Enhanced Tribological Properties of Polymer Composite Coating Containing Graphene at Room and Elevated Temperatures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Polymer Composite Coating

2.2. Characterization

3. Results and Discussion

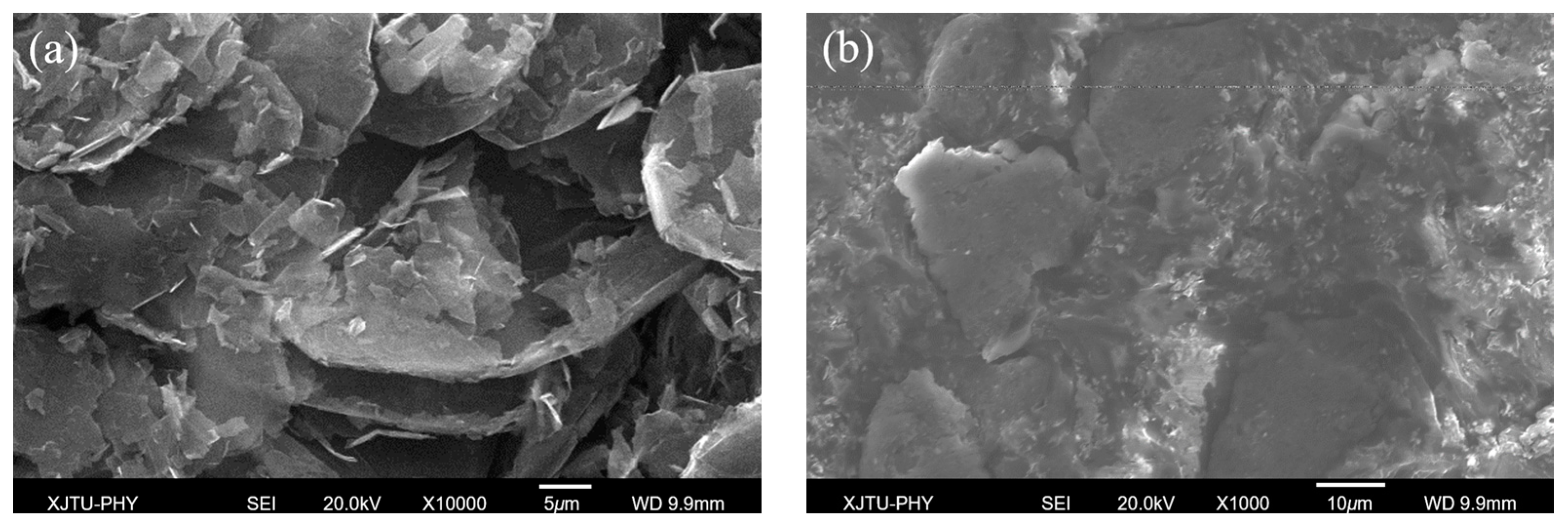

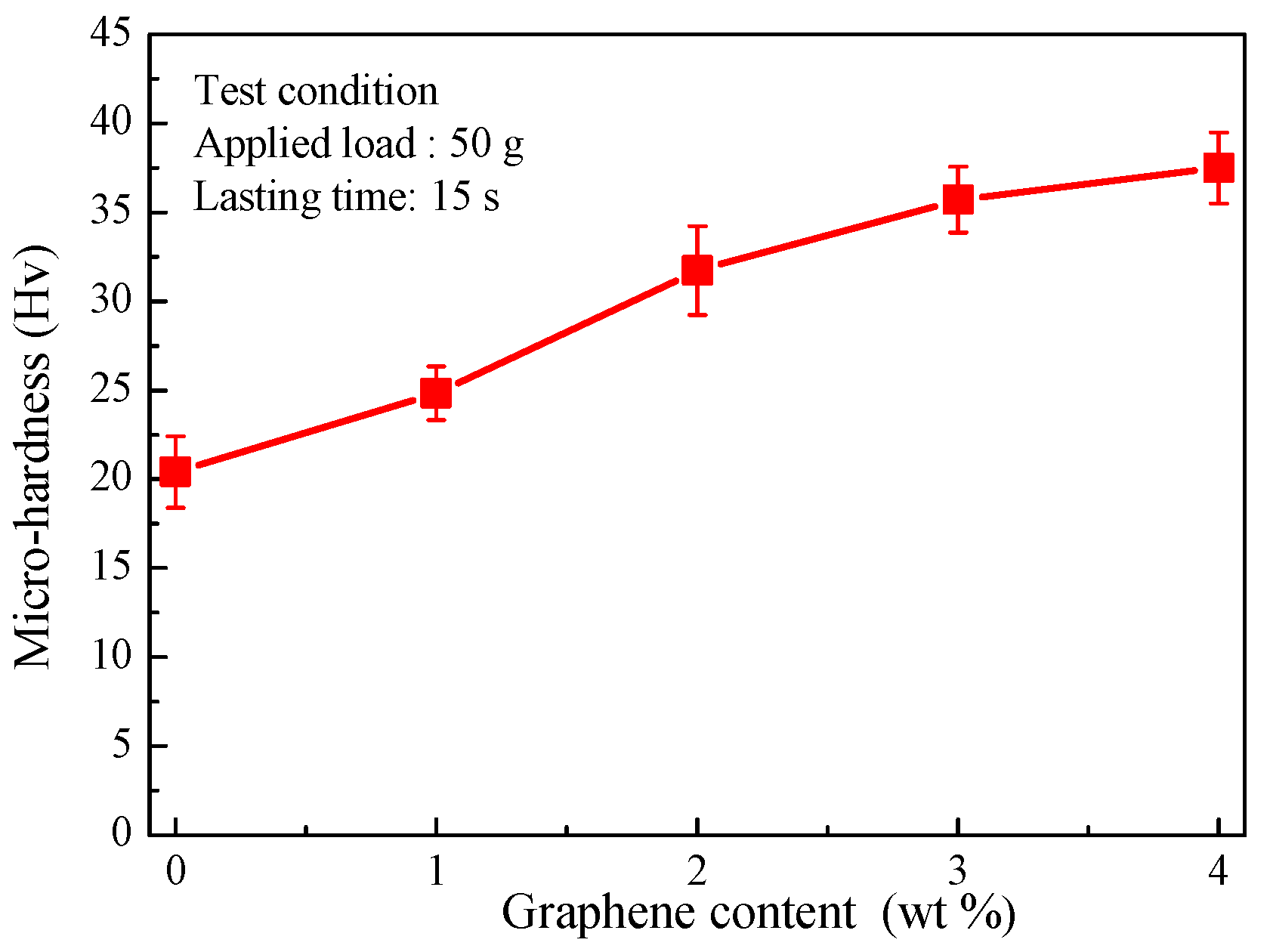

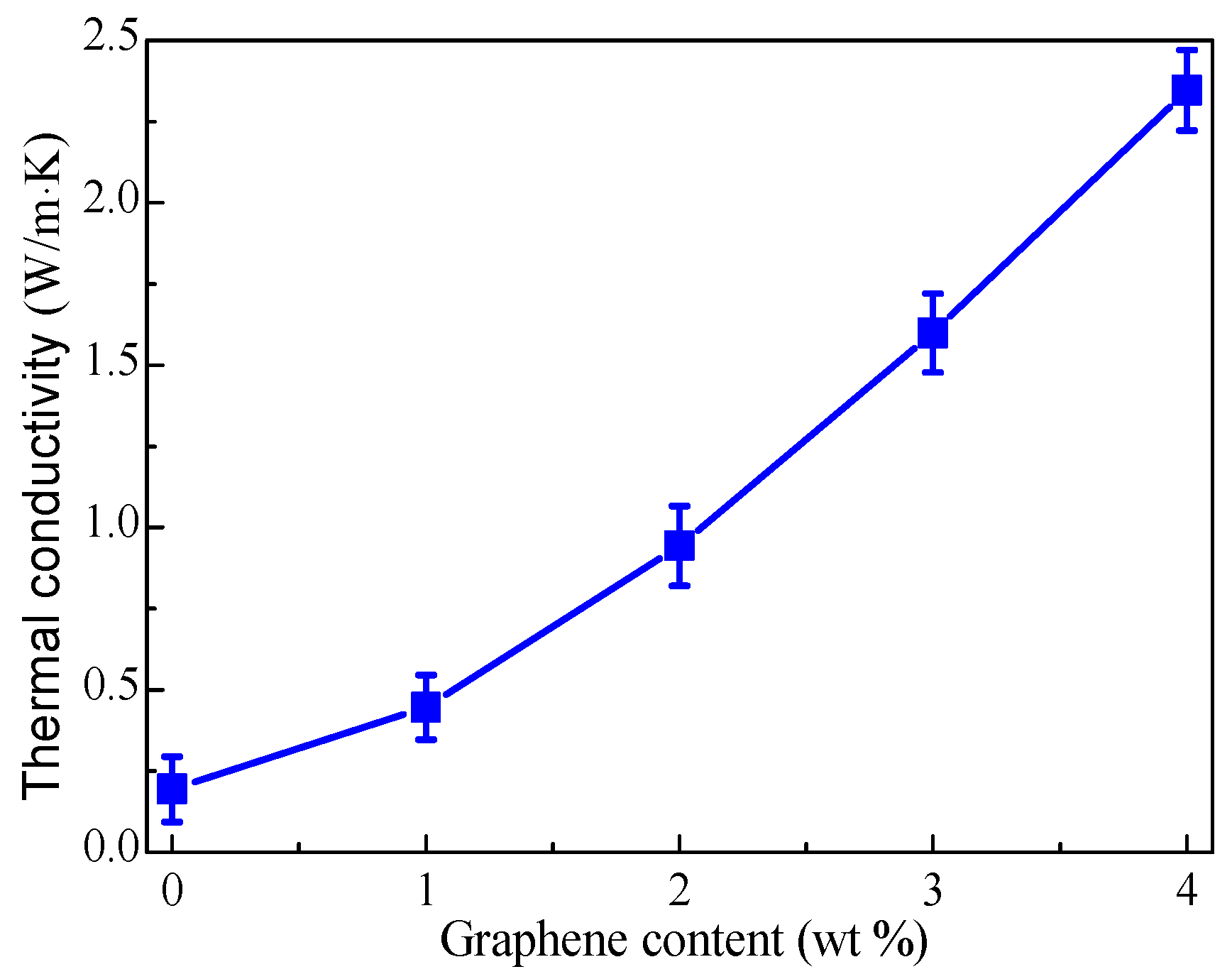

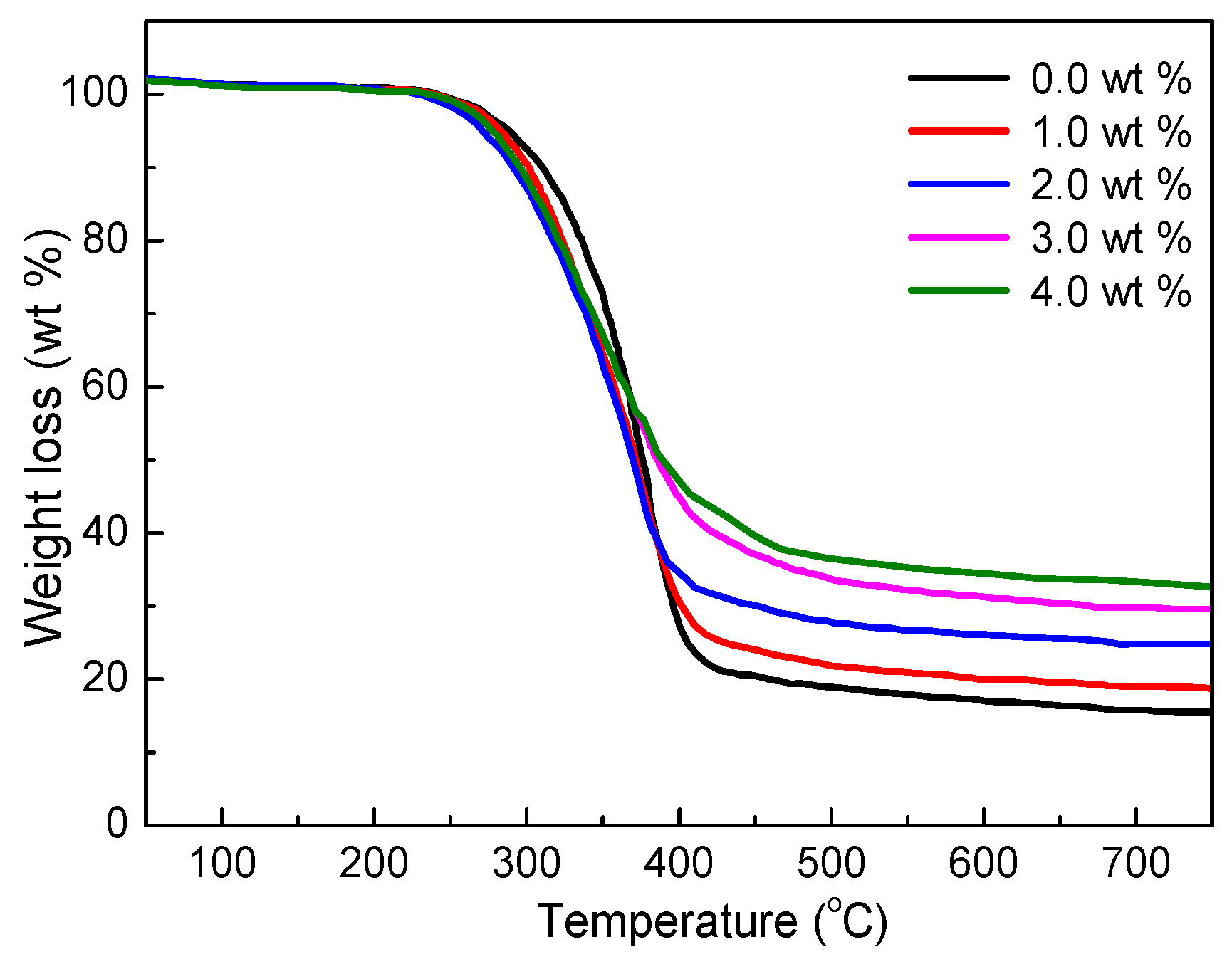

3.1. Characterization of the Composite Coating

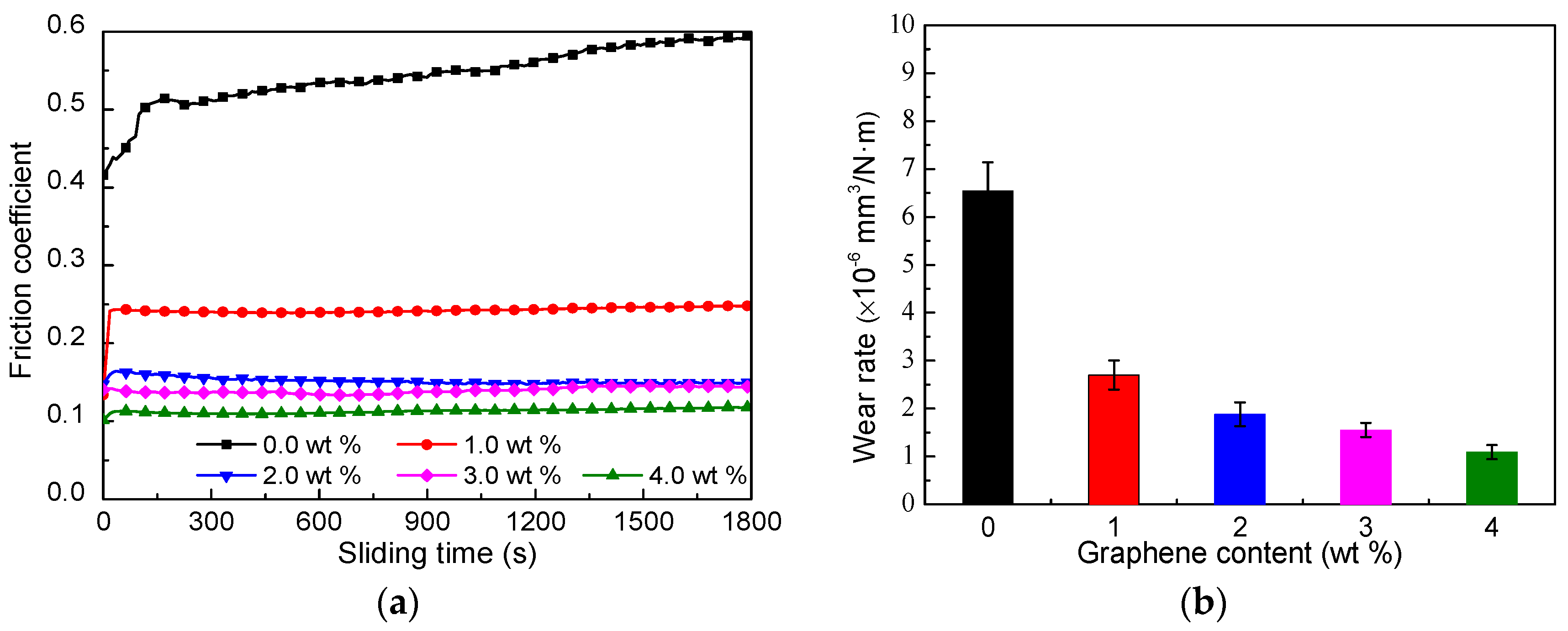

