Corrosion Damage Mechanism of TiN/ZrN Nanoscale Multilayer Anti-Erosion Coating

Abstract

1. Introduction

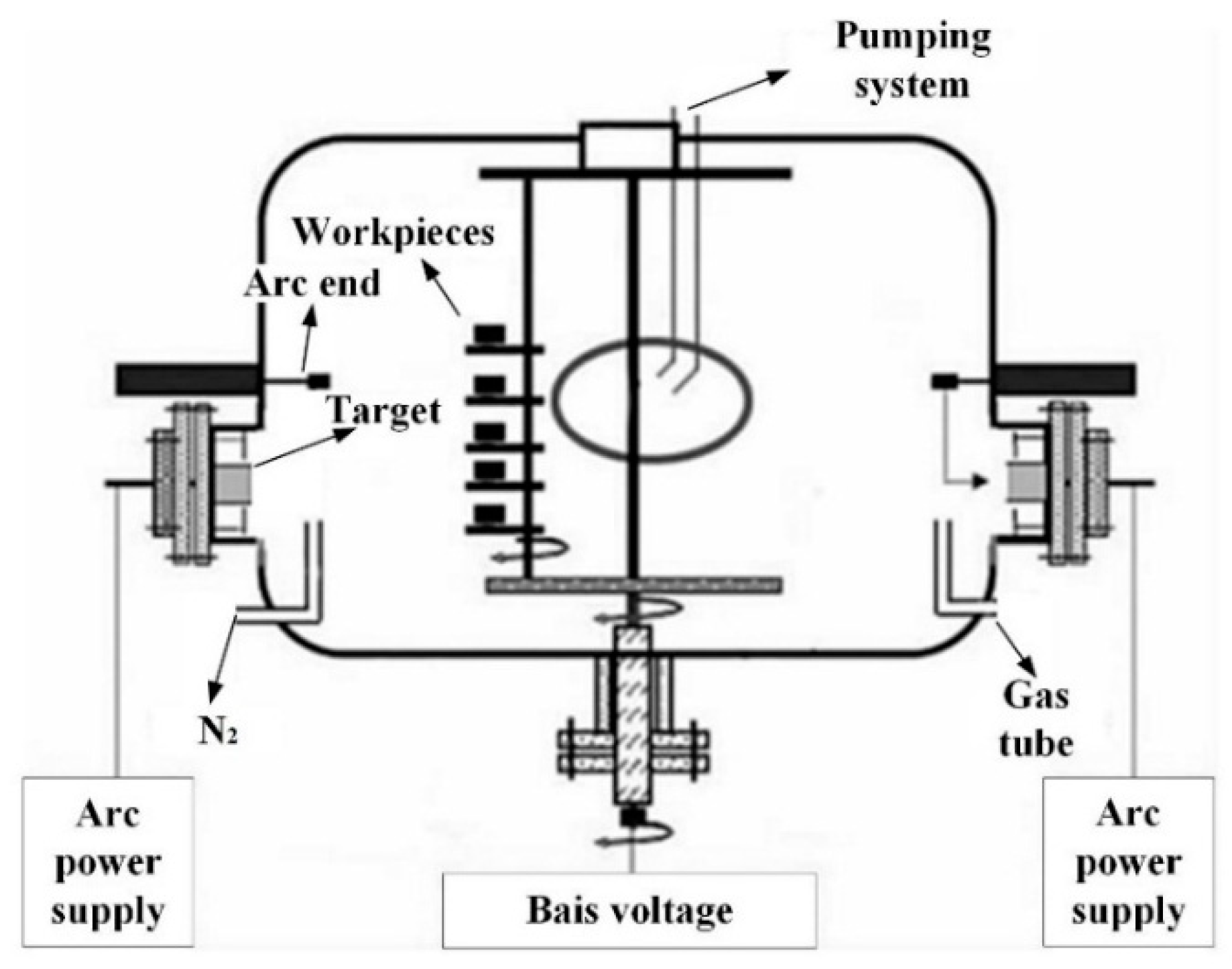

2. Materials and Methods

