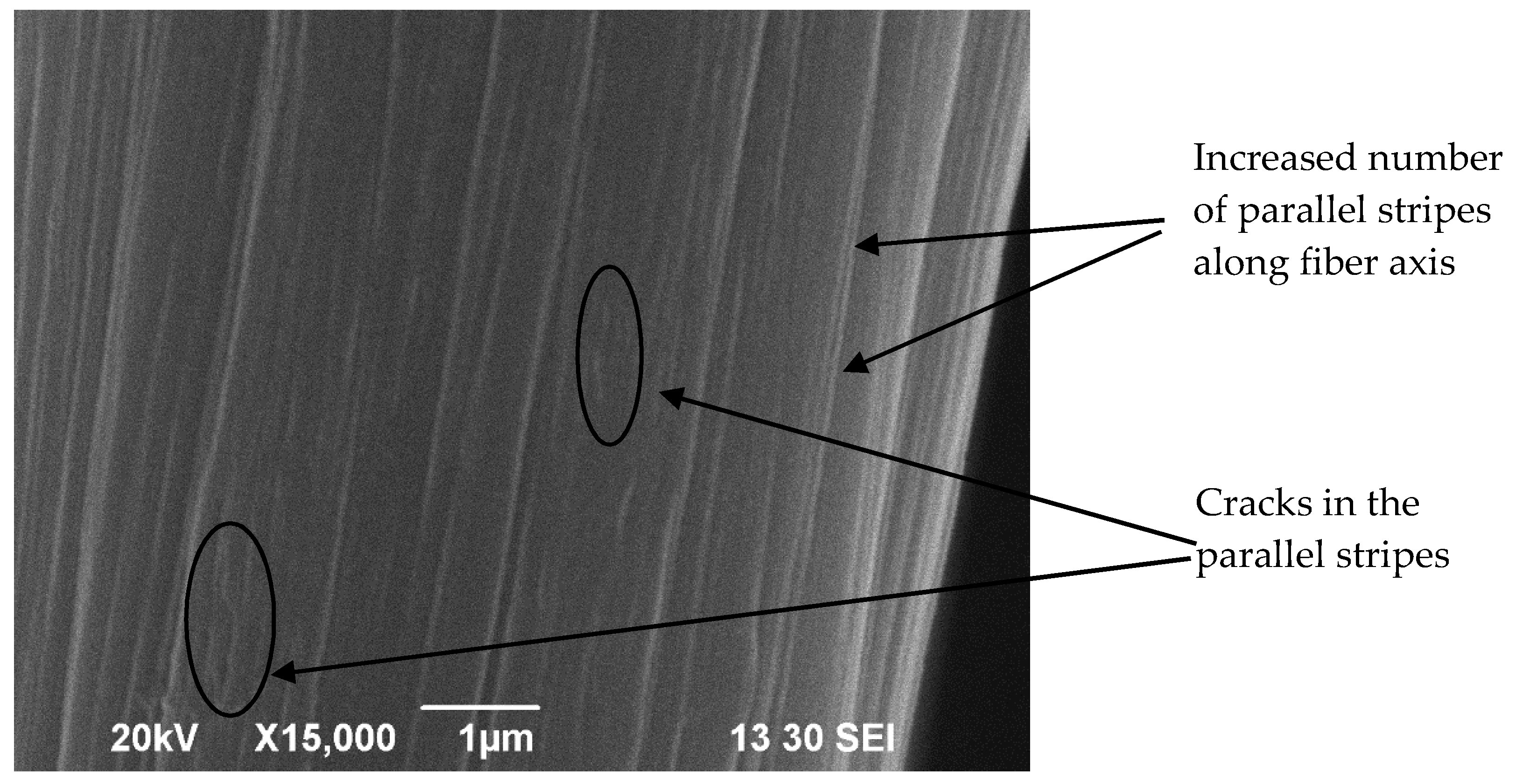

2.5. Scanning Electron Microscopy (SEM)

2.6. Fourier Transform Infrared Spectroscopy-Attenuated Total Internal Reflectance (FTIR-ATR)

3. Results and Discussion

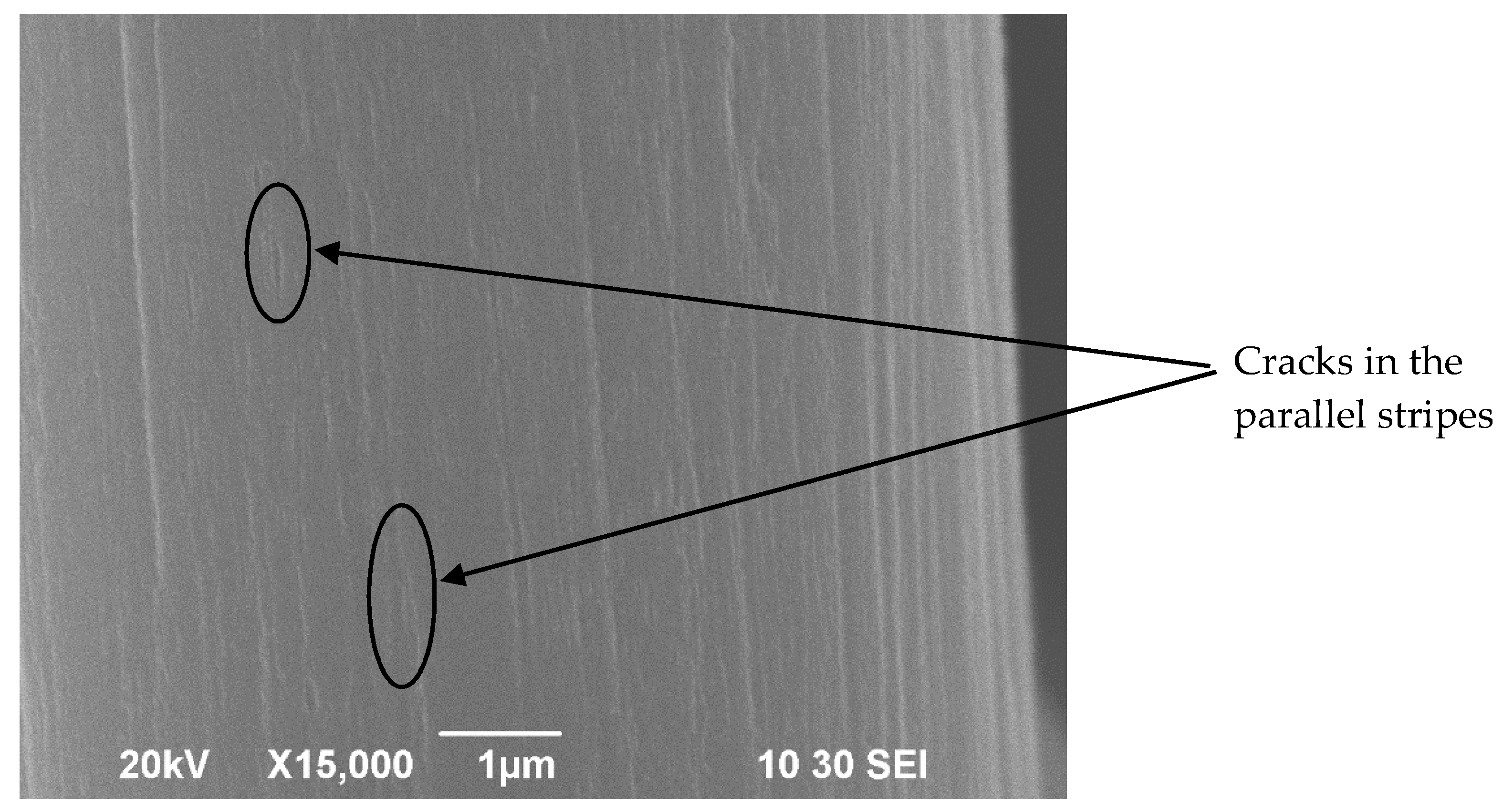

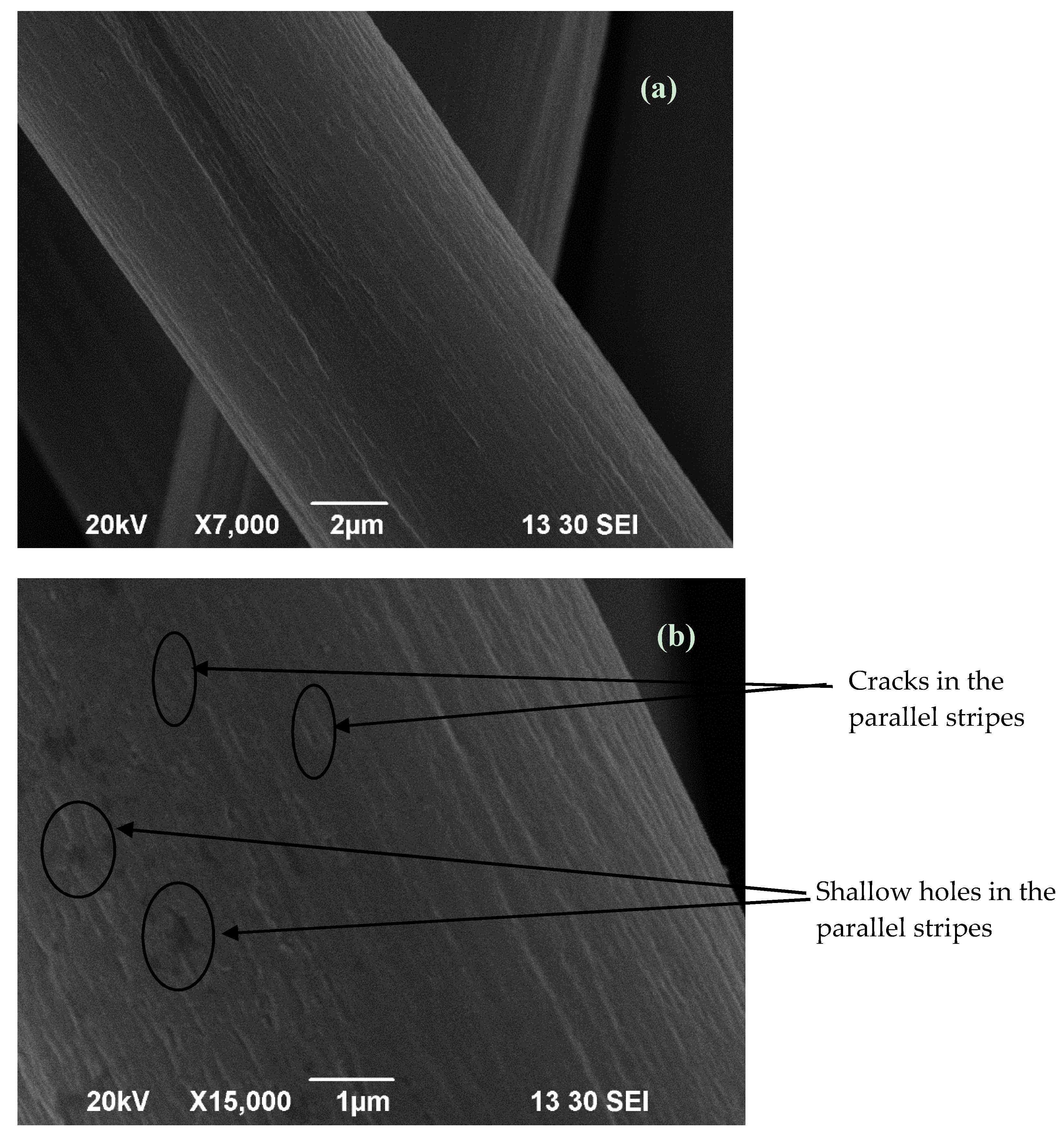

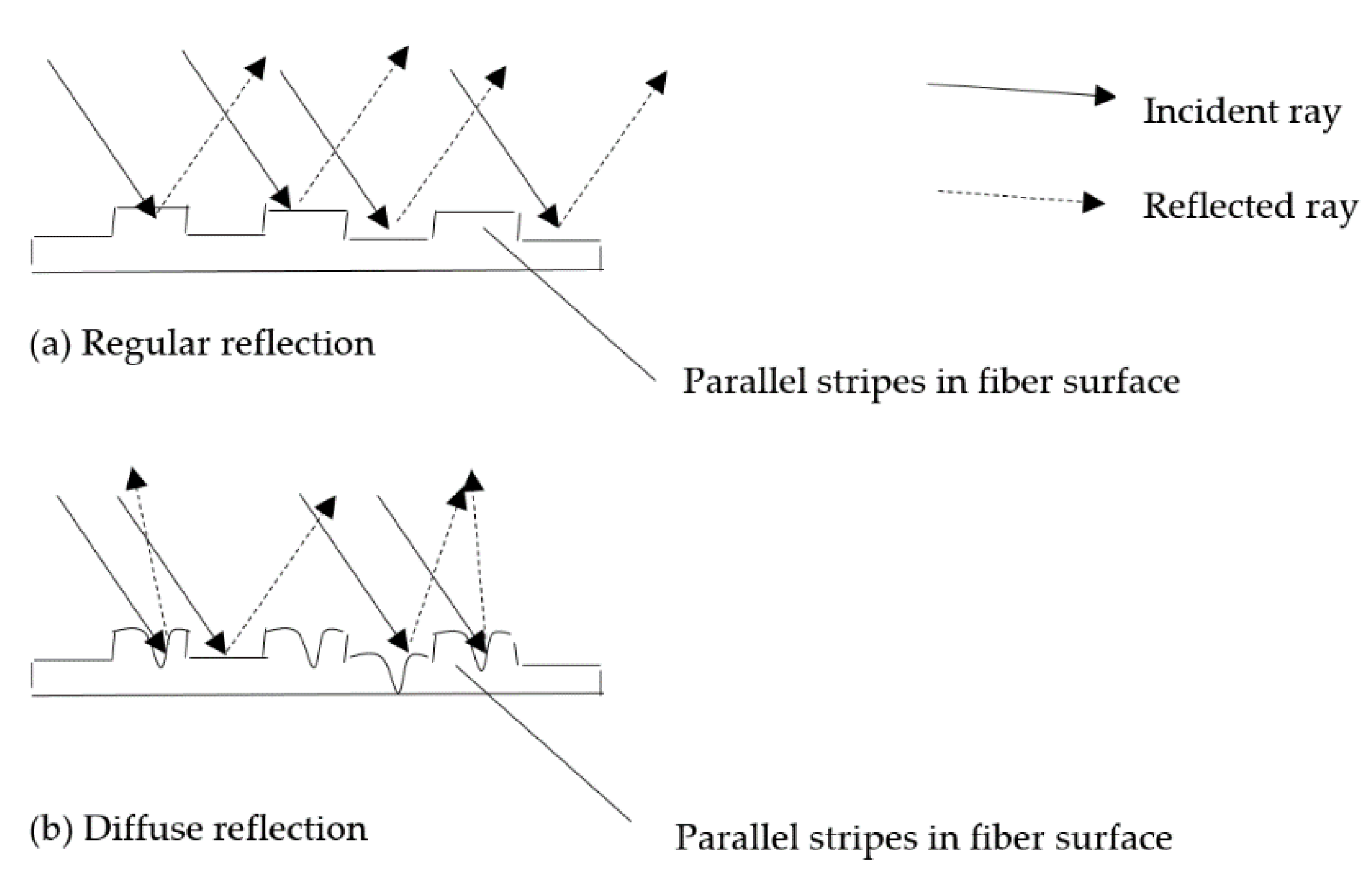

