Enhancing UV Radiation Resilience of DLC-Coated Stainless Steel with TiO2: A Dual-Layer Approach

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate Preparation

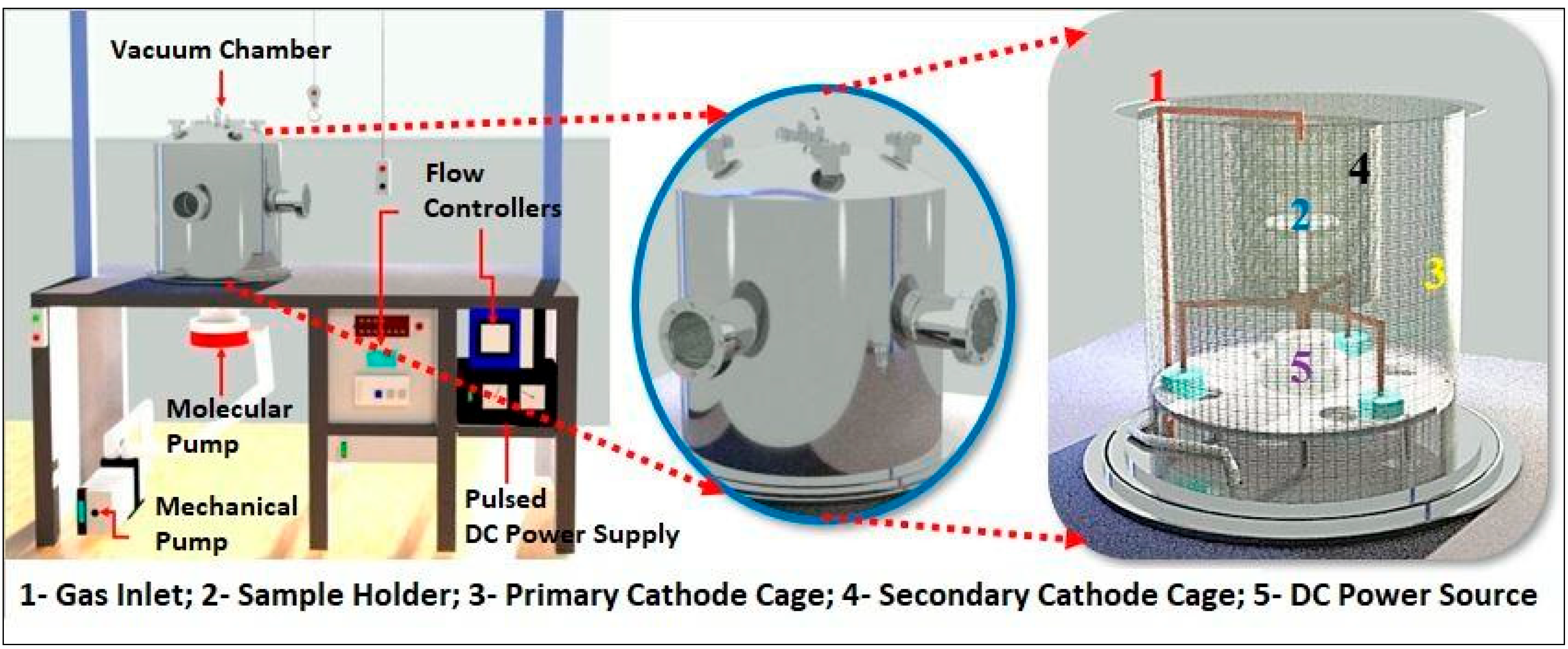

2.2. DLC Deposition Process

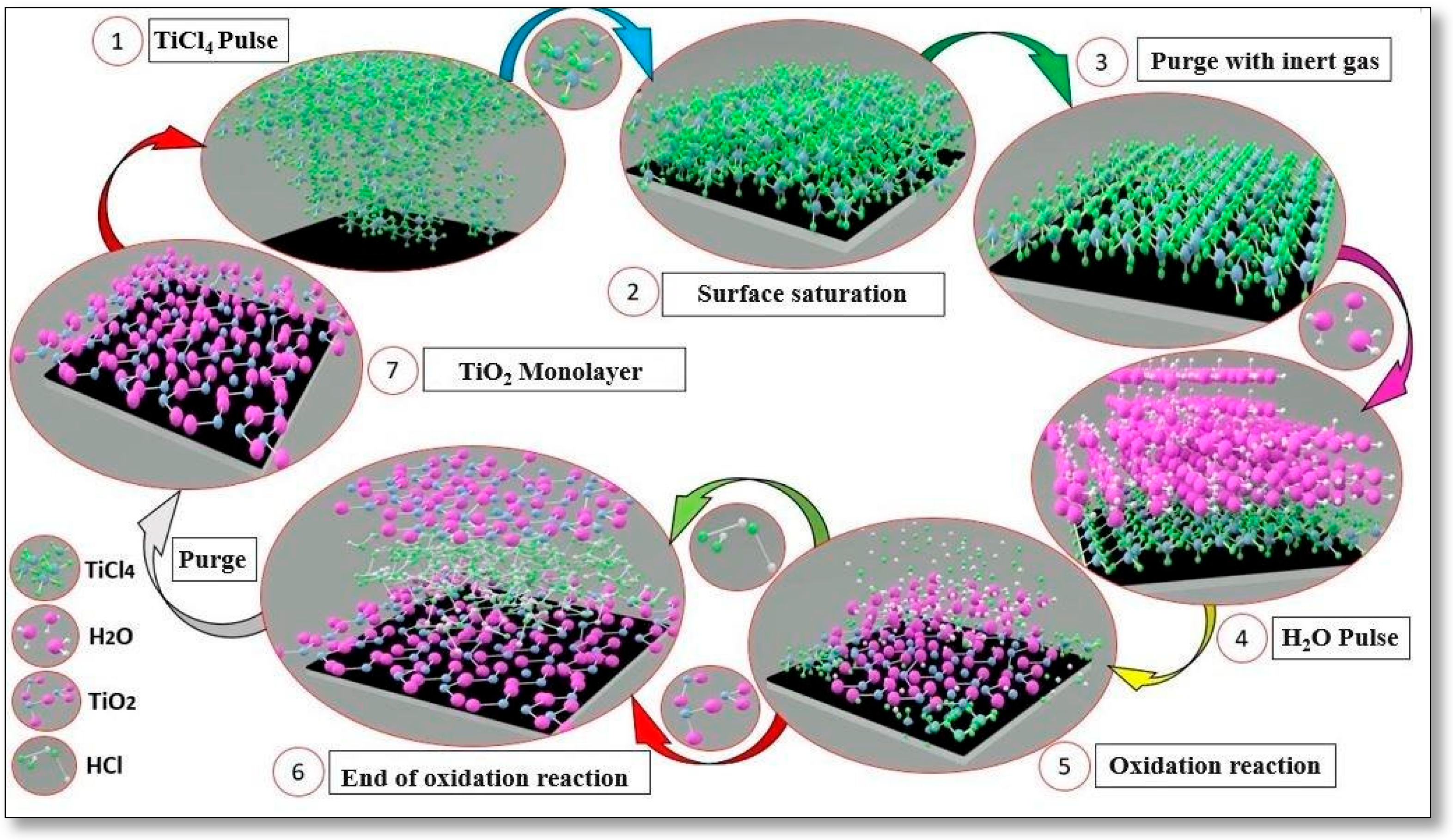