3. Results and Discussion

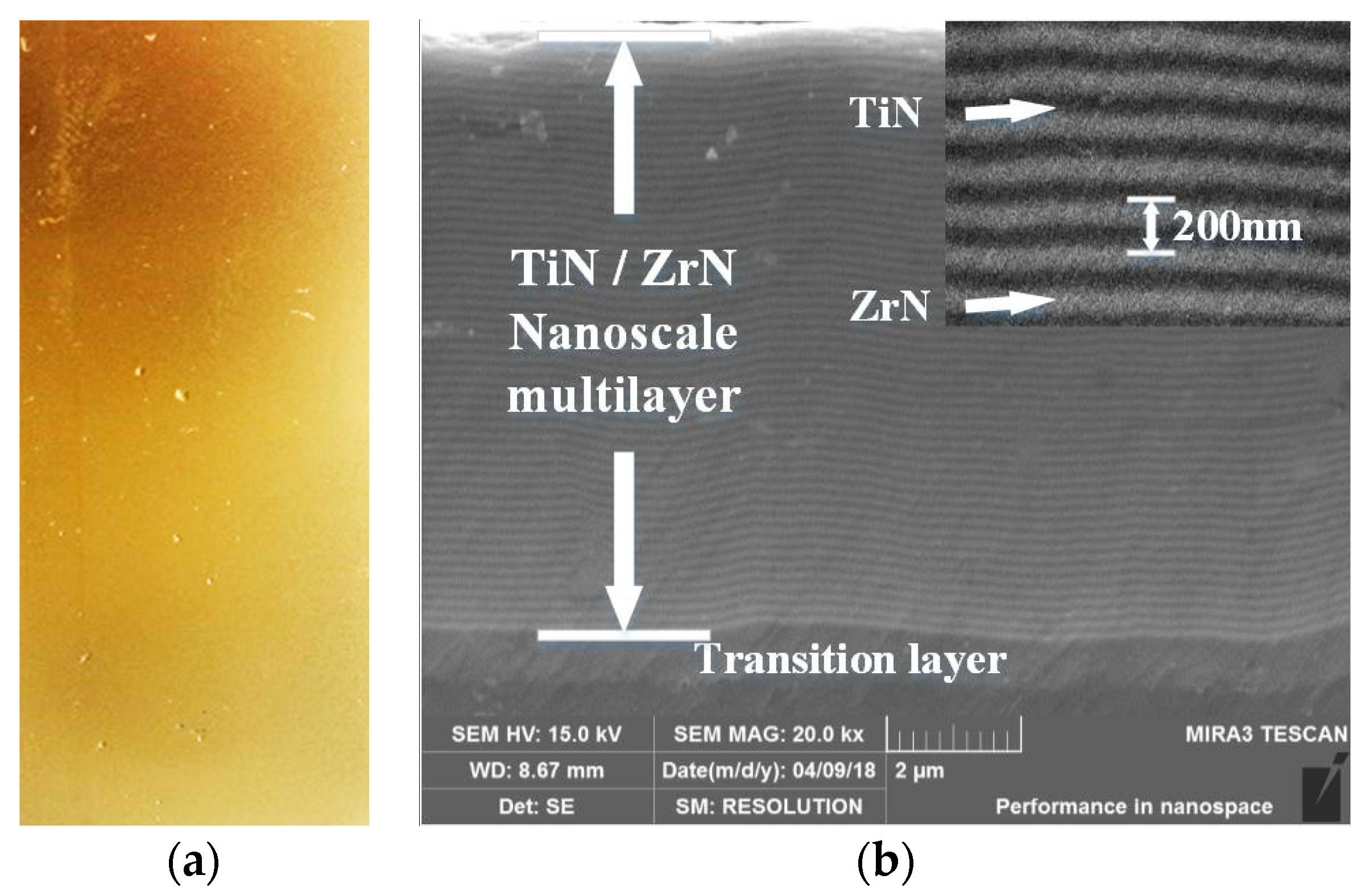

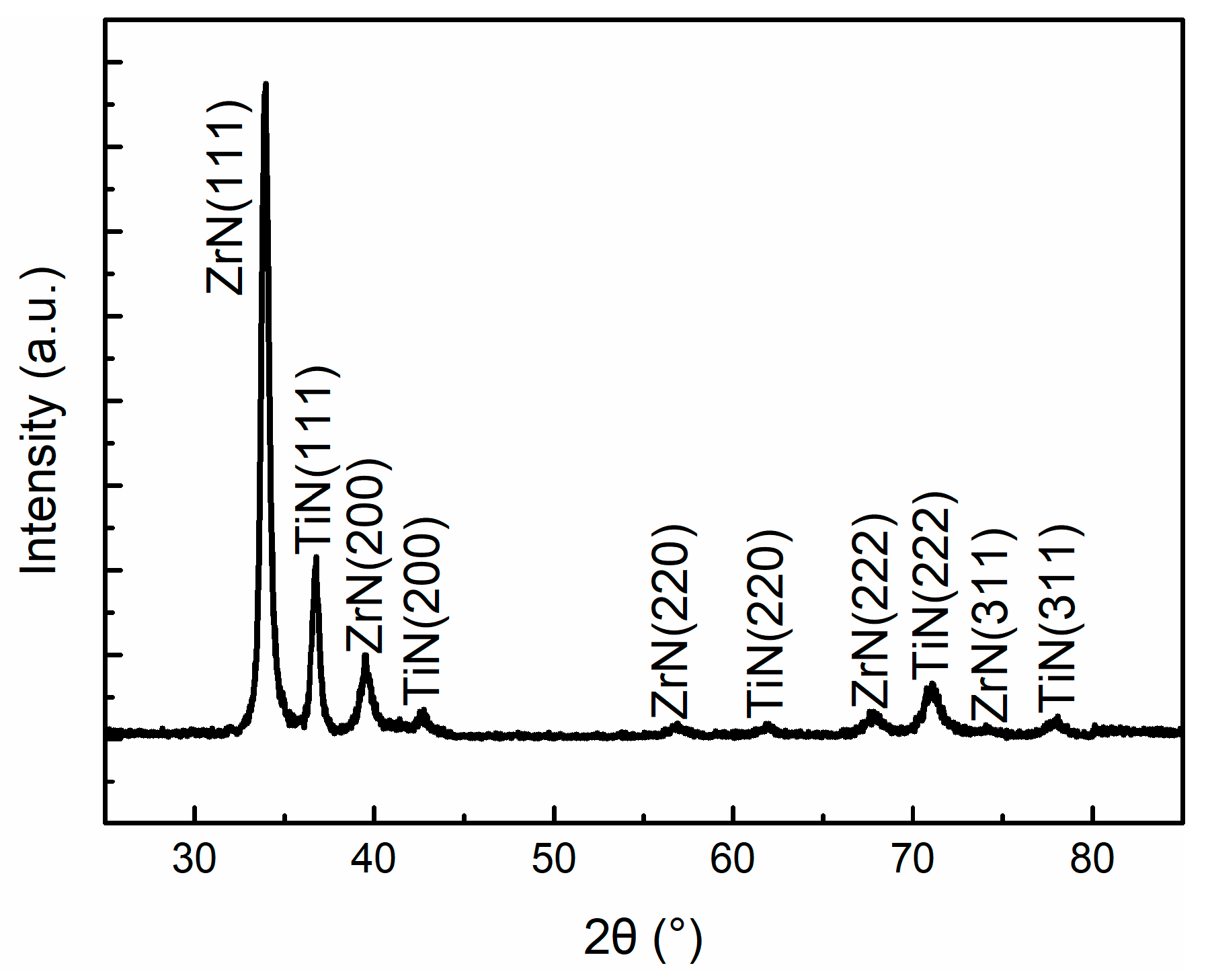

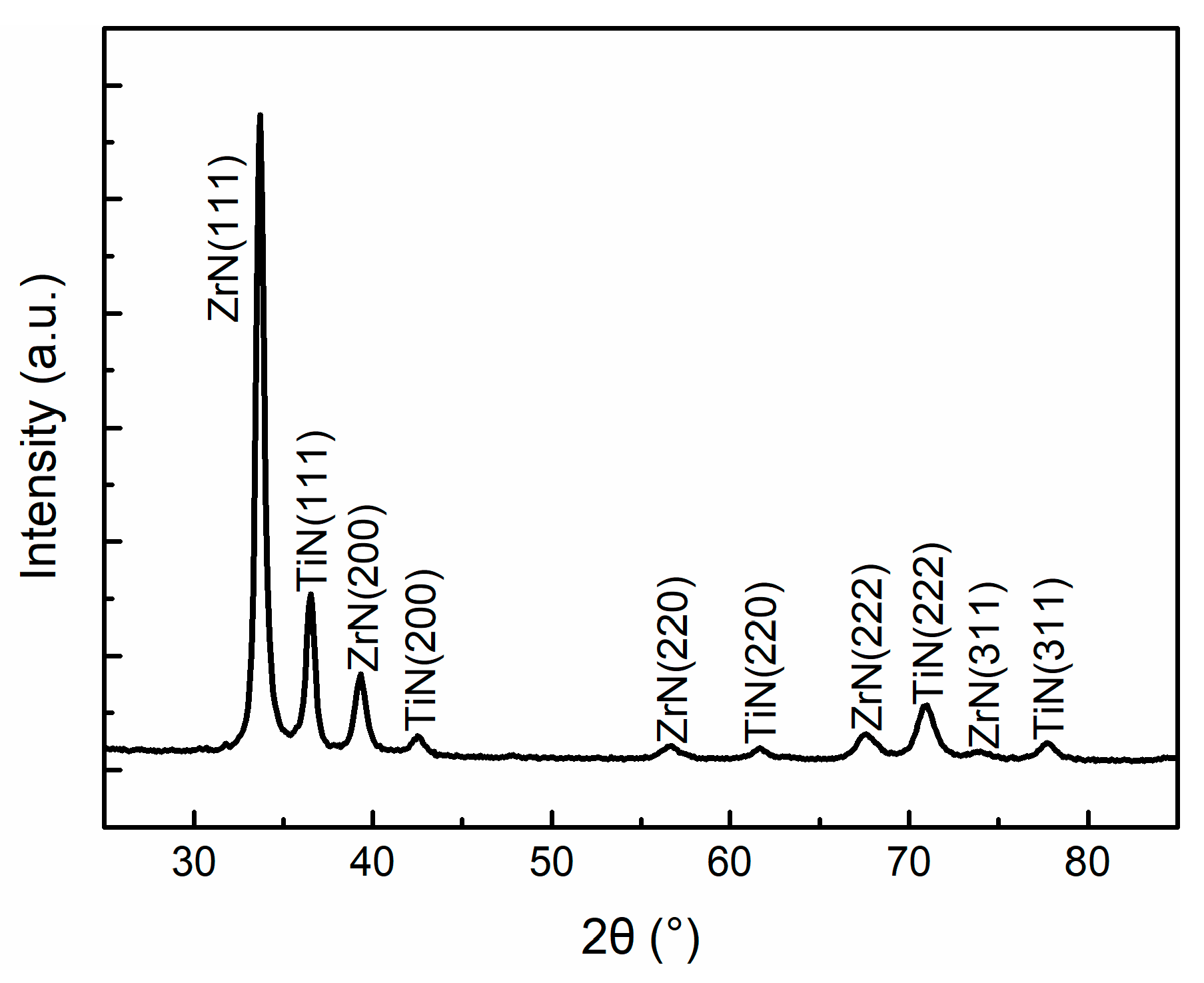

