Abstract

Wood, a natural and renewable material, is extensively utilized in furniture, construction, and outdoor landscapes due to its sustainability and esthetic appeal. However, exposure to environmental elements, particularly sunlight, leads to photodegradation, affecting wood’s chemical and physical structure. This degradation results in color fading, increased surface roughness, and reduced mechanical properties, shortening the lifespan of wooden products. Artificial accelerated photodegradation tests have become a crucial method for studying wood’s aging process under controlled laboratory conditions, mimicking prolonged exposure to sunlight. This review explores the mechanisms behind wood photodegradation, focusing on the effects of UV radiation on wood’s major components—cellulose, hemicellulose, lignin, and extractives. Additionally, it summarizes the latest advancements in experimental design for artificial aging tests, including factors like radiation source selection, temperature, and humidity control. The paper also highlights performance characterization methods for evaluating the impact of photodegradation on wood’s physical, chemical, and mechanical properties. Understanding these processes is essential for enhancing the durability of wood products and developing effective treatments for wood preservation in outdoor environments.

1. Introduction

Wood is a widely used natural and renewable resource, valued for its sustainability and esthetic appeal in industries such as construction, furniture, and landscaping [1,2,3]. However, wood’s durability in outdoor applications is significantly compromised by environmental factors, particularly sunlight [4]. Ultraviolet (UV) radiation, a key component of sunlight, triggers photodegradation, causing structural damage, discoloration, and surface roughness, which ultimately reduces the service life of wood products [5].

Understanding the mechanisms of wood photodegradation is essential for improving its resistance to environmental stressors, particularly for applications where long service life is critical [6], such as outdoor decking and facades. Despite significant progress in this area, there remain gaps in knowledge regarding the precise interactions between UV radiation and wood’s components, as well as the long-term effects of photodegradation under varying environmental conditions.

This article aims to provide a comprehensive review of the current state of research on the artificial accelerated photodegradation of wood, emphasizing experimental design, performance characterization, and the factors influencing degradation, such as radiation source, temperature, and humidity. This article discusses the advances in understanding wood’s aging behavior, the methods used to evaluate its physical, chemical, and mechanical properties under accelerated aging conditions, and the challenges that remain in developing effective treatments to enhance durability [7].

Furthermore, this review highlights areas where further investigation is needed, particularly in refining experimental protocols and identifying the most effective strategies for enhancing wood’s long-term performance in outdoor applications. By synthesizing existing knowledge and addressing these gaps, this review aims to contribute to the development of more effective wood preservation techniques and guide future research in the field of wood photoaging.

2. Mechanism of Wood Photodegradation

2.1. Definition of Wood Photodegradation

Wood is a natural polymer that undergoes significant changes when exposed to sunlight and atmospheric conditions, particularly under ultraviolet (UV) radiation in the wavelength range of 295–400 nm. This process, known as photo-oxidation, leads to physical and chemical deterioration, including color fading, surface brittleness, gloss loss, and a decline in mechanical properties [8]. These effects are attributed to the presence of internal factors in wood, such as unsaturated double bonds, carbonyl groups, and hydroxyl groups, which enhance its susceptibility to degradation [9].

Photodegradation in polymers, including wood, follows a depolymerization process driven by photochemical reactions [10]. According to the First and Second Laws of Photochemistry, these reactions occur when the energy of a photon exceeds the bond energy of a polymer, resulting in degradation [11]. When wood absorbs light energy, its molecular chains are excited to higher energy states, initiating reactions with oxygen that lead to molecular bond breakage and structural changes at the macroscopic level, which manifest as aging [12].

2.2. Spectrum Distribution of Light Sources

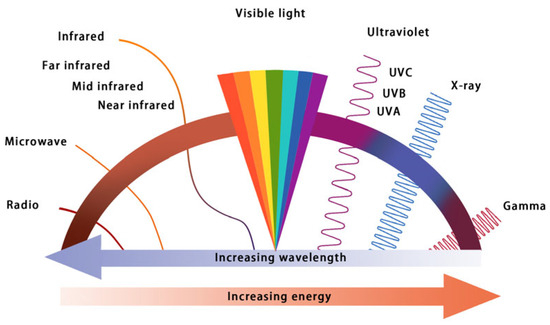

Electromagnetic waves are a crucial form of energy transmission, encompassing natural forms such as gamma rays, X-rays, ultraviolet rays, visible light, infrared rays, microwaves, and radio waves (Figure 1) [13]. Generally, the shorter the wavelength, the greater the radiative energy. Solar radiation is primarily composed of ultraviolet (UV) rays and visible light, and its UV component plays a particularly significant role in the degradation of wood in outdoor environments. To replicate the natural sunlight spectrum, artificial light sources in accelerated aging tests are designed accordingly [14]. The solar spectrum includes both visible and non-visible light, such as ultraviolet and infrared (IR) radiation. Ultraviolet light, particularly within the 295–400 nm range, is divided into UVA, UVB, and UVC rays. UVA rays (315–400 nm) are the most prevalent and can penetrate glass and clouds, while UVB rays (280–315 nm) have shorter wavelengths but cause greater surface damage to wood. UVC rays, mostly absorbed by Earth’s ozone layer, are less relevant in studies on wood aging [15]. UV radiation induces photochemical reactions on wood surfaces, hastening degradation processes. Additionally, infrared radiation (wavelengths above 750 nm) contributes to wood degradation by raising the material’s temperature, leading to moisture loss and increased thermal expansion and contraction [16]. Together, UV and IR radiation lead to both chemical and physical deterioration of wood over time [17].

