Study on the Effects of GO on the Microstructure and Wear Resistance of CuCrZr Plasma Cladding Coatings

Abstract

1. Introduction

2. Materials and Methods

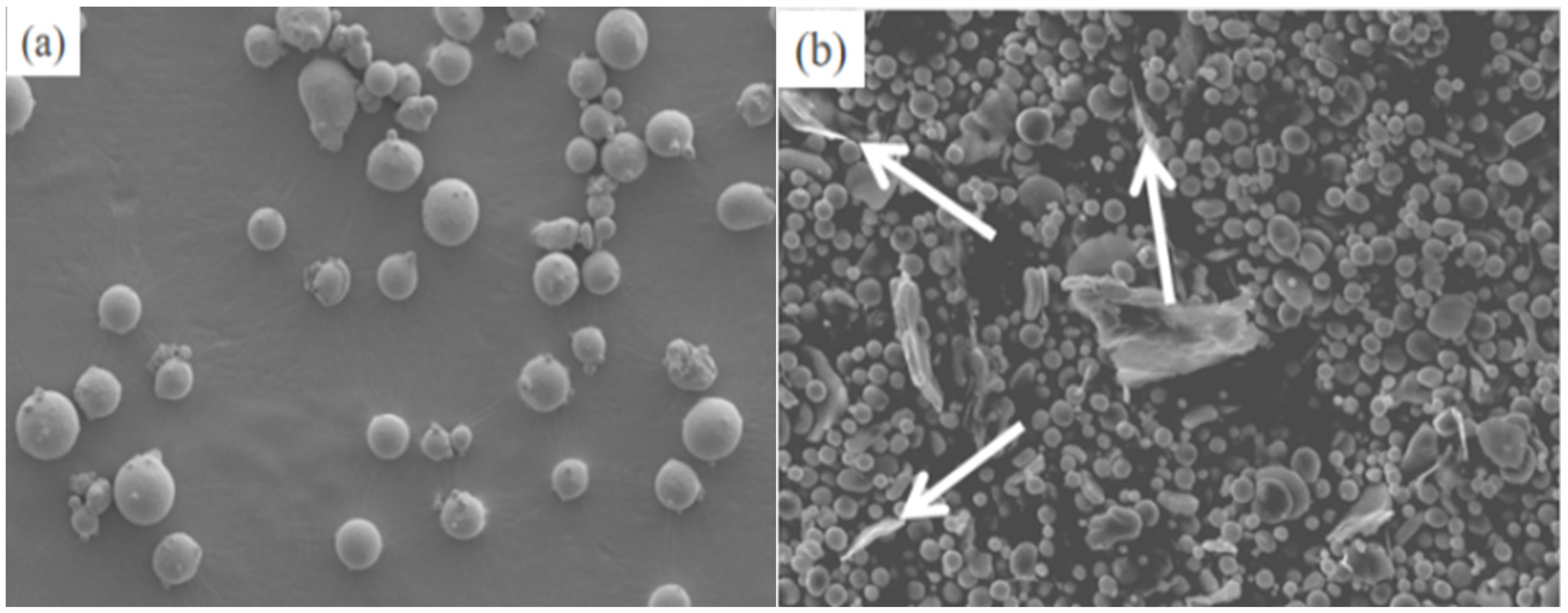