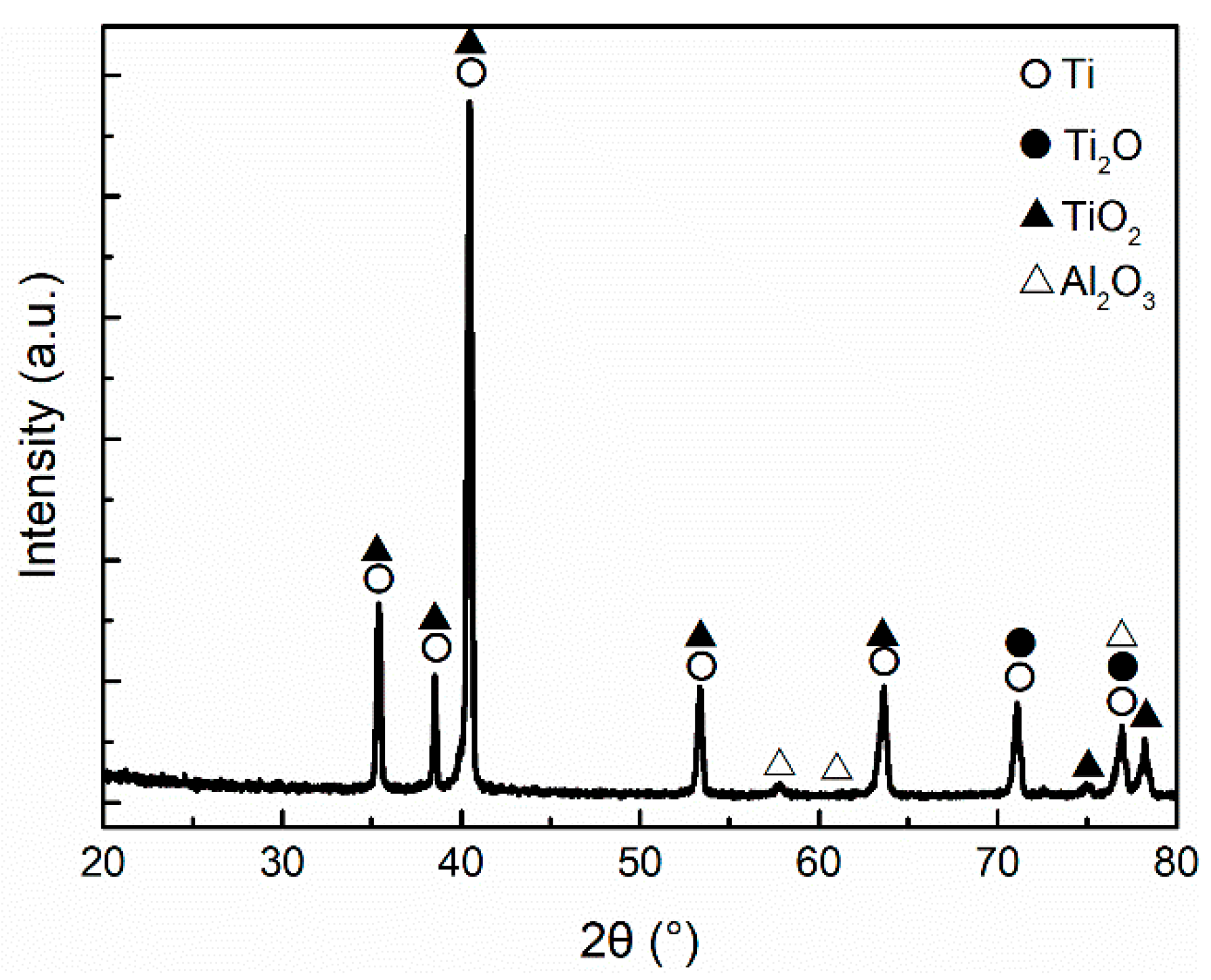

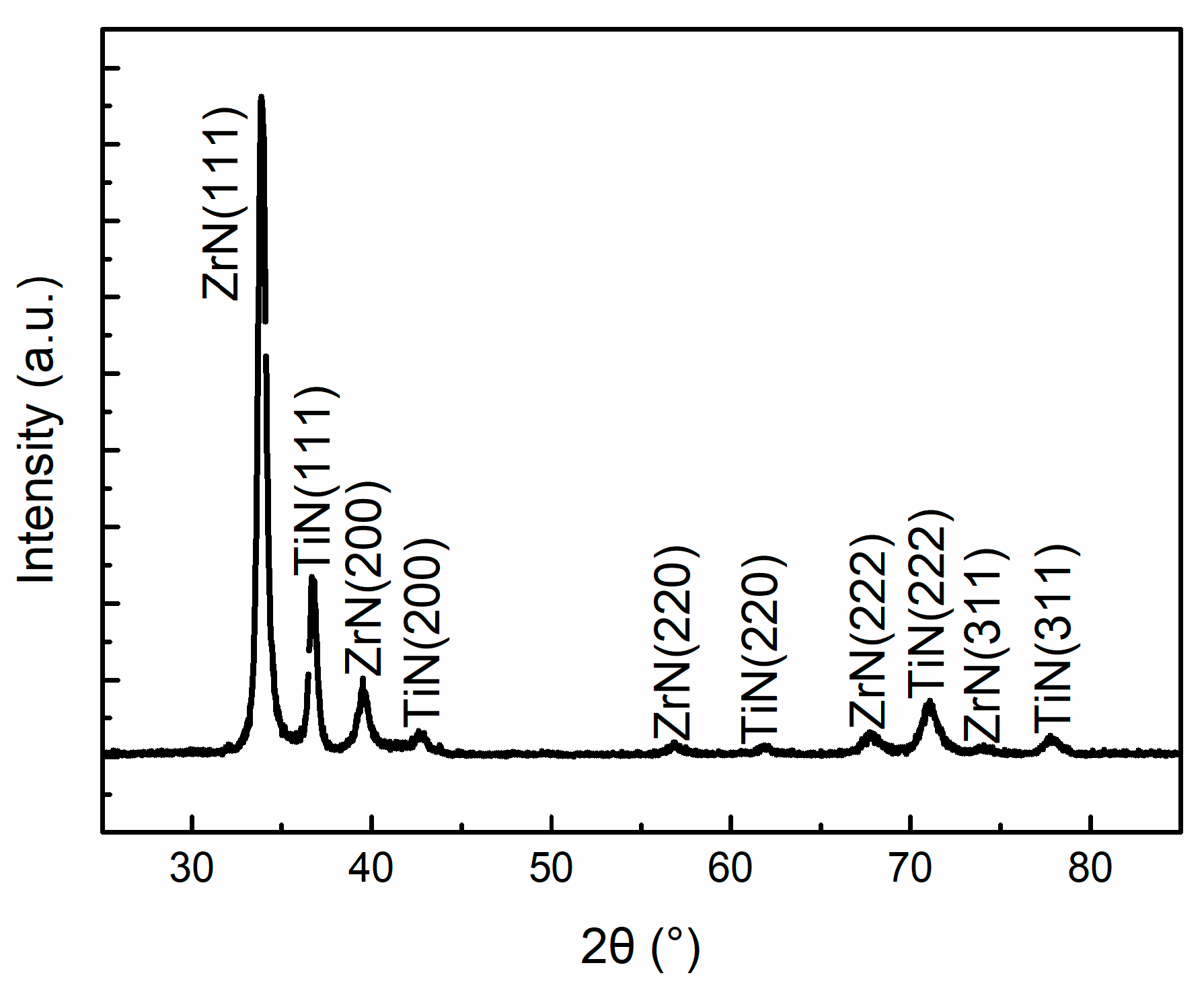

3.1. Coating Characterization

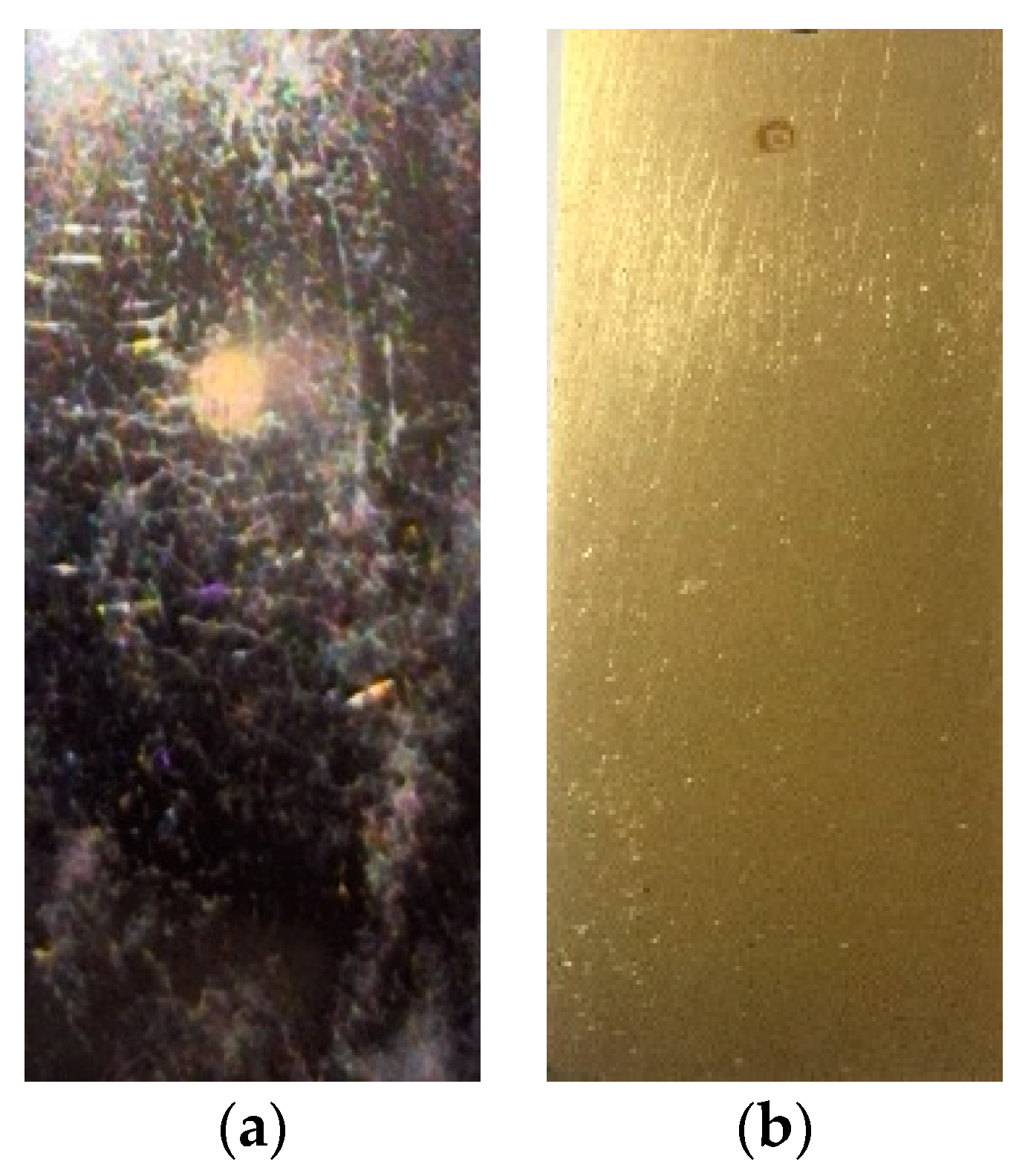

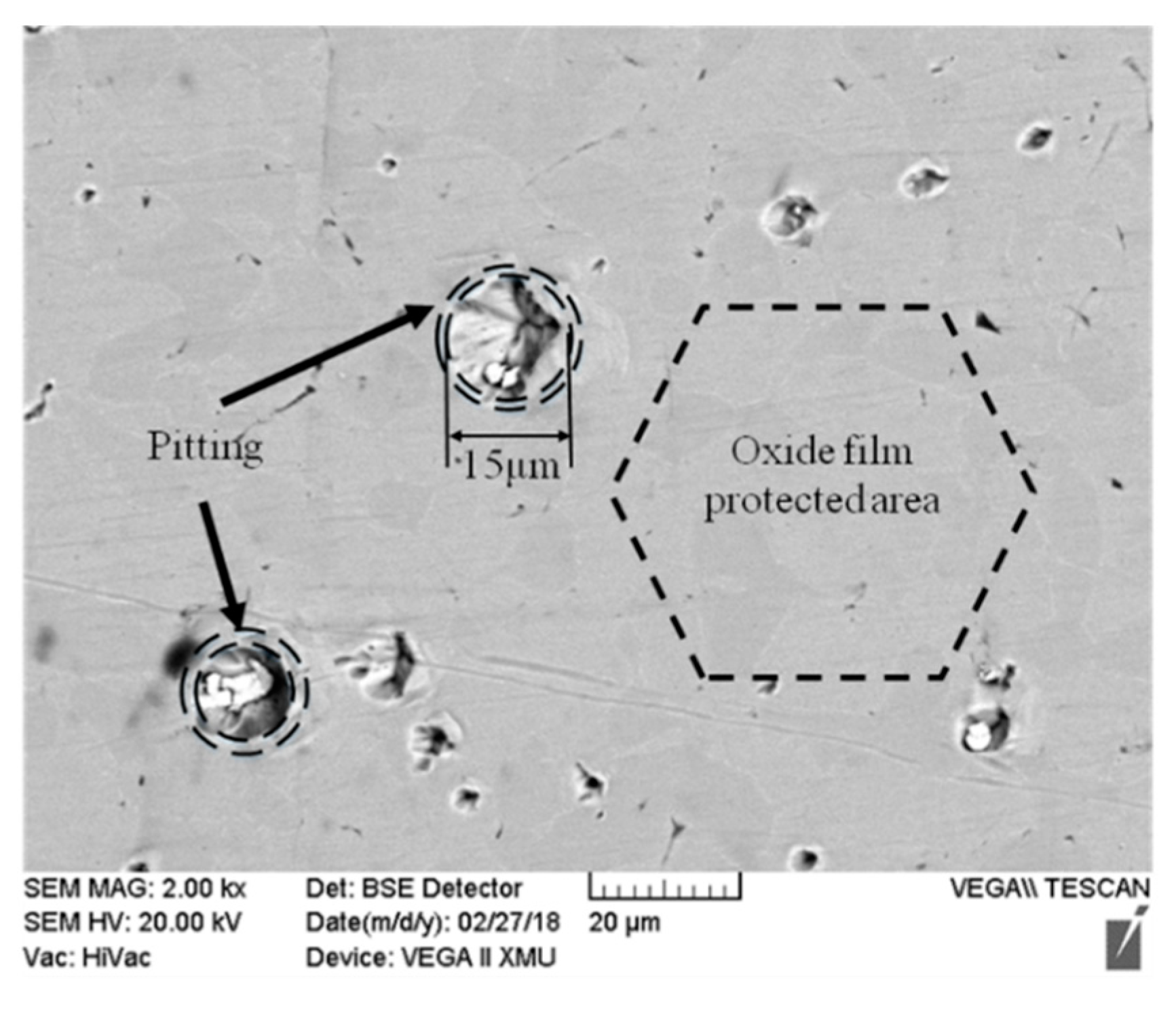