2.3. TiO2 Layer Deposition Process

2.4. Films Characterization

2.4.1. Raman Spectroscopy

2.4.2. Roughness and Thickness

2.4.3. Adherence Evaluation

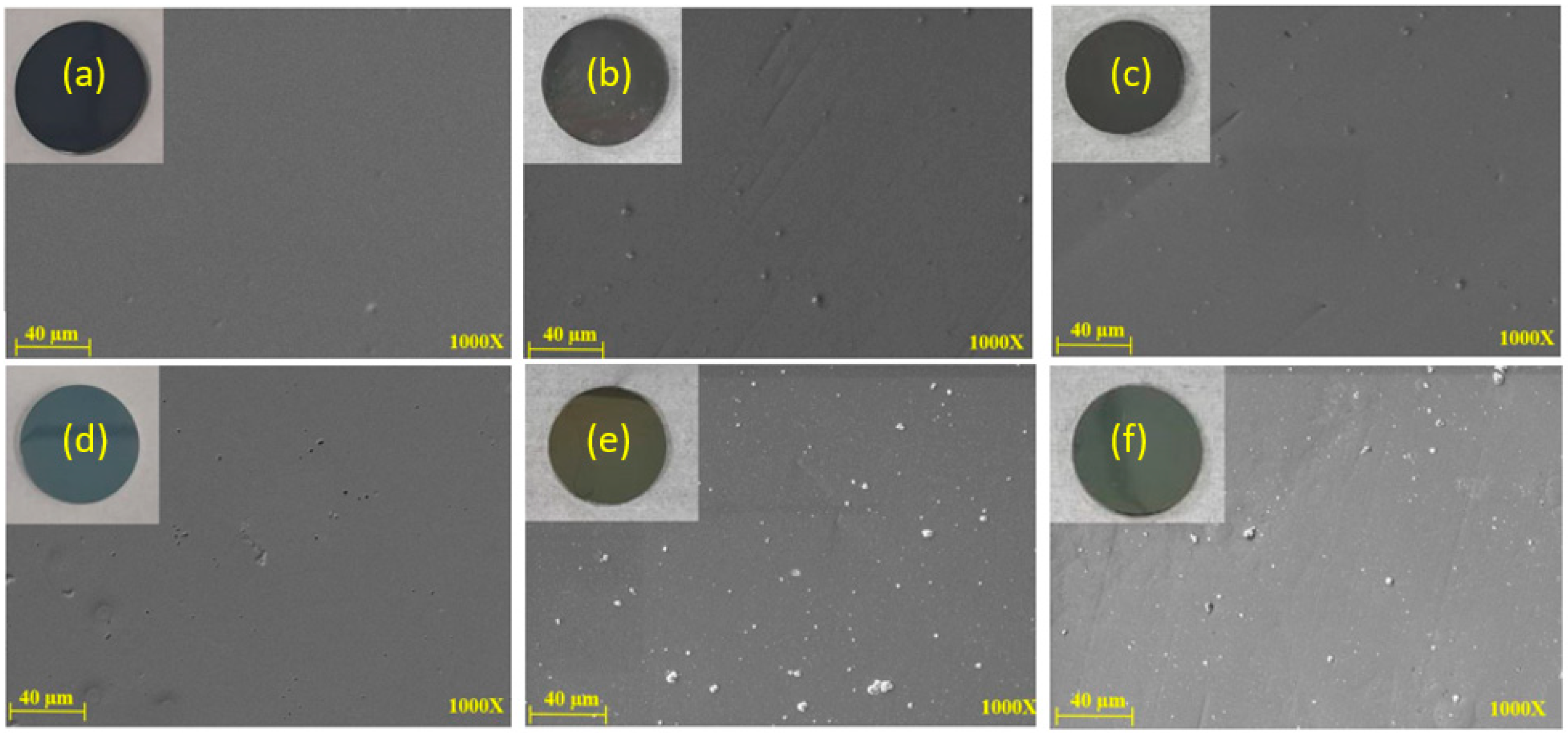

2.4.4. Surface Evaluation

2.4.5. Hardness Evaluation

