Structural Design and Mechanical Properties Analysis of Laminated SiAlON Ceramic Tool Materials

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Generation of Residual Stress

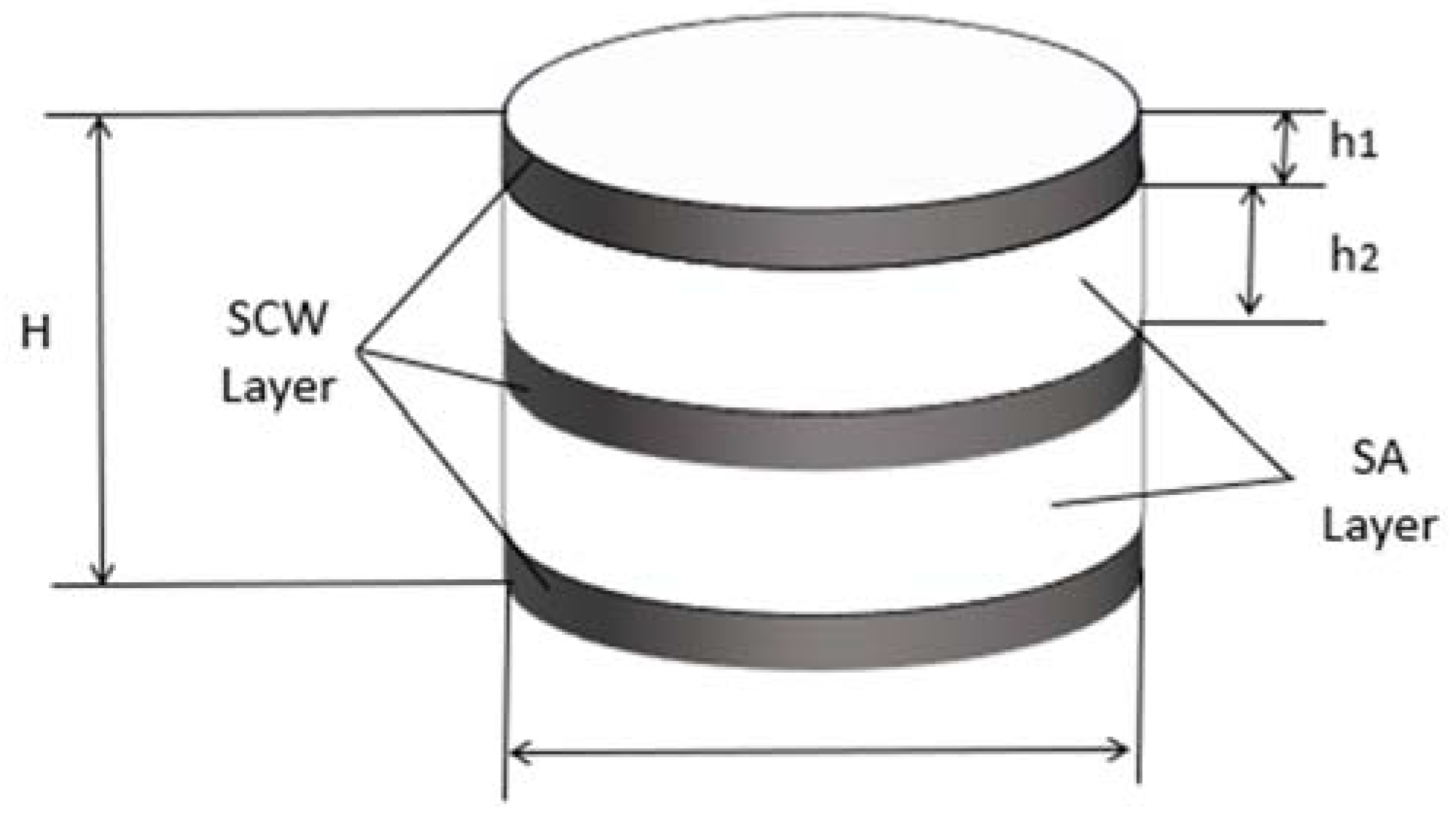

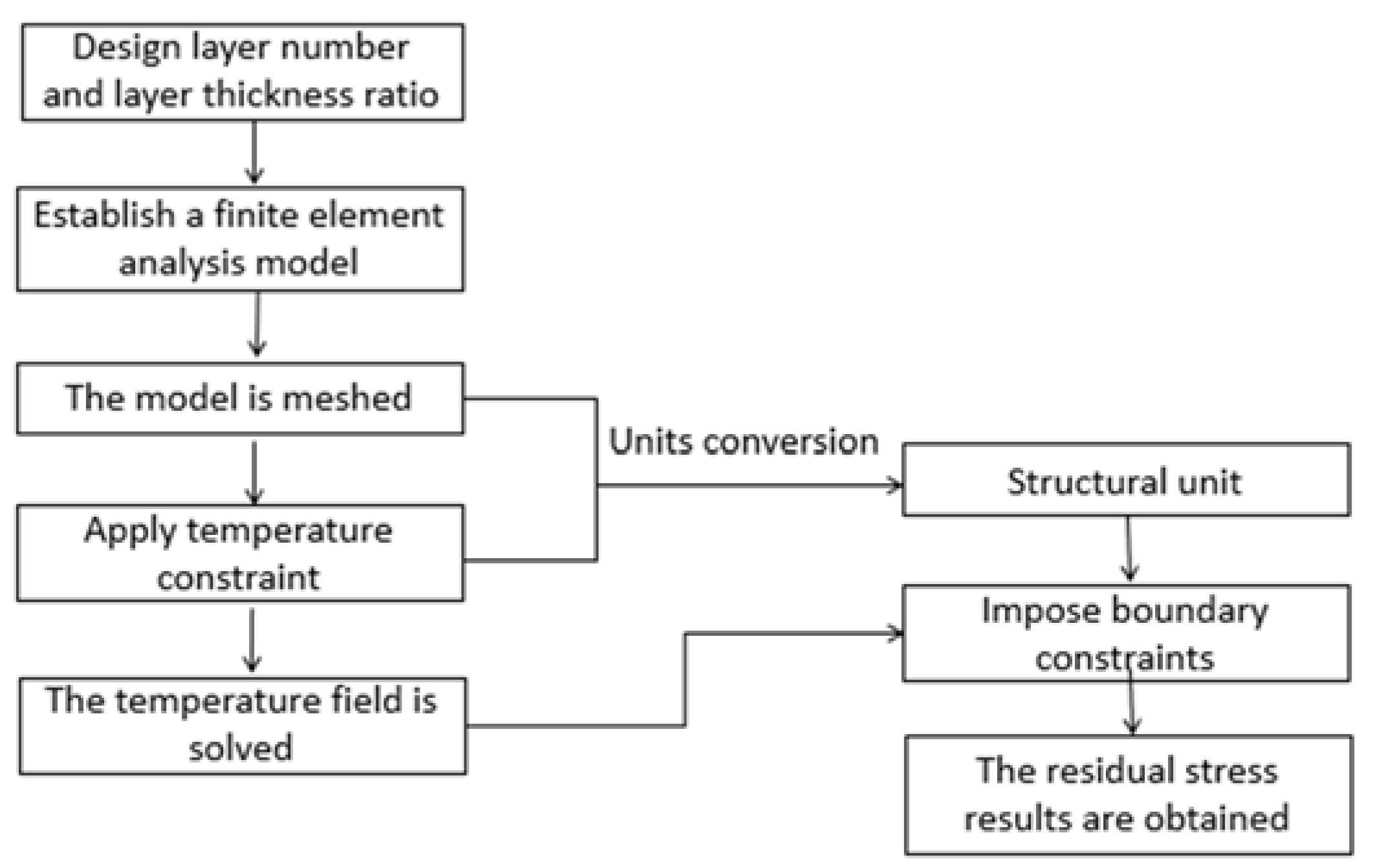

2.2. Finite Element Model

2.3. Experimental Procedure

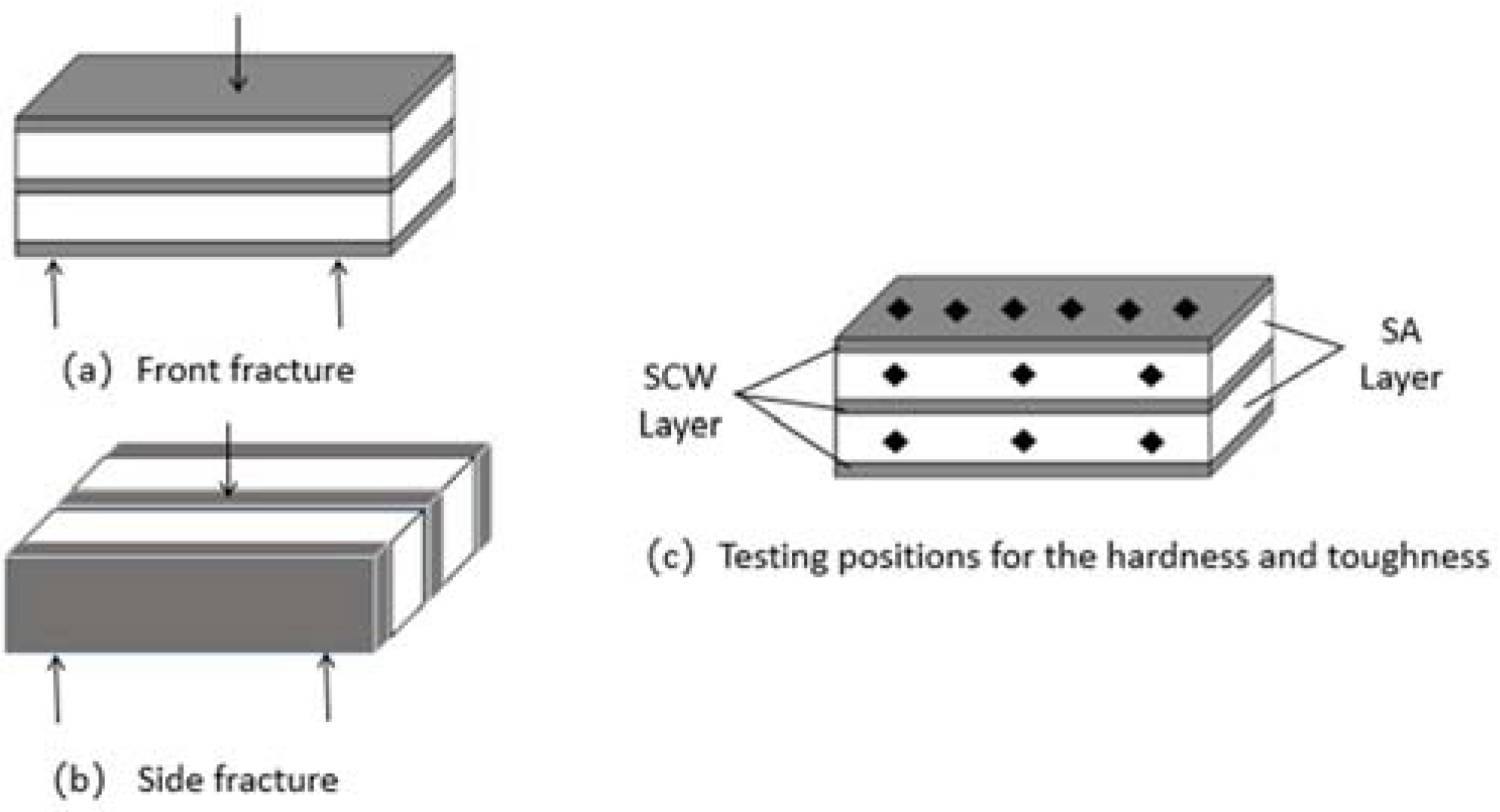

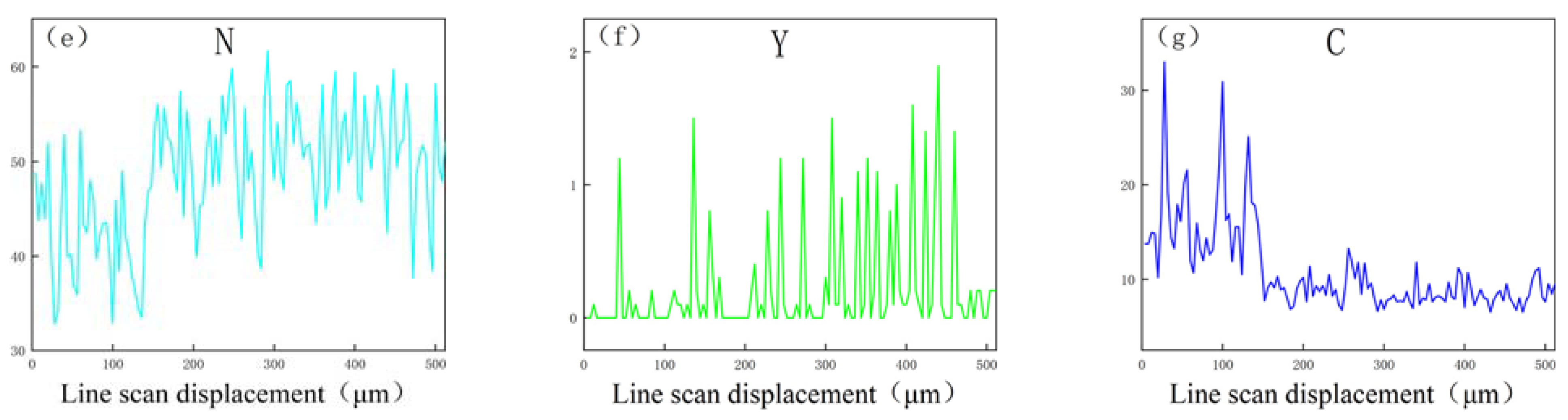

2.4. Characterization

3. Results and Discussion

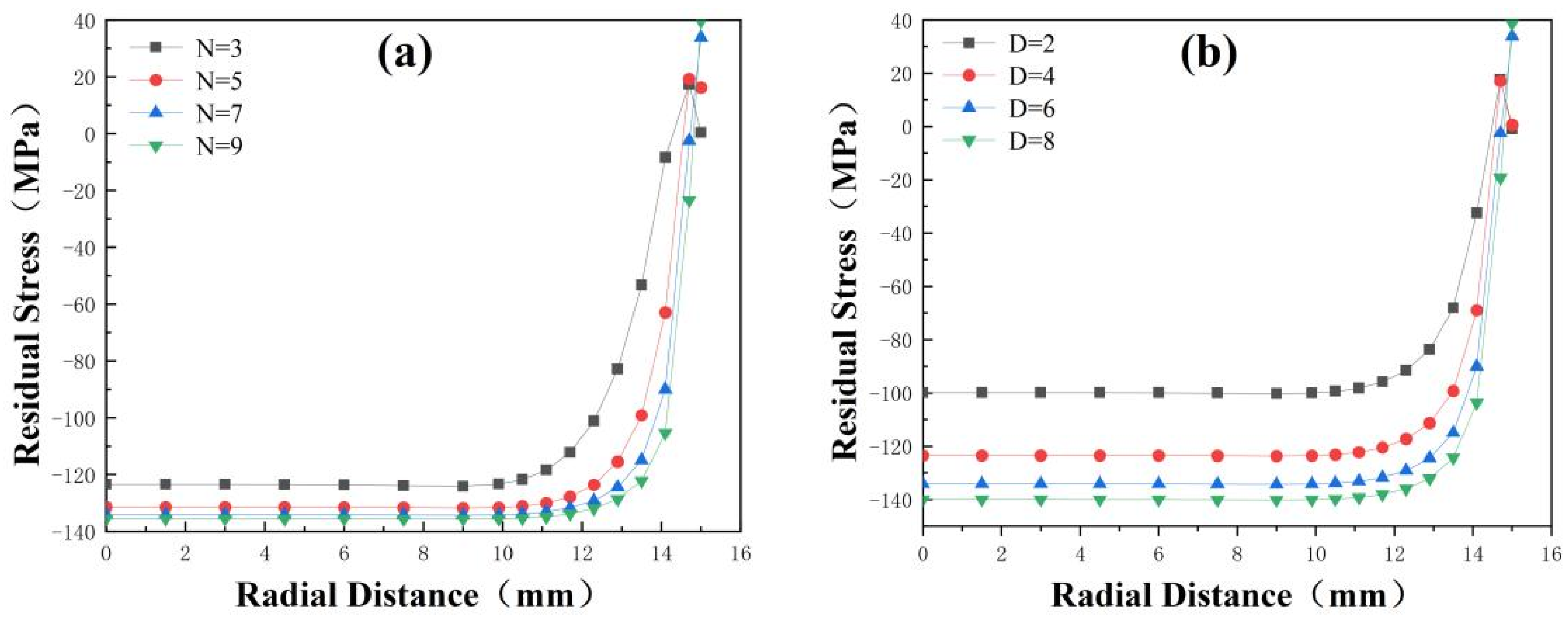

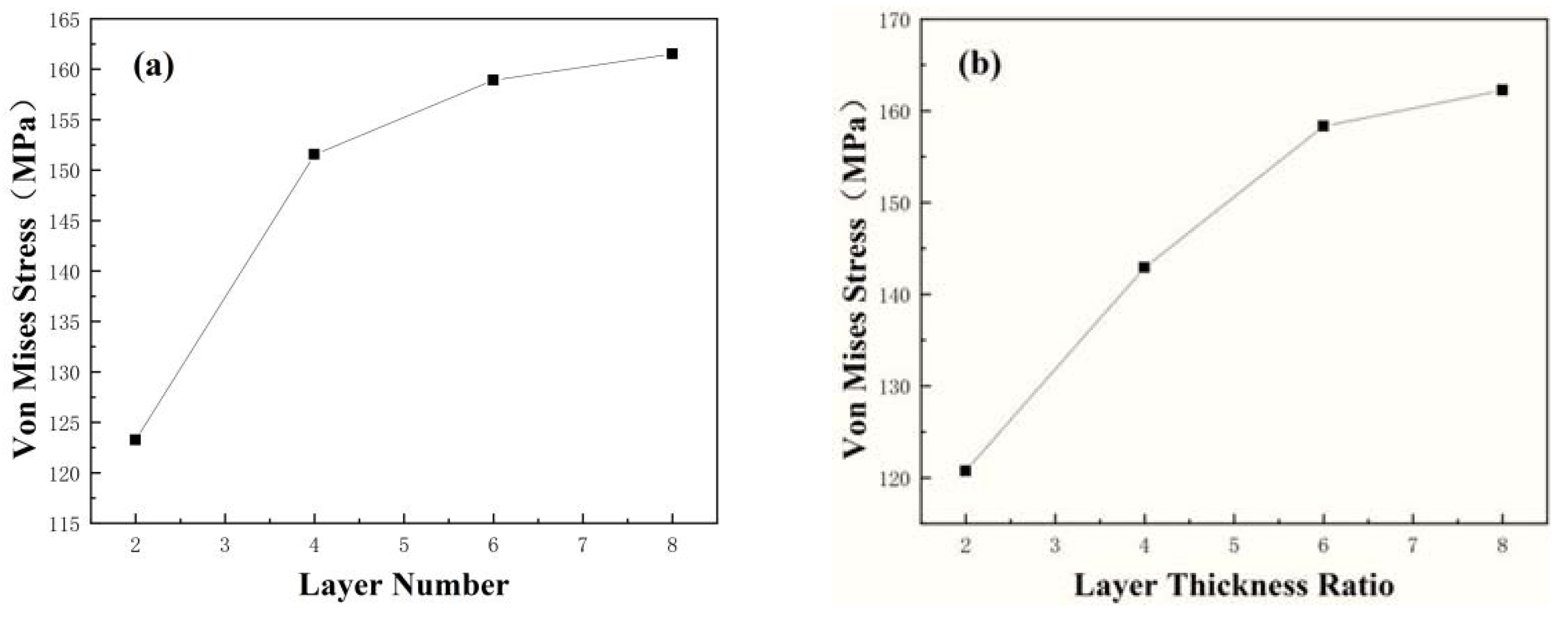

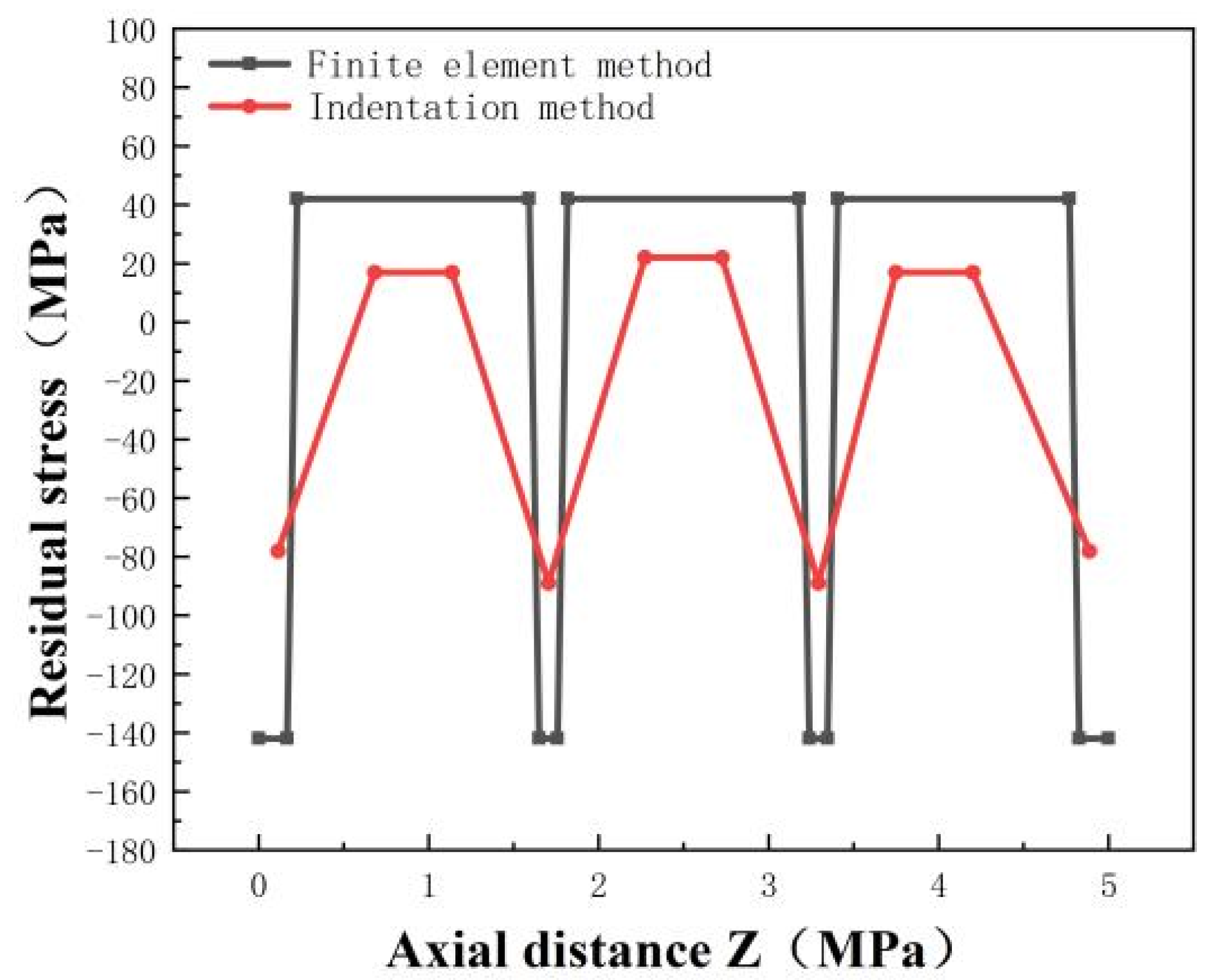

3.1. Finite Element Simulation Analysis

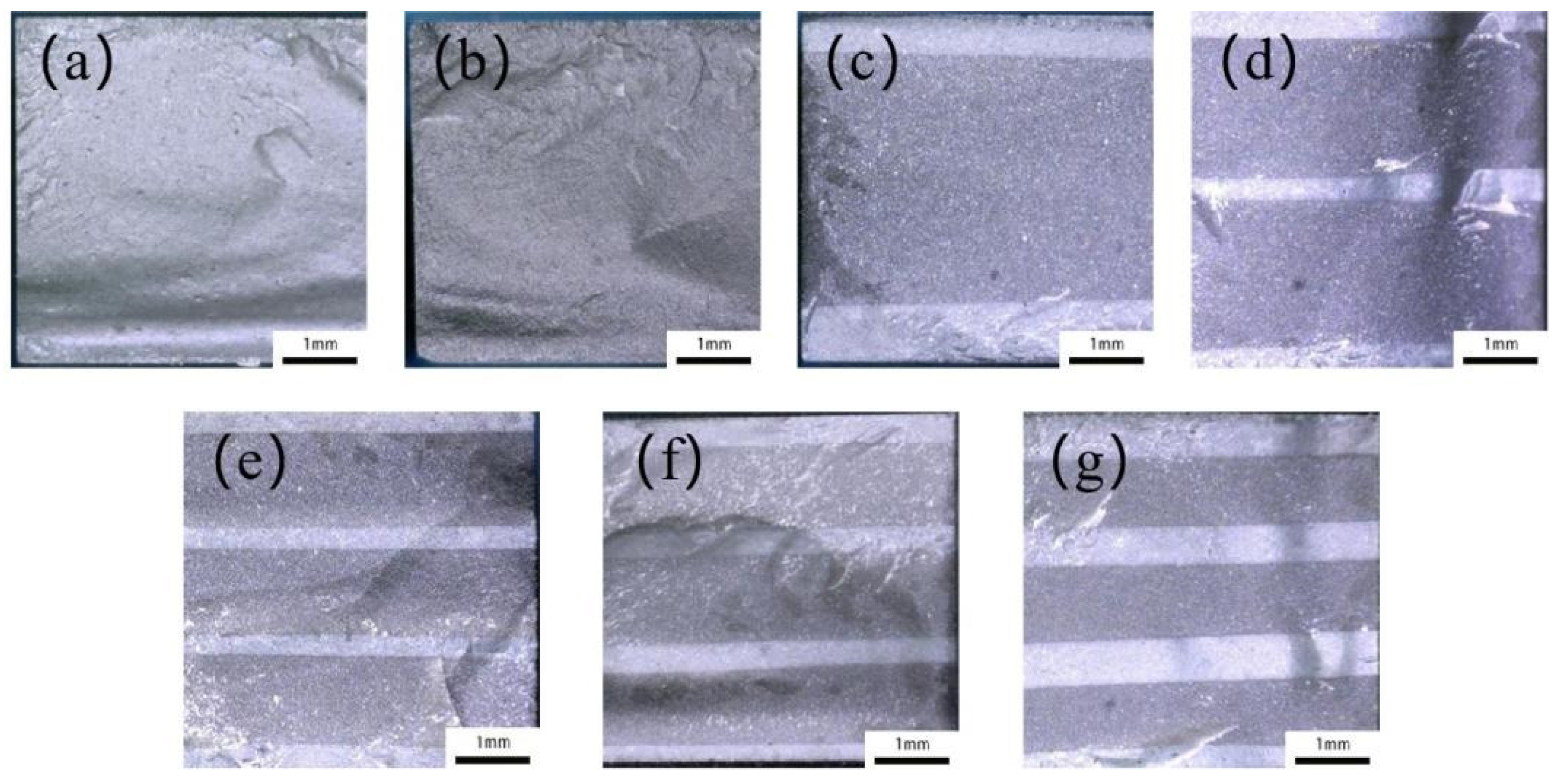