3.2. Salt Spray Corrosion

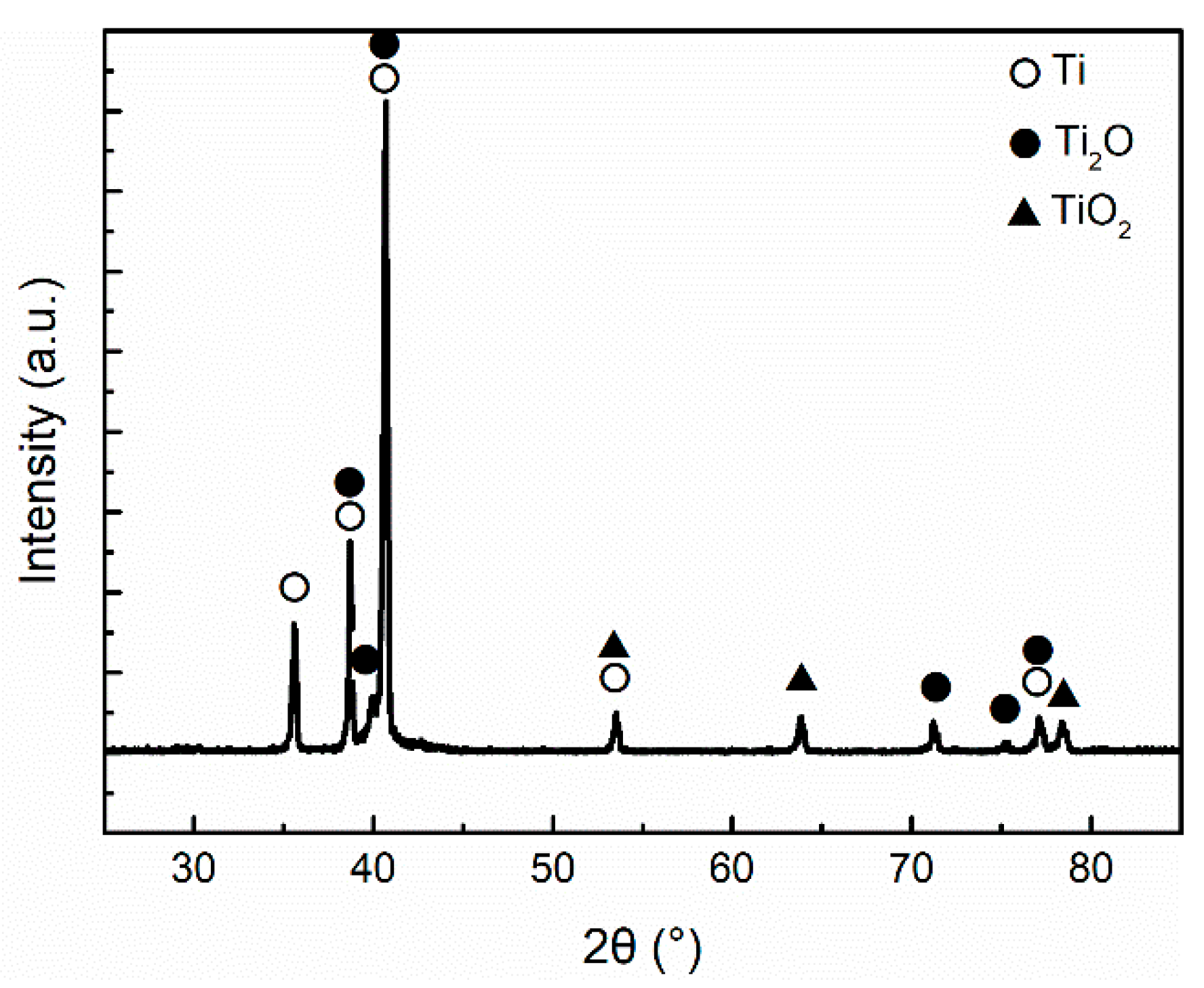

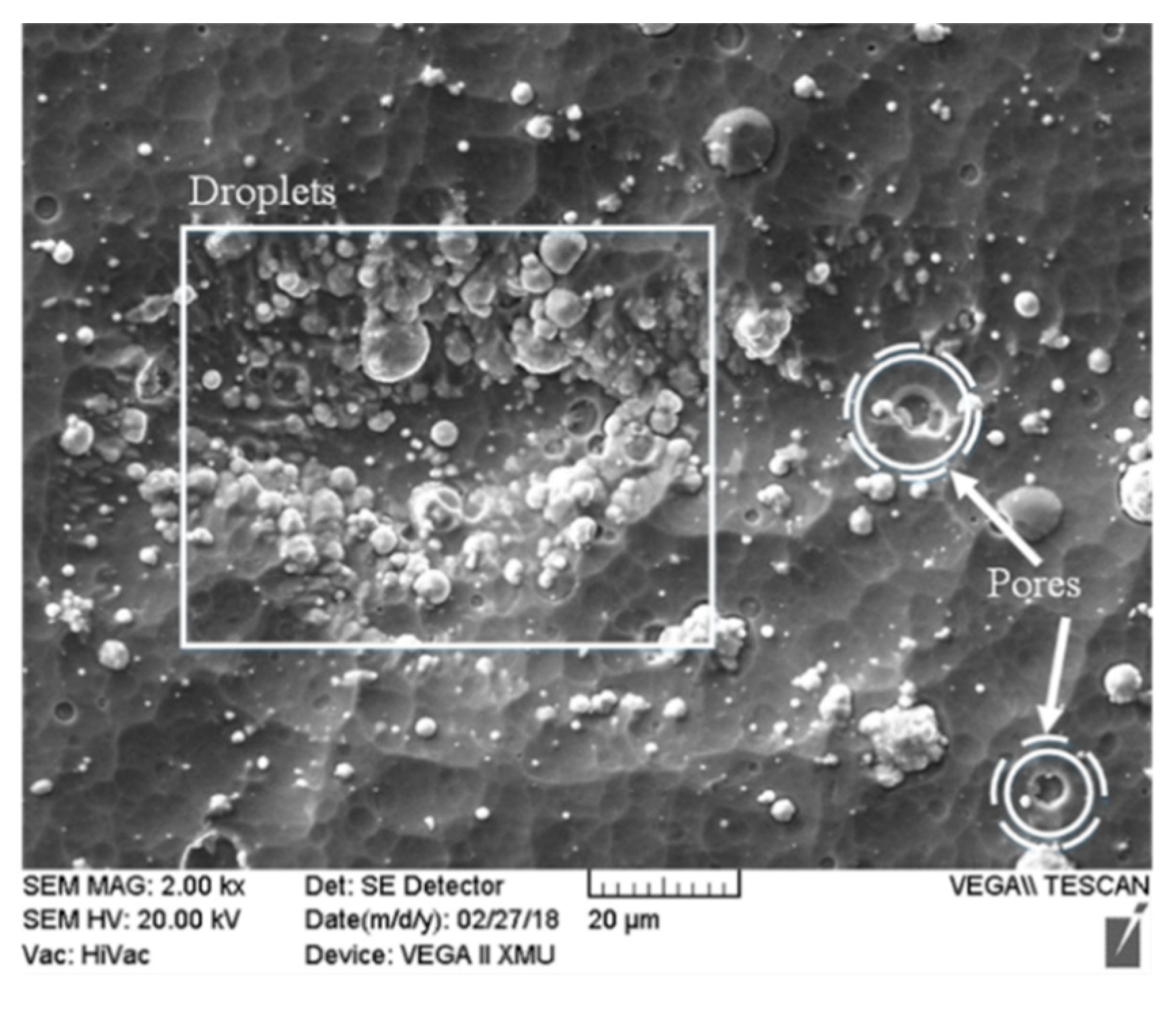

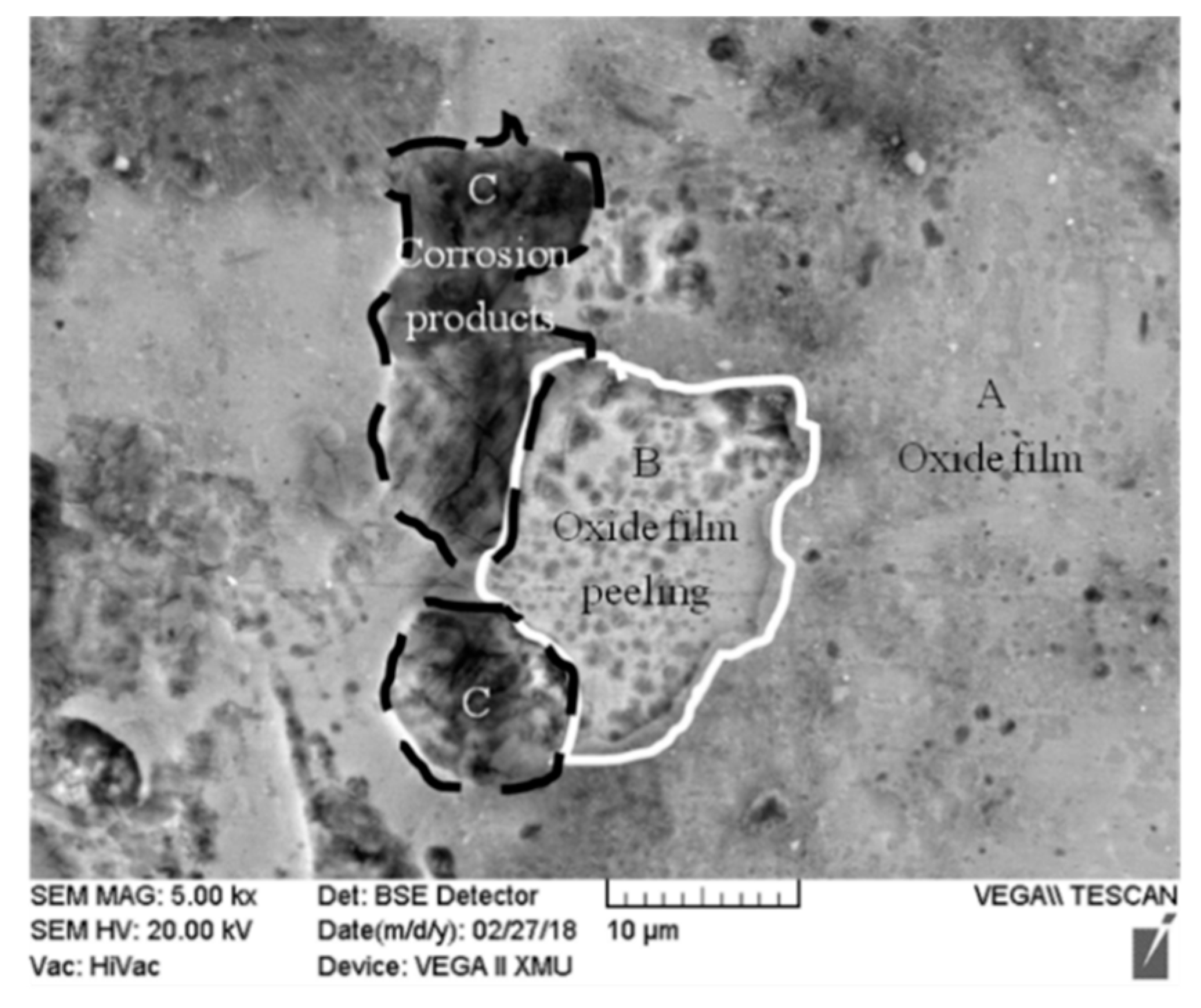