2.4.6. UV Light Ageing Test

3. Results and Discussion

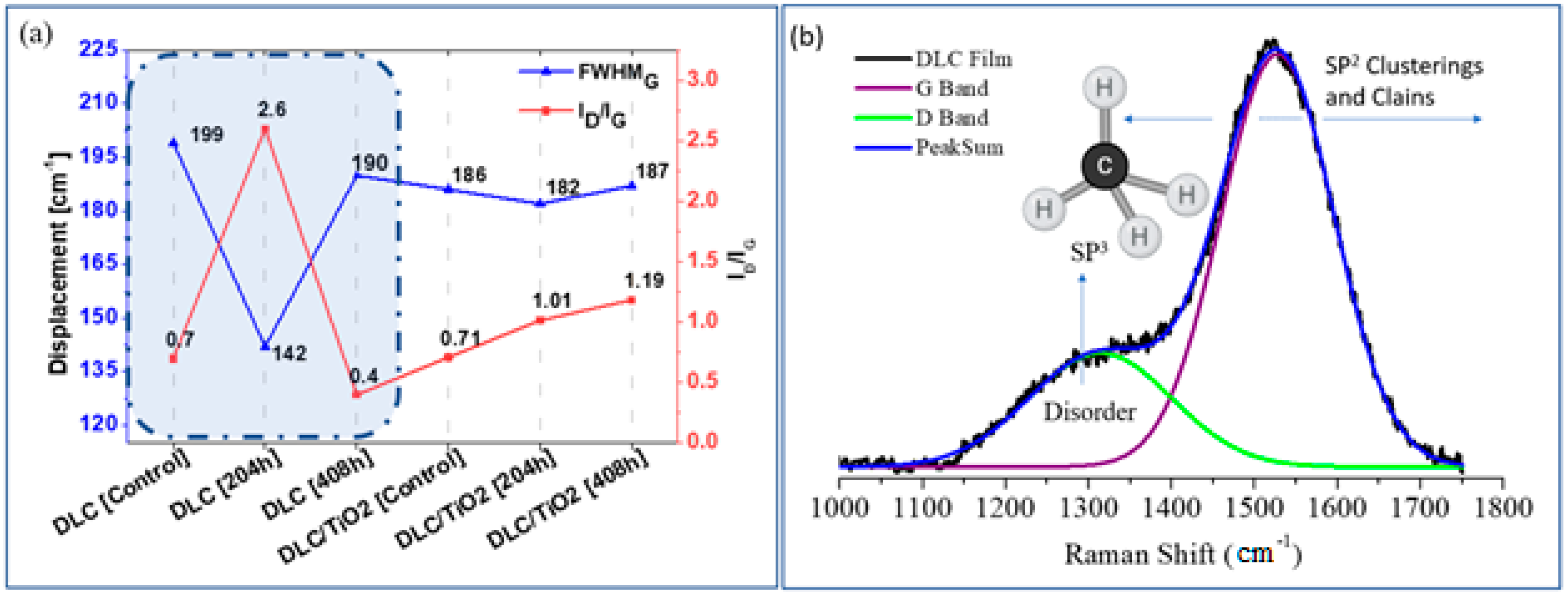

3.1. DLC and TiO2 Chemical Structure

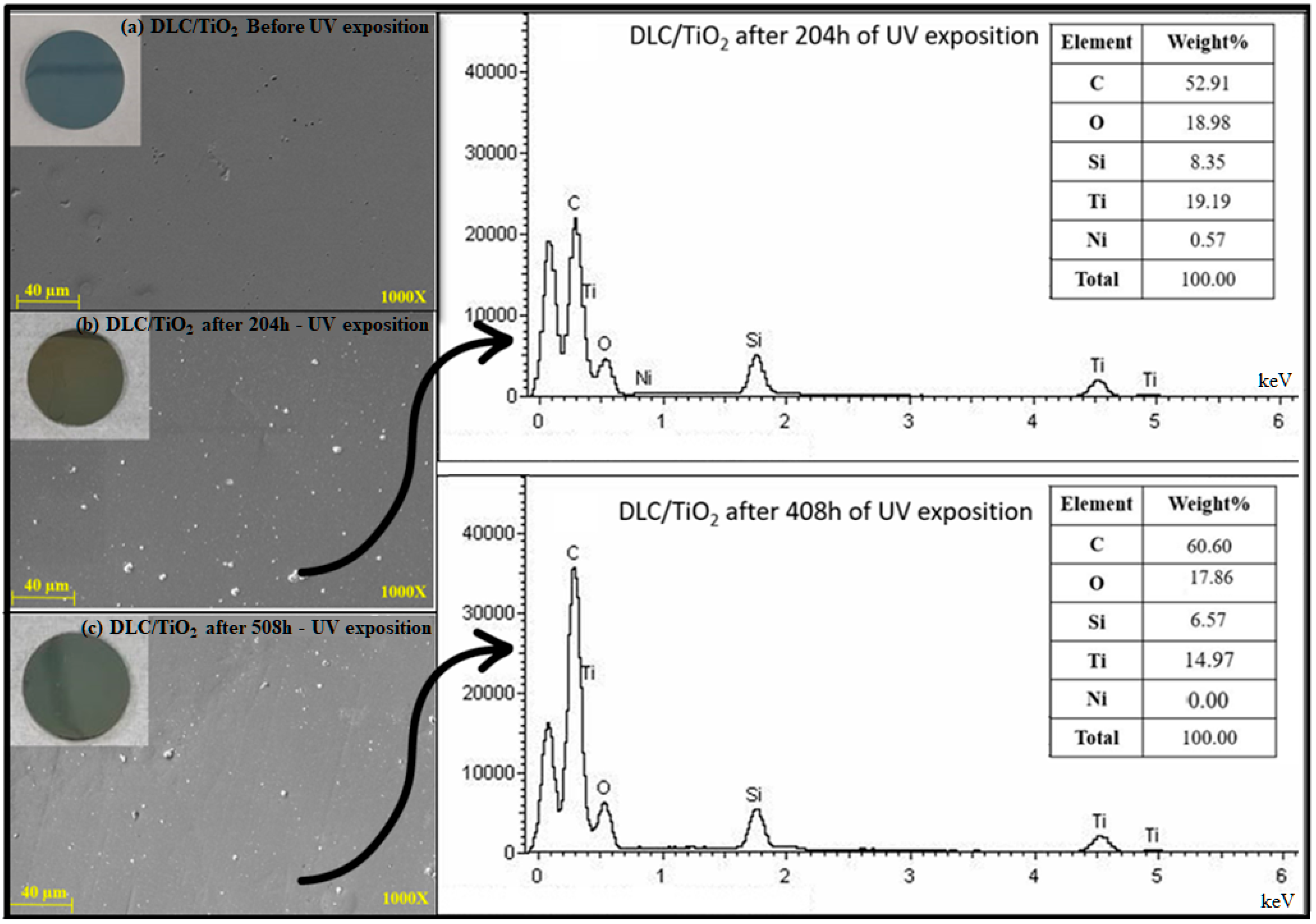

3.2. Results of the UV Ageing Test

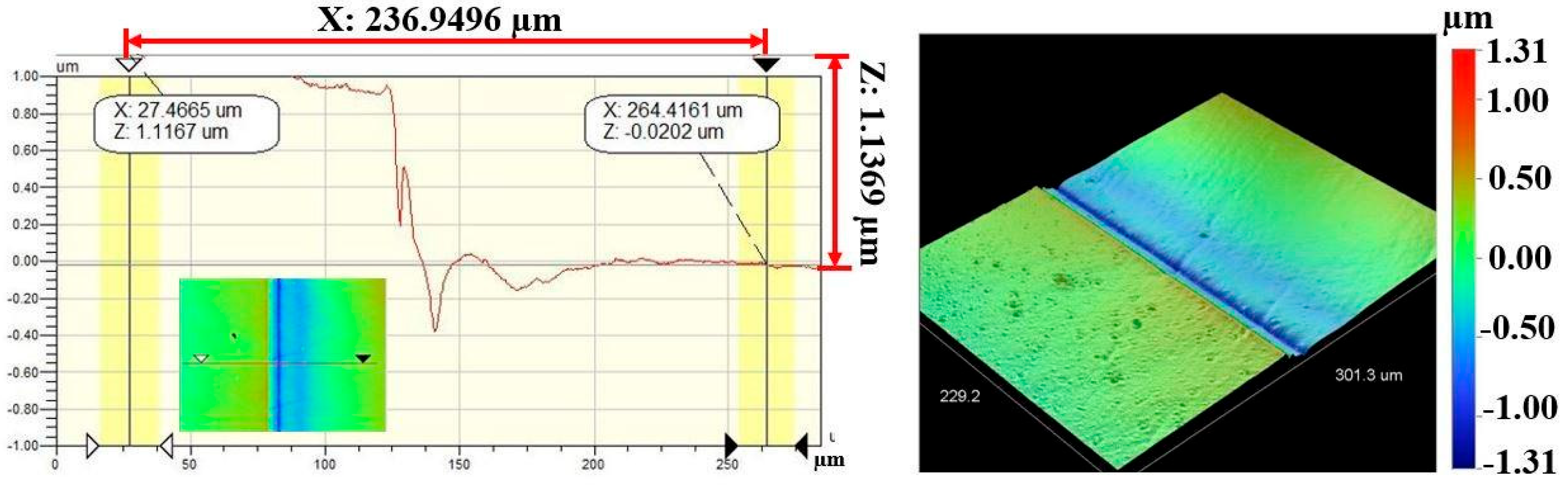

