Simulation of Acoustic Wave Propagation in Aluminium Coatings for Material Characterization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample

2.2. Scanning Acoustic Microscopy (SAM)

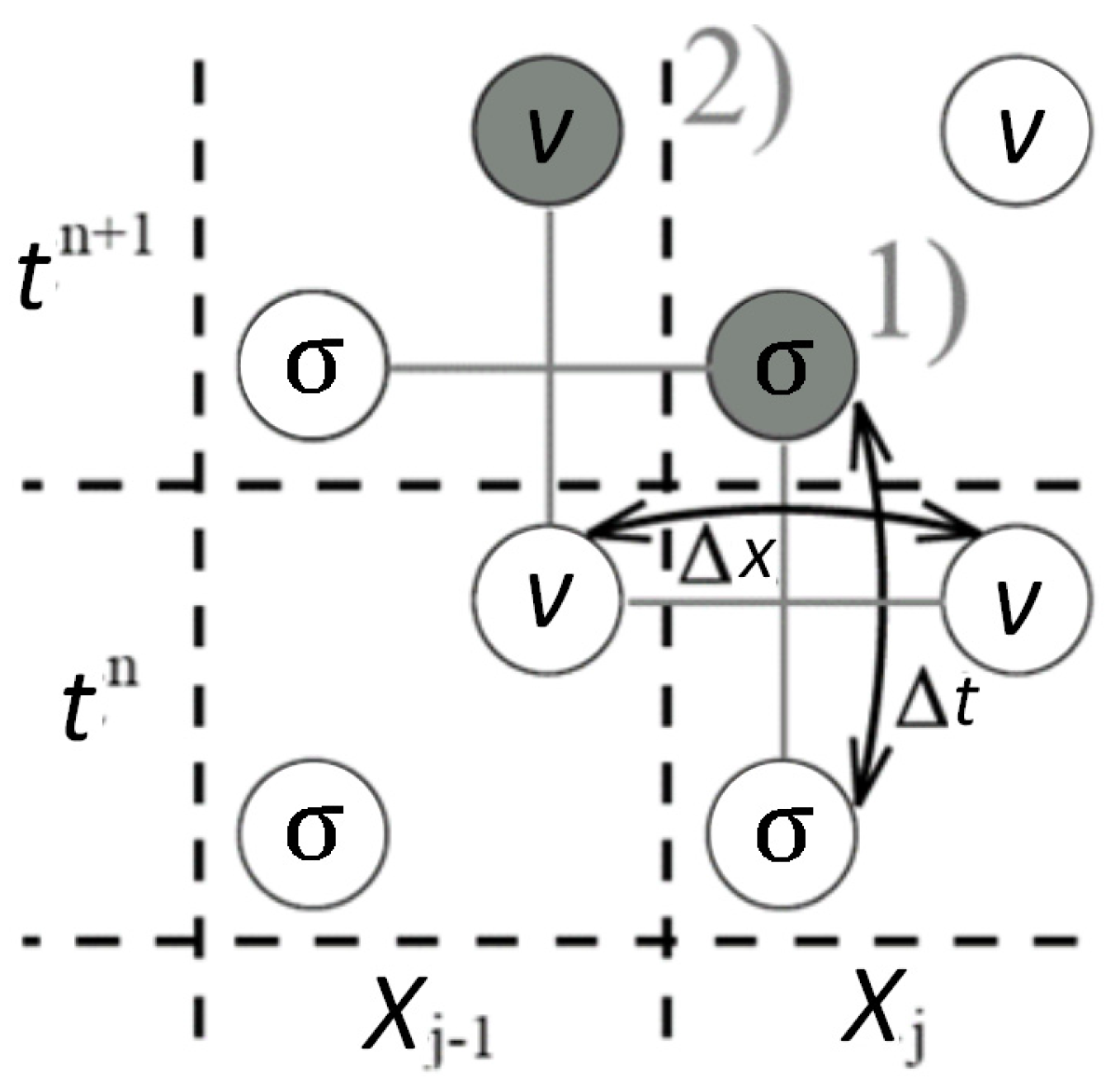

2.3. Elastodynamic Finite Integration Technique (EFIT)

2.4. Laser Ultrasound (LUS)

3. Results

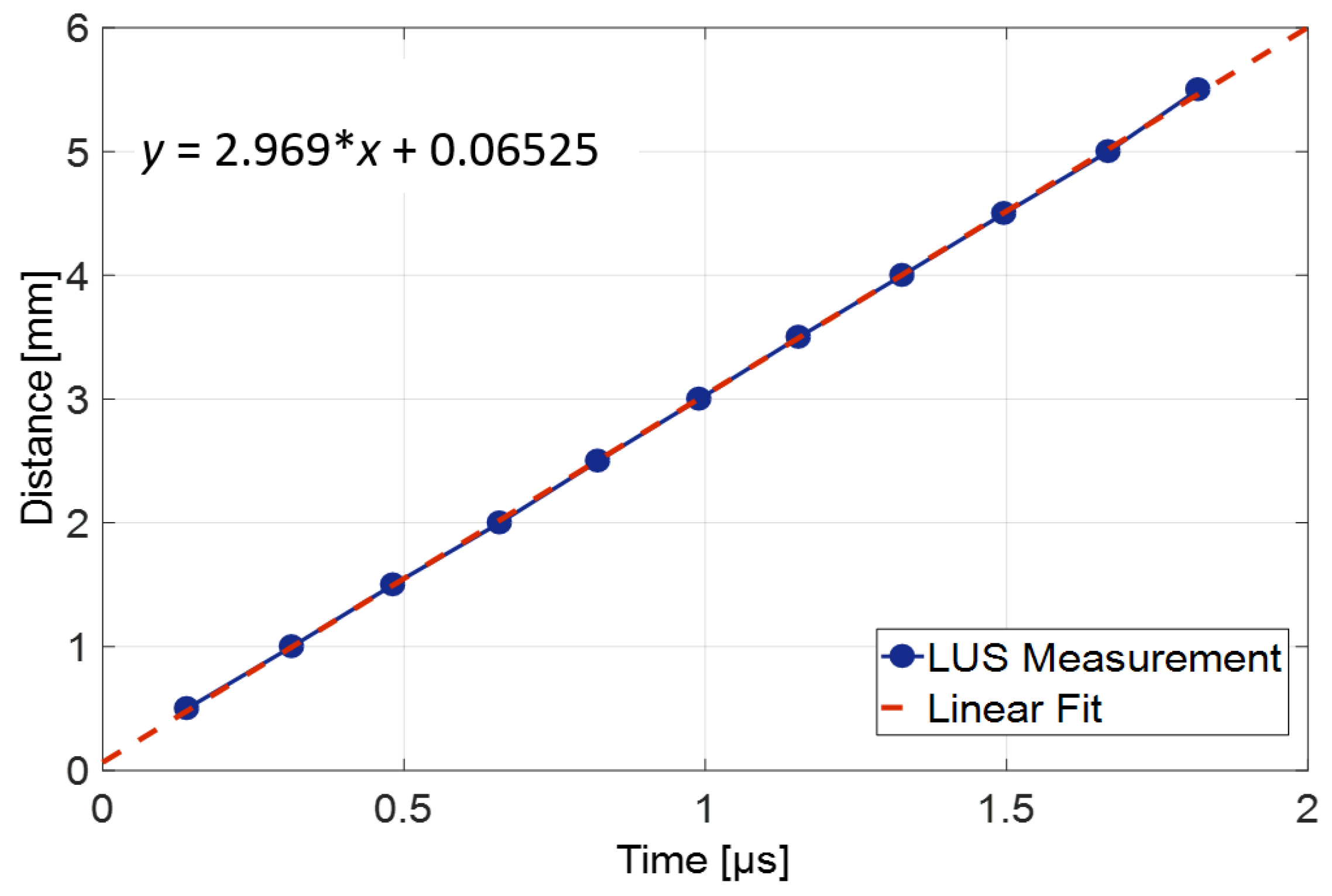

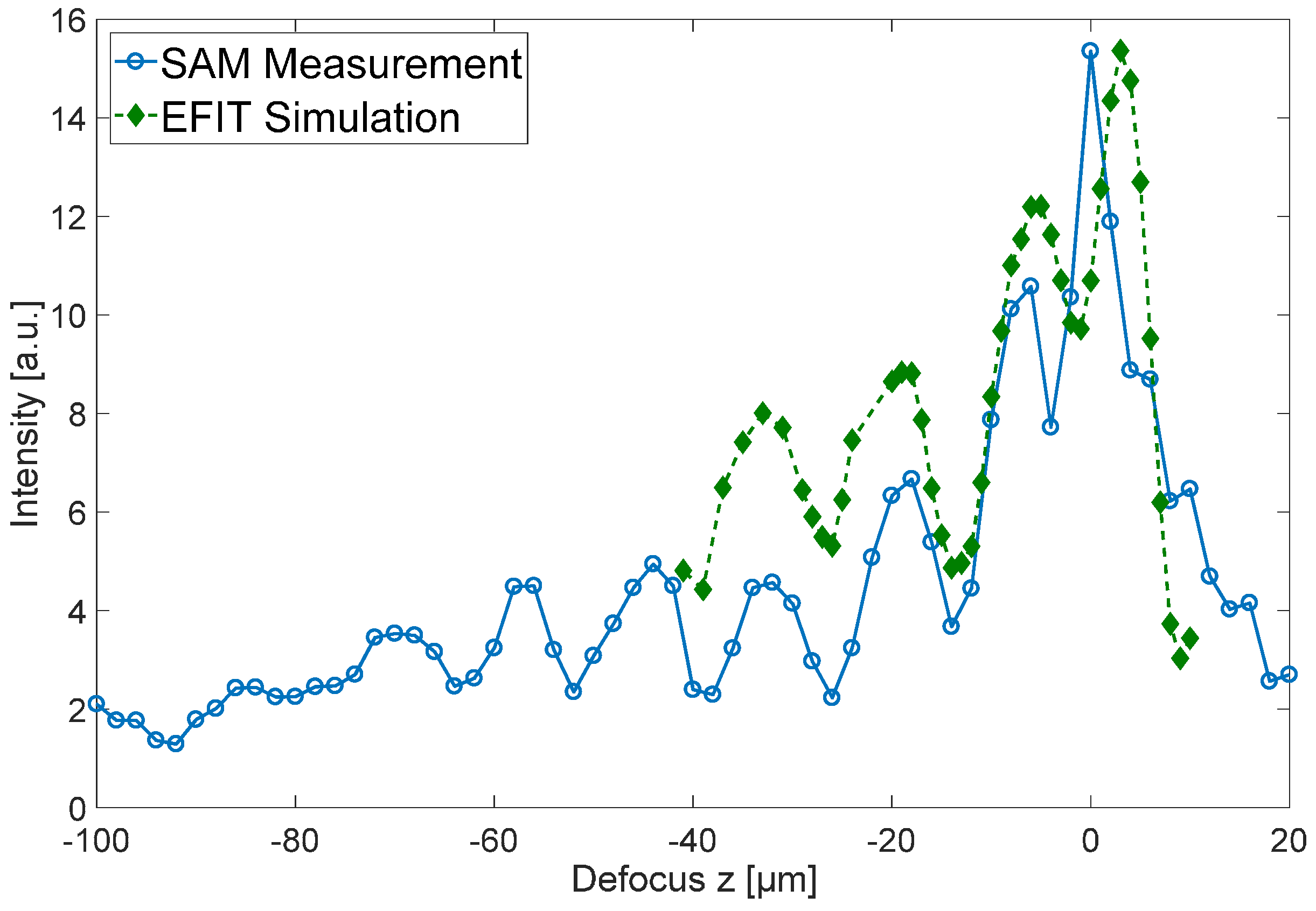

3.1. Aluminium Bulk Sample for Calibration

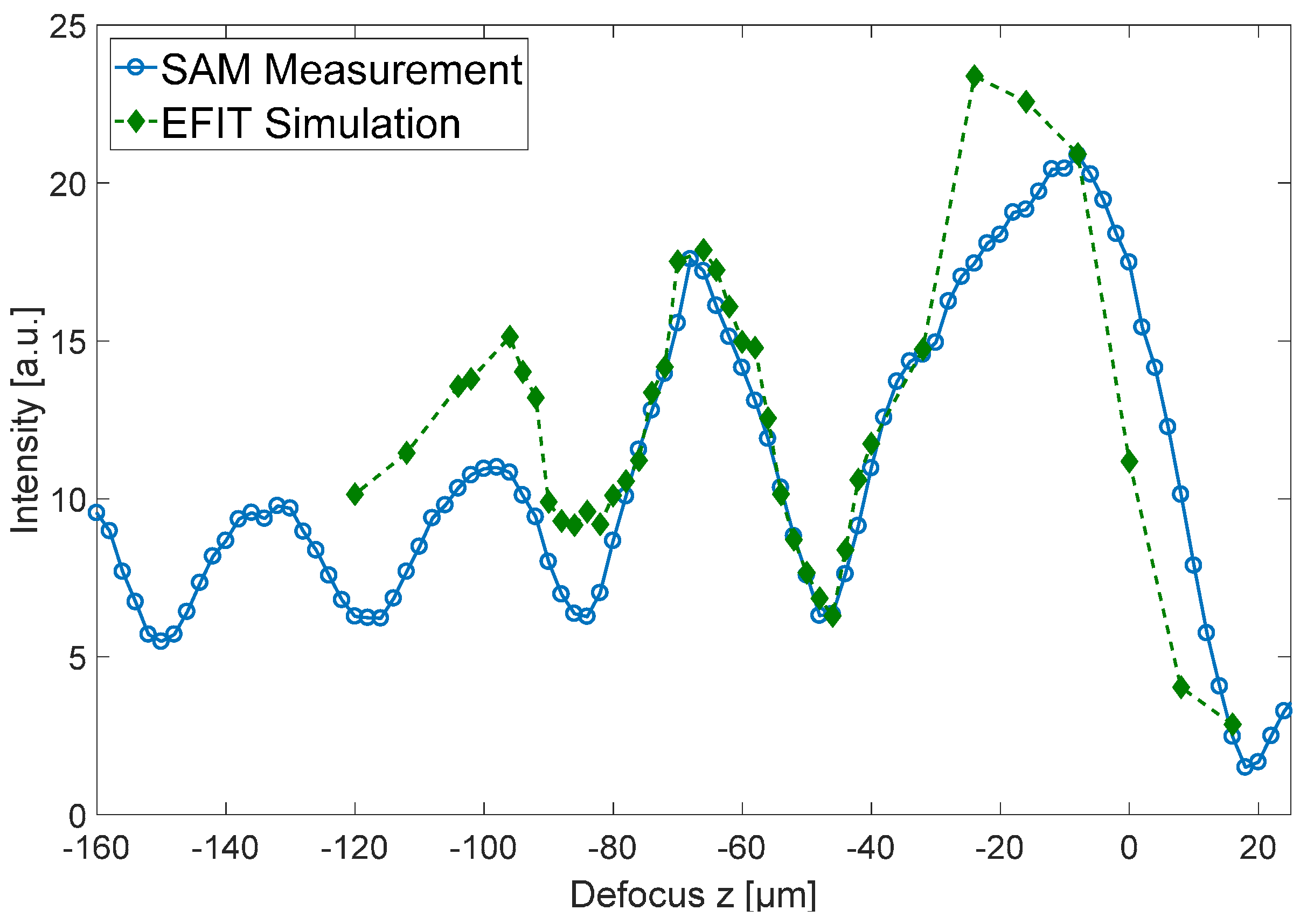