Figure 1.

Scheme of electromagnetic waves.

2.3. Wood Chemical Components’ Response to Light

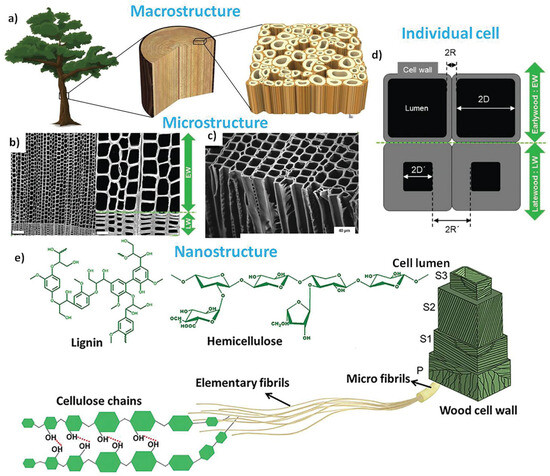

Wood, as a natural polymer-based biomass composite, features a distinctly anisotropic, multi-level cellular structure and diverse composition (Figure 2). Its primary constituents include cellulose, lignin, and hemicellulose, along with minor extractives. These components respond uniquely to light radiation [18].

Figure 2.

The hierarchical structure of wood: (a) Macrostructure, (b,c) Microstructure, (d) Individual Cell, (e) Nanostructure [19].

- Cellulose: A linear polymer that accounts for 40–50% of wood’s structure, providing essential mechanical strength [20]. Ultraviolet (UV) light, particularly at wavelengths below 300 nm, directly degrades cellulose by breaking the β-D-glucan bonds that link the glucose units in the polymer chain. This degradation intensifies in the presence of oxygen and moisture, leading to bond breakage, dehydrogenation, and a subsequent loss in mechanical strength [21]. The breakage of these covalent bonds is a primary mechanism of cellulose degradation under UV exposure.

- Hemicellulose: A lower molecular weight polymer made up of various sugar monomers, comprising 25–30% of wood [22]. Hemicellulose is more prone to UV degradation than cellulose, primarily due to its amorphous structure and the presence of reactive functional groups, such as hydroxyl (-OH) and carbonyl (C=O) groups, which are more susceptible to UV radiation. UV exposure, especially in the presence of moisture, results in the formation of carbonyl groups, leading to a decline in mechanical properties such as tensile strength, flexural rigidity, and elongation at break [23]. The lower degree of polymerization and the more irregular, less crystalline structure of hemicellulose make it more vulnerable to photodegradation compared to cellulose, affecting these key mechanical parameters.

- Lignin: A biopolymer that constitutes 20–30% of wood and is primarily responsible for reinforcing cell walls [24]. Lignin is highly susceptible to UV radiation, especially in the UVB range (280–315 nm). The degradation of lignin results in the generation of phenoxy radicals and quinone compounds, which cause wood discoloration, shifting toward yellow and red hues upon exposure [25].

- Extractives: Low molecular weight compounds, including resins and polyphenols, that either absorb or block UV radiation [26]. Some extractives degrade under UV exposure, leading to color changes (photo-discoloration), while others act as natural UV blockers, enhancing wood’s resistance to photodegradation [27,28]. The degradation of certain extractives, particularly polyphenolic compounds, under UV exposure causes the formation of quinonoid and carbonyl groups. These chemical changes contribute to the color shifts observed in wood surfaces, as they alter the light-absorbing properties of the wood. Studies on Acacia auriculaeformis have shown that extractive-free specimens exhibit a monotonous increase in color change with prolonged UV exposure, whereas unextracted wood surfaces undergo a rapid color change initially, followed by a decrease in rate over time [27,28]. This phenomenon is attributed to the accelerated degradation of polyphenolic extractives, which also increases the rate of delignification in the early stages of exposure. Moreover, the presence of extractives has been found to reduce the overall rate of wood degradation by acting as natural protectants against UV-induced damage [29].

Photodegradation primarily affects wood’s surface layers, where UV light penetrates and interacts with its polymeric components (cellulose, hemicellulose, and lignin) [30]. This interaction causes chemical breakdowns, leading to a loss of mechanical properties, surface discoloration, and roughening. These changes cumulatively reduce the functional lifespan of wood, particularly in outdoor applications exposed to environmental stressors, such as sunlight and moisture.

3. Experimental Design for Artificial Accelerated Photodegradation

Artificial accelerated photodegradation is a critical method for understanding the degradation of wood when exposed to outdoor conditions [31]. By simulating natural sunlight in a controlled environment, researchers can rapidly assess wood’s resistance to photodegradation, allowing for a more efficient evaluation of various wood species, surface treatments, and protective coatings. This approach significantly shortens the testing time compared to natural weathering, providing valuable insights into wood performance and helping develop materials with improved durability for outdoor applications. Furthermore, the ability to control factors such as radiation source, temperature, and humidity ensures repeatability and precision, which are essential for optimizing wood preservation techniques.

