On the Possibility of Improving Surface Geometrical Texture During High-Performance Machining of Aluminium Without the Use of Coolant

Abstract

1. Introduction

2. Materials and Methods

3. Results

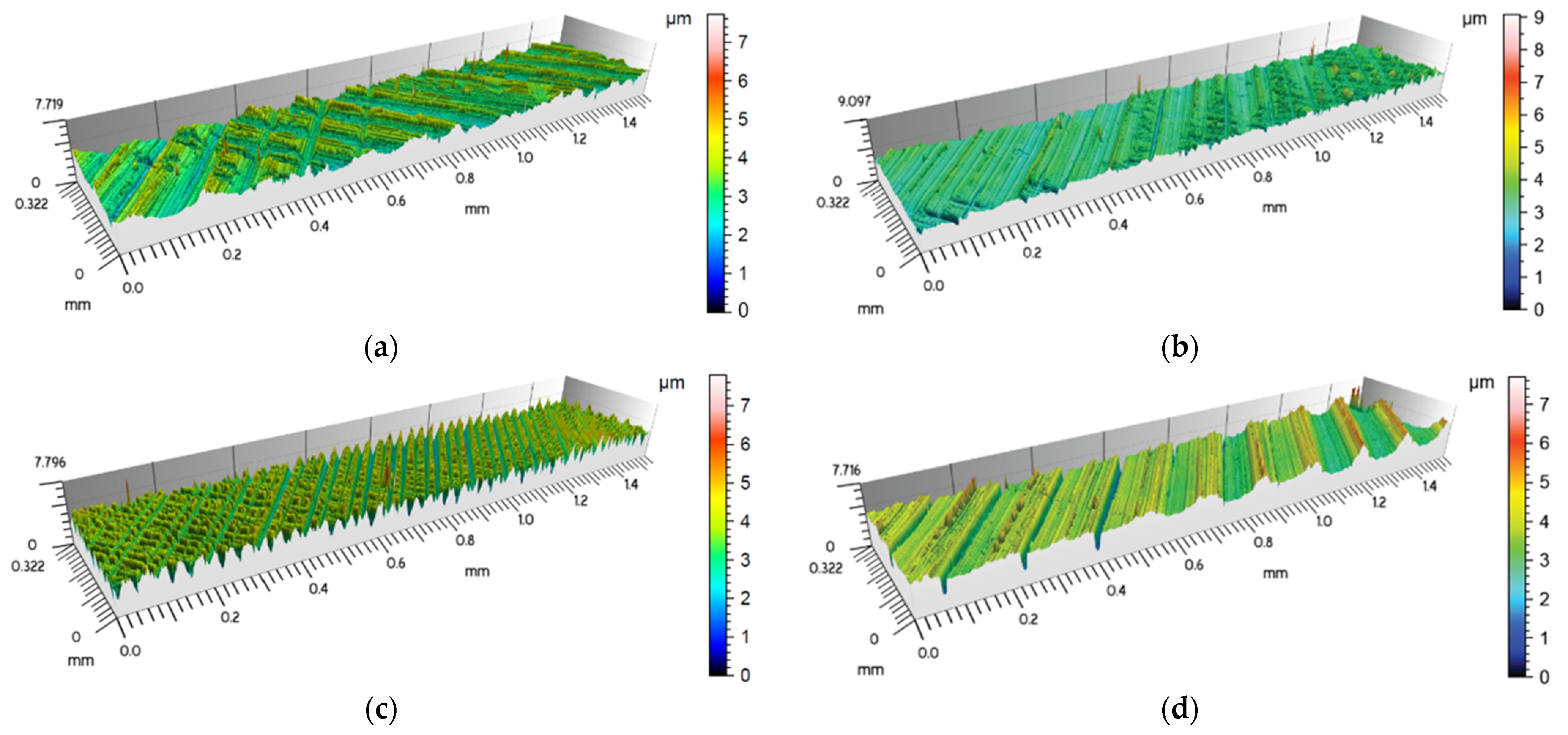

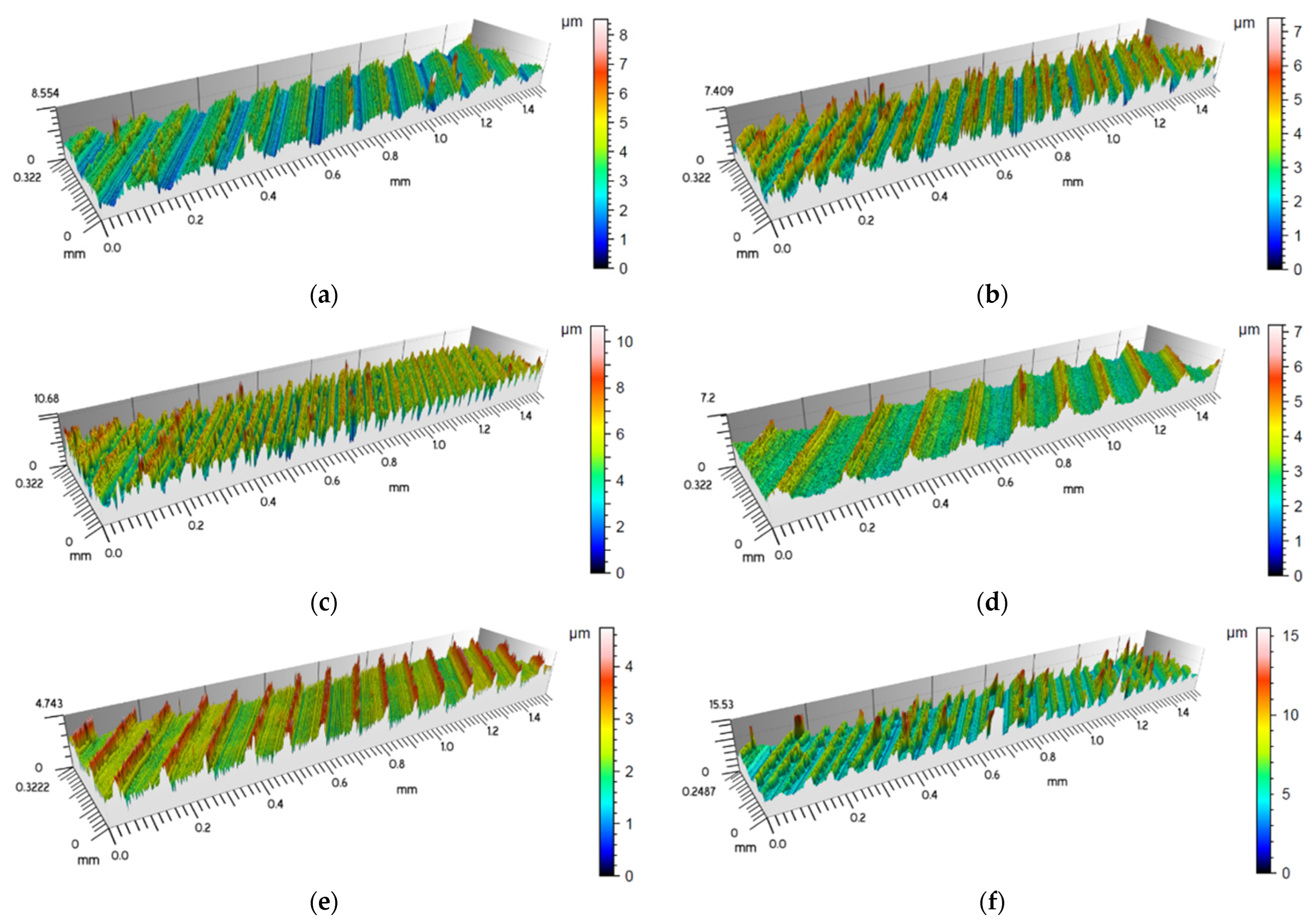