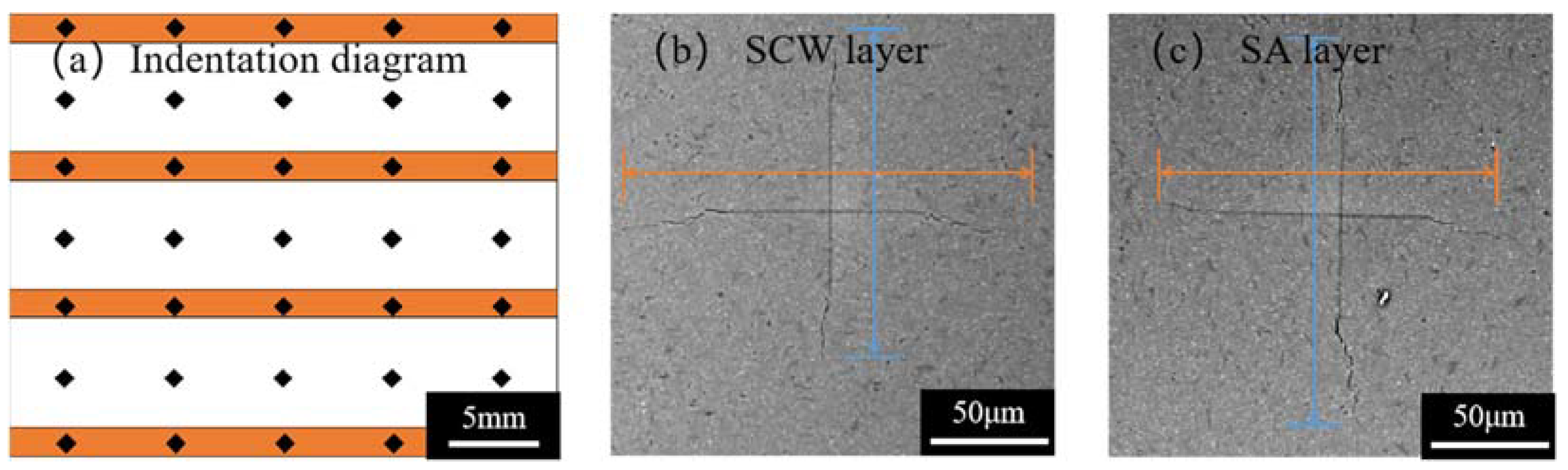

3.2. Mechanical Properties and Microstructure

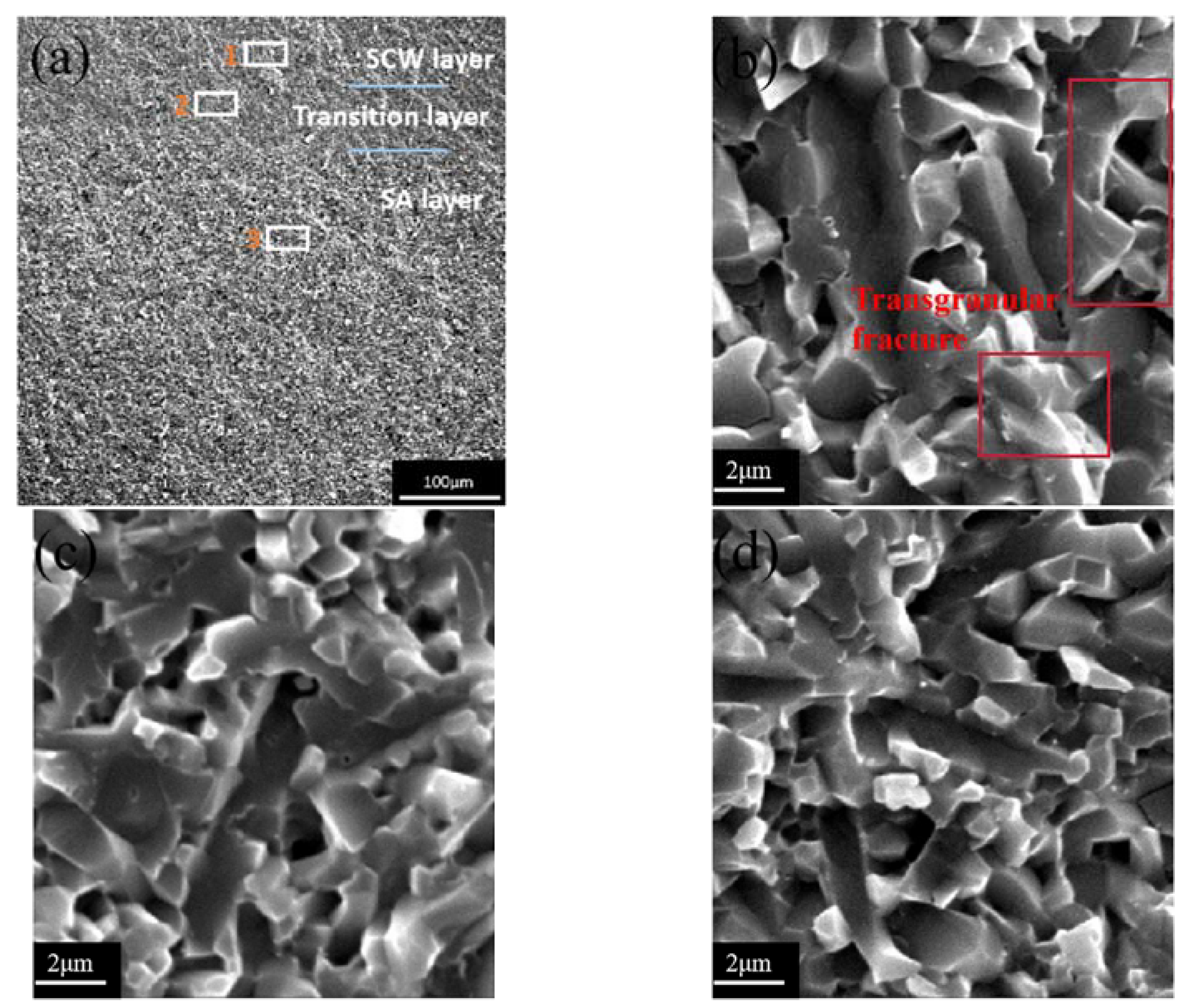

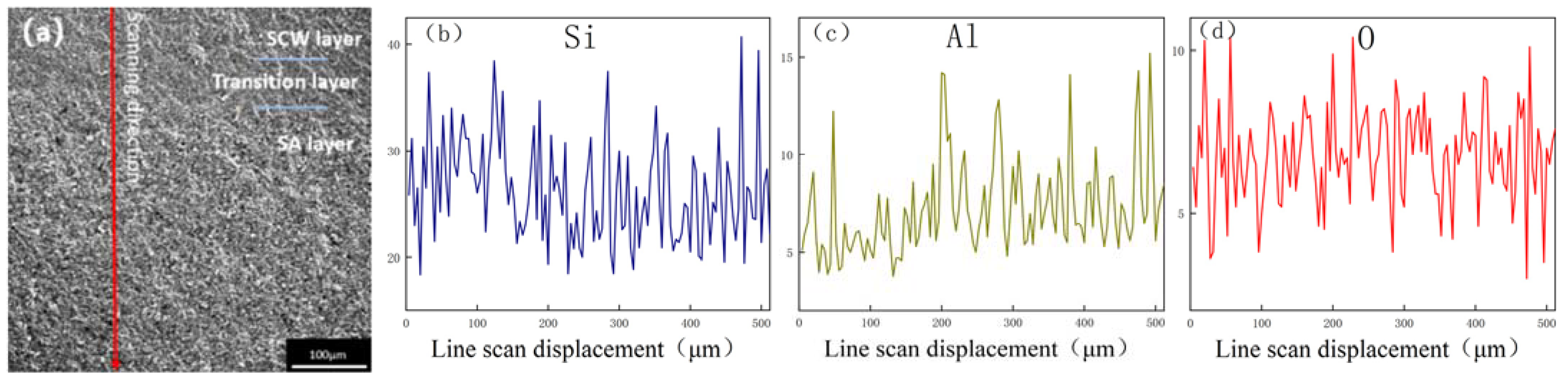

3.3. Toughening Mechanism

4. Conclusions

- ANSYS simulation was used to analyze the distribution of residual stresses in SCWA ceramic tool materials as they were lowered from 1700 °C to 25 °C. The results showed that residual compressive stresses were generated in the surface layer of the material, and residual tensile stresses were generated in the matrix layer. With an increase in the number of layers and layer thickness ratio, the residual compressive stress on the surface layer also increases gradually.

