High-Temperature Rheological Behavior and Fatigue Performance of Montmorillonite-Modified Asphalt

Abstract

1. Introduction

2. Materials and Methods

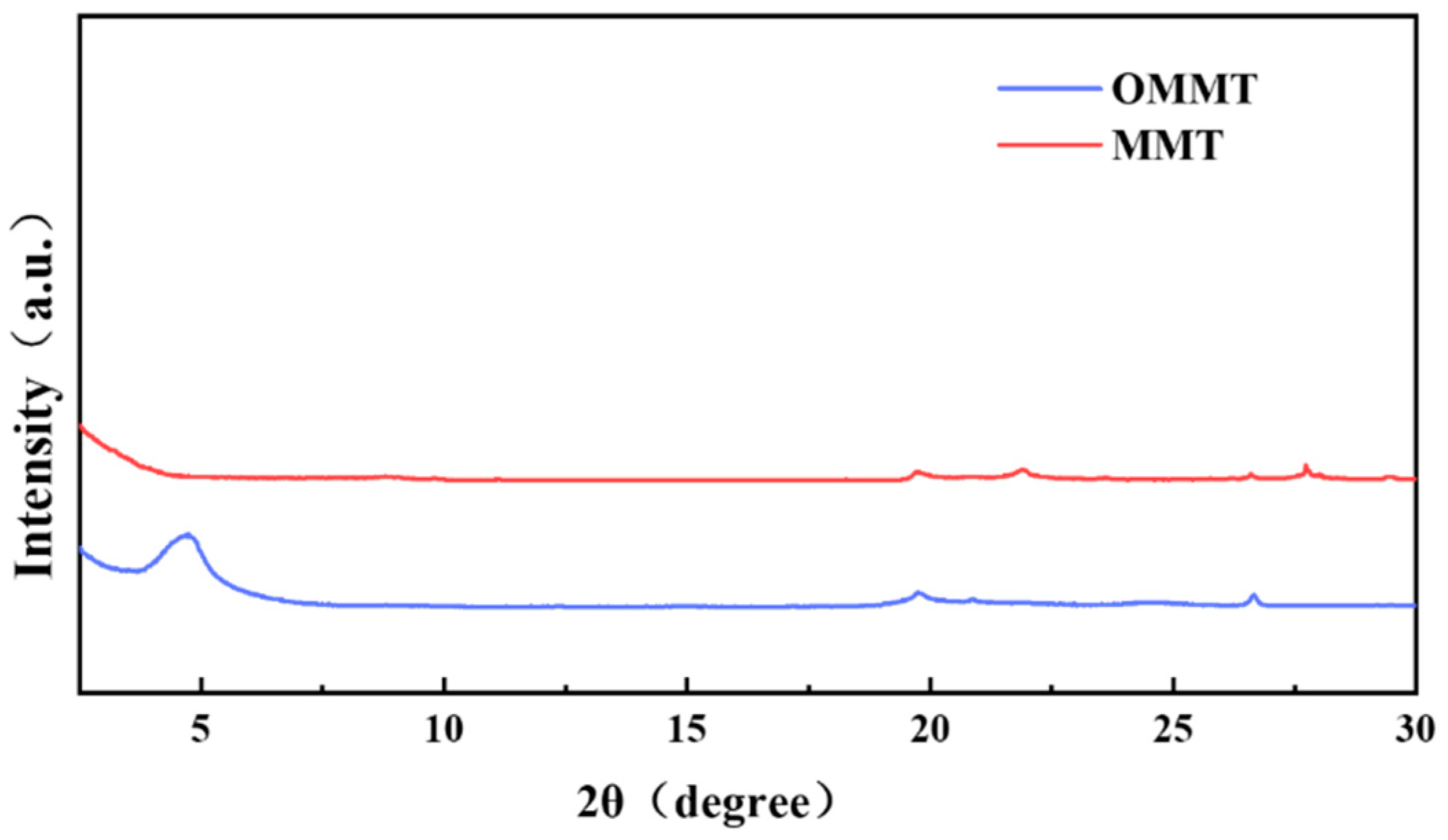

2.1. Materials

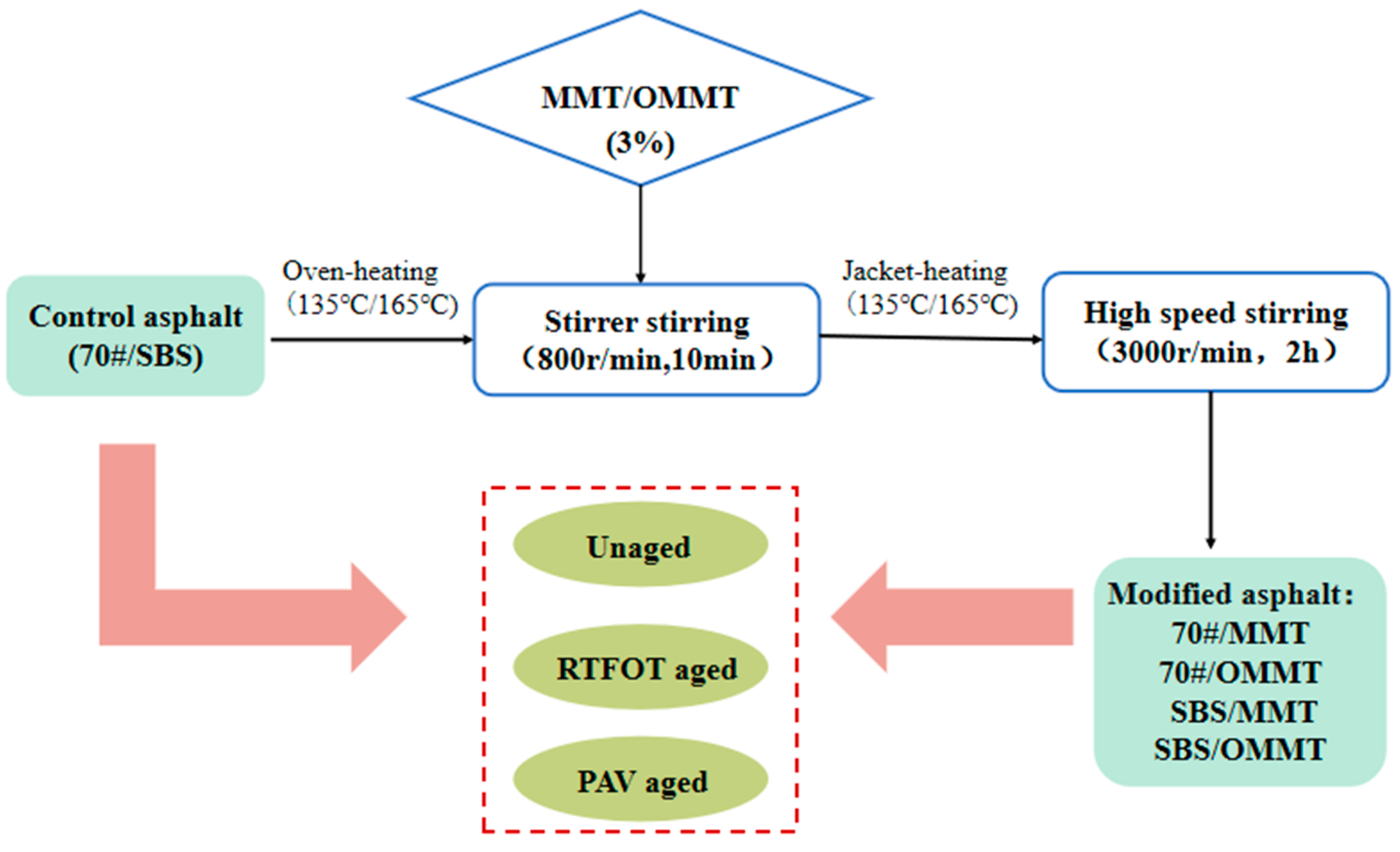

2.2. Preparation of Asphalt Sample

2.3. Temperature Sweep Test

2.4. Linear Amplitude Sweep Test

2.5. Nanoindentation Test

