Application of Thermal Spraying Technology in Concrete Surface Ceramic-Based Coating

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

2.1.1. Coating Materials

2.1.2. Concrete Materials

2.2. Specimen Design and Investigated Cases

2.2.1. Specimen Design

2.2.2. Investigated Cases

2.3. Coating Preparation Procedures

2.4. Experimental Methods

2.4.1. Mechanical Testing

Compressive Testing and Splitting Tensile Testing

Interface Adhesion Testing

Wearing Testing

2.4.2. Characterization Testing

SEM-XRD Analysis

SEM-EDS Testing

X-CT Three-Dimensional Meso-Structure Test

3. Results and Discussion

3.1. Coating Mechanical Testing

3.1.1. Interface Bonding Ability

3.1.2. Coating Wear Resistance

3.2. Characterization Testing

3.2.1. Appearance and Phase Analysis

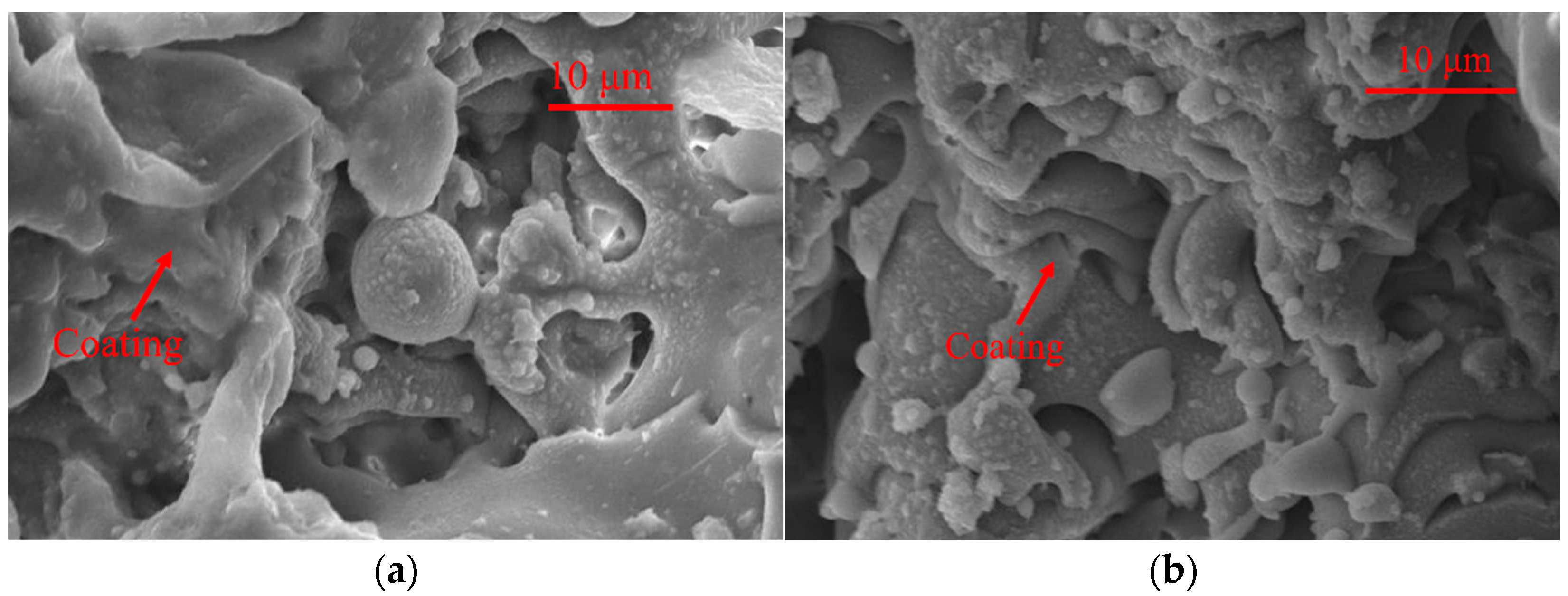

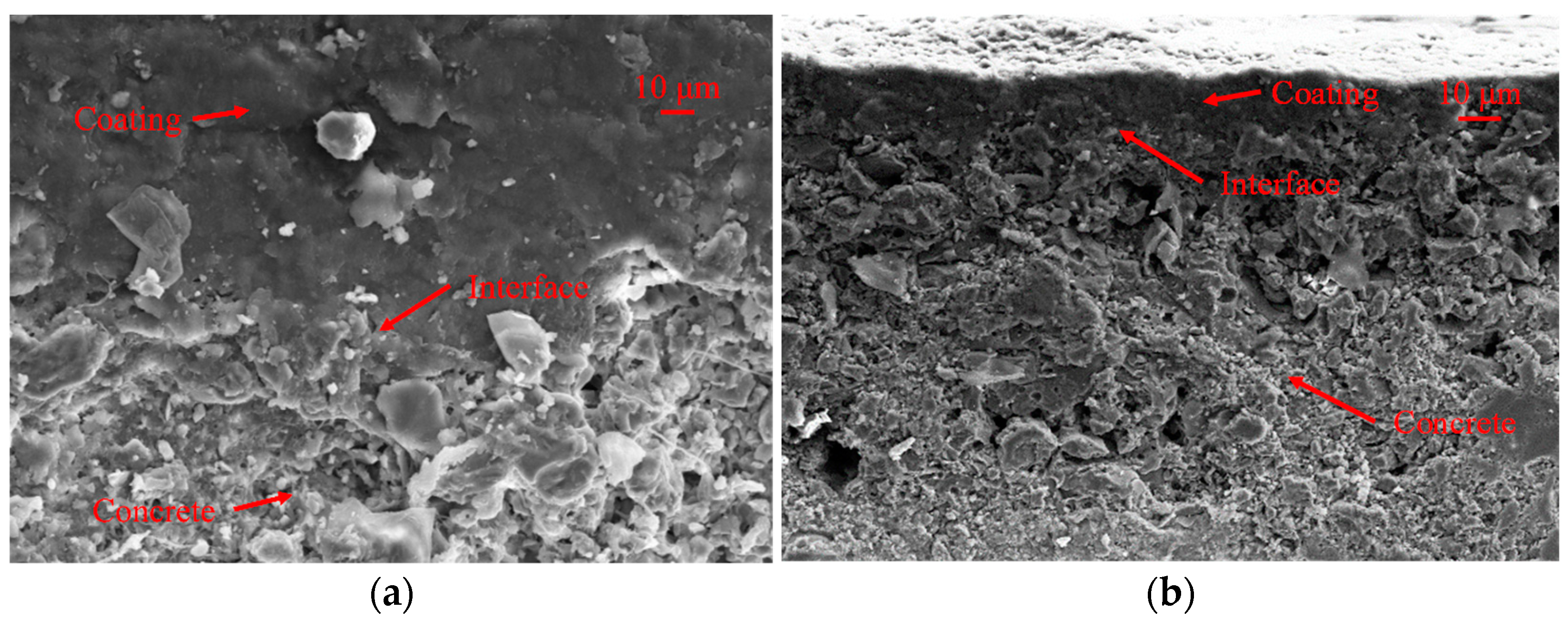

3.2.2. SEM-EDS Microstructure Analysis

3.2.3. X-CT Three-Dimensional Microstructure Test

3.3. Discussion

4. Conclusions

- The thermal expansion coefficient of mullite powder used in the test matches those of the concrete products. The prepared coating uniformly covers the concrete surface, demonstrating good interfacial bonding ability and an adhesion strength of 3.82 MPa. Friction and wear tests reveal that, compared to the concrete substrate, the coating surface achieves a lower wear rate and higher friction coefficient, indicating superior wear resistance of the coating material.