3.1. Surface Morphology

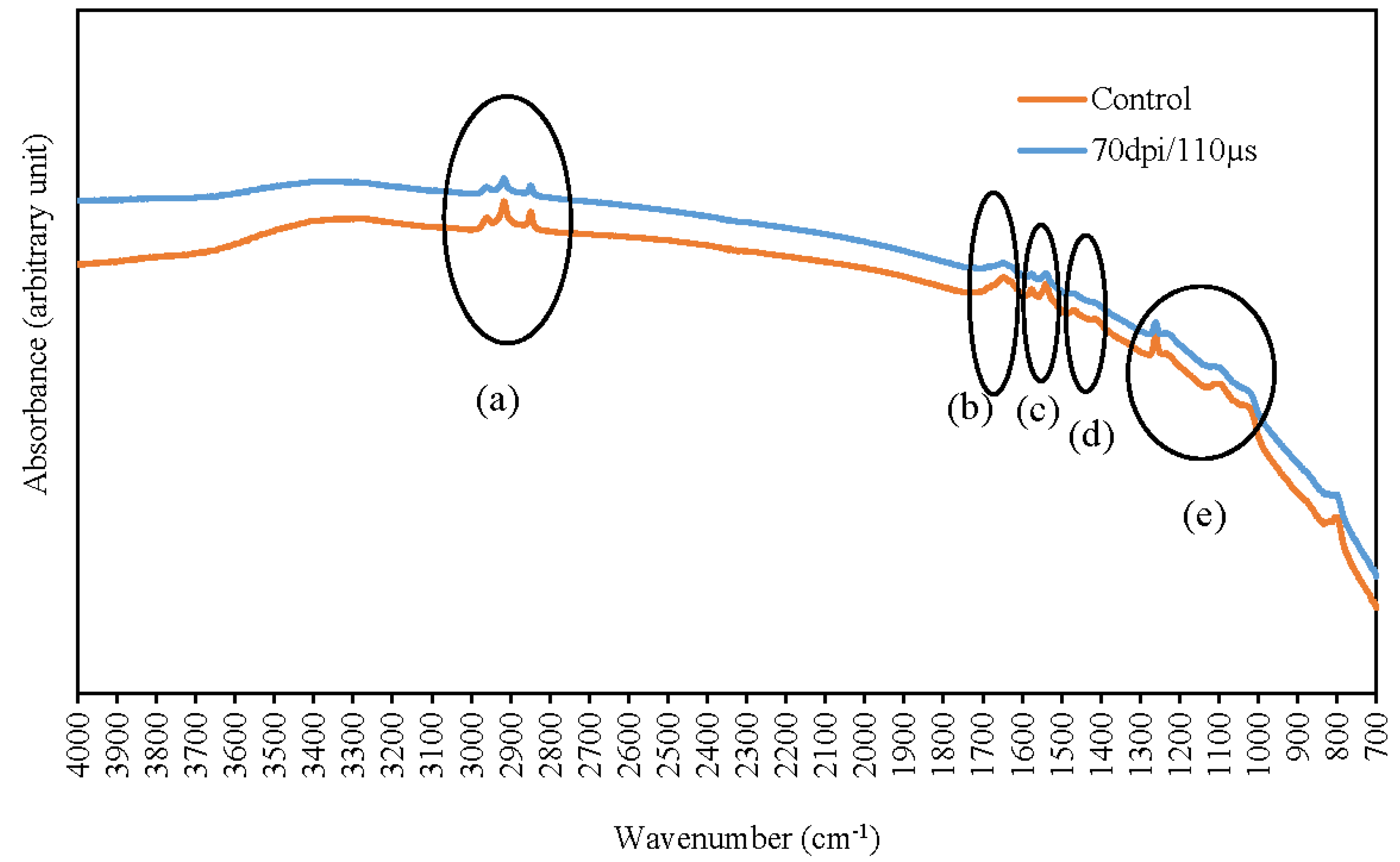

3.2. Surface Functional Groups

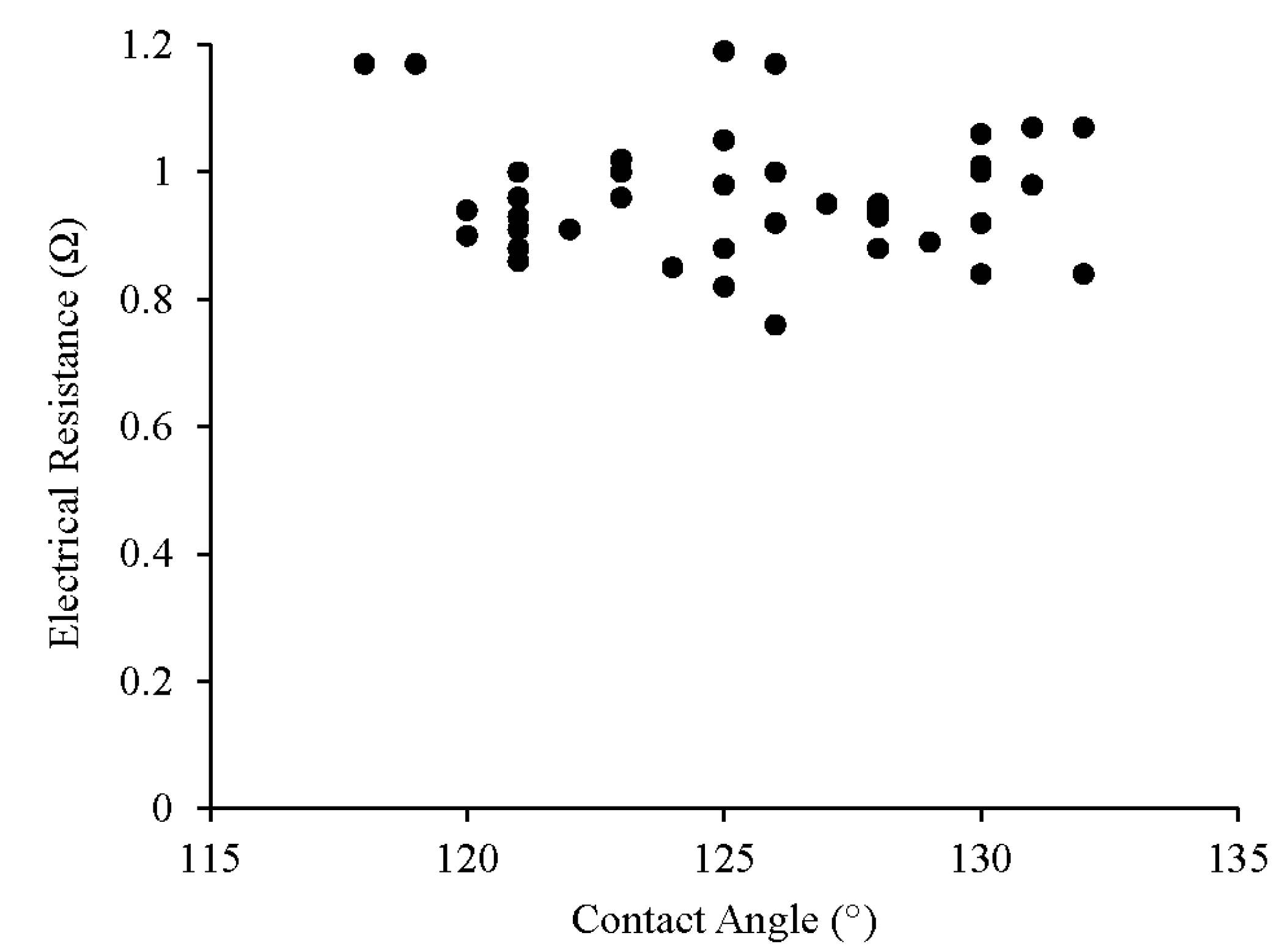

3.3. Contact Angle

3.4. Electrical Resistance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Frank, E.; Steudle, L.M.; Ingildeev, D.; Spörl, J.M.; Buchmeiser, M.R. Carbon