Spin Coating on Spherical Surface with Large Central Angles

Abstract

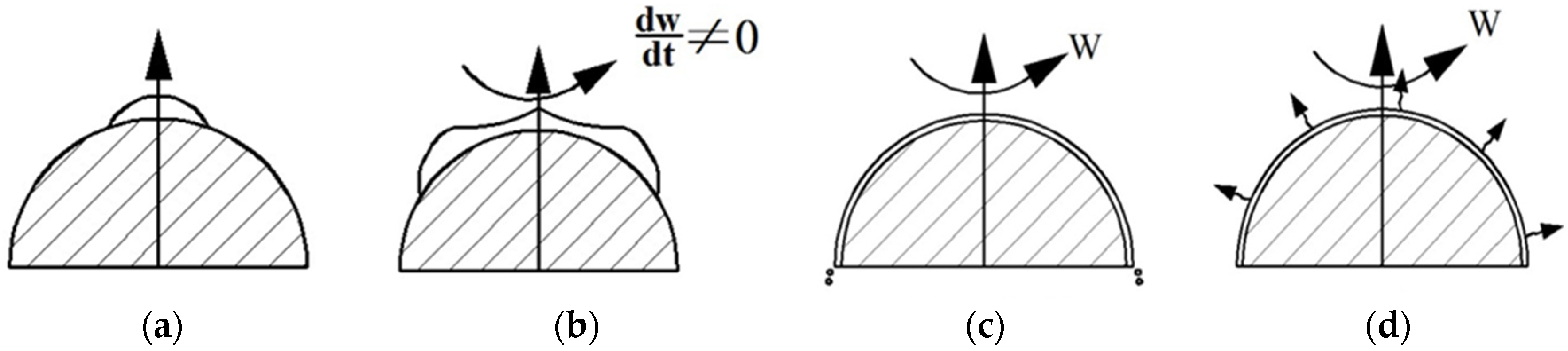

:1. Introduction

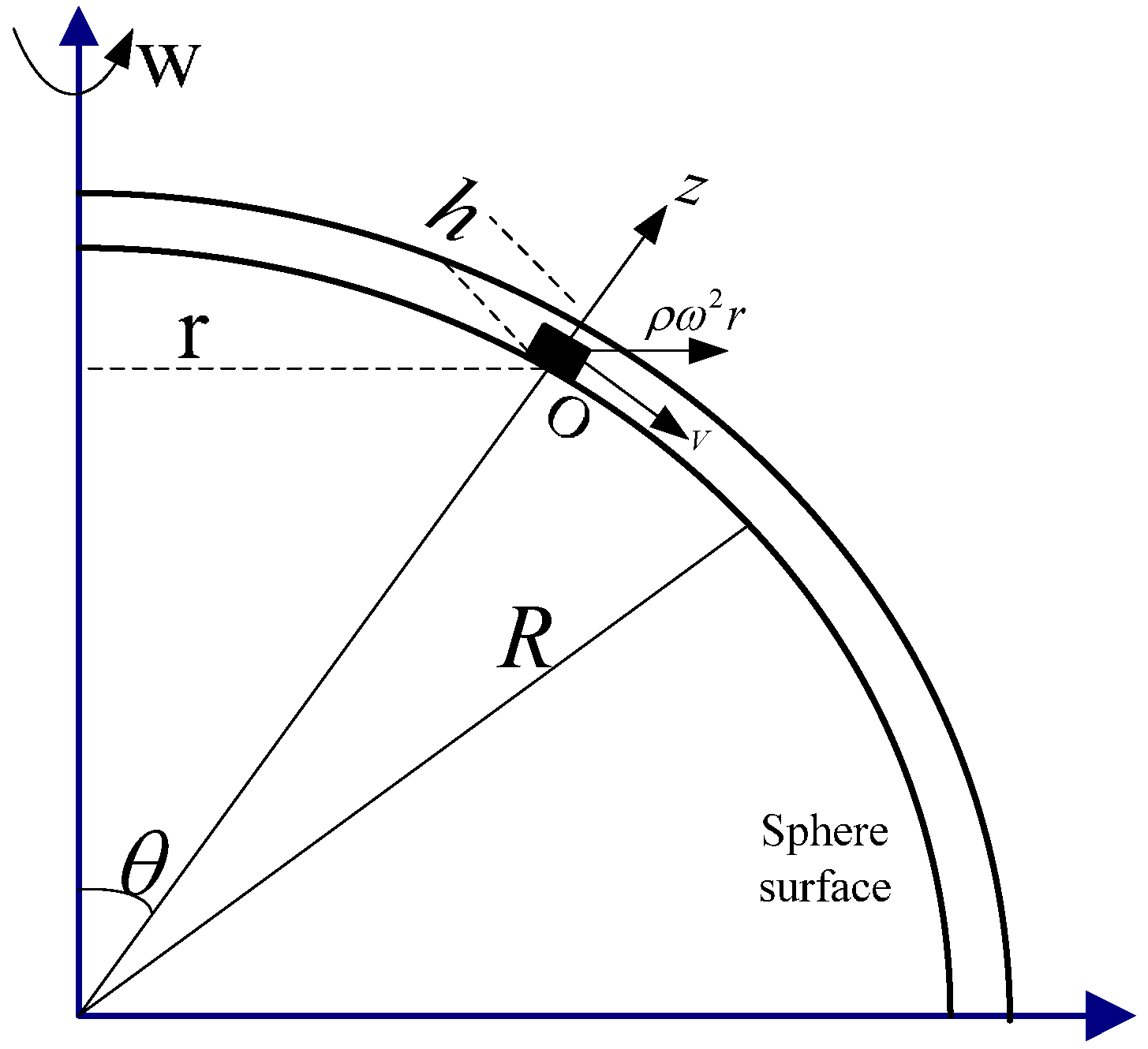

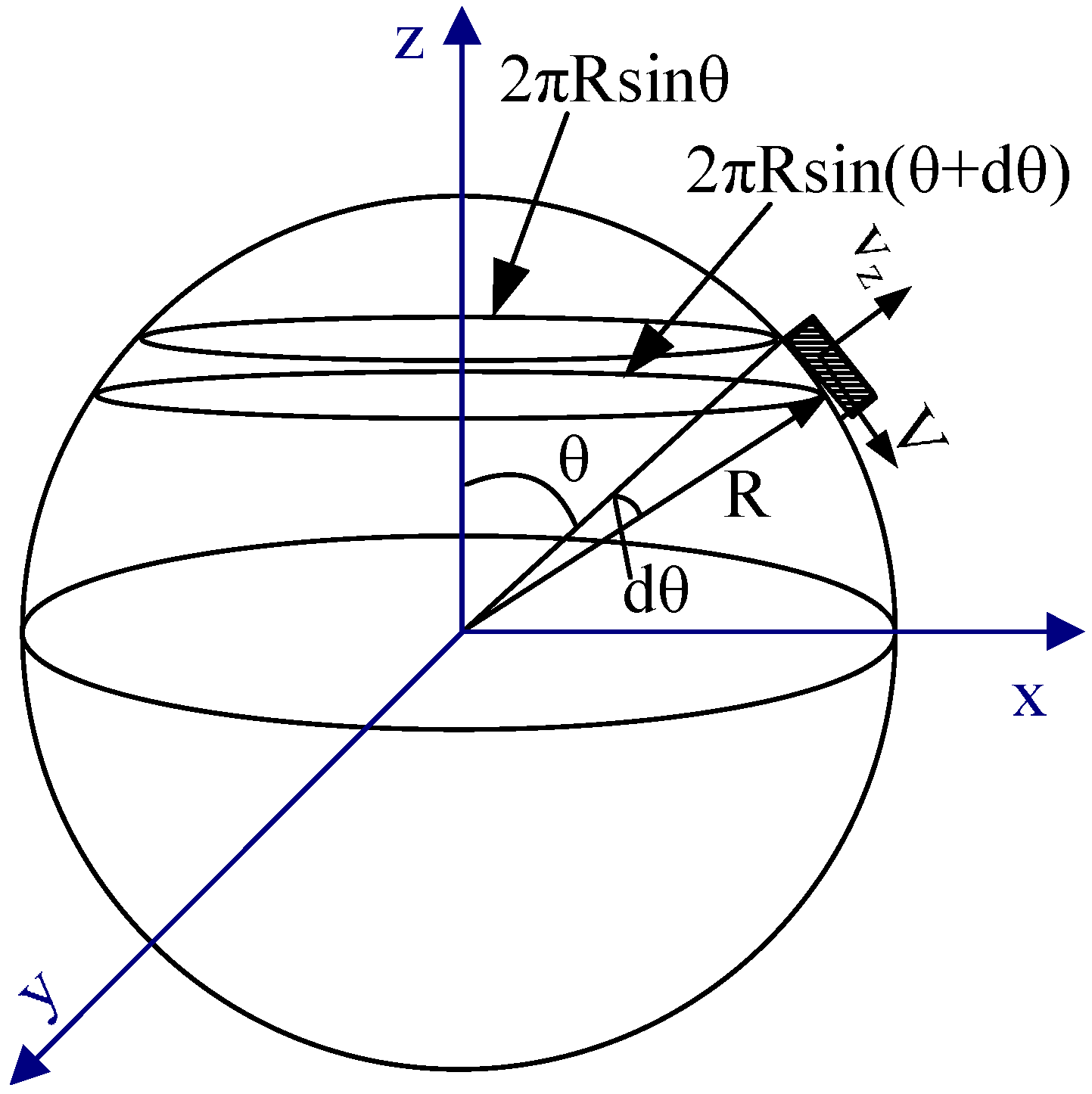

2. Mathematical Model

- (1)

- The liquid is incompressible and homogenous, which means the density of fluid ρ is constant in the process;

- (2)

- The liquid is a Newtonian fluid;

- (3)

- Lubrication approximation is adopted;

- (4)

- Evaporation is negligible;

- (5)

- Gravitational force and Coriolis force are not considered.