3. Results and Discussion

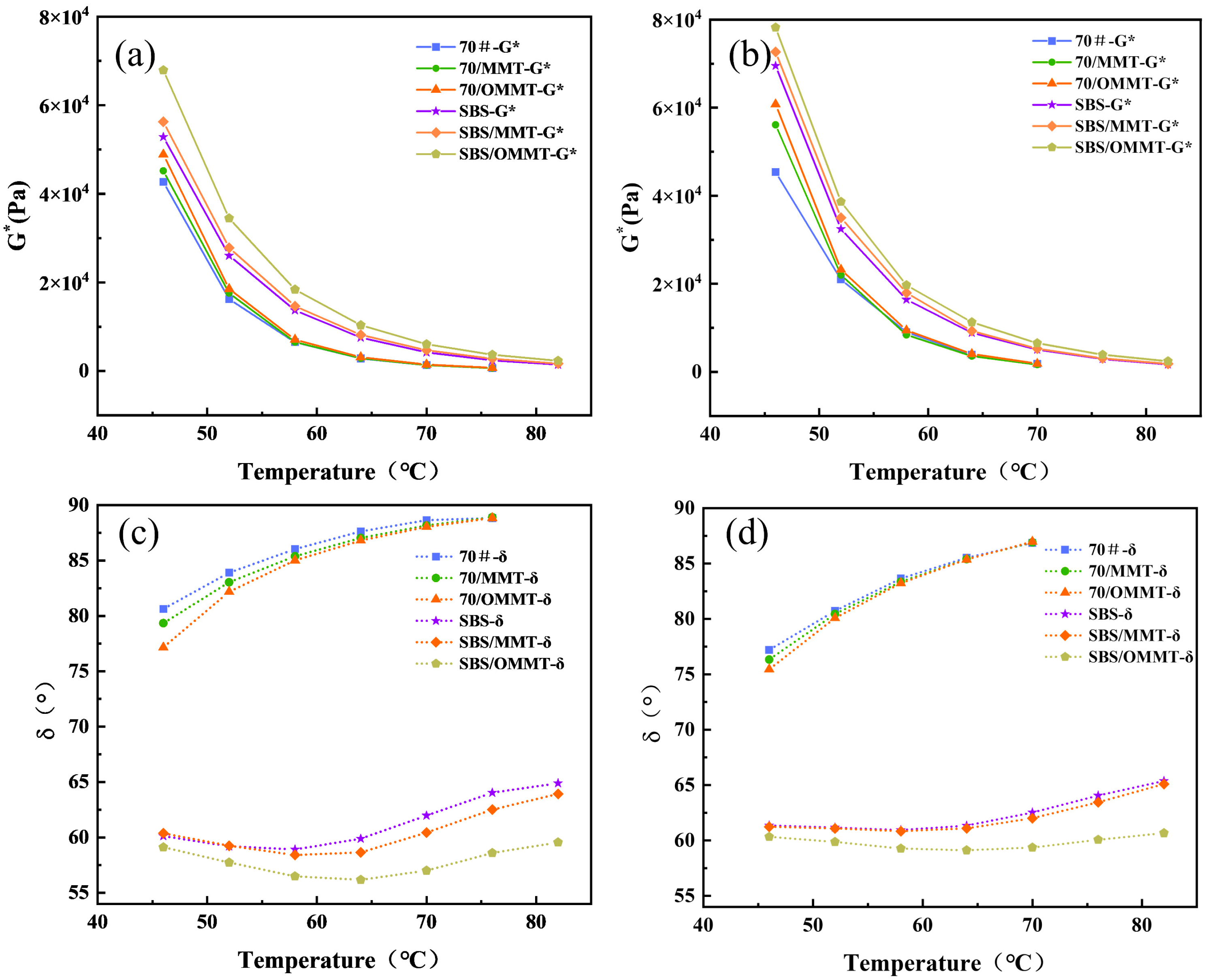

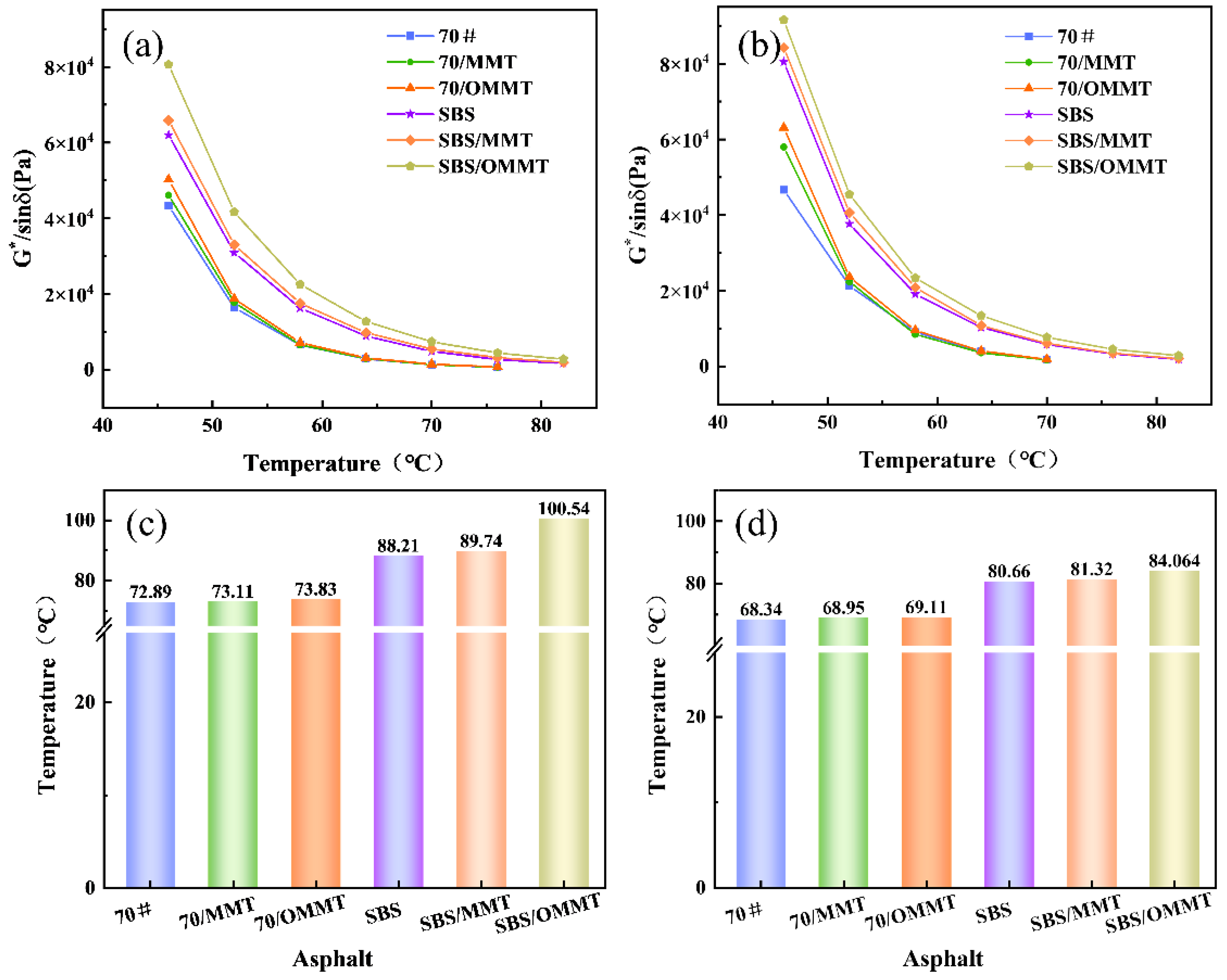

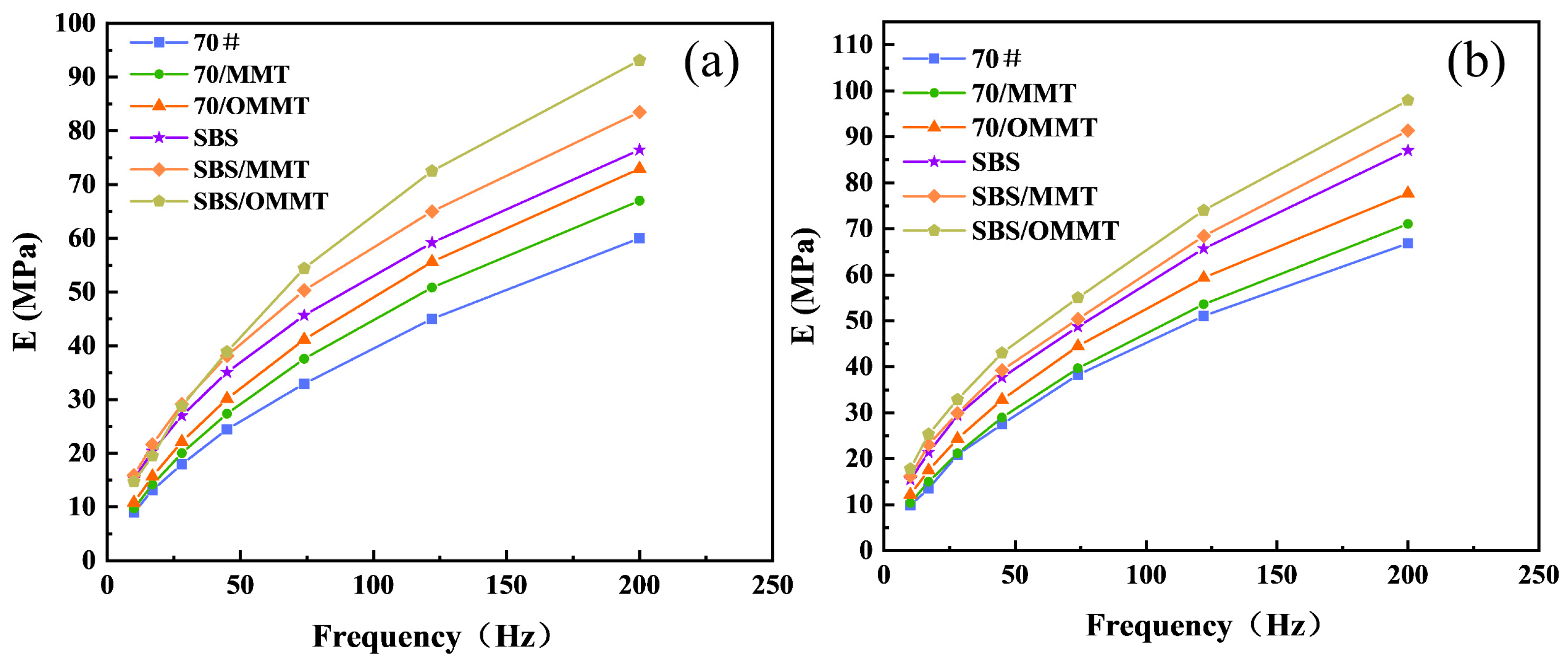

3.1. High-Temperature Rheological Properties

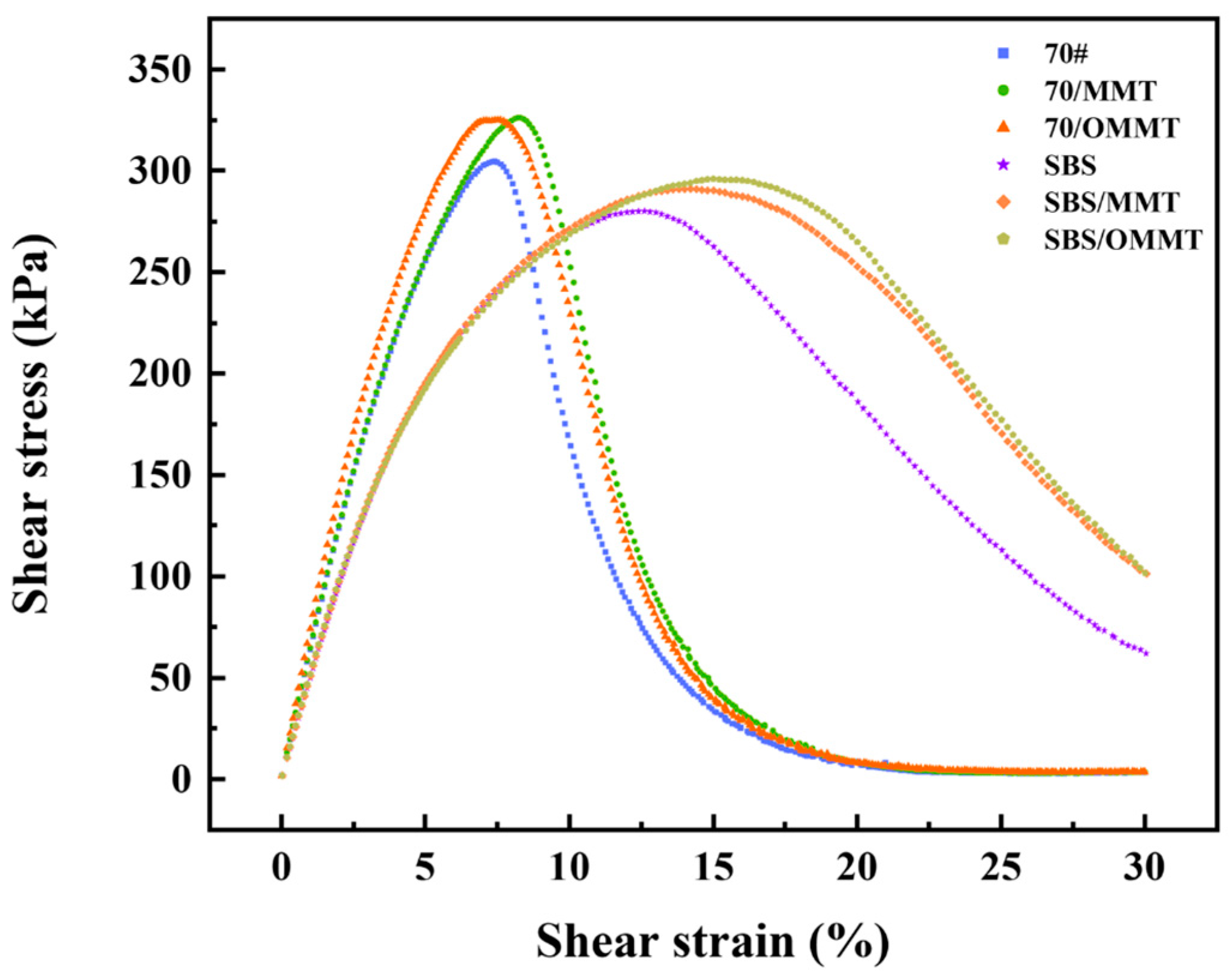

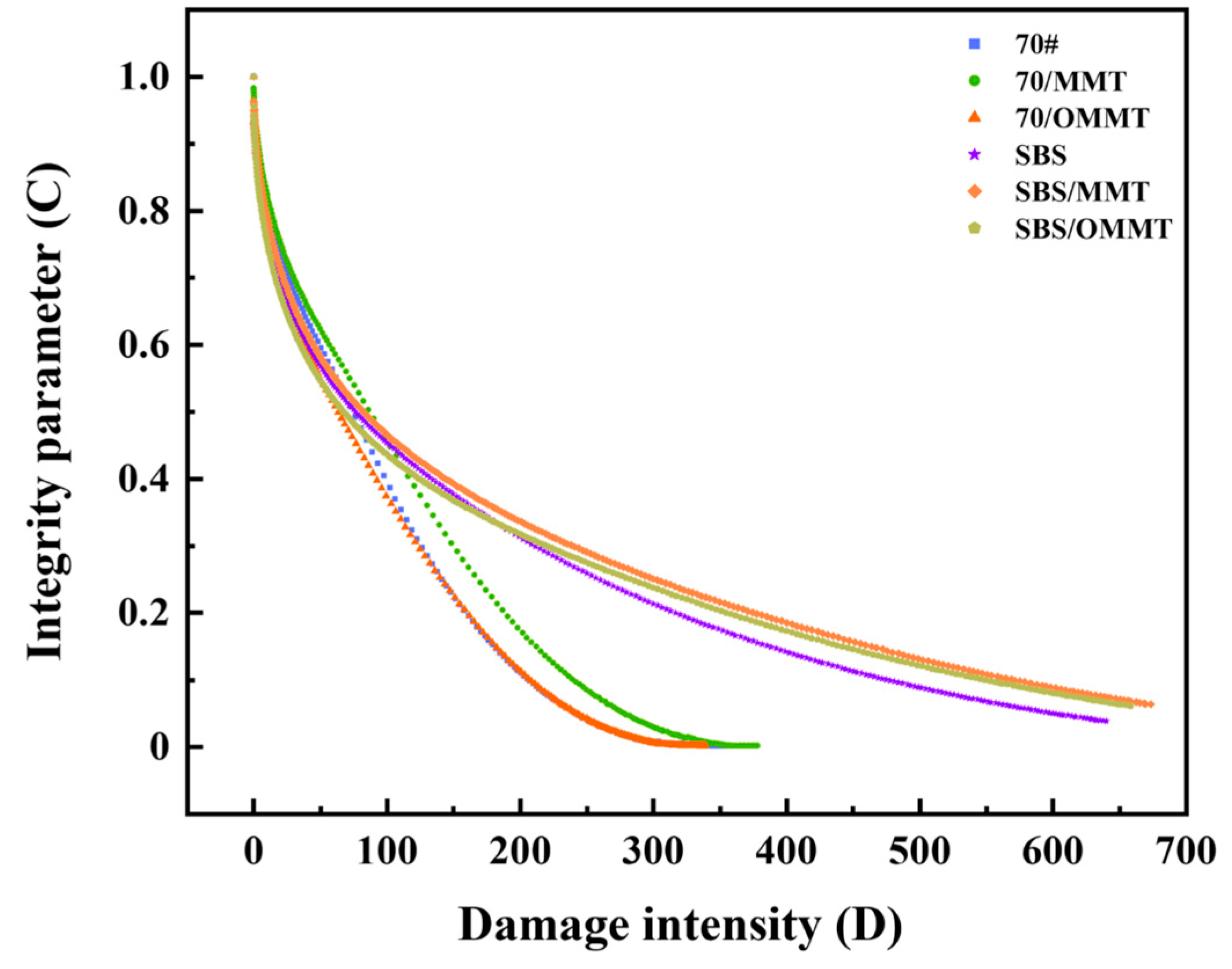

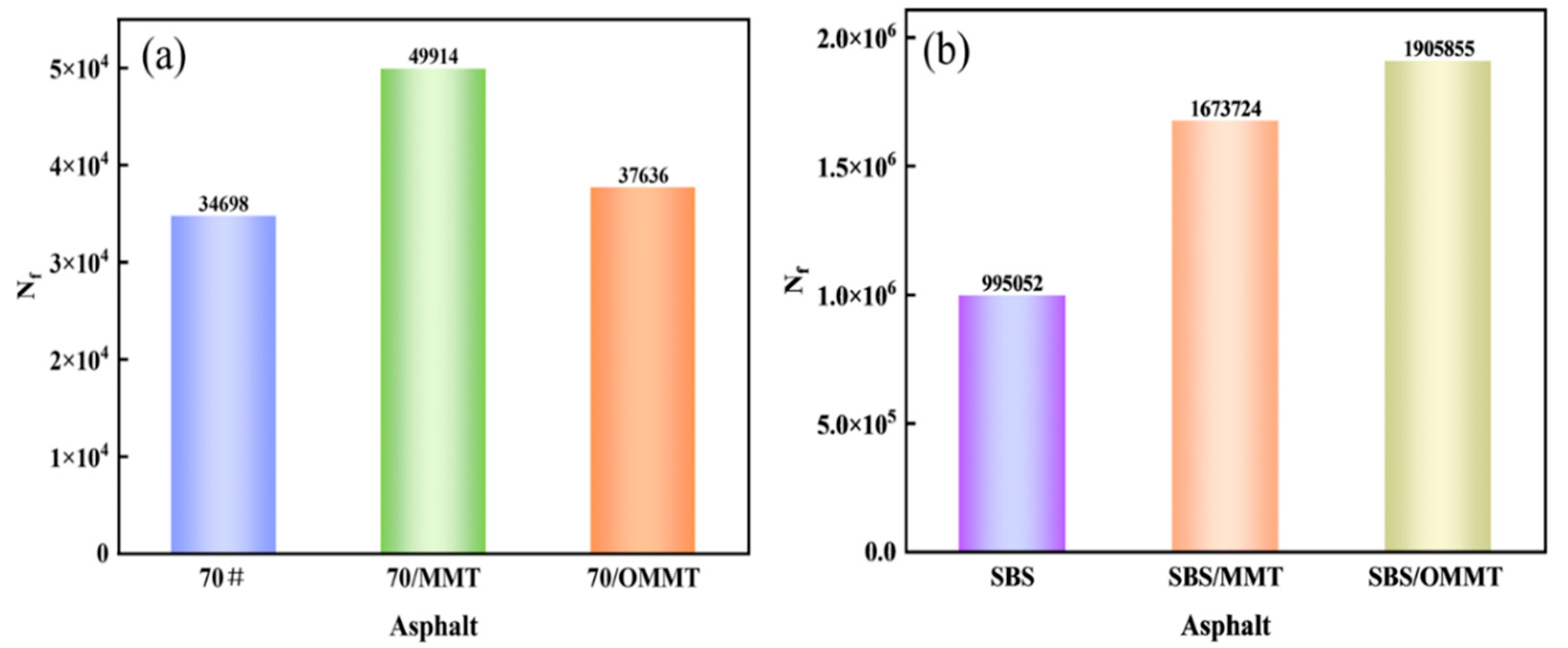

3.2. Fatigue Properties

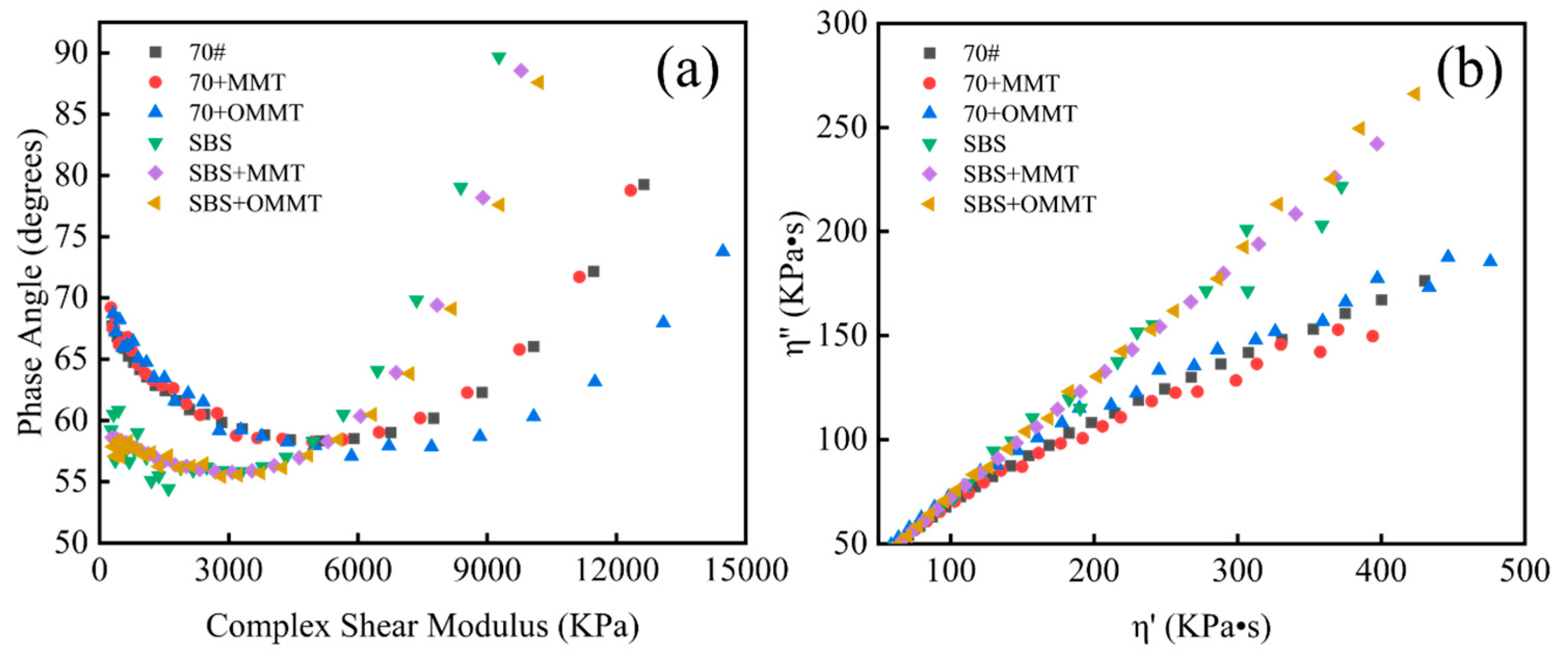