fibers: Precursor, systems, processing, structure, and properties. Angew. Chem. Int. Ed. 2014, 53, 5262–5298. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.W.; Lee, J.S. Preparation of carbon fibers from linear low density polyethylene. Carbon 2015, 94, 524–530. [Google Scholar] [CrossRef]

- Frank, E.; Hermanutz, F.; Buchmeiser, M.R. Carbon fibers: Precursors, manufacturing, and properties. Macromol. Mater. Eng. 2012, 297, 493–501. [Google Scholar] [CrossRef]

- Feldhoof, A.; Pippel, E.; Wolterdorf, J. Interface engineering of carbon fiber reinforced Mg-Al alloys. Adv. Eng. Mater. 2000, 2, 471–480. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef] [PubMed]

- Helmer, T.; Peterlik, H.; Kromp, K. Coating of carbon fibers—The strength of the fibers. J. Am. Ceram. Soc. 1995, 78, 133–136. [Google Scholar] [CrossRef]

- Chen, F.; Yang, H.; Li, K.; Deng, B.; Li, Q.; Liu, X.; Dong, B.; Xiao, X.; Wang, D.; Qin, Y.; et al. Facile and effective coloration of dye-inert carbon fibers fabrics with tunable colors and excellent laundering durability. ACS Nano 2017, 11, 10330–10336. [Google Scholar] [CrossRef] [PubMed]

- Stepankova, M.; Wiener, J.; Rusinova, K. Decolourization of vat dyes on cotton fabric with infrared laser light. Cellulose 2011, 18, 469–478. [Google Scholar] [CrossRef]