3.1. Images of Machined Surfaces

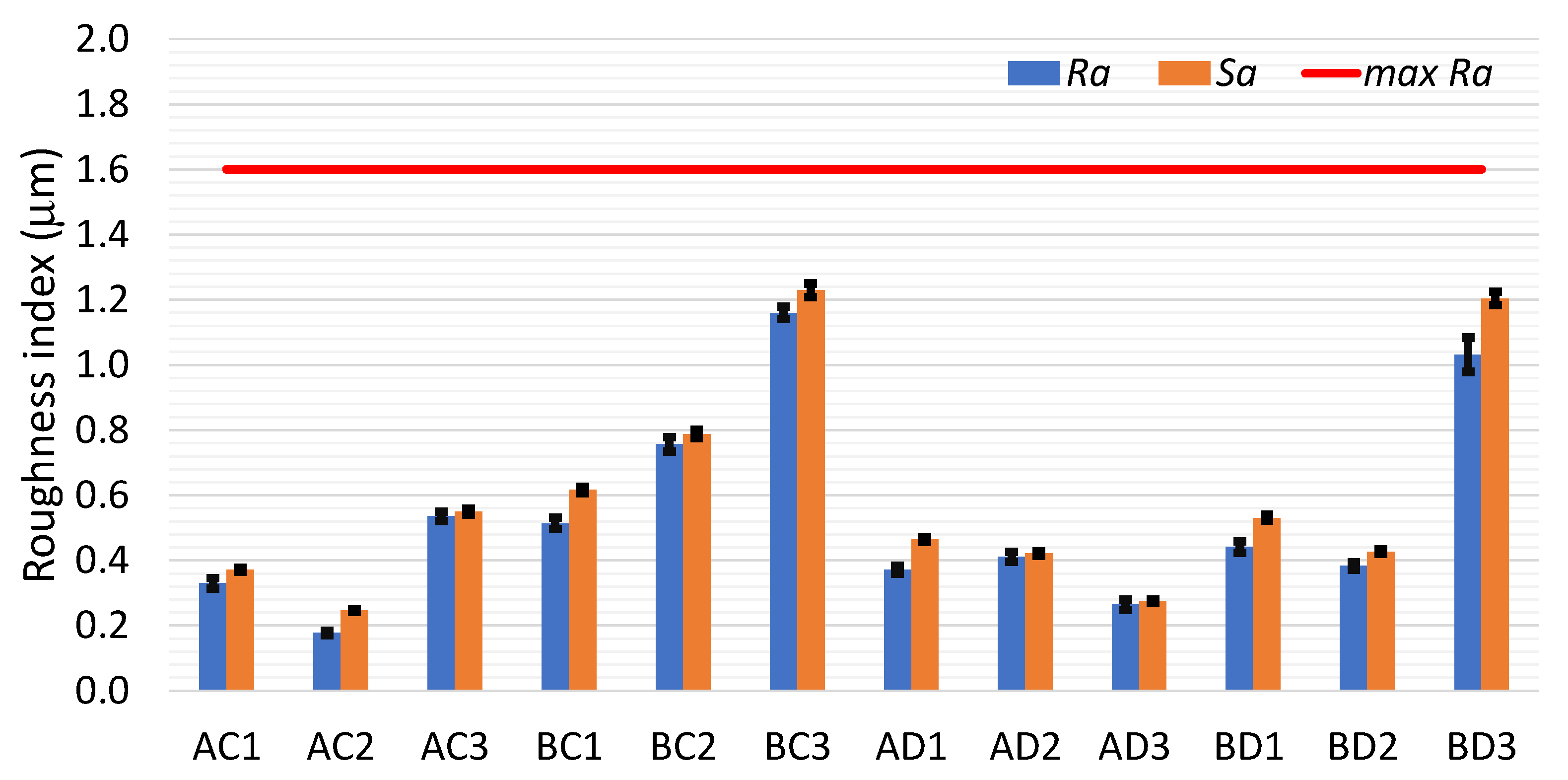

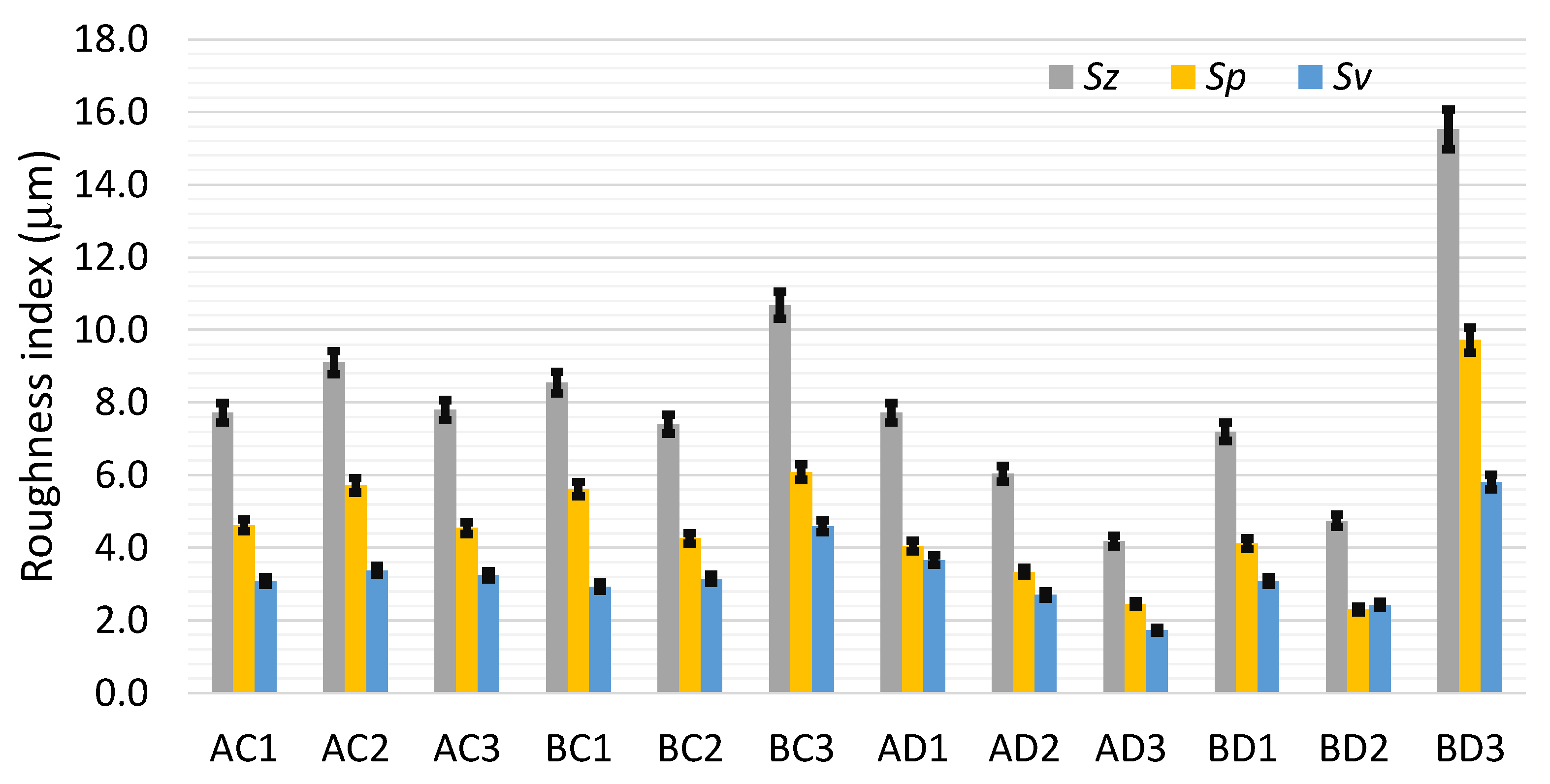

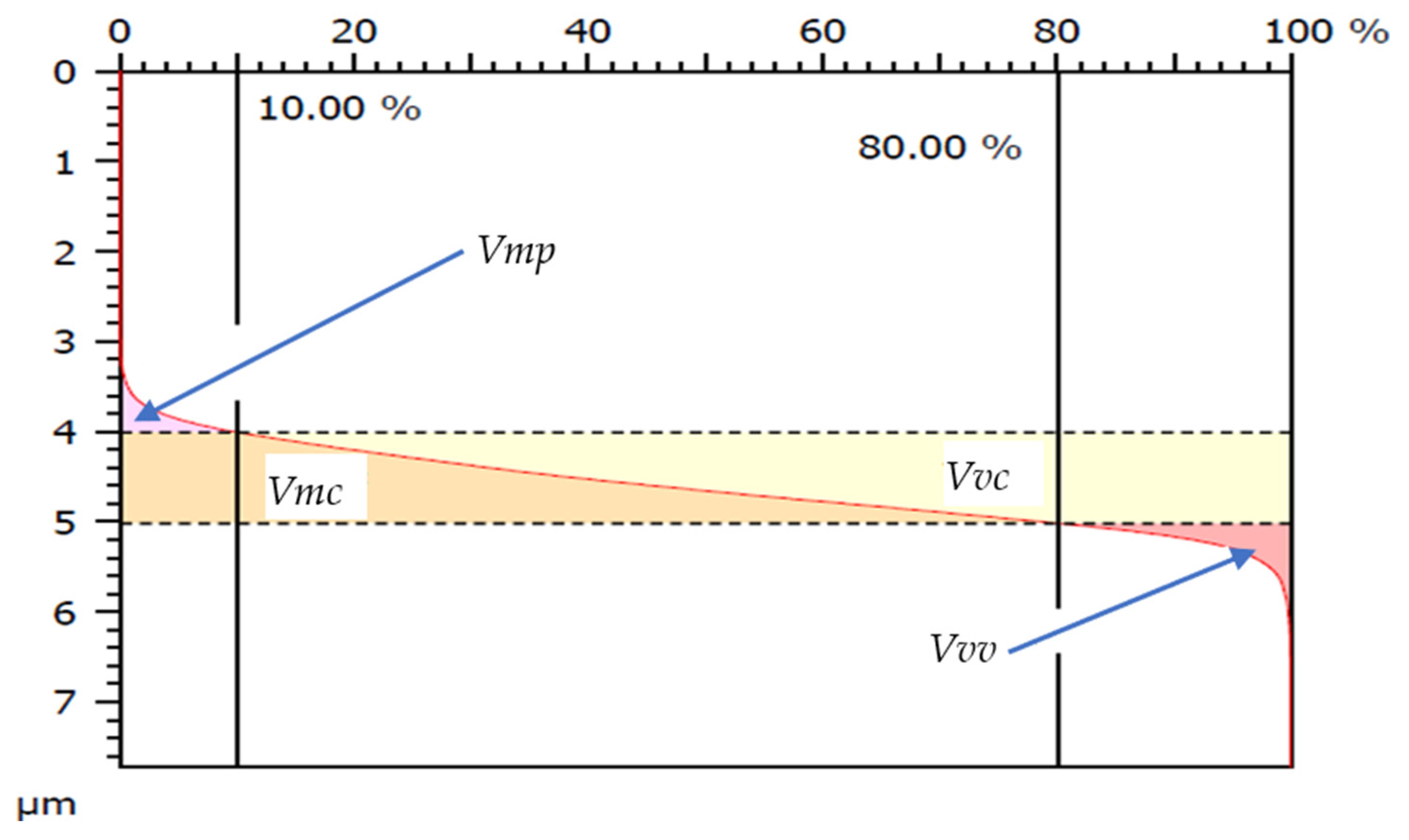

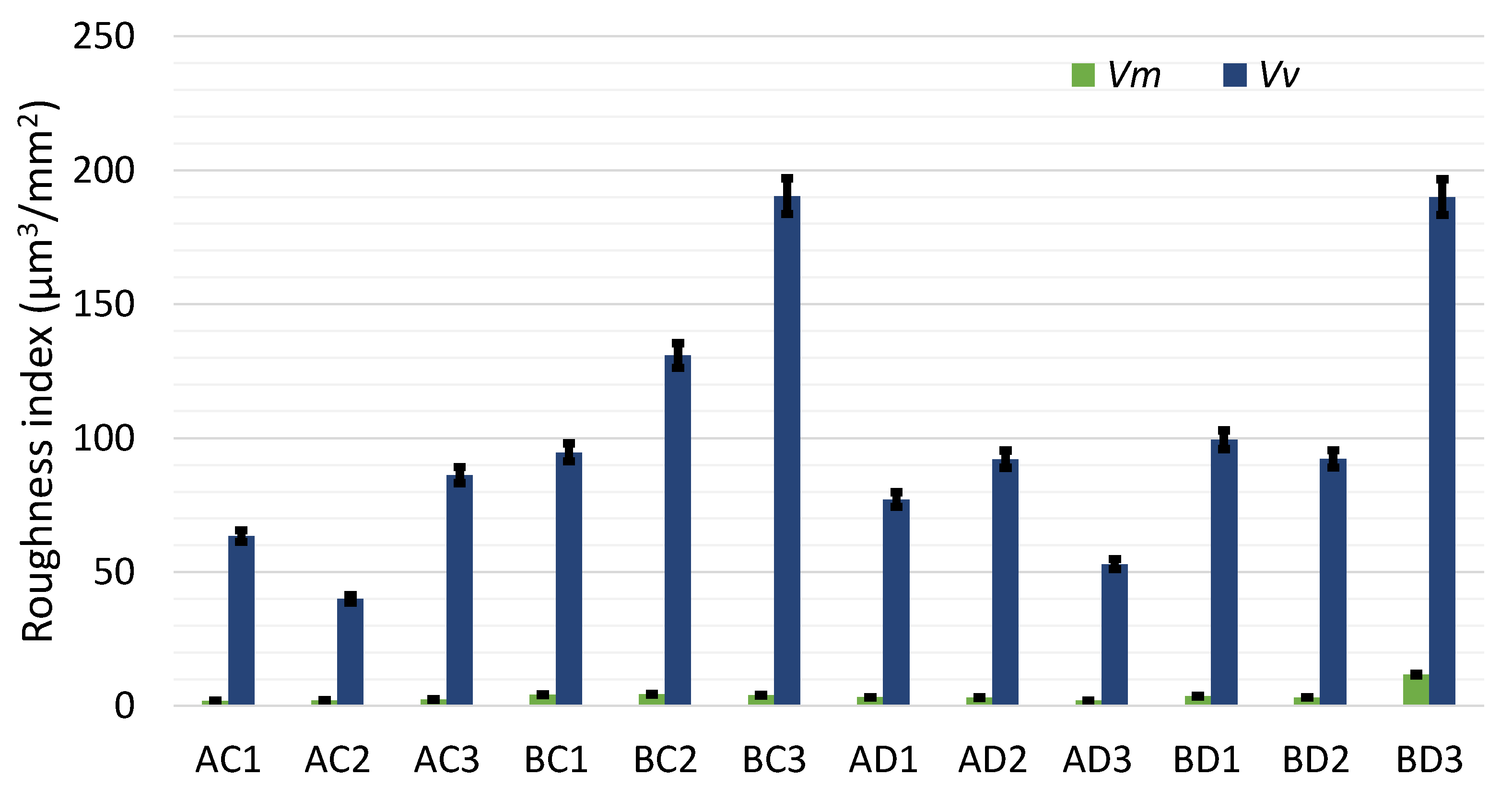

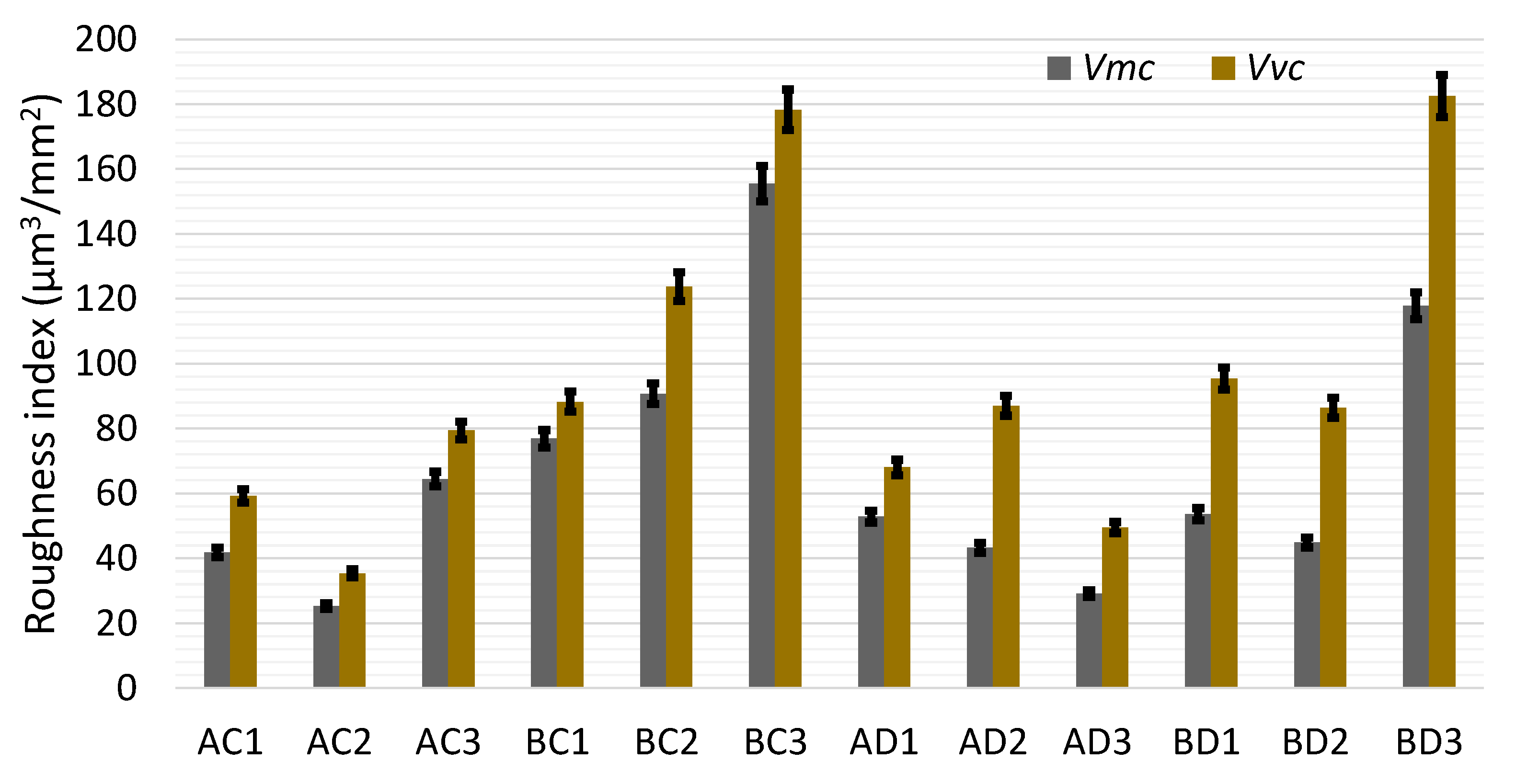

3.2. SGT Measurement Results

4. Discussion

4.1. Evaluation of Images of Machined Surfaces

4.2. Evaluation of SGT Indices

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| HPM | High-performance machining |

| MQL | Minimum quantity lubrication |

| SGT | Surface geometrical texture |

Appendix A. Environmental and Human Impact of Machining

References

- Podgórska, M.; Zdonek, I. Sustainable technologies supported by Project-Based Learning in the education of engineers: A case study from Poland. Energies 2022, 15, 278. [Google Scholar] [CrossRef]

