Erosion Wear Investigation of HVOF Sprayed WC-10Co4Cr Coating on Slurry Pipeline Materials

Abstract

:1. Introduction

2. Material and Methods

2.1. Specimen

2.2. Coating Deposition

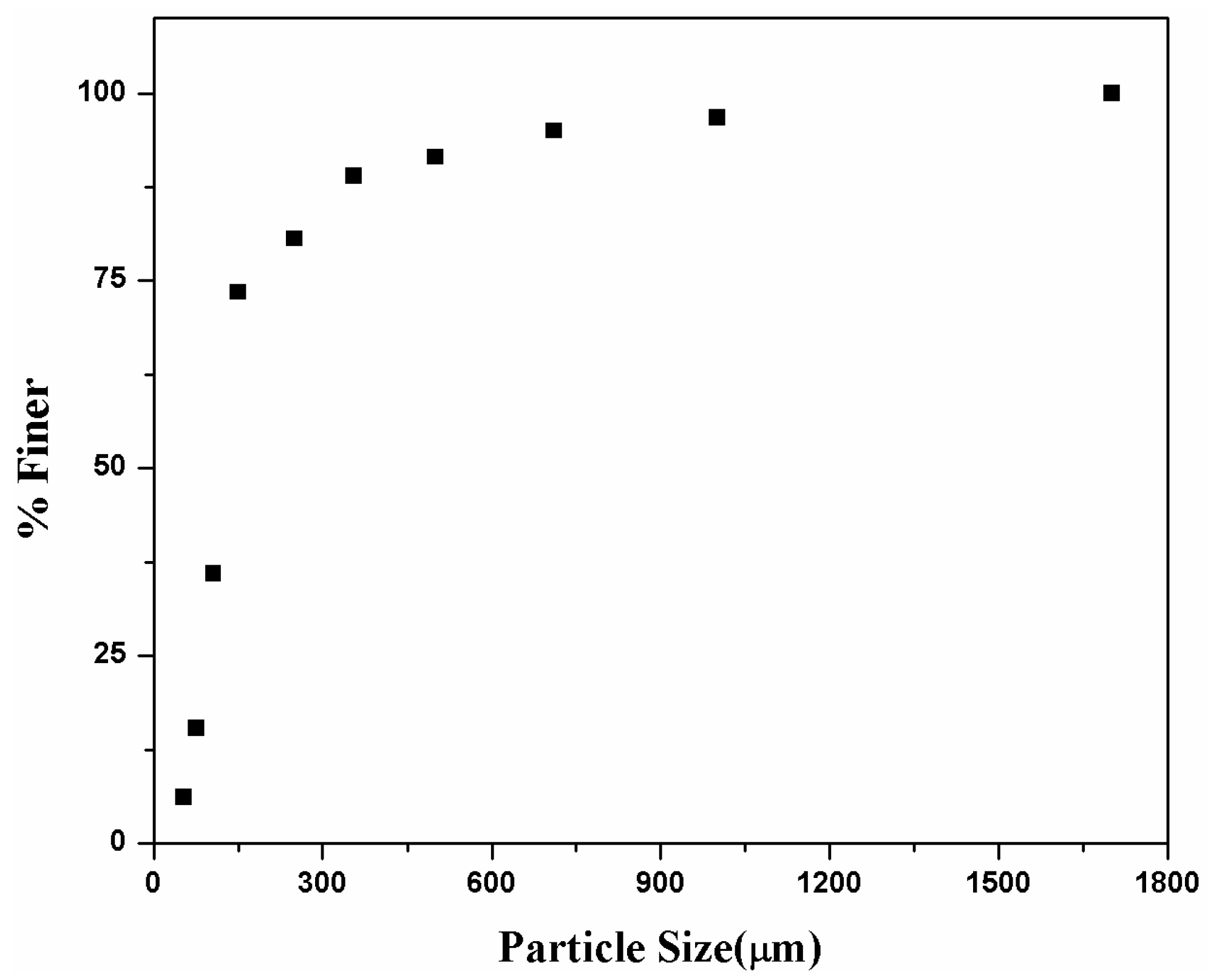

2.3. Slurry Preparation

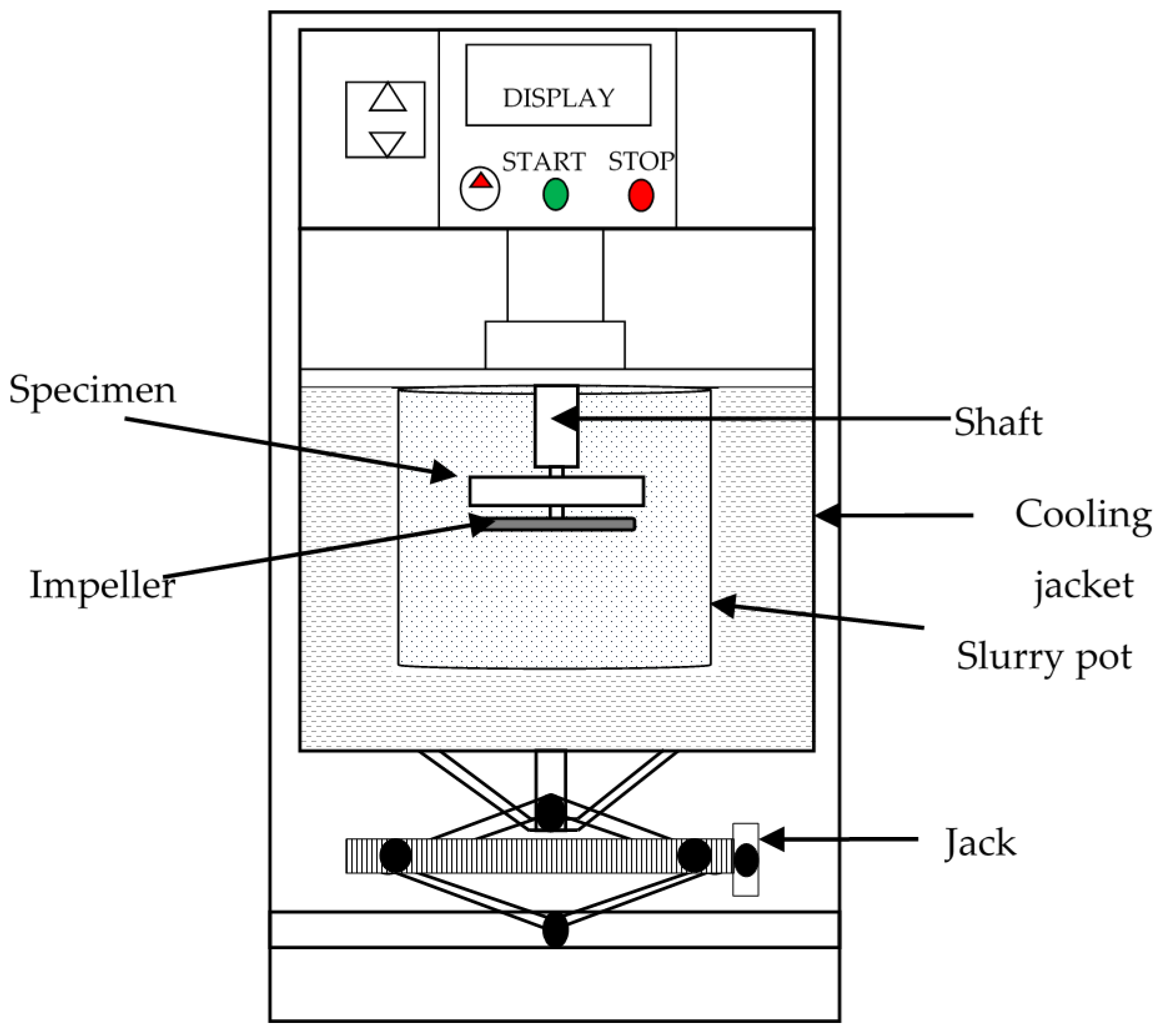

2.4. Slurry Erosion Test Rig

3. Results and Discussion

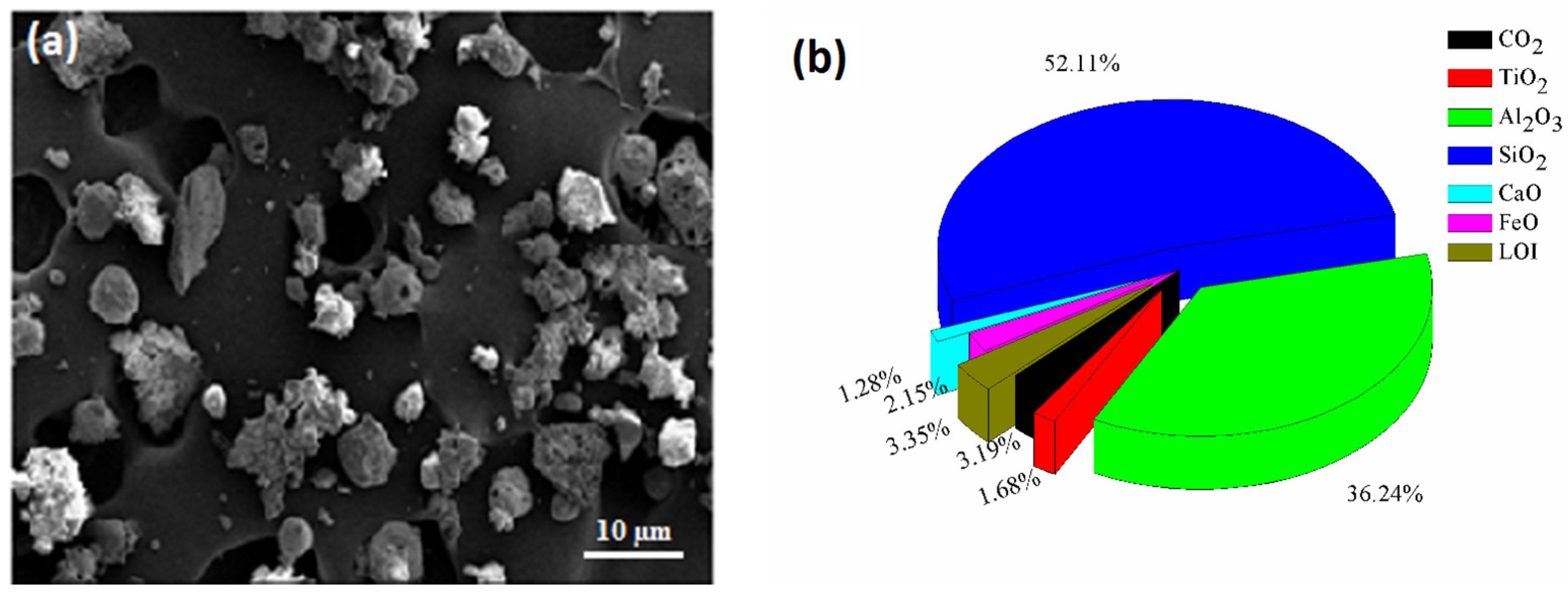

3.1. Characterization of Erodent Material

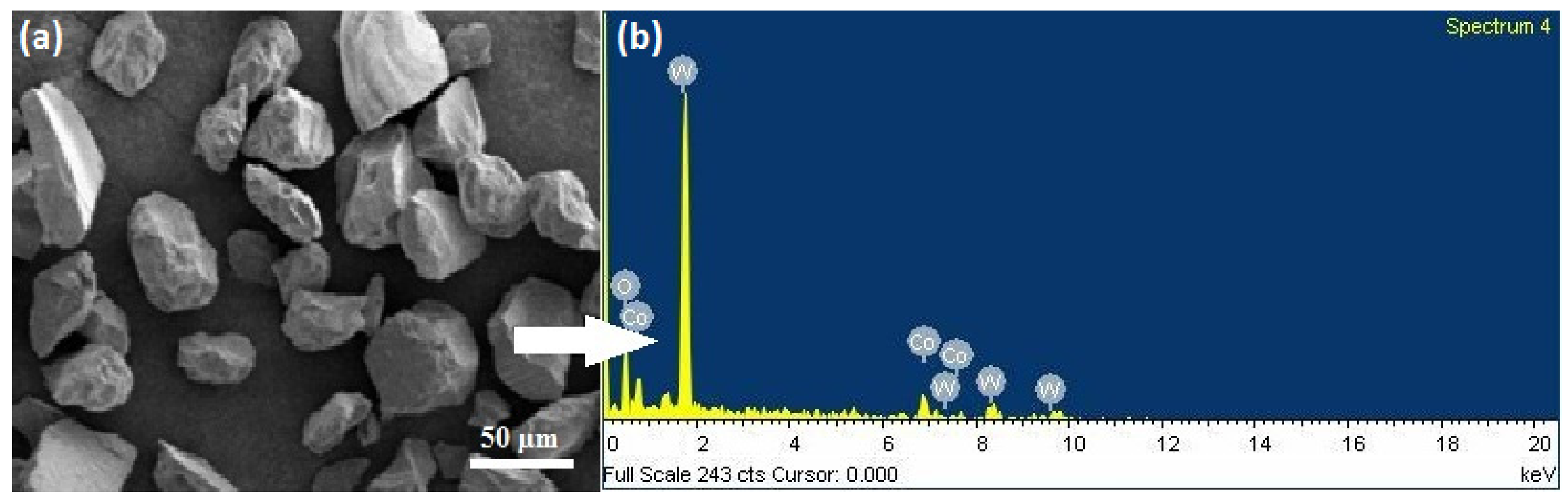

3.2. Effect of WC-10Co4Cr Coating Powder Deposition on Substrate