3. Results and Discussion

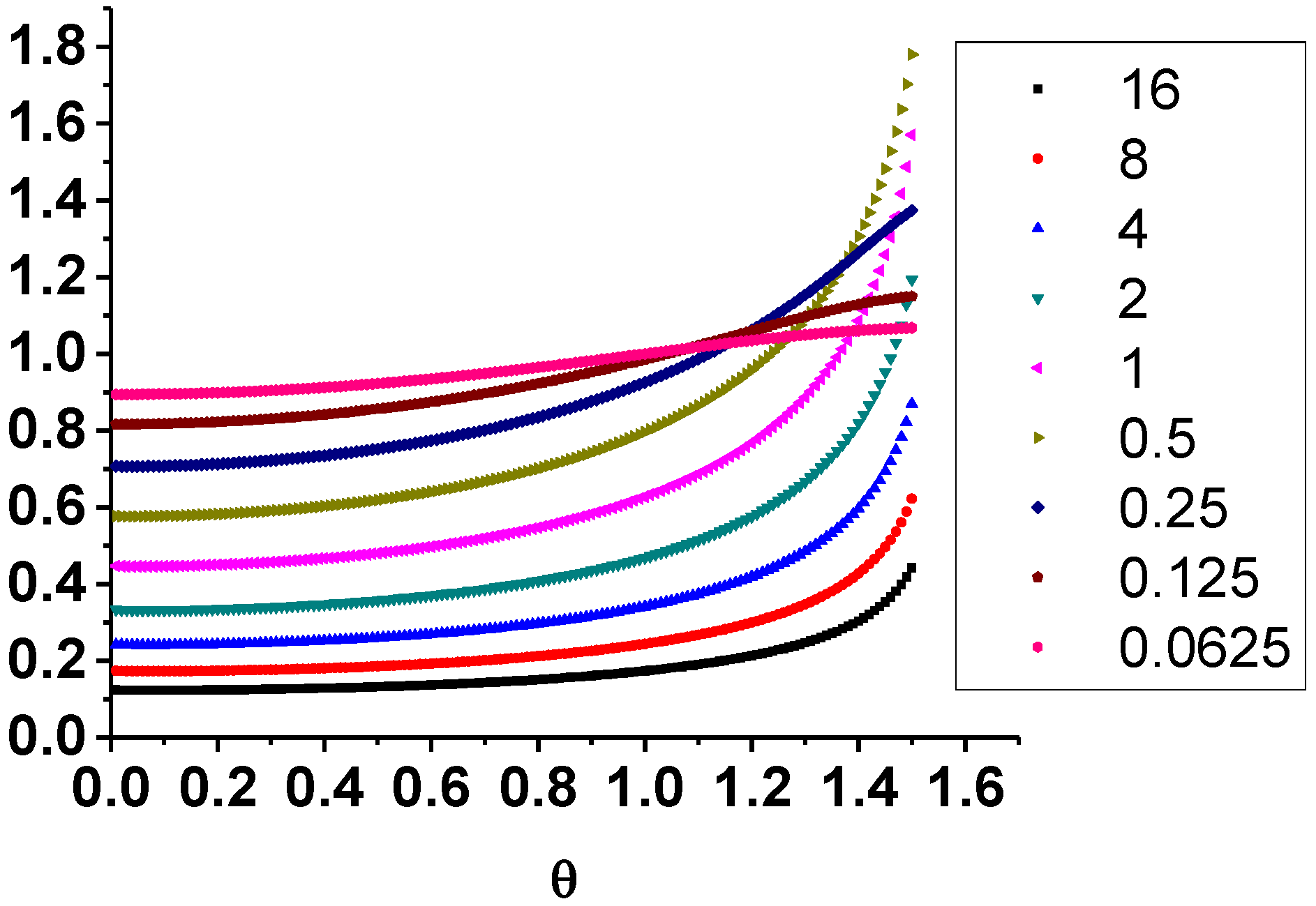

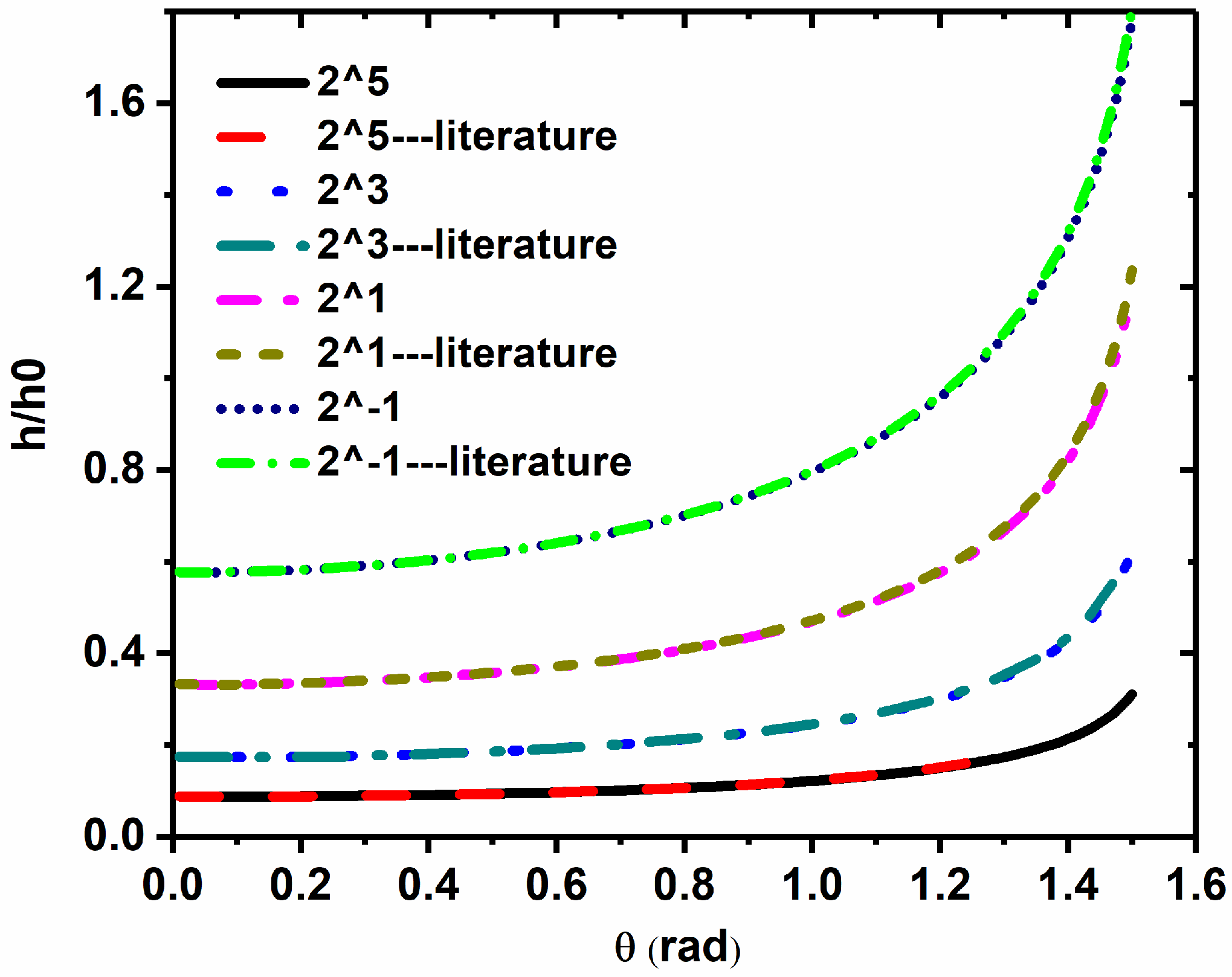

3.1. Numerical Simulation

3.1.1. Uniform Initial Film

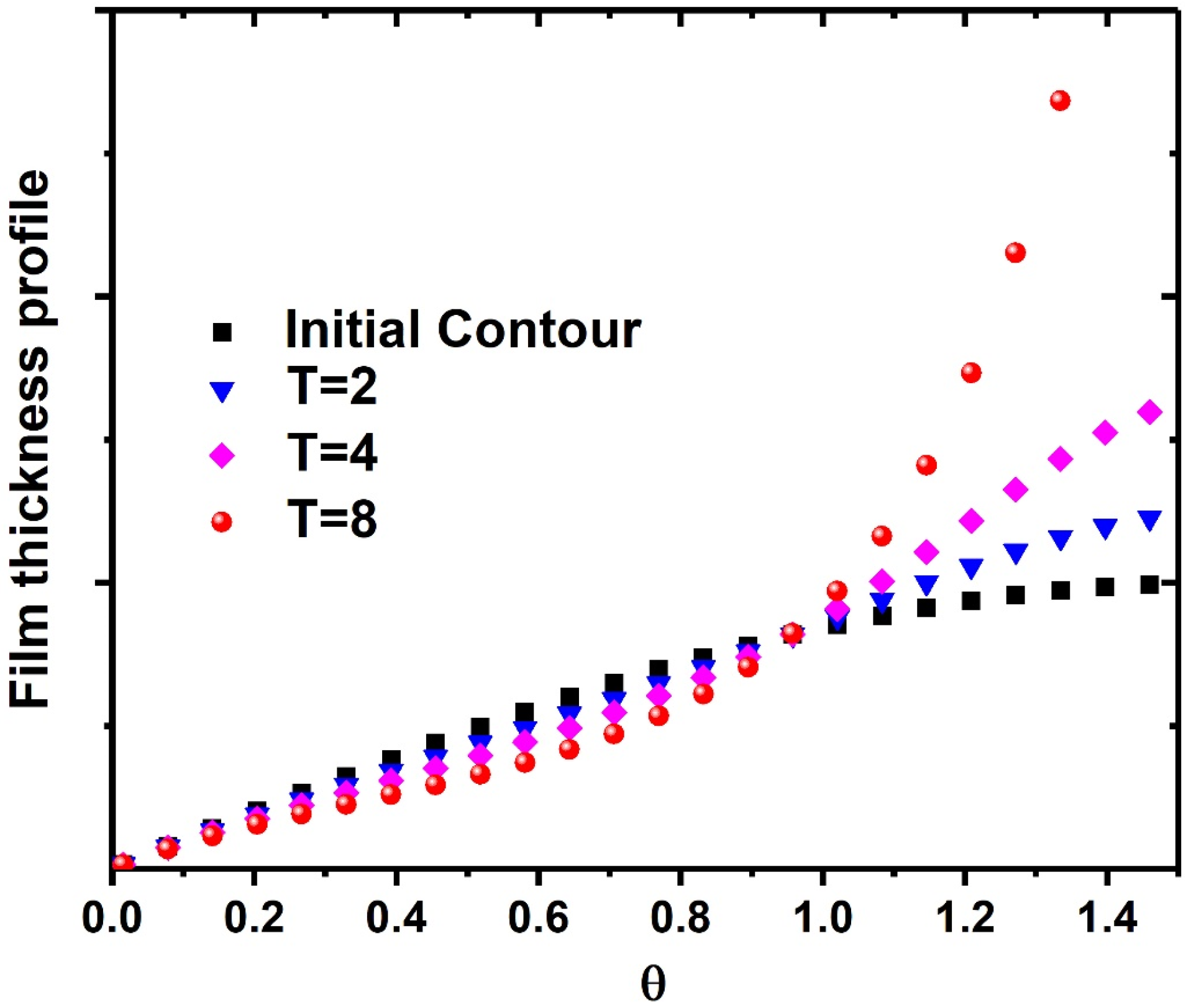

3.1.2. Non-Uniform Initial Film

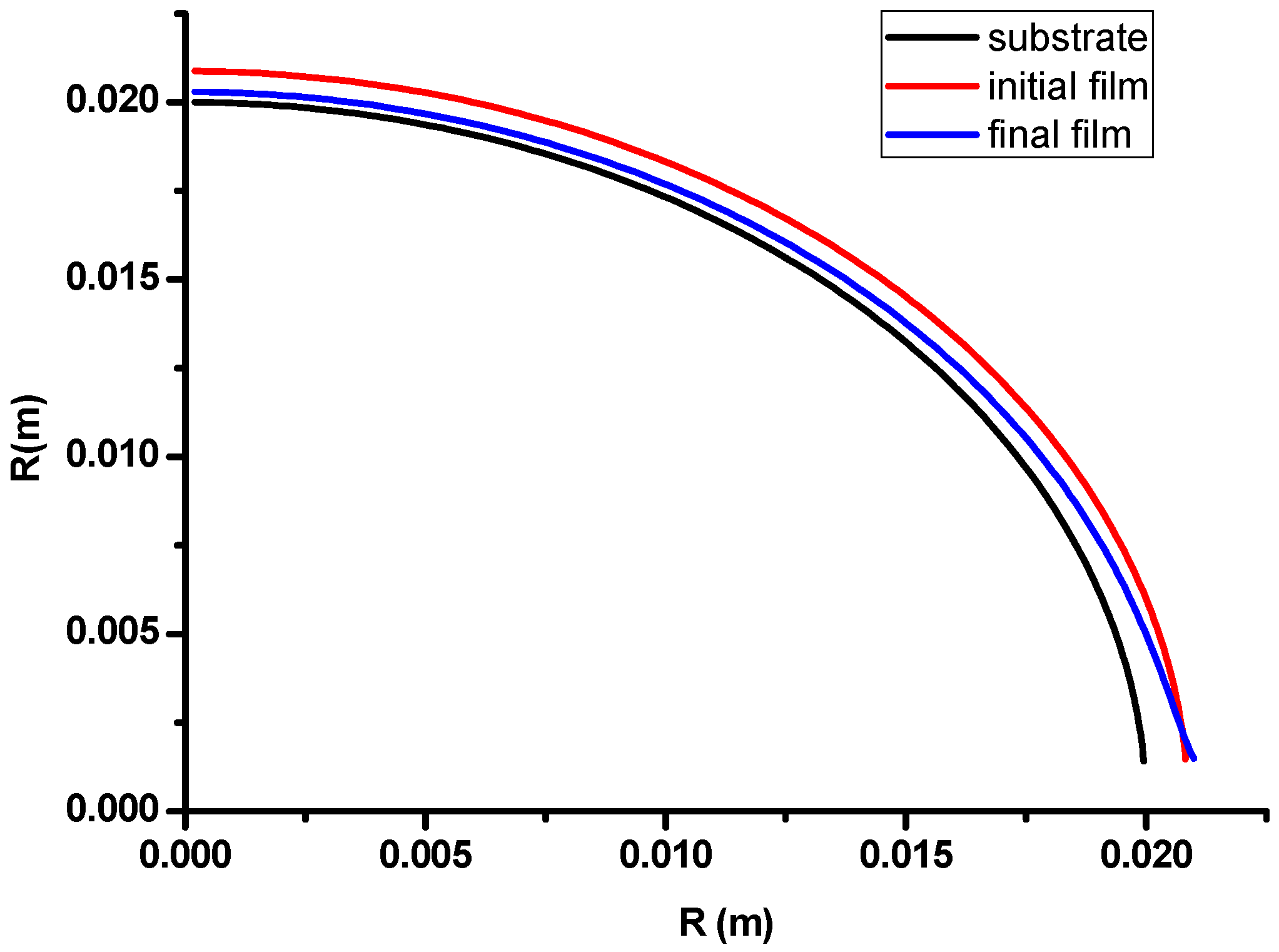

3.2. Experimental Validation

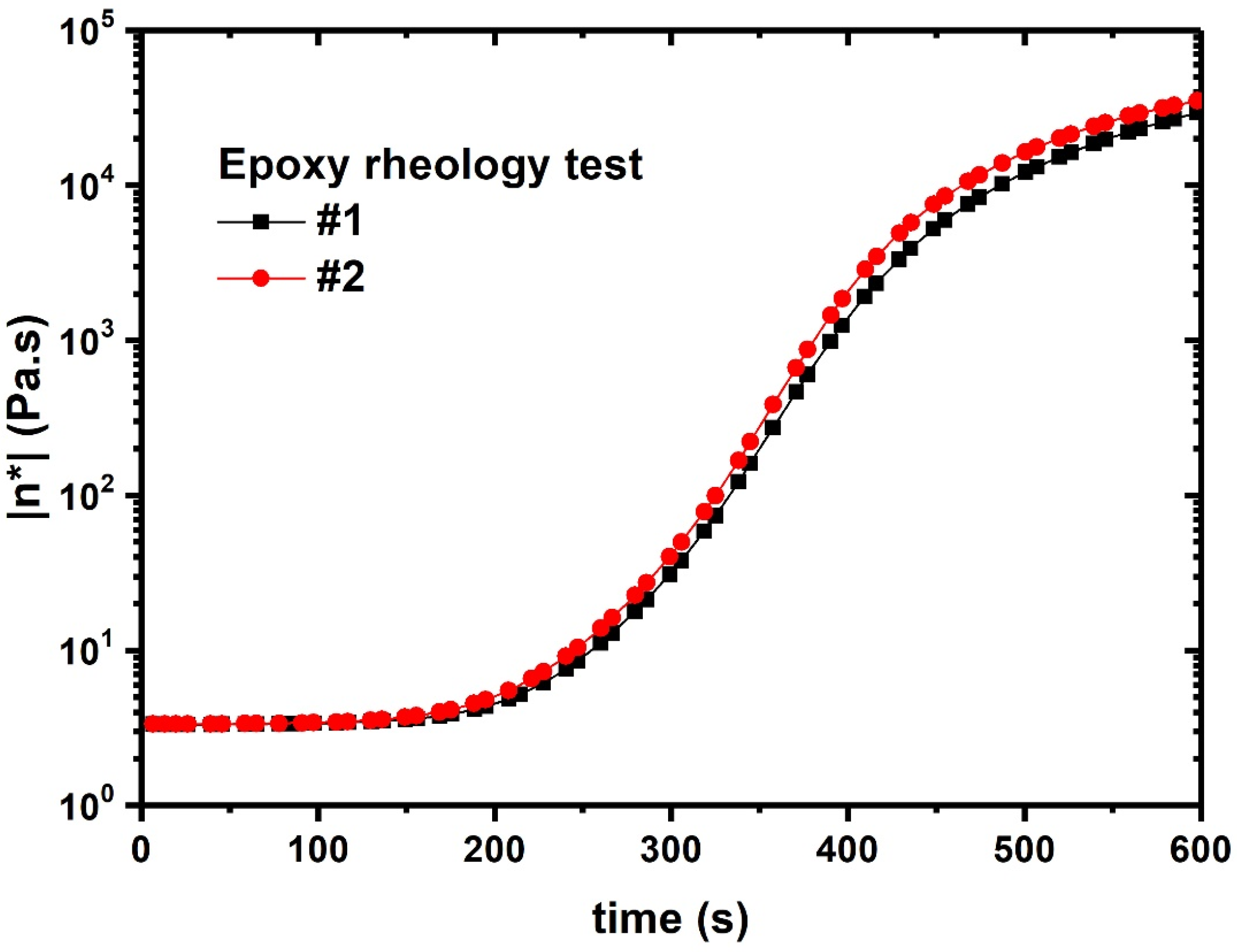

3.2.1. Materials

3.2.2. Measurement

3.2.3. Experimental Setup

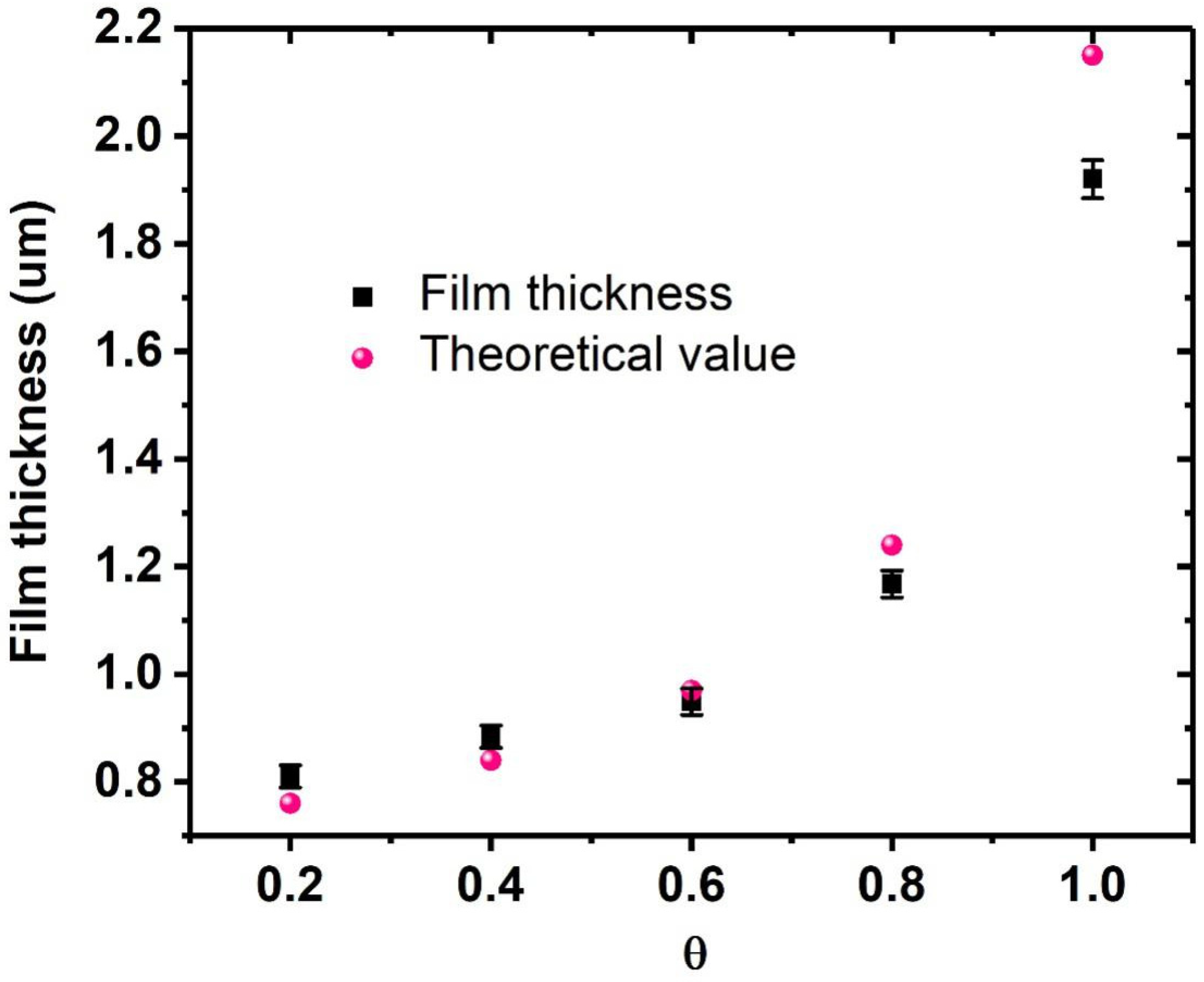

3.2.4. Experimental Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Emslie, A.G.; Bonner, F.T.; Peck, L.G. Flow of a viscous liquid on a rotating disk. J. Appl. Phys. 1958, 29, 858–862. [Google Scholar] [CrossRef]

