The Influence of Microstructure Characteristics on Thickness Measurement of TBCs Using Terahertz Time-Domain Spectroscopy

Abstract

1. Introduction

2. Materials and Methods

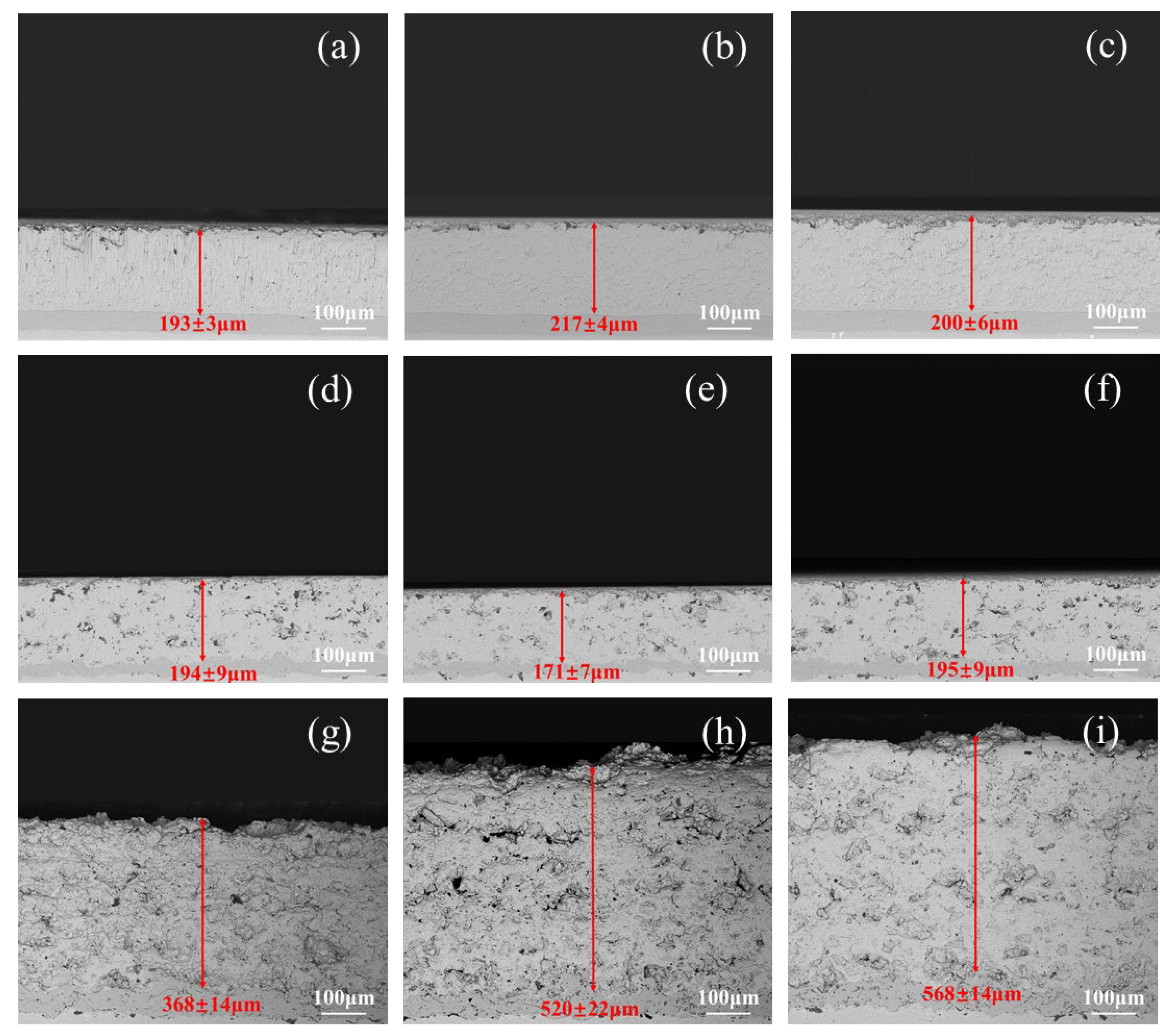

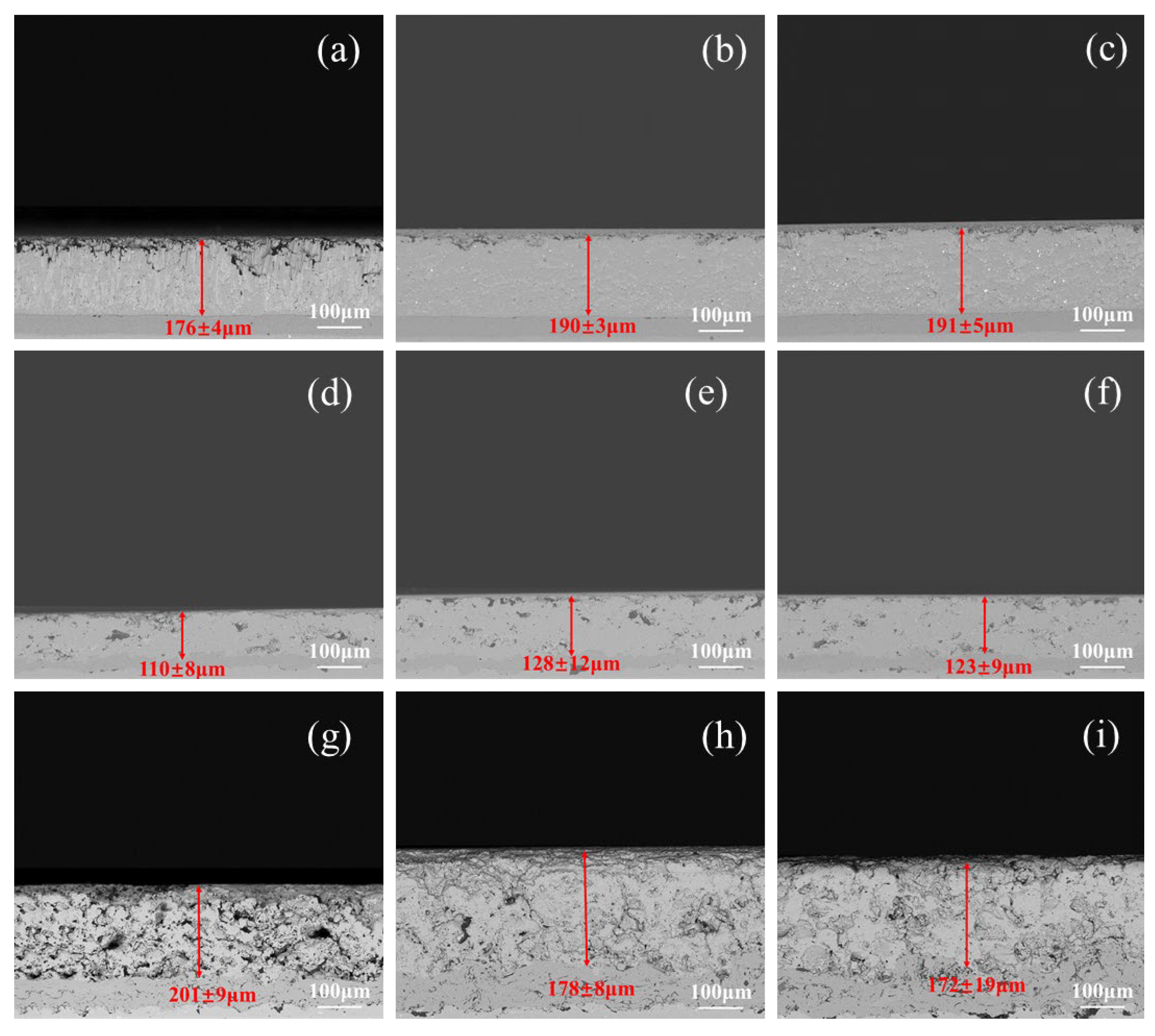

2.1. Specimen Preparation

2.2. Terahertz Time-Domain Spectroscopy Test

2.3. Phase Composition and Microstructure Characterization

3. Results and Discussion

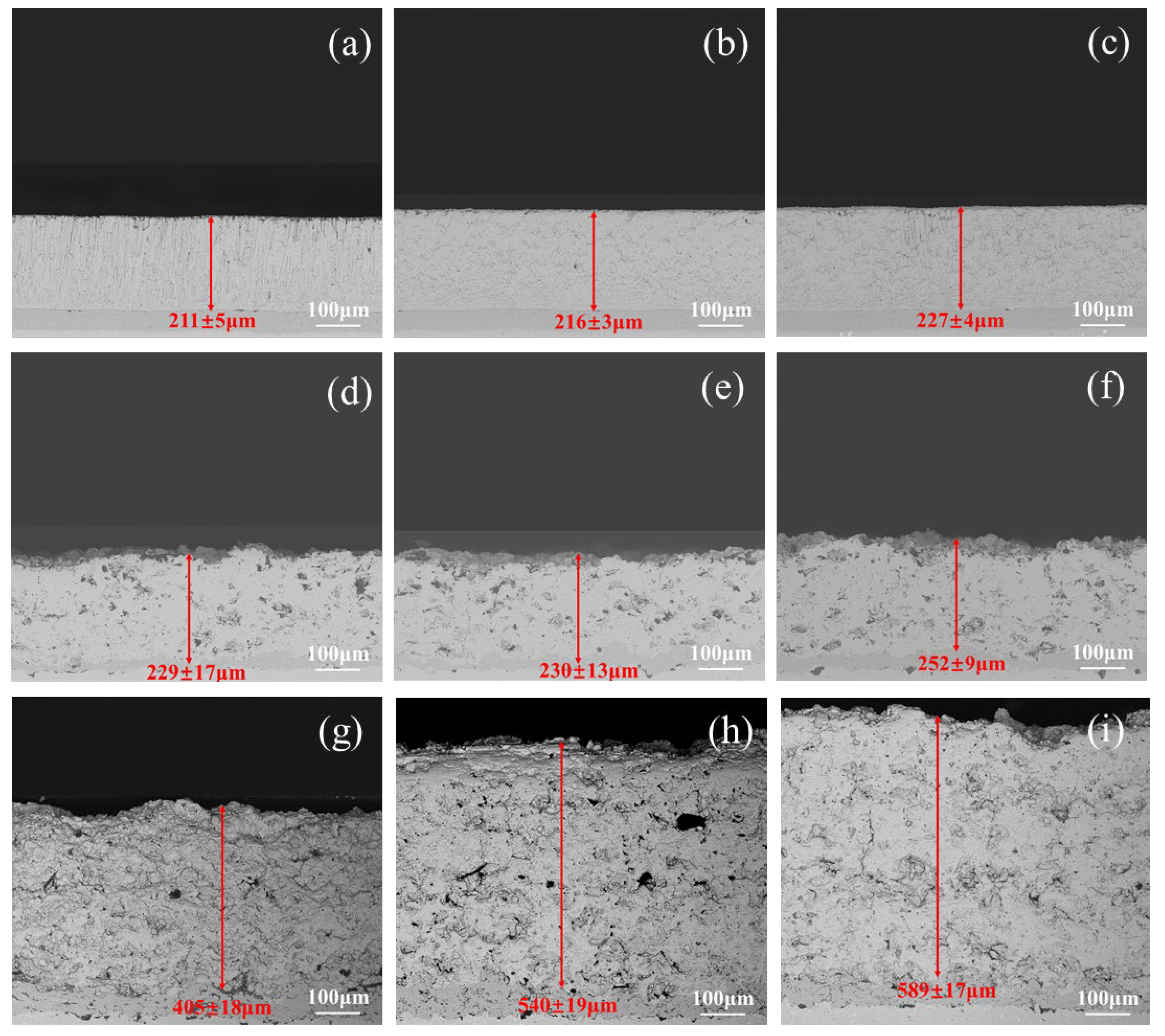

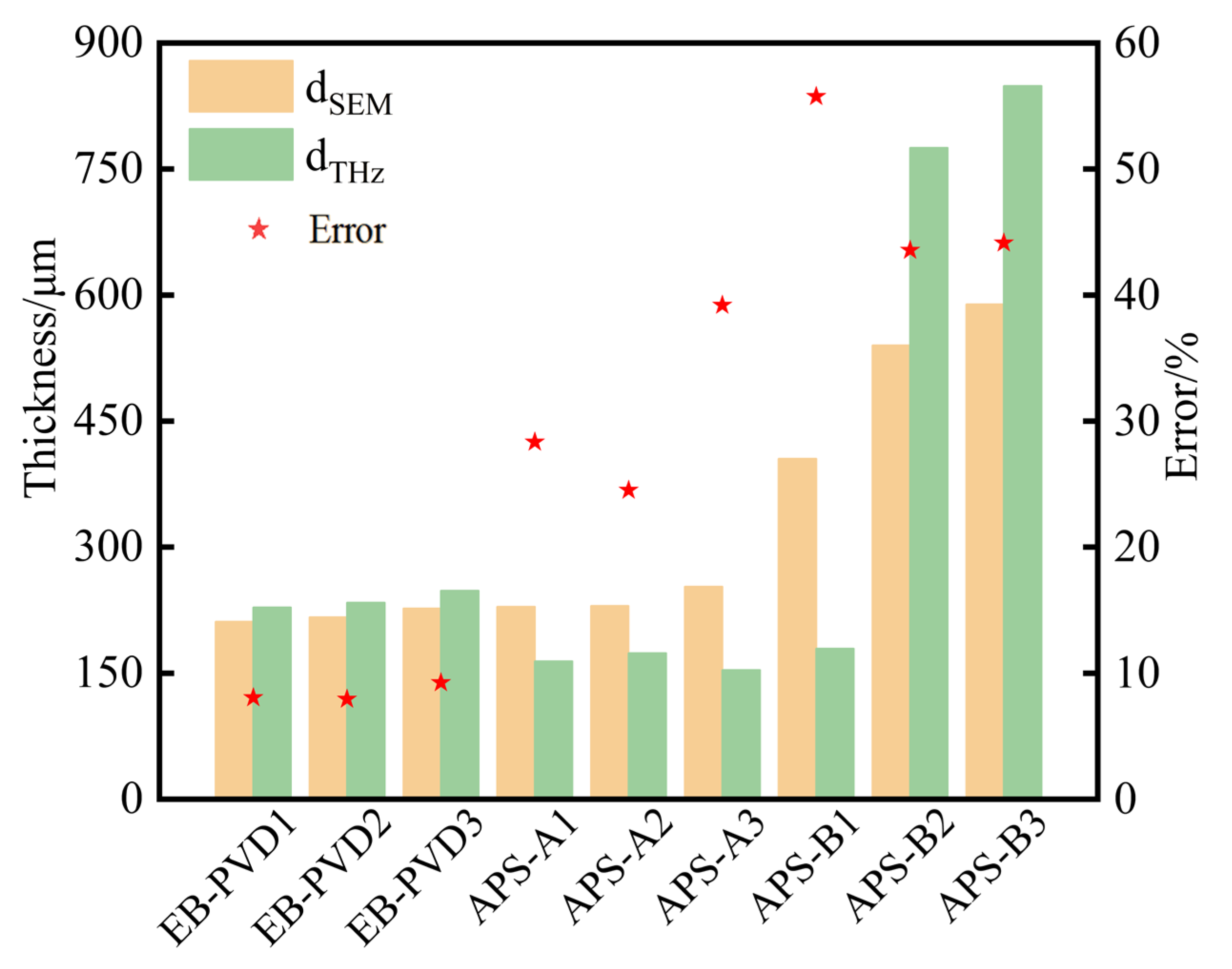

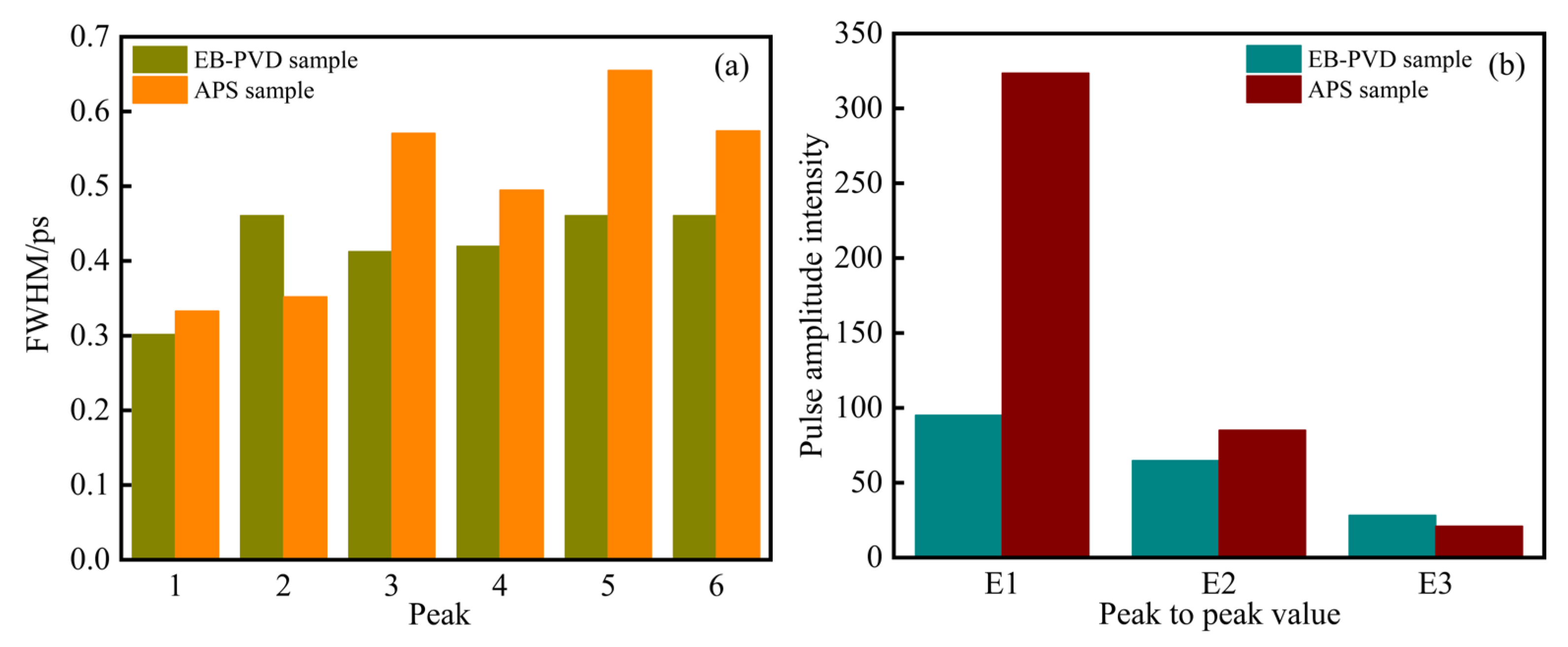

3.1. Thickness Measured by Terahertz Time Domain Amplitude Signals

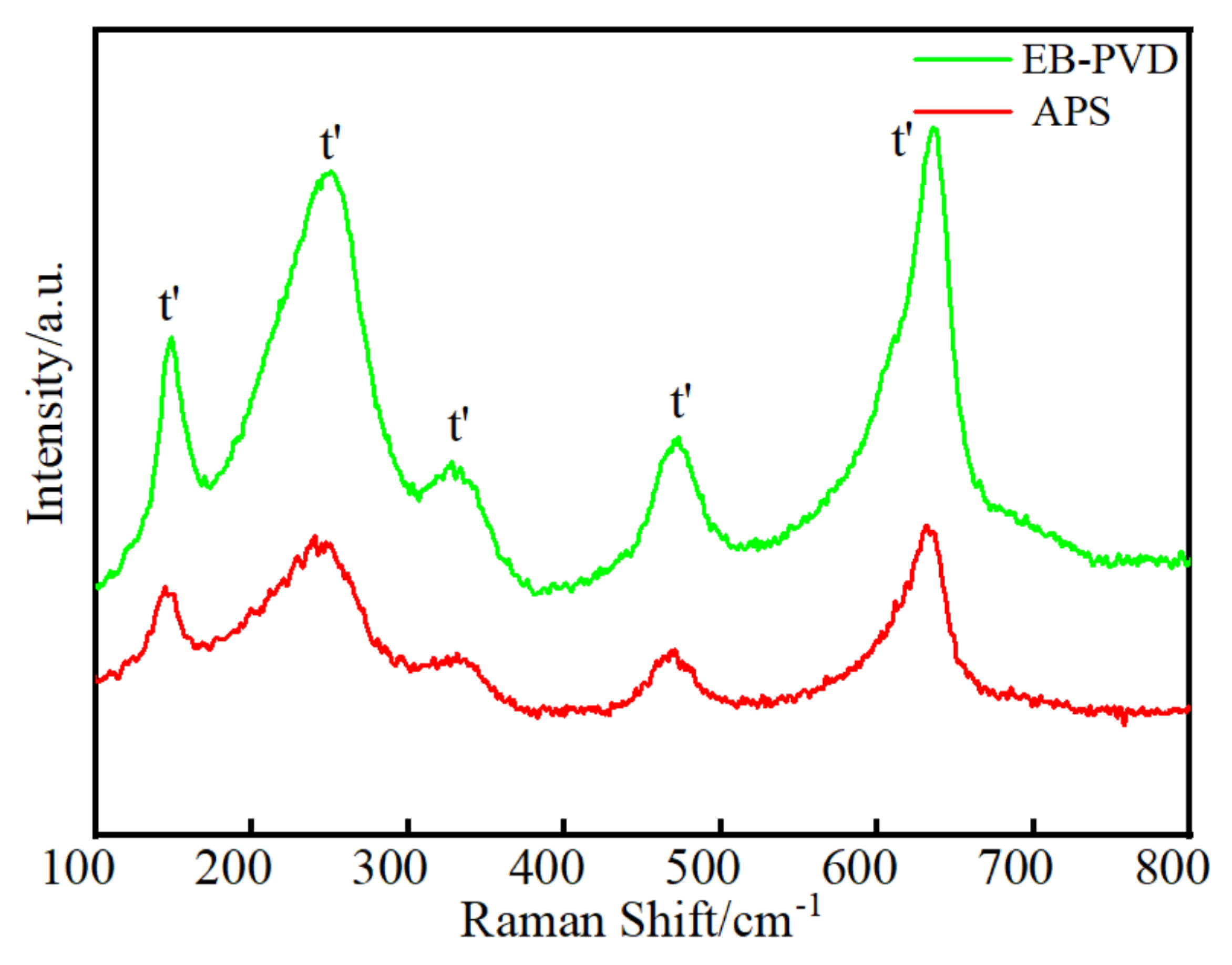

3.2. Phase Composition and Grain Morphology

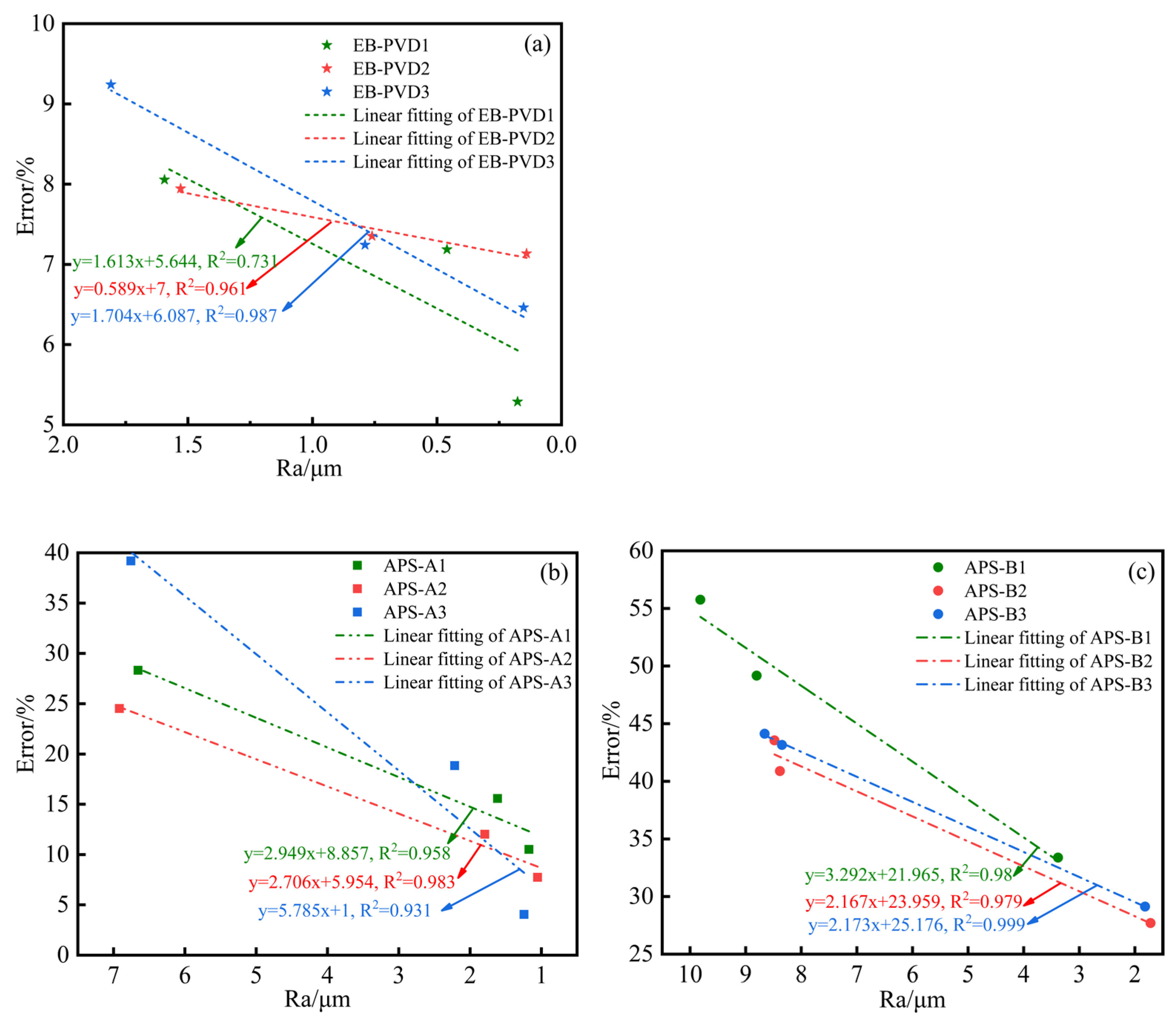