- Ferrero, F.; Testore, F.; Tonin, C.; Innocenti, R. Surface degradation of linen textiles induced by laser treatment: Comparison with electron beam and heat source. AUTEX Res. J. 2002, 2, 109–114. [Google Scholar]

- Stepankova, M.; Wiener, J.; Dembicky, J. Impact of laser thermal stress on cotton fabric. Fiber. Text. East. Eur. 2010, 18, 70–73. [Google Scholar]

- Juciene, M.; Urbelis, V.; Juchneviciene, Z.; Cepukone, L. The effect of laser technological parameters on the color and structure if denim fabric. Text. Res. J. 2014, 84, 662–670. [Google Scholar] [CrossRef]

- Ondogan, Z.; Pamuk, O.; Ondogan, E.N.; Ozguney, A. Improving the appearance of all textile products from clothing to home textile using laser technology. Opt. Laser Technol. 2005, 37, 631–637. [Google Scholar] [CrossRef]

- Hung, O.N.; Kan, C.W. A study of CO2 laser treatment on the colour properties of cotton-based Fabrics. Coatings 2017, 7, 131. [Google Scholar] [CrossRef]

- Hung, O.N.; Chan, C.K.; Kan, C.W.; Yuen, C.W.M.; Song, L.J. Artificial neural network approach for predicting colour properties of laser-treated denim fabrics. Fiber. Polym. 2014, 15, 1330–1336. [Google Scholar] [CrossRef]

- Kan, C.W. Colour fading effect of indigo-dyed cotton denim fabric by CO2 laser. Fiber. Polym. 2014, 15, 426–429. [Google Scholar] [CrossRef]

- Hung, O.N.; Chan, C.K.; Kan, C.W.; Yuen, C.W.M. Microscopic study of the surface morphology of CO2 laser-treated cotton and cotton/polyester blended fabric. Text. Res. J. 2017, 87, 1107–1120. [Google Scholar] [CrossRef]

- Hung, O.N.; Chan, C.K.; Kan, C.W.; Yuen, C.W.M. Effect of the CO2 laser treatment on properties of 100% cotton knitted fabrics. Cellulose 2017, 24, 1915–1926. [Google Scholar] [CrossRef]

- Hung, O.N.; Chan, C.K.; Kan, C.W.; Yuen, C.W.M. An analysis of some physical and chemical properties of CO2 laser-treated cotton-based fabrics. Cellulose 2017, 24, 363–381. [Google Scholar] [CrossRef]

- Kan, C.W.; Yuen, C.W.M. Effect of atmospheric pressure plasma treatment on wettability and dryability of synthetic textile fibres. Surf. Coat. Technol. 2013, 228, S607–S610. [Google Scholar] [CrossRef]

- Hung, O.N.; Kan, C.W. Effect of CO2 laser treatment on the fabric hand of cotton and cotton/polyester blended fabric. Polymers 2017, 9, 609. [Google Scholar] [CrossRef]

- Blaker, J.J.; Anthony, D.B.; Tang, G.; Shamsuddin, S.-R.; Kalinka, G.; Weinrich, M.; Abdolvand, A.; Shaffer, M.S.P.; Bismarck, A. Property and shape modulation of carbon fibers using lasers. ACS Appl. Mater. Interfaces 2016, 8, 16351–16358. [Google Scholar] [CrossRef] [PubMed]

- Finger, J.; Weinand, M.; Wortmann, D. Ablation and cutting of carbon-fiber reinforced plastics using picosecond pulsed laser radiation with high average power. J. Laser Appl. 2013, 25, 042007. [Google Scholar] [CrossRef]

- Voisey, K.T.; Fouquet, S.; Roy, D.; Clyne, T.W. Fibre swelling during laser drilling of carbon fibre composites. Opt. Lasers Eng. 2006, 44, 1185–1197. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, C.G.; Zhang, S.; Lin, X. Effect of surface modification on carbon fiber and its reinforced phenolic matrix composite. Appl. Surf. Sci. 2012, 259, 288–293. [Google Scholar] [CrossRef]

- Characteristic IR Absorption Frequencies of Organic Functional Groups. Available online: http://www2.ups.edu/faculty/hanson/Spectroscopy/IR/IRfrequencies.html#carbonylIR (accessed on 5 January 2018).