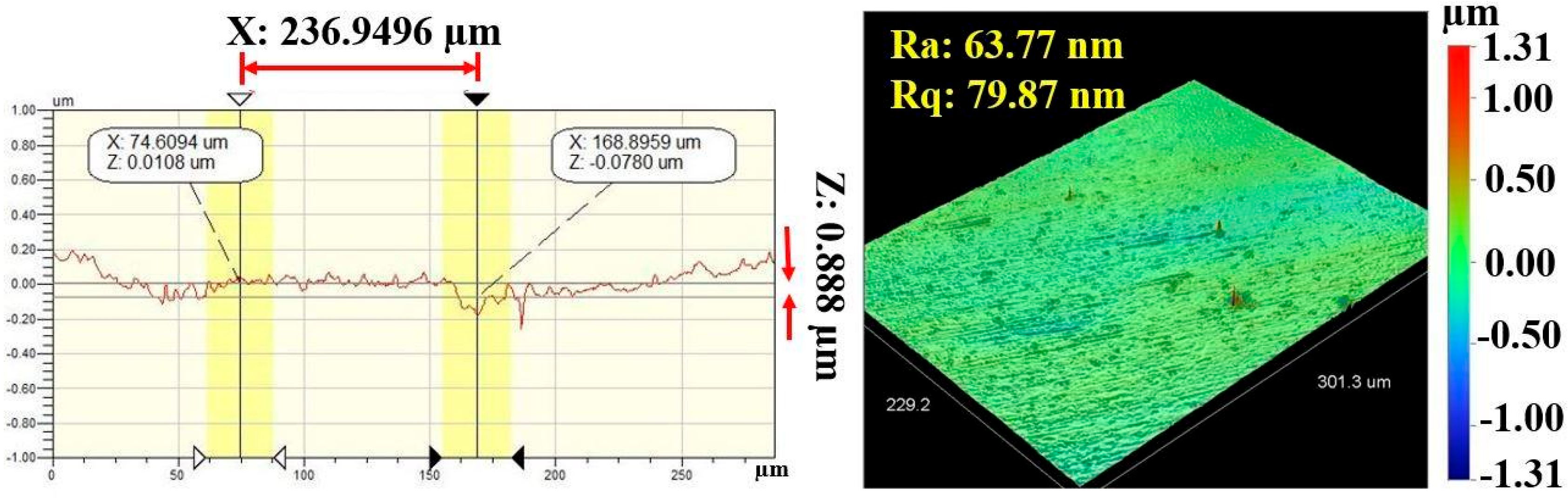

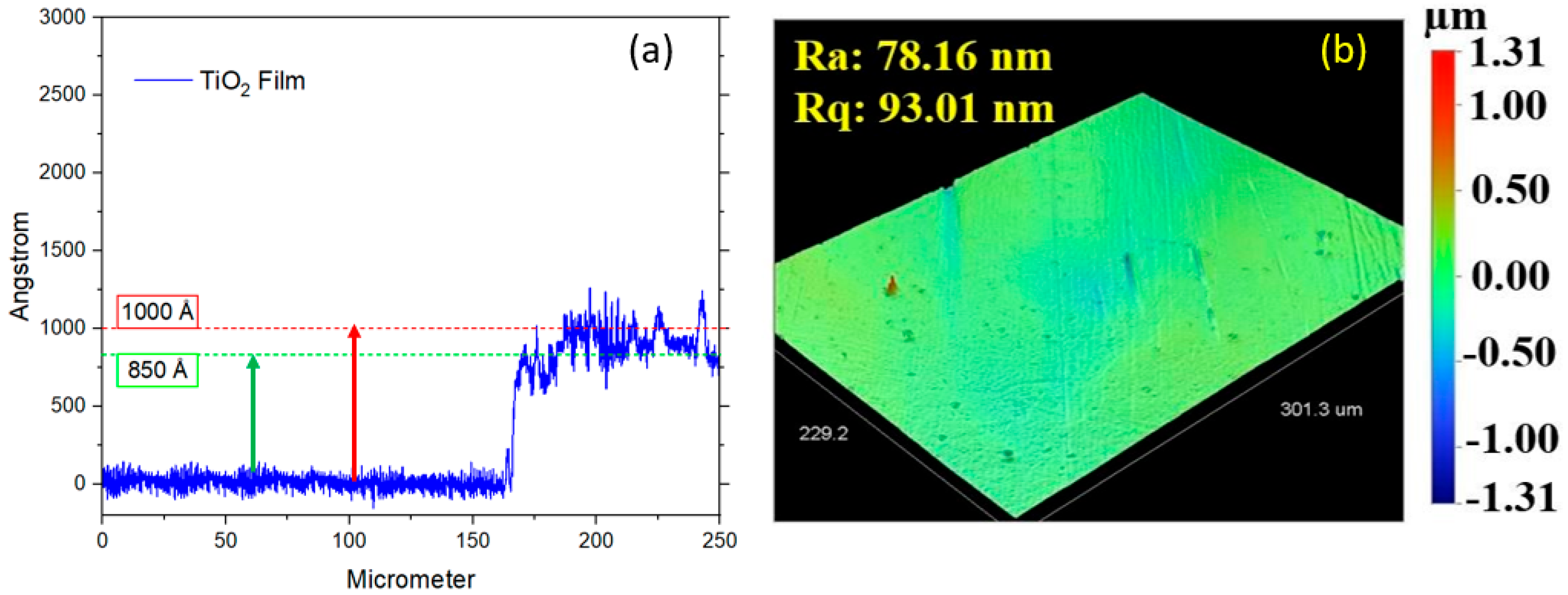

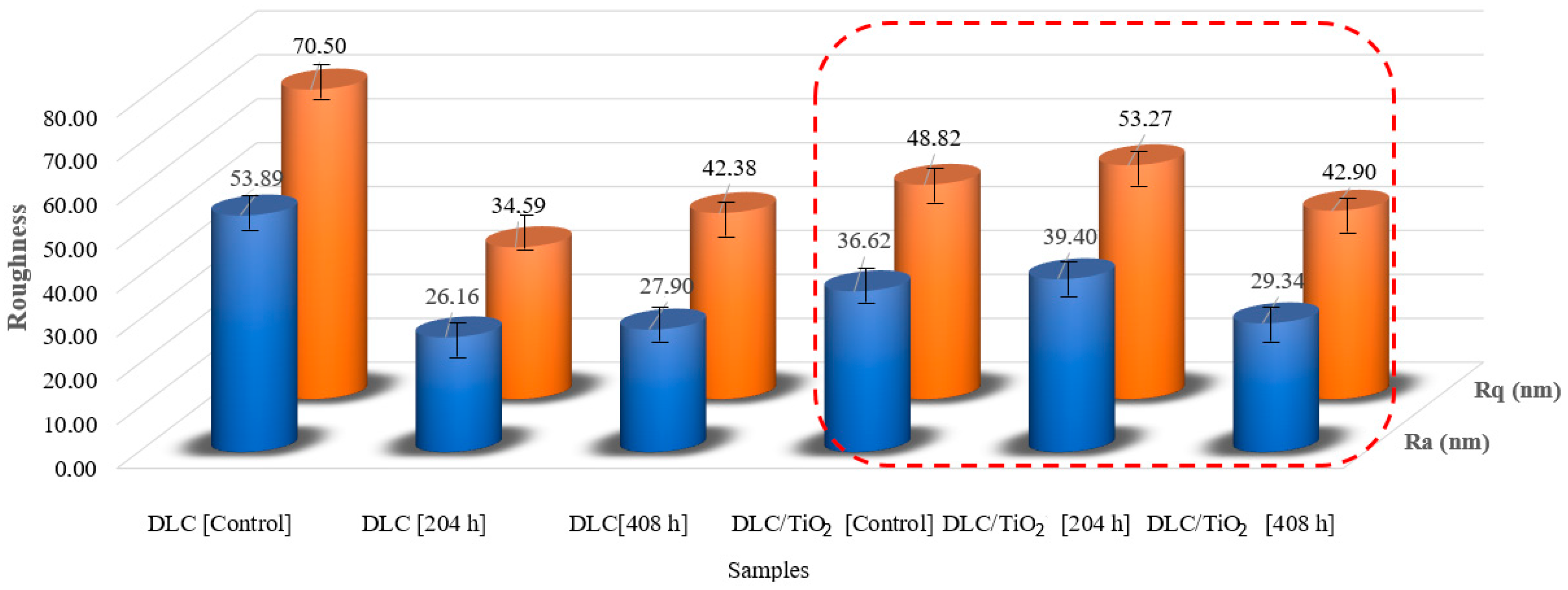

3.3. Film Thickness and Roughness Measurements

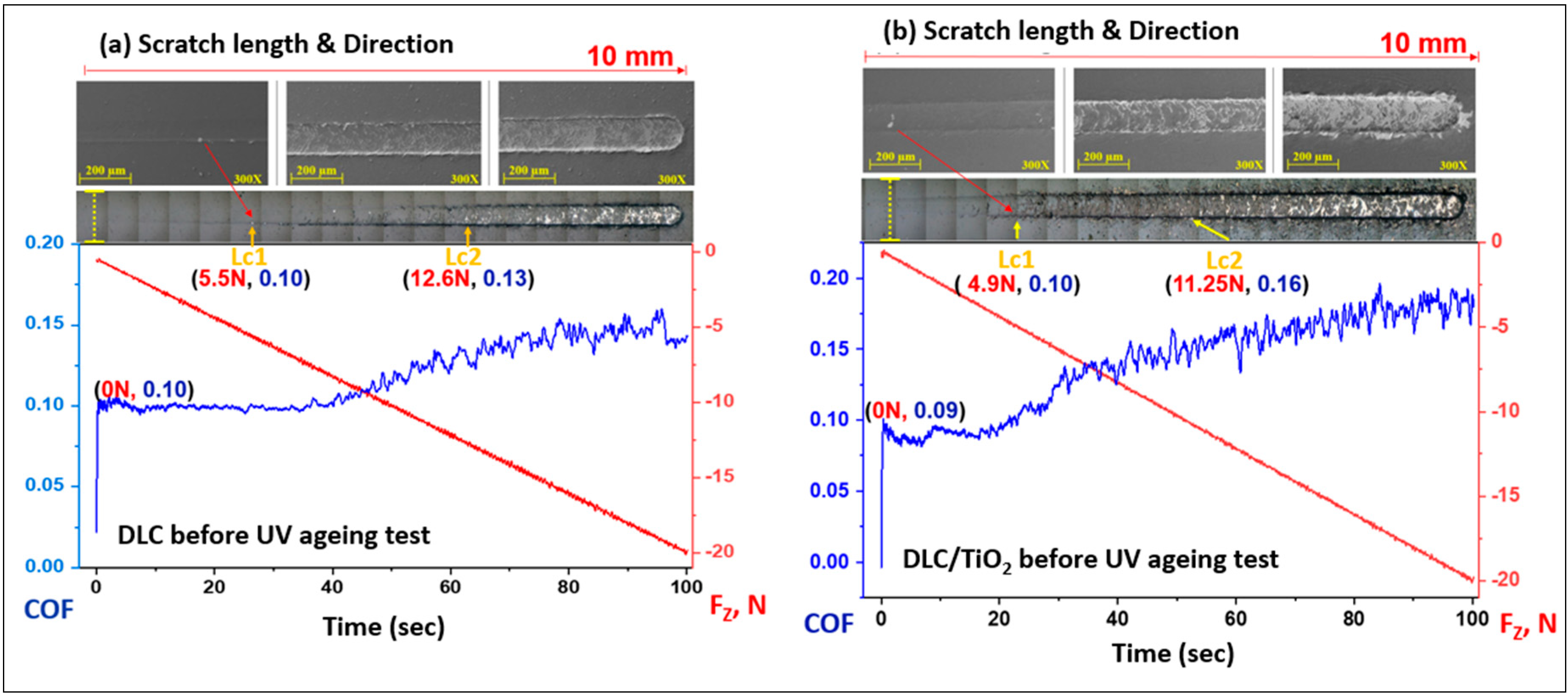

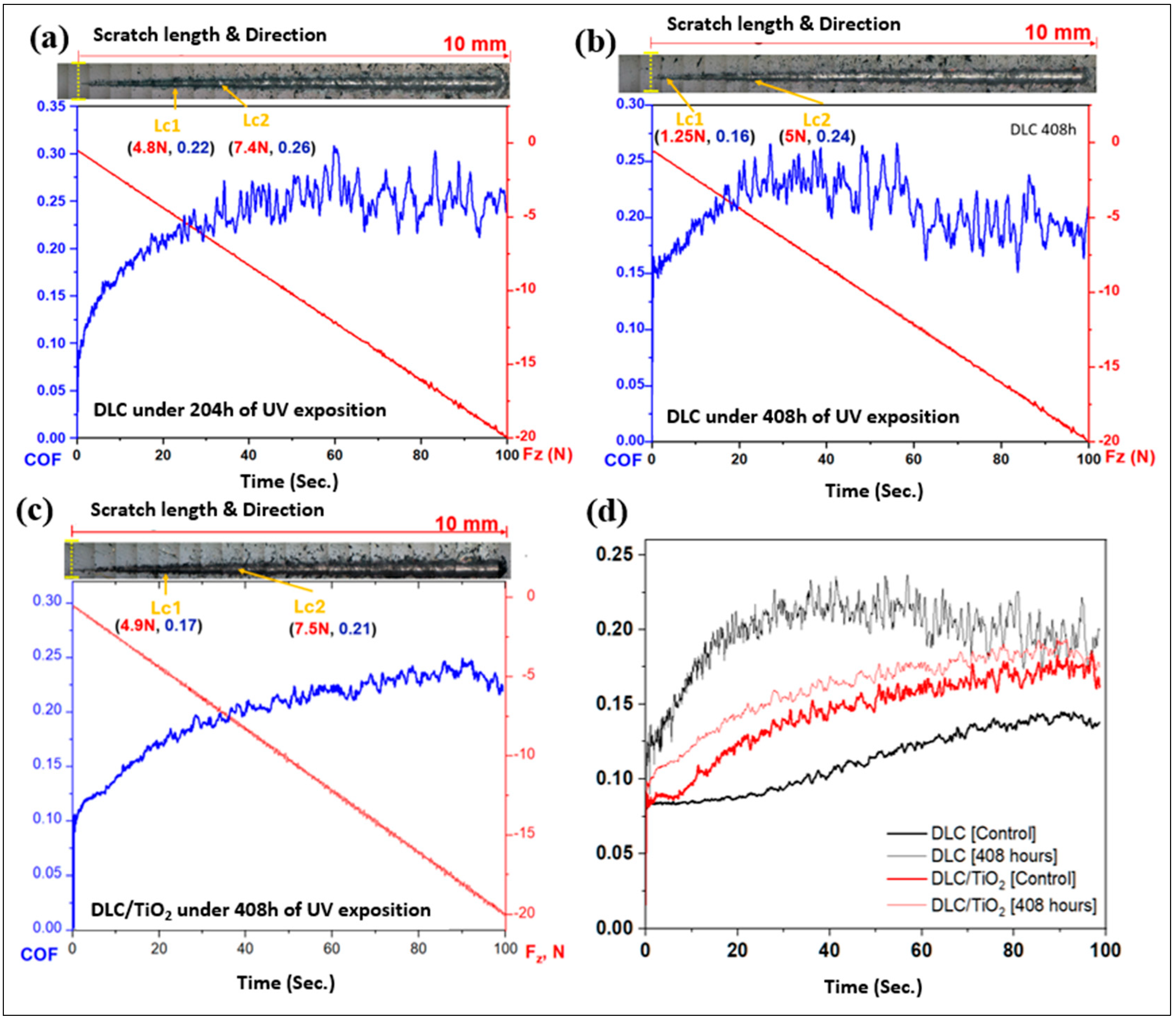

3.4. Adhesion Strength

3.5. Hardness and Elastic Modulus

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rajak, D.K.; Kumar, A.; Behera, A.; Menezes, P.L. Diamond-Like Carbon (DLC) Coatings: Classification, Properties, and Applications. Appl. Sci. 2021, 11, 4445. [Google Scholar] [CrossRef]