- The SEM-EDS results demonstrate that the thermal-sprayed coating can completely cover the non-homogeneous multiphase concrete matrix. However, the formation mechanism of the interface between thermal-sprayed coating and concrete and its effect on the coating performance need to be studied. Based on X-CT three-dimensional scanning technology, the characteristics of porous structures inside the coating products can be intuitively grasped from a microscopic point of view.

- To improve the coating performance and enhance the protective ability of concrete structures, it is necessary to improve the compactness and uniformity of the coating structure. At the same time, the composite of single-phase coating materials and the powder refinement of coating particles are also solutions to improve the toughness of the coating and enhance the wear resistance and mechanical properties of the coating. In the field of water conservancy and hydropower engineering, hydrophobic treatment and the long-term performance tracking of coating materials are also planned research directions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kannangara, T.; Joseph, P.; Fragomeni, S.; Guerrieri, M. Existing theories of concrete spalling and test methods relating to moisture migration patterns upon exposure to elevated temperatures—A review. Case Stud. Constr. Mater. 2022, 16, e01111. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, G.; Ye, H.; Zeng, Q.; Zhang, Z.; Tian, Z.; Jin, X.; Jin, N.; Chen, Z.; Wang, J. Corrosion of steel rebar in concrete induced by chloride ions under natural environments. Constr. Build. Mater. 2023, 369, 130504. [Google Scholar] [CrossRef]

