Environmentally Friendly Plasma Activation of Acrylonitrile–Butadiene–Styrene and Polydimethylsiloxane Surfaces to Improve Paint Adhesion

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Treatment

2.3. Characterization of the Paints’ Adhesion to Polymeric Surfaces

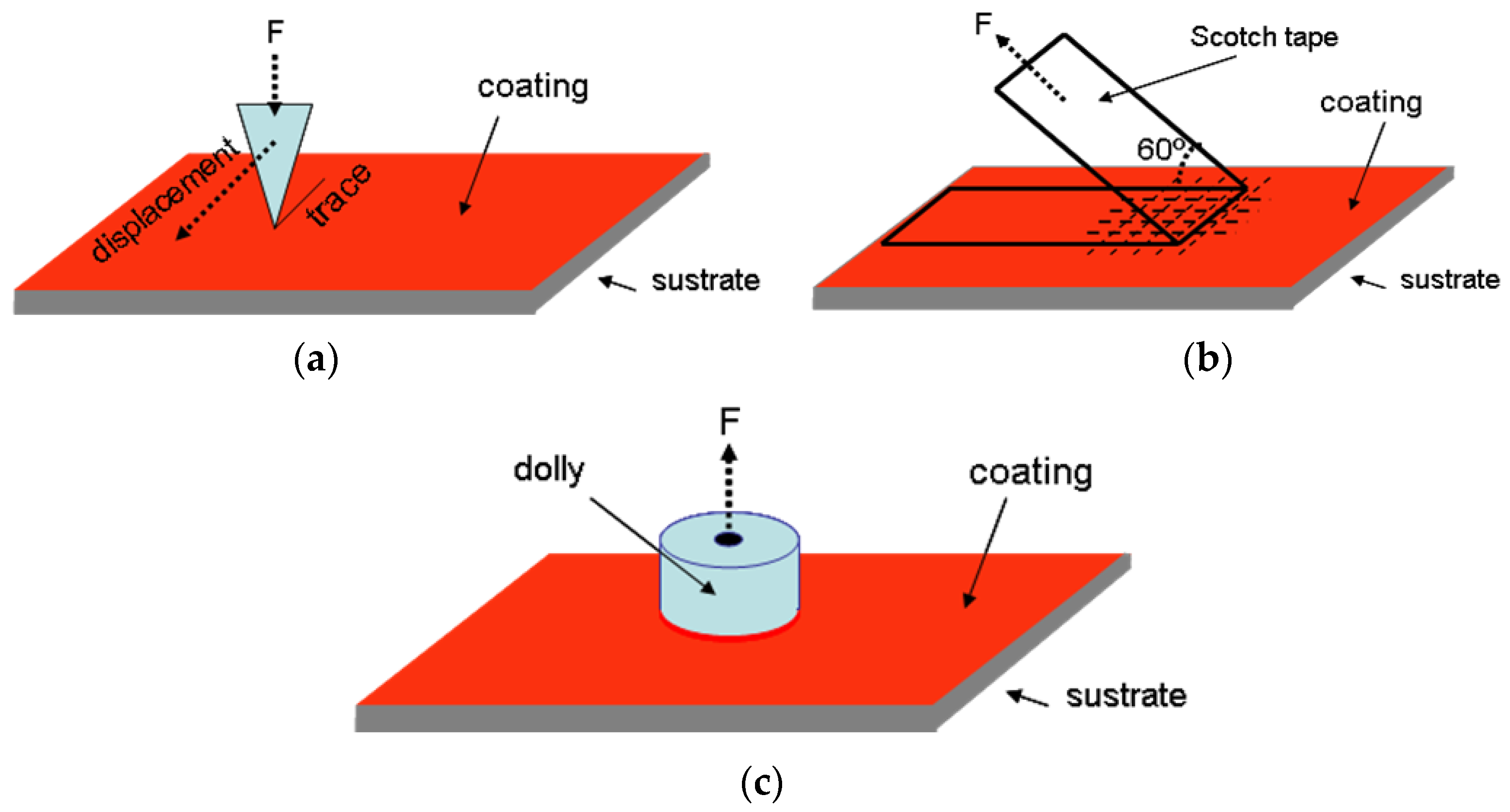

2.3.1. Scratch Test

2.3.2. Cross-Cut Test

2.3.3. Adhesion Pull-Off Test

3. Results and Discussion

3.1. Roughness Modification

3.2. Effect of Aging on the Surface Energy after Atmospheric Pressure Plasma Torch Treatment (APPT)

3.3. Scratch Test

3.4. Cross-Cut Test

3.5. Adhesion Pull-Off Test

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Potrich, C.; Lunelli, L.; Cocuzza, M.; Marasso, S.L.; Pirri, C.F.; Pederzolli, C. Simple PDMS microdevice for biomedical applications. Talanta 2019, 193, 44–50. [Google Scholar] [CrossRef] [PubMed]

- Eduok, U.; Faye, O.; Szpunar, J. Recent developments and applications of protective silicone coatings: A review of PDMS functional materials. Prog. Org. Coat. 2017, 111, 124–163. [Google Scholar] [CrossRef]

- Seethapathy, S.; Górecki, T. Applications of polydimethylsiloxane in analytical chemistry: A review. Anal. Chim. Acta 2012, 750, 48–62. [Google Scholar] [CrossRef] [PubMed]

- Caputo, D.; de Cesare, G.; Lo Vecchio, N.; Nascetti, A.; Parisi, E.; Scipinotti, R. Polydimethylsiloxane material as hydrophobic and insulating layer in electrowetting-on-dielectric systems. Microelectr. J. 2014, 45, 1684–1690. [Google Scholar] [CrossRef]

- De Buyl, F. Silicone sealants and structural adhesives. Int. J. Adhes. Adhes. 2001, 21, 411–422. [Google Scholar] [CrossRef]