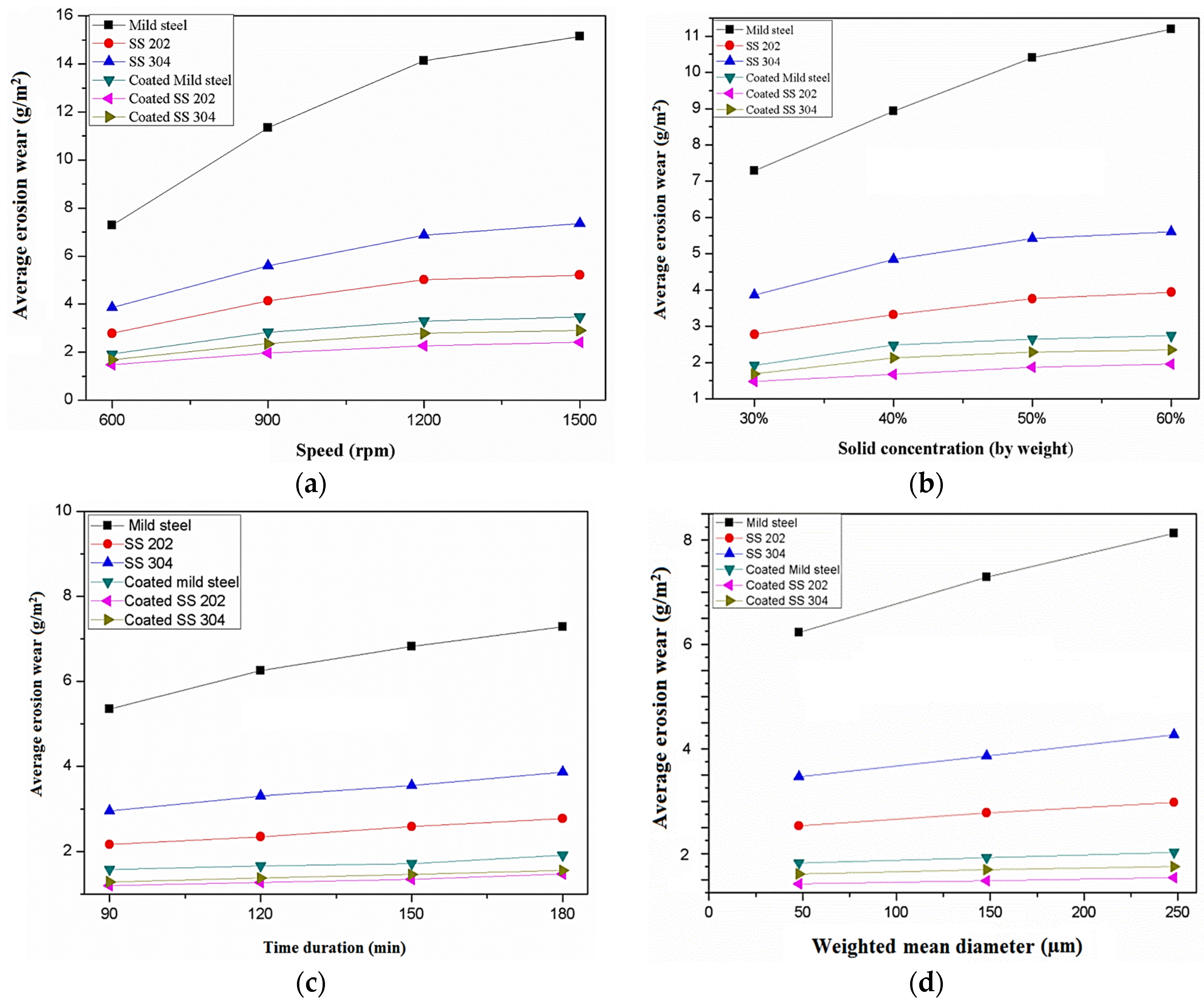

3.3. Effect of Rotational Speed/Velocity on Average Erosion Wear

3.4. Effects of Solid Concentration on Average Erosion Wear

3.5. Effects of Time Duration on Average Erosion Wear

3.6. Effect of Weighted Mean Diameter on Average Erosion Wear

3.7. Effect of WC-10Co4Cr Coating on Average Erosion Wear

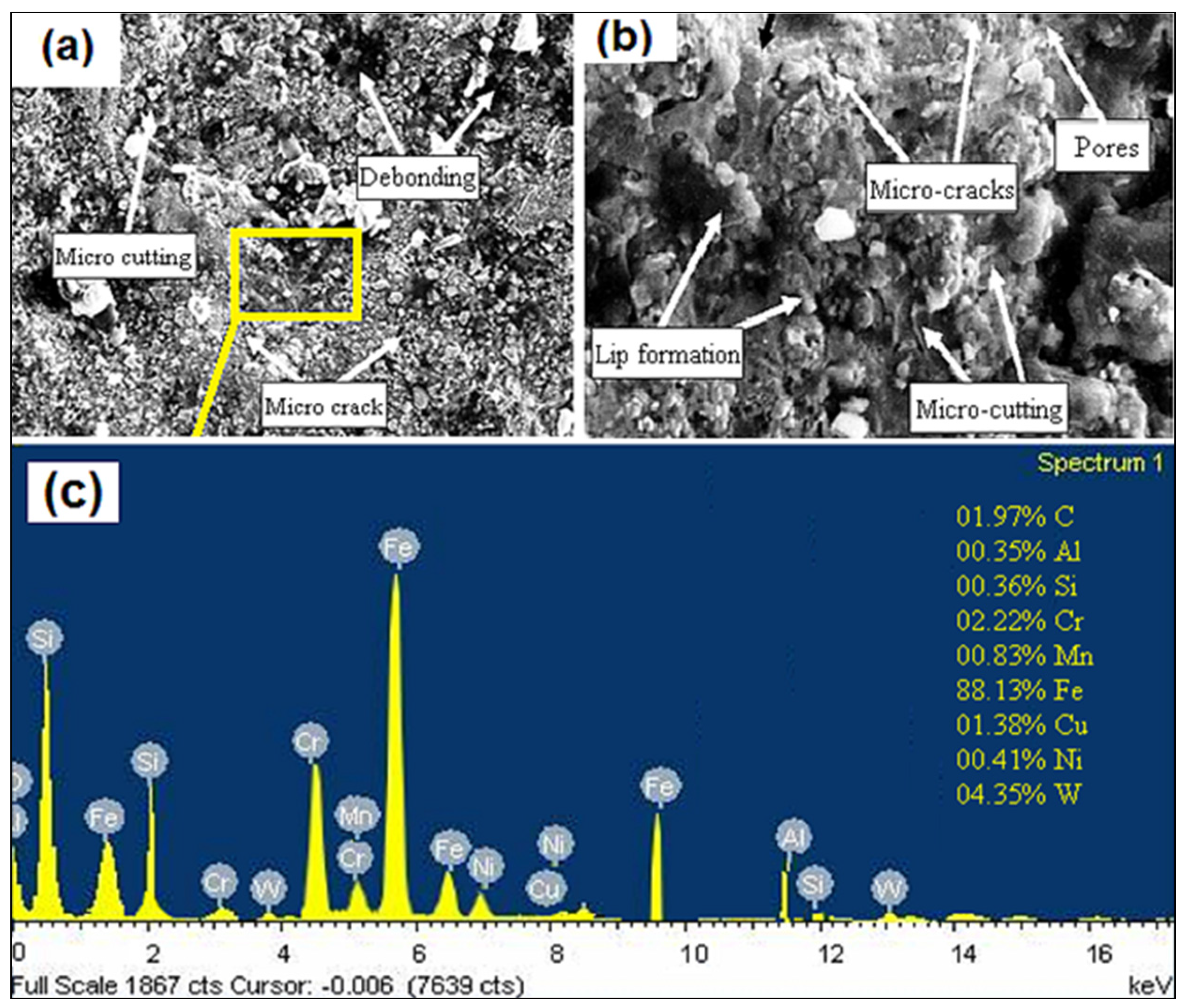

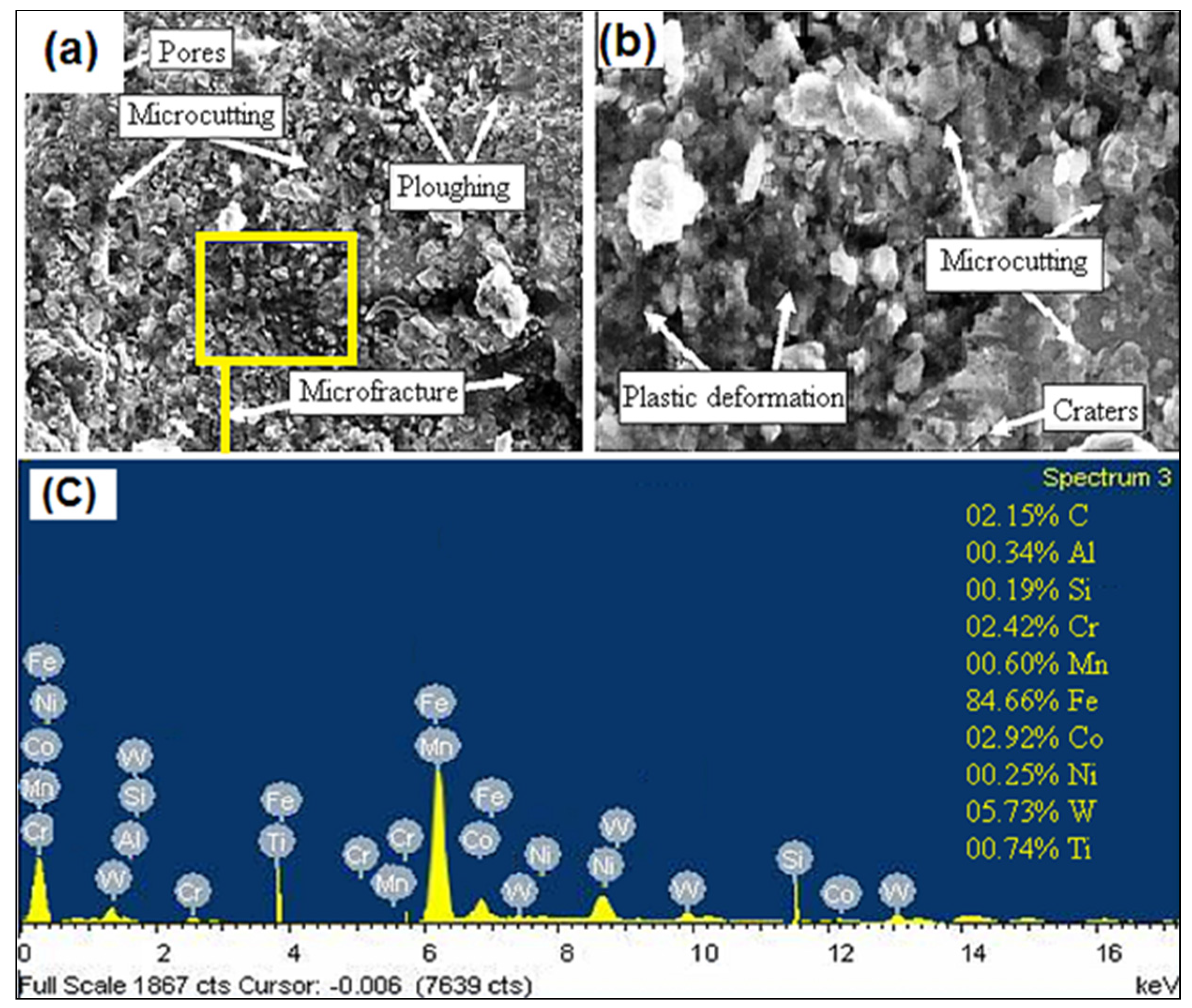

3.8. Visual Examination of Eroded Coated Surfaces

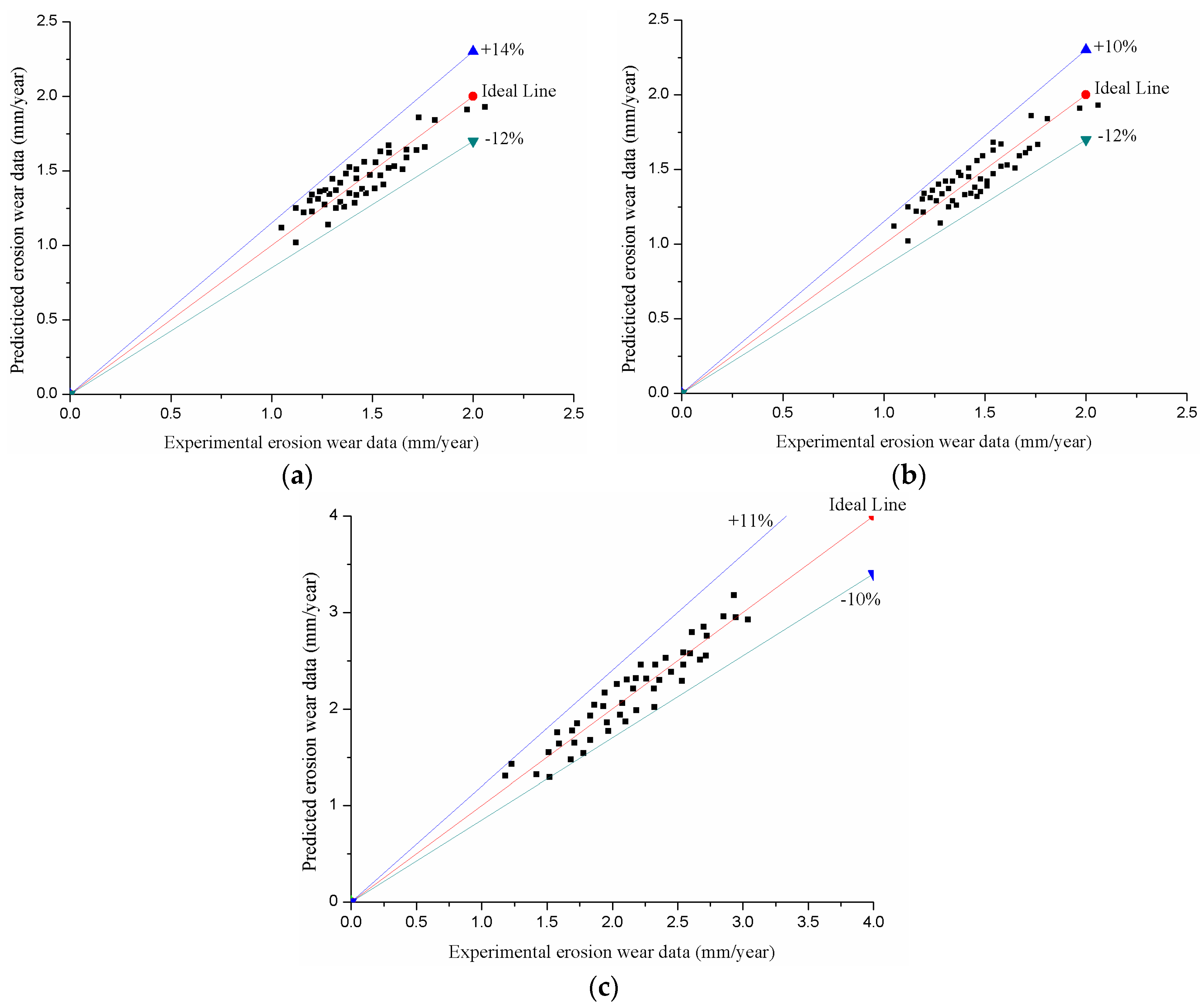