- Zahedi, A.; Komar, A.; Sanchez, L.F.; Boyd, A.J. Global assessment of concrete specimens subjected to freeze-thaw damage. Cem. Concr. Compos. 2022, 133, 104716. [Google Scholar] [CrossRef]

- Jiang, L.; Pettitt, T.R.; Buenfeld, N.; Smith, S.R. A critical review of the physiological, ecological, physical and chemical factors influencing the microbial degradation of concrete by fungi. Build. Environ. 2022, 214, 108925. [Google Scholar] [CrossRef]

- Liu, P.; Chen, Y.; Yu, Z. Effects of temperature, relative humidity and carbon dioxide concentration on concrete carbonation. Mag. Concr. Res. 2020, 72, 936–947. [Google Scholar] [CrossRef]

- Kayondo, M.; Combrinck, R.; Boshoff, W.P. State-of-the-art review on plastic cracking of concrete. Constr. Build. Mater. 2019, 225, 886–899. [Google Scholar] [CrossRef]

- Woyciechowski, P.; Łukowski, P.; Szmigiera, E.; Adamczewski, G.; Chilmon, K.; Spodzieja, S. Concrete corrosion in a wastewater treatment plant–A comprehensive case study. Constr. Build. Mater. 2021, 303, 124388. [Google Scholar] [CrossRef]

- Moon, H.Y.; Shin, D.G.; Choi, D.S. Evaluation of the durability of mortar and concrete applied with inorganic coating material and surface treatment system. Constr. Build. Mater. 2007, 21, 362–369. [Google Scholar] [CrossRef]

- Pan, X.; Shi, Z.; Shi, C.; Ling, T.C.; Li, N. A review on concrete surface treatment Part I: Types and mechanisms. Constr. Build. Mater. 2017, 132, 578–590. [Google Scholar] [CrossRef]

- Almusallam, A.; Khan, F.M.; Maslehuddin, M. Performance of concrete coating under varying exposure conditions. Mater. Struct. 2002, 35, 487–494. [Google Scholar] [CrossRef]

- Li, G.; Dong, L.; Lei, M.; Du, J. Predicting carbonation depth for concrete with organic film coatings combined with ageing effects. Constr. Build. Mater. 2017, 142, 59–65. [Google Scholar] [CrossRef]

- Shohide, M.A. Fabrication and application of an innovative low cost-efficient polymer nano-composite as concrete protective coating. Int. J. Adhes. Adhes. 2024, 128, 103542. [Google Scholar] [CrossRef]

- Qu, H.; Feng, M.; Li, M.; Tian, D.; Zhang, Y.; Chen, X.; Li, G. Enhancing the carbonation and chloride resistance of concrete by nano-modified eco-friendly water-based organic coatings. Mater. Today Commun. 2023, 37, 107284. [Google Scholar] [CrossRef]

- Chi, J.; Zhang, G.; Xie, Q.; Ma, C.; Zhang, G. High performance epoxy coating with cross-linkable solvent via Diels-Alder reaction for anti-corrosion of concrete. Prog. Org. Coat. 2020, 139, 105473. [Google Scholar] [CrossRef]

- Wang, H.; Feng, P.; Lv, Y.; Geng, Z.; Liu, Q.; Liu, X. A comparative study on UV degradation of organic coatings for concrete: Structure, adhesion, and protection performance. Prog. Org. Coat. 2020, 149, 105892. [Google Scholar] [CrossRef]

- Chen, S.C.; Lin, W.T.; Huang, R.; Hsu, H.M. Performance of green concrete and inorganic coating materials. Materials 2021, 14, 832. [Google Scholar] [CrossRef] [PubMed]

- Franzoni, E.; Pigino, B.; Pistolesi, C. Ethyl silicate for surface protection of concrete: Performance in comparison with other inorganic surface treatments. Cem. Concr. Compos. 2013, 44, 69–76. [Google Scholar] [CrossRef]

- Jia, L.; Shi, C.; Pan, X.; Zhang, J.; Wu, L. Effects of inorganic surface treatment on water permeability of cement-based materials. Cem. Concr. Compos. 2016, 67, 85–92. [Google Scholar] [CrossRef]

- Li, G.; Ding, Y.; Gao, T.; Qin, Y.; Lv, Y.; Wang, K. Chloride resistance of concrete containing nanoparticle-modified polymer cementitious coatings. Constr. Build. Mater. 2021, 299, 123736. [Google Scholar] [CrossRef]