- Sreedharan, J.; Jeevanantham, A.K. Analysis of shrinkages in ABS injection molding parts for automobile applications. Mater. Today Proc. 2018, 5, 12744–12749. [Google Scholar] [CrossRef]

- Shu, Z.; Wang, X. Environment-friendly Pd free surface activation technics for ABS surface. Appl. Surf. Sci. 2012, 258, 5328–5331. [Google Scholar] [CrossRef]

- Tibbitt, M.W.; Shadish, J.A.; DeForest, C.A. Photopolymers for multiphoton lithography in biomaterials and hydrogels. In Multiphoton Lithography: Techniques, Materials and Applications, 1st ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2017; pp. 183–220. [Google Scholar]

- Wypych, G. Selection of adhesion promoters for different substrates. In Handbook of Adhesion Promoters; ChemTec Publishing: Toronto, ON, Canada, 2018; pp. 139–175. [Google Scholar]

- Hollahan, J.R.; Bell, A.T. Techniques and Applications of Plasma Chemistry; John Wiley & Sons Inc.: New York, NY, USA, 1975. [Google Scholar]

- Okazaki, S.; Kogoma, M. Development of atmospheric pressure glow discharge plasma and its application on a surface with curvature. J. Photopolym. Sci. Tec. 1993, 6, 339–342. [Google Scholar] [CrossRef]

- Holc, M.; Zaplotnik, R.; Mozetic, M.; Vesel, A. Surface Modification and Aging of Polyacrylonitrile Butadiene Styrene Polymer Induced by Treatment in RF Oxygen Plasma. IEEE Trans. Plasma Sci. 2018, 99, 3669–3676. [Google Scholar] [CrossRef]

- Chen, C. Characterization of fracture energy and toughness of air plasma PDMS-PDMS bonding by T-peel testing. J. Adhes. Sci. Technol. 2017, 32, 1239–1252. [Google Scholar] [CrossRef]

- Du, K.; Jiang, Y.; Huang, P.-S.; Ding, J.; Gao, T.; Choi, C.-H. Self-formation of polymer nanostructures in plasma etching: Mechanisms and applications. J. Micromech. Microeng. 2017, 28, 014006. [Google Scholar] [CrossRef]