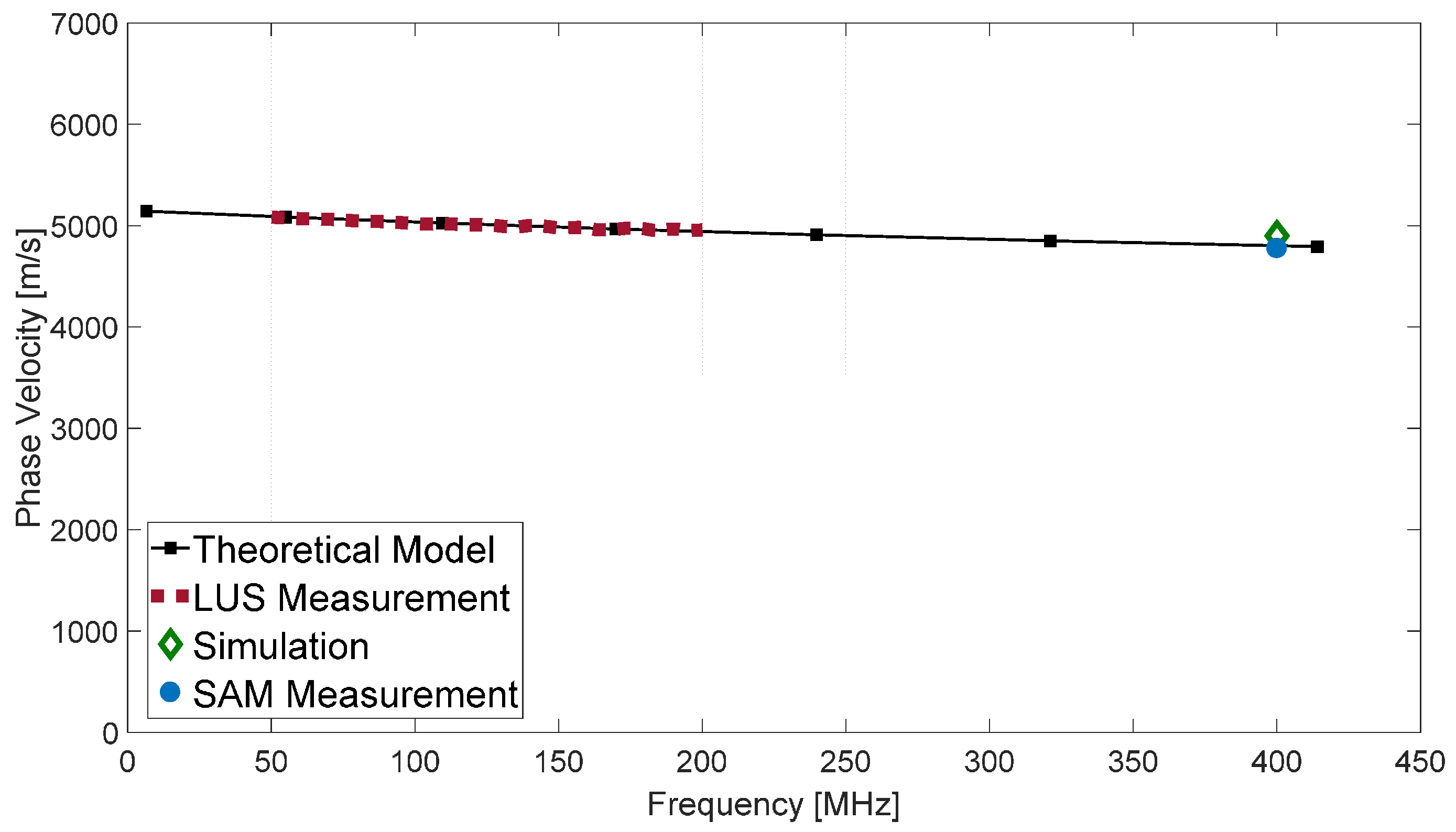

3.2. Aluminium Thin Film on Silicon Substrate

4. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Grovenor, C.R.M. Microelectronic Materials; Plenum Press: New York, NY, USA, 1989. [Google Scholar]

- Zhang, F.; Kirshnaswamy, S.; Fei, D.; Rebinsky, D.A.; Feng, B. Ultrasonic characterization of mechanical properties of Cr- and W-doped diamond-like carbon hard coatings. Thin Solid Films 2006, 503, 250–258. [Google Scholar] [CrossRef]