3.1. Selection of Radiation Sources

The degradation of wood is primarily driven by ultraviolet (UV) and visible light components of solar radiation [32], with artificial aging equipment playing a crucial role in simulating the photodegradation process [33]. Common light sources include mercury UV lamps, xenon lamps, and natural sunlight. UV light sources typically emit wavelengths in the range of 254–420 nm, including specific wavelengths such as 254, 313, 340, 351, 365, and 420 nm. Xenon lamps more closely mimic natural sunlight, emitting wavelengths up to 580 nm but cutting off below 280 nm. The effects of these light sources vary significantly, influencing the rate and pattern of wood degradation. Research has shown that wood discoloration is closely related to lignin concentration, dye degradation, and changes in chromophores like aromatic and carbonyl groups [34]. Shorter UV wavelengths, particularly UV-B (290–315 nm), are especially effective in triggering molecular degradation by exciting chromophores such as phenolic hydroxyl groups, aromatic rings, and carbonyl groups, thereby inducing structural changes. Although UV radiation accounts for a small fraction of sunlight, its high energy in the 290–380 nm range makes it particularly damaging. Studies on various wood species, such as Japanese larch, teak, hickory, and rosewood, have revealed that light in the 300–580 nm range causes significant color changes, whereas wavelengths above 580 nm have minimal impact [35]. Moreover, xenon light aging accelerates photodegradation up to 30 times faster than natural sunlight, with discoloration stabilizing over time as extractives migrate to the surface [36]. Comparative research on sunlight, xenon lamps, and mercury vapor lamps further highlights the variability among light sources. While sunlight and xenon lamps require extended exposure (around 200 h) to cause significant degradation, mercury vapor lamps with broader UV coverage induce rapid degradation within 20 h [37]. These findings underscore the variability of light sources in simulating sunlight and their roles in accelerating wood aging, providing valuable insights for wood preservation and material performance. Additionally, studies have found that wavelengths below 335 nm contribute minimally to overall color change, while a narrow band (360–435 nm) induces the greatest discoloration. Visible light wavelengths up to 515 nm also significantly contribute to surface discoloration in wood, underscoring the broad-spectrum effects of solar radiation on wood materials [37].

3.2. Temperature Control

Research has shown that temperature significantly impacts the photodegradation of wood, influencing both the rate of photochemical reactions and the patterns of surface degradation. Elevated temperatures accelerate photodegradation by increasing molecular activity and promoting UV- and visible-light-induced chemical reactions. For example, studies have reported that photodegradation rates at 80 °C are significantly faster than those at 30 °C [38]. This temperature rise increases the concentration of carbonyl compounds from lignin decomposition and oxidation, resulting in more pronounced wood discoloration. High temperatures also promote the formation of oxidative products, as indicated by enhanced absorption in the carbonyl region of infrared spectra. The effects of temperature vary across wood species, with hardwoods showing more prominent carbonyl absorption than softwoods, suggesting different degradation mechanisms. Additionally, humidity exacerbates thermal degradation by accelerating chemical reactions and color changes in the wood. In artificial aging experiments, the temperature is an essential variable due to its influence on photodegradation dynamics. Mercury and xenon lamps, commonly used for UV exposure, also emit heat, raising the environmental temperature to 50–60 °C for mercury lamps and up to 40 °C for xenon lamps, which filter wavelengths below 280 nm [39]. Elevated temperatures intensify surface discoloration, particularly through lignin degradation and chromophore transformations such as aromatic and carbonyl group modifications. Furthermore, neural network analyses confirm that both temperature and UV radiation significantly impact wood color changes. High temperatures, combined with xenon lamp exposure or natural sunlight, accelerate surface oxidation and discoloration, while lower temperatures slow these processes. Elevated temperatures also enhance the migration of extractives to the wood surface, amplifying discoloration, although degradation product accumulation may alter the final photodegradation patterns [40]. Thus, controlling temperature in artificial aging experiments is crucial for ensuring the reliability and reproducibility of results.

3.3. Humidity Control

Humidity and rain simulation are crucial factors in photodegradation experiments, as water plays a significant role in the chemical and physical reactions of wood exposed to light. Although atmospheric water accounts for only 0.001% of Earth’s water, it significantly influences solar radiation absorption and scattering, with nearly a quarter of solar radiation being used for water evaporation, which regulates surface temperature and moisture content. Rain simulation in artificial aging systems mimics natural conditions by introducing periodic wetting and drying cycles, accelerating photodegradation by swelling wood fibers, increasing porosity, and allowing deeper light penetration. These cycles also wash away degradation products, such as colored lignin compounds, exposing fresh, reactive wood layers to UV radiation. Studies have shown that wood samples subjected to water immersion or rain simulation experience more significant lignin degradation than those exposed solely to UV light [41]. Tolvaj (2012) observed that beech and pine wood darkened faster under 100% relative humidity, highlighting moisture’s role in promoting lignin oxidation and chromophore formation [42]. Rain simulation systems, often combined with UV exposure, help researchers evaluate the combined effects of light, temperature, and moisture on wood durability, providing essential insights into the long-term effects of photodegradation under realistic outdoor conditions [43].

3.4. Wood Species Comparison

Different wood species exhibit varied responses to photodegradation, which can be influenced by their intrinsic properties such as density, strength, and chemical composition. These properties help explain the variations in color change tendencies. For instance, during the first 24 h of irradiation, softwood species generally darken more rapidly compared to hardwood species, which tend to show more gradual color changes over extended periods—up to 120 h [41]. After this period, some species such as Norway maple, European oak, and black poplar reach color change equilibrium after approximately 600 h of exposure. The response of wood to UV radiation is also influenced by various factors, including the testing equipment, irradiation intensity, and exposure duration. For example, Laura Oltean (2008) simulated indoor sunlight exposure using xenon lamps on a range of European hardwood and softwood species [44]. The study found that softwoods exhibited the earliest signs of discoloration, which is consistent with their generally higher resin content and lower density, which are factors that may enhance their susceptibility to UV-induced degradation. In contrast, hardwoods displayed slower but more sustained color changes over time. These findings highlight the importance of considering both wood species and environmental factors when conducting artificial aging experiments.