- Acrivos, A.; Shah, M.J.; Petersen, E.E. On the flow of a non-Newtonian liquid on a rotating disk. J. Appl. Phys. 1960, 31, 963–968. [Google Scholar] [CrossRef]

- Jenekhe, S.A.; Schuldt, S.B. Flow and film thickness of bingham plastic liquids on a rotating disk. Chem. Eng. Commun. 1985, 33, 135–147. [Google Scholar] [CrossRef]

- Meyerhofer, D. Characteristics of resist film produced by spinning. J. Appl. Phys. 1978, 49, 3993–3997. [Google Scholar] [CrossRef]

- Hall, D.B.; Underhill, P.; Torkelson, J.M. Spin coating of thin and ultrathin polymer films. Polym. Eng. Sci. 1998, 38, 2039–2045. [Google Scholar] [CrossRef]

- Mitzi, D.B.; Kosbar, L.L.; Murray, C.E.; Copel, M.; Afzali, A. High-mobility ultrathin semiconducting films prepared by spin coating. Nature 2004, 428, 299–303. [Google Scholar] [CrossRef] [PubMed]

- Lawrence, C. The mechanics of spin coating of polymer films. Phys. Fluids 1988, 31, 2786–2795. [Google Scholar] [CrossRef]

- Bornside, D.E.; Macosko, C.W.; Scriven, L.E. Spin coating: One-dimensional model. J. Appl. Phys. 1989, 66, 5185–5193. [Google Scholar] [CrossRef]

- Bornside, D.E.; Macosko, C.W.; Scriven, L.E. On the modeling of spin coating. J. Imaging Technol. 1987, 13, 122–130. [Google Scholar]

- Bornside, D.E. Mechanism for the local planarization of microscopically rough surfaces by drying thin films of spin-coated polymer/solvent solutions. J. Electrochem. Soc. 1990, 137, 2589–2595. [Google Scholar] [CrossRef]