- Liu, X.; Wang, L.; Pu, J.; Xue, Q. Surface composition variation and high-vacuum performance of DLC/ILs solid-liquid lubricating coatings: Influence of space irradiation. Appl. Surf. Sci. 2012, 258, 8289–8297. [Google Scholar] [CrossRef]

- Wu, Y.; Li, H.; Ji, L.; Liu, L.; Ye, Y.; Chen, J.; Zhou, H. Effect of vacuum annealing on the microstructure and tribological behaviour of hydrogenated amorphous carbon films prepared by magnetron sputtering. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 729–737. [Google Scholar] [CrossRef]

- Rao, J.; Lawson, K.J.; Nicholls, J.R. The characterisation of e-beam evaporated and magnetron sputtered carbon films fabricated for atomic oxygen sensors. Surf. Coat. Technol. 2005, 197, 154–160. [Google Scholar] [CrossRef]

- Adliene, D.; Laurikaitiene, J.; Tamulevičius, S. Modification of amorphous DLC films induced by MeV photon irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2008, 266, 2788–2792. [Google Scholar] [CrossRef]

- Vankar, V.D.; Dilawar, N. Ion irradiation effects in diamond and diamond-like carbon thin films. Vacuum 1996, 47, 1275–1280. [Google Scholar] [CrossRef]

- Shan, C.X.; Hou, X.; Choy, K.L. Corrosion resistance of TiO2 films grown on stainless steel by atomic layer deposition. Surf. Coat. Technol. 2008, 202, 2399–2402. [Google Scholar] [CrossRef]

- Mohr, L.C.; Capelezzo, A.P.; Baretta, C.R.D.M.; Martins, M.A.P.M.; Fiori, M.A.; Mello, J.M.M. Titanium dioxide nanoparticles applied as ultraviolet radiation blocker in the polylactic acid biodegradable polymer. Polym. Test. 2019, 77, 105867. [Google Scholar] [CrossRef]

- Hanaor, D.A.H.; Sorrell, C.C. Review of the anatase to rutile phase transformation. J. Mater. Sci. 2011, 46, 855–874. [Google Scholar] [CrossRef]

- Weng, K.W.; Huang, Y.P. Preparation of TiO2 thin films on glass surfaces with self-cleaning characteristics for solar concentrators. Surf. Coat. Technol. 2013, 231, 201–204. [Google Scholar] [CrossRef]

- Matějová, L.; Cieslarová, M.; Matěj, Z.; Daniš, S.; Peikertová, P.; Šihor, M.; Lang, J.; Matějka, V. Microstructure, optical and photocatalytic properties of TiO2 thin films prepared by chelating-agent assisted sol-gel method. J. Nanosci. Nanotechnol. 2016, 16, 504–514. [Google Scholar] [CrossRef]

- Colmenares, J.C.; Luque, R.; Campelo, J.M.; Colmenares, F.; Karpiński, Z.; Romero, A.A. Nanostructured photocatalysts and their applications in the photocatalytic transformation of lignocellulosic biomass: An overview. Materials 2009, 2, 2228–2258. [Google Scholar] [CrossRef]

- Zia, A.W.; Birkett, M. Deposition of diamond-like carbon coatings: Conventional to non-conventional approaches for emerging markets. Ceram. Int. 2021, 47, 28075–28085. [Google Scholar] [CrossRef]

- Schlebrowski, T.; Acharchi, H.; Hahn, B.; Wehner, S.; Fischer, C.B. Refinement of sustainable polybutylene adipate terephthalate (PBAT) with amorphous hydrogenated carbon films (a-C:H) Revealing Film Instabilities Influenced by a thickness-dependent change of sp2/sp3 ratio. Materials 2020, 13, 1077. [Google Scholar] [CrossRef]

- Vitelaru, C.; Parau, A.C.; Constantin, L.R.; Kiss, A.E.; Vladescu, A.; Sobetkii, A.; Kubart, T. A strategy for alleviating micro arcing during HiPIMS deposition of DLC coatings. Materials 2020, 13, 1038. [Google Scholar] [CrossRef] [PubMed]

- Malisz, K.; Świeczko-Żurek, B.; Sionkowska, A. Preparation and Characterization of Diamond-like Carbon Coatings for Biomedical Applications—A Review. Materials 2023, 16, 3420. [Google Scholar] [CrossRef]

- Capote, A.; Capote, G.; Corat, E.J.; Trava-Airoldi, V.J. Effect of low-pressure deposition on the mechanical and tribological properties of a-C:H films deposited via modified pulsed-DC PECVD with active screen as an additional cathode. Surf. Coat. Technol. 2022, 445, 128716. [Google Scholar] [CrossRef]

- Zheng, J.; Liu, Q.; Li, Z. Effect of negative bias voltage on properties of hydrogenated diamond-like carbon films. Guangxue Jingmi Gongcheng/Opt. Precis. Eng. 2022, 30, 411–420. [Google Scholar] [CrossRef]

- Liu, Z.; Yin, P.; Wei, X.; Ding, Q.; Cao, X.; Zhang, G.; Xue, Q. Simultaneous deposition of DLC film on the internal surface of multiple pipes. Diam. Relat. Mater. 2022, 127, 109187. [Google Scholar] [CrossRef]

- Bora, J.; Basumatary, B.; Podder, S.; Gogoi, D.; Sharma, B.; Bhagowati, P.; Choudhury, B.; Patil, D.S.; Pal, A.R. A substrate constituent Na-catalyzed growth of carbon nanotubes on glass substrate by atmospheric pressure PECVD. Appl. Surf. Sci. 2024, 648, 158988. [Google Scholar] [CrossRef]

- Guo, C.Q.; Li, H.Q.; Peng, Y.L.; Dai, M.J.; Lin, S.S.; Shi, Q.; Wei, C.B. Residual stress and tribological behavior of hydrogen-free Al-DLC films prepared by HiPIMS under different bias voltages. Surf. Coat. Technol. 2022, 445, 128713. [Google Scholar] [CrossRef]

- Liaqat, M.A.; Hussain, Z.; Khan, Z.; Akram, M.A.; Shuja, A. Effects of Ag doping on compact TiO2 thin films synthesized via one-step sol–gel route and deposited by spin coating technique. J. Mater. Sci. Mater. Electron. 2020, 31, 7172–7181. [Google Scholar] [CrossRef]

- Yang, B. Applications of Titania Atomic Layer Deposition in the Biomedical Field and Recent Updates. Am. J. Biomed. Sci. Res. 2020, 8, 465–468. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, X.; Chen, H.; Zhang, K.; Qin, C.; Liu, J.; Peng, W.; Islam, A.; Bi, E.; Ye, F.; et al. Highly compact TiO2 layer for efficient hole-blocking in perovskite solar cells. Appl. Phys. Express 2014, 7, 052301. [Google Scholar] [CrossRef]

- Aghaee, M.; Verheyen, J.; Stevens, A.A.E.; Kessels, W.M.M.; Creatore, M. TiO2 thin film patterns prepared by chemical vapor deposition and atomic layer deposition using an atmospheric pressure microplasma printer. Plasma Process. Polym. 2019, 16, 1900127. [Google Scholar] [CrossRef]

- Bonetti, L.F.; Capote, G.; Santos, L.V.; Corat, E.J.; Trava-Airoldi, V.J. Adhesion studies of diamond-like carbon films deposited on Ti6Al4V substrate with a silicon interlayer. Thin Solid Film. 2006, 515, 375–379. [Google Scholar] [CrossRef]

- Macário, P.F.; Vieira, A.; Manfroi, L.; da Silva, M.G.P.; Leite, P.; Vieira, L. Corrosion behavior of Al2024-T3, Al5052-H32, and Al6061-T6 aluminum alloys coated with DLC films in aviation fuel medium, Jet A-1 and AVGAS 100LL. Mater. Corros. 2019, 70, 2278–2291. [Google Scholar] [CrossRef]

- ASTM C1624-05; Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing. ASTM-International: West Conshohocken, PA, USA, 2005; pp. 1–28.