2.1. Coating Preparation

2.2. Characterization and Testing Methods

3. Results and Discussion

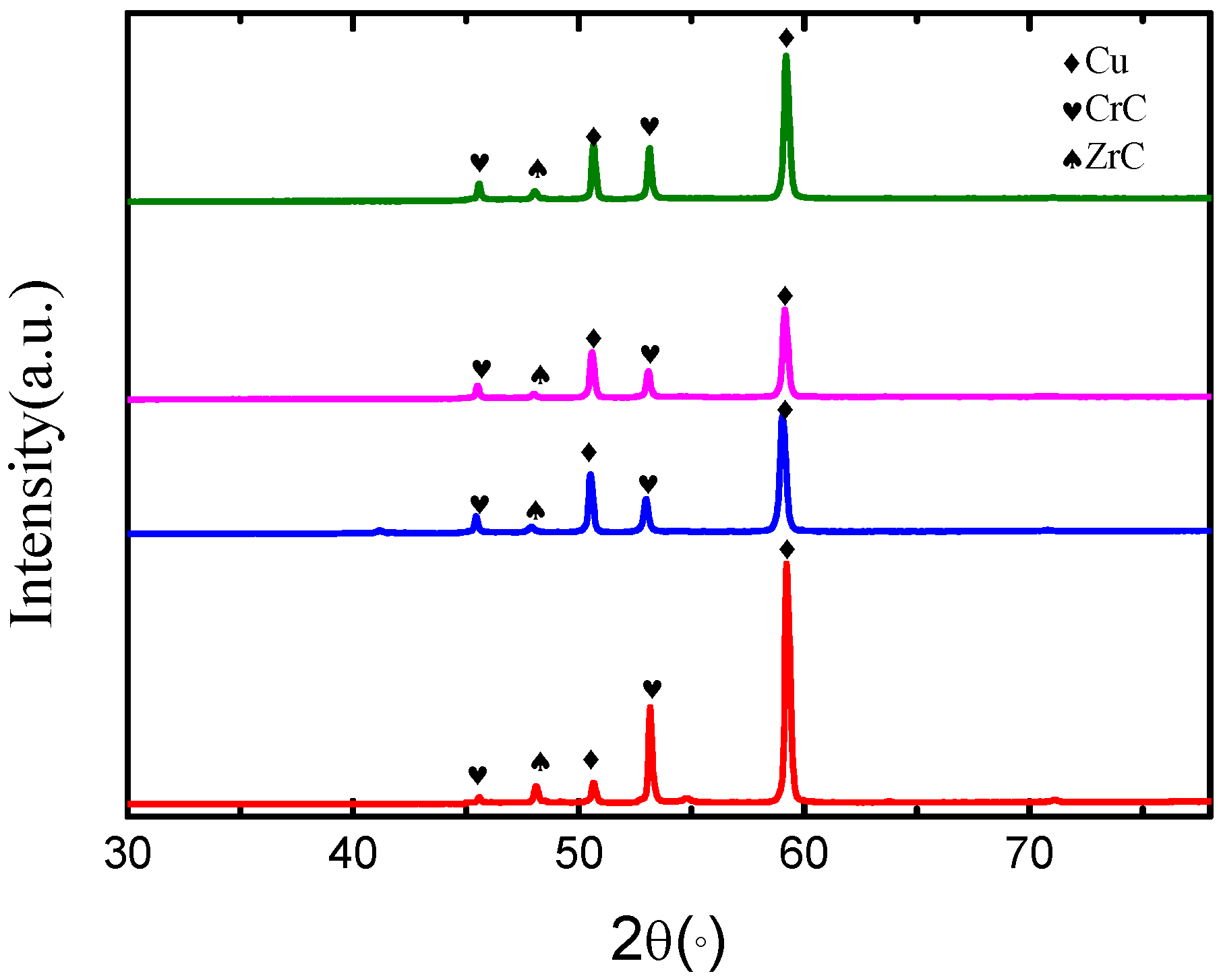

3.1. XRD Phase Analysis

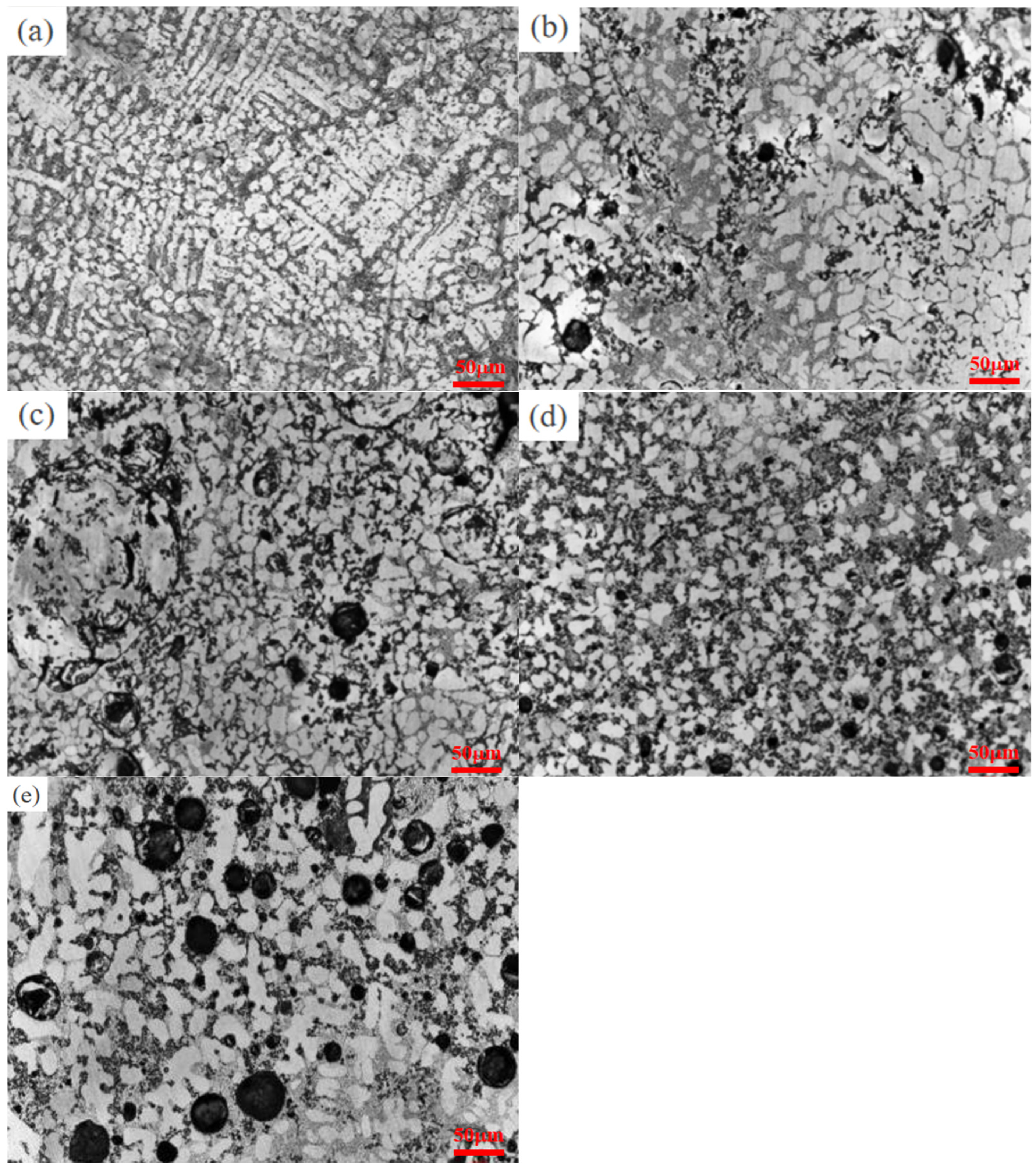