3.2. Effect of Graphene Content on the Tribological Properties

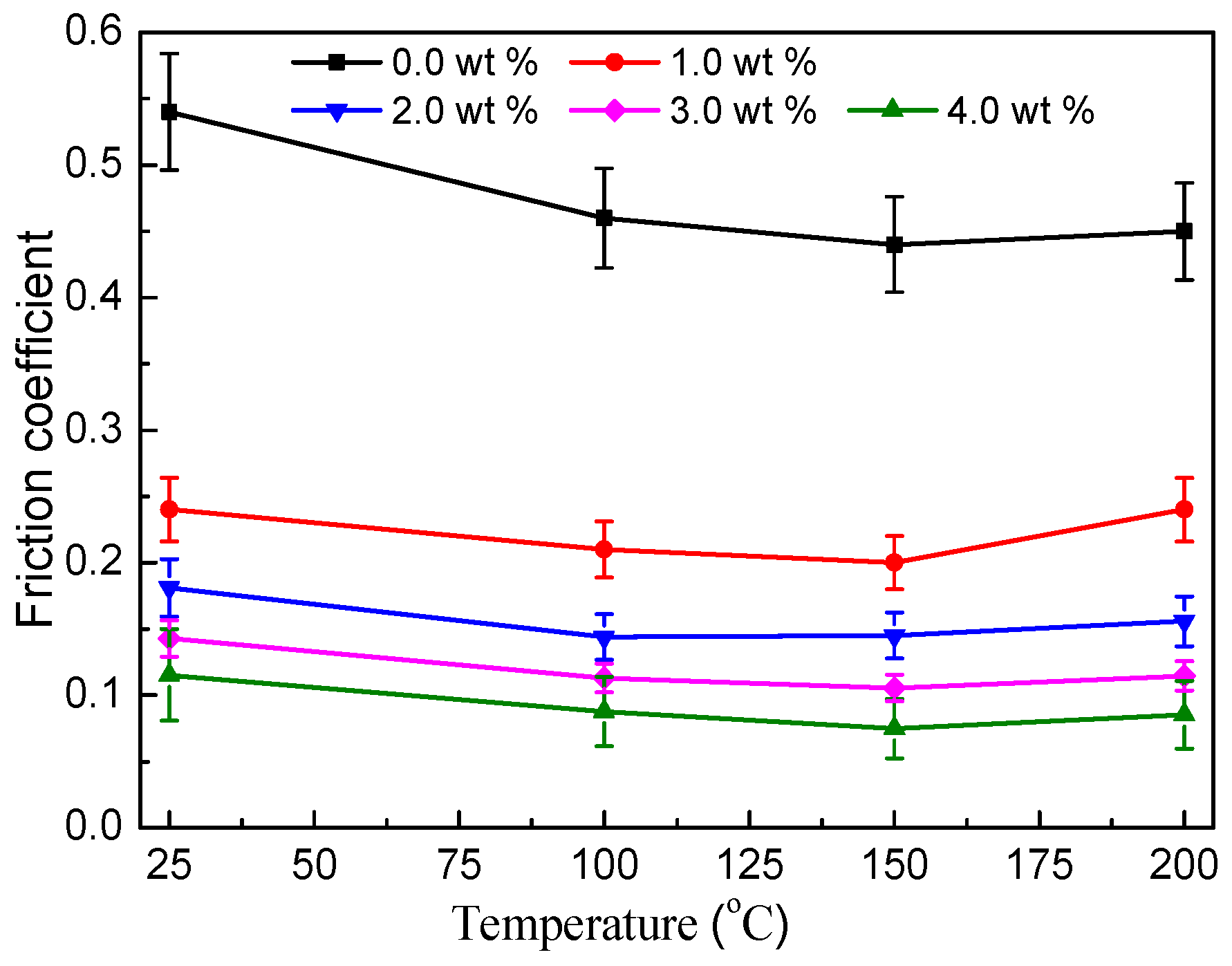

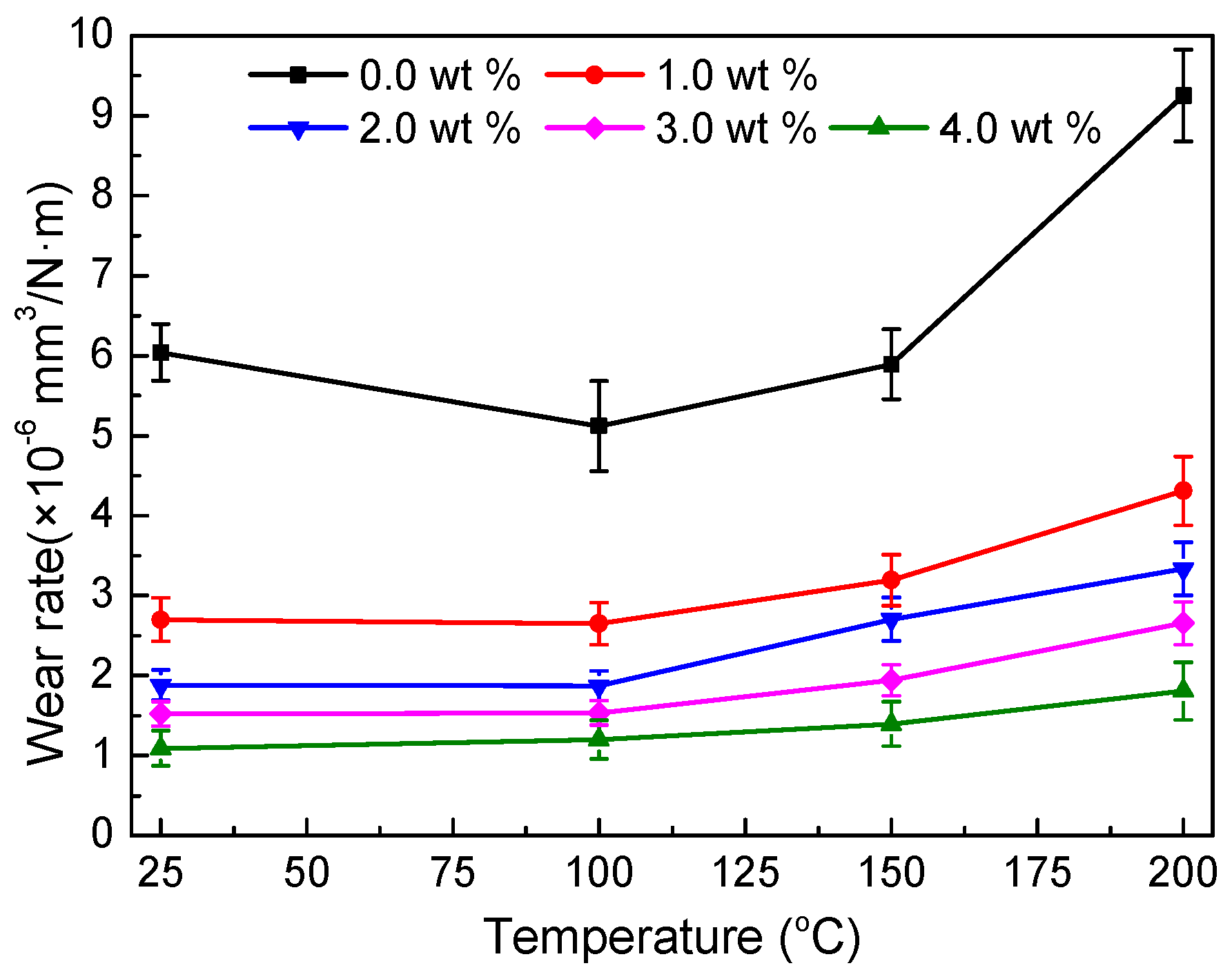

3.3. Effect of Elevated Temperature on the Tribological Properties

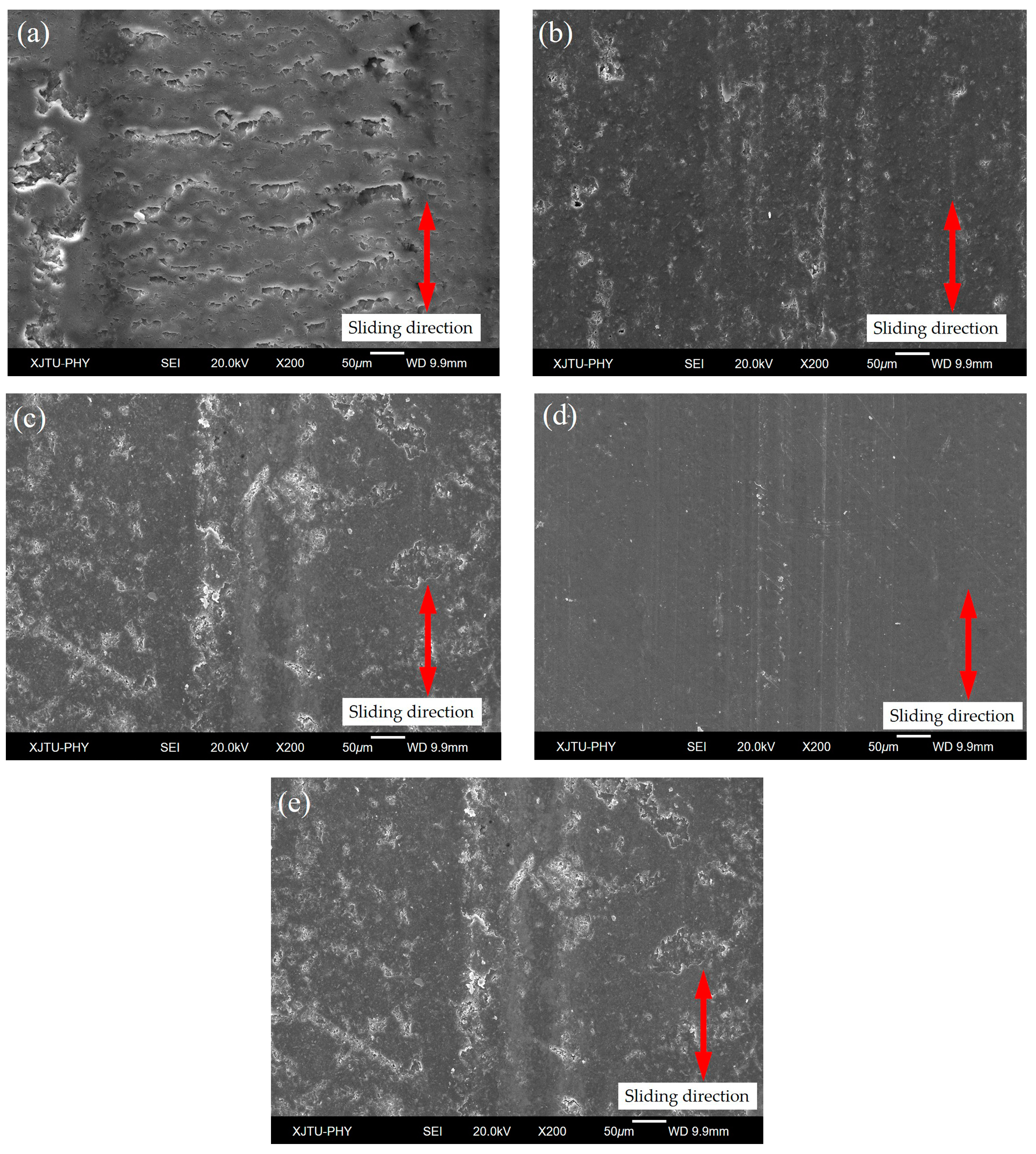