- Krajčo, K.; Habánik, J.; Grenčíková, A. The impact of new technology on sustainable development. Inž. Ekon. Eng. Econ. 2019, 30, 41–49. [Google Scholar] [CrossRef]

- Nozdrzykowski, K.; Grzejda, R. Analysis of the influence of the choice of method parameters and support conditions on the evaluation of the geometric condition of large crankshafts based in roller prisms. Measurement 2025, 256, 118422. [Google Scholar] [CrossRef]

- Vadera, S.; Khan, S. A critical analysis of the rising global demand of plastics and its adverse impact on environmental sustainability. J. Environ. Pollut. Manag. 2021, 3, 105. [Google Scholar] [CrossRef]

- Diakun, J.; Grzejda, R. Product design analysis with regard to recycling and selected mechanical properties. Appl. Sci. 2025, 15, 512. [Google Scholar] [CrossRef]

- Mosiño, A. Producing energy in a stochastic environment: Switching from non-renewable to renewable resources. Resour. Energy Econ. 2012, 34, 413–430. [Google Scholar] [CrossRef]

- Opeyemi, B.M. Path to sustainable energy consumption: The possibility of substituting renewable energy for non-renewable energy. Energy 2021, 228, 120519. [Google Scholar] [CrossRef]

- Wang, S.; Wang, X.; Chen, S. Global value chains and carbon emission reduction in developing countries: Does industrial upgrading matter? Environ. Impact Assess. Rev. 2022, 97, 106895. [Google Scholar] [CrossRef]

- Yadav, D.; Singh, R.; Kumar, A.; Sarkar, B. Reduction of pollution through sustainable and flexible production by controlling by-products. J. Environ. Inform. 2022, 40, 106–124. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, Y.; Peng, J.; Wang, X.; Ding, W.; Lei, X.; Wu, B.; Zhang, M.; Xu, J.; Zhang, L.; et al. Overcoming challenges: Advancements in cutting techniques for high strength-toughness alloys in aero-engines. Int. J. Extrem. Manuf. 2024, 6, 062012. [Google Scholar] [CrossRef]

- Empower Your Aluminium Machining. Available online: https://mapal.com/en-int/sectors-solutions/empower-your-aluminium-machining (accessed on 17 July 2025).

- Davim, J.P.; Maranhão, C.; Jackson, M.J.; Cabral, G.; Grácio, J. FEM analysis in high speed machining of aluminium alloy (Al7075-0) using polycrystalline diamond (PCD) and cemented carbide (K10) cutting tools. Int. J. Adv. Manuf. Technol. 2008, 39, 1093–1100. [Google Scholar] [CrossRef]

- Boing, D.; Martinez, E.N.; Norgren, S.; Hardell, J. Attrition wear in Polycrystalline Diamond cutting tools during interaction with aluminium. Wear 2025, 571, 205781. [Google Scholar] [CrossRef]

- Brzezinka, T.L.; Rao, J.; Chowdhury, M.; Kohlscheen, J.; Fox Rabinovich, G.S.; Veldhuis, S.C.; Endrino, J.L. Hybrid Ti-MoS2 coatings for dry machining of aluminium alloys. Coatings 2017, 7, 149. [Google Scholar] [CrossRef]

- OptiMill®-Tro-Inox and OptiMill®-Uni-HPC-Pocket. Available online: https://mapal.com/en-int/product-innovations-2025/optimill-product-addition (accessed on 17 July 2025).

- Krajewski, S.J.; Grochała, D.; Tomków, J.; Grzejda, R. Analysis of the surface stereometry of alloyed austenitic steel after fibre laser cutting using confocal microscopy. Coatings 2023, 13, 15. [Google Scholar] [CrossRef]

- Diniz, A.E.; de Oliveira, A.J. Optimizing the use of dry cutting in rough turning steel operations. Int. J. Mach. Tools Manuf. 2004, 44, 1061–1067. [Google Scholar] [CrossRef]

- List, G.; Nouari, M.; Géhin, D.; Gomez, S.; Manaud, J.P.; Le Petitcorps, Y.; Girot, F. Wear behaviour of cemented carbide tools in dry machining of aluminium alloy. Wear 2005, 259, 1177–1189. [Google Scholar] [CrossRef]

- Rubaiee, S.; Danish, M.; Gupta, M.K.; Ahmed, A.; Yahya, S.M.; Yildirim, M.B.; Sarikaya, M.; Korkmaz, M.E. Key initiatives to improve the machining characteristics of Inconel-718 alloy: Experimental analysis and optimization. J. Mater. Res. Technol. 2022, 21, 2704–2720. [Google Scholar] [CrossRef]

- Cantero, J.L.; Díaz-Álvarez, J.; Infante-Garcia, D.; Rodríguez, M.; Criado, V. High speed finish turning of Inconel 718 using PCBN tools under dry conditions. Metals 2018, 8, 192. [Google Scholar] [CrossRef]

- Tanabe, I.; Isobe, H. Development of a cutting fluid with abrasive for increasing a tools life during milling. J. Mach. Eng. 2024, 24, 37–49. [Google Scholar] [CrossRef]

- Diniz, A.E.; Micaroni, R. Cutting conditions for finish turning process aiming: The use of dry cutting. Int. J. Mach. Tools Manuf. 2002, 42, 899–904. [Google Scholar] [CrossRef]

- Mabrouki, T.; Girardin, F.; Asad, M.; Rigal, J.-F. Numerical and experimental study of dry cutting for an aeronautic aluminium alloy (A2024-T351). Int. J. Mach. Tools Manuf. 2008, 48, 1187–1197. [Google Scholar] [CrossRef]

- Su, Y.; Li, Z.; Li, L.; Wang, J.; Gao, H.; Wang, G. Cutting performance of micro-textured polycrystalline diamond tool in dry cutting. J. Manuf. Process. 2017, 27, 1–7. [Google Scholar] [CrossRef]

- Sugihara, T.; Singh, P.; Enomoto, T. Development of novel cutting tools with dimple textured surfaces for dry machining of aluminum alloys. Procedia Manuf. 2017, 14, 111–117. [Google Scholar] [CrossRef]