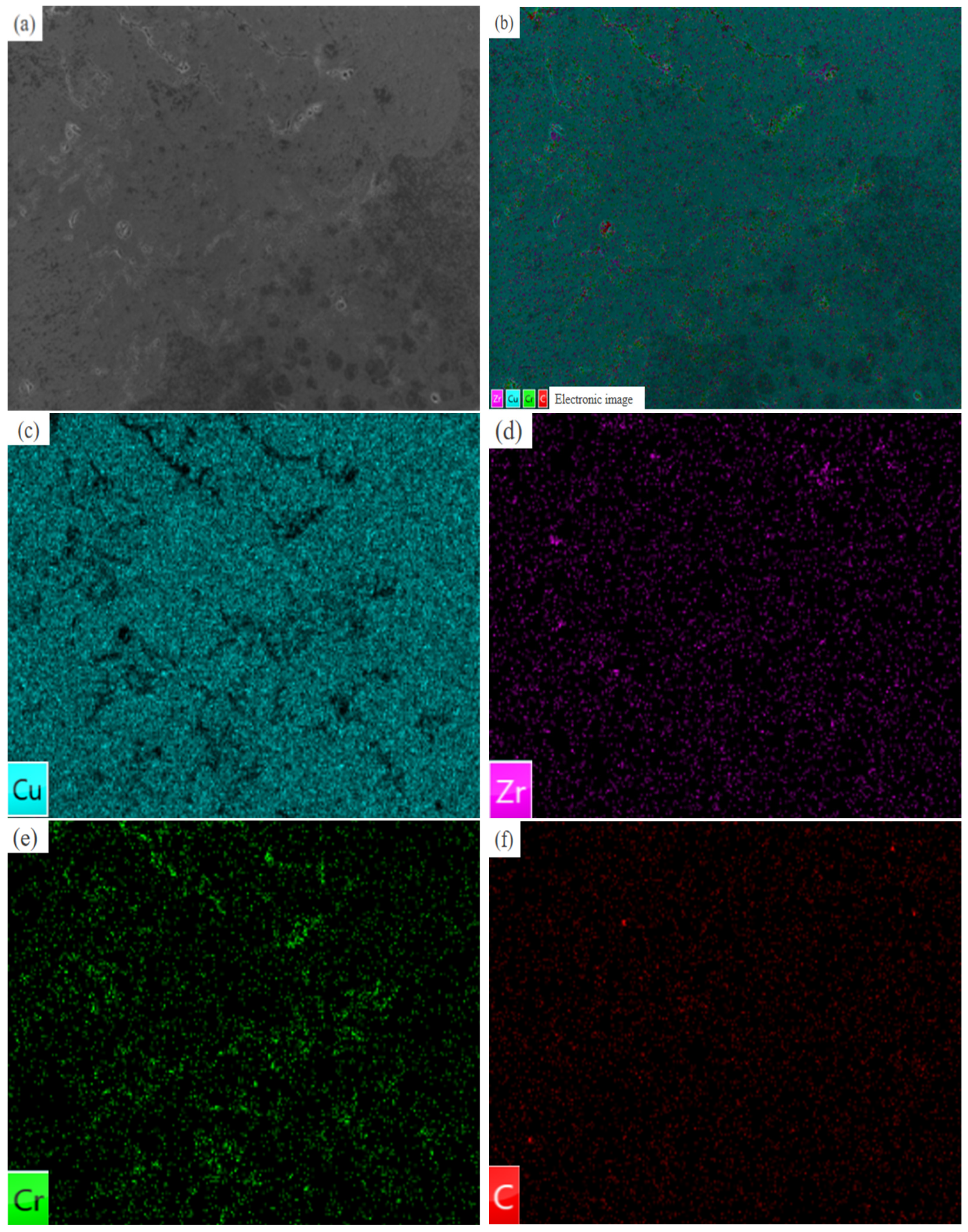

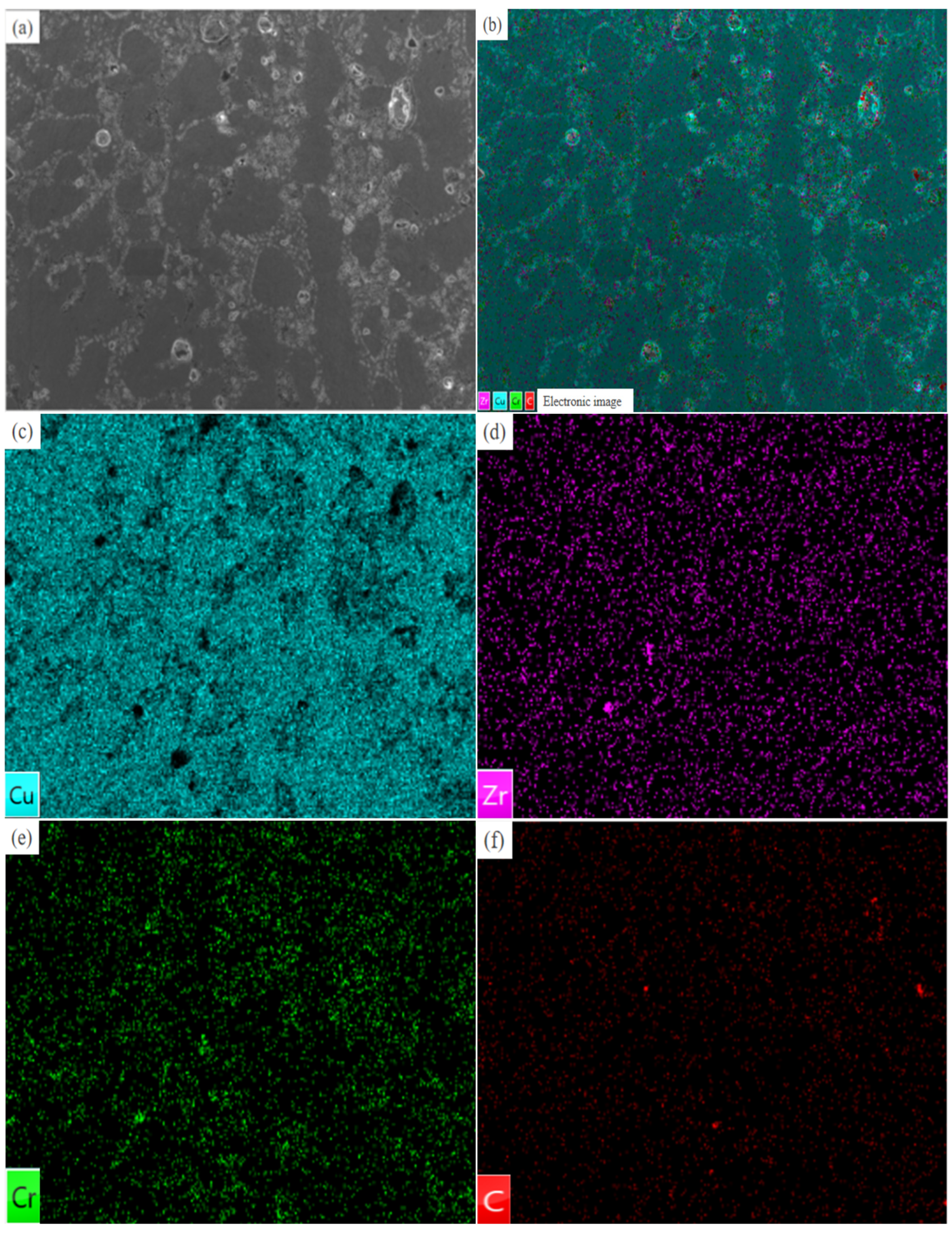

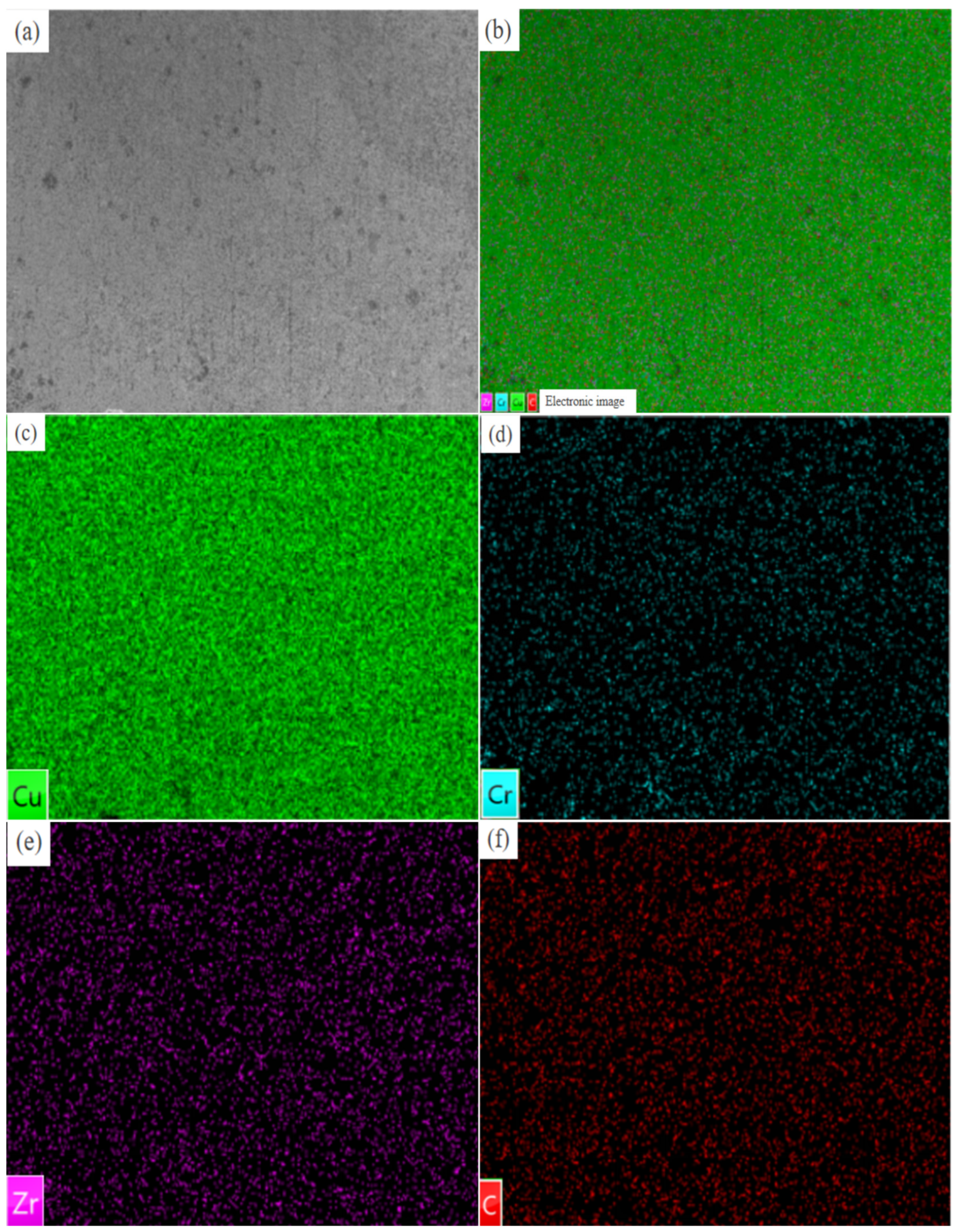

3.2. Microstructure and Element Distribution of Coatings

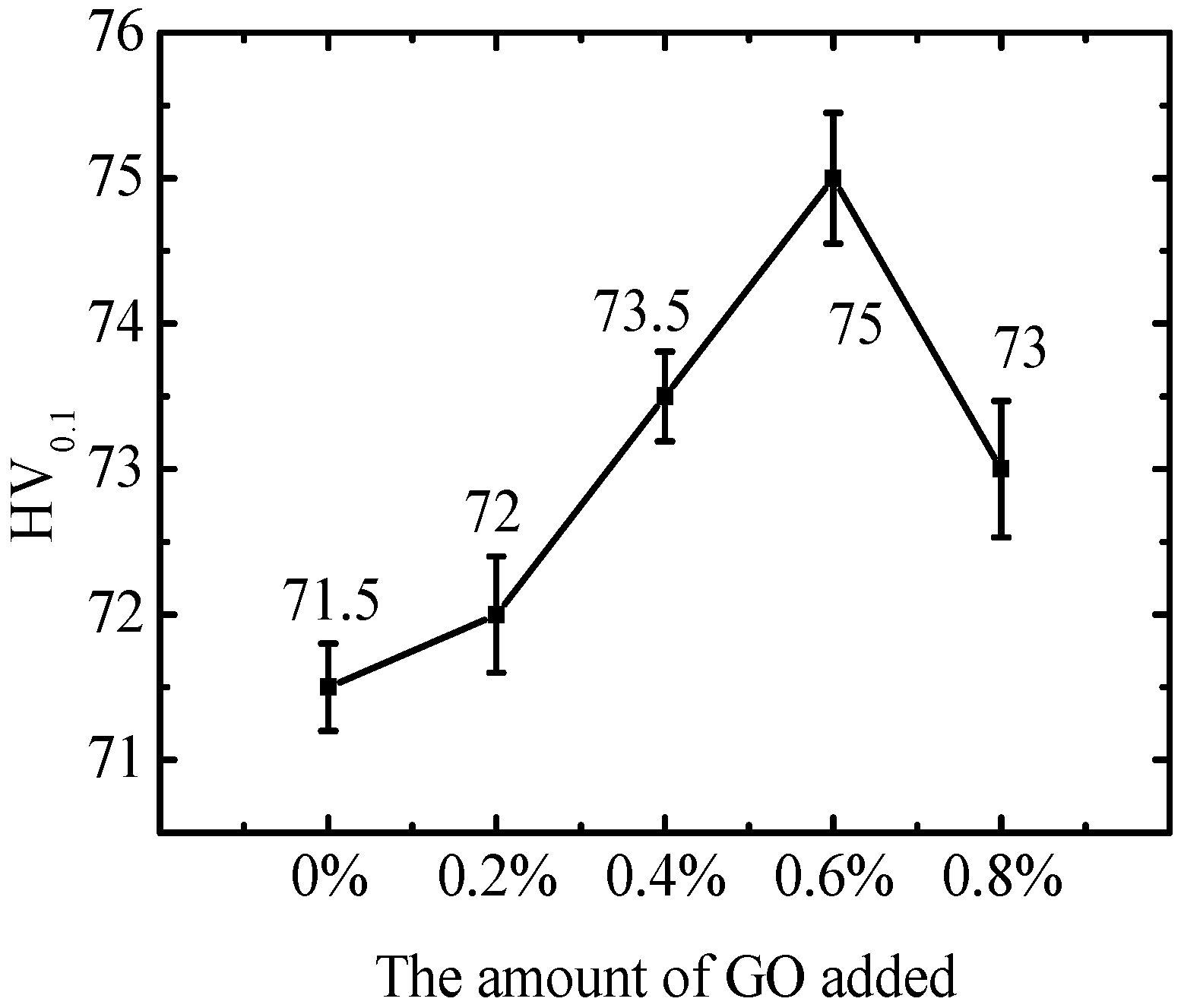