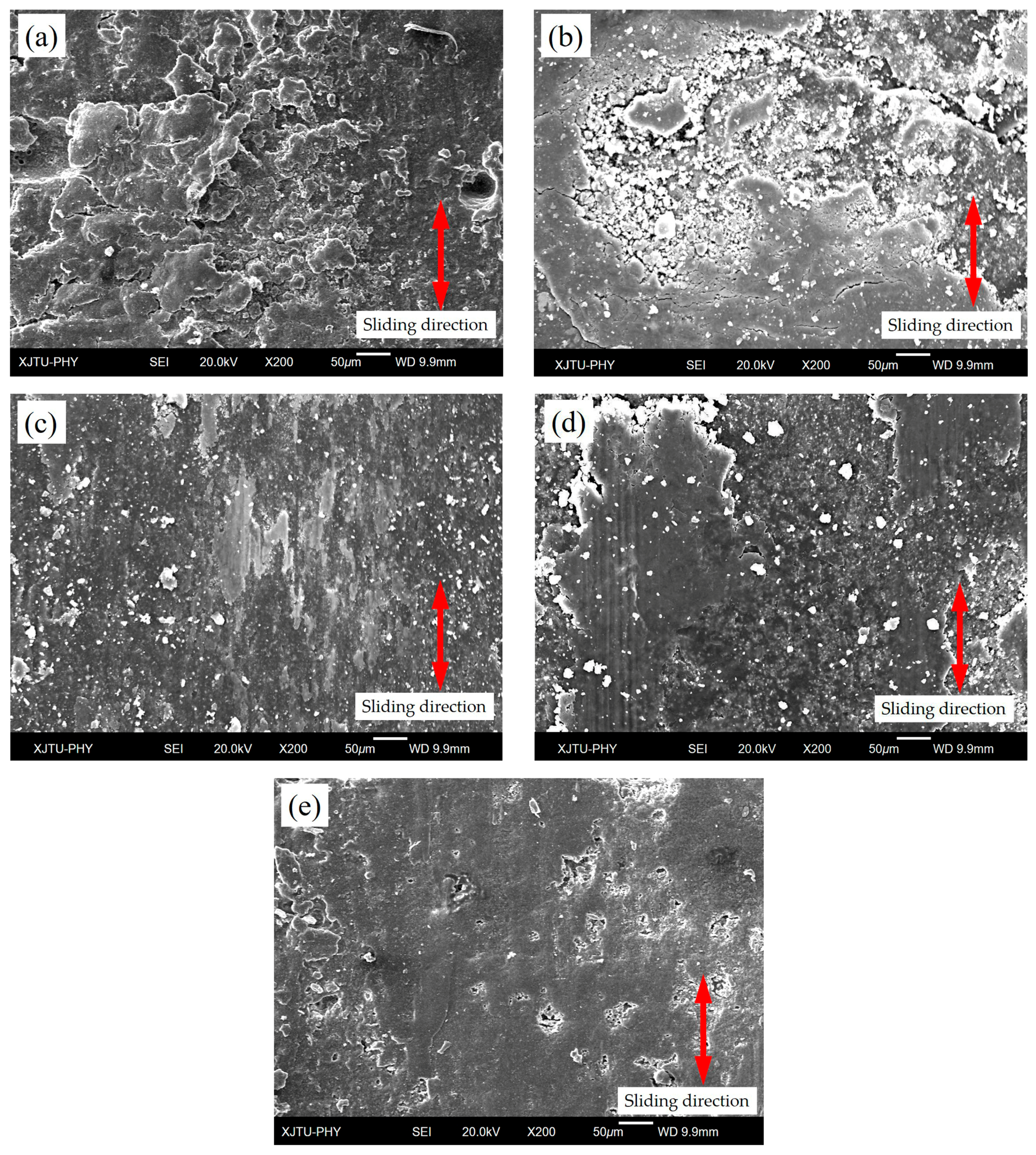

3.4. Analysis of Wear Morphology

4. Conclusions

- When filling with various content of graphene, the micro-hardness, heat resistance, and thermal conductivity properties of epoxy resin coating are significantly enhanced.

- Under the room temperature condition, epoxy coating containing graphene has excellent tribological properties, the friction coefficient and wear rate of the neat epoxy coating is 0.55 and 6.54 × 10−6 mm3/N·m, the friction coefficient and wear rate is 0.11 and 1.52 × 10−6 mm3/N·m for the composite coating contains 4.0 wt % graphene. With the increase of graphene content, the friction coefficient and wear rate of the composite coating are gradually reduced.