3.3. Black Space Rheological Assessment

3.4. NI Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ameli, A.; Pakshir, A.H.; Babagoli, R.; Norouzi, N.; Nasr, D.; Davoudinezhad, S. Experimental investigation of the influence of Nano TiO2 on rheological properties of binders and performance of stone matrix asphalt mixtures containing steel slag aggregate. Constr. Build. Mater. 2020, 265, 120750. [Google Scholar] [CrossRef]

- Ke, Y.; Cao, J.; Xu, S.; Bian, C.; Zhang, C.; Jia, X. Storage stability and anti-aging performance of SEBS/organ-montmorillonite modified asphalt. Constr. Build. Mater. 2022, 341, 127875. [Google Scholar] [CrossRef]

- Al-Mosawe, H.; Thom, N.; Airey, G.; Albayati, A. Linear viscous approach to predict rut depth in asphalt mixtures. Constr. Build. Mater. 2018, 169, 775–793. [Google Scholar] [CrossRef]

- Nazari, H.; Naderi, K.; Nejad, F.M. Improving aging resistance and fatigue performance of asphalt binders using inorganic nanoparticles. Constr. Build. Mater. 2018, 170, 591–602. [Google Scholar] [CrossRef]

- Lakes, R.S. Viscoelastic Materials; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Bonnetti, K.S.; Nam, K.; Bahia, H.U. Measuring and defining fatigue behavior of asphalt binders. Transp. Res. Rec. 2002, 1810, 33–43. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.-M.; Wu, S.-J.; Wang, H.-R.; Liu, X.-C.; Sun, H.-D.; Fan, L. Effect of montmorillonite modification on resistance to thermal oxidation aging of asphalt binder. Case Stud. Constr. Mater. 2022, 16, e00971. [Google Scholar] [CrossRef]