- SCWA ceramic cutting tool materials with different layer structures were experimentally prepared and the actual residual stresses in the surface and matrix layers of SCWA4 were calculated using the indentation method. The actual residual stresses are in general agreement with the ANSYS simulation analysis. This indicates that the simulation can provide guidance for actual experiments.

- Laminated SiAlON ceramic tool materials obtained better comprehensive mechanical properties. The Vickers hardness and fracture toughness of the SCW layer in the SCWA4 ceramic cutting tool material were 19.4 ± 0.2 GPa and 6.02 ± 0.19 MPa·m1/2, respectively. The frontal and side flexural strengths were 602 ± 19 MPa and 595 ± 17 MPa, respectively.

- The change rule of the mechanical properties of the laminated SiAlON ceramic cutting tool material was consistent with the change rule of the maximum residual compressive stress in the surface layer. This indicates that finite element analysis can provide a theoretical and technical basis for the application and research of laminated structures in composite ceramic cutting tools. Due to technical constraints, this paper prepares a limited variety of laminated structures. In the future, more complex laminated structures can be designed to research their properties and perform cutting experiments.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Oketola, A.; Jamiru, T.; Adegbola, A.T.; Ogunbiyi, O.; Rominiyi, A.L.; Smith, S. Spark plasma sintering of ceramic-reinforced binary/ternary nickel and titanium metal matrix composites: Mechanical properties, microstructure, and densification—A review. J. Alloys Metall. Syst. 2023, 3, 100031. [Google Scholar] [CrossRef]

- Gao, J.; Song, J.; Wang, Y.; Wang, Z.; Song, J.; Zhao, X. Microstructures and mechanical properties of functionally graded TiCN–TaC ceramics prepared by a novel layer processing strategy. Ceram. Int. 2022, 48, 16990–16996. [Google Scholar] [CrossRef]

- Tian, X.; Yan, K.; Zhao, J.; Cheng, Y.; Wang, Z. Thermal and mechanical shock resistances of Si3N4/(W, Ti)C graded nano-composite ceramic tool material. Ceram. Int. 2020, 46, 2317–2324. [Google Scholar] [CrossRef]

- Sang, G.; Zhang, Q.; Zhao, S.; Zhao, Y.; Yang, M.; Xi, X.; Yang, J. Strong and tough laminated ceramics prepared from ceramic foams. J. Eur. Ceram. Soc. 2023, 43, 2578–2585. [Google Scholar] [CrossRef]

- Hadraba, H.; Chlup, Z.; Drdlík, D.; Šiška, F. Characterisation of mechanical and fracture behaviour of Al2O3/ZrO2/BaTiO3 laminate by indentation. J. Eur. Ceram. Soc. 2020, 40, 4799–4807. [Google Scholar] [CrossRef]