4. Performance Characterization of Wood Under Artificial Accelerated Photodegradation

4.1. Physical Properties Characterization

4.1.1. Surface Color

The stability of wood’s surface color is a key indicator of wood product quality [44,45]. Studies have shown that species with higher density generally maintain more stable color characteristics [46]. Among the physical effects of photodegradation, color change is one of the most visible and sensitive indicators for evaluating the extent of degradation. The Commission Internationale de l’Eclairage (CIE) standard colorimetric system is commonly employed to quantify these changes using three main parameters: lightness (L), red-green index (a), and yellow-blue index (b). Lignin degradation is the main factor responsible for the yellowing of wood [47], while the oxidation of extractives leads to an increase in redness, which can also delay lignin’s photodegradation.

4.1.2. Gloss

Wood gloss is closely linked to surface smoothness. As lignin degrades under UV exposure, changes in the surface’s extractives and cellulose content influence gloss levels [48]. Gloss is also correlated with color parameters: denser woods tend to scatter light more effectively, resulting in higher gloss, while less dense woods exhibit lower gloss [49]. The anatomical structure of the wood and fiber arrangement also affects mirror-like reflectance, influencing the perceived level of gloss.

4.1.3. Surface Roughness

UV radiation induces chemical reactions within the wood, breaking down components such as lignin, leading to the loss of surface material due to environmental factors like rain and wind. This degradation exposes a cellulose-rich surface. Research by Professor Imren and colleagues found that wood surface roughness increases progressively with aging, regardless of wood orientation (cross-cut or radial), with minimal differences between orientations [50]. Broadleaf species tend to exhibit greater surface roughness compared to conifers, although broadleaf species age more slowly. Temperature also plays a role in reducing surface roughness over time [51].

4.1.4. Hydrophobicity

The hydrophobic or hydrophilic nature of wood surfaces evolves throughout the photodegradation process, varying across species. Hydrophobicity is typically measured by the contact angle between a liquid and the wood surface; a contact angle less than 90° indicates a hydrophilic surface, while angles greater than 90° indicate hydrophobicity. During weathering, lignin degrades under UV radiation, and along with extractives, it leaches from the surface. Many studies have shown that wood’s wettability increases with time, evidenced by a reduction in the contact angle [52,53], as cellulose becomes more exposed, making the surface more hydrophilic.

4.2. Chemical Properties Characterization

The chemical properties of wood are primarily evaluated through changes in its major components—cellulose, hemicellulose, lignin, and extractives. Exposure to UV light during photodegradation alters the concentrations of these components. Lignin’s degradation is particularly significant, as it results in the formation of carbonyl chromophores, which contribute to noticeable changes in the wood’s chemical properties [54,55,56,57,58,59,60]. FTIR spectra reveal two critical peaks at 1595 cm−1 and 1505 cm−1, both attributed to lignin. The pronounced reduction in these peaks indicates severe lignin degradation, suggesting a substantial loss of structural integrity and protective functionality within the wood matrix. This degradation not only impacts the esthetic qualities of the wood but also compromises its mechanical properties, emphasizing the need for protective measures against UV exposure. The dramatic changes observed in these FTIR peaks underscore the importance of monitoring lignin degradation in preserving wood’s longevity and functionality.

4.3. Mechanical Properties Characterization

Photodegradation also has a profound impact on the mechanical properties of wood, particularly in terms of paint adhesion and bonding strength. As extractives migrate to the wood’s surface during aging, they can alter the flow and wettability of adhesives, creating a barrier that reduces bonding performance. Research by Williams et al. demonstrated that wood exposed to UV light for just 2–4 weeks can lose up to 50% of its paint adhesion strength and bonding strength, significantly reducing the durability of subsequent coatings [54,61].

5. Outlook for Artificial Photodegradation Research

Wood photodegradation can be studied using two primary methods: natural outdoor weathering and artificial accelerated weathering. Natural weathering involves exposing wood samples directly to outdoor conditions such as sunlight, wind, rain, and pollutants. Samples are typically mounted on racks at various angles, such as 0°, 5°, 45°, and 90°, following standards like ASTM D1006-01 in the U.S. [62] and EN 927-3 in Europe [49]. While this method is cost-effective, its lengthy testing duration and susceptibility to uncontrollable environmental variables limit its utility in optimizing wood products efficiently.

In contrast, artificial photodegradation testing is conducted under controlled laboratory conditions, where sunlight exposure is simulated to accelerate the aging process. Common artificial light sources include carbon arc lamps, fluorescent UV lamps, and xenon lamps, with xenon lamps being particularly effective because they closely mimic the UV and visible light spectra of natural sunlight. Standards such as ASTM G154 (U.S.) [63] and GB/T14522-2008 (China) [64] define the parameters for these tests, allowing for more consistent and repeatable results in wood weathering research.