- Under high temperature conditions, graphene-enhanced composite coating shows better friction reduction and wear resistance than neat epoxy coating, and the values are reduced as the increase of graphene content. Meanwhile, the friction coefficient and the wear rate of the composite coatings containing graphene slightly decrease or increase with the increase of test temperature. Such phenomena are mainly caused by the formation of a transfer film on the surface which suppresses the huge heat and contact pressure.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ke, H.; Huang, W.; Wang, X. Insights into the effect of thermocapillary migration of droplet on lubrication. Proc. Inst. Mech. Eng. Part J-J. Eng. Tribol. 2016, 230, 583–590. [Google Scholar] [CrossRef]

- Donnet, C.; Erdemir, A. Solid lubricant coatings: Recent developments and future trends. Tribol. Lett. 2004, 17, 389–397. [Google Scholar] [CrossRef]

- Zhang, D.-Y.; Zhang, P.-B.; Lin, P.; Dong, G.-N.; Zeng, Q.-F. Tribological properties of self-lubricating polymer-steel laminated composites. Tribol. Trans. 2013, 56, 908–918. [Google Scholar] [CrossRef]

- Katiyar, J.K.; Sinha, S.K.; Kumar, A. Friction and wear durability study of epoxy-based polymer (SU-8) composite coatings with talc and graphite as fillers. Wear 2016, 362–363, 199–208. [Google Scholar] [CrossRef]

- Wan, H.; Jia, Y.; Ye, Y.; Xu, H.; Cui, H.; Chen, L.; Zhou, H.; Chen, J. Tribological behavior of polyimide/epoxy resin-polytetrafluoroethylene bonded solid lubricant coatings filled with in situ-synthesized silver nanoparticles. Prog. Org. Coat. 2017, 106, 111–118. [Google Scholar] [CrossRef]

- Turssi, C.P.; Purquerio, B.M.; Serra, M.C. Wear of dental resin composites: Insights into underlying processes and assessment methods—A review. J. Biomed. Mater. Res. B 2003, 65, 280–285. [Google Scholar] [CrossRef] [PubMed]

- Bijwe, J.; Indumathi, J.; Ghosh, A.K. On the abrasive wear behaviour of fabric-reinforced polyetherimide composites. Wear 2002, 253, 768–777. [Google Scholar] [CrossRef]

- Bastani, D.; Esmaeili, N.; Asadollahi, M. Polymeric mixed matrix membranes containing zeolites as a filler for gas separation applications: A review. J. Ind. Eng. Chem. 2013, 19, 375–393. [Google Scholar] [CrossRef]

- Shen, X.-J.; Pei, X.-Q.; Fu, S.-Y.; Friedrich, K. Significantly modified tribological performance of epoxy nanocomposites at very low graphene oxide content. Polymer 2013, 54, 1234–1242. [Google Scholar] [CrossRef]

- Lin, J.; Wang, L.; Chen, G. Modification of graphene platelets and their tribological properties as a lubricant additive. Tribol. Lett. 2011, 41, 209–215. [Google Scholar] [CrossRef]

- Kandanur, S.S.; Rafiee, M.A.; Yavari, F.; Schrameyer, M.; Yu, Z.Z.; Blanchet, T.A.; Koratkar, N. Suppression of wear in graphene polymer composites. Carbon 2012, 50, 3178–3183. [Google Scholar] [CrossRef]

- Liu, D.; Zhao, W.S.; Liu, Q.; Cen, Q.; Xue, Q. Comparative tribological and corrosion resistance properties of epoxy composite coatings reinforced with functionalized fullerene C60 and graphene. Surf. Coat. Technol. 2016, 286, 354–364. [Google Scholar] [CrossRef]

- Liu, H.; Li, Y.; Wang, T.; Wang, Q. In situ synthesis and thermal, tribological properties of thermosetting polyimide/graphene oxide nanocomposites. J. Mater. Sci. 2012, 47, 1867–1874. [Google Scholar] [CrossRef]

- Ren, G.; Zhang, Z.; Zhu, X.; Ge, B.; Guo, F.; Men, X.; Liu, W. Influence of functional graphene as filler on the tribological behaviors of Nomex fabric/phenolic composite. Compos. Part A-Appl. Sci. Manuf. 2013, 49, 157–164. [Google Scholar] [CrossRef]

- Lahiri, D.; Hec, F.; Thiesse, M.; Durygin, A.; Zhang, C.; Agarwal, A. Nanotribological behavior of graphene nanoplatelet reinforced ultrahigh molecular weight polyethylene composites. Tribol. Int. 2014, 70, 165–169. [Google Scholar] [CrossRef]

- Muhammad, T.M.; Evie, L.P.; José, A.H.G.; Ilker, S.B.; Athanassi, A.; Luca, C. Graphene and polytetrafluoroethylene synergistically improve the tribological properties and adhesion of nylon 66 coatings. Carbon 2017, 123, 26–33. [Google Scholar]

- Shen, X.-J.; Pei, X.-Q.; Liu, Y.; Fu, S.-Y. Tribological performance of carbon nanotube–graphene oxide hybrid/epoxy composites. Compos. Part B-Eng. 2014, 57, 120–125. [Google Scholar] [CrossRef]

- Jiang, T.; Kuila, T.; Kim, N.H.; Ku, B.-C.; Lee, J.H. Enhanced mechanical properties of silanized silica nanoparticle attached graphene oxide/epoxy composites. Compos. Sci. Technol. 2013, 79, 115–125. [Google Scholar] [CrossRef]

- Golchin, A.; Wikner, A.; Emami, N. An investigation into tribological behaviour of multi-walled carbon nanotube/graphene oxide reinforced UHMWPE in water lubricated contacts. Tribol. Int. 2016, 95, 156–161. [Google Scholar] [CrossRef]

- Marcano, D.C.; Kosynkin, D.V.; Berlin, J.M.; Sinitskii, A.; Sun, Z.; Slesarev, A.; Alemany, L.B.; Lu, W.; Tour, J.M. Improved synthesis of graphene oxide. ACS Nano 2010, 4, 4806–4814. [Google Scholar] [CrossRef] [PubMed]

- ASTM E1461-01 Standard Test Method for Thermal Diffusivity by the Flash Method; ASTM International: West Conshohocken, CA, USA, 2001.