- Neubrand, A.; Hess, P. Laser generation and detection of surface acoustic waves: Elastic properties of surface layers. J. Appl. Phys. 1992, 71, 227–238. [Google Scholar] [CrossRef]

- Schneider, D.; Witke, T.; Schwarz, T.; Schöneich, B.; Schultrich, B. Testing ultra-thin films by laser-acoustics. Surf. Coat. Technol. 2000, 126, 136–141. [Google Scholar] [CrossRef]

- Schneider, D.; Schwarz, T. A photoacoustic method for characterizing thin films. Surf. Coat. Technol. 1997, 91, 136–146. [Google Scholar] [CrossRef]

- Hurley, D.C.; Tewary, V.K.; Richards, A.J. Surface acoustic wave methods to determine the anisotropic elastic properties of thin films. Meas. Sci. Technol. 2001, 12, 1486–1494. [Google Scholar] [CrossRef]

- Briggs, G.A.D. Advances in Acoustic Microscopy, 2nd ed.; Plenum Press: New York, NY, USA, 1995. [Google Scholar]

- Yu, Z.; Boseck, S. Scanning acoustic microscopy and its applications to material characterization. Rev. Mod. Phys. 1995, 67, 863. [Google Scholar] [CrossRef]

- Grünwald, E.; Rosc, J.; Hammer, R.; Czurratis, P.; Koch, M.; Kraft, J.; Schrank, F.; Brunner, R. Automatized failure analysis of tungsten coated TSVs via scanning acoustic microscopy. Microelectron. Reliab. 2016, 64, 370–374. [Google Scholar] [CrossRef]

- Shin, S.W.; Yun, C.B.; Popovics, J.S.; Kim, J.H. Improved rayleigh wave velocity measurement for nondestructive early-age concrete monitoring. Res. Nondestruct. Eval. 2017, 18, 45–68. [Google Scholar] [CrossRef]

- Debboub, S.; Boumaïza, Y.; Boudour, A.; Tahraoui, T. Attenuation of Rayleigh surface waves in a porous material. Chin. Phys. Lett. 2012, 29, 044301. [Google Scholar] [CrossRef]

- Levy, M.; Bass, H.E.; Stern, R. Modern Acoustical Techniques for the Measurement of Mechanical Properties; Academic Press: San Diego, CA, USA, 2001. [Google Scholar]

- Tiersten, H.F. Elastic surface waves guided by thin films. J. Appl. Phys. 1969, 40, 770–789. [Google Scholar] [CrossRef]

- Farnell, G.W.; Adler, E.L. Elastic wave propagation in thin layers. Phys. Acoust. 1972, 9, 35–127. [Google Scholar] [CrossRef]