3.3. Surface Roughness

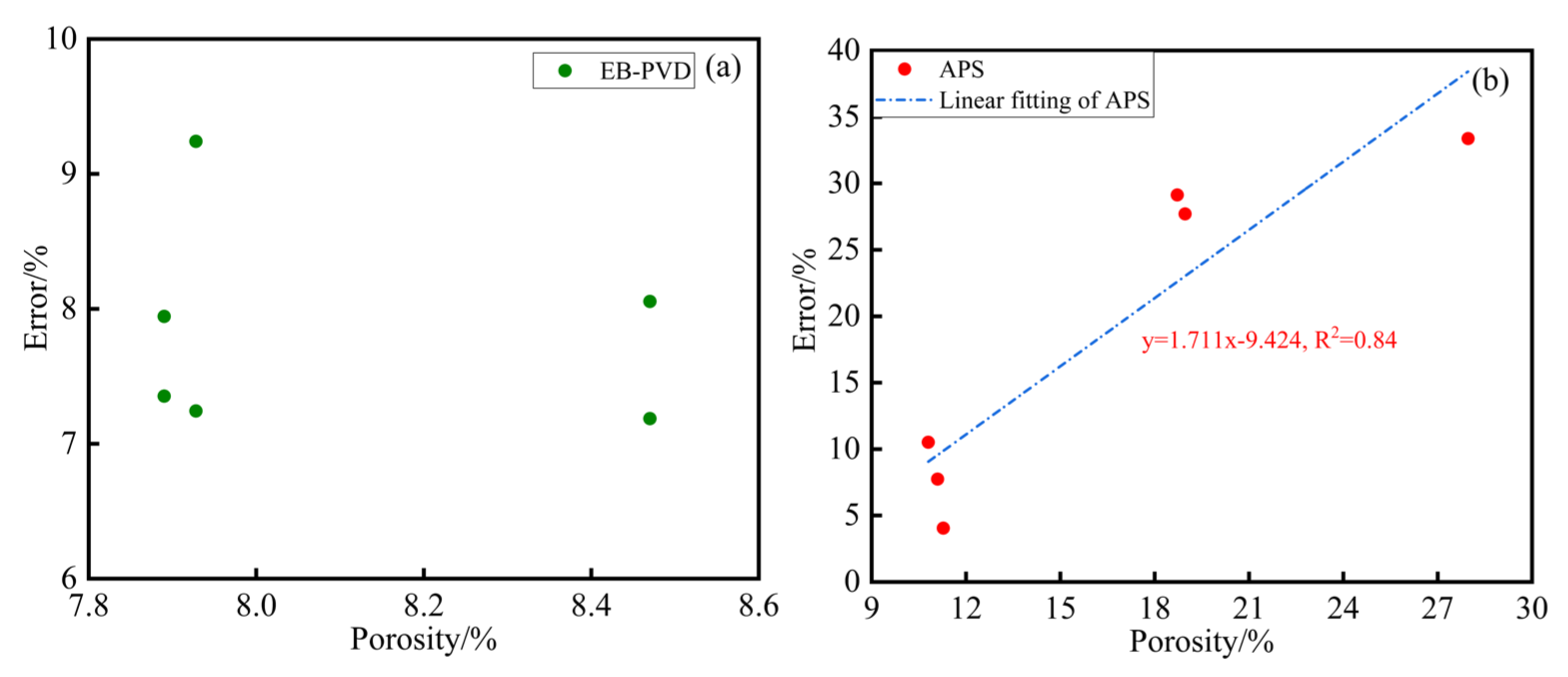

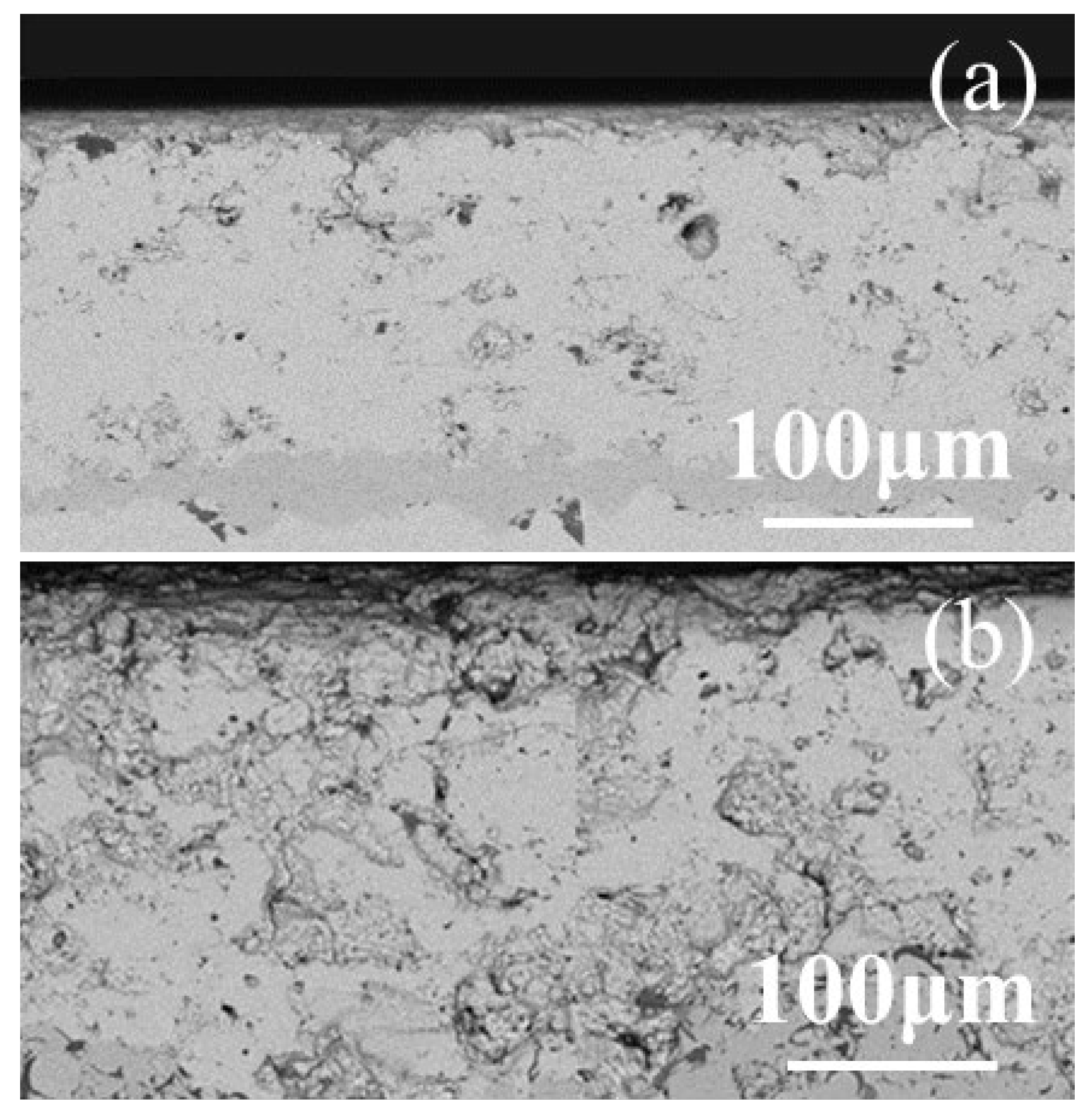

3.4. Porosity

4. Conclusions

- (1)

- In EB-PVD samples, the dendrite aligns closely with the direction of terahertz wave incidence and propagation. Consequently, encounters with transverse grain boundaries and cracks during wave propagation within the grain are less frequent compared to APS samples. This configuration results in relatively lower energy losses during propagation. Conversely, in APS samples, terahertz waves traverse a heterogeneous layered structure comprising YSZ and air due to the overlapping nature of the coatings and the presence of gaps. The scattering accumulation of terahertz photons