3.3. Mechanical Properties of Coating

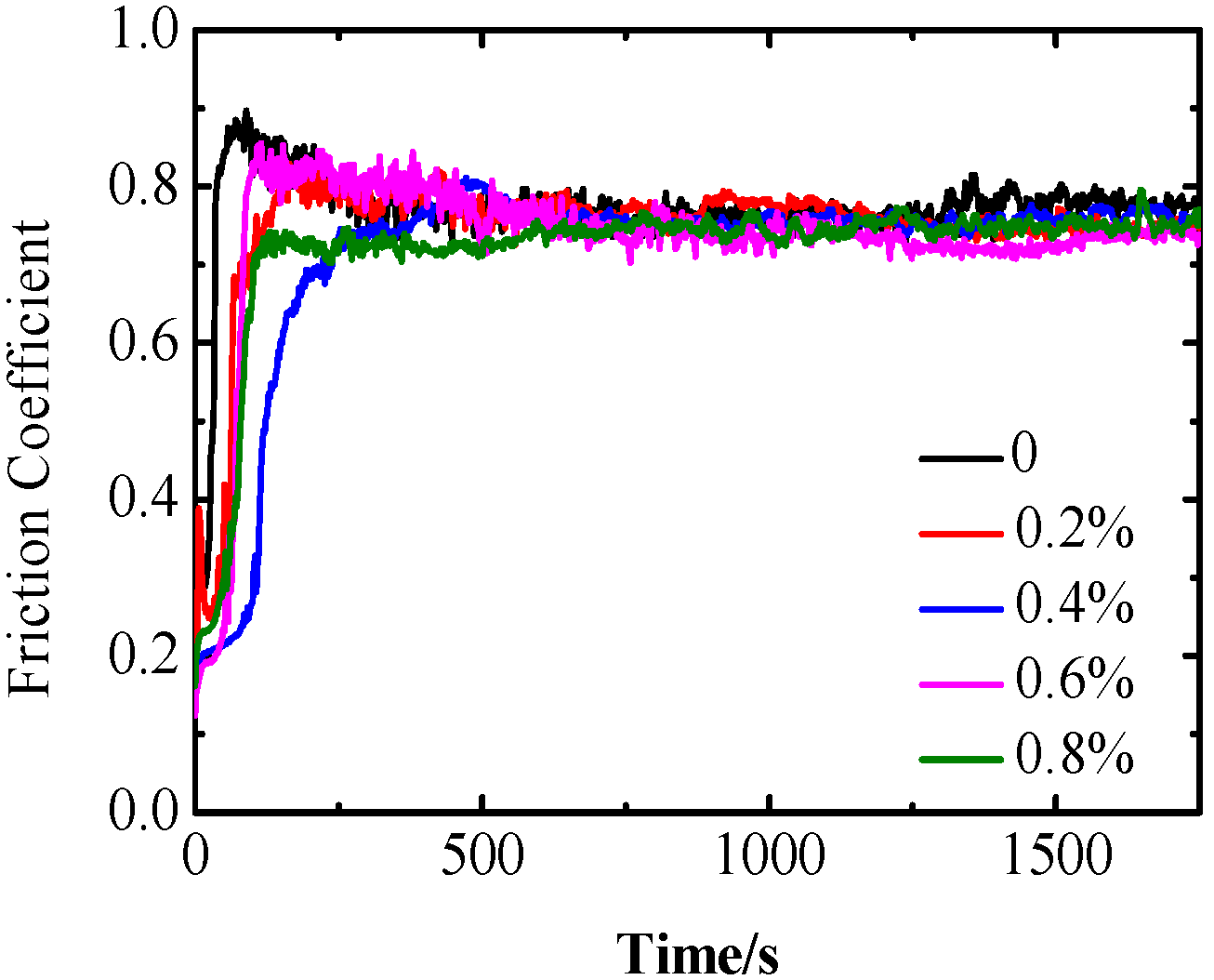

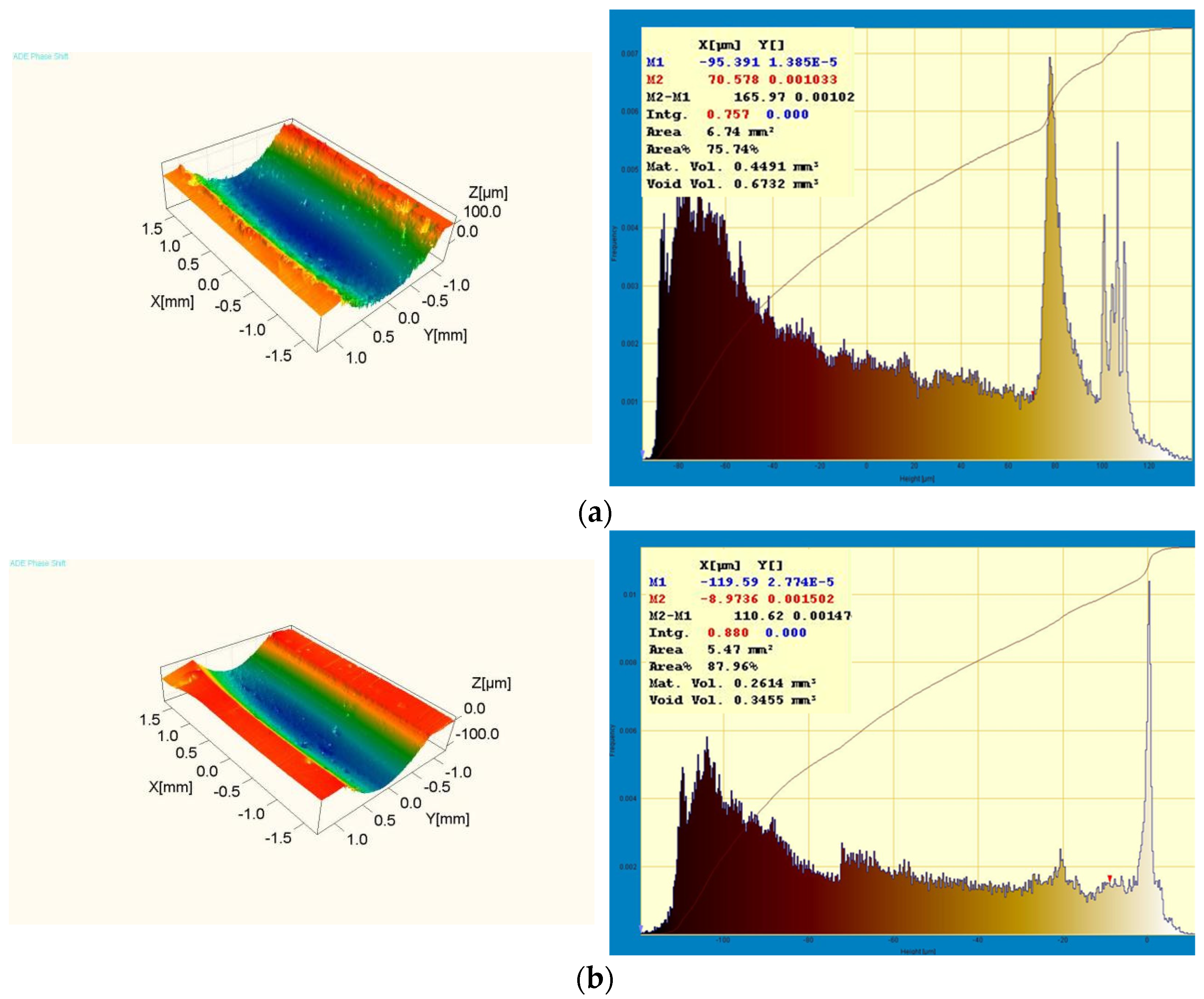

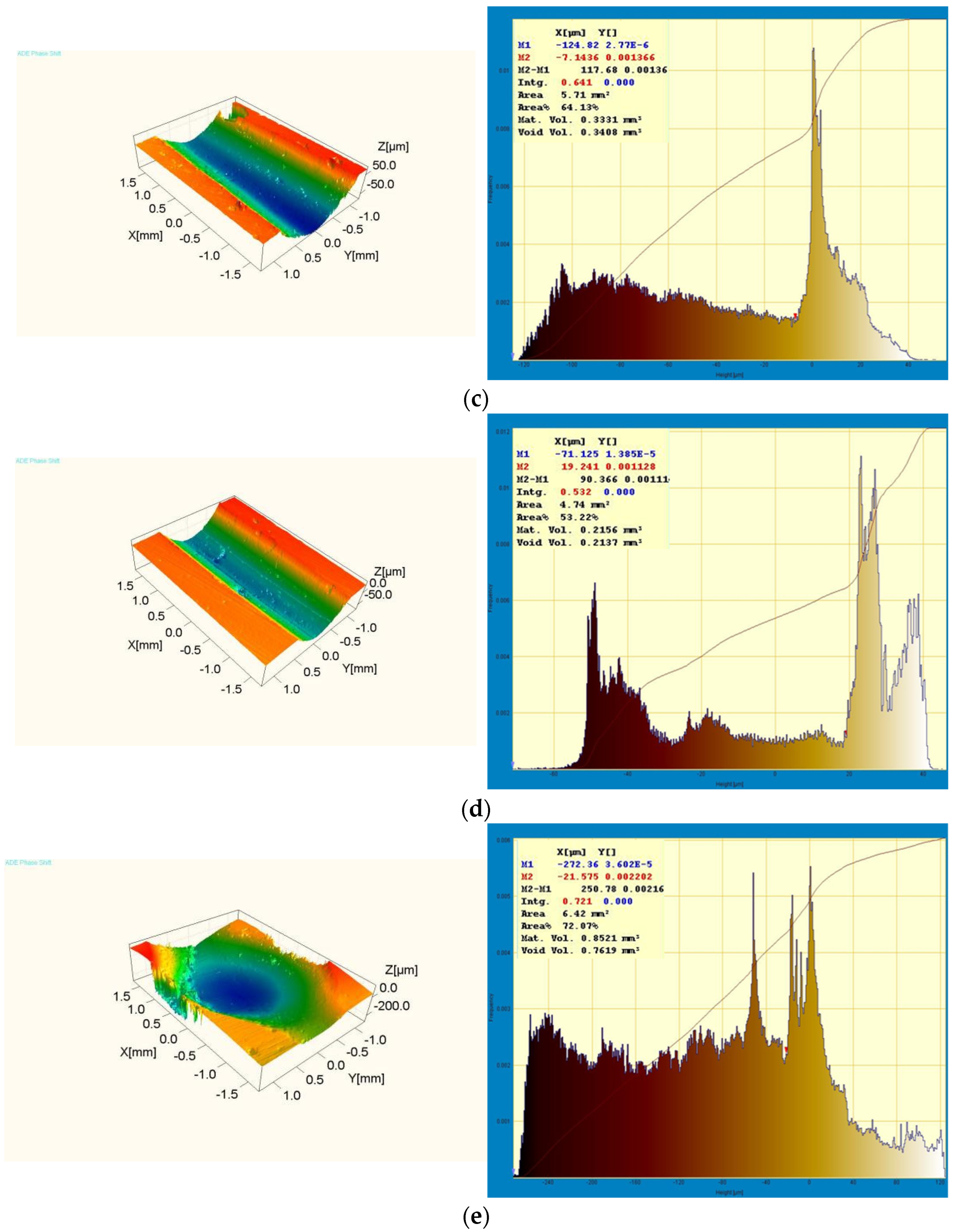

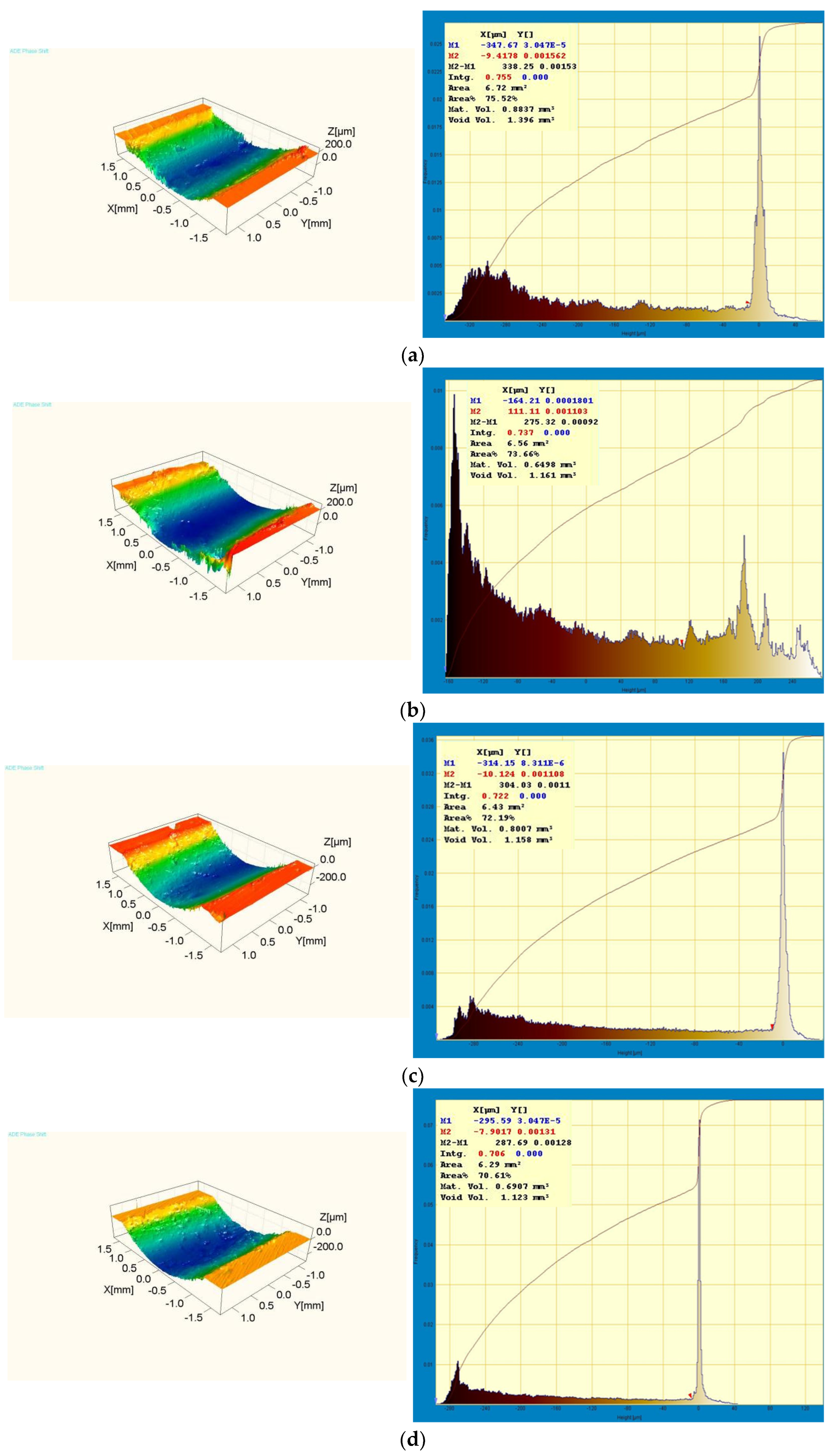