- Chimenti, D.E.; Nayfeh, A.H.; Butler, D.L. Leaky Rayleigh waves on a layered halfspace. J. Appl. Phys. 1982, 53, 170–176. [Google Scholar] [CrossRef]

- Liang, K.K.; Kino, G.S.; Khuri-Yakub, B.T. Material characterization by the inversion of V(z). IEEE Trans. Sonics Ultrason. 1985, 32, 213–224. [Google Scholar] [CrossRef]

- Ghosh, T.; Maslov, K.I.; Kundu, T. A new method for measuring surface acoustic wave speeds by acoustic microscopes and its application in characterizing laterally inhomogeneous materials. Ultrasonics 1997, 35, 357–366. [Google Scholar] [CrossRef]

- Bamber, M.J.; Cooke, K.E.; Man, A.B.; Derby, B. Accurate determination of Young’s modulus and Poisson’s ratio of thin films by a combination of acoustic microscopy and nanoindentation. Thin Solid Films 2001, 398, 299–305. [Google Scholar] [CrossRef]

- Comte, C.; Von Stebut, J. Microprobe-type measurement of Young’s modulus and Poisson coefficient by means of depth sensing indentation and acoustic microscopy. Surf. Coat. Technol. 2002, 154, 42–48. [Google Scholar] [CrossRef]

- Weglein, R.D. A model for predicting acoustic material signatures. Appl. Phys. Lett. 1979, 34, 179–181. [Google Scholar] [CrossRef]

- Henry, L.B. Ray-optical evaluation of V(z) in the reflection acoustic microscope. IEEE Trans. Sonics Ultrason. 1984, 31, 105–116. [Google Scholar]

- Kim, J.N. Multilayer Transfer Matrix Characterization of Complex Materials with Scanning Acoustic Microscopy. Master’s Thesis, The Pennsylvania State University, Pennsylvania, PA, USA, 2013. [Google Scholar]

- Guddati, M.N.; Yue, B. Modified integration rules for reducing dispersion error in finite element methods. Comput. Methods Appl. Mech. Eng. 2004, 193, 275–287. [Google Scholar] [CrossRef]

- Willberg, C.; Duczek, S.; Perez, J.M.V.; Schmicker, D.; Gabbert, U. Comparison of different higher order finite element schemes for the simulation of Lamp waves. Comput. Methods Appl. Mech. Eng. 2012, 241, 246–261. [Google Scholar] [CrossRef]

- Ham, S.; Bathe, K.J. A finite element method enriched for wave propagation problems. Comput. Struct. 2012, 94, 1–12. [Google Scholar] [CrossRef]

- Komatitsch, D.; Vilotte, J.-P. The spectral element method, an efficient tool to simulate seismic response. Bull. Seismol. Soc. Am. 1998, 88, 368–392. [Google Scholar]

- Zampieri, E.; Pavarino, L.F. Approximation of acoustic waves by explicit Newmark’s schemes and spectral element methods. J. Comput. Appl. Math. 2006, 185, 308–325. [Google Scholar] [CrossRef]

- Fornberg, B. The pseudospectral method comparisons with finite differences for the elastic wave equation. Geophysics 1987, 52, 483–501. [Google Scholar] [CrossRef]

- Zhao, Z.; Xu, J.; Horiuchi, S. Differentiation operation in the wave equation for the pseudospectral method with a staggered mesh. Earth Planets Space 2001, 53, 327–332. [Google Scholar] [CrossRef]

- LeVeque, R.J. Wave propagation algorithms for multidimensional hyperbolic systems. J. Comput. Phys. 1997, 113, 327–353. [Google Scholar] [CrossRef]

- Virieux, J. SH-wave propagation in heterogeneous media: Velocity-stress finite-difference method. Geophysics 1984, 49, 1933–1942. [Google Scholar] [CrossRef]

- Graves, R.W. Simulating seismic wave propagation in 3D elastic media using staggered-grid. Bull. Seismol. Soc. Am. 1996, 86, 1091–1106. [Google Scholar]