within the transverse gaps leads to reduced energies received by the detector. This reduction in signal intensities within the thickness calculation equation ultimately increases thickness errors.

- (2)

- When compared to the terahertz time-domain spectra of APS samples, the pulse intensity ratios observed in the first three instances of EB-PVD coatings more closely resemble the ideal state where there is minimal energy loss due to scattering. Consequently, this similarity results in smaller errors.

- (3)

- When the terahertz waves interact with rough surfaces, the detected reflected signals undergo reduction due to attenuation and distortion caused by scattering phenomena. Through polishing the samples to decrease surface roughness, it was observed that the thickness errors of the samples diminish proportionally with reduced roughness. Notably, owing to their inherently low initial surface roughness, the impacts of surface roughness alterations on EB-PVD samples are comparatively smaller than on APS samples. In future scientific research and engineering, the exploration of coating preparation processes with the lowest possible surface roughness to avoid compromising coating properties is imperative. This pursuit aims to enhance the role of the terahertz method in accurately measuring the thickness of TBC samples.

- (4)

- The presence of pores and agglomerates within the samples leads to a broadening of the pulse echoes in the time-domain spectra. This extension increases the time interval Δt within the calculation formula, consequently reducing the accuracy of thickness measurement, particularly noticeable in APS samples. While estimating the trends in error variations concerning porosities, the lower R2 value is believed to stem from distinct size distributions in the raw powders utilized in APS samples. Future research will involve utilizing TBC samples exhibiting broader porosity ranges while maintaining consistent size distributions through a controlled preparation process. This strategic approach aims to further scientifically investigate the relationships between porosities and measurement errors.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- David, R.C.; Simon, R.P. Thermal barrier coating materials. Mater. Today 2005, 8, 22–29. [Google Scholar] [CrossRef]

- Lee, P.H.; Lee, S.Y.; Kwon, J.Y.; Myoung, S.W.; Lee, J.H.; Jung, Y.G.; Jung, Y.G.; Cho, H.; Paik, U. Thermal cycling behavior and interfacial stability in thick thermal barrier coatings. Surf. Coat. Technol. 2010, 205, 1250–1255. [Google Scholar] [CrossRef]

- Ahmaniemi, S.; Vuoristo, P.; Mäntylä, T.; Cernuschi, F.; Lorenzoni, L. Modified thick thermal barrier coatings: Thermophysical characterization. J. Eur. Ceram. Soc. 2004, 24, 2669–2679. [Google Scholar] [CrossRef]

- Available online: http://www.gepower.com/prod_serv/products/tech_docs/en/downloads/ger3569g.pdf (accessed on 15 December 2023).