3.9. Correlation for Erosion Wear

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kumar, S.; Mohapatra, S.K.; Gandhi, B.K. Effect of addition of fly ash and drag reducing on the rheological properties of bottom ash. Int. J. Mech. Mater. Eng. 2013, 8, 1–8. [Google Scholar]

- Gandhi, B.K.; Singh, S.N.; Seshadri, V. Study of the parametric dependence of erosion wear for the parallel flow of solid–liquid mixtures. Tribol. Int. 1999, 32, 275–282. [Google Scholar] [CrossRef]

- Gandhi, B.K.; Singh, S.N.; Seshadri, V. A study on the effect of surface orientation on erosion wear of flat specimens moving in a solid-liquid suspension. Wear 2003, 254, 1233–1238. [Google Scholar] [CrossRef]

- Chandel, S.; Singh, S.N.; Seshadri, V. An experimental study of erosion wear in a centrifugal slurry pump using coriolis wear test rig. Particul. Sci. Technol. 2012, 30, 179–195. [Google Scholar] [CrossRef]

- Kosa, E.; Göksenli, A. Effect of impact angle on erosive abrasive wear of ductile and brittle materials. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2015, 9, 1638–1642. [Google Scholar]

- Modi, O.P.; Dasgupta, R.; Prasad, B.K. Erosion of a high carbon steel in coal and bottom ash slurries. J. Mater. Eng. Perform. 2000, 9, 522–529. [Google Scholar] [CrossRef]

- Desale, G.R.; Gandhi, B.K.; Jain, S.C. Slurry erosion of ductile materials under normal impact condition. Wear 2008, 264, 322–330. [Google Scholar] [CrossRef]

- Prasad, B.K.; Jha, A.K.; Modi, O.P. Effect of sand concentration in the medium and travel distance and speed