- Infrared Spectroscopy Table. Available online: http://www.chem.ucla.edu/~bacher/General/30BL/IR/ir.html (accessed on 5 January 2018).

- Kan, C.W.; Yuen, C.W.M. Plasma technology in wool. Text. Prog. 2007, 39, 121–187. [Google Scholar] [CrossRef]

- Geroge, K.M.; Ruthenburg, T.C.; Smith, J.; Yu, L.; Zhang, Q.; Anasyasio, C.; Dillner, A.M. FT-IR quantification of the carbonyl functional group in aqueous-phase secondary organic aerosol from phenols. Atmos. Environ. 2015, 100, 230–237. [Google Scholar] [CrossRef]

- Cecen, V.; Seki, Y.; Sarikanat, M.; Tavman, I.H. FTIR and SEM analysis of polyester- and epoxy-based composites manufactured by VARTM process. J. Appl. Polym. Sci. 2008, 108, 2163–2170. [Google Scholar] [CrossRef]

| Functional Group | Peak Range (cm−1) | Assigned Peak (cm−1) | Peak Ratio | |

|---|---|---|---|---|

| Control | 70 dpi/110 µs | |||

| C–H | 2850–3000 | 3000 [28] | 1.11 | 1.17 |

| C=O | 1670–1820 | 1700 [28] | 1.08 | 1.12 |

| N–H | 1500–1600 | 1600 [25] | 1.08 | 1.11 |

| –CH2 and –CH3 | 1400–1500 | 1453 [29] | 1.07 | 1.10 |

| C–O–C | 1050–1250 | 1121 [29] | 1.03 | 1.06 |

| Pixel Time ( µs) | 110 | 120 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Resolution (dpi) | |||||||||||

| 70 | 131 | 130 | 130 | 132 | 128 | 127 | 121 | 121 | 121 | 126 | |

| 80 | 132 | 130 | 130 | 130 | 129 | 125 | 121 | 123 | 124 | 126 | |

| 90 | 120 | 121 | 122 | 131 | 125 | 123 | 121 | 118 | 119 | 120 | |

| 100 | 128 | 126 | 125 | 128 | 128 | 123 | 121 | 125 | 126 | 125 | |

| Pixel Time ( µs) | 110 | 120 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Resolution (dpi) | |||||||||||

| 70 | 1.07 | 1.01 | 1.06 | 1.07 | 0.93 | 0.95 | 0.86 | 0.91 | 0.96 | 1.00 | |

| 80 | 0.84 | 0.84 | 0.92 | 1.00 | 0.89 | 0.82 | 0.88 | 0.96 | 0.85 | 0.92 | |

| 90 | 0.94 | 0.93 | 0.91 | 0.98 | 0.98 | 1.00 | 1.00 | 1.17 | 1.17 | 0.90 | |

| 100 | 0.94 | 0.76 | 0.88 | 0.88 | 0.95 | 1.02 | 1.00 | 1.05 | 1.17 | 1.19 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liou, Y.-d.; Chau, K.-h.; Hui, C.-y.; He, J.-l.; Lam, Y.-l.; Kan, C.-w. An Analysis of Effect of CO2 Laser Treatment on Carbon Fibre Fabric. Coatings 2018, 8, 178. https://doi.org/10.3390/coatings8050178

Liou Y-d, Chau K-h, Hui C-y, He J-l, Lam Y-l, Kan C-w. An Analysis of Effect of CO2 Laser Treatment on Carbon Fibre Fabric. Coatings. 2018; 8(5):178. https://doi.org/10.3390/coatings8050178

Chicago/Turabian StyleLiou, Yu-de, Kam-hong Chau, Chi-yuen Hui, Ju-liang He, Yin-ling Lam, and Chi-wai Kan. 2018. "An Analysis of Effect of CO2 Laser Treatment on Carbon Fibre Fabric" Coatings 8, no. 5: 178. https://doi.org/10.3390/coatings8050178

APA StyleLiou, Y.-d., Chau, K.-h., Hui, C.-y., He, J.-l., Lam, Y.-l., & Kan, C.-w. (2018). An Analysis of Effect of CO2 Laser Treatment on Carbon Fibre Fabric. Coatings, 8(5), 178. https://doi.org/10.3390/coatings8050178