- Ye, F.; Yin, W.; Lu, H.; Dong, Y. Property improvement of Nano-Montmorillonite/SBS modified asphalt binder by naphthenic oil. Constr. Build. Mater. 2020, 243, 118200. [Google Scholar] [CrossRef]

- Yu, J.-Y.; Feng, P.-C.; Zhang, H.-L.; Wu, S.-P. Effect of organo-montmorillonite on aging properties of asphalt. Constr. Build. Mater. 2009, 23, 2636–2640. [Google Scholar] [CrossRef]

- Jahromi, S.G. Rutting and fatigue behavior of nanoclay modified bitumen. In Proceedings of the EACEF-International Conference of Civil Engineering, Yogyakarta, Indonesia, 20–22 September 2011; p. 045. [Google Scholar]

- Hintz, C.; Velasquez, R.; Johnson, C.; Bahia, H. Modification and validation of linear amplitude sweep test for binder fatigue specification. Transp. Res. Rec. 2011, 2207, 99–106. [Google Scholar] [CrossRef]

- Veytskin, Y.; Bobko, C.; Castorena, C. Nanoindentation investigation of asphalt binder and mastic viscoelasticity. Int. J. Pavement Eng. 2016, 17, 363–376. [Google Scholar] [CrossRef]

- Jäger, A.; Lackner, R.; Eberhardsteiner, J. Identification of viscoelastic properties by means of nanoindentation taking the real tip geometry into account. Meccanica 2007, 42, 293–306. [Google Scholar] [CrossRef]

- Faisal, H.M.; Mannan, U.A.; Tarefder, R.A.; Arifuzzaman, M. Evaluating the relationship between dynamic shear modulus and nano scale modulus of asphalt binders at different aging conditions. GEOMATE J. 2017, 13, 1–7. [Google Scholar] [CrossRef]

- Ma, F.; Li, C.; Fu, Z.; Huang, Y.; Dai, J.; Feng, Q. Evaluation of high temperature rheological performance of polyphosphoric acid-SBS and polyphosphoric acid-crumb rubber modified asphalt. Constr. Build. Mater. 2021, 306, 124926. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.-M.; Wu, Y.-L.; Wang, H.-R.; Chen, M.; Sun, H.-D.; Fan, L. Properties and modification mechanism of asphalt with graphene as modifier. Constr. Build. Mater. 2021, 272, 121919. [Google Scholar] [CrossRef]

- Babagoli, R.; Nasr, D.; Ameli, A.; Moradi, M.R. Rutting and fatigue properties of modified binders with polymer and titanium dioxide nanoparticles. Constr. Build. Mater. 2022, 345, 128423. [Google Scholar] [CrossRef]

- Yu, J.; Zeng, X.; Wu, S.; Wang, L.; Liu, G. Preparation and properties of montmorillonite modified asphalts. Mater. Sci. Eng. A 2007, 447, 233–238. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, J.; Wu, S. Effect of montmorillonite organic modification on ultraviolet aging properties of SBS modified bitumen. Constr. Build. Mater. 2012, 27, 553–559. [Google Scholar] [CrossRef]

- Yılmaz, B.; Gürbüz, H.E. Rheological and morphological evaluation of nanoclay modified asphalt binder. Constr. Build. Mater. 2021, 313, 125479. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, S.B.; Xu, Y. Evaluation of cracking properties of SBS-modified binders containing organic montmorillonite. Constr. Build. Mater. 2018, 175, 196–205. [Google Scholar] [CrossRef]

- Pei, J.; Wen, Y.; Li, Y.; Zhang, Z.; Shi, X.; Zhang, J.; Li, R.; Cao, L.; Du, Q. Organic montmorillonite modified asphalt materials: Preparation and characterization. J. Test. Eval. 2014, 42, 118–125. [Google Scholar] [CrossRef]

- AASHTO T 315-12; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- AASHTO TP101-12; Standard Method of Test for Estimating Fatigue Resistance of Asphalt Binders Using the Linear Amplitude Sweep. AASHTO: Washington, DC, USA, 2018.

- Cao, W.; Wang, C. A new comprehensive analysis framework for fatigue characterization of asphalt binder using the Linear Amplitude Sweep test. Constr. Build. Mater. 2018, 171, 1–12. [Google Scholar] [CrossRef]

- Shu, S.; Zhuang, C.; Ren, R.; Xing, B.; Chen, K.; Li, G. Effect of Different Anti-Stripping Agents on the Rheological Properties of Asphalt. Coatings 2022, 12, 1895. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Z.; Xu, G.; Shi, C. Evaluation of aging behaviors of asphalt binders through different rheological indices. Fuel 2018, 221, 78–88. [Google Scholar] [CrossRef]

- Qu, X.; Liu, Q.; Guo, M.; Wang, D.; Oeser, M. Study on the effect of aging on physical properties of asphalt binder from a microscale perspective. Constr. Build. Mater. 2018, 187, 718–729. [Google Scholar] [CrossRef]

- Anderson, D.A.; Kennedy, T.W. Development of SHRP binder specification (with discussion). J. Assoc. Asph. Paving Technol. 1993, 62, 481–507. [Google Scholar]

- Liu, X.; Wu, S.; Ye, Q.; Qiu, J.; Li, B. Properties evaluation of asphalt-based composites with graphite and mine powders. Constr. Build. Mater. 2008, 22, 121–126. [Google Scholar] [CrossRef]

- Elkashef, M.; Williams, R.C.; Cochran, E. Effect of asphalt binder grade and source on the extent of rheological changes in rejuvenated binders. J. Mater. Civ. Eng. 2018, 30, 04018319. [Google Scholar] [CrossRef]

- Yan, C.; Yuan, L.; Yu, X.; Ji, S.; Zhou, Z. Characterizing the fatigue resistance of multiple modified asphalts using time sweep test, LAS test and elastic recovery test. Constr. Build. Mater. 2022, 322, 125806. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; Liu, C.; Ge, D.; You, Z.; Yu, M. High-temperature rheological behavior and fatigue performance of lignin modified asphalt binder. Constr. Build. Mater. 2020, 230, 117063. [Google Scholar] [CrossRef]