- ASTM G133-05 Standard Test Method for Linearly Reciprocating Ball-on-flat Sliding Wear; ASTM International: West Conshohocken, CA, USA, 2005.

- Zhang, D.; Dong, G.; Chen, Y.; Zeng, Q. Electrophoretic deposition of PTFE particles on porous anodic aluminum oxide film and its tribological properties. Appl. Surf. Sci. 2014, 290, 466–474. [Google Scholar] [CrossRef]

- Tai, Z.; Chen, Y.; An, Y.; Yan, X.; Xue, Q. Tribological behavior of UHMWPE reinforced with graphene oxide nanosheets. Tribol. Lett. 2012, 46, 55–63. [Google Scholar] [CrossRef]

- Naves, L.Z.; Santana, F.R.; Castro, C.G.; Valdivia, A.D.C.M.; da Mota, A.S.; Estrela, C.; Sobrinho, L.C.; Soares, C.J. Surface treatment of glass fiber and carbon fiber posts: SEM characterization. Microsc. Res. Tech. 2011, 74, 1088–1092. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.H.; Yan, M. Functionalization of pristine graphene with perfluorophenyl azides. J. Mater. Chem. 2012, 21, 3273–3276. [Google Scholar] [CrossRef]

- Chatterjee, S.; Wang, J.W.; Kuo, W.S.; Tai, N.H.; Salzmann, C.; Li, W.L.; Hollertz, R.; Nüesch, F.A.; Chu, B.T.T. Mechanical reinforcement and thermal conductivity in expanded graphene nanoplatelets reinforced epoxy composites. Chem. Phys. Lett. 2012, 531, 6–10. [Google Scholar] [CrossRef]

- Lin, Z.; Mcnamara, A.; Liu, Y.; Moon, K.S.; Wong, C.P. Exfoliated hexagonal boron nitride-based polymer nanocomposite with enhanced thermal conductivity for electronic encapsulation. Compos. Sci. Technol. 2014, 90, 123–128. [Google Scholar] [CrossRef]

- Wang, F.; Drzal, L.T.; Qin, Y.; Huang, Z. Mechanical properties and thermal conductivity of graphene nanoplatelet/epoxy composites. J. Mater. Sci. 2015, 50, 1082–1093. [Google Scholar] [CrossRef]

- Ganguli, S.; Roy, A.K.; Anderson, D.P. Improved thermal conductivity for chemically functionalized exfoliated graphite/epoxy composites. Carbon 2008, 46, 806–817. [Google Scholar] [CrossRef]

- Pan, B.; Zhang, S.; Li, W.; Zhao, J.; Liu, J.; Zhang, Y.; Zhang, Y. Tribological and mechanical investigation of MC nylon reinforced by modified graphene oxide. Wear 2012, 294–295, 395–401. [Google Scholar] [CrossRef]

- Min, C.; Nie, P.; Song, H.J.; Zhang, Z.; Zhao, K. Study of tribological properties of polyimide/graphene oxide nanocomposite films under seawater-lubricated condition. Tribol. Int. 2014, 80, 131–140. [Google Scholar] [CrossRef]

- Feng, J.; Guo, Z. Temperature-frequency-dependent mechanical properties model of epoxy resin and its composites. Compos. Part B-Eng. 2016, 85, 161–169. [Google Scholar] [CrossRef]

- Li, C.; Zhong, Z.; Lin, Y.; Friedrich, K. Tribological properties of high temperature resistant polymer composites with fine particles. Tribol. Int. 2007, 40, 1170–1178. [Google Scholar]

- Rapoport, L.; Bilik, Y. Hollow nanoparticles of WS2 as potential solid-state lubricants. Nature 1997, 387, 791–793. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, D.; Wei, X.; Zhong, S.; Wang, J. Enhanced Tribological Properties of Polymer Composite Coating Containing Graphene at Room and Elevated Temperatures. Coatings 2018, 8, 91. https://doi.org/10.3390/coatings8030091

Zhang Y, Zhang D, Wei X, Zhong S, Wang J. Enhanced Tribological Properties of Polymer Composite Coating Containing Graphene at Room and Elevated Temperatures. Coatings. 2018; 8(3):91. https://doi.org/10.3390/coatings8030091

Chicago/Turabian StyleZhang, Yanchao, Dongya Zhang, Xian Wei, Shanjun Zhong, and Jianlei Wang. 2018. "Enhanced Tribological Properties of Polymer Composite Coating Containing Graphene at Room and Elevated Temperatures" Coatings 8, no. 3: 91. https://doi.org/10.3390/coatings8030091

APA StyleZhang, Y., Zhang, D., Wei, X., Zhong, S., & Wang, J. (2018). Enhanced Tribological Properties of Polymer Composite Coating Containing Graphene at Room and Elevated Temperatures. Coatings, 8(3), 91. https://doi.org/10.3390/coatings8030091