Researchers have long sought to establish correlations between artificial and natural aging processes. For instance, early work by Tolvaj showed that artificial aging with xenon lamps (in the absence of rain) is roughly three times faster than natural aging [35]. More recent studies by Liu et al. found a strong correlation between natural sunlight and xenon lamp exposure during the early stages of degradation, with artificial aging accelerating the process by a factor of 30 [36]. However, this relationship becomes less linear in the later stages of aging.

Other researchers, such as Xin You Liu (2019), have conducted tests using xenon lamps filtered through window glass and compared the results with natural indoor sunlight exposure [65,66]. Their findings suggest that artificial aging can be 60 to 90 times faster than natural aging, particularly in terms of color change. Despite differences in species, light sources, and test durations, artificial aging has consistently been shown to significantly outpace natural weathering, making it an invaluable tool for studying wood’s photodegradation.

6. Conclusions and Future Research Directions for Wood Photodegradation

6.1. Correlation Between Artificial and Natural Photodegradation

Artificial accelerated photodegradation has emerged as a widely accepted technique for studying wood’s aging resistance, primarily due to its controlled environment and ability to produce faster results than natural weathering. However, while xenon lamp exposure closely mimics sunlight, it cannot fully replicate the complexity of natural environmental factors such as rain, wind, and temperature fluctuations, and biological agents like fungi, which play critical roles in wood degradation. In natural environments, fungi and other microorganisms can significantly influence the color change and mechanical properties of wood, often accelerating degradation by breaking down the wood’s cell wall components [67]. These biological agents are especially active in outdoor conditions, contributing to the darker, more varied color changes observed on wood surfaces exposed to natural weathering [68]. Therefore, while artificial aging provides valuable insights into photodegradation, it does not fully capture the effects of biological processes that are integral to natural aging. Further research is needed to refine the relationship between artificial and natural aging by incorporating biological factors, which will enhance the accuracy and reliability of laboratory simulations.

Studies have shown that the rate of artificial photodegradation can be 30 to 90 times faster than natural sunlight exposure, but the two processes are not always directly comparable. In particular, the mechanisms of degradation can diverge in the later stages of aging due to the involvement of biological agents in natural environments. Establishing more robust models to correlate artificial and natural weathering will be essential for improving predictions of wood aging in real-world environments, ultimately optimizing material selection and treatment methods.

6.2. Mathematical Models for Energy and Photodegradation in Wood

To better understand how light energy affects wood photodegradation, researchers have developed mathematical models that estimate the impact of different wavelengths and light intensities on degradation rates. These models help predict the long-term performance of wood by analyzing energy absorption, molecular changes, and surface deterioration. However, there is still a need for further refinement of these models to incorporate additional environmental factors like moisture, temperature, and biological agents, which play significant roles in wood aging.

6.3. Future Research Trends

The future of artificial accelerated photodegradation testing for wood will likely follow several key trends:

Improved Simulation of Natural Conditions: Enhancing artificial aging tests by better simulating environmental factors such as moisture, temperature fluctuations, and biological exposure (e.g., fungi and insects) is crucial for achieving a more comprehensive understanding of wood degradation in real-world settings.

Development of Protective Coatings and Treatments: Future research will likely focus on advancing protective coatings and treatments to enhance wood’s resistance to photodegradation. This could include UV-blocking chemicals, heat treatments, or surface modifications aimed at slowing the breakdown of lignin and cellulose.

Sustainability and Reusability: As environmental concerns continue to grow, there will be an increasing emphasis on developing sustainable wood treatments and improving the reusability and longevity of wood products. Research into bio-based coatings and environmentally friendly aging retardants will likely play a pivotal role in this area.

Advancements in Analytical Techniques: The continued development of analytical techniques will be critical for accurately characterizing changes in wood at the chemical, physical, and mechanical levels. Techniques such as spectroscopy, surface imaging, and micro-mechanical testing will provide deeper insights into how wood responds to aging.

Cross-disciplinary Approaches: Collaborations across material science, chemistry, physics, and environmental science will be essential for developing more sophisticated models of wood degradation and enhancing our understanding of how complex environmental factors influence aging processes.

Author Contributions

Conceptualization, Y.C. and X.X.; methodology, Y.C.; software, Y.G.; validation, X.X.; formal analysis, H.D.; investigation, H.D.; writing—original draft preparation, Y.G.; writing—review and editing, Y.G. and Y.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key R & D Program of China (Grant No. 2016YFD0600704) and the Priority Academic Program Development (PAPD) of Jiangsu Province, China.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing is not applicable. No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yang, W.W.; Ma, W.R.; Liu, X.Y.; Wang, W. Consolidation and Dehydration Effects of Mildly Degraded Wood from Luoyang Canal No. 1 Ancient Ship. Forests 2024, 15, 1089. [Google Scholar] [CrossRef]

- Yang, W.W.; Ma, W.R.; Liu, X.Y. Evaluation of Deterioration Degree of Archaeological Wood from Luoyang Canal No. 1 Ancient Ship. Forests 2024, 15, 963. [Google Scholar] [CrossRef]

- Xia, F.; Wang, W.; Zhang, J.H.; Yang, Y.T.; Wang, Q.Y.; Liu, X.Y. Improving Weed Control through the Synergy of Waste Wood-Based Panels Pyrolysis Liquid and Rice Husks: A Sustainable Strategy. BioResources 2024, 19, 7606–7618. [Google Scholar] [CrossRef]

- Hon, D.N.-S. Photodegradation of Wood and Its Components. Photochem. Photobiol. 1981, 34, 23–28. [Google Scholar]