- Jesudass Thomas, S.; Kalaichelvan, K. Comparative study of the effect of surface texturing on cutting tool in dry cutting. Mater. Manuf. Process. 2018, 33, 683–694. [Google Scholar] [CrossRef]

- Ronadson, B.J.; Vijayan, K.; Sanmugam, S.; Badhirappan, G.P. Improving dry machining performance of surface modified cutting tools through combined effect of texture and TiN-WS2 coating. J. Manuf. Process. 2023, 85, 101–108. [Google Scholar]

- Fukui, H.; Okida, J.; Omori, N.; Moriguchi, H.; Tsuda, K. Cutting performance of DLC coated tools in dry machining aluminum alloys. Surf. Coat. Technol. 2004, 187, 70–76. [Google Scholar] [CrossRef]

- Dasch, J.M.; Ang, C.C.; Wong, C.A.; Waldo, R.A.; Chester, D.; Cheng, Y.T.; Powell, B.R.; Weiner, A.M.; Konca, E. The effect of free-machining elements on dry machining of B319 aluminum alloy. J. Mater. Process. Technol. 2009, 209, 4638–4644. [Google Scholar] [CrossRef]

- Pawanr, S.; Gupta, K. Dry machining techniques for sustainability in metal cutting: A review. Processes 2024, 12, 417. [Google Scholar] [CrossRef]

- Hu, W.; Du, P.; Qiu, X.; Zhao, X.; Hu, Z.; Zhang, J.; Liu, Y. Enhanced dry machinability of TC4 titanium alloy by longitudinal- bending hybrid ultrasonic vibration-assisted milling. J. Clean. Prod. 2022, 379, 134866. [Google Scholar] [CrossRef]

- Deswal, N.; Kant, R. Machinability and surface integrity analysis of magnesium AZ31B alloy during laser assisted turning. J. Manuf. Process. 2023, 101, 527–545. [Google Scholar] [CrossRef]

- Pattnaik, S.K.; Bhoi, N.K.; Padhi, S.; Sarangi, S.K. Dry machining of aluminum for proper selection of cutting tool: Tool performance and tool wear. Int. J. Adv. Manuf. Technol. 2018, 98, 55–65. [Google Scholar] [CrossRef]

- Sukonna, R.T.; Zaman, P.B.; Dhar, N.R. Estimation of machining responses in hard turning under dry and HPC conditions using different AI based and statistical techniques. Int. J. Interact. Des. Manuf. 2022, 16, 1705–1725. [Google Scholar] [CrossRef]

- Nouari, M.; List, G.; Girot, F.; Coupard, D. Experimental analysis and optimisation of tool wear in dry machining of aluminium alloys. Wear 2003, 255, 1359–1368. [Google Scholar] [CrossRef]

- Rivero, A.; Aramendi, G.; Herranz, S.; López de Lacalle, L.N. An experimental investigation of the effect of coatings and cutting parameters on the dry drilling performance of aluminium alloys. Int. J. Adv. Manuf. Technol. 2006, 28, 1–11. [Google Scholar] [CrossRef]

- Sugihara, T.; Nishimoto, Y.; Enomoto, T. On-machine tool resharpening for dry machining of aluminum alloys. Procedia CIRP 2014, 24, 68–73. [Google Scholar] [CrossRef]

- Sugihara, T.; Nishimoto, Y.; Enomoto, T. On-machine tool resharpening process for dry machining of aluminum alloys employing LME phenomenon. Precis. Eng. 2015, 40, 241–248. [Google Scholar] [CrossRef]

- Hricova, J.; Kovac, M.; Sugar, P. Experimental investigation of high speed milling of aluminium alloy. Tech. Gaz. 2014, 21, 773–777. [Google Scholar]

- Zaghbani, I.; Songmene, V. A force-temperature model including a constitutive law for Dry High Speed Milling of aluminium alloys. J. Mater. Process. Technol. 2009, 209, 2532–2544. [Google Scholar] [CrossRef]

- Salguero, J.; Batista, M.; Calamaz, M.; Girot, F.; Marcos, M. Cutting forces parametric model for the dry high speed contour milling of aerospace aluminium alloys. Procedia Eng. 2013, 63, 735–742. [Google Scholar] [CrossRef]

- Khettabi, R.; Nouioua, M.; Djebara, A.; Songmene, V. Effect of MQL and dry processes on the particle emission and part quality during milling of aluminum alloys. Int. J. Adv. Manuf. Technol. 2017, 92, 2593–2598. [Google Scholar] [CrossRef]

- Chirita, B.; Tampu, N.C.; Brabie, G.; Radu, M.C. Experimental investigation on the effects of cooling system on surface quality in high speed milling of an aluminium alloy. IOP Conf. Ser. Mater. Sci. Eng. 2016, 145, 022006. [Google Scholar] [CrossRef]

- Zaghbani, I.; Songmene, V.; Khettabi, R. Fine and ultrafine particle characterization and modeling in high-speed milling of 6061-T6 aluminum alloy. J. Mater. Eng. Perform. 2009, 18, 38–48. [Google Scholar] [CrossRef]

- Yoshimura, H.; Moriwaki, T.; Ohmae, N.; Nakai, T.; Shibasaka, T.; Kinoshita, H.; Matsui, M.; Shimizu, M. Study on near dry machining of aluminum alloys. JSME Int. J. Ser. C Mech. Syst. Mach. Elem. Manuf. 2006, 49, 83–89. [Google Scholar] [CrossRef][Green Version]

- Arumugam, P.U.; Malshe, A.P.; Batzer, S.A. Dry machining of aluminum–silicon alloy using polished CVD diamond-coated cutting tools inserts. Surf. Coat. Technol. 2006, 200, 3399–3403. [Google Scholar] [CrossRef]

- Jomaa, W.; Songmene, V.; Bocher, P. Surface finish and residual stresses induced by orthogonal dry machining of AA7075-T651. Materials 2014, 7, 1603–1624. [Google Scholar] [CrossRef] [PubMed]

- Torres, A.; Puertas, I.; Luis, C.J. Surface roughness analysis on the dry turning of an Al-Cu alloy. Procedia Eng. 2015, 132, 537–544. [Google Scholar] [CrossRef]

- Okonkwo, U.C.; Okokpujie, I.P.; Sinebe, J.E.; Ezugwu, C.A.K. Comparative analysis of aluminium surface roughness in end-milling under dry and minimum quantity lubrication (MQL) conditions. Manuf. Rev. 2015, 2, 30. [Google Scholar] [CrossRef]

- Béjar, S.M.; Vilches, F.J.T.; Gamboa, C.B.; Hurtado, L.S. Fatigue behavior parametric analysis of dry machined UNS A97075 aluminum alloy. Metals 2020, 10, 631. [Google Scholar] [CrossRef]