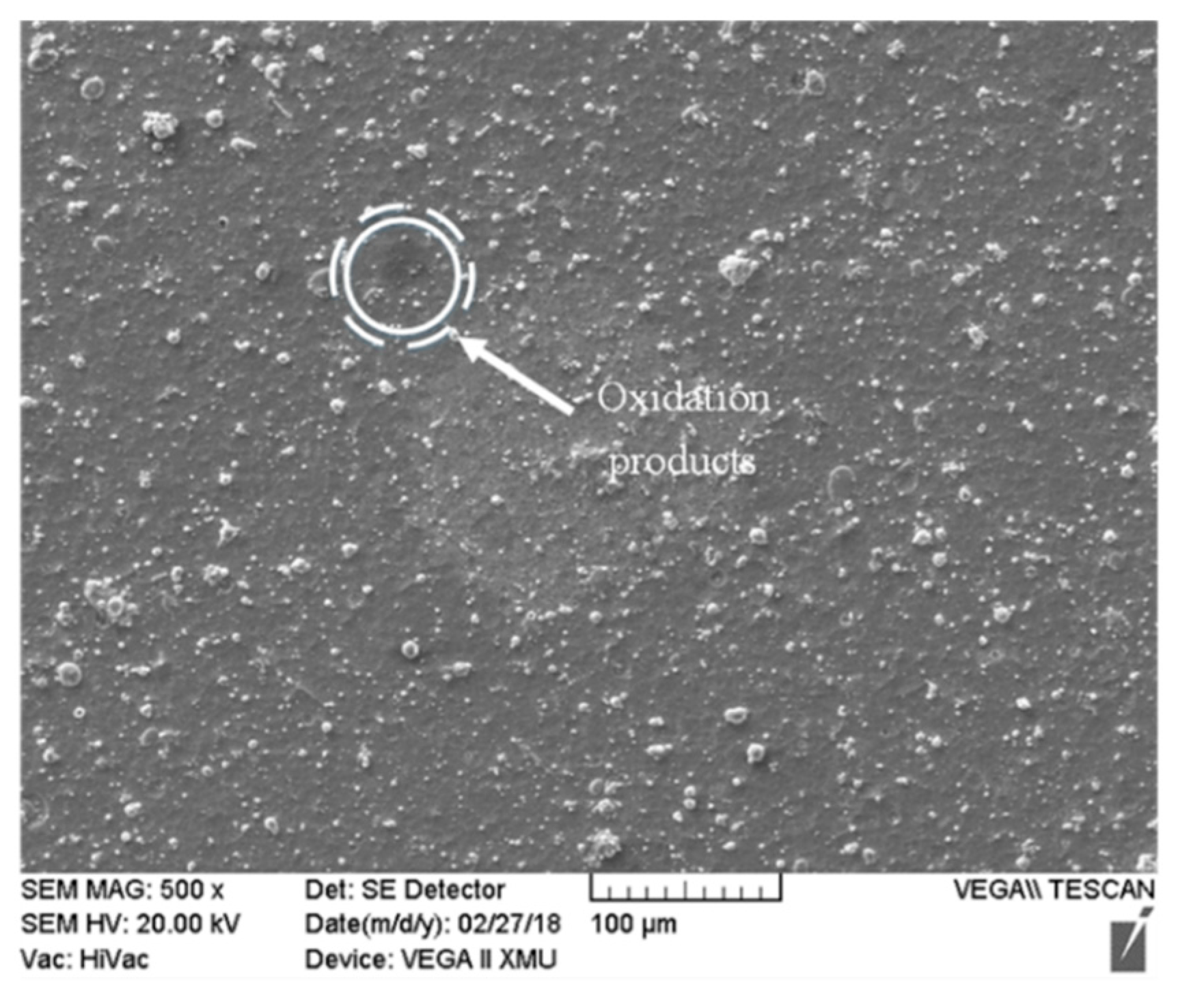

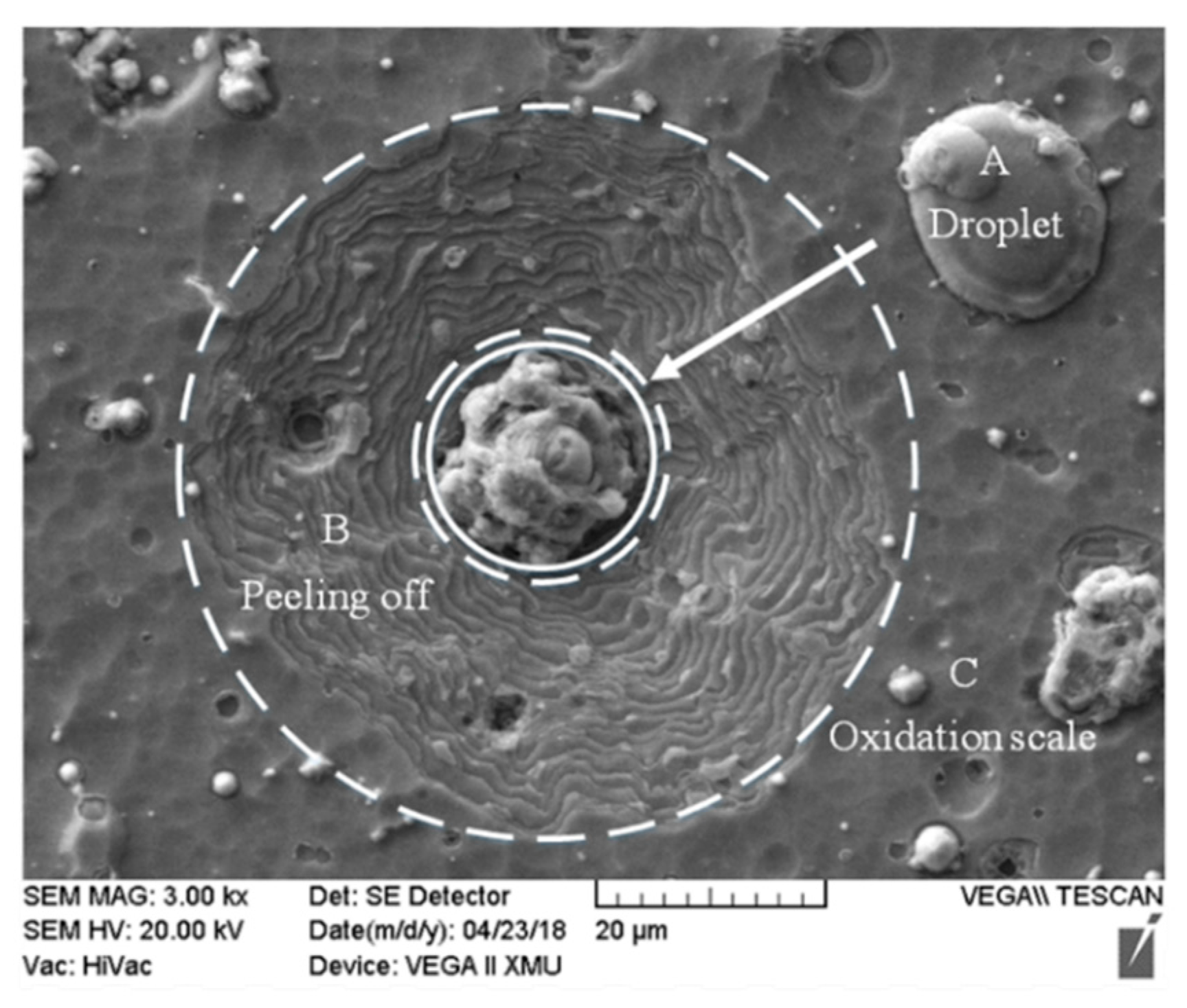

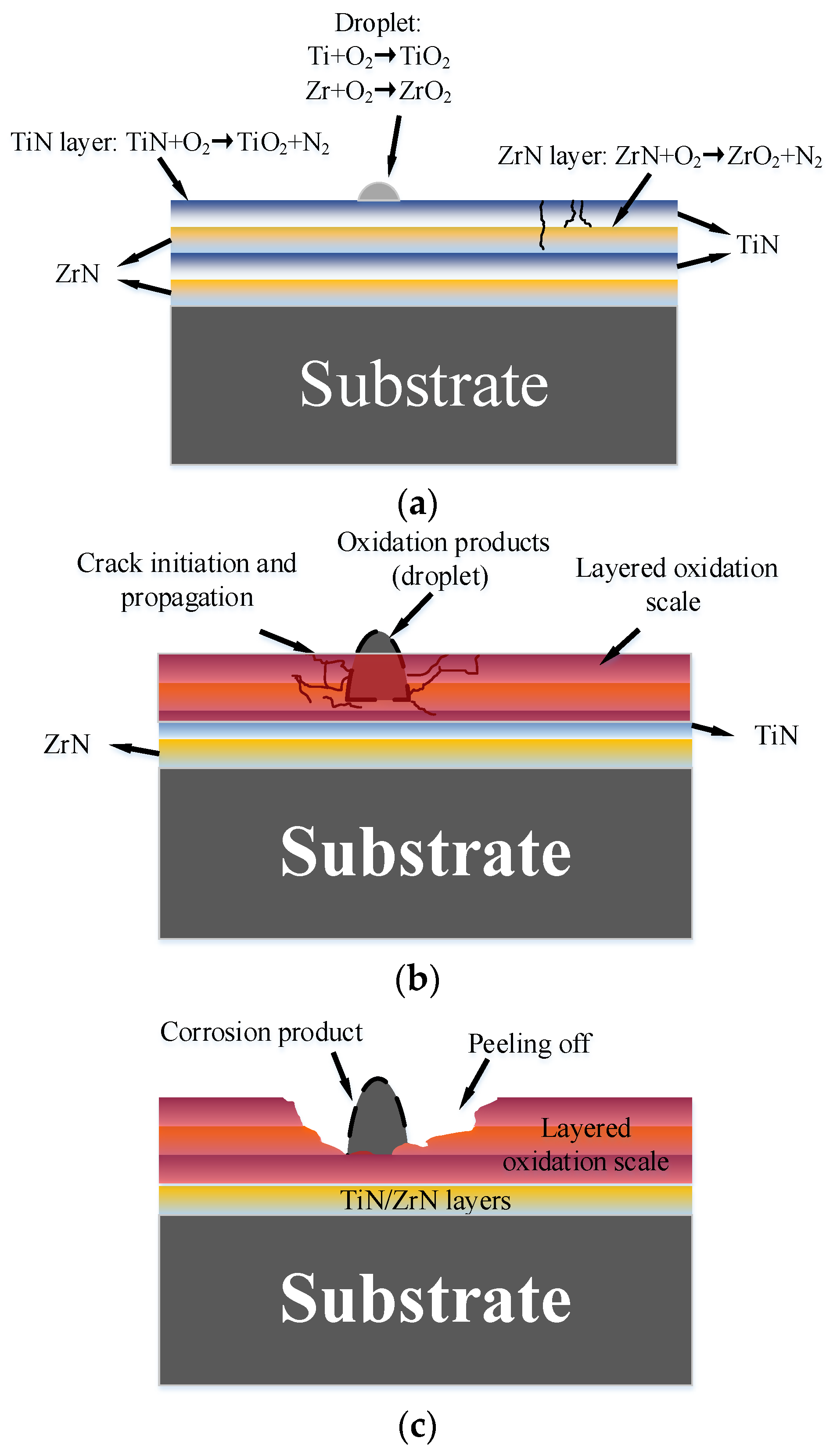

3.3. Low Temperature Hot Corrosion

4. Conclusions

- The coating exhibited good corrosion resistance in aggressive conditions. After 576 h spray salt corrosion test, the composition and appearance of coating were not significantly changed. After 88 h low temperature hot corrosion test, the coating was oxidized and the oxidized layers might protect substrate against the corrosion and oxidation.