- Amer, M.; Curry, N.; Hayat, Q.; Sharma, R.; Janik, V.; Zhang, X.; Nottingham, J.; Bai, M. Cracking behavior of Gd2Zr2O7/YSZ multi-layered thermal barrier coatings deposited by suspension plasma spray. Coatings 2023, 13, 107. [Google Scholar] [CrossRef]

- Amer, M.; Curry, N.; Arshad, M.; Hayat, Q.; Janik, V.; Nottingham, J.; Bai, M. Unraveling the Cracking Mechanisms of Air Plasma-Sprayed Thermal Barrier Coatings: An In-Situ SEM Investigation. Coatings 2023, 13, 1493. [Google Scholar] [CrossRef]

- Lee, H.S.; Park, J.; Singh, J.K.; Choi, H.J.; Mandal, S.; Jang, J.M.; Yang, H.M. Electromagnetic shielding performance of carbon black mixed concrete with Zn–Al metal thermal spray coating. Materials 2020, 13, 895. [Google Scholar] [CrossRef]

- Wang, Y.P. A Study on Thermal Spraying Sacrificial Anode Applied in Concrete Structure Cathodic Protection. Adv. Mater. Res. 2014, 1015, 215–218. [Google Scholar] [CrossRef]

- Wang, L.; Ming, C.; Zhong, X.H.; Ni, J.X.; Tao, S.Y.; Zhou, F.F.; Wang, Y. Prediction of critical rupture of plasma-sprayed yttria stabilized zirconia thermal barrier coatings under burner rig test via finite element simulation and in-situ acoustic emission technique. Surf. Coat. Technol. 2019, 367, 58–74. [Google Scholar] [CrossRef]

- Madlmeir, S.; Radl, S. A coarse-grained parcel method for heat and mass transfer simulations of spray coating processes. Adv. Powder Technol. 2022, 33, 103590. [Google Scholar] [CrossRef]

- Guo, S.Y.; Luo, H.H.; Tan, Z.; Chen, J.Z.; Zhang, L.; Ren, J. Impermeability and interfacial bonding strength of TiO2-graphene modified epoxy resin coated OPC concrete. Prog. Org. Coat. 2021, 151, 106029. [Google Scholar] [CrossRef]

- Rogé, B.; Fahr, A.; Giguere, J.S.R.; McRae, K.I. Nondestructive measurement of porosity in thermal barrier coatings. J. Therm. Spray Technol. 2003, 12, 530–535. [Google Scholar] [CrossRef]

- Mather, B. Concrete durability. Cem. Concr. Compos. 2004, 26, 3–4. [Google Scholar] [CrossRef]

- GB/T 175-2020; Common Portland Cement; State Administration for Market Regulation. Standardization Administration of the People’s Republic of China: Beijing, China, 2020.

- DL/T 5055-2007; Technical Specification of Fly Ash for Use in Hydraulic Concrete. National Development and Reform Commission: Beijing, China, 2007.

- Yu, Q.; Rauf, A.; Zhou, C. Microstructure and Thermal Properties of Nanostructured 4 wt.% Al2 O3-YSZ Coatings Produced by Atmospheric Plasma Spraying. J. Therm. Spray Technol. 2010, 19, 1294–1300. [Google Scholar] [CrossRef]

- Loser, R.; Münch, B.; Lura, P. A volumetric technique for measuring the coefficient of thermal expansion of hardening cement paste and mortar. Cem. Concr. Res. 2010, 40, 1138–1147. [Google Scholar] [CrossRef]

- Szczucka-Lasota, B.; Węgrzyn, T.; Stanik, Z.; Piwnik, J.; Sidun, J. Selected parameters of micro-jet cooling gases in hybrid spraying process. Arch. Metall. Mater. 2016, 61, 621–624. [Google Scholar] [CrossRef]

- SL/T 3520-2020; Test Code for Hydraulic Concrete. Ministry of Water Resources of the People’s Republic of China: Beijing, China, 2020.

- ASTM D4541; Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers. ASTM International: West Conshohocken, PA, USA, 2009.