- Gupta, V.K.; Abbott, N.L. Design of surfaces for patterned alignment of liquid crystals on planar and curved substrates. Science 1997, 276, 1533–1536. [Google Scholar] [CrossRef]

- Brytsche, H.H.; Farley, E.D.; White, S.S. Method for Spin Coating a Multifocal Lens. U.S. Patent 5,753,301, 19 March 1998. [Google Scholar]

- Blackburn, W.P.; Bowles, R.J., III; Levesque, M.B.; Maldonado, E. Spin and Spray Coating Process for Curved Surfaces. U.S. Patent 6,352,747, 5 March 2002. [Google Scholar]

- Brassard, J.-D.; Sarkar, D.K.; Perron, J. Fluorine based superhydrophobic coatings. Appl. Sci. 2012, 2, 453–464. [Google Scholar] [CrossRef]

- Chen, L.J.; Liang, Y.-Y.; Wang, K.W.; Luo, J.-B.; Zhang, C.-H.; Liang, J.-Y.; Yang, G.G. Research on the optical field distribution and micro-fabrication model in convex-surface laser lithography. Opt. Commun. 2010, 283, 2631–2639. [Google Scholar] [CrossRef]

- Xie, Y.; Lu, Z.; Li, F.; Zhao, J.; Weng, Z. Lithographic fabrication of large diffractive optical elements on a concave lens surface. Opt. Express 2002, 10, 1043–1047. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Lu, Z.; Li, F. Fabrication of large diffractive optical elements in thick film on a concave lens surface. Opt. Express 2003, 11, 992–995. [Google Scholar] [CrossRef] [PubMed]

- Lenz, M.; Mazzon, C.; Dillmann, C.; Gerhardt, N.C.; Welp, H.; Prange, M.; Hofmann, M.R. Spectral domain optical coherence tomography for non-destructive testing of protection coatings on metal substrates. Appl. Sci. 2017, 7, 364. [Google Scholar] [CrossRef]