- Chaudhary, M.; Saboo, N.; Gupta, A.; Miljković, M. Contribution of mineral filler to the fatigue damage behaviour of bituminous mastic. Constr. Build. Mater. 2022, 334, 127120. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, H.; Feng, Y.; Li, J.; Gao, M.; Wu, G. Study on rheological and micro-structural properties of different modified asphalt by using organic and inorganic modifier. Case Stud. Constr. Mater. 2023, 18, e02072. [Google Scholar] [CrossRef]

- Saboo, N.; Kumar, R.; Kumar, P.; Gupta, A. Ranking the rheological response of SBS-and EVA-modified bitumen using MSCR and LAS tests. J. Mater. Civ. Eng. 2018, 30, 04018165. [Google Scholar] [CrossRef]

- Yu, Y.; Shi, C.; Xu, G.; Yao, Z.; Wang, T.; Wu, Y.; Yi, X.; Wang, H.; Yang, J. Application of nanoindentation in asphalt material aging and characterization of actual pavement aging. Constr. Build. Mater. 2022, 331, 127348. [Google Scholar] [CrossRef]

- Airey, G.D.; Rowe, G.M.; Sias, J.E.; Di Benedetto, H.; Sauzeat, C.; Dave, E.V. Black Space Rheological Assessment of Asphalt Material Behavior. J. Test. Eval. 2022, 50. [Google Scholar] [CrossRef]

- Airey, G.; Grenfell, J.; Apeagyei, A.; Subhy, A.; Lo Presti, D. Time dependent viscoelastic rheological response of pure, modified and synthetic bituminous binders. Mech. Time-Depend. Mater. 2016, 20, 455–480. [Google Scholar] [CrossRef]

| Type of Asphalt | Penetration (25 °C, 0.1 mm) | Softening Point (°C) | Ductility (5 cm/min, 10 °C, cm) | Ductility (5 cm/min, 5 °C, cm) | ||||

|---|---|---|---|---|---|---|---|---|

| Original | TFOT | Original | TFOT | Original | TFOT | Original | TFOT | |

| 70# | 68.82 | 42.08 | 47.84 | 56.68 | 21.65 | 6.20 | ––– | ––– |

| 70/MMT | 55.00 | 36.65 | 51.21 | 54.65 | 16.60 | 6.55 | ––– | ––– |

| 70/OMMT | 57.95 | 40.88 | 52.34 | 54.11 | 17.80 | 9.65 | ––– | ––– |

| SBS | 58.56 | 45.48 | 76.69 | 75.45 | ––– | ––– | 28.65 | 23.10 |

| SBS/MMT | 49.63 | 42.68 | 81.25 | 75.99 | ––– | ––– | 24.65 | 22.06 |

| SBS/OMMT | 50.16 | 45.35 | 82.38 | 76.25 | ––– | ––– | 25.08 | 22.80 |

| Asphalt Type | α | C1 | C2 | Dr | K | B | A35 |

|---|---|---|---|---|---|---|---|

| 70# | 2.534 | 0.086 | 0.495 | 1542.253 | 2.281 | −5.068 | 121,054,316.248 |

| 70/MMT | 2.518 | 0.068 | 0.515 | 1727.357 | 2.221 | −5.035 | 165,116,909.215 |

| 70/OMMT | 2.531 | 0.127 | 0.456 | 1943.765 | 2.377 | −5.062 | 129,921,066.415 |

| SBS | 2.655 | 0.172 | 0.364 | 2445.928 | 2.689 | −5.310 | 5,122,591,239.929 |

| SBS/MMT | 2.655 | 0.160 | 0.364 | 2845.849 | 2.688 | −5.310 | 8,616,443,532.055 |

| SBS/OMMT | 2.667 | 0.221 | 0.333 | 2983.646 | 2.780 | −5.334 | 10,193,382,512.793 |

| Type of Asphalt | Unaged | RTFOT Aged | ||

|---|---|---|---|---|

| G-NI (MPa) | G-DSR (MPa) | G-NI (MPa) | G-DSR (MPa) | |

| 70# | 3.00 | 7.09 | 3.30 | 7.80 |

| 70/MMT | 3.24 | 7.22 | 3.47 | 8.66 |

| 70/OMMT | 3.61 | 8.38 | 4.08 | 11.74 |

| SBS | 5.06 | 11.3 | 5.15 | 14.69 |

| SBS/MMT | 5.30 | 12.12 | 5.40 | 16.97 |

| SBS/OMMT | 5.54 | 12.45 | 5.94 | 17.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.-X.; Du, W.; Li, Y.-X.; Wang, Y.-M.; Wang, X.-N.; Liu, X.-C. High-Temperature Rheological Behavior and Fatigue Performance of Montmorillonite-Modified Asphalt. Coatings 2024, 14, 1038. https://doi.org/10.3390/coatings14081038

Zhang M-X, Du W, Li Y-X, Wang Y-M, Wang X-N, Liu X-C. High-Temperature Rheological Behavior and Fatigue Performance of Montmorillonite-Modified Asphalt. Coatings. 2024; 14(8):1038. https://doi.org/10.3390/coatings14081038

Chicago/Turabian StyleZhang, Ming-Xin, Wei Du, Yong-Xu Li, Yan-Min Wang, Xiao-Ning Wang, and Xiao-Cun Liu. 2024. "High-Temperature Rheological Behavior and Fatigue Performance of Montmorillonite-Modified Asphalt" Coatings 14, no. 8: 1038. https://doi.org/10.3390/coatings14081038

APA StyleZhang, M.-X., Du, W., Li, Y.-X., Wang, Y.-M., Wang, X.-N., & Liu, X.-C. (2024). High-Temperature Rheological Behavior and Fatigue Performance of Montmorillonite-Modified Asphalt. Coatings, 14(8), 1038. https://doi.org/10.3390/coatings14081038