- Li, S.; Wei, C.; Wang, W.; Wang, P.; Liu, Y.; Li, S.; Wen, G. Fracture toughness and R-curve behavior of laminated ZrB2–SiC/SiCw ceramic. J. Alloys Compd. 2019, 784, 96–101. [Google Scholar] [CrossRef]

- Liu, C.; Sun, J.; Li, G.; Li, B.; Gong, F. Fabrication, mechanical properties and fracture behaviors of the laminated Al2O3–ZrB2–MgO/Al2O3–TiN–MgO ceramic composite. Ceram. Int. 2020, 46, 857–865. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, C.; Zhang, Y.; Liang, Z. Fractural process and toughening mechanism of laminated ceramic composites. Acta Mech. Solida Sin. 2007, 20, 141–148. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, X.; Hu, P.; Han, W.; Tian, G. The fabrication and mechanical properties of bionic laminated ZrB2–SiC/BN ceramic prepared by tape casting and hot pressing. Scr. Mater. 2011, 65, 791–794. [Google Scholar] [CrossRef]

- Cui, Y.; Chen, B.; Xiao, G.; Yi, M.; Zhang, J.; Chen, H.; Zhou, T.; Chen, Z.; Wu, J.; Xu, C. Mechanical properties and cutting performance of laminated graphene composite ceramic tools. J. Manuf. Process 2022, 81, 717–726. [Google Scholar] [CrossRef]

- Chen, B.; Xiao, G.; Yi, M.; Zhang, J.; Chen, H.; Zhou, T.; Chen, Z.; Xu, C. Structural design and toughening mechanism of laminated graphene ceramic tool materials. Ceram. Int. 2021, 47, 32264–32275. [Google Scholar] [CrossRef]

- Bitterlich, B.; Bitsch, S.; Friederich, K. SiAlON based ceramic cutting tools. J. Eur. Ceram. Soc. 2008, 28, 989–994. [Google Scholar] [CrossRef]

- Liu, X.; Liu, H.; Huang, C.; Zhao, B.; Zheng, L. High temperature mechanical properties of Al2O3-based ceramic tool material toughened by SiC whiskers and nanoparticles. Ceram. Int. 2017, 43, 1160–1165. [Google Scholar]

- Sun, J.; Zhao, J.; Chen, Y.; Wang, L.; Yun, X.; Huang, Z. Macro-micro-nano multistage toughening in nano-laminated graphene ceramic composites. Mater. Today Phys. 2022, 22, 100595. [Google Scholar] [CrossRef]

- Farhadi, K.; Sabahi Namini, A.; Asl, M.S.; Mohammadzadeh, A.; Kakroudi, M.G. Characterization of hot pressed SiC whisker reinforced TiB2 based composites. Int. J. Refract. Met. Hard Mater. 2016, 61, 84–90. [Google Scholar] [CrossRef]

- Namini, A.S.; Gogani, S.N.S.; Asl, M.S.; Farhadi, K.; Kakroudi, M.G.; Mohammadzadeh, A. Microstructural development and mechanical properties of hot pressed SiC reinforced TiB2 based composite. Int. J. Refract. Met. Hard Mater. 2015, 51, 169–179. [Google Scholar] [CrossRef]

- Dong, Y.; Xu, F.; Shi, X.; Zhang, C.; Zhang, Z.; Yang, J.; Tan, Y. Fabrication and mechanical properties of nano-/micro-sized Al2O3/SiC composites. Mater. Sci. Eng.: A 2009, 504, 49–54. [Google Scholar] [CrossRef]

- Khan, R.M.A.; Ahmed, B.A.; Al Malki, M.M.; Hakeem, A.S.; Laoui, T. Synthesis of hard and tough calcium stabilized α-SiAlON/SiC ceramic composites using nano-sized precursors and spark plasma sintering. J. Alloys Compd. 2018, 757, 200–208. [Google Scholar] [CrossRef]

- Son, Y.; Chung, H.B.; Lee, S. A two-dimensional Monte Carlo model for pore densification in a bi-crystal via grain boundary diffusion: Effect of diffusion rate, initial pore distance, temperature, boundary energy and number of pores. J. Eur. Ceram. Soc. 2020, 40, 3158–3171. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Z.; Yang, G.; Zhou, A.; Wang, G.; Qin, S.; Wang, A.; Wang, W.; Zhang, X. Finite element analysis and wear mechanism of B4C–TiB2 ceramic tools in turning AISI 4340 workpieces. Ceram. Int. 2022, 48, 5459–5467. [Google Scholar] [CrossRef]

- Low, I.M. (Ed.) 1—Advances in ceramic matrix composites: Introduction. In Advances in Ceramic Matrix Composites; Woodhead Publishing: Sawston, UK, 2018; pp. 1–7. [Google Scholar]

- Wang, Y.; Wang, H.; Wei, J.; Lin, B.; Xu, J.; Fang, S. Finite element analysis of grinding process of long fiber reinforced ceramic matrix woven composites: Modeling, experimental verification and material removal mechanism. Ceram. Int. 2019, 45, 15920–15927. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, L.; Gao, K.; Yang, H.; Wang, Y. Finite element analysis of the effect of TiC or graphite modified composite fillers on the thermal residual stress of AMB ceramic substrates. Ceram. Int. 2019, 45, 19098–19104. [Google Scholar] [CrossRef]

- Gao, J.; Song, J.; Ping, P.; Meng, W. Effect of sintering temperature on residual stress, microstructure and mechanical properties of TiC–HfN/TiC–TiN laminated ceramic. Ceram. Int. 2023, 49, 38432–38438. [Google Scholar]

- Burlachenko, A.G.; Mirovoi, Y.A.; Dedova, E.S.; Buyakova, S.P. Mechanical Response of ZrB2–SiC–ZrO2 Composite Laminate. Russ. Phys. J. 2019, 62, 1438–1444. [Google Scholar] [CrossRef]

- Doitrand, A.; Estevez, R.; Leguillon, D. Comparison between cohesive zone and coupled criterion modeling of crack initiation in rhombus hole specimens under quasi-static compression. Theor. Appl. Fract. Mech. 2019, 99, 51–59. [Google Scholar] [CrossRef]

- dos Reis Araújo, M.; Hotza, D.; Janssen, R.; Acchar, W. Processing and properties of tape-cast alumina/zirconia laminates composites. J. Eur. Ceram. Soc. 2019, 39, 3462–3465. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, H.; Qin, B.; Zhao, Z. Design, fabrication and properties of TiB2/TiN/WC gradient ceramic tool materials. Ceram. Int. 2020, 46, 6497–6506. [Google Scholar] [CrossRef]