- Korzeniewski, D.; Znojkiewicz, N. Surface texture of the milled surface of aluminum-ceramic composite. J. Mech. Sci. Technol. 2021, 35, 2879–2884. [Google Scholar] [CrossRef]

- Sługocka, M.; Grochała, D.; Kwiatkowski, K.; Grzejda, R.; Zmarzły, P. Study of the impact of surface topography on selected mechanical properties of adhesive joints. Coatings 2024, 14, 944. [Google Scholar] [CrossRef]

- Grochała, D.; Jasiewicz, M.; Filipowicz, K.; Parus, A.; Powałka, B.; Grzejda, R.; Zmarzły, P. Assessment of the functional properties of the surfaces of ductile cast iron parts. Appl. Sci. 2024, 14, 9129. [Google Scholar] [CrossRef]

- Govindarajan, S.; Dasari, B.P.; Jayaram, V. Effect of humidity and temperature on PVD TiAlN-coating wear. Metall. Mater. Trans. A 2025, 56, 387–399. [Google Scholar] [CrossRef]

- QUAKERCOOL® 7101 ALF. Available online: https://optimumoils.com/wp-content/uploads/2016/08/Quakercool-7101-ALF.TDS_-1.pdf (accessed on 23 July 2025).

- PN-EN ISO 25178-1; Geometrical Product Specifications (GPS), Surface Texture: Areal, Part 1: Indication of Surface Texture. Polish Committee for Standardization: Warsaw, Poland, 2016.

- PN-EN ISO 25178-2; Geometrical Product Specifications (GPS), Surface Texture: Areal, Part 2: Terms, Definitions and Surface Texture Parameters. Polish Committee for Standardization: Warsaw, Poland, 2022.

- PN-EN ISO 25178-3; Geometrical Product Specifications (GPS), Surface Texture: Areal, Part 3: Specification Operators. Polish Committee for Standardization: Warsaw, Poland, 2012.

- Macek, W. Correlation between fractal dimension and areal surface parameters for fracture analysis after bending-torsion fatigue. Metals 2021, 11, 1790. [Google Scholar] [CrossRef]

- Grochała, D.; Grzejda, R.; Parus, A.; Berczyński, S. The wavelet transform for feature extraction and surface roughness evaluation after micromachining. Coatings 2024, 14, 210. [Google Scholar] [CrossRef]

- Franco, L.A.; Sinatora, A. 3D surface parameters (ISO 25178-2): Actual meaning of Spk and its relationship to Vmp. Precis. Eng. 2015, 40, 106–111. [Google Scholar] [CrossRef]

- Podulka, P.; Macek, W.; Rozumek, D.; Żak, K.; Branco, R. Topography measurement methods evaluation for entire bending-fatigued fracture surfaces of specimens obtained by explosive welding. Measurement 2024, 224, 113853. [Google Scholar] [CrossRef]

- Ochal, A.; Grochała, D.; Grzejda, R.; Kochmańska, A.E. Investigations on changes in the surface geometrical texture caused by the use of corrosion product removers. Coatings 2025, 15, 539. [Google Scholar] [CrossRef]

- Qutubuddin, S.M.; Hebbal, S.S.; Kumar, A.C.S. A review on effect of industrial noise on the performance of worker and productivity. Int. Rev. Appl. Eng. Res. 2012, 2, 43–54. [Google Scholar]

- Eleftheriou, P.C. Industrial noise and its effects on human hearing. Appl. Acoust. 2002, 63, 35–42. [Google Scholar] [CrossRef]

- Dietmair, A.; Verl, A. Energy Consumption Modeling and Optimization for Production Machines. In Proceedings of the 2008 IEEE International Conference on Sustainable Energy Technologies, Singapore, 24–27 November 2008; pp. 574–579. [Google Scholar]

- Bi, Z.M.; Wang, L. Energy modeling of machine tools for optimization of machine setups. IEEE Trans. Autom. Sci. Eng. 2012, 9, 607–613. [Google Scholar] [CrossRef]

- 5-Axis Machining Centres F 10000–16000. Available online: https://www.heller.biz/en/machines-and-solutions/5-axis-machining-centres-f/10000-16000 (accessed on 16 July 2025).

- Grudzień, J.; Grochała, D.; Grzejda, R.; Kochmański, P. Testing the effectiveness of hybrid milling and surface burnishing in improving the wear resistance of machine parts made of structural steel. Lubricants 2024, 12, 458. [Google Scholar] [CrossRef]

- Grochała, D.; Grzejda, R.; Józwik, J.; Siemiątkowski, Z. Improving the degree of surface isotropy of parts manufactured using hybrid machining processes. Coatings 2025, 15, 461. [Google Scholar] [CrossRef]

- Diaz, N.; Helu, M.; Jarvis, A.; Tönissen, S.; Dornfeld, D.; Schlosser, R. Strategies for Minimum Energy Operation for Precision Machining; Laboratory for Manufacturing and Sustainability, University of California: Berkeley, CA, USA, 2009. [Google Scholar]

- Aspects of Energy Efficiency in Machine Tools. Available online: https://www.heidenhain.us/wp-content/uploads/25-AspectsofEnergyEfficiencyinMT.pdf (accessed on 16 July 2025).

- Alsayyed, B.; Hamdan, M.O.; Aldajah, S. Vortex Tube Impact on Cooling Milling Machining. In Proceedings of the ASME 2012 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 9–15 November 2012; pp. 773–776. [Google Scholar]

- Djebara, A.; Jomaa, W.; Bahloul, A.; Songmene, V. Dust Emission During Dry Machining of Aeronautic Aluminum Alloys. In Proceedings of the 1st International Conference on Aeronautics Sciences (ICAS), Oran, Algeria, 27–28 May 2013. [Google Scholar]

- Celent, L.; Bajić, D.; Jozić, S.; Mladineo, M. Hard milling process based on compressed cold air-cooling using vortex tube for sustainable and smart manufacturing. Machines 2023, 11, 264. [Google Scholar] [CrossRef]

- Stachurski, W.; Sawicki, J.; Krupanek, K.; Nadolny, K. A model and its experiment using compressed cold air to clean the active surface of a grinding wheel during sharping of a hob cutter. Int. J. Adv. Manuf. Technol. 2022, 122, 911–931. [Google Scholar] [CrossRef]

- Swain, S.; Patra, S.K.; Roul, M.K.; Sahoo, L.K. A short review on cooling process using compressed cold air by vortex tube in machining. Mater. Today Proc. 2022, 64, 382–389. [Google Scholar] [CrossRef]