- Evans, P.D.; Urban, K.; Chowdhury, M. Surface Checking of Wood is Increased by Photodegradation Caused by Ultraviolet and Visible Light. Wood Sci. Technol. 2008, 42, 251–265. [Google Scholar] [CrossRef]

- Evans, P.D.; Thay, P.D.; Schmalzl, K. Degradation of Wood Surfaces During Natural Weathering. Effects on Lignin and Cellulose and on the Adhesion of Acrylic Primers. Wood Sci. Technol. 1996, 30, 411–422. [Google Scholar] [CrossRef]

- Teacă, C.A.; Roşu, D.; Bodîrlău, R.; Roşu, L. Structural Changes in Wood under Artificial UV Light Irradiation Determined by FTIR Spectroscopy and Color Measurements—A Brief Review. BioResources 2013, 8, 1478–1507. [Google Scholar] [CrossRef]

- George, B.; Suttie, E.; Merlin, A.; Deglise, X. Photodegradation and Photostabilisation of Wood—The State of the Art. Polym. Degrad. Stab. 2005, 88, 268–274. [Google Scholar] [CrossRef]

- Evans, P.; Chowdhury, M.J.; Mathews, B.; Schmalzl, K.; Ayer, S.; Kiguchi, M.; Kataoka, Y. Weathering and Surface Protection of Wood. In Handbook of Environmental Degradation of Materials; Elsevier: Amsterdam, The Netherlands, 2005; pp. 277–297. [Google Scholar]

- Kulkarni, A.; Dasari, H. Current Status of Methods Used in Degradation of Polymers: A Review. In MATEC Web of Conferences; EDP Sciences: Yulis, France, 2018; Volume 144, p. 02023. [Google Scholar]

- Ershov, Y.A.; Kuzina, S.I.; Neiman, M.B. The Mechanism of Light-Induced Ageing and Light Stabilisation of Polymers. Russ. Chem. Rev. 1969, 38, 147. [Google Scholar] [CrossRef]

- Tian, R.; Li, K.; Lin, Y.; Lu, C.; Duan, X. Characterization Techniques of Polymer Aging: From Beginning to End. Chem. Rev. 2023, 123, 3007–3088. [Google Scholar] [CrossRef] [PubMed]

- Ayesha, S.; Abideen, Z.; Haider, G.; Zulfiqar, F.; El-Keblawy, A.; Rasheed, A.; Siddique, K.H.; Khan, M.B.; Radicetti, E. Enhancing Sustainable Plant Production and Food Security: Understanding the Mechanisms and Impacts of Electromagnetic Fields. Plant Stress 2023, 9, 100198. [Google Scholar] [CrossRef]

- Kropat, M.; Hubbe, M.A.; Laleicke, F. Natural, Accelerated, and Simulated Weathering of Wood: A Review. BioResources 2020, 15, 9998. [Google Scholar] [CrossRef]

- World Health Organization. Ultraviolet Radiation: An Authoritative Scientific Review of Environmental and Health Effects of UV, with Reference to Global Ozone Layer Depletion; World Health Organization: Geneva, Switzerland, 1994. [Google Scholar]

- Cserta, E.; Hegedus, G.; Németh, R. Evolution of Temperature and Moisture Profiles of Wood Exposed to Infrared Radiation. Bioresources 2012, 7, 5304–5311. [Google Scholar] [CrossRef][Green Version]

- Niu, K.; Song, K. Hot Waxing Treatment Improves the Aging Resistance of Wood Surface under UV Radiation and Water. Prog. Organ. Coat. 2021, 161, 106468. [Google Scholar] [CrossRef]

- Wang, Q.; Feng, X.; Liu, X.Y. Technological Advances in the Consolidation of Historical Woods. Mater. Rep. 2024, 38, 22070091-19. [Google Scholar]

- Gomez, I.; Lizundia, E. Biomimetic Wood-Inspired Batteries: Fabrication, Electrochemical Performance, and Sustainability within a Circular Perspective. Adv. Sustain. Syst. 2021, 5, 2100236. [Google Scholar] [CrossRef]

- Jakob, M.; Mahendran, A.R.; Gindl-Altmutter, W.; Bliem, P.; Konnerth, J.; Müller, U.; Veigel, S. The Strength and Stiffness of Oriented Wood and Cellulose-Fibre Materials: A Review. Prog. Mater. Sci. 2022, 125, 100916. [Google Scholar] [CrossRef]

- Hallett, K.; Bradley, S. Ultraviolet-Filtered Lighting and Cellulose Degradation: Evaluating the Effect of Light Exposure on Ethnographic Collections. Conservator 2003, 27, 3–12. [Google Scholar] [CrossRef]

- Pettersen, R.C. The Chemical Composition of Wood. In The Chemistry of Solid Wood; American Chemical Society: Washington, DC, USA, 1984; pp. 57–126. [Google Scholar]

- Lin, Y.; King, J.Y.; Karlen, S.D.; Ralph, J. Using 2D NMR Spectroscopy to Assess Effects of UV Radiation on Cell Wall Chemistry during Litter Decomposition. Biogeochemistry 2015, 125, 427–436. [Google Scholar] [CrossRef]

- Neutelings, G. Lignin Variability in Plant Cell Walls: Contribution of New Models. Plant Sci. 2011, 181, 379–386. [Google Scholar] [CrossRef]