- Kinloch, J. Adhesion and Adhesives: Science and Technology; Chapman and Hall: London, UK, 1987. [Google Scholar]

- Al-Harthi, M.; Kahraman, R.; Yilbas, B.; Sunar, M.; Abdul Aleem, B.J. Influence of water immersion on the single-lap shear strength of aluminum joints bonded with aluminum-powder-filled epoxy adhesive. J. Adhes. Sci. Technol. 2004, 18, 1699–1710. [Google Scholar] [CrossRef]

- Jofre-Reche, J.A.; Pulpytel, J.; Arefi-Khonsari, F.; Martin-Martinez, J.M. Increased adhesion of polydimethylsiloxane (PDMS) to acrylic adhesive tape for medical use by surface treatment with an atmospheric pressure rotating plasma jet. J. Phys. D Appl. Phys. 2016, 49, 334001. [Google Scholar] [CrossRef]

- Do Nascimento, F.; Parada, S.; Moshkalev, S.; Machida, M. Plasma treatment of poly(dimethylsiloxane) surfaces using a compact atmospheric pressure dielectric barrier discharge device for adhesion improvement. Jpn. J. Appl. Phys. 2016, 55, 021602. [Google Scholar] [CrossRef]

- Encinas, N.; Dillingham, R.G.; Oakley, B.R.; Abenojar, J.; Martínez, M.A.; Pantoja, M. Atmospheric pressure plasma hydrophilic modification of a silicone surface. J. Adhes. 2012, 88, 321–336. [Google Scholar] [CrossRef]

- Owen, M.J.; Smith, P.J. Plasma treatment of polydimethylsiloxane. J. Adhes. Sci. Technol. 1994, 8, 1063–1075. [Google Scholar] [CrossRef]

- Everaert, E.P.; Van der Mei, H.C.; de Vries, J.; Busscher, H.J. Hydrophobic recovery of repearedly plasma-treated silicone rubber. Part 1. Storage in air. J. Adhes. Sci. Techol. 1995, 9, 1263–1278. [Google Scholar] [CrossRef]

- Abenojar, J.; Torregrosa, R.; Martínez, M.A.; Martín, J.M. Surface modifications of polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) copolymer by treatment with atmospheric plasma. Surf. Coat. Technol. 2009, 203, 2173–2180. [Google Scholar] [CrossRef]

- Encinas, N.; Díaz-Benito, B.; Abenojar, J.; Martínez, M.A. Extreme durability of wettability changes on polyolefin surfaces by atmospheric pressure plasma torch. Surf. Coat. Technol. 2010, 205, 396–402. [Google Scholar] [CrossRef]

- UNE-EN 828:2013 Adhesives–Wettability–Determination by Measurement of Contact Angle and Critical Surface Free Energy of Solid Surface; The Spanish Association for Standardization (UNE): Madrid, Spain, 2013.

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- ISO 1518-1:2011 Paints and Varnishe—Determination of Scratch Resistance. Part 1: Constant-loading Method; ISO: Geneva, Switzerland, 2011.

- ISO 2409:2013 Paints and Varnishes—Cross-Cut Test; ISO: Geneva, Switzerland, 2013.

- ISO 4624:2016 Paints and Varnishes—Pull-off Test for Adhesion; ISO: Geneva, Switzerland, 2016.

- Kim, H.T.; Jeong, O.C. PDMS surface modification using atmospheric pressure plasma. Microelectron. Eng. 2011, 88, 2281–2285. [Google Scholar] [CrossRef]

- Abenojar, J.; Martínez, M.A.; Velasco, F.; Rodríguez-Pérez, M.A. Atmospheric plasma torch treatment of polyethylene/boron composites: Effect on thermal stability. Surf. Coat. Technol. 2014, 239, 70–77. [Google Scholar] [CrossRef]

- Abenojar, J.; Barbosa, A.Q.; Ballesteros, Y.; del Real, J.C.; da Silva, L.F.M.; Martinez, M.A. Effect of surface treatments on natural cork: Surface energy, adhesion, and acoustic insulation. Wood Sci. Technol. 2014, 48, 207–224. [Google Scholar] [CrossRef]