- Tilmann, B.; Olena, T.; Roland, H.; Singheiser, L. TBCs for Gas Turbines under Thermomechanical Loadings: Failure Behaviour and Life Prediction. J. Energy Power Eng. 2013, 7, 647–653. [Google Scholar] [CrossRef]

- Padture, N.P. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Mehboob, G.; Liu, M.J.; Xu, T.; Hussain, S.; Mehboob, G.; Tahir, A. A review on failure mechanism of thermal barrier coatings and strategies to extend their lifetime. Ceram. Int. 2019, 46, 8497–8521. [Google Scholar] [CrossRef]

- Cao, X.Q.; Vassen, R.; Stöver, D. Ceramic materials for thermal barrier coatings. J. Eur. Ceram. Soc. 2004, 24, 1–10. [Google Scholar] [CrossRef]

- Lu, Z.; Myoung, S.W.; Kim, E.H.; Lee, J.H.; Jung, Y.G. Microstructure evolution and thermal durability with coating thickness in APS thermal barrier coatings. Mater. Today Proc. 2014, 1, 35–43. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, Y.; Lai, C.; Tian, G. Thickness measurement of multi-layer conductive coatings using multifrequency eddy current techniques. Nondestruct. Test. Eval. 2016, 31, 191–208. [Google Scholar] [CrossRef]

- Lescribaa, D.; Vincent, A. Ultrasonic characterization of plasma-sprayed coatings. Surf. Coat. Technol. 1996, 81, 297–306. [Google Scholar] [CrossRef]

- Newaz, G.; Chen, X. Progressive damage assessment in thermal barrier coatings using thermal wave imaging technique. Surf. Coat. Technol. 2005, 190, 7–14. [Google Scholar] [CrossRef]

- Shrestha, R.; Kim, W. Evaluation of coating thickness by thermal wave imaging: A comparative study of pulsed and lock-in infrared thermography-part I: Simulation. Infrared Phys. Technol. 2017, 83, 124–131. [Google Scholar] [CrossRef]

- Lee, Y.S. Principles of Terahertz Science and Technology; National Defence Industry Press: Beijing, China, 2012; p. 8. [Google Scholar]

- White, J.; Fichter, G.; Chernovsky, A.; Whitaker, J.F.; Das, D.; Pollock, T.M.; Zimdars, D.; Thompson, D.O.; Chimenti, D.E. Time-domain terahertz non-destructive evaluation of aeroturbine blade thermal barrier coatings. AIP Conf. Proc. 2009, 28, 434–439. [Google Scholar] [CrossRef]

- Chen, C.C.; Lee, D.J.; Pollock, T.; Whitaker, J.F. Pulsed-terahertz reflectometry for health monitoring of ceramic thermal barrier coatings. Opt. Express 2010, 18, 3477–3486. [Google Scholar] [CrossRef] [PubMed]

- Fukuchi, T.; Fuse, N.; Okada, M.; Fujii, T.; Mizuno, M.; Fukunaga, K. Measurement of refractive index and thickness of topcoat of thermal barrier coating by reflection measurement of terahertz waves. Electron. Commun. Jpn. 2013, 96, 37–45. [Google Scholar] [CrossRef]

- Fukuchi, T.; Fuse, N.; Okada, M.; Ozeki, T.; Fujii, T.; Mizuno, M.; Fukunaga, K. Topcoat Thickness Measurement of Thermal Barrier Coating of Gas Turbine Blade Using Terahertz Wave. Electr. Eng. Jpn. 2014, 189, 1–8. [Google Scholar] [CrossRef]

- Yuan, B.; Wang, W.; Ye, D.; Zhang, Z.; Fang, H.; Yang, T.; Wang, Y.; Zhong, S. Nondestructive Evaluation of Thermal Barrier Coatings Thickness Using Terahertz Technique Combined with PCA–GA–ELM Algorithm. Coatings 2022, 12, 390. [Google Scholar] [CrossRef]

- Ye, D.; Wang, W.; Zhou, H.; Huang, J.; Wu, W.; Gong, H.; Li, Z. In-situ evaluation of porosity in thermal barrier coatings based on the broadening of terahertz time-domain pulses: Simulation and experimental investigations. Opt. Express 2019, 27, 28150–28165. [Google Scholar] [CrossRef]

- Ye, D.; Wang, W.; Zhou, H.; Fang, H.; Huang, J.; Li, Y.; Gong, H.; Li, Z. Characterization of thermal barrier coatings microstructural features using terahertz spectroscopy. Surf. Coat. Technol. 2020, 394, 125836. [Google Scholar] [CrossRef]

- Ye, D.; Li, R.; Xu, J.; Pan, J. Data-Driven Method for Porosity Measurement of Thermal Barrier Coatings Using Terahertz Time-Domain Spectroscopy. Coatings 2023, 13, 1060. [Google Scholar] [CrossRef]

- Li, R.; Ye, D.; Zhang, Q.; Xu, J.; Pan, J. Nondestructive Evaluation of Thermal Barrier Coatings’ Porosity Based on Terahertz Multi-Feature Fusion and a Machine Learning Approach. Appl. Sci. 2023, 13, 8988. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; pp. 324–333. [Google Scholar]

- Zhao, W.; Wang, S.; Li, L.A.; Liu, D.; Li, C.; Wang, Z. Characterizing the Thermally Grown Oxide in Thermal Barrier Coating by Terahertz Time Domain Spectroscopy. Coatings 2023, 13, 376. [Google Scholar] [CrossRef]

- Jiang, X.; Xu, Y.; Hu, H.; Xie, W. Nondestructive testing of corrosion thickness in coated steel structures with THz-TDS. Measurement 2023, 217, 113088. [Google Scholar] [CrossRef]

- Liu, L.; Yu, H.; Zheng, C.; Ye, D.; He, W.; Wang, S.; Li, J.; Wu, L.; Zhang, Y.; Xie, J.; et al. Nondestructive Thickness Measurement of Thermal Barrier Coatings for Turbine Blades by Terahertz Time Domain Spectroscopy. Photonics 2023, 10, 105. [Google Scholar] [CrossRef]