- Pitarka, A. 3D elastic finite-difference modeling of seismic motion using staggered grids with nonuniform spacing. Bull. Seismol. Soc. Am. 1999, 89, 54–68. [Google Scholar]

- Saenger, E.H.; Gold, N.; Shapiro, S.A. Modeling the propagation of elastic waves using a modified finite-difference grid. Wave Motion 2000, 31, 77–92. [Google Scholar] [CrossRef]

- Fellinger, P.; Marklein, R.; Langenberg, K.J.; Klaholz, S. Numerical modeling of elastic wave propagation and scattering with EFIT–elastodynamic finite integration technique. Wave Motion 1995, 21, 47–66. [Google Scholar] [CrossRef]

- Schubert, F.; Köhler, B. Time domain modelling of axisymmetric wave propagation in isotropic elastic media with CEFIT–cylindrical elastodynamic finite integration technique. J. Comput. Acoust. 2001, 9, 1127–1146. [Google Scholar]

- Taflove, A.; Hagness, S.C. Computational Electrodynamics: The Finite-Difference Time-Domain Method; Artech House: Boston, MA, USA, 2005. [Google Scholar]

- Hammer, R.; Pötz, W.; Arnold, A. Single-cone real-space finite difference scheme for the time-dependent Dirac equation. J. Comput. Phys. 2014, 265, 50–70. [Google Scholar] [CrossRef]

- Grünwald, E.; Hammer, R.; Rosc, J.; Maier, G.A.; Bärnthaler, M.; Cordill, M.J.; Brand, S.; Nuster, R.; Krivec, T.; Brunner, R. Advanced 3D failure characterization in multi-layered PCBs. NDT E Int. 2016, 84, 99–107. [Google Scholar] [CrossRef]

- Royer, D.; Dieulesaint, E. Elastic Waves in Solids. I. Free and Guided Propagation; Springer: Berlin, Germany, 2000. [Google Scholar]

| Method | Δz (µm) | vR (m/s) |

|---|---|---|

| EFIT | 13 | 2896 |

| SAM | 13 | 2896 |

| LUS | – | 2969 |

| Literature [7] | – | 2906 |

| Method | Δz (µm) | vR (m/s) |

|---|---|---|

| EFIT | 38 | 4775 |

| SAM | 40 | 4899 |

| Theoretical Model | – | 4819 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grünwald, E.; Hammer, R.; Nuster, R.; Wieser, P.A.; Hinderer, M.; Wiesler, I.; Zelsacher, R.; Ehmann, M.; Brunner, R. Simulation of Acoustic Wave Propagation in Aluminium Coatings for Material Characterization. Coatings 2017, 7, 230. https://doi.org/10.3390/coatings7120230

Grünwald E, Hammer R, Nuster R, Wieser PA, Hinderer M, Wiesler I, Zelsacher R, Ehmann M, Brunner R. Simulation of Acoustic Wave Propagation in Aluminium Coatings for Material Characterization. Coatings. 2017; 7(12):230. https://doi.org/10.3390/coatings7120230

Chicago/Turabian StyleGrünwald, Eva, René Hammer, Robert Nuster, Philipp Aldo Wieser, Martin Hinderer, Ingo Wiesler, Rudolf Zelsacher, Michael Ehmann, and Roland Brunner. 2017. "Simulation of Acoustic Wave Propagation in Aluminium Coatings for Material Characterization" Coatings 7, no. 12: 230. https://doi.org/10.3390/coatings7120230

APA StyleGrünwald, E., Hammer, R., Nuster, R., Wieser, P. A., Hinderer, M., Wiesler, I., Zelsacher, R., Ehmann, M., & Brunner, R. (2017). Simulation of Acoustic Wave Propagation in Aluminium Coatings for Material Characterization. Coatings, 7(12), 230. https://doi.org/10.3390/coatings7120230