- Brito, V.R.S.S.; Bastos, I.N.; Costa HR, M. Corrosion resistance and characterization of metallic coatings deposited by thermal spray on carbon steel. Mater. Des. 2012, 41, 282–288. [Google Scholar] [CrossRef]

- Vuoristo, P. Thermal spray coating processes. In Comprehensive Materials Processing, 1st ed.; Volume 4: Coatings and films; Elsevier: Amsterdam, The Netherlands, 2014; pp. 229–276. [Google Scholar]

- Gizynski, M.; Chen, X.; Dusautoy, N.; Araki, H.; Kuroda, S.; Watanabe, M.; Pakiela, Z. Comparative study of the failure mechanism of atmospheric and suspension plasma sprayed thermal barrier coatings. Surf. Coat. Technol. 2019, 370, 163–176. [Google Scholar] [CrossRef]

- Jia, D.; Yi, P.; Liu, Y.; Sun, J.; Yue, S.; Zhao, Q. Effect of laser textured groove wall interface on molybdenum coating diffusion and metallurgical bonding. Surf. Coat. Technol. 2021, 405, 126561. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, Z.; Liang, H.; Wang, Y. Research progress of coating material/concrete interface. New Chem. Mater. 2020, 48, 281–284. [Google Scholar]

- Morales, A.; Piamba, O.; Olaya, J. Influence of gas pressure on the mechanical and tribological properties of Cu-Al coatings deposited via thermal spray. Coatings 2019, 9, 722. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, X.; Liu, M.; Jia, L.; Huang, Y.; Wang, H. Research Progress of the Sealant Decreased Thermal Spray Coating Porosity. Mater. Rep. 2023, 37, 210–228. [Google Scholar]

| Materials | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | Ignition Loss |

|---|---|---|---|---|---|---|---|

| Cement | 62.53 | 19.90 | 4.94 | 4.55 | 2.54 | 1.77 | 0.82 |

| Fly ash | 7.14 | 54.23 | 18.78 | 6.81 | 4.30 | 2.79 | 3.80 |

| Materials | Blain Area (m2/kg) | Setting Time | Compressive Strength | Flexural Strength | |||

|---|---|---|---|---|---|---|---|

| Initial Setting Time | Final Setting Time | 3 Days | 28 Days | 3 Days | 28 Days | ||

| Cement | 315.2 | 213 min | 318 h:min | 15.3 | 45.3 | 3.76 | 7.81 |

| GB175-2020 | ≥250 | ≥60 min | ≤720 h:min | ≥12.0 | ≥42.5 | ≥3.0 | ≥6.5 |

| Materials | Fineness | Blain Area | Density | Ratio of Water Requirements | Compressive Strength Ratio (%) | |

|---|---|---|---|---|---|---|

| 7 Days | 28 Days | |||||

| Fly ash | 9.5% | 330.2 m2/kg | 2140 kg/m3 | 94% | 64.0 | 71.1 |

| DL/T5055-2007 | ≤12.0% | - | - | ≤95% | - | - |

| Test Type | Test Materials | Test Methods | Test Indicators |

|---|---|---|---|

| Macro test | Concrete matrix | Compressive testing | Compressive strength |

| Tensile testing | Splitting tensile strength | ||

| Wear tests | Rate of wear | ||

| Coating | Interface adhesion testing | Interface adhesion | |

| Wearing testing | Rate of wear | ||

| Microscopic test | Coating and matrix | SEM-XRD analysis | Microstructure and phase composition |

| SEM-EDS testing | Microstructure and elemental composition | ||

| X-CT three-dimensional meso-structure testing | Three-dimensional visual reflection of the internal structure |

| Strength of Concrete Matrix (MPa) | Average Interface Coating Adhesion (MPa) | |

|---|---|---|

| Compression | Tension | |

| 40.0 | 3.26 | 3.82 |

| Reference Sample (g) | After Testing (g) | Rate of Wear (‰) | |

|---|---|---|---|

| Concrete matrix | 12.7396 | 12.7388 | 0.06 |

| Coating | 12.4662 | 12.4659 | 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Wang, Y.; Lv, X.; Jiang, W.; Wu, C. Application of Thermal Spraying Technology in Concrete Surface Ceramic-Based Coating. Coatings 2024, 14, 885. https://doi.org/10.3390/coatings14070885

Shi Y, Wang Y, Lv X, Jiang W, Wu C. Application of Thermal Spraying Technology in Concrete Surface Ceramic-Based Coating. Coatings. 2024; 14(7):885. https://doi.org/10.3390/coatings14070885

Chicago/Turabian StyleShi, Yan, Yupu Wang, Xingdong Lv, Wenguang Jiang, and Cai Wu. 2024. "Application of Thermal Spraying Technology in Concrete Surface Ceramic-Based Coating" Coatings 14, no. 7: 885. https://doi.org/10.3390/coatings14070885

APA StyleShi, Y., Wang, Y., Lv, X., Jiang, W., & Wu, C. (2024). Application of Thermal Spraying Technology in Concrete Surface Ceramic-Based Coating. Coatings, 14(7), 885. https://doi.org/10.3390/coatings14070885