- Maruda, R.W.; Wojciechowski, S.; Szczotkarz, N.; Legutko, S.; Mia, M.; Gupta, M.K.; Nieslony, P.; Krolczyk, G.M. Metrological analysis of surface quality aspects in minimum quantity cooling lubrication. Measurement 2021, 171, 108847. [Google Scholar] [CrossRef]

- Lisowicz, J.; Krupa, K.; Leksycki, L.; Rusinek, R.; Wojciechowski, S. Analysis of tool wear in finish turning of titanium alloy Ti-6Al-4V under minimum quantity lubrication conditions observed with recurrence quantification analysis. Materials 2025, 18, 79. [Google Scholar] [CrossRef]

- Semanová, P.; Kučera, M. Health effects from occupational exposure to metalworking fluid mist. Key Eng. Mater. 2013, 581, 112–118. [Google Scholar]

- The F 8000 High-Performance Machining Centre. Available online: https://www.heller.biz/en/news/the-f-8000-high-performance-machining-centre (accessed on 17 July 2025).

| Component | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Pb | Sn | Ti | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Percentage | 8 ÷ 11 | 0.6 ÷ 1.1 | 2 ÷ 4 | 0.55 | 0.15 ÷ 0.55 | 0.15 | 0.55 | 1.2 | 0.29 | 0.15 | 0.20 | 0.25 |

| Cutting Speed vc (m/min) | 1760 | 1130 | 1760 | 1130 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample | AC1 | AC2 | AC3 | BC1 | BC2 | BC3 | AD1 | AD2 | AD3 | BD1 | BD2 | BD3 |

| Cutter Feed fm (mm/min) | 2000 | 1000 | 500 | 1500 | 1000 | 500 | 2000 | 1000 | 500 | 1500 | 1000 | 500 |

| Feed per Blade fb (mm/blade) | 0.04 | 0.02 | 0.01 | 0.04 | 0.03 | 0.01 | 0.04 | 0.02 | 0.01 | 0.04 | 0.03 | 0.01 |

| Sample | AC1 | AC2 | AC3 | BC1 | BC2 | BC3 | AD1 | AD2 | AD3 | BD1 | BD2 | BD3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ra (μm) | 0.33 | 0.18 | 0.54 | 0.51 | 0.76 | 1.16 | 0.37 | 0.41 | 0.26 | 0.44 | 0.38 | 1.03 |

| Sa (μm) | 0.37 | 0.25 | 0.55 | 0.62 | 0.79 | 1.23 | 0.46 | 0.42 | 0.28 | 0.53 | 0.43 | 1.20 |

| Sz (μm) | 7.72 | 9.10 | 7.80 | 8.55 | 7.41 | 10.7 | 7.72 | 6.05 | 4.19 | 7.20 | 4.74 | 15.5 |

| Sp (μm) | 4.62 | 5.72 | 4.55 | 5.62 | 4.26 | 6.08 | 4.05 | 3.34 | 2.45 | 4.12 | 2.31 | 9.72 |

| Sv (μm) | 3.10 | 3.38 | 3.25 | 2.93 | 3.15 | 4.60 | 3.67 | 2.71 | 1.73 | 3.08 | 2.44 | 5.81 |

| Vm (μm3/mm2) | 2.00 | 2.20 | 2.40 | 4.20 | 4.40 | 4.00 | 3.30 | 3.10 | 2.00 | 3.70 | 3.20 | 11.7 |

| Vv (μm3/mm2) | 63.5 | 40.0 | 86.1 | 94.7 | 131 | 190 | 77.1 | 92.1 | 52.9 | 99.4 | 92.2 | 190 |

| Vmp (μm3/mm2) | 2.00 | 2.20 | 2.40 | 4.20 | 4.40 | 4.00 | 3.30 | 3.10 | 2.00 | 3.70 | 3.20 | 11.7 |

| Vmc (μm3/mm2) | 41.8 | 25.3 | 64.4 | 76.9 | 90.7 | 156 | 52.8 | 43.3 | 29.1 | 53.6 | 44.9 | 118 |

| Vvc (μm3/mm2) | 59.2 | 35.4 | 79.4 | 88.3 | 124 | 178 | 68.0 | 87.0 | 49.5 | 95.4 | 86.5 | 183 |

| Vvv (μm3/mm2) | 4.2 | 4.7 | 6.7 | 6.4 | 7.0 | 12 | 9.1 | 5.1 | 3.5 | 4.0 | 5.7 | 7.3 |

| Index | vc = 1760 m/min | vc = 1130 m/min | ||||

|---|---|---|---|---|---|---|

| fm (mm/min) | fm (mm/min) | |||||

| 2000 | 1000 | 500 | 1500 | 1000 | 500 | |

| KRa | −0.11 | −0.57 | 1.02 | 0.16 | 0.97 | 0.12 |

| KSa | −0.20 | −0.42 | 0.99 | 0.16 | 0.85 | 0.02 |

| KSz | 0.00 | 0.50 | 0.86 | 0.19 | 0.56 | −0.31 |

| KSp | 0.14 | 0.71 | 0.85 | 0.37 | 0.85 | −0.37 |

| KSv | −0.16 | 0.25 | 0.88 | −0.05 | 0.29 | −0.21 |

| KVv | −0.18 | −0.57 | 0.63 | −0.05 | 0.42 | 0.00 |

| KVmp | −0.40 | −0.30 | 0.19 | 0.16 | 0.38 | −0.66 |

| KVmc | −0.21 | −0.42 | 1.21 | 0.43 | 1.02 | 0.32 |

| KVvc | −0.13 | −0.59 | 0.60 | −0.07 | 0.43 | −0.02 |

| KVvv | −0.53 | −0.09 | 0.95 | 0.61 | 0.23 | 0.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zgrzeblak, S.; Grochała, D.; Grzejda, R. On the Possibility of Improving Surface Geometrical Texture During High-Performance Machining of Aluminium Without the Use of Coolant. Coatings 2025, 15, 971. https://doi.org/10.3390/coatings15080971

Zgrzeblak S, Grochała D, Grzejda R. On the Possibility of Improving Surface Geometrical Texture During High-Performance Machining of Aluminium Without the Use of Coolant. Coatings. 2025; 15(8):971. https://doi.org/10.3390/coatings15080971

Chicago/Turabian StyleZgrzeblak, Szymon, Daniel Grochała, and Rafał Grzejda. 2025. "On the Possibility of Improving Surface Geometrical Texture During High-Performance Machining of Aluminium Without the Use of Coolant" Coatings 15, no. 8: 971. https://doi.org/10.3390/coatings15080971

APA StyleZgrzeblak, S., Grochała, D., & Grzejda, R. (2025). On the Possibility of Improving Surface Geometrical Texture During High-Performance Machining of Aluminium Without the Use of Coolant. Coatings, 15(8), 971. https://doi.org/10.3390/coatings15080971