- Ye, D.; Wang, W.; Zhou, H.; Li, Y.; Fang, H.; Huang, J.; Gong, H.; Li, Z. Quantitative Determination of Porosity in Thermal Barrier Coatings Using Terahertz Reflectance Spectrum: Case Study of Atmospheric-Plasma-Sprayed YSZ Coatings. IEEE Trans. Terahertz Sci. Technol. 2020, 10, 383–390. [Google Scholar] [CrossRef]

- Hakobyan, D.; Hamdi, M.; Redon, O.; Ballestero, A.; Mayaudon, A.; Boyer, L.; Durand, O.; Abraham, E. Non-destructive evaluation of ceramic porosity using terahertz time-domain spectroscopy. J. Eur. Ceram. Soc. 2022, 42, 525–533. [Google Scholar] [CrossRef]

- Ye, D.; Wang, W.; Xu, Z.; Yin, C.; Zhou, H.; Li, Y. Prediction of Thermal Barrier Coatings Microstructural Features Based on Support Vector Machine Optimized by Cuckoo Search Algorithm. Coatings 2020, 10, 704. [Google Scholar] [CrossRef]

- Cao, B.; Wang, M.; Li, X.; Fan, M.; Tian, G. Noncontact Thickness Measurement of Multilayer Coatings on Metallic Substrate Using Pulsed Terahertz Technology. IEEE Sens. J. 2020, 20, 3162–3171. [Google Scholar] [CrossRef]

- Watanabe, M.; Kuroda, S.; Yamawaki, H.; Shiwa, M. Terahertz dielectric properties of plasma-sprayed thermal-barrier coatings. Surf. Coat. Technol. 2011, 205, 4620–4626. [Google Scholar] [CrossRef]

- Cacciari, I.; Siano, S. THz Characterization of Corroded Metals: The Influence of Surface Roughness. In Proceedings of the 18th Italian National Conference on Photonic Technologies (Fotonica 2016), Rome, Italy, 6–8 June 2016. [Google Scholar]

- Cacciari, I.; Siano, S. Use of THz Reflectometry for Roughness Estimations of Archeological Metal Surfaces. J. Infrared Millim. Terahertz Waves 2017, 38, 503–517. [Google Scholar] [CrossRef]

- Fukuchi, T.; Fuse, N.; Mizuno, M.; Fukunaga, K. Surface Roughness Measurement Using Terahertz Waves. In Proceedings of the 3rd International Conference on Industrial Application Engineering, Kitakyushu, Japan, 28–31 March 2015; pp. 294–299. [Google Scholar]

- Cacciari, I.; Agresti, J.; Siano, S. Combined THz and LIPS analysis of corroded archaeological bronzes. Microchem. J. 2016, 126, 76–82. [Google Scholar] [CrossRef]

- Anastasi, R.F.; Madaras, E.I. Terahertz NDE for metallic surface roughness evaluation. In Proceedings of the Nondestructive Evaluation for Health Monitoring and Diagnostics, San Diego, CA, USA, 26 February–2 March 2006. [Google Scholar]

- Ye, D.; Wang, W.; Huang, J.; Lu, X.; Zhou, H. Nondestructive Interface Morphology Characterization of Thermal Barrier Coatings Using Terahertz Time-Domain Spectroscopy. Coatings 2019, 9, 89. [Google Scholar] [CrossRef]

| Technologies | Basic Parameters |

|---|---|

| HVAF | Spray distance of 150 mm; Air flow rate of 84.2 L/min; Propane flow rate of 86.5 L/min; Robot traverse speed of 800 mm/s; Powder delivery rate of 15–20 g/min |

| APS | Arc current of 560 A; Arc voltage of 59 V; Primary plasma gas (Ar) flow of 35 L/min; Secondary plasma gas (H2) flow of 6.5 L/min; Powder feeding gas (Ar) flow of 3.5 L/min; Spray distance of 120 mm; Powder delivery rate of 40 g/min |

| AIP | Arc current of 170 A Evaporation temperature of 450 °C; Bias voltage of −30 V; Vacuum degree of 0.03 Pa |

| EB-PVD | Current of 0.5~1 A; Voltage of 22 ± 2 KV; Substrate temperature of 900 °C; Rotate speed of 15 r/min; Feed rate of 0.3 mm/min |

| Items | Parameters |

|---|---|

| terahertz beam diameter | 2.5 mm |

| dynamic range | 100 dB |

| spectral bandwidth | 50 μm |

| spectral resolution | 4.9 GHz |

| delay line scanning range | 0–200 ps |

| Sample Labels | dSEM/μm | Porosity/% | Ra/μm | Error/% |

|---|---|---|---|---|

| EB-PVD3 | 227.12 | 7.93 | 1.81 | 9.24 |

| P1-APS-A2 | 170.51 | 11.09 | 1.79 | 12.02 |

| P2-APS-B3 | 171.63 | 18.72 | 1.812 | 29.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Xing, Y.; Feng, Y.; Geng, L.; Shang, Y.; Pei, Y.; Bi, X.; Gong, S. The Influence of Microstructure Characteristics on Thickness Measurement of TBCs Using Terahertz Time-Domain Spectroscopy. Coatings 2024, 14, 79. https://doi.org/10.3390/coatings14010079

Zhou H, Xing Y, Feng Y, Geng L, Shang Y, Pei Y, Bi X, Gong S. The Influence of Microstructure Characteristics on Thickness Measurement of TBCs Using Terahertz Time-Domain Spectroscopy. Coatings. 2024; 14(1):79. https://doi.org/10.3390/coatings14010079

Chicago/Turabian StyleZhou, Han, Yifeng Xing, Yang Feng, Lilun Geng, Yong Shang, Yanling Pei, Xiaofang Bi, and Shengkai Gong. 2024. "The Influence of Microstructure Characteristics on Thickness Measurement of TBCs Using Terahertz Time-Domain Spectroscopy" Coatings 14, no. 1: 79. https://doi.org/10.3390/coatings14010079

APA StyleZhou, H., Xing, Y., Feng, Y., Geng, L., Shang, Y., Pei, Y., Bi, X., & Gong, S. (2024). The Influence of Microstructure Characteristics on Thickness Measurement of TBCs Using Terahertz Time-Domain Spectroscopy. Coatings, 14(1), 79. https://doi.org/10.3390/coatings14010079