- Patil, S.V.; Argyropoulos, D.S. Stable Organic Radicals in Lignin: A Review. ChemSusChem 2017, 10, 3284–3303. [Google Scholar] [CrossRef]

- Jansson, M.B.; Nilvebrant, N.O. Wood Extractives. In Pulp and Paper Chemistry and Technology; Walter de Gruyter: Berlin, Germany, 2009; pp. 147–171. [Google Scholar]

- Chang, T.C.; Chang, H.T.; Wu, C.L.; Chang, S.T. Influences of Extractives on the Photodegradation of Wood. Polym. Degrad. Stab. 2010, 95, 516–521. [Google Scholar] [CrossRef]

- Chang, T.C.; Chang, H.T.; Wu, C.L.; Lin, H.Y.; Chang, S.T. Stabilizing Effect of Extractives on the Photo-Oxidation of Acacia confusa Wood. Polym. Degrad. Stab. 2010, 95, 1518–1522. [Google Scholar] [CrossRef]

- Pandey, K.K. A note on the influence of extractives on the photo-discoloration and photo-degradation of wood. Polym. Degrad. Stab. 2005, 87, 375–379. [Google Scholar] [CrossRef]

- Chang, S.-T. Photodegradation and Photoprotection of Wood Surfaces; US Forest Products Laboratory: Madison, WI, USA, 1982. [Google Scholar]

- Andrady, A.L.; Heikkilä, A.M.; Pandey, K.K.; Bruckman, L.S.; White, C.C.; Zhu, M.; Zhu, L. Effects of UV Radiation on Natural and Synthetic Materials. Photochem. Photobiol. Sci. 2023, 22, 1177–1202. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Wu, Q.; Lu, W.; Zhang, J.; Yue, Z.; Jie, Y.; Zhang, J.; Cheng, Z.; Ji, W.; Wu, J. Effects of Different Accelerated Aging Modes on the Mechanical Properties, Color and Microstructure of Wood. J. Build. Eng. 2024, 98, 111026. [Google Scholar] [CrossRef]

- Zayat, M.; Garcia-Parejo, P.; Levy, D. Preventing UV-Light Damage of Light Sensitive Materials Using a Highly Protective UV-Absorbing Coating. Chem. Soc. Rev. 2007, 36, 1270–1281. [Google Scholar] [CrossRef]

- Liu, Y.; Shao, L.; Gao, J.; Guo, H.; Chen, Y.; Cheng, Q.; Via, B.K. Surface photo-discoloration and degradation of dyed wood veneer exposed to different wavelengths of artificial light. Appl. Surf. Sci. 2015, 331, 353–361. [Google Scholar] [CrossRef]

- Hon, D.N.S.; Minemura, N. Color and Discoloration. In Wood and Cellulosic Chemistry; CRC Press: Boca Raton, FL, USA, 2000; pp. 385–442. [Google Scholar]

- Liu, R.; Zhu, H.; Li, K.; Yang, Z. Comparison on the Aging of Woods Exposed to Natural Sunlight and Artificial Xenon Light. Polymers 2019, 11, 709. [Google Scholar] [CrossRef]

- Tolvaj, L.; Varga, D. Photodegradation of Timber of Three Hardwood Species Caused by Different Light Sources. Acta Silv. Et Lignaria Hung. 2012, 8, 145–155. [Google Scholar] [CrossRef]

- Kuka, E.; Andersons, B.; Cirule, D.; Andersone, I.; Kajaks, J.; Militz, H.; Bicke, S. Weathering Properties of Wood-Plastic Composites Based on Heat-Treated Wood and Polypropylene. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106102. [Google Scholar] [CrossRef]

- Kollmann, F.; Fengel, D. Changes in the Chemical Composition of Wood by Thermal Treatment. Holz als Roh-und Werkst. 1965, 23, 461–468. [Google Scholar] [CrossRef]

- Tolvaj, L.; Molnar, Z.; Nemeth, R. Photodegradation of Wood at Elevated Temperature: Infrared Spectroscopic Study. J. Photochem. Photobiol. B Biol. 2013, 121, 32–36. [Google Scholar] [CrossRef]

- Monachon, M.; Albelda-Berenguer, M.; Pelé, C.; Cornet, E.; Guilminot, E.; Rémazeilles, C.; Joseph, E. Characterization of Model Samples Simulating Degradation Processes Induced by Iron and Sulfur Species on Waterlogged Wood. Microchem. J. 2020, 155, 104756. [Google Scholar] [CrossRef]

- Tolvaj, L.; Papp, G.; Varga, D.; Lang, E. Effect of Steaming on the Colour Change of Softwoods. BioResources 2012, 7, 2799–2808. [Google Scholar] [CrossRef]

- Gonzalez-Pena, M.M.; Hale, M.D.C. Colour in Thermally Modified Wood of Beech, Norway Spruce and Scots Pine. Part 1: Colour Evolution and Colour Changes. Holzforschung 2009, 63, 385–393. [Google Scholar] [CrossRef]

- Oltean, L.; Teischinger, A.; Hansmann, C. Wood surface discolouration due to simulated indoor sunlight exposure. Holz Roh Werkst. 2008, 66, 51–56. [Google Scholar] [CrossRef]

- Csanády, E.; Magoss, E.; Tolvaj, L. Wood Surface Stability. In Quality of Machined Wood Surfaces; Springer: Berlin/Heidelberg, Germany, 2015; pp. 13–108. [Google Scholar]