on the slurry wear response of a zinc-based alloy alumina particle composite. Tribol. Lett. 2004, 17, 301–309. [Google Scholar] [CrossRef]

- Shitole, P.P.; Gawande, S.H.; Desale, G.R. Effect of impacting particle kinetic energy on slurry erosion wear. J. Bio- Tribo-Corros. 2015, 1, 29. [Google Scholar] [CrossRef]

- Kulu, P.; Käerdi, H.; Surzenkov, A. Recycled hard metal-based powder composite coatings: Optimisation of composition, structure and properties. Int. J. Mater. Prod. Technol. 2014, 49, 180–202. [Google Scholar] [CrossRef]

- Xie, Y.; Pei, X.; Wei, S. Investigation of erosion resistance property of WC-Co coatings. Int. J. Surf. Sci. Eng. 2016, 10, 365–374. [Google Scholar] [CrossRef]

- Cho, T.Y.; Yoon, J.H.; Kim, K.S. A study on HVOF coatings of micron and nano WC-Co powders. Surf. Coat. Technol. 2008, 202, 5556–5559. [Google Scholar] [CrossRef]

- Ma, H.R.; Li, J.W.; Jiao, J. Wear resistance of Fe-based amorphous coatings prepared by AC-HVAF and HVOF. Mater. Sci. Technol. 2017, 33, 65–71. [Google Scholar] [CrossRef]