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Fang, T.H.; Chang, W.J. Nanomechanical characterization of amorphous hydrogenated carbon thin films. Appl. Surf. Sci. 2006, 252, 6243–6248. [Google Scholar] [CrossRef]

- ASTM-G154; Standard Practice for Operating Fluorescent Light Apparatus for UV Exposure of Nonmetallic Materials. ASTM-International: West Conshohocken, PA, USA, 2000.

- Ouyang, Y.; Cong, L.M.; Chen, L.; Liu, Q.X.; Fang, Y. Raman study on single-walled carbon nanotubes and multi-walled carbon nanotubes with different laser excitation energies. Phys. E Low-Dimens. Syst. Nanostruct. 2008, 40, 2386–2389. [Google Scholar] [CrossRef]

- Fontaine, J.; Donnet, C.; Erdemir, A. Fundamentals of the tribology of DLC coatings. In Tribology of Diamond-Like Carbon Films; Springer: Boston, MA, USA, 2008; pp. 139–154. [Google Scholar]

- Pierson, H.O. Handbook of Carbon, Graphite, Diamonds and Fullerenes; Noyes Publications: Norwich, NY, USA, 1993; pp. 43–69. [Google Scholar]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Resonant Raman spectroscopy of disordered, amorphous, and diamondlike carbon. Phys. Rev. B 2001, 64, 075414. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Raman spectroscopy of amorphous, nanostructured, diamond-like carbon, and nanodiamond. Philos. Trans. A Math. Phys. Eng. Sci. 2004, 362, 2477–2512. [Google Scholar] [CrossRef]

- Grill, A. Diamond-like carbon: State of the art. Diam. Relat. Mater. 1999, 8, 428–434. [Google Scholar] [CrossRef]

- Guo, D.; Zhang, S.; Huang, T.; Wu, S.; Ma, X.; Guo, F. Corrosion Properties of DLC Film in Weak Acid and Alkali Solutions. Coatings 2022, 12, 1776. [Google Scholar] [CrossRef]

- Zavaleyev, V.; Walkowicz, J.; Sawczak, M.; Moszyński, D.; Ryl, J. Effect of substrate bias on the properties of DLC films created using a combined vacuum arc. Bull. Mater. Sci. 2021, 44, 170. [Google Scholar] [CrossRef]

- Zhang, C.Z.; Tang, Y.; Li, Y.S.; Yang, Q. Adhesion enhancement of diamond-like carbon thin films on Ti alloys by incorporation of nanodiamond particles. Thin Solid Film. 2013, 528, 111–115. [Google Scholar] [CrossRef]

- Fayed, S.M.; Chen, D.; Li, S.; Zhou, Y.; Wang, H.; Sadawy, M.M. Corrosion behavior and passive stability of multilayer DLC-Si coatings. Surf. Coat. Technol. 2022, 431, 128001. [Google Scholar] [CrossRef]

- Schwan, J.; Ulrich, S.; Batori, V.; Ehrhardt, H.; Silva, S.R.P. Raman spectroscopy on amorphous carbon films. J. Appl. Phys. 1996, 80, 440–447. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordrred and amorphous carbon. Surf. Coat. Technol. 2000, 61, 14095. [Google Scholar]

- Marciano, F.R.; Bonetti, L.F.; Pessoa, R.S.; Massi, M.; Santos, L.V.; Trava-Airoldi, V.J. Oxygen plasma etching of silver-incorporated diamond-like carbon films. Thin Solid Film. 2009, 517, 5739–5742. [Google Scholar] [CrossRef]

- Capote, G.; Silva, G.F.; Trava-Airoldi, V.J. Effect of hexane precursor diluted with argon on the adherent diamond-like properties of carbon films on steel surfaces. Thin Solid Film. 2015, 589, 286–291. [Google Scholar] [CrossRef]

- Rodriguez, B.J.; Navabpour, P.; Proprentner, D.; Walker, M.; Sun, H.; Schiller, T.L. An alternative approach to the tribological analysis of Si-doped DLC coatings deposited with different bias voltages using Raman spectroscopy mapping. Emergent Mater. 2021, 4, 1595–1604. [Google Scholar] [CrossRef]

- Rao, X.; Yang, J.; Chen, Z.; Yuan, Y.; Chen, Q.; Feng, X.; Qin, L.; Zhang, Y. Tuning C–C sp2/sp3 ratio of DLC films in FCVA system for biomedical application. Bioact. Mater. 2020, 5, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Aobo Wei Guozheng Ma, G.L.Z.L.C.H.H.Z.W.G.Z.X.; Haidou, W. Effect of space UV irradiation on the mechanical and tribological properties of Cr and B doped hydrogen-containing diamond-like films. Fuller. Nanotub. Carbon Nanostruct. 2023, 31, 513–522. [Google Scholar]

- Staszuk, M. Application of PVD and ALD methods for surface treatment of Al-Si-Cu alloys. Solid State Phenom. 2019, 293, 97–109. [Google Scholar] [CrossRef]

- Chiappim, W.; Testoni, G.E.; de Lima, J.S.B.; Medeiros, H.S.; Pessoa, R.S.; Grigorov, K.G.; Vieira, L.; Maciel, H.S. Effect of Process Temperature and Reaction Cycle Number on Atomic Layer Deposition of TiO2 Thin Films Using TiCl4 and H2O Precursors: Correlation Between Material Properties and Process Environment. Braz. J. Phys. 2016, 46, 56–69. [Google Scholar] [CrossRef]

- Aarik, L.; Arroval, T.; Rammula, R.; Mändar, H.; Sammelselg, V.; Aarik, J. Atomic layer deposition of TiO2 from TiCl4 and O3. Thin Solid Film. 2013, 542, 100–107. [Google Scholar] [CrossRef]

- Wadullah, H.M.; Ajeel, S.A.; Abbass, M.K. Synthesis and Characterization of Nanocoatings Thin films by Atomic Layer Deposition for Medical Applications. IOP Conf. Ser. Mater. Sci. Eng. 2019, 518, 032057. [Google Scholar] [CrossRef]

- Abas, M.; Al Awadh, M.; Habib, T.; Noor, S. Analyzing Surface Roughness Variations in Material Extrusion Additive Manufacturing of Nylon Carbon Fiber Composites. Polymers 2023, 15, 3633. [Google Scholar] [CrossRef]