- Ji, W.; Zou, B.; Huang, C.; Liu, Y.; Huang, C. Fabrication, microstructure and mechanical properties of self-diffusion gradient cermet composite tool materials. Mater. Sci. Eng.: A 2017, 685, 332–341. [Google Scholar] [CrossRef]

- Hu, S.; Song, J.; Gao, J.; Liu, J.; Meng, W.; Wang, Y. Effect of layer thickness ratio on microstructure and mechanical properties of TiCN–HfN/TiCN–WC laminated ceramics. Ceram. Int. 2023, 49, 20763–20771. [Google Scholar] [CrossRef]

| Powder | Purity (%) | Average Particle Size (μm) | Supplier |

|---|---|---|---|

| Si3N4 | 99.9 | 0.5 | Shanghai CW-Nano Science & Technology Co., Ltd., Shanghai, China |

| Al2O3 | 99.9 | 0.2 | |

| AlN | 99.9 | 0.5 | |

| Y2O3 | 99.9 | 0.5 | |

| SiC | 99.9 | 0.5 | |

| SiCw | 99.9 | D0.5, L10 |

| Materials | Composition (wt%) | ||||||

|---|---|---|---|---|---|---|---|

| Si3N4 | Al2O3 | AlN | Y2O3 | SiC | SiCw | ||

| SCW | SiAlON/SiC/SiCw | 50.99 | 1.79 | 11.62 | 6.6 | 20 | 9 |

| SA | SiAlON/Al2O3 | 66.09 | 10.33 | 14.99 | 8.59 | 0 | 0 |

| Materials | Thermal Expansion Coefficient ) | Elastic Modulus (GPa) | Poisson’s ) | Thermal (W·m−1·K−1) |

|---|---|---|---|---|

| Si3N4 | 2.75 | 372 | 0.24 | 20 |

| Al2O3 | 8.5 | 380 | 0.26 | 40.37 |

| AlN | 4.5 | 320 | 0.26 | 20 |

| Y2O3 | 5.8 | 220 | 0.28 | 27 |

| SiC | 4.5 | 440 | 0.14 | 44 |

| SiCw | 4.35 | 440 | 0.17 | 45 |

| Materials | Thermal Expansion Coefficient ) | Elastic Modulus (GPa) | Poisson’s ) | Thermal (W·m−1·K−1) |

|---|---|---|---|---|

| SCW | 3.57 | 375 | 0.22 | 26.15 |

| SA | 3.67 | 355 | 0.25 | 21.96 |

| Materials | Laminated Structures | SA/SCW Thickness Ratio (D) | Number of Layer (n) |

|---|---|---|---|

| SCWA1 | SCW + SA + SCW + SA + SCW + SA + SCW | 8 | 7 |

| SCWA2 | SCW + SA + SCW | 6 | 3 |

| SCWA3 | SCW + SA + SCW + SA + SCW | 6 | 5 |

| SCWA4 | SCW + SA + SCW + SA + SCW + SA + SCW | 6 | 7 |

| SCWA5 | SCW + SA + SCW + SA + SCW + SA + SCW + SA + SCW | 6 | 9 |

| SCWA6 | SCW + SA + SCW + SA + SCW + SA + SCW | 4 | 7 |

| SCWA7 | SCW + SA + SCW + SA + SCW + SA + SCW | 2 | 7 |

| Materials | Fracture Toughness (MPa·m1/2) | Flexural Strength (MPa) | Vickers Hardness (GPa) | |||

|---|---|---|---|---|---|---|

| SiAlON | 4.85 ± 0.19 | 433 ± 9 | 17.89 ± 0.16 | |||

| SCW | 5.76 ± 0.18 | 544 ± 21 | 18.89 ± 0.21 | |||

| SA | 5.21 ± 0.17 | 475 ± 22 | 18.34 ± 0.19 | |||

| SCW | SA | Front | Side | SCW | SA | |

| SCWA2 | 5.97 ± 0.16 | 5.28 ± 0.18 | 565 ± 21 | 551 ± 18 | 19.1 ± 0.2 | 18.4 ± 0.2 |

| SCWA3 | 6.35 ± 0.17 | 5.35 ± 0.17 | 583 ± 17 | 572 ± 21 | 19.2 ± 0.2 | 18.5 ± 0.2 |

| SCWA4 | 6.61 ± 0.19 | 5.41 ± 0.18 | 602 ± 19 | 595 ± 17 | 19.4 ± 0.2 | 18.2 ± 0.2 |

| SCWA6 | 6.42 ± 0.17 | 5.36 ± 0.17 | 582 ± 17 | 576 ± 21 | 19.1 ± 0.2 | 18.5 ± 0.2 |

| SCWA7 | 6.25 ± 0.16 | 5.29 ± 0.18 | 571 ± 21 | 561 ± 18 | 18.9 ± 0.2 | 18.4 ± 0.2 |

| Elements | Composition (wt%) (SCW Layer) | Composition (wt%) (SA Layer) |

|---|---|---|

| Si | 21.05 | 21.22 |

| Al | 3.26 | 7.62 |

| O | 2.28 | 2.44 |

| N | 13.31 | 19.96 |

| Y | 3.50 | 3.58 |

| C | 1.62 | 0.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, W.; Xiao, G.; Jia, Y.; Chen, H.; Zhang, J.; Yi, M.; Chen, Z.; Xu, C. Structural Design and Mechanical Properties Analysis of Laminated SiAlON Ceramic Tool Materials. Coatings 2024, 14, 1218. https://doi.org/10.3390/coatings14091218

Wu W, Xiao G, Jia Y, Chen H, Zhang J, Yi M, Chen Z, Xu C. Structural Design and Mechanical Properties Analysis of Laminated SiAlON Ceramic Tool Materials. Coatings. 2024; 14(9):1218. https://doi.org/10.3390/coatings14091218

Chicago/Turabian StyleWu, Wenhao, Guangchun Xiao, Yanjun Jia, Hui Chen, Jingjie Zhang, Mingdong Yi, Zhaoqiang Chen, and Chonghai Xu. 2024. "Structural Design and Mechanical Properties Analysis of Laminated SiAlON Ceramic Tool Materials" Coatings 14, no. 9: 1218. https://doi.org/10.3390/coatings14091218

APA StyleWu, W., Xiao, G., Jia, Y., Chen, H., Zhang, J., Yi, M., Chen, Z., & Xu, C. (2024). Structural Design and Mechanical Properties Analysis of Laminated SiAlON Ceramic Tool Materials. Coatings, 14(9), 1218. https://doi.org/10.3390/coatings14091218