- Chen, L.; Liang, Y.-Y.; Luo, J.-B.; Zhang, C.-H.; Yang, G.G. Mathematical modeling and experimental study on photoresist whirl-coating in convex-surface laser lithography. J. Opt. A Pure Appl. Opt. 2009, 11, 105408. [Google Scholar] [CrossRef]

- Feng, X.G.; Sun, L.C. Mathematical model of spin-coated photoresist on a spherical substrate. Opt. Express 2005, 13, 7070–7075. [Google Scholar] [CrossRef] [PubMed]

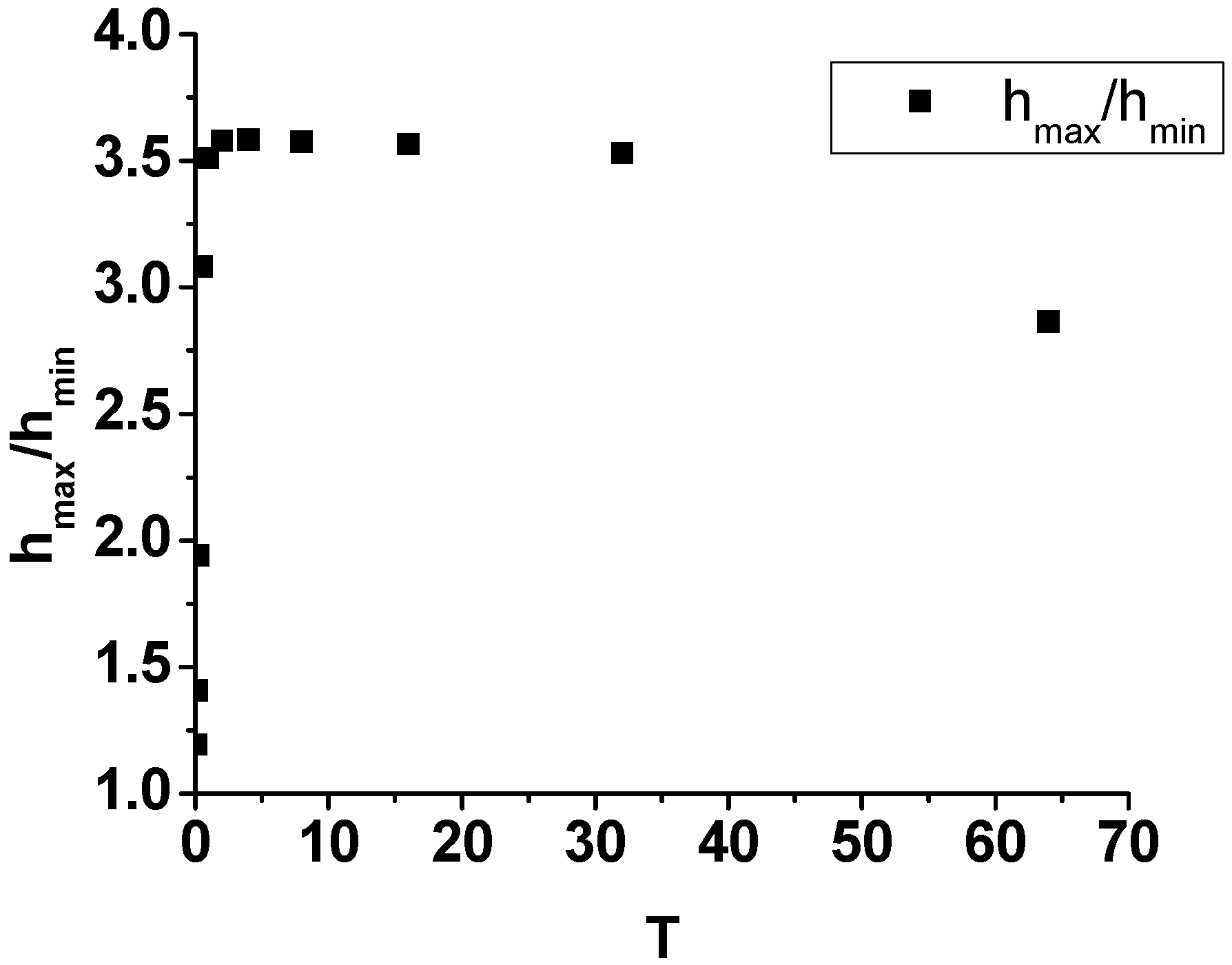

| T | hmax/hmin |

|---|---|

| 26 | 2.8647 |

| 25 | 3.5315 |

| 24 | 3.5658 |

| 23 | 3.577 |

| 22 | 3.5849 |

| 21 | 3.5795 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Fang, X.; Meng, L.; Wang, S. Spin Coating on Spherical Surface with Large Central Angles. Coatings 2017, 7, 124. https://doi.org/10.3390/coatings7080124

Liu H, Fang X, Meng L, Wang S. Spin Coating on Spherical Surface with Large Central Angles. Coatings. 2017; 7(8):124. https://doi.org/10.3390/coatings7080124

Chicago/Turabian StyleLiu, Huan, Xudong Fang, Le Meng, and Shanshan Wang. 2017. "Spin Coating on Spherical Surface with Large Central Angles" Coatings 7, no. 8: 124. https://doi.org/10.3390/coatings7080124

APA StyleLiu, H., Fang, X., Meng, L., & Wang, S. (2017). Spin Coating on Spherical Surface with Large Central Angles. Coatings, 7(8), 124. https://doi.org/10.3390/coatings7080124