- Awaja, F.; Gilbert, M.; Kelly, G.; Fox, B.; Pigram, P.J. Adhesion of polymers. Prog. Polym. Sci. 2009, 34, 948–968. [Google Scholar] [CrossRef]

- Moghadamzadeh, H.; Rahimi, H.; Asadollahzadeh, M.; Hemmati, A.R. Surface treatment of wood polymer composites for adhesive bonding. Int. J. Adhes. Adhes. 2011, 31, 816–821. [Google Scholar] [CrossRef]

| Surface Energy | Untreated | 3 min | 1 h | 48 h | 168 h | 336 h |

|---|---|---|---|---|---|---|

| Total | 30 ± 2 | 59 ± 2 | 59 ± 2 | 62 ± 2 | 62 ± 2 | 53 ± 2 |

| Dispersive | 16 ± 2 | 18 ± 2 | 19 ± 2 | 16 ± 2 | 14 ± 2 | 19 ± 2 |

| Polar | 14 ± 2 | 41 ± 2 | 39 ± 2 | 45 ± 2 | 47 ± 2 | 34 ± 2 |

| Surface Energy | Untreated | 3 min | 5 min | 15 min | 30 min | 1 h |

|---|---|---|---|---|---|---|

| Total | 27 ± 2 | 43 ± 2 | 41 ± 2 | 37 ± 2 | 35 ± 2 | 30 ± 2 |

| Dispersive | 24 ± 2 | 32 ± 2 | 30 ± 2 | 31 ± 2 | 32 ± 2 | 27 ± 2 |

| Polar | 2 ± 1 | 11 ± 2 | 11 ± 2 | 6 ± 1 | 3 ± 1 | 3 ± 1 |

| Substrate | Paint | Treatment | Classification | % Detached |

|---|---|---|---|---|

| ABS | Epoxy | Untreated | 5 | >65 |

| APPT | 0 | 0 | ||

| Polyurethane | Untreated | 0 | 0 | |

| APPT | 0 | 0 | ||

| PDMS | Epoxy | Untreated | 5 | >65 |

| APPT | 4 | ≈50 | ||

| Polyurethane | Untreated | 5 | >65 | |

| APPT | 2 | <10 |

| Coating | PDMS | ABS | ||

|---|---|---|---|---|

| APPT-treated | Untreated | APPT-treated | Untreated | |

| EP | 37 ± 2 | – | 1025 ± 10 | – |

| PU | 199 ± 5 | – | 577 ± 5 | 59 ± 4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinez, M.A.; Abenojar, J.; Lopez de Armentia, S. Environmentally Friendly Plasma Activation of Acrylonitrile–Butadiene–Styrene and Polydimethylsiloxane Surfaces to Improve Paint Adhesion. Coatings 2018, 8, 428. https://doi.org/10.3390/coatings8120428

Martinez MA, Abenojar J, Lopez de Armentia S. Environmentally Friendly Plasma Activation of Acrylonitrile–Butadiene–Styrene and Polydimethylsiloxane Surfaces to Improve Paint Adhesion. Coatings. 2018; 8(12):428. https://doi.org/10.3390/coatings8120428

Chicago/Turabian StyleMartinez, Miguel Angel, Juana Abenojar, and Sara Lopez de Armentia. 2018. "Environmentally Friendly Plasma Activation of Acrylonitrile–Butadiene–Styrene and Polydimethylsiloxane Surfaces to Improve Paint Adhesion" Coatings 8, no. 12: 428. https://doi.org/10.3390/coatings8120428

APA StyleMartinez, M. A., Abenojar, J., & Lopez de Armentia, S. (2018). Environmentally Friendly Plasma Activation of Acrylonitrile–Butadiene–Styrene and Polydimethylsiloxane Surfaces to Improve Paint Adhesion. Coatings, 8(12), 428. https://doi.org/10.3390/coatings8120428