- Valentinelli, L.; Valente, T.; Casadei, F. Mechanical and tribocorrosion properties of HVOF sprayed WC–CO coatings. Corros. Eng. Sci. Technol. 2004, 39, 301–307. [Google Scholar] [CrossRef]

- Gupta, R.; Singh, S.N.; Seshadri, V. Prediction of uneven wear in a slurry pipeline on the basis of measurements in a pot tester. Wear 1995, 184, 169–178. [Google Scholar] [CrossRef]

- Desale, G.R.; Gandhi, B.K.; Jain, S.C. Improvement in the design of a pot tester to simulate erosion wear due to solid–liquid mixture. Wear 2005, 259, 196–202. [Google Scholar] [CrossRef]

- Goyal, D.K.; Singh, H.; Kumar, H.; Sahni, V. Slurry erosion behavior of HVOF sprayed WC–10Co4Cr and Al2O3 + 13TiO2 coatings on a turbine steel. Wear 2012, 289, 46–57. [Google Scholar] [CrossRef]

- Truscott, G.F. A Literature Survey on Wear on Pipelines; Publication TN 1295; BHRA Fluid Engineering: Cranfield, UK, 1975. [Google Scholar]

- Bajracharya, T.R.; Acharya, B.; Joshi, C.B.; Saini, R.P.; Dahlhaug, O.G. Sand erosion of Pelton turbine nozzles and buckets: A case study of Chilime hydropower plant. Wear 2008, 264, 177–184. [Google Scholar] [CrossRef]

| Medium | Spray Distance (mm) | Flow Rate (L/min) | Pressure (kPa) | Feed Rate (g/min) | Particle Size (μm) |

|---|---|---|---|---|---|

| Air | 138 | 640 | 10 | 30 | 15 |

| Oxygen | 138 | 260 | 5 | 30 | 15 |

| Fuel | 138 | 75 | 6.2 | 30 | 15 |

| Time (min) | Static Settled Concentration (wt %) | Time (min) | Static Settled Concentration (wt %) |

|---|---|---|---|

| 0 | 30 | 20 | 37.75 |

| 1 | 30.12 | 30 | 41.05 |

| 2 | 30.35 | 60 | 45.73 |

| 3 | 30.72 | 180 | 49.92 |

| 4 | 31.16 | 420 | 51.36 |

| 5 | 31.95 | 660 | 52.15 |

| 10 | 34.92 | – | – |

| Material | Fe | Cr | Ni | Mn | C | Si | Co | P | Al | S | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mild Steel | 98.90 | 0.04 | 0.05 | 0.45 | 0.14 | 0.20 | – | 0.07 | 0.02 | 0.06 | 0.07 |

| SS202 | 74.54 | 13.42 | 0.18 | 9.67 | 0.09 | 0.42 | 0.05 | 0.07 | 0.04 | 0.04 | 1.48 |

| SS304 | 69.65 | 18.65 | 8.94 | 1.43 | 0.13 | 0.55 | 0.18 | 0.11 | – | 0.06 | 0.30 |

| Materials | Indentation Depth (μm) | Average Hardness (HV) | Average Roughness (μm) | |||

|---|---|---|---|---|---|---|

| Uncoated | Coated | Uncoated | Coated | Uncoated | Coated | |

| Mild steel | 103 | 37 | 138 | 952 | 2.23 | 5.48 |

| SS202 | 82 | 25 | 276 | 1158 | 1.63 | 5.81 |

| SS304 | 96 | 29 | 237 | 1129 | 1.56 | 5.78 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, K.; Kumar, S.; Singh, G.; Singh, J.P.; Singh, J. Erosion Wear Investigation of HVOF Sprayed WC-10Co4Cr Coating on Slurry Pipeline Materials. Coatings 2017, 7, 54. https://doi.org/10.3390/coatings7040054

Kumar K, Kumar S, Singh G, Singh JP, Singh J. Erosion Wear Investigation of HVOF Sprayed WC-10Co4Cr Coating on Slurry Pipeline Materials. Coatings. 2017; 7(4):54. https://doi.org/10.3390/coatings7040054

Chicago/Turabian StyleKumar, Kaushal, Satish Kumar, Gurprit Singh, Jatinder Pal Singh, and Jashanpreet Singh. 2017. "Erosion Wear Investigation of HVOF Sprayed WC-10Co4Cr Coating on Slurry Pipeline Materials" Coatings 7, no. 4: 54. https://doi.org/10.3390/coatings7040054

APA StyleKumar, K., Kumar, S., Singh, G., Singh, J. P., & Singh, J. (2017). Erosion Wear Investigation of HVOF Sprayed WC-10Co4Cr Coating on Slurry Pipeline Materials. Coatings, 7(4), 54. https://doi.org/10.3390/coatings7040054