- Kadhim, H.K.; Alyounis, M. Effect of surface roughness on the interface behavior of clayey soils. Open Eng. 2024, 14, 20220578. [Google Scholar] [CrossRef]

- Sveen, S.; Andersson, J.M.; M’Saoubi, R.; Olsson, M. Scratch adhesion characteristics of PVD TiAlN deposited on high speed steel, cemented carbide and PCBN substrates. Wear 2013, 308, 133–141. [Google Scholar] [CrossRef]

- Ligot, J.; Benayoun, S.; Hantzpergue, J.J. Analysis of cracking induced by scratching of tungsten coatings on polyimide substrate. Wear 2000, 243, 85–91. [Google Scholar] [CrossRef]

- Burnett, P.J.; Rickerby, D.S. The relationship between hardness and scratch adhession. Thin Solid Film. 1987, 154, 403–416. [Google Scholar] [CrossRef]

- Bull, S.J. Failure mode maps in the thin film scratch adhesion test. Tribol. Int. 1997, 30, 491–498. [Google Scholar] [CrossRef]

- Savvides, N.; Bell, T.J. Microhardness and Young’s modulus of diamond and diamondlike carbon films. J. Appl. Phys. 1992, 72, 2791–2796. [Google Scholar] [CrossRef]

- Bec, S.; Tonck, A.; Fontaine, J. Nanoindentation and nanofriction on DLC films. Philos. Mag. 2006, 86, 5465–5476. [Google Scholar] [CrossRef]

- Bewilogua, K.; Hofmann, D. History of diamond-like carbon films—From first experiments to worldwide applications. Surf. Coat. Technol. 2014, 242, 214–225. [Google Scholar] [CrossRef]

| Series 300 | Type | Chemical Composition | Specific Weight [g/cm3] | Elasticity Module [N/mm2] | Structure | Brinell Hardness |

|---|---|---|---|---|---|---|

| ASTM (AISI) 316L | Chrome Nickel Molybdenum Steel | C% 0.03 max. Mn% 2.00 max. Si% 1.00 max. Cr% 16.00 Ni% 10.00 Mo% 2.00 | 7.95 | 193.000 | Austenitic | Annealed HRB 120–170 |

| Stage | Gas | Work Pressure [Pa] | Voltage [V] | Current [A] | Gas Flow [sccm] | Time [min] |

|---|---|---|---|---|---|---|

| Cleaning | Argon | 0.4 | 600 | 0.10 | 10 | 20 |

| Transition | Argon | 2.26 | 700 | 0.05 | 5 | 5 |

| Silane | 5 | |||||

| Interlayer | Silane | 2.66 | 700 | 0.05 | 5 | 15 |

| Transition | Silane | 1.06 | 700 | 0.07 | 5 | 5 |

| Acetylene | 15 | |||||

| Deposition | Acetylene | 0.8 to 0.93 | 700 | 0.07 | 15 | 120 |

| Sample Type | Band D | Band G | ||

|---|---|---|---|---|

| Band Position [cm−1] | Band Position [cm−1] | FWHM [cm−1] | ID/IG | |

| DLC | 1346–1365 | 1539–1544 | 195–203 | 0.52–0.73 |

| DLC/TiO2 | 1369–1375 | 1547–1549 | 186–188 | 0.68–071 |

| Sample Type | Band D | Band G | ||

|---|---|---|---|---|

| Band Position [cm−1] | Band Position [cm−1] | FWHM [cm−1] | ID/IG | |

| DLC [204 h] | 1363–1412 | 1546–1577 | 114–170 | 2.4–2.8 |

| DLC [408 h] | 1243–1336 | 1528–1541 | 190–255 | 0.3–0.5 |

| DLC/TiO2 [204 h] | 1368–1370 | 1544–1546 | 179–181 | 1.08–1.15 |

| DLC/TiO2 [408 h] | 1374–1388 | 1545–1546 | 182–188 | 1.2–1.3 |

| FWHMG | FWHMG %Comp. | ID/IG | ID/IG %Comp. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DLC | control | 199 |  |  | 28.64% |  | 0.7 |  |  | 371.4% |  |

| [204 h] | 142 | 2.6 | |||||||||

| [408 h] | 190 | 4.52% | 0.4 | 42.8% | |||||||

| DLC/TiO2 | control | 186 |  |  | 2.15% | 0.71 |  |  | 42.0% |  | |

| [204 h] | 182 | 1.01 | |||||||||

| [408 h] | 187 | 0.53% | 1.19 | 67.60 | |||||||

| Comparison of Friction Coefficient [COF] | ||||||

|---|---|---|---|---|---|---|

| Sample Type | Mean | Minimum | Median | Maximum | Standard Deviation | Avg. % Variation vs. Control |

| [DLC/TiO2 408 h] | 0.15 | 0.022 | 0.16 | 0.19 | 0.030 | 7.14 |

| [DLC/TiO2 control] | 0.14 | 0.016 | 0.14 | 0.18 | 0.032 | - |

| [DLC 408 h] | 0.19 | 0.042 | 0.20 | 0.24 | 0.034 | 72.72 |

| [DLC control] | 0.11 | 0.024 | 0.10 | 0.14 | 0.022 | - |

| DLC [Control] | DLC [204 h] | DLC [408 h] | DLC/TiO2 [Control] | DLC/TiO2 [204 h] | DLC/TiO2 [408 h] | Literature a-C:H | |

|---|---|---|---|---|---|---|---|

| Hardness (GPa) | 26.29 | 18.10 | 19.38 | 12.80 | 10.58 | 9.9 | 7–30 |

| Elastic Modulus (GPa) | 204.21 | 183.17 | 189.54 | 191.93 | 198.82 | 229.08 | 60–210 |

| H/E ratio | 0.13 | 0.1 | 0.1 | 0.07 | 0.053 | 0.043 | 0.1–0.16 |

| References | [30,33,60,61,62] | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Macário, P.F.; da Silveira, C.H.; Vieira, A.A.M.; Marcondes, A.R.; Marques, F.d.C.; Fechine, G.J.M.; Vieira, L. Enhancing UV Radiation Resilience of DLC-Coated Stainless Steel with TiO2: A Dual-Layer Approach. Coatings 2024, 14, 777. https://doi.org/10.3390/coatings14060777

Macário PF, da Silveira CH, Vieira AAM, Marcondes AR, Marques FdC, Fechine GJM, Vieira L. Enhancing UV Radiation Resilience of DLC-Coated Stainless Steel with TiO2: A Dual-Layer Approach. Coatings. 2024; 14(6):777. https://doi.org/10.3390/coatings14060777

Chicago/Turabian StyleMacário, Paulo Fabrício, Carolina Hahn da Silveira, Angela Aparecida Moraes Vieira, André Ricardo Marcondes, Francisco das Chagas Marques, Guilhermino José Macêdo Fechine, and Lúcia Vieira. 2024. "Enhancing UV Radiation Resilience of DLC-Coated Stainless Steel with TiO2: A Dual-Layer Approach" Coatings 14, no. 6: 777. https://doi.org/10.3390/coatings14060777

APA StyleMacário, P. F., da Silveira, C. H., Vieira, A. A. M., Marcondes, A. R., Marques, F. d. C., Fechine, G. J. M., & Vieira, L. (2024). Enhancing UV Radiation Resilience of DLC-Coated Stainless Steel with TiO2: A Dual-Layer Approach. Coatings, 14(6), 777. https://doi.org/10.3390/coatings14060777