- Guller, B. Effects of Heat Treatment on Density, Dimensional Stability and Color of Pinus nigra Wood. Afr. J. Biotechnol. 2012, 11, 2204–2209. [Google Scholar]

- Weigl-Kuska, M.; Kandelbauer, A.; Hansmann, C.; Pham, T. Wood—From Natural Color Patterns Toward Naturally Altered Color Impressions. In Handbook of Natural Colorants; John Wiley & Sons: Hoboken, NJ, USA, 2023; pp. 469–505. [Google Scholar]

- Feist, W.C. Outdoor Wood Weathering and Protection. In Archaeological Wood, Properties, Chemistry, and Preservation; Advances in Chemistry Series; American Chemical Society: Washington, DC, USA, 1990; Volume 225, pp. 263–298. [Google Scholar]

- EN 927-3; Paints and Varnishes-Coating Materials and Coating Systems for Exterior Wood: Part 3: Natural Weathering Test: EN 927-3. European Committee for Standardization: London, UK, 2005.

- Oberhofnerová, E.; Pánek, M.; García-Cimarras, A. The Effect of Natural Weathering on Untreated Wood Surface. Maderas. Cienc. y Tecnol. 2017, 19, 173–184. [Google Scholar] [CrossRef]

- Şenol, S.; Budakçı, M. Effect of Thermo-Vibro-Mechanic® Densification Process on the Gloss and Hardness Values of Some Wood Materials. BioResources 2019, 14, 9611–9627. [Google Scholar] [CrossRef]

- Imren, E. Effect of Weathering Conditions on Wood Surface Roughness: Optimal Parameters Determined via Taguchi Analysis. BioResources 2022, 17, 6668. [Google Scholar] [CrossRef]

- Papp, E.A.; Csiha, C. Contact Angle as Function of Surface Roughness of Different Wood Species. Surf. Interfaces 2017, 8, 54–59. [Google Scholar] [CrossRef]

- Williams, R.S. Finishing of Wood. In Wood Handbook–Wood as an Engineering Material; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; pp. 16-1–16-39. [Google Scholar]

- Popescu, C.M.; Tibirna, C.M.; Vasile, C. XPS Characterization of Naturally Aged Wood. Appl. Surf. Sci. 2009, 256, 1355–1360. [Google Scholar] [CrossRef]

- Huang, C.; Su, Y.; Shi, J.; Yuan, C.; Zhai, S.; Yong, Q. Revealing the Effects of Centuries of Ageing on the Chemical Structural Features of Lignin in Archaeological Fir Woods. N. J. Chem. 2019, 43, 3520–3528. [Google Scholar] [CrossRef]

- Ghavidel, A.; Scheglov, A.; Karius, V.; Mai, C. In-Depth Studies on the Modifying Effects of Natural Ageing on the Chemical Structure of European Spruce (Picea abies) and Silver Fir (Abies alba) Woods. J. Wood Sci. 2020, 66, 77. [Google Scholar] [CrossRef]

- Zachar, M.; Čabalová, I.; Kačíková, D.; Jurczyková, T. Effect of Natural Aging on Oak Wood Fire Resistance. Polymers 2021, 13, 2059. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.Y.; Timar, M.C.; Varodi, A.M.; Yi, S.L. Effects of Ageing on the Color and Surface Chemistry of Paulownia Wood (P. elongata) from Fast Growing Crops. BioResources 2016, 11, 9400–9420. [Google Scholar] [CrossRef]

- Cheng, L.; Zhao, P.; Di, Y.; Dai, J.; Wang, W. Correlation of Wood Properties with Chemical Composition and Microstructure of Wood Components. 2023. Available online: https://www.researchsquare.com/article/rs-2611726/v1 (accessed on 18 December 2024).

- Williams, R.S. Weathering of Wood. In Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2005; pp. 139–185. [Google Scholar]

- ASTM Standard D1006-1; Standard Practice for Conducting Exterior Exposure Tests of Paints on Wood. ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM G154-16; Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- GB/T 14522-2008; Artificial Weathering Test Method for Plastics, Coating and Rubber Materials Used for Machinery Industrial Products-Fluorescent UV Lamps. Standardization Administration of China (SAC): Beijing, China, 2008.

- Liu, X.Y.; Liu, M.; Lv, M.Q.; Lv, J.F. Photodegradation of Three Hardwood Species by Sunlight and Xenon Light Sources. BioResources 2019, 14, 6909–6922. [Google Scholar] [CrossRef]

- Liu, X.Y.; Timar, M.C.; Varodi, A.M. A Comparative Study on the Artificial UV and Natural Ageing of Beeswax and Chinese Wax and Influence of Wax Finishing on the Ageing of Chinese Ash (Fraxinus mandshurica) Wood Surfaces. J. Photochem. Photobiol. B Biol. 2019, 201, 111607. [Google Scholar] [CrossRef] [PubMed]

- Ganne-Chédeville, C.; Jääskeläinen, A.-S.; Froidevaux, J.; Hughes, M.; Navi, P. Natural and Artificial Ageing of Spruce Wood as Observed by FTIR-ATR and UVRR Spectroscopy. Holzforschung 2011, 65, 913–920. [Google Scholar] [CrossRef]

- Obataya, E. Effects of Natural and Artificial Ageing on the Physical and Acoustic Properties of Wood in Musical Instruments. J. Cult. Herit. 2017, 27, S63–S69. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).