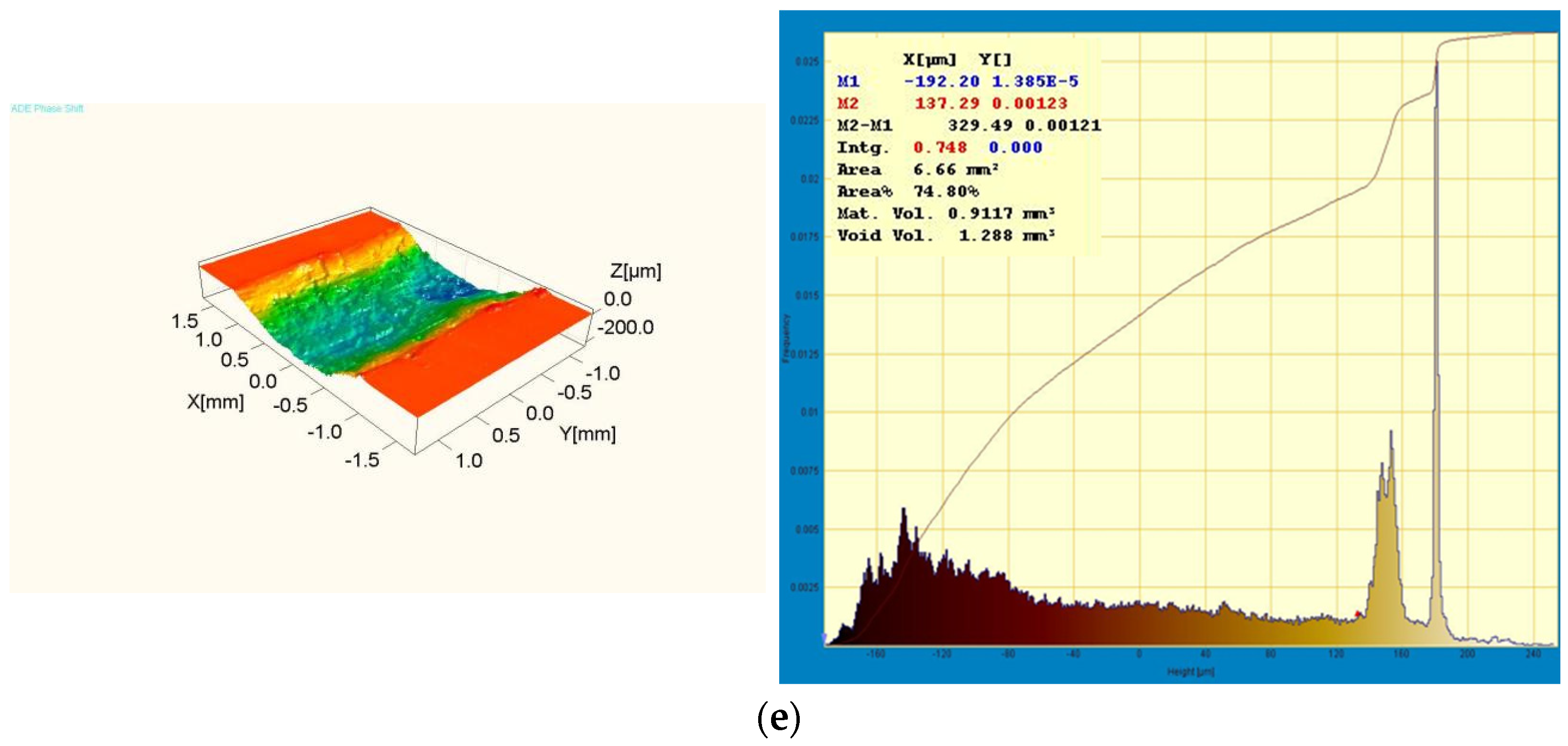

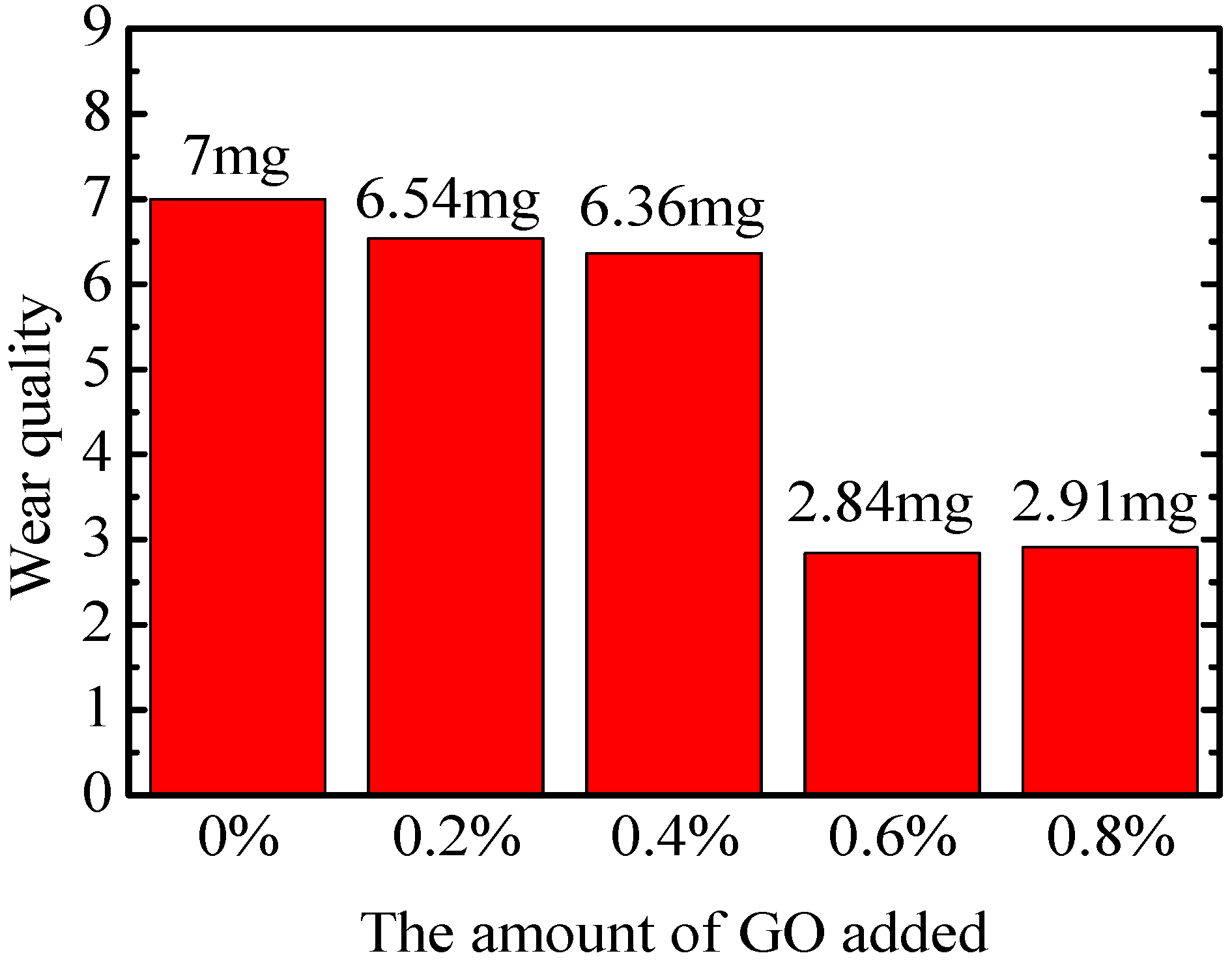

3.4. Coating Friction and Wear

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiang, H.J.; Qiao, Z.M.; Lv, Q.A. Principle and Technology of Electromagnetic Railgun; Beijing Institute of Technology Press: Beijing, China, 2022. [Google Scholar]

- Lu, J.Y.; Ma, W.M. Electromagnetic Orbital Launch Theory and Technology; Science Press: Beijing, China, 2020. [Google Scholar]

- Du, X.Y.; Liu, S.W.; Guan, J. Design and Performance Analysis of an Electromagnetic Railgun. J. Phys. Conf. Ser. 2022, 2378, 012008. [Google Scholar] [CrossRef]