- The oxidation and expansion of droplets led to squeezing and peeling of the coating in low temperature hot condition. The low temperature hot corrosion resistance of TiN/ZrN nanolaminate coating could be effectively improved, by improving the quality of the coating and reducing the number of droplets.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, Y.; Xiao, G.; Zhao, H.; Zou, L.; Zhao, L.; Liu, Y.; Dai, W. Residual stress of belt polishing for the micro-stiffener surface on the titanium alloys. Procedia CIRP 2018, 71, 11–15. [Google Scholar] [CrossRef]

- Evstifeev, A.; Kazarinov, N.; Petrov, Y.; Witek, L.; Bednarz, A. Experimental and theoretical analysis of solid particle erosion of a steel compressor blade based on incubation time concept. Eng. Fail. Anal. 2018, 87, 15–21. [Google Scholar] [CrossRef]

- Pedram, O.; Poursaeidi, E. Total life estimation of a compressor blade with corrosion pitting, SCC and fatigue cracking. J. Fail. Anal. Prev. 2018, 4, 423–434. [Google Scholar] [CrossRef]

- Cai, F.; Gao, F.; Pant, S.; Huang, X.; Yang, Q. Solid particle erosion behaviors of carbon-fiber epoxy composite and pure titanium. J. Mater. Eng. Perform. 2016, 25, 290–296. [Google Scholar] [CrossRef]

- Urbahs, A.; Rudzitis, J.; Savkovs, K.; Urbaha, M.; Boiko, I.; Leitans, A.; Lungevics, J. Titanium compound erosion-resistant nano-coatings. Key Eng. Mater. 2016, 674, 283–288. [Google Scholar] [CrossRef]

- Mednikov, A.F.; Kachalin, G.V.; Ryzhenkov, A.V.; Tkhabisimov, A.B. An investigation of ion-plasma coatings solid particle erosion resistance at high-speed impact of gas-abrasive flow. In Proceedings of the 2nd International Conference on High Performance and Optimum Design of Structures and Materials (HPSM 2016), Siena, Italy, 19–21 September 2016; pp. 487–497. [Google Scholar] [CrossRef]

- Bondar, O. Dependence of mechanical and tribotechnical properties of multilayered TiN/ZrN coatings on deposition. Przegląd Elektrotechniczny 2015, 1, 233–236. [Google Scholar] [CrossRef]

- Muboyadzhyan, S.A.; Aleksandrov, D.A.; Gorlov, D.S. Ion-plasma erosion-resistant nanocoatings based on metal carbides and nitrides. Rus. Metall. 2010, 9, 790–799. [Google Scholar] [CrossRef]

- Chou, W.J.; Yu, G.P.; Huang, J.H. Corrosion behavior of TiN-coated 304 stainless steel. Corros. Sci. 2001, 43, 2023–2035. [Google Scholar] [CrossRef]

- Chen, B.F.; Pan, W.L.; Yu, G.P.; Hwang, J.; Huang, J.H. On the corrosion behavior of TiN-coated AISI D2 steel. Surf. Coat. Technol. 1999, 111, 16–21. [Google Scholar] [CrossRef]

- Brown, R.; Alias, M.N.; Fontana, R. Effect of composition and thickness on corrosion behavior of TiN and ZrN thin films. Surf. Coat. Technol. 1993, 62, 467–473. [Google Scholar] [CrossRef]

- Gurrappa, I. Characterization of titanium alloy Ti-6Al-4V for chemical, marine and industrial applications. Mater. Charact. 2003, 51, 131–139. [Google Scholar] [CrossRef]

- Vega, J.; Scheerer, H.; Andersohn, G.; Oechsner, M. Experimental studies of the effect of Ti interlayers on the corrosion resistance of TiN PVD coatings by using electrochemical methods. Corros. Sci. 2018, 133, 240–250. [Google Scholar] [CrossRef]

- Ghasemia, S.; Shanaghia, A.; Chub, P.K. Corrosion behavior of reactive sputtered Ti/TiN nanostructured coating and effects of intermediate titanium layer on self-healing properties. Surf. Coat. Technol. 2017, 326, 156–164. [Google Scholar] [CrossRef]

- Huang, J.H.; Tsai, Z.E.; Yu, G.P. Mechanical properties and corrosion resistance of nanocrystalline ZrNxOy coatings on AISI 304 stainless steel by ion plating. Surf. Coat. Technol. 2008, 202, 4992–5000. [Google Scholar] [CrossRef]

- Lei, Z.; Zhang, Q.; Zhu, X.; Ma, D.; Ma, F.; Song, Z.; Fu, Y. Corrosion performance of ZrN/ZrO2, multilayer coatings deposited on 304 stainless steel using multi-arc ion plating. Appl. Surf. Sci. 2017, 431, 170–176. [Google Scholar] [CrossRef]

- Dobrzański, L.A.; Lukaszkowicz, K.; Zarychta, A.; Cunha, L. Corrosion resistance of multilayer coatings deposited by PVD techniques onto the brass substrate. J. Mater. Process. Technol. 2006, 15, 816–821. [Google Scholar] [CrossRef]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium alloys for aerospace applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Wagner, C. Theoretical analysis of the diffusion processes determining the oxidation rate of alloys. J. Electrochem. Soc. 1952, 99, 369–380. [Google Scholar] [CrossRef]

- Wagner, C. Oxidation of alloys involving noble metals. J. Electrochem. Soc. 1956, 103, 571–580. [Google Scholar] [CrossRef]

- Milošev, I.; Strehblow, H.H.; Navinšek, B. XPS in the study of high-temperature oxidation of CrN and TiN hard coatings. Surf. Coat. Technol. 1995, 74, 897–902. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Ivasishin, O.M.; Beresnev, V.M. Arc-evaporated nanoscale multilayer nitride-based coatings for protection against wear, corrosion, and oxidation. Usp. Fiz. Met. 2016, 17, 1–28. [Google Scholar] [CrossRef]

- Muneshwar, T.; Cadien, K. Comparing XPS on bare and capped ZrN films grown by plasma enhanced ALD: Effect of ambient oxidation. Appl. Surf. Sci. 2018, 435, 367–376. [Google Scholar] [CrossRef]

- Qi, Z.B.; Wu, Z.T.; Liang, H.F.; Zhang, D.F.; Wang, J.H.; Wang, Z.C. In situ and ex situ studies of microstructure evolution during high-temperature oxidation of ZrN hard coating. Scr. Mater. 2015, 97, 9–12. [Google Scholar] [CrossRef]

- Soriano, L.; Abbate, M.; Fuggle, J.C.; Prieto, P.; Jiménez, C.; Sanz, J.M.; Galán, L. Thermal oxidation of TiN studied by means of soft X-ray absorption spectroscopy. J. Vac. Sci. Technol. A 1993, 11, 47–51. [Google Scholar] [CrossRef]

- Xu, X.M.; Wang, J.; Zhang, Q.Y. Oxidation behavior of TiN/ZrN multilayers annealed in air. Thin Solid Films 2008, 516, 1025–1028. [Google Scholar] [CrossRef]

- Pogrebnjak, A.; Ivashchenko, V.; Bondar, O.; Beresnev, V.; Sobol, O.; Załęski, K.; Jurga, E.; Coy, E.; Konarski, P.; Postolnyi, B. Multilayered vacuum-arc nanocomposite TiN/ZrN coatings before and after annealing: Structure, properties, first-principles calculations. Mater. Charact. 2017, 134, 55–63. [Google Scholar] [CrossRef]

| Fe | V | Al | C | O | N | H | Ti |

|---|---|---|---|---|---|---|---|

| 0.10 | 4.00 | 5.70 | 0.02 | 0.05 | <0.01 | <0.001 | Bal. |

| N2 Pressure (Pa) | Bias Voltage (V) | Arc Current (A) | Coating Thickness | Layer |

|---|---|---|---|---|

| 1.0 | −100 | 100 | 10 μm | 100 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, M.; He, G.; Sun, Z.; Chen, J.; Yang, Z.; Li, Y. Corrosion Damage Mechanism of TiN/ZrN Nanoscale Multilayer Anti-Erosion Coating. Coatings 2018, 8, 400. https://doi.org/10.3390/coatings8110400

Geng M, He G, Sun Z, Chen J, Yang Z, Li Y. Corrosion Damage Mechanism of TiN/ZrN Nanoscale Multilayer Anti-Erosion Coating. Coatings. 2018; 8(11):400. https://doi.org/10.3390/coatings8110400

Chicago/Turabian StyleGeng, Mingrui, Guangyu He, Zhiping Sun, Jiao Chen, Zhufang Yang, and Yuqin Li. 2018. "Corrosion Damage Mechanism of TiN/ZrN Nanoscale Multilayer Anti-Erosion Coating" Coatings 8, no. 11: 400. https://doi.org/10.3390/coatings8110400

APA StyleGeng, M., He, G., Sun, Z., Chen, J., Yang, Z., & Li, Y. (2018). Corrosion Damage Mechanism of TiN/ZrN Nanoscale Multilayer Anti-Erosion Coating. Coatings, 8(11), 400. https://doi.org/10.3390/coatings8110400