- Liu, Z.Y. Preparation of Conductive Antifriction Coating for Electromagnetic Gun Armature and Study on Current-Carrying Friction Properties; Xiangtan University: Xiangtan, China, 2022. [Google Scholar]

- Lv, Q.A. Physical Principle and Relevant Restraining Methods About Velocity Skin Effect. IEEE Trans. Plasma Sci. 2015, 43, 1523–1530. [Google Scholar]

- Lei, B.; Du, C.T.; Lv, Q.A. Experimental study on the effect of graphene coating on the performance of electromagnetic railgun. High Volt. Technol. 2019, 45, 1929–1935. [Google Scholar]

- Wang, X.; Yao, P.P.; Zhou, H.B. Research Progress on Surface Damage and Protection Strategies of Armature–Rail Friction Pair Materials for Electromagnetic Rail Launch. Materials 2024, 17, 277. [Google Scholar] [CrossRef] [PubMed]

- Kosowska, K.; Korycka, P.; Jankowska-Snopkiewicz, K. Graphene Oxide (GO)-Based Bioink with Enhanced 3D Printability and Mechanical Properties for Tissue Engineering Applications. Nanomaterials 2024, 14, 760. [Google Scholar] [CrossRef]

- Ahmed, F.; Kumar Brajpuriya, R.; Handa, Y. Properties, Applications and Synthesis of Graphene. J. Res. Sci. Eng. 2021, 3, 1. [Google Scholar]

- Xie, Y.J.; Wen, X.; Yan, J.K. Microstructure and wear resistance of AlCoCrFeNiCuSnX high-entropy alloy coatings by plasma cladding. Vacuum 2023, 214, 112176. [Google Scholar] [CrossRef]

- Wen, F.J.; Long, Z.; Xing, Z.G. Effect of Mo Content on Microstructure and Fatigue Properties of Ni60 Coating Produced by Plasma Cladding. J. Therm. Spray Technol. 2023, 32, 1389–1405. [Google Scholar] [CrossRef]

- Xie, F.G.; He, Y.H.; Yuan, Z.R. Microstructure and high-temperature sliding wear performance of Fe-Co-Mo alloy coating fabricated by plasma cladding. Surf. Coat. Technol. 2022, 444, 128667. [Google Scholar] [CrossRef]

- Hu, R.; Wang, R.D.; Zhang, J. An in-situ synthesised TiC/Ni60A composite coating on copper by plasma cladding. Mater. Sci. Technol. 2023, 39, 729–735. [Google Scholar] [CrossRef]

- Peng, Y.B.; Zhang, W.; Li, T.C. Effect of WC content on microstructures and mechanical properties of FeCoCrNi high-entropy alloy/WC composite coatings by plasma cladding. Surf. Coat. Technol. 2020, 38, 125326–125327. [Google Scholar] [CrossRef]

- Cao, L.; Xia, Y.; Cui, H. Microstructural characteristics of TiBsub2/sub–TiC–NiAl composite coatings via Plasma Cladding Process. Surf. Eng. 2019, 35, 997–1002. [Google Scholar] [CrossRef]

- Sun, J.; Fan, Z.S.; Yang, Y. Tribological properties of aluminum alloy coated with graphene oxide/polyvinyl alcohol composites after micro-arc oxidation. Ind. Lubr. Tribol. 2024, 76, 500–512. [Google Scholar] [CrossRef]

- Broniszewski, K.; Woźniak, J.; Cygan, T.; Kostecki, M.; Moszczyńska, D.; Chmielewski, M.; Dydek, K.; Olszyna, A. Effect of Anisotropy of Reduced Graphene Oxide on Thermal and Electrical Properties in Silicon Carbide Matrix Composites. Nanomaterials 2024, 14, 555. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Cao, Y.; Wan, J.; Zhang, M.; Li, Y.; Wang, Y.; Song, D.; Zhang, T.; Wang, J. pH-Responsive Graphene Oxide-Based 2D/3D Composite for Enhancing Anti-Corrosion Properties of Epoxy Coating. Nanomaterials 2024, 14, 323. [Google Scholar] [CrossRef] [PubMed]

- Bordbar-Khiabani, A.; Ebrahimi, S.; Yarmand, B. Highly corrosion protection properties of plasma electrolytic oxidized titanium using rGO nanosheets. Appl. Surf. Sci. 2019, 486, 153–165. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, B.; Zhao, D.; Gao, P.; Naumov, A.; Li, Q.; Li, F.; Yang, Z.; Guo, Y.; Li, J.; et al. Microstructure and Properties of FeAlC-x(WC-Co) Composite Coating Prepared through Plasma Transfer Arc Cladding. Coatings 2024, 14, 128. [Google Scholar] [CrossRef]

- Zhang, H.; Zhuang, J.; Li, J. The Effect of Laser-Cladded Co6, T400, and Ni-Based 30WC Coatings on the Wear Resistance of H13 Steel. Coatings 2024, 14, 114. [Google Scholar] [CrossRef]

| Cu | Cr | Zr |

|---|---|---|

| Bal. | 0.79% | 0.12% |

| Cu | Cr | Zr |

|---|---|---|

| Bal. | 0.7%–0.8% | 0.1%–0.25% |

| Parameter | Value |

|---|---|

| Cladding type | Plasma cladding |

| Cladding mode | Hand cladding |

| Powder feeding method | Pneumatic powder feed |

| Protective gas type | High purity argon |

| Cladding current | Main arc current 143 (141–145) |

| Ionic gas | 2.5 L/min |

| Shielding gas velocity | 5 L/min |

| Speed of powder gas delivery | 2.8 L/min |

| The quantity of powder dispensed. | 280 g/min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Xiang, H.; Qiao, Z.; Zhen, J.; Lv, Q.-A.; Yuan, X.; Liang, C.; Cao, G. Study on the Effects of GO on the Microstructure and Wear Resistance of CuCrZr Plasma Cladding Coatings. Coatings 2024, 14, 763. https://doi.org/10.3390/coatings14060763

Wang Y, Xiang H, Qiao Z, Zhen J, Lv Q-A, Yuan X, Liang C, Cao G. Study on the Effects of GO on the Microstructure and Wear Resistance of CuCrZr Plasma Cladding Coatings. Coatings. 2024; 14(6):763. https://doi.org/10.3390/coatings14060763

Chicago/Turabian StyleWang, Yang, Hongjun Xiang, Zhiming Qiao, Jianwei Zhen, Qing-Ao Lv, Xichao Yuan, Chunyan Liang, and Genrong Cao. 2024. "Study on the Effects of GO on the Microstructure and Wear Resistance of CuCrZr Plasma Cladding Coatings" Coatings 14, no. 6: 763. https://doi.org/10.3390/coatings14060763

APA StyleWang, Y., Xiang, H., Qiao, Z., Zhen, J., Lv, Q.-A., Yuan, X., Liang, C., & Cao, G. (2024). Study on the Effects of GO on the Microstructure and Wear Resistance of CuCrZr Plasma Cladding Coatings. Coatings, 14(6), 763. https://